Abstract

Superchilling entails lowering the fish temperature to between the initial freezing point of the fish and about 1–2°C lower. The temperature of superchilled fresh fishery products (SFFP) in boxes without ice was compared to that of products subject to the currently authorised practice in boxes with ice (CFFP) under the same conditions of on‐land storage and/or transport. A heat transfer model was developed and made available as a tool to identify under which initial configurations of SFFP the fish temperature, at any time of storage/transport, is lower or equal to CFFP. A minimum degree of superchilling, corresponding to an ice fraction in the fish matrix of SFFP equal or higher than the proportion of ice added per mass of fish in CFFP, will ensure with 99–100% certainty (almost certain) that the fish temperature of SFFP and the consequent increase of relevant hazards will be lower or equal to that of CFFP. In practice, the degree of superchilling can be estimated using the fish temperature after superchilling and its initial freezing point, which are subject to uncertainties. The tool can be used as part of ‘safety‐by‐design’ approach, with the reliability of its outcome being dependent on the accuracy of the input data. An evaluation of methods capable of detecting whether a previously frozen fish is commercially presented as ‘superchilled’ was carried out based on, amongst others, their applicability for different fish species, ability to differentiate fresh fish from fish frozen at different temperatures, use as a stand‐alone method, ease of use and classification performance. The methods that were considered ‘fit for purpose’ are Hydroxyacyl‐coenzyme A dehydrogenase (HADH) test, α‐glucosidase test, histology, ultraviolet–visible–near–infrared (UV‐VIS/NIR) spectroscopy and hyperspectral imaging. These methods would benefit from standardisation, including the establishment of threshold values or classification algorithms to provide a practical routine test.

Keywords: superchilling, transport, storage, fresh fishery products, biological hazards, freezing, HADH enzymatic test

Summary

Following a request from the European Commission, the Scientific Panel on Biological Hazards (BIOHAZ) was asked to provide a scientific opinion on the use of the so‐called ‘superchilling’ technique for transporting fresh fishery products from the first on‐land establishment onwards.

In Term of Reference 1 (ToR1), EFSA was requested to compare the impact that the use of ‘superchilling’ could have on the survival and growth of biological hazards when compared with the current authorised practices (i.e. a temperature approaching that of melting ice). ToR2 was to evaluate the use of the HADH (Hydroxyacyl‐coenzyme A dehydrogenase) enzymatic test, or if possible, any other test that could be used by the competent authorities, to differentiate ‘superchilling’ from freezing (i.e. temperature of not more than –18°C).

The assessment focuses on domestic trade and import into the EU/EEA regarding the transport and storage of unpackaged, wrapped, prepared fresh fishery products (FFP) from the first on‐land establishment onwards, using the authorised practice ‘in boxes with ice’ (reference condition referred to as conventional FFP or ‘CFFP’), in comparison with FFP that, after being superchilled in the first on‐land establishment, are transported in ‘boxes without ice’ (alternative condition referred to as ‘SFFP’). Both CFFP and SFFP are considered until they are marketed or processed. The boxes used to store/transport CFFP and SFFP are generally made of expanded polystyrene (EPS), with other types of containers being outside the scope of the current mandate. Fish are expected to be kept in the boxes for a maximum duration of 5 days. The definition considered in the assessment was ‘superchilling includes temperatures between the initial freezing point of the fish (always below the temperature of melting ice, i.e. < 0°C) to about 1–2°C lower’.

Regarding ToR1, the requestor clarified that the purpose is to know if the SFFP stored/transported in boxes without ice is at least as safe (from a microbiological food safety perspective) as CFFP stored/transported in boxes with ice. In this context, it was agreed to follow a step‐wise approach: firstly, focusing the assessment on the reasonably foreseeable fish temperature during the storage/transport of SFFP in boxes without ice compared to CFFP in boxes with ice. Secondly, and only if higher temperatures can occur in SFFP compared to CFFP, to assess the impact on the growth of biological hazards. The assessment questions (AQ) were as follows.

AQ1a: Which SFFP configurations (i.e. initial degree of superchilling) ensure that the fish temperature, at any time of the storage/transport, is lower or equal to CFFP when exposed to the same conditions of on‐land storage and/or transport?

AQ1b: If the SFFP conditions allow fish temperatures to be higher than in CFFP during the on‐land storage and/or transport, what is the potential increase of relevant biological hazards (i.e. pathogen log 10 increase or change in histamine concentration) for on‐land SFFP compared to CFFP upon exposure to the same conditions of storage and/or transport?

A heat transfer modelling approach was developed to identify under which initial configurations the fish temperature of SFFP, at any time of the storage/transport, is lower or equal to CFPP, when exposed to the same conditions of on‐land storage and/or transport. This approach is feasible since the boxes used to transport the fish are the same (e.g. EPS boxes).

For simulation purposes, three types of fish were considered: salmon (as an example of fish with a high fat content), cod (as a lean fish) and Nile Perch (as a temperate freshwater fish). It was concluded that the capacity of the CFFP and SFFP to maintain the temperature when exposed to the same conditions of storage and/or transport depends on their capacity to absorb heat, which is determined by their initial configurations. These are:

for CFFP: the initial fish and ice temperatures and the proportion of ice:fish in the box; and

for SFFP: the degree of superchilling, i.e. the ice fraction in the fish matrix, which depends on the fish temperature after superchilling and the initial freezing point of the fish.

The identified assumptions and other sources of uncertainty were listed and, in some cases, the impact was quantified. The experts elicited the overall uncertainty associated with the final outcome of the AQs through expert group judgement taking into account the quantified and non‐quantified sources of uncertainty.

A degree of superchilling of SFFP equal to or higher than the proportion of ice:fish in the EPS box of CFFP properly adjusted to the envisaged conditions of transport and storage will ensure with 99–100% certainty (almost certain) that the fish temperature of SFFP and the consequent increase of the relevant hazards, including histamine will be lower or equal than those of CFFP (close to 0°C, i.e. the temperature of melting ice) at any time point during storage/transport.

When the degree of superchilling is unknown, which is normally the case, it can be estimated using the fish temperature after superchilling and its initial freezing point. These two parameters are subjected to uncertainties: (a) the fish temperature after superchilling is influenced by the application of the superchilling technology and the temperature measurement procedure; (b) the initial freezing point can be derived from the fish proximate composition, which is influenced by fish species and other factors such as seasonal variation and temperature of the catching waters.

An MS Excel spreadsheet tool, named the heat transfer model tool for the heat absorption capacity of superchilled fresh fishery products (HTM‐SFFP Tool), based on the developed model was built and made available through the Knowledge Junction under https://doi.org/10.5281/zenodo.4304283 that can be used as part of the ‘safety‐by‐design’ approach. More specifically, it allows the identification of scenarios of initial configuration under which the SFFP have an equivalent or higher capacity to absorb heat than CFFP. The reliability of the outcome provided by the tool depends on the accuracy of the input data introduced by the user.

Regarding ToR2, it was agreed to focus the assessment on analytical and instrumental methods, including the HADH enzymatic test and/or other methods, providing effective detection of the fraudulent use of previously frozen fish to market it as a superchilled product. The AQ was as follows:

AQ2: Which methods (including the HADH enzymatic test) are capable of detecting whether a previously frozen fish is commercially presented as ‘superchilled’?

A literature review was carried out to assess potential methods capable of differentiating between fresh/superchilled and frozen fish. The methods were listed, summarising key features, advantages and disadvantages for their use to assess whether a fish that has been previously frozen has been commercially presented as ‘superchilled’. An appraisal of the relevance of each study was carried out based on predefined criteria regarding the appropriateness to answer the ToR. Finally, an evaluation was carried out considering their applicability for different fish species; ability to differentiate fresh fish from fish frozen at various temperatures; use as a stand‐alone method; ease of use; classification performance in discriminating as either frozen/not frozen; evidence that superchilled fish will behave like fresh fish for the given method; and strength of evidence.

Following five out of 28 methods were considered ‘fit for purpose’:

HADH test proved suitable for almost all tested fish species. Superchilled Nile perch fillet has been proven to be distinguishable from deeply frozen fish based on the profile of the measured absorbance during the enzymatic test. The threshold value is generally species‐specific.

α‐glucosidase test proved suitable for almost all tested fish species but post‐harvest quality changes may interfere with the results. The threshold value is species‐specific.

histology proved suitable for all tested species, but it is laborious and requires specialised skills.

UV‐VIS/NIR spectroscopy and hyperspectral imaging proved suitable for all tested species and can be applied on‐line with handheld equipment or equipment mounted on the processing line. The threshold value may be species or group of species‐specific.

Some methods have the potential to be used, but the evidence is limited, or they currently require advanced instrumental infrastructure and user expertise, making them not suitable for routine applications, while for some methods, there is no evidence that they are suitable or there is evidence that they cannot be applied to all types of SFFP.

For the five ‘fit for purpose’ methods, based on the ice crystal formation and the limited structural changes, SFFP is considered to behave, under analytical procedures, with 90–95% certainty (very likely) like a fresh fishery product, rather than a frozen one.

Recommendations were formulated related to the need for reliable methods and data generation to accurately determine the initial freezing point (T*) and the ice fraction (Xice) of fish after superchilling and standardisation of methods aiming to differentiate fresh (never frozen) chilled and superchilled fish from frozen/thawed fish, including the establishment of threshold values or classification algorithms. The development of guidelines was recommended, covering key aspects of the superchilling technology, as well as procedures for the validation and verification of the degree of superchilling, thereby ensuring the safety of superchilled fish during the storage and transport on‐land.

1. Introduction

1.1. Background and Terms of Reference as provided by the requestor

Annex III to Regulation (EC) No 853/2004,1 Section VIII, Chapter VIII, point 1 reads as follows:

“1. During transport, fishery products must be maintained at the required temperature. In particular:

-

a)

fresh fishery products, thawed unprocessed fishery products, (…), must be maintained at a temperature approaching that of melting ice;

-

b)

frozen fishery products, (…), must be maintained during transport at an even temperature of not more than –18°C in all parts of the product (…)”.

Superchilling2 of fish is a method in which the temperature of fish is uniformly reduced to a point slightly below that obtained in melting ice. The method is also referred to as partial freezing, deep chilling or “sub‐chilling”. In current practice superchilling means reducing the fish temperature until 5–30% of the total water content of the fish is frozen, and keeping it at that temperature. Bacterial and enzymatic activity, and hence spoilage, are slowed somewhat at this lower temperature, so that the fish remains edible longer.

The slow freezing of fish flesh is undesirable because large ice crystals form which can damage the structure of the muscle, resulting in a thawed product that is less attractive and less palatable than the original fresh fish. The slower the water freezes, the larger the ice crystals and the greater the damage. For quality purposes, close control of the superchilling temperature is essential if the damaging effects of slow freezing are to be avoided.

According to a study3 coordinated by the Dutch Fish Importers Association using Nile perch (Lates niloticus) fillet (attached) “superchilling is a good alternative to maintain the cold chain of fresh fisheries products. Moreover, literature studies and microbiological analyses show that superchilling suppresses bacterial activity, maintains food freshness and preserves nutritional quality.”

The above‐referred study also included a HADH (Hydroxyacyl‐coenzyme A dehydrogenase) enzymatic test, carried out by a European Referential Laboratory, to measure the mitochondrial enzyme HADH in the Nile perch fillets. It showed that HADH could be a good indicator to assess whether the Nile perch fillets used had previously been deep frozen.

EFSA is asked to provide a scientific opinion on the use of the so called “superchilling technique” for transporting fresh fishery products from the first on‐land establishment onwards. In particular, EFSA is requested:

Terms of Reference (ToR) 1: To compare the impact that the use of ‘superchilling’ could have on the survival and growth of biological hazards when compared with the current authorised practices (i.e. temperature approaching that of melting ice);

ToR 2: To evaluate the use of the HADH (Hydroxyacyl‐coenzyme A dehydrogenase) enzymatic test, or if possible, any other test that could be used by the competent authorities, to differentiate ‘superchilling’ from freezing (i.e. temperature of not more than –18°C).

1.2. Interpretation of the Terms of Reference

The term ‘fishery products’ as defined by Regulation (EC) No 853/2004,1 Annex I, comprises all seawater and freshwater animals (except for live bivalve molluscs, live echinoderms, live tunicates and live marine gastropods, and all mammals, reptiles and frogs) whether wild or farmed and including all edible forms, parts and products of such animals. In Annex I, ‘fresh fishery products’ (FFP) are defined as unprocessed fishery products, whether whole or prepared, including products packaged under vacuum or in a modified atmosphere, that have not undergone any treatment to ensure preservation other than chilling. However, the current mandate is restricted to unpackaged FFP, with packaged FFP being beyond the scope of this assessment. It was clarified that the specific FFP to which the ToRs apply include ‘prepared fishery products’, in particular unprocessed fishery products that have undergone an operation affecting their anatomical wholeness, such as gutting, heading and filleting and are wrapped after this preparation. The FFP considered in the assessment are derived from the marine and land‐based environment, either wild or farmed.

The assessment focuses on domestic trade and import into the EU/EEA regarding the transport and storage of unpackaged, wrapped, prepared FFP from the first on‐land establishment onwards using the authorised practice ‘in boxes with ice’ (as the reference condition, referred to as conventional FFP or ‘CFFP’ throughout the rest of the document), in comparison with FFP that after being superchilled (referred to as ‘SFFP’ throughout the rest of the document) in the first on‐land establishment are transported in ‘boxes without ice’ (as alternative condition). Both CFFP and SFFP are considered until they are marketed or processed. The simple storage of FFP at superchilling temperatures without a preceding superchilling process is not considered in the present mandate (see Section 1.3.1.4 for further details about the superchilling technology for FFP).

The CFFP fillets are usually wrapped, with at least one layer of plastic being placed around the fresh fish fillets and either ice or ice/gel packs placed on the top. The fillets of SFFP are wrapped together (see Figure 1), while the headed and gutted SFFP are individually wrapped. The boxes used to store/transport CFFP and SFFP are generally made of expanded polystyrene (EPS), with other types of containers being outside the scope of the current mandate as agreed with the requestor. Fish are envisaged to be kept in the boxes for a maximum duration of 5 days.

Figure 1.

Superchilled Nile perch fillet (a) and headed and gutted Nile perch (b) after arrival at the European establishment (Source of picture: FIORITAL (Solimeo, 2020c))

It was agreed with the requestor to assume that the ice used to fill the boxes is made from potable or clean water (fresh water), according to their definitions in Regulation (EC) 852/20044 and Regulation (EC) No 853/2004,1 and thus should not be a source of microbiological contamination of the fish. Although ice made from salted or sea water is also allowed according to the current regulation, this is a practice used on‐board but not on‐land, and therefore, it is not to be considered in the present mandate. The growth and survival of spoilage microorganisms as well as quality traits of fish (e.g. sensory, commercial value etc.) are also beyond the scope of this mandate.

Regarding ToR1, the requestor clarified that the purpose is to know if the SFFP stored/transported in boxes without ice is at least as safe (from a microbiological food safety perspective) as CFFP stored/transported in boxes with ice. Temperature is known to be the major factor determining microbial growth in fresh fishery products during storage and transport, from catching to the end user (i.e. a processing plant or the consumer). The maintenance of the cold chain is necessary to control the growth of biological hazards. As detailed in the previous opinion (EFSA BIOHAZ Panel, 2020), the impact of survival of the biological hazards in chilled FFP is considered of no relevance from the safety point of view, either because it is negligible (equivalent to no change) or because the reduction of the levels of the biological hazards is not temperature dependent for the time span of the assessment. In this context, it was agreed with the requestor to follow a step‐wise approach: first focus the assessment on the reasonably foreseeable fish temperature during the storage/transport of SFFP in boxes without ice compared to CFFP in boxes with ice. Secondly, and only if higher temperatures can occur in SFFP compared to CFFP, to assess the impact on the growth of biological hazards.

The term ‘impact’ of a given condition on the growth of a biological hazard (including accumulation of histamine) was interpreted as the change in the concentration of the hazard, e.g. microorganism log10 increase or histamine concentration increase (EFSA BIOHAZ Panel, 2020). The requestor clarified that the associated public health impact was not to be assessed.

Regarding ToR2, the European Commission clarified that the differentiation of the use of fresh fish (not frozen) and superchilled fish from non‐conforming freezing of fish has a public health implication and is not just a quality issue. The legal basis used is Regulations (EC) No 853/20041 and Commission Delegated Regulation 2019/6255 and Commission Implementing Regulation (EU) 2019/6276 that cover public health requirements for food of animal origin. Those regulations consider that freezing at a temperature higher than –18°C could have public health implications. This is the reason why the distinction between the use of superchilling and illegal/fraudulent freezing is fundamental, particularly at the border control points. It was agreed to focus the assessment on analytical and instrumental methods, including the HADH enzymatic test and/or other methods, providing effective detection of the fraudulent use of previously frozen fish to market it as a superchilled product.

Based on the interpretations described above, the following assessment questions (AQs) were formulated in order to address the ToR:

AQ1a: Which SFFP configurations (i.e. initial degree of superchilling) ensure that the fish temperature, at any time of the storage/transport, is lower or equal to CFFP when exposed to the same conditions of on‐land storage and/or transport?

AQ1b: If the SFFP conditions allow fish temperatures to be higher than in CFFP during the on‐land storage and/or transport, what is the potential increase of relevant biological hazards (i.e. pathogen log10 increase or change in histamine concentration) for on‐land SFFP compared to CFFP upon exposure to the same conditions of storage and/or transport?

AQ2: Which methods (including the HADH enzymatic test) are capable of detecting whether a previously frozen fish is commercially presented as ‘superchilled’?

1.3. Additional information

1.3.1. Additional background information

1.3.1.1. Nile perch fillet study by the Dutch Fish Importers Association

The mandate included a study coordinated by the Dutch Fish Importers Association using Nile perch (Lates niloticus) fillets. The aim of the research was to give more insights into the superchilling technique used in the Nile perch value chain. According to the report, ‘The research describes how the cold chain for superchilled Nile perch works and what impact it has on quality and food safety of the fresh fish product’. Secondly, it provides the results of a study using the HADH enzymatic test to determine if fish products were (previously) frozen, to confirm that the raw material was fresh fish that had been superchilled, and that no deep‐frozen fish was used. This study will be referred to as the ‘Nile perch study’ in this scientific opinion.

Representatives of the study from FIORITAL (Vincenzo Di Leva, Antonio Solimeo) and from the Dutch Fish Importers Association (Mike Turenhout) attended the Working Group meeting on 26 June 2020 as hearing experts to provide information about the Nile perch study and to provide an overview of the superchilling technique used in the Nile perch value chain. The report of the Nile perch study is available in Annex A and additional information is available at Appendix A and Annex B as provided by Mike Turenhout (Manager Dutch Fish Importers Association) on behalf of FIORITAL and the members of the Dutch Fish Importers Association by e‐mail on 16 July 2019 (Turenhout, 2019).

1.3.1.2. Previous EFSA scientific opinions and reports

In 2015, EFSA published a report on the assessment of the temperature conditions, including a possible tolerance, to be applied for the storage and transport of packaged FFP, gutted or entire, including some parts of them, at retail level where icing is not possible. The main temperature‐dependent hazards identified were histamine as well as psychrotrophic bacteria such as Listeria monocytogenes,Clostridium botulinum and Yersinia enterocolitica. It was concluded that it is possible to store packaged FFP at refrigeration temperatures above 0°C (e.g. 3–5°C) and still be compliant with the current EU and international regulated microbiological criteria. For this, the storage time and the concentration of CO2 in the packaging headspace needed to be adjusted accordingly. The report provides several scenarios equivalent to storage at 0°C, consisting of combinations of storage temperature, shelf‐life and CO2 concentration in the packaged product (EFSA, 2015).

In 2017, EFSA assessed the incidents of histamine intoxication in some EU countries that were linked to consumption of tuna and were notified through the Rapid Alert System for Food and Feed (RASFF). All incidents of histamine intoxication were evaluated to highlight common factors in the food distribution chain that potentially contributed to the human cases, and to verify the possible correlation upstream in the food supply chain through the food business operators (FBO) involved. Due to the nature of histamine and the conditions that favour its production, it was concluded that it is likely that several concurrent factors had occurred at different stages along the food chain. It was recommended to maintain adequate chilling rates, carefully manage the cold chain and ensure hygienic conditions at each step of the supply chain of this product (EFSA, 2017).

Recently, EFSA evaluated the on‐land transport/storage of FFP for up to 3 days in the so‐called ‘tubs’ (made of three‐layered polyethylene; PE) filled with freshwater and ice in comparison with the currently authorised practice (fish boxes of high‐density polyethylene (HDPE) filled with ice). The impact on the survival and growth of biological hazards in fish and histamine production in fish species associated with a high amount of histidine was assessed considering that the FFP are stored on‐board in freshwater or seawater/ice (in tubs) and once on‐land they are ‘handled’ (i.e. sorted or gutted and/or filleted) and transferred to either tubs or boxes. The temperature of the FFP was assumed to be the most influential factor affecting relevant hazards. Under reasonably foreseeable ‘abusive’ scenarios and using a conservative modelling approach, the growth of the relevant hazards (i.e. L. monocytogenes,Aeromonas spp. and non‐proteolytic Cl. botulinum) was expected to be < 0.2 log10 units higher in tubs than in boxes after 3 days when the initial temperature of the fish is 0°C (‘keeping’ process). Starting at 7°C (‘cooling‐keeping’ process), the expected difference in the growth potential was higher (< 1 log10 for A. hydrophila and < 0.5 log10 for the other two hazards) due to the poorer cooling capacity of water and ice (tub) compared with ice (box). The survival of relevant hazards was not, or only negligibly, impacted. Histamine formation due to growth of Morganella psychrotolerans under the ‘keeping’ or ‘cooling‐keeping’ process was up to 0.4 ppm and 1.5 ppm higher, respectively, in tubs as compared to boxes after 3 days, without reaching the legal limit of 100 ppm. The water uptake associated with the storage of FFP in tubs (which may be up to 6%) was not found to make a relevant contribution to the differences in microbial growth potential compared to boxes (EFSA BIOHAZ Panel, 2020).

1.3.1.3. Legal background

According to the food safety requirements of Regulation (EC) No 178/2002,7 food shall not be placed on the marked if it is unsafe, i.e. if it is considered to be injurious to health and/or unfit for consumption (e.g. due to spoilage) taking into account the normal conditions of use at each stage of production, processing distribution and the consumer.

Regulation (EC) No 853/20041 lays down specific rules on the hygiene of food of animal origin for FBOs and supplements Regulation (EC) No 852/20044 on the hygiene of foodstuffs. Section VIII of Annex III of Regulation (EC) No 853/20041 deals with fishery products.

Relevant information from the Chapters in Annex III, Section VIII of the Regulation (EC) No 853/20041 is summarised here. Chapter I states that vessels designed and equipped to preserve fishery products for more than 24 h must be equipped with holds, tanks or containers for the storage of fishery products at the temperatures laid down in Chapter VII (see below).

Chapter II defines the requirements during and after landing. It specifies that, when it is not possible to refrigerate them on board vessels, FFPs shall be refrigerated as soon as possible after their landing and stored at a temperature close to that of melting ice. It also states that FBOs displaying FFPs for sale must ensure their refrigerated storage.

Chapter III defines the requirements for establishments, including vessels, which handle fishery products. It states that:

Where chilled, unpackaged products are not distributed, dispatched, prepared or processed immediately after reaching an establishment on land, they must be stored under ice in appropriate facilities. Re‐icing must be carried out as often as necessary. Packaged FFPs must be chilled to a temperature approaching that of melting ice.

Operations such as heading and gutting must be carried out hygienically and as quickly as possible after the products have been caught or landed. The products must be washed thoroughly immediately after these operations.

Operations such as filleting and cutting must be carried out so as to avoid contamination or spoilage of fillets and slices. Fillets and slices must not remain on the worktables beyond the time necessary for their preparation and must be wrapped and, where necessary, packaged and must be chilled as quickly as possible after their preparation.

Containers used for the dispatch or storage of unpackaged prepared FFPs stored under ice must ensure that water from melted ice does not remain in contact with the fish.

Establishment on land that freeze fishery products must have equipment satisfying the requirements for freezer vessels (in Section VIII, Chapter I, part I.C., points 1 and 2) in order to rapidly lower the fish core temperature to not more than –18°C and maintain frozen fishery product at not more than –18°C; recording the temperature of the storage holds in the area where the temperature in the hold is the highest.

Chapter VI states that containers in which FFPs are kept on ice must be water resistant. Chapter VII states that FFPs must be maintained at a temperature approaching that of melting ice during their storage, while Chapter VIII states that this also applies during their transport and reiterates that melt water must not remain in contact with the FFPs, when kept under ice. For frozen fishery products, Chapters VII (storage) and VIII (transport) state that they must be stored at a temperature of not more than –18°C in all parts of the products and maintained at this even temperature, possibly with short upward fluctuations of not more than 3°C; while whole fish initially frozen in brine intended for the manufacture of canned food may be kept at temperature of not more than –9°C. When frozen fishery products are transported from a cold store to an approved establishment to be thawed on arrival for the purposes of preparation and/or processing, if the journey is short and the competent authority so permits, there is no need to comply with the frozen temperature requirement during transport.

1.3.1.4. Superchilling of fresh fishery products

The primary purpose of superchilling of FFP is the extension of the shelf‐life of fresh fish as a result of the reduction of the growth rate of spoilage bacteria at superchilling temperatures in comparison with the conventional chilling temperature. The main principle behind the term ‘superchilling’ is that the product appears non‐frozen despite the presence of ice crystals. It is also referred to as ‘deep‐chilling’, ‘sub‐chilling’, ‘partial freezing’ or ‘shell freezing’ as superchilled products have a certain fraction of ice present inside the food matrix (Kaale et al., 2011; Bantle et al., 2016). Despite some papers considering superchilling to have occurred when the temperature is just below 0°C (i.e. melting ice temperature) without ice crystals being generated, this definition corresponds to the conditions for ‘supercooling’8 (Bantle et al., 2016). Thus, the term ‘supercooling’ refers to products that are also stored at temperatures between 0°C and the initial freezing point of the fish.

There is no commonly agreed definition of superchilling in the literature (Bantle et al., 2016). In the earliest times of the implementation of superchilling strategy, first described by Le Danois (1920) as a new method to refrigerate fish, the fish were immersed in salted water at –4°C and then quickly immersed in freshwater at 0°C to form a thin layer of ice on the fish surface. In 2001, the FAO defined superchilling as ‘reducing the temperature of fish uniformly to a point slightly below that obtained in melting ice’ and more specifically, ‘in present practice superchilling means reducing the fish temperature to about –2.2°C (28°F), at which point half the water is frozen, and keeping it there’ (FAO, 2001). ‘Superchilling’ is usually defined as a technological process causing the freezing of a certain part of the product's water content by quickly lowering the temperature of a food product below its initial freezing point. This temperature is variably described in literature depending on the authors: either just below the initial freezing point (Beaufort et al., 2009), between the initial freezing point of the products (including it) and 1–2°C below this (Duun and Rustad, 2007; Magnussen et al., 2008; Wu et al., 2014); to 1–2°C below its initial freezing point (Zhou et al., 2010; Kaale et al., 2011; Yu et al., 2019) and also between –1°C and –4°C without reference to the initial freezing point (Bahuaud et al., 2010; Pan et al., 2019). According to the definition of the International Institute of Refrigeration, superchilling of a product relates to conditions ‘very near its freezing point or even a few degrees below’.

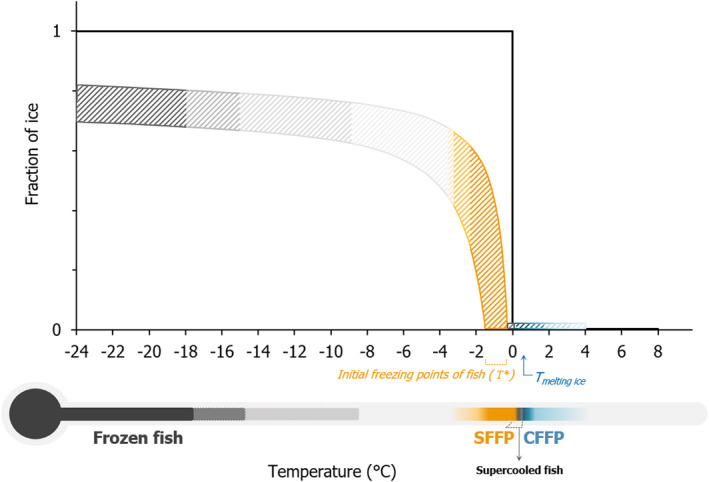

In order to illustrate the range of temperatures associated with the different fish status and fish storage conditions included in the present opinion, a conceptual representation was developed (Figure 2), which relates the fish temperature to a range of fractions of frozen water within the fish matrix (i.e. ice fraction).

Figure 2.

Conceptual representation of the fraction of frozen water (ice fraction) in fish (coloured pattern area) and in water (dark grey line) as a function of temperature

- CFFP: conventional fresh fishery products; SFFP: superchilled fresh fishery products.The initial freezing point of fish (T*) constitutes the boundary between the supercooling and superchilling status and varies depending on the fish composition.

Properly frozen fish must be kept at a temperature not higher than –18°C (with a maximum fluctuation of +3°C), although fish frozen in brine intended to be canned may be kept at ≤ –9°C. Fish frozen at higher temperatures are considered improperly frozen, thus not complying with the current legislation (see Section 1.3.1.3). Under the legally defined freezing temperature conditions, almost all the freezable water (which can be up to approximately 80% of the total water depending on the fish composition) of the fish matrix will be frozen. CFFP must be stored at a temperature close to that of melting ice, at which, no fraction of the fish water content is frozen. Although no upward tolerance limits are stated in the legislation, some competent authorities (CA) recommend CFFP not to exceed 4°C (e.g. in Belgium (Bekaert et al., 2016)). The superchilling of fish is not specifically covered by the legislation; therefore, the panel and working group relied on the most common definition found in the scientific literature, considering that superchilling includes fish temperatures between the initial freezing point of the fish (always below the temperature of melting ice, i.e. < 0°C) to about 1–2°C lower. This results in a variable fraction of frozen water within the fish matrix, which is lower than that occurring in deep‐frozen fish. The temperature of the supercooled fish ranges from 0°C (melting ice point) to the initial freezing point of the fish, and no ice is formed in the fish matrix. Supercooled fish is not considered CFFP and thus outside the scope of the present opinion. As the initial freezing point is product‐specific and varies depending on the fish composition, it is only possible to define from which temperature fish in general enters into the superchilling status if the initial freezing point of the given fish is known. As an example, a fish with an initial freezing point of –0.9°C would be considered supercooled at temperatures between 0°C and –0.9°C and superchilled at temperatures between –0.9°C and –1.9 to –2.9°C. Another fish with an initial freezing point of –0.5°C would be considered supercooled at temperatures between 0°C and –0.5°C and superchilled at temperatures between –0.5°C and –1.5 to –2.5°C.

The scientific publications dealing with SFFP generally consider that an ice fraction of 5–30% in fish is acceptable and low enough to keep its fresh appearance. Higher levels can cause an excessive drip loss with the consequent negative impact on the fish quality (Claussen, 2011; Margeirsson et al., 2012bb; Wu et al., 2014). However, the ice fraction was not measured in most of the published studies. Instead, the more easy and direct measurement of the superchilled fish temperature is reported.

The superchilling technology comprises two stages – the actual superchilling process and the subsequent superchilling storage. Additionally, in the superchilling technology for fish, the pre‐cooling (to lower the temperature difference between pre‐ and post‐superchilling) is also key for the quality of the superchilled fish as it influences the ice crystal formation during superchilling, together with the rate of the superchilling and the storage conditions (Kaale, 2014; Wu et al., 2014).

The superchilling process can be conducted in an impingement tunnel or cryogenic freezer at a temperature range from of –30°C to –40°C (air temperature) for 1.5–2 min (Duun and Rustad, 2007; Kaale et al., 2011; Cropotova et al., 2019), as well as in blast freezers usually taking longer time, e.g. up to 20–72 min (Bahuaud et al., 2008; Bantle et al., 2016) (Nile perch study), either alone or in combination with contact cooling (Valtýsdóttir et al., 2010; Erikson et al., 2011; Ólafsdóttir et al., 2012). The surface area/product weight ratio is a key parameter determining the rate of superchilling (Magnussen et al., 2008). On‐board practices, such as slurry ice or refrigerated salted water, could also be used for superchilling fish that will be subsequently transported/stored as superchilled on‐land (Thordarson et al., 2017).

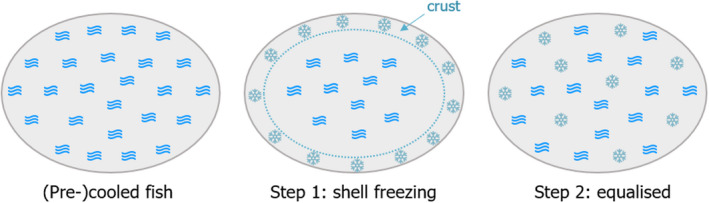

After the first stage of initial surface freezing (shell freezing), the 1–3 mm layer of ice formed on the surface of the product (as a crust) absorbs heat from the inner parts eventually resulting in equalisation of the temperature (Figure 3). Once superchilled, the capacity of the fish to absorb heat is the same before and after the temperature equalisation, but with a more homogeneous spatial distribution after the equalisation. The superchilled product will have an internal ice (cold) reservoir capable of absorbing heat9 from the external environment during storage and distribution, without changing significantly the product temperature (Magnussen et al., 2008; Margeirsson et al., 2012b). This is mainly due to latent heat, which is the heat energy that when added (absorbed) or removed (released) causes a change in the state of a material with no change in temperature (e.g. from ice to water). Relatively large quantities of heat are needed for the change in state (Pham, 2016).

Figure 3.

Steps in fish superchilling technology (adapted from Bantle et al. (2016)), where fish is represented as a section

The control of the superchilling process through the selection of optimal technological conditions depends on the equipment used as well as on the food product, dimensions (size and geometry) and the target degree of superchilling (as the ice fraction after the equalization step) depends on the intended use or processing after storage (Magnussen et al., 2008; Stevik et al., 2010). In practice, the key temperature measurement is the one performed after the temperature equalisation is complete (Magnussen et al., 2008; Wu et al., 2014).

According to Kaale et al. (2011), superchilling gives the food product an internal ice reservoir so that there is no need for external ice around the product during transportation or storage for short periods. However, for long‐term superchilled storage, refrigerated (chill environmental temperatures) storage keeping the fish at superchilled temperatures is required. To maintain the superchilled state, minimising the increase of the size of ice crystals inside the product, superchilled fish should not be exposed to temperature fluctuations (Kaale et al., 2011). Therefore, appropriate insulated packaging such as EPS boxes and strict control of temperature throughout the storage period should be used. This might be particularly important for fish supply chains including periods with no refrigeration e.g. loading and uploading for air transport (Mai et al., 2012). Temperature data loggers may be inserted into insulated packaging with the fish to monitor fluctuations of temperature during superchilled storage (Cropotova et al., 2019). Any disturbance in temperature or storage conditions may cause melting of small ice crystals inside the fish flesh and their further recrystallisation into large‐sized ice crystals (Wu et al., 2014), thus, reducing the fish quality. If the storage temperature melts all the ice in the fish matrix, the temperature of the fish will quickly increase, which can compromise the safety and quality of the product (Wu et al., 2014). This is due to sensible heat, which is the heat energy that is added or removed from a material that causes a change in temperature without a change of state, e.g. to warm up water (Pham, 2016).

Overall, superchilled storage and transport of fish allows not only the extension of shelf‐life but also a reduction in the amount of ice needed in the whole supply chain, with the consequent increase in the energy efficiency of the fish supply chain (Wang et al., 2008; Wu et al., 2014).

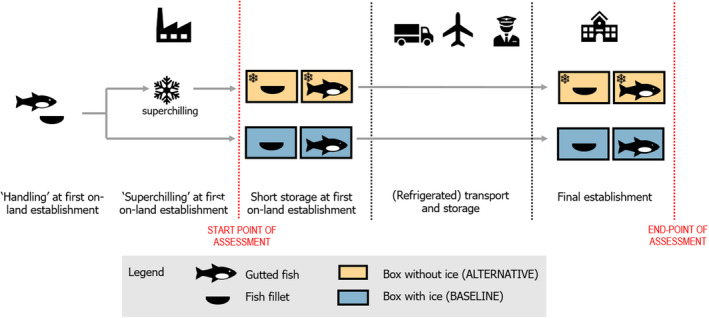

1.3.2. Approach to answer the ToR

A conceptual map of the conditions to be addressed in the current assessment is depicted in Figure 4. Upon arrival at the first on‐land establishment, the conditions to be compared in the assessment include:

Baseline or current condition: the CFFP are placed in expanded polystyrene (EPS) boxes with ice, where they are kept during transport and storage until the final establishment; and

Alternative condition: the SFFP are placed in EPS boxes without ice, where they are kept during transport and storage until the final establishment.

Figure 4.

Conceptual map of the conditions to be addressed in the current assessment

For the present assessment, the FFP are handled (gutted and/or filleted) at the first establishment and may be chilled (baseline) or superchilled (alternative condition) for the subsequent storage and/or transport to the final establishment. Good practice when handling fish catches, as well as the use of sufficient ice, was assumed. It was also assumed that the factors contributing to the initial status of the fish (e.g. intrinsic characteristics, conditions on‐board, hygienic status) were equal for the two conditions, and thus, the relative impact during the on‐land transport and storage would be equivalent.

To address the AQs to answer the ToRs, the following steps were undertaken:

Step 1: The temperature range of melting ice made from freshwater, under baseline conditions (CFFP) was defined (0°C). The temperature of the fish after a superchilling process under the alternative conditions (SFFP) was assessed in relation to the percentage of frozen water in the fish matrix.

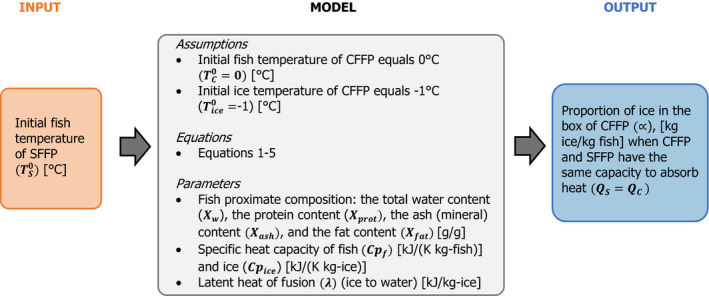

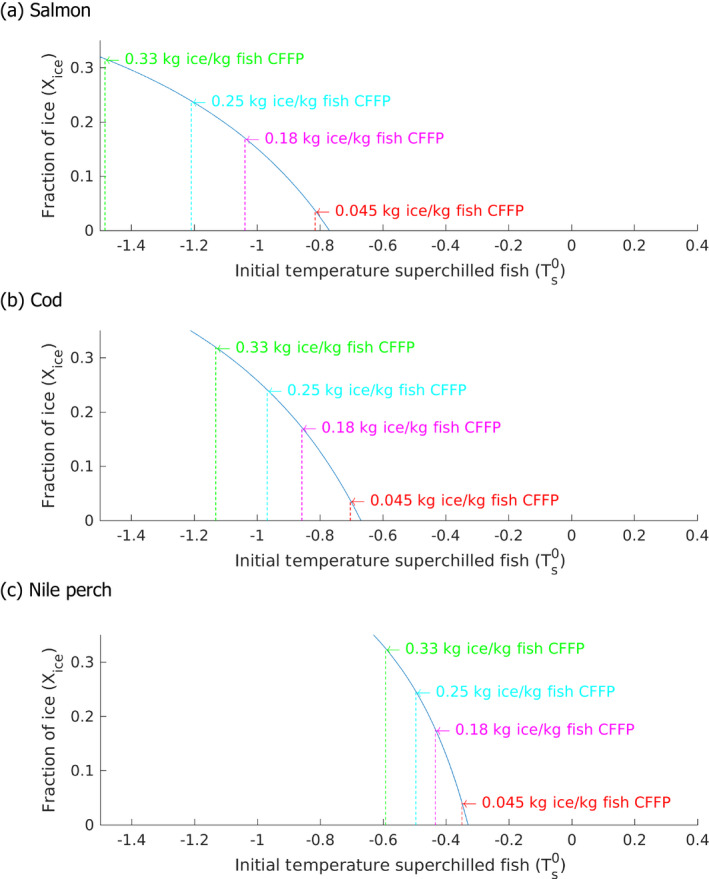

Step 2: A heat transfer modelling approach was developed to identify under which initial configurations the fish temperature of SFFP, at any time during the storage/transport, is lower or equal to CFPP, when exposed to the same conditions of on‐land storage and/or transport. This approach is feasible since the boxes used to transport the fish are the same (e.g. EPS boxes). A MS Excel spreadsheet tool based on this model was built to calculate the initial configurations of SFFP (i.e. ice fraction within the fish matrix associated with an initial superchilled fish temperature) that can be used by the FBO as part of the ‘safety‐by‐design’ approach. More specifically, this approach allows identification of scenarios under which initial configurations the SFFP will be equivalent or have a higher capacity to absorb heat than CFFP. For simulation purposes, three types of fish were considered: salmon (as an example of fish with a high fat content), cod (as a lean fish) and Nile Perch (as a temperate freshwater fish).

Step 3: A literature review was carried out to find data on the time/temperature profiles occurring during the storage and transport of SFFP, recording when available the critical parameters/factors determining the performance of the system to keep the fish temperature under control (e.g. initial fish temperature, outside temperature conditions). The search was particularly focused on the studies comparing SFFP with CFFP stored/transported under the same outside conditions. The data in the Nile perch study were also used.

Step 4: the temperature conditions of the alternative condition (SFFP) are more favourable for microbial growth compared to the baseline condition (CFFP), the relevant biological hazards for growth would be derived from the tubs opinion (EFSA BIOHAZ Panel, 2020) and the potential growth assessed by applying available predictive models for specific pathogens and histamine accumulation. Otherwise, the alternative condition would be considered as at least equivalent to the baseline condition (i.e. SFFP are considered at least equally efficient to control pathogen growth compared to CFFP based on their temperature).

Step 5: A literature review was carried out to assess potential methods (including the HADH enzymatic test as evaluated in the Nile perch study) capable of differentiating between fresh/superchilled and frozen fish. The methods were listed, summarising key features, advantages and disadvantages for their use to assess whether a fish that has been previously frozen has been commercially presented as ‘superchilled’.

Step 6: The methods were appraised based on predefined criteria, taking into account several criteria including their capability and performance to differentiate fresh fish from fish frozen at various temperatures and the strength of evidence.

2. Data and methodologies

2.1. Fish temperatures under both conditions

2.1.1. Heat transfer modelling

Temperatures of fish stored or transported in ice under the current authorised practices (CFFP) are close to the temperature of melting ice, i.e. 0°C, provided that ice is made of freshwater (EFSA BIOHAZ Panel, 2020). Fish is usually not pre‐cooled below 0°C before storage or transport and the minimum temperatures during storage are close to 0°C for fish in close contact with the melting ice. Re‐icing is necessary to avoid a rise in the temperature of the fish if the whole mass of ice is melted. The ratio of ice mass per fish mass (α) is a critical parameter in CFFP determining the amount of heat that the system can absorb before the whole mass of ice is melted. This ratio needs to be adjusted depending on factors such as initial fish temperature, temperature and duration of storage/transport, and the insulating properties of the box used (EFSA BIOHAZ Panel, 2020).

The superchilling process reduces the fish temperature below the initial fish freezing point (T*) before its storage or transport. The initial freezing point is the highest temperature at which ice crystals first appear in the fish. Below the initial freezing point, the freezable water inside the fish is in thermodynamic equilibrium with the ice. The ice fraction (Xice) expressed as kg‐ice/kg‐fish depends on the superchilled fish temperature (Ts) as follows (Pham, 2014b):

| (1) |

where (Xfree) is the free water content, i.e. freezable water content (kg‐water/kg‐fish), i.e. the total water content (XW) minus bound water content (Xb). The degree of superchilling is determined by the initial ice fraction in the fish matrix (Xice) after the superchilling process and depends on the fish temperature after the equalisation and the free water content as described by Equation 1).

This approximation holds for temperatures close to and below the initial freezing point, i.e. (Ts ≤ T*), and for non‐processed fish without added solutes (such as sodium chloride). The bound water and initial freezing point can be estimated from the proximate composition10 of the fish with the following empirical equations (Pham, 1996):

| (2) |

| (3) |

where Xash is the ash (mineral) mass fraction, Xprot is the protein fraction and Xother is the mass fraction of components (such as carbohydrates) other than ash, water, proteins or fat.

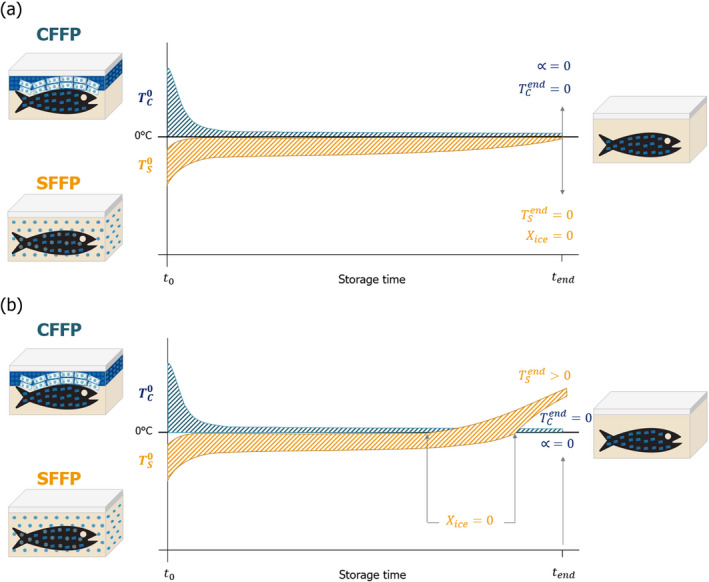

To assess under which conditions fish temperatures in SFFP may exceed temperatures in CFFP under equivalent storage conditions, a heat transfer balance was derived to know the heat absorbed by SFFP and CFFP. The following assumptions were made:

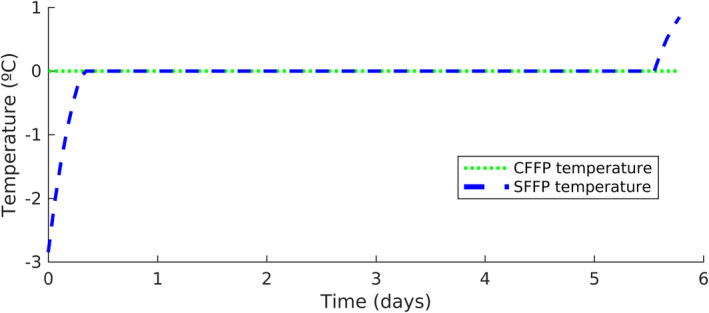

Before transport or storage, the initial fish temperature is homogeneous (assumption 1 in Table 4, with details in Appendix B.1) in the fish matrix (muscle, fat, bones, gut, tail) and denoted by for CFFP and for SFFP. The latter corresponds to the fish temperature after equalisation (once the initial layer of ice in the surface of the fish formed during superchilling has absorbed the heat from inner parts of the fish to reach an equilibrium), assuming that there will still be some ice in the matrix (Magnussen et al., 2008). Note that is higher than .

After transport and storage (end point of the assessment), ice becomes totally melted for both conditions (α = 0, Xice = 0) and fish temperatures are homogenous and equal to 0°C .

Table 4.

Potential sources of uncertainty identified in the assessment of the fish temperature and assessment of the impact that these uncertainties could have on the conclusion (i.e. over/underestimation of fish temperaturea and the extent of the over/underestimation)

| Source or location of the uncertainty | Nature or cause of the uncertainty | Impact of the uncertainty on the conclusions (e.g. over/underestimation) |

|---|---|---|

| Heat transfer model. Assumption 1: no spatial distribution was considered |

The temperature distribution was assumed to be homogenous in both CFFP and SFFP. For CFFP, this assumption implies an ideal situation in which the ice in the box is in perfect contact with all of the fish. |

The impact of the assumption depends on the Biot number (representing the fish internal resistance compared with the surface of the fish resistance) and it would be high if the Biot number is much larger than 1 (Pham, 2014a). Estimations of the Biot number considering the parameters for a box made for HDPE with geometry and conductivities as defined in (EFSA BIOHAZ Panel, 2020), are always below 1 and therefore the impact is expected low (see Appendix B.1). The direction of the impact depends on the spatial location of the temperature inside the fish. For example, when the outside temperature is higher than the fish temperature, in general as the model estimates a temperature for the whole fish, it is an underestimation of the fish surface temperature and an overestimation of the temperature in the centre of the fish. In CFFP, this will be affected by the ice spatial distribution close to the fish, i.e. the underestimation of surface temperature would be only relevant for the fish surface far from the ice. In SFFP, this will have little influence as ice is inside the fish matrix. |

| Heat transfer model. Assumption 2: heat is absorbed at similar rate in SFFP and CFFP | Rate of absorption depends on the heat transfer coefficient (h), the box exposed area (A) and the differences between the outside‐of‐the‐box temperature and the fish temperature. Note that box and outside temperatures are equal for CFFP and SFFP, but not for the fish temperature (usually lower in SFFP) and therefore absorption rate might be faster in SFFP than in CFFP |

To assess the impact of this assumption, a model based on time‐to‐melt‐all‐ice, which does not rely on this assumption, was derived in Appendix B.2. In the worst case, when the capacity to absorb heat is equal in SFFP and CFFP and in a system without insulation, SFFP temperatures might be higher than CFFP only for the last 3% of the storage time. Therefore, the impact is low and results could slightly underestimate the temperature of SFFP, but only for a short period of time and always for less than 0.85°C in a configuration with a box without insulating material. As SFFP and CFFP are stored in insulating EPS boxes, and the temperature of the SFFP at the beginning of the storage will always be lower than CFFP, the impact will be very limited. |

| Heat transfer model. Assumption 3: specific heat capacities were considered constant |

Specific heat capacities (Cp parameter) used in the model are known to be temperature dependent, though mathematical functions are not easy to find/estimate. For the fish type assessed the quantitative relationship between Cp and temperature were not available. For the main assessment and the MS Excel tool developed, constant values at temperatures slightly above zero were used for fish, ice and water. As the Cp for Nile Perch is unknown, the Cp for cod (lean fish) has been used for the simulations. |

Cp values below 0°C are usually greater (see for example values for cod in (Margeirsson et al., 2012b) than those considered in the model. The values used were conservative and provided a slight overestimation of the temperature of SFFP. In any case, the impact of this approximation is low as it affects at sensible heat that was not as relevant as the latent heat in the current assessment. |

| Heat transfer model. Uncertainty in the estimation of the ice fraction in the fish matrix of SFFP X ice |

This uncertainty appears only when Xice is unknown and is to be estimated from the initial freezing point T*. Xice is calculated using a function of free water content: and initial freezing point (T*), as shown in the semi‐mechanistic Equation 1), based on thermodynamic equilibrium of freezable water and ice inside the fish). Xfree and T* are calculated with their relationship with the proximate composition. T* in raw muscle foods are often quoted as –2°C or lower, despite there is scientific evidence that according to measurements it is much nearer to –1°C (Miles et al., 1997). T* was calculated from an empirical equation using the fish composition (Equations 2 and 3). The food composition information is not always complete and subject to analytical and specific analysed sample uncertainty. Moreover, the composition provided in literature and databases is not always complete, particularly for the ash content. |

In Appendix B.3, the uncertainty on the capacity to absorb heat in SFFP was derived when there are uncertainties in Xfree and T* (that will impact the initial Xice in superchilling and therefore the degree of superchilling). The impact of this assumption is the largest of all the identified uncertainties, as it is proportional to the latent heat (λ), which is a large number. The direction depends on the direction of the errors in T* and Xfree as described in Appendix B.3. For instance, an overestimation of T* (assume T* = –0.3°C when it is T* = –0.4°C) will cause an overestimation of Xice, leading to consider that SFFP has a similar capacity to absorb heat compared to CFFP (QS = QC) when in reality it has lower capacity to absorb heat (QS < QC). Consequently, temperatures in SFFP will be actually higher than the estimated and could rise above 0°C before all ice is melted in CFFP. In this case, the temperatures of SFFP can be higher than those of CFFP at the end of storage/transport, but still lower than CFFP at the beginning. The impact of this uncertainty is particularly relevant when the degree of superchilling (as Xice) is monitored through the initial superchilled fish temperature ( ). In addition, the latter is subjected to uncertainties related to the superchilling technology (e.g. variability of the capacity to decrease the fish temperature within a batch of fish) and can also be subjected to measurement error (instrumental error) and variability depending on when and where (within the fish matrix) point it is measured. This additional uncertainty can cause both under‐ and overestimation of the initial superchilled temperature. In the current assessment, the capacity to absorb heat for CFFP and SFFP has been focused on the comparison of the initial configuration parameters α (proportion of ice:fish in CFFP) and Xice to minimise the impact of the uncertain estimation of Xice from T* and Xfree. However, the tool made available based on the developed heat transfer model, uses T* and Xfree to make the simulations. Therefore, the accuracy of the input data is key for obtaining reliable outputs. |

| Literature data. Search methodology. |

In the absence of a commonly agreed definition of superchilling in literature, data on time–temperature profiles of SFFP (particularly in grey literature) may have gone undetected due to variability of terminology used. A critical appraisal of the retrieved studies was not performed. |

Under‐ or overestimation of the performance of SFFP compared to CFFP. Given the use of an extensive literature search (and use of various terms related to superchilling such as partial freezing, deep chilling or sub‐chilling) and the criteria adopted for literature screening, uncertainty associated with missing evidence in this step was minimised. |

| Literature data. Number of retrieved data. | Limited availability of data directly comparing SFFP and CFFP during transport/storage. Particularly, given the few records addressing the topic, the effect on SFFP of factors such as different superchilling technologies and variability in the transport/storage chains was not investigated. | Under‐ or overestimation of the performance of SFFP compared to CFFP in relation to different superchilling technologies. |

HDPE: high‐density polyethylene

unless stated otherwise fish temperature refers both to CFFP and SFFP.

The capacity to absorb heat in CFFP during storage and transport relies on increasing the ice temperature from its initial value to 0°C and on melting ice and must compensate the energy needed to cool the fish from its initial temperature to 0°C and to keep it close to 0°C during storage and transport. Therefore, the capacity to absorb heat per kg of fish (QC) can be expressed through the next equation:

| (4) |

being λ the latent heat of ice, αα the mass of ice (mice) per mass of fish (mf) (kg‐ice/kg‐fish), Cpf the fish heat capacity and Cpice the ice heat capacity. Both Cpf and Cpice were assumed to be constant (see uncertainty Section 3.1.4).

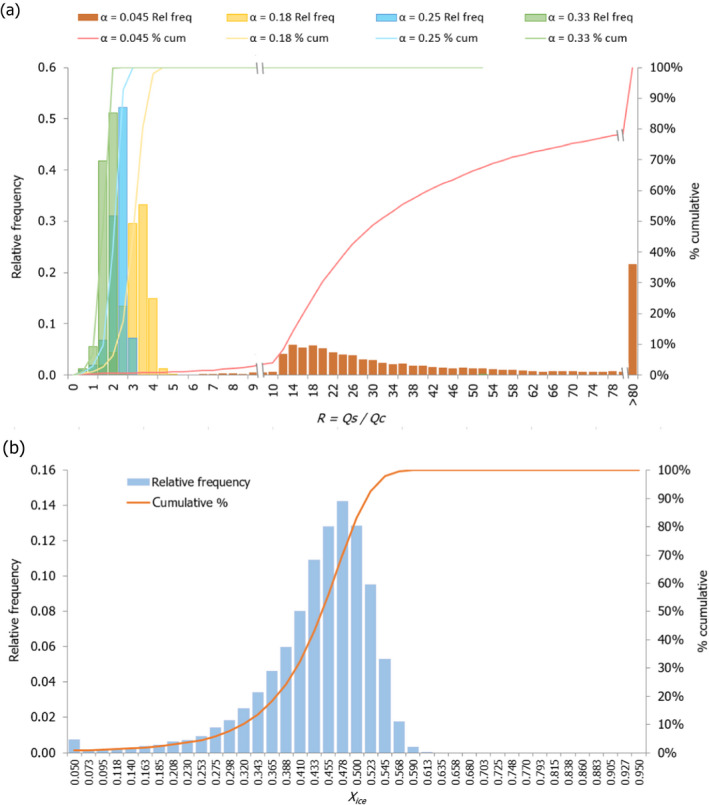

The proportion of ice and fish (α) that is used to store and transport the CFFP varies notably as it is usually adjusted to ensure that enough ice is present to keep the fish temperature close to that of the melting ice, taking into account of the initial fish temperature and the storage and transport conditions, including the time (Alasavar and Quantick, 1997; EFSA BIOHAZ Panel, 2020). The following foreseeable scenarios were considered:

1 kg ice for 22 kg of fish (α = 0.045) of fish at an initial temperature of maximum 4°C (Lynum, 2007).

4 kg ice for 22 kg of fish (α = 0.18) as a reasonable foreseeable condition (fish temperature not stated) (Margeirsson et al., 2017).

0.75 kg ice for 3 kg of fish (α = 0.25) (fish pre‐cooled but often rising in temperature of up to 7°C after being filleted and handled) as applied in Flemish fish auction as provided by Sven Van Acker (Director Operations at the Vlaamse Visveiling nv) by e‐mail on 2 December 2020 (Van Acker, 2020).

1 kg ice for 3 kg of fish (α = 0.33) with the fish temperature not stated (Alasavar and Quantick, 1997; Laguerre et al., 2018).

Capacity to absorb heat in SFFP during storage and transport relies on raising the fish temperature from its initial value to 0°C and keeping it close to 0°C, while frozen water inside the fish matrix melts. Mathematically, the capacity of absorbing heat per kg of fish (QS) can be expressed through:

| (5) |

being Xice the ice fraction (kg‐ice/kg‐fish) as described by Equation 1) and Cpf the heat capacity of superchilled fish, assumed constant.

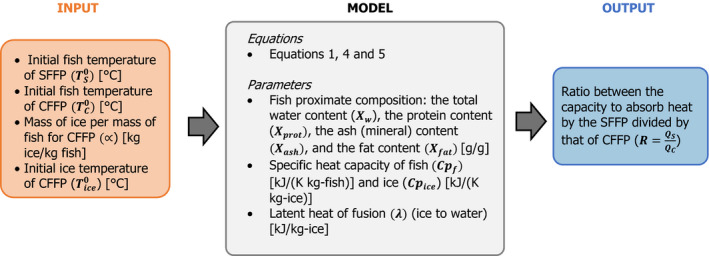

For the main assessment, it was assumed that both conditions absorb heat at the same rate. The impact of this assumption was evaluated in Appendix B.2 and included in the uncertainty analysis (assumption 2 in Table 4). Therefore, only when the capacity to absorb heat of the SFFP system is lower than that of the CFFP (Qs < Qc), ice in SFFP will melt before ice in CFFP is melted and the temperatures of SFFP may be (but not necessarily be) higher than those of CFFP. In this respect, the ratio (R) between the capacity to absorb heat between both systems can be determined as:

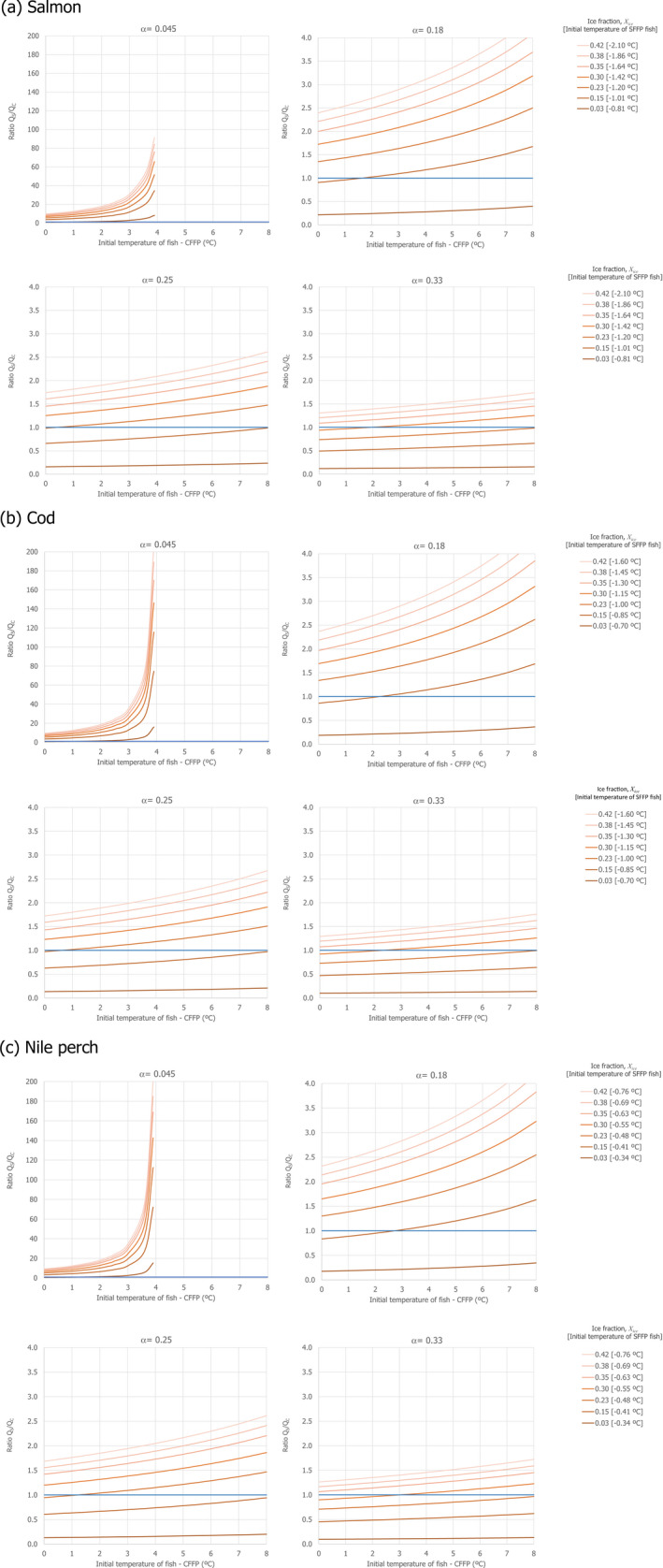

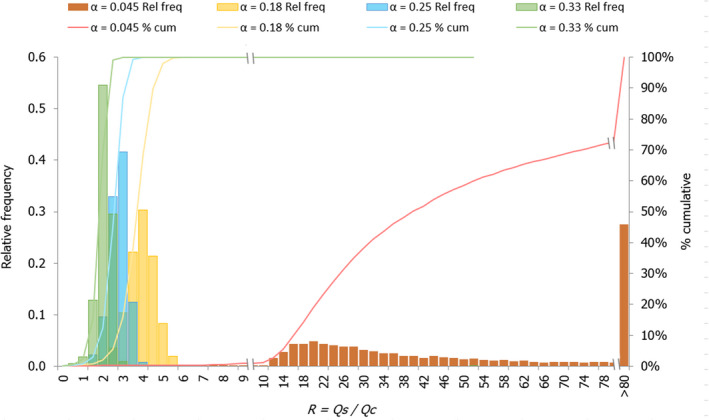

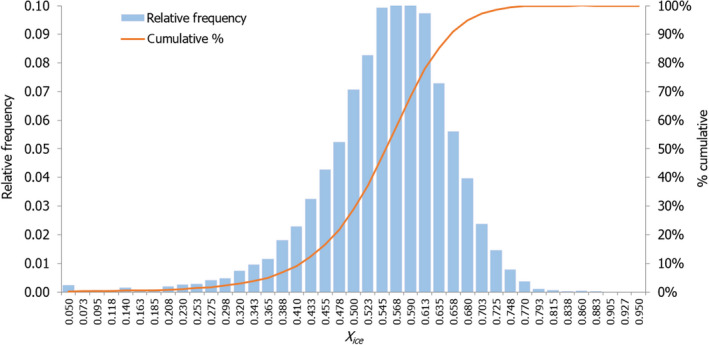

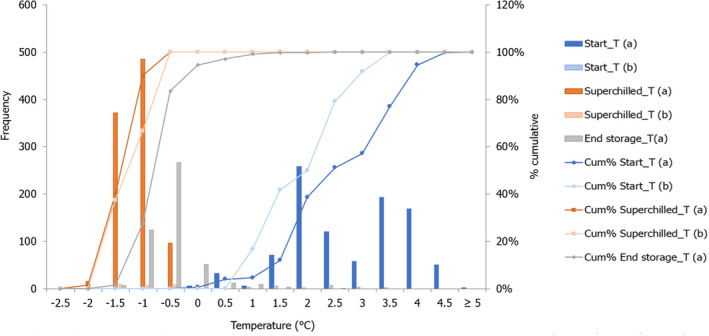

For the particular case of Nile perch, a stochastic approach was applied in order to assess the impact of the variability distribution of key parameters, such as the initial freezing point of the fish, the free water content of the fish, the initial temperature of the ice and the fish in the CFFP and the initial fish temperature of the SFFP, on the probability that the capacity to absorb heat by the SFFP was at least equivalent to that of CFFP (i.e. R ≥ 1). This stochastic assessment was applied for four scenarios of the proportion of ice:fish (α) regarding the CFFP initial configuration considered in the deterministic approach.

Table 1 summarises the input parameters used for the deterministic simulations and stochastic assessment carried out with the heat transfer model together with the supporting references.

Table 1.

Input parameters for the simulations carried out with the heat transfer model using a deterministic approach for salmon, cod and Nile perch and using a stochastic approach for Nile perch

| Parameter [units] | Nomenclature | Input and parameter values for the deterministic approach | Input and parameter values or distribution functions for the stochastic approacha | Supporting information | |

|---|---|---|---|---|---|

| Specific heat capacity of ice [kJ/(K kg‐ice)] | Cpice | 2.052 | 2.052 | Comsol (example of ‘phase change’ in library)f and EFSA BIOHAZ Panel (2020) | |

| Latent heat of fusion (ice to water) [kJ/kg‐ice] | λ | 333.5 | 333.5 | Comsolf (example of ‘phase change’ in library) and EFSA BIOHAZ Panel (2020) | |

| Specific heat capacity of fish [kJ/(K kg‐fish)] | Cpf | 3.5 (for fat fish, salmon) | NA | (Rahman, 2009), (Tolstorebrov et al., 2019) and (Radhakrishnan, 1997) in EFSA BIOHAZ Panel (2020) | |

| 3.73 (for lean fish, cod and Nile perch) | 3.73 | (Margeirsson et al., 2012b) and EFSA BIOHAZ Panel (2020) | |||

| Initial freezing point of fish [°C] | T* |

–0.77 for salmon –0.67 for cod –0.33 for Nile perch |

NA NA Normal (–0.33; 0.14) |

Calculated from the proximate composition data found in literature (see Table 2) and Equation 3) | |

| Free water content in fish [kg water/kg fish] | Xfree |

0.6577 for salmon 0.7828 for cod 0.7279 for Nile perch |

NA NA Normal (0.7279; 0.0230) |

Calculated from proximate composition data found in literature (see Table 2) and Equation 2) | |

| Kg ice per kg of fish for CFFP [kg ice/kg fish] | α | 0.045; 0.18; 0.25; 0.33 | 0.045; 0.18; 0.25; 0.33 | Four different foreseeable scenarios of CFFP initial configuration (see Section 2.1.1) | |

| Initial ice temperature of CFFP [°C] |

|

–1°C | Triangular (–1.5; –1; 0) | Conservativeb assumption based on Laguerre et al. (2018); Jain et al. (2005) and EFSA BIOHAZ Panel (2020) | |

| Initial fish temperature of CFFP [°C] |

|

From 0 to 8°C | Triangular (0.25; 3.5 ;4.81) |

Deterministic approach: different foreseeable scenarios considering pre‐cooled fish (0°C) to fish showing a higher temperature after handling (gutting, filleting etc. up to 8°C) (Erikson et al., 2011; EFSA BIOHAZ Panel, 2020) Stochastic approach: distribution of temperature of Nile Perch before the superchilling process (‘Nile perch study’) |

|

| Initial ice fraction [kg ice/kg fish] | Xice | From ca. 0.03 to 0.42 | NA | Estimated with Equation 1) using different foreseeable scenarios of initial SFFP temperature ( )c | |

| Initial fish temperature of SFFP [°C]d |

|

NAe | Normal (–1.35; 0.32) | Distribution of temperature of Nile Perch after the superchilling process (‘Nile perch study’) |

NA: not applicable.

10,000 iterations made with @Risk (Palisade).

For the present comparative assessment framework, –1°C constitutes a conservative input value because compared to the slightly higher value usually considered (–0.5°C to 0°C), it favours the capacity to absorb heat by CFFP, and leads to a decrease in the R value.

The initial SFFP fish temperature (and the initial ice fraction, Xice in %) was: –0.88°C to –2.10°C (i.e. 3% to 42% ice fraction) for salmon; –0.70°C to –1.60°C (3% to 42% ice fraction) for cod; –0.34°C to –0.76°C (i.e. 3% to 42% ice fraction) for Nile perch. For each fish species, the initial ice fraction (Xice) in the SFFP matrix was calculated from Equation 1), using the T* and Xfree values described from the proximate composition of fish (Equations 2 and 3).

This parameter can be easily and routinely measured by the FBO. For the stochastic approach of the present assessment, this parameter was used to derive the initial ice fraction (Xice) used in the deterministic assessment.

In the deterministic approach the initial fish temperature of SFFP is derived from the initial ice fraction (degree of superchilling).

An MS Excel spreadsheet tool was built, based on the developed conservative heat transfer model, that can be used as part of ‘safety‐by‐design’ approach of the FBO to identify under which initial configurations the SFFP will be at least equivalent or better than CFFP in terms of total heat absorption capacity. The tool enables the setting of the degree of superchilling for SFFP (i.e. the ice fraction in the fish matrix, which depends on the fish temperature after superchilling and the initial freezing point of fish) that is considered able to maintain fish temperature below or equal to that of a given configuration of CFFP regarding the initial fish temperature and the proportion of ice added per mass of fish (ice:fish) in the box (R ≥ 1, corresponding to ≥). The tool facilitates identification of configurations under which the SFFP cannot be proved to be equivalent or better than CFFP (R < 1, corresponding to Qs < Qc). The tool has been made available through the Knowledge Junction under https://doi.org/10.5281/zenodo.4304283. It is named the heat transfer model tool for the heat absorption capacity of superchilled fresh fishery products (HTM‐SFFP Tool). It has following options and in each option there is the possibility to estimate the initial freezing point of fish and free water of fish from the proximate composition:

-

To derive if superchilling is able to maintain fish temperature below or equal to that of CFFP at any time of storage before all ice melts, based on

-

o

the target % of frozen free water in SFFP (option 1)

-

o

the initial superchilled fish temperature (option 2)

-

o

To derive the initial superchilled fish temperature and percentage of ice in superchilled fish needed to equal the absorbing heat capacity of CFFP before all ice melts (option 3)

-

To derive the proportion of ice in CFFP to equal the absorbing heat capacity of SFFP before all ice melts, based on

-

o

the target % of frozen free water in SFFP (option 4)

-

o

the initial superchilled fish temperature (option 5)

-

o

2.1.2. Literature

The strategy for conducting the literature searches and screening is provided in Appendix C. A general search was conducted in Web of ScienceTM Core Collection (1975–present) to retrieve various types of information on superchilling of FFP. The records were screened for information on the use of superchilling of FFP (with the exception of bivalve shellfish, as this was not relevant for this assessment) and on the temperatures of SFFP during subsequent storage. Further information on temperatures of SFFP during transport and/or storage was retrieved through the literature review, as detailed in Appendix C.1, and through expert consultation.

The information in the ‘Nile perch study’ was used to gather data observed in actual commercial superchilled fish from the Lake Victoria region to the EU (see Section 1.3.1.1).

2.2. Potential methods to detect whether a previously frozen fish is commercially presented as ‘superchilled’

Two searches were conducted in Web of ScienceTM Core Collection (1975–present). The searches aimed to retrieve information on potential markers to distinguish fresh/superchilled fish meat from frozen/thawed fish meat. The strategy for conducting the literature searches and screening is provided in Appendix C.2.

Two tables were compiled with information at record level. The first one referred to as ‘record overview table’ was organised by method category, i.e. biochemical or morphological and physico‐chemical, with subgrouping within each group (e.g. enzymatic). Data were extracted about the methodology used, the conditions tested considering the fish species, the temperatures, duration and method used for fish freezing. The information extracted about the results included (if applicable and/or provided):

if a statistically significant difference in the measured parameter between fresh and frozen/thawed fish was found;

the analytical threshold values;

the influence of freezing temperatures, i.e. the minimum (tested) freezing temperature for which the method could detect the fish as frozen;

the influence of the freezing duration, i.e. the minimum (tested) freezing time for which the method could detect the reaction or the change that the method analyses;

the influence of freezing technology or process;

the influence of post‐harvest changes occurring in fish, either from biochemical or microbiological origin; and

the classification performance in discriminating fish as either frozen/not frozen through validation with additional/external samples.

An appraisal of the relevance of each study (appropriateness to answer the ToR) was carried out based on the following criteria to be answered by yes (score 1) or no (score 0). All criteria have the same weight:

Q1: Could different groups of samples (fresh and frozen/thawed) successfully be differentiated based on statistical tests?

-

Q2: Did the study include method validation?

-

o

For the biochemical methods, this refers to the analytical accuracy, precision, sensitivity, specificity and reproducibility.

-

o

For the physico‐chemical methods, this refers to testing the algorithm with samples (calibration/training set of samples) used for the developing the algorithm, i.e. cross‐validation describing the determination or correlation coefficient, accuracy (or overall rate of correct classification), sensitivity, specificity, etc.

-

o

Q3: Did the study consider different freezing temperatures?

Q4: Were freezing temperatures above –18°C included?

Q5: Did the study include superchilled samples or slightly frozen (e.g. ≥ –5°C) samples?

Q6: Did the study consider different frozen storage durations?

Q7: Did the study consider the influence of post‐harvest quality changes in fish?

Q8: Is there information available on the freezing technology or process (e.g. rate) in the study?

Q9: Was the method applied to different fish species?

Q10: Was a threshold or any differentiation tool/criteria proposed for each fish species in the study?

Q11: Was a classification performance (e.g. percentage of correct classification) included in the study using an independent set of samples (i.e. not part of the samples used for method validation in Q2 and/or fish coming from a different batch)?

The second table called ‘analytical capability table’ summarises the retrieved information related to the capability of the method to detect previously frozen fish, frozen at different temperatures and for different fish species.

Furthermore, two additional tables were compiled on method subgroup level. The third table called ‘advantages/disadvantages table’ describes the advantages and disadvantages by method subgroup based on the results of the different studies and other characteristics of the methods related to the ease of use and technical resources required (i.e. fast or slow execution, destructive or not, laborious or not, standard or more advanced (expensive or uncommon) laboratory equipment needed, simple or specialised skills needed, need of threshold/calibration setting by species or group of species; the technological readiness for commercial applications).

A fourth table called ‘evaluation table’ includes the evaluation of each method subgroup based on a scoring system for different evaluation criteria. The criteria are:

Applicability of the method towards species;

Ability of the method to differentiate fresh fish from fish frozen at various temperatures;

Use as a stand‐alone method;

Ease of use of the method (e.g. fast, not too laborious, not destructive);

The method was validated (e.g. determination of accuracy, precision, intra/interlaboratory‐reproducibility, sensitivity, specificity);

Classification performance in discriminating as either frozen/not frozen using an independent set of samples;

Evidence that superchilled fish will behave like fresh fish for the given method; and

Strength of evidence expressed as the number of records and the average appraisal score (from the 11 questions listed above), the latter being the division of the total appraisal score of all the records and the number of records; from the record overview tables.

The scoring system is defined in the following way:

0 = no information available;

– = poor performance;

+ = weak performance/weak evidence;

++ = good performance/good evidence; and

+++ = excellent performance/good evidence.

An overall score by method was given based on the information gathered from the literature. The scores were cross‐checked and validated by peers within the working group.

2.3. Uncertainty analysis

Based on the EFSA guidance on Uncertainty Analysis in Scientific Assessments (EFSA Scientific Committee, 2018a) and scientific opinion on the principles and methods behind EFSA's Guidance on Uncertainty Analysis in Scientific Assessment (EFSA Scientific Committee, 2018b), special attention was given to: (i) the interpretation of the ToRs, i.e. framing of the mandate and the AQs, (ii) identifying sources of uncertainty and (iii) their impact on the outcome of the assessment. The identified assumptions and other sources of uncertainty were listed and, in some cases, the impact was quantified. The experts elicited the overall uncertainty associated with the final outcome of the AQs through expert group judgement taking into account the quantified and non‐quantified sources of uncertainty.

3. Assessment

3.1. Temperature profile of transported/stored SFFP and CFFP and, if relevant, its impact on the increase of biological hazards

3.1.1. Modelling the temperature profile of transported/stored SFFP and CFFP

3.1.1.1. Temperature of melting ice and initial freezing point of fish

The temperature of melting ice is the freezing point of water at which the first ice crystal appears. If ice is made of freshwater, the melting ice temperature is 0°C at atmospheric pressure (Pham, 2016).

In fish, the temperature required to obtain the first crystals of ice in fish during the superchilling process is lower than in freshwater because free water in fish has solutes that makes the initial freezing point (T*) lower than the freezing point of freshwater. The soluble components such as ions, acids and soluble proteins contribute to freezing point depression, while insoluble components such as fat and insoluble proteins do not (Miles et al., 1997). Moreover, during superchilling and freezing of fish, when fish water freezes, it leaves increasing concentrations of solutes in the remaining non frozen water, which lowers its freezing point further (note that in water ‘initial freezing point’ and ‘freezing point’ are the same and equal to 0°C). In fish, there might be some water bound to the solid matrix (water associated with changed ionic groups of food components with restricted mobility) not participating in the freezing process (Rahman, 2009; Pham, 2016; Damodaran and Parkin, 2017), which needs to be taken into account when estimating the initial freezing point and the ice fraction in the fish matrix (see Section 2.1.1).

Therefore, T* in fish is below the temperature of melting ice. In fresh non‐dehydrated and non‐processed (added solutes) food, T* depends on several factors (Pham, 1987; Miles et al., 1997). The composition linked to the fish species in terms of free water content and solutes on free water explains why T* in freshwater fish is usually higher compared to seawater fish and that of pelagic fish is lower compared to demersal fish (Wu et al., 2014). The sea temperature where the fish lives before its capture influences the amount of solutes and thus the initial freezing point; e.g. in Atlantic cod (Gadus morhua), it was reported to vary between –0.8°C in July–August and –1.3°C in March (Simpson and Haard, 1987).