Abstract

Bone tissue engineering (BTE) encompasses the field of biomaterials, cells, and bioactive molecules to successfully guide the growth and repair of bone tissue. Current BTE strategies rely on delivering osteogenic molecules or cells via scaffolding materials. However, growth factor- and stem cell-based treatments have several limitations, such as source restriction, low stability, difficulties in predicting long-term efficacy, and high costs, among others. These issues have promoted the development of material-based therapy with properties of accessibility, high stability, tunable efficacy, and low-cost production. Hydrogels are widely used in BTE applications because of their unique hydrophilic nature and tunable physicochemical properties to mimic the native bone environment. However, current hydrogel materials are not ideal candidates due to minimal osteogenic capability on their own. Therefore, recent studies of BTE hydrogels attempt to counterbalance these issues by modifying their biophysical properties. In this article, we review recent progress in the design of hydrogels to instruct osteogenic potential, and present strategies developed to precisely control its bone healing properties.

Graphical Abstract

Introduction

Bone is a highly mineralized tissue with a solid intercellular matrix. It has a biphasic extracellular matrix (ECM) that is composed of both an inorganic mineral and an organic phase, consisting of 90% collagen and 10% non-collagenous proteins, including growth factors1. Bone also preserves bone marrow producing mesenchymal stem cells and possesses a set of bone cells that include osteoblasts, osteocytes, and osteoclasts2.

Bone remodeling is a dynamic process that involves recruitment of cells, cytokines, and growth factors. However, a self-remodeling is not achievable with the severe defects or in the presence of complications, such as osteoporosis, osteoarthritis, or osteogenesis imperfecta3. Common treatments such as autografts or allografts are difficult to utilize extensively because of their source limitations, potential for infection, and adverse immune responses. Therefore, the demand for effective bone repair strategy is growing and has led to increased research in bone tissue engineering (BTE). The success of BTE is governed by several key factors, such as the osteogenic scaffold, osteogenic cells, and osteogenic stimulating factors. A treatment based on each component or a combined strategy is appealing, but the field of BTE is currently dominated by growth factor-based treatment. A treatment using bone morphogenetic proteins (BMPs) is well-established because of its high efficacy; however it is associated with severe side effects when supraphysiological doses are administered and poor delivery efficiency using currently available delivery system4.

A hydrogel is a viscoelastic polymeric scaffold with significant water uptake ability mimicking bone ECM5. An aqueous three-dimensional environment provides the hydrogel with unique properties, such as injectability, swelling, and surface absorption. A hydrogel has potential to entrap and attract native cells by providing anchoring sites on its mesh network. It is able to deliver proteins or small molecule drugs locally, and its ion adsorption ability initiates mineralization on the hydrogel surface to provide a bone-like environment. Therefore, hydrogel is a promising candidate for use as an osteogenic scaffold, and as an osteogenic carrier for delivery of cells or stimulating factors.

The ideal attributes of a hydrogel for BTE are 1) biocompatibility, 2) biodegradability, 3) in-situ gel formation ability, 4) integration with surrounding tissues, 5) delivery of cells or drugs, and 6) osteogenic properties. These properties can be diversified by a choice of hydrogel polymer backbone, crosslinking, and various functionalizations. Advances in engineering hydrogels have provided many candidate hydrogels with the above-mentioned properties; however, osteogenic capacity is still very limited. Improvement of osteogenic performance of a hydrogel enables the simple biomaterials based (cell- and growth factor-free) strategy of BTE. Osteogenic performance of a hydrogel requires a delicate balance of osteoinduction, osteoconduction, and osseointegration over a long period of bone healing6. However, many hydrogels used in bone repair have insufficient intrinsic osteogenic function, leading to limited healing in clinical settings7. In this article, we will focus on reviewing the fundamentals and various state-of-the-art approaches used to design an osteogenic hydrogel system, and the ongoing challenges and subsequent opportunities in the field.

1. Hydrogel fundamentals

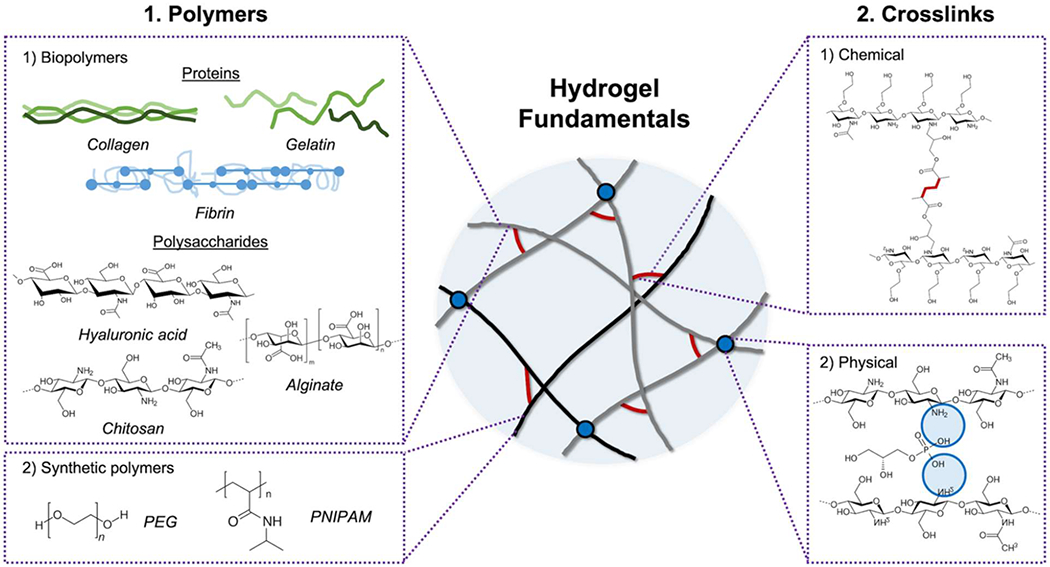

The use of hydrogels is attractive in BTE due to its ability to mimic the bone ECM with high water contents that could provide suitable microenvironments to encapsulate cells or bioactive molecules. Additionally, hydrogels with injectable capability enable filling irregular bone defects with a good integration into the surrounding tissues, while avoiding complex surgery. However, there are challenges concerning osteoconductivity, mechanical stability, and the loss of encapsulated bioactive components that need to be further investigated for successful BTE. The characteristics of a hydrogel can be modulated by its source and crosslinking methods. Polymeric hydrogels are widely used in tissue engineering because of their tunable physicochemical properties. Crosslinking is usually required to protect a hydrogel from rapid degradation and improve its stability. In this section, we will introduce polymer sources and crosslinking technologies being used to construct BTE hydrogels and discuss their advantages and limitations for use in bone repair (Figure 1).

Figure 1.

Scheme of hydrogel fundamentals. Hydrogel is formed by crosslinking of polymer network, and its physicochemical properties can be modulated by the choices of polymers and crosslinking methods. Various types of biopolymers, including proteins (collagen, gelatin, and fibrin) and polysaccharides (hyaluronic acid, chitosan, and alginate), and synthetic polymers are widely used in BTE hydrogels. Diverse crosslinking technologies (chemical and physical) support the mechanical stability of hydrogels. The representative scheme of the chemical and physical crosslink is a radical crosslinking of methacrylated glycol chitosan and an ionic crosslinking of chitosan with glycerol phosphate, respectively.

1.1. Polymers used as backbones of hydrogels for BTE

Polymers are promising materials to prepare BTE hydrogels and can be classified into natural and synthetic polymers by their sources. The main advantages and drawbacks are listed in Table 1. No single material meets all requirements for successful bone regeneration, requiring further modifications to obtain desired biophysical properties.

Table 1.

Comparative table of polymers to fabricate hydrogels for bone regeneration

| Polymer | Advantages | Drawbacks |

|---|---|---|

| Collagen | - Most abundant ECM in bone - Providing cell attachment sites - Natural growth factor reservoir |

- Potentially provoking immune response - Hard to control the quality due to heterogeneity of sources |

| Gelatin | - Mimicking bone ECM - Lower immunogenicity than collagen - Easy to functionalize |

- Fast degradation - Low mechanical strength |

| Fibrin | - Providing cell attachment sites - Easy to tune mechanical strength - Fast gelation |

- Significant shrinking during gelation - Fast degradation - Low bone specific bioactivity |

| Hyaluronic acid | - Interacting with growth factors - Low immunogenicity - Easy to functionalize |

- Low mechanical stability without crosslinking - Fast degradation |

| Chitosan | - Inherent antibacterial properties - Easy to functionalize - Low immunogenicity |

- Requiring additional modification to improve solubility |

| Alginate | - Fast gelation - Easy to functionalize |

- Possibility to lose structure by cation leaching |

| Nucleic acid | - Easy to control structure due to its specific basepairing properties | - Difficult to make a bulk hydrogel |

| PEG | - Easy to functionalize - Stable in physiological condition |

- Nondegradable - Low cell adhesion - Some immunogenicity |

| PNIPAM | - Temperature sensitive - Low immunogenicity |

- Nondegradable - Weak mechanical strength |

1.1.1. Biopolymers

Biopolymers derived from natural macromolecules are an advantageous hydrogel source in BTE resulting from their biocompatibility, biodegradability, and similarity to natural bone ECM. Natural proteins, such as collagen, gelatin, or fibrin, and polysaccharides, such as hyaluronic acid, chitosan, or alginate, are extensively used in the field. These biopolymers can be used alone, or blended with other polymers to form a composite depending on the application.

1) Collagen is the main constructional protein in bone ECM and type I collagen is the most abundant among the five common types of collagen, I, II, III, IV, and V. The molecular weight of collagen is approximately 300 kDa with a long triple helix fibril structure. This elongated structure provides mechanical strength by hierarchical assembly. The integration of hydroxyapatite in fibril networks can enhance the mechanical properties of the materials, as well as provide biochemical cues. Collagen is known for successful cell attachment and differentiation of osteoprogenitor cells, which makes it widely used in BTE8. In the context of bone regeneration, type I collagen has been found to be a regulator of osteogenic differentiation of mesenchymal stem cells (MSCs) derived from rat bone marrow or dental pulp in vitro and in a rat calvarial defect9, 10. Collagen matrices are already being used in clinical practice to deliver BMP-2 for bone regeneration but premature leakage of BMP-2 could induce ectopic bone formation11. There are also continued concerns about the widespread use of collagen due to its challenging purification process, a risk of disease transmission and immune response12–14.

2) Gelatin originates from collagen and is usually referred to an irreversibly hydrolyzed collagen. Because of hydrolysis, the molecular weight of gelatin varies from 20 to 220 kDa, which is smaller than collagen. It undergoes undemanding degradation, which leads to lower immunogenicity in comparison to collagen. Gelatin possesses similar amino acid profiles to collagen and thus exhibits the ability to support cellular attachment and growth15. Different gelatin processing from collagen allows various physicochemical properties, providing versatile platforms for tissue engineering scaffolds or delivery vehicles16. On the other hand, the functional and bioactive properties of gelatin may differ from native collagen. Moreover, lower mechanical strength is a recurring issue in gelatin applications. A recent gelatin hydrogel was specifically designed to possess macroporosity and was shown to support robust endochondral ossification of human MSCs in a mouse subcutaneous model17. The compressive modulus of the engineered bone constructs was 10-fold higher compared to conventional gelatin hydrogels17.

3) Fibrin, a main part of the hemostatic clot, is formed by rapid reaction of thrombin protease on fibrinogen. Its mechanical properties and stability are easily tunable by adjusting fibrinogen and thrombin concentration. Fibrin is already being used widely as tissue adhesives and its intrinsic angiogenic properties make fibrin matrix attractive biomaterials for BTE18, 19. Fibrin prepared from platelet-rich plasma was successfully used in combination with dental implants to enhance osseointegration in elderly patients20. However, the specific effects of the growth factors present in platelets on bone repair is poorly understood.

4) Hyaluronic acid (HA) is a linear glycosaminoglycan with alternating β1→4 and β1→3 glycosidic bonds of D-glucuronic acid and N-acetyl-D-glucosamine. Because of the presence of repeating carboxylic acids in the HA backbone, it is negatively charged at physiological pH. It can bind to proteins, such as CD44, noncovalently and affects the diffusion of cells and proteins21. It is also known to have low immunogenicity, anti-inflammatory, antioxidant properties, and can induce the migration of MSCs22, which make it as an interesting candidate for BTE applications. A recent study demonstrated enhanced bone formation capability of bone graft materials when mixed with HA in a rat mandibular defect while minimal bone healing was observed in a defect treated with HA alone23. In addition, HA is used as a carrier for commercially available demineralized bone allografts to improve its handling properties24.

5) Chitosan is a linear cationic polysaccharide with β1→4 linkages of D-glucosamine and N-acetyl-D-glucosamine. It has an intrinsic ability to interact with cells and can be degraded by chitosanases25 or lysozymes26. The degree of deacetylation of chitosan alters the free amine ratio in the chitosan backbone, which influences the charge and provides further modification potential. The cationic nature of chitosan makes it an attractive candidate in BTE applications because chitosan can bind oppositely charged red blood cells or bacterial cell walls to exert hemostasis and antimicrobial properties in the infected wound site27. Chitosan provided an osteocompatible environment to promote the proliferation of osteoblasts and calcium deposition28. Chitosan also form a polyelectrolyte complex with many anionic glycosaminoglycans such as heparin that is known to modulate the bioactivity of growth factors such as BMP-2 important to bone regeneration29. Various bioconjugation techniques can modify the amine groups to other functional moieties such as methacrylate30 or bone-specific phosphate groups31.

6) Alginate is a linear anionic polysaccharide composed of both a β1→4 linkage for D-mannuronate and an α1→4 linkage for L-guluronate. Alginate can rapidly form a gel, with the addition of divalent cationic ions, such as Ca2+ or Zn2+, which create ionic bridges between chains via the egg-box model32. The fast gelation property of alginate makes it widely used in calcium containing solutions mimicking the bone environment33. Despite its low cost and convenient gelation, alginate presents no cell-binding motifs, limiting cell attachment, and undergoes slow degradation due to the lack of specific enzymes to degrade it in vivo34. These properties limit the use of alginate on its own for BTE. A study demonstrated that cell-laden alginate hydrogels induced inferior bone formation compared to type I collagen hydrogels in a porcine calvarial defect35.

1.1.2. Synthetic polymers

Synthetic polymers have multiple benefits, such as low batch-to-batch variability, convenience for functionalization with specific bioactive moieties, and relatively stable structural properties. The widely used synthetic polymers for BTE hydrogels are polyethylene glycol (PEG) and poly(N-isopropylacrylamide) (PNIPAM).

1). Polyethylene glycol (PEG)

PEG is a water-soluble polymer with a chemical formula of H-[OCH2CH2]n–OH, also known as polyethylene oxide (PEO). The molecular weight of PEG is directly linked to its physical properties, such as viscosity and it is available in different forms, such as branched or star-shaped PEG. It is biologically inert and safe, as a result, it is widely used in biomedical applications such as an excipient of pharmaceutical drugs36. PEG hydrogels were evaluated as barrier membranes for guided bone regeneration for the treatment of periodontal bone defects37. PEG hydrogel membranes were found to be as effective as conventional collagen membranes at enhancing bone growth at implant sites37. Furthermore, the solubility of PEG is dependent on its molecular weight, which makes PEG gels more attractive for use as controlled delivery vehicles to mediate sustained release of osteoinductive factors36, 38.

2). Poly(N-isopropylacrylamide) (PNIPAM)

PNIPAM is a temperature-responsive polymer with a chemical formula of [C6H11NO]n. It has a lower critical solution temperature (LCST) phase transition at 32 °C, such that it is highly solvated below LCST and can reversibly interchange to shrink above its LCST, because of the hydrophobic aggregation of isopropyl groups39. The LCST of PNIPAM is close to the human body temperature, as a result, it is widely used as a thermo-gel in biomedical applications40. In spite of its distinct thermo-responsive properties, the use of PNIPAM hydrogels is limited for BTE applications due to its intrinsic nature of poor mechanical strength and biodegradability39. For this reason, PNIPAM is often used in copolymers with other polymer blocks to produce hydrogels with improved physicochemical properties. Gelatin was grafted with PNIPAM to create biodegradable in situ gelling systems and injection of the resultant hydrogels encapsulating BMSCs successfully induced new bone formation in a rat cranial model41.

1.2. Crosslinks to form hydrogel networks for BTE

Crosslinking is an essential process to fabricate a stable hydrogel structure, which cannot be dissolved in aqueous conditions and maintains good mechanical strength until the desired time point. A variety of techniques including both chemical and physical approaches are used to crosslink hydrogels (Table 2). Besides the efficiency of crosslinking, it is also very important to consider a mild reaction environment, which will not damage the encapsulated cells or drugs.

Table 2.

Comparative table of crosslinking methods to fabricate hydrogels for bone regeneration

| Crosslinking | Advantages | Drawbacks |

|---|---|---|

| Photo-radical |

- Fast and mild reaction by not altering pH or temperature enormously - Forming a stable crosslinked network |

- May damage cells or bioactive molecules depending on the light sources - Irreversible reaction |

| Schiff base |

- Reversible reaction with self-healing properties - Mild reaction condition |

- Relatively low stability of pseudocovalent bond - Need to prepare two separate reactive polymers |

| Michael addition |

- Forming a stable crosslinked network - Self-healing properties under certain conditions such as excess presence of thiols |

- Potential side reaction to form unexpected disulfide bonds - Need to prepare two separate reactive polymers |

| Diels-Alder |

- Specific bio-orthogonal reaction - No side reactions and byproducts |

- Need to prepare two separate reactive polymers - Considered as an irreversible reaction under physiological condition (reversible at extremely high temperature above 800K) |

Enzyme

|

- Fast and mild reaction with controlled gelation kinetics - Forming a stable crosslinked network |

- Short half-life of enzymes - Enzyme potentially involving in inflammatory reaction by activating cytokines - Irreversible reaction |

| Ionic |

- Fast and mild reaction - Reversible reaction with self-healing properties |

- Relatively low stability - Possibly disrupt the crosslinking by ion bleaching |

| Hydrogen bond |

- Fast and mild reaction - Reversible reaction with self-healing properties |

- Relatively low stability - Require multiple multivalent hydrogen bond to form hydrogel |

| Hydrophobic |

- Reversible reaction with self-healing properties - Can form a fixed geometry using a host-guest interaction |

- Relatively low stability - Potentially form a brittle network by pushing water from hydrogel network |

1.2.1. Chemical crosslinks

Chemical crosslinking creates covalent bonds at the inter- and intra-molecular level. It can be initiated by a radical reaction, a linkage between specific functional groups, or enzymatic activity. Covalent bonds are more stable and stronger than non-covalent bonds, leading to the excellent stability and mechanical properties under physiological conditions.

1). Radical chemistry

Radical crosslinking is initiated by radical initiators, which can generate free radicals in the presence of various stimuli, such as photo-, thermal-, or redox reactions. A photoreaction, such as UV- or visible-light is widely applied in tissue engineering hydrogel formation, because of its mild reaction conditions in comparison to the extreme changes in temperature or pH. Photoinitiators can be chosen differently depending on light sources with differences in excitation wavelength. Common photoinitiators are Irgacure 295930, 42 or Irgacure 65143 used for UV crosslinking (250-370 nm), and camphorquinone42, 44 or riboflavin45 used for visible light crosslinking (400-700 nm). Radical reactive groups in the polymer backbone can be activated by free radicals to form a network structure in hydrogels. An unsaturated vinyl group is usually introduced into a polymer as a radical reactive group. Amine, carboxyl, or hydroxyl groups in the polymer backbone can be converted to acrylate or methacrylate groups by simple bioconjugation.

Gelatin and HA modified with methacrylate functional groups have been extensively explored as modified natural ECM components for BTE applications. For example, photo-crosslinked gelatin methacryloyl (GelMA) hydrogels encapsulating osteogenic and angiogenic cells were effective for the formation of vascularized bone tissue constructs46. Moreover, bioactivity of osteogenic growth factors such as BMP-2 was significantly enhanced when delivered from GelMA hydrogels compared to exogenous BMP-247. There has also been an increased use of photo-crosslinkable hydrogels in combination with 3D bioprinting techniques for complex bone regeneration. Researchers took advantages of the fast gelation ability of photopolymerization and produced cell-laden complex 3D hydrogel constructs via 3D printing systems based on stereolithography. Photosensitive methacrylate HA was successfully printed into porous and anatomically shaped bone constructs under UV light radiation with the high level of cell survival incorporated48. However, photo-crosslinkable hydrogels have not been translated into clinical practice due to concerns associated with oxygen inhibition in polymerization reactions and the nature of a random chain growth mode, which may decrease curing efficiency and polymer network homogeneity with the production of unreacted toxic residues49, 50. Moreover, UV irradiation is known to have harmful effects on host tissues including oxidative damage to DNA and premature aging. Alternative visible light or near-infrared has been demonstrated to be safe with deeper tissue penetration.

2). Click chemistry

Click chemistry that allows for very selective and specific reactions with a high yield of desired covalent bonds51, 52 has been widely utilized in hydrogel network formation. Numerous functional moieties can be involved in this reaction; the established reactions are, (a) Schiff base, (b) Michael addition, and (c) Diels-Alder reaction.

(a). Schiff base reaction

The Schiff reaction is a condensation reaction used to form a covalent imine type bond via nucleophilic addition of an amine to an electrophilic aldehyde or ketone under physiological conditions53. Additionally, aldehyde groups can bind to tissues firmly because of the abundant amine groups on the tissue surface54. Among imine type bonds, hydrazone and oxime are more stable than imine because of mesomeric effects55. The resulting bond is biocompatible, pH-responsive, and reversible, which is advantageous for application in dynamic hydrogels with self-healing properties. Compared to other chemical crosslinking, the Schiff reaction enables rapid gelation under very mild conditions without initiators or light irradiation. A recent study demonstrated that injectable hydrogels based on glycol chitosan and oxidized HA successfully induced osteogenesis and bone formation in vitro and in a rat calvarial defect56. In addition, dynamic covalent bonds in Schiff base crosslinking hydrogels add advantage of using this system for 3D printing bioinks due to its shear thinning and cytoprotective ability during extrusion and subsequent self-healing to form stabilized printed constructs57.

(b). Michael addition

A Michael type reaction is a nucleophilic addition to unsaturated carbonyl groups. Typically, amines, thiols, or phosphines act as nucleophiles, and alkynes or olefins act as acceptors in the reaction. It is often seen in the coupling of a thiol and a vinyl containing polymers, or crosslinker in a basic environment. However, it can also form undesired disulfide bonds as a side reaction. A pair of acrylated HA and tetrathiolated PEG was used to form a hydrogel to deliver BMP-2 and cells58. The thiol Michael reaction is much slower compared to Schiff base crosslinking, requiring excessive modification with thiol groups to form stable hydrogels. A drawback with the thiol-Michael click chemistry is unwanted thiol oxidation that could affect protein stability by breaking disulfide bridges in the protein. A recent study found that crosslinking chemistry could influence the bioactivity of osteogenic growth factors loaded in a hydrogel by evaluating two HA hydrogels loaded with BMP-2, HA-thiol-michael and HA-hydrazone gels59. In this study, BMP-2 delivered from HA-hydrazone gels promoted a better ectopic bone formation in a rat subcutaneous model, indicating a detrimental effect of thiol-based crosslinking on the bioactivity of growth factors.

(c). Diels-Alder reaction

The Diels-Alder reaction is a cycloaddition of an electron donating diene and an electron withdrawing alkene. It is a one-step, catalyst-free, bio-orthogonal reaction without byproduct formation. It is usually applied in hydrogel formation with polymers modified with furan and maleimide derivatives. A previous study demonstrated the potential of Diels-Alder crosslinking hydrogels for sustained drug release and osteogenic differentiation of human MSCs based on maleimide PEG and furan dexamethasone60. However, Diels-Alder click chemistry is less effective for use as BTE hydrogels due to its relatively longer gelation time and substantial degradation under physiological conditions. A recent study reported an improved Diels-Alder reaction with significantly increased gelation rates and hydrolytic stability by replacing the furans with more electron-rich fulvene dienes61.

3). Enzyme-catalyzed chemistry

Enzymatic crosslinking has proven to be specific, efficient, cell-friendly, with mild reaction conditions, which are beneficial for in situ gelation62. Transglutaminase, binding with calcium cofactor, catalyzes post-translational modifications and promotes amide formation between carboxamide and amine. A fibrin gel formed by factor XIII, a transglutaminase isoenzyme, could deliver BMP as a bone substitute63. There has been a more extensive use of the transglutaminase crosslinking strategy since more cost-effective microbial transglutaminase (mTG) was discovered. mTG-crosslinked gelatin has been shown to support proliferation and osteogenic differentiation of MSCs as well as the release of osteogenic growth factors for potential BTE64, 65. Another promising enzymatic crosslinking approach is through a peroxidase-catalyzed reaction due to its ability to fine-tune the various physico-mechanical properties of formed hydrogels66. Peroxidase, in the presence of hydrogen peroxide, catalyzes the oxidation of various organic substrates, such as tyramine, phenol or aniline, and creates polymer-phenol conjugates. A recent study illustrated versatile manipulation for the gelation rate, stiffness and degradation behavior of tyramine-modified HA and chondroitin sulfate by varying the concentration of horseradish peroxidase and hydrogen peroxide67. Such an enzyme catalyzed hydrogel promoted osteogenic differentiation of BMSCs in vitro and bone regeneration in a rat femoral defect67.

1.2.2. Physical crosslinks

Physical crosslinks are driven by non-covalent reversible intermolecular interactions. It does not require any chemical agents, which may be potentially toxic to the encapsulated cells or biologies. Additionally, it exhibits stimulus-responsive properties by responding to changes in the surrounding environment, such as a change in ionic concentration, temperature, or pH.

1). Ionic interactions

Electrostatic interactions, driven by opposite electric charges attracting each other, can crosslink a network. A polyanionic polymer can be crosslinked with a cationic ion, and a polycationic polymer can be crosslinked with an anionic ion. Alginate crosslinks with divalent cations including calcium or magnesium to form an egg-box structure at room temperature in physiological pH68. Chitosan also rapidly crosslinks with anions such as glycerol phosphate69. Moreover, a pair of polyanionic and polycationic polymers can easily form a polyelectrolyte complex, such as alginate-chitosan70, collagen-chitosan71, and chondroitin sulfate-chitosan72 for BTE applications. Although ionically crosslinked gels can be prepared under very mild process conditions without covalent modification, the fast gelation rate may lead to inhomogeneous precipitation, making it difficult to achieve injectable or moldable preparations. Several studies have been conducted on control over the gelation kinetics of hydrogels based on retarded gelation-inhibiting buffers73, 74. Another challenge to ionic gelling is its unpredictable long-term stability in vivo due to rapid ion exchange and gel dissolution in a physiological medium. Moreover, crosslinked ions released from the gel may cause unwanted biological reactions.

2). Hydrogen bond

A hydrogen bond is a specific dipole-dipole interaction between hydrogens and electronegative atoms, such as oxygen, nitrogen, or sulfur. It is an essential interaction for stabilization of the three-dimensional structure of DNA, proteins, and other synthetic polymers. A DNA-based hydrogel with tunable properties is available by controlling DNA sequences and its nanostructures75, 76. A supramolecular polymer, P(NAGA-VPA), was based on copolymerization of N-acryloyl glycinamide and vinylphosphonic acid directly crosslinked by hydrogen bonding between glycinamide groups in an aqueous solution77. This hydrogel mineralized in situ to improve mechanical strength and deliver BMP-2 to support bone regeneration in rat forelimb defects77. Hydrogen bond-based hydrogels are weak and fragile compared to covalently crosslinked or other physical hydrogels. Recent developments seek multiple hydrogen bonding motifs in preparing hydrogels with improved structural integrity. In particular, ureido-pyrimidinone (UPy) is a well-studied quadruple hydrogel bonding unit that can form strong intermolecular bonds compared to a single hydrogel bond78. A previous study developed injectable hydrogels with rapid self-integrating properties by grafting UPy to a dextran backbone and the resultant hydrogels successfully regenerated both bone and cartilage tissues in a mouse subcutaneous model79.

3). Hydrophobic interactions

Non-polar groups in a hydrophilic polymer tend to aggregate and fold the network to form a hydrophobically associated hydrogel. A hydrophobic interaction is also triggered by an external stimulus, such as temperature. A gelation of PNIPAM can be initiated by the aggregation of isopropyl moieties at a temperature above its LCST (32 °C), and reversibly interchange its gelation state at this point39, 40. Poly(N-acryloyl glycinamide) is an example of an upper critical solution temperature (UCST) induced hydrogel, and its composite hydrogel with transforming growth factor β-1 (TGFβ-1) and β-tricalcium phosphate (β-TCP) was effective in rat osteochondral regeneration80. A hydrogel can be designed to possess hydrophobic guest and host molecules, adamantane and cyclodextrin groups, to direct crosslinking in a fixed geometry81. A pair of cyclodextrin modified gelatin and aromatic residue possessing gelatin could form a stable hydrogel by guest-host interaction, and supported bone regeneration in a rat calvarial defect82. Although gelation caused by hydrophobic interactions occurs under mild conditions with a low risk of damaging encapsulated cells and bioactive agents, there are some disadvantages to this approach for applications as BTE scaffolds. Thermosensitive hydrogels exhibit a slow response rate to temperature changes, high shrinkage after dehydration, and poor mechanical properties. Many efforts have been made to modify the hydrogel features, including interpenetrating polymer networks, nanocomposites, etc41, 83. Hydrophobic domains are often introduced to polymer chains to create high-toughness hydrogels84, 85. However, incorporation of hydrophobic units could lead to nonuniform arrangement or phase separation of hydrophobic domains.

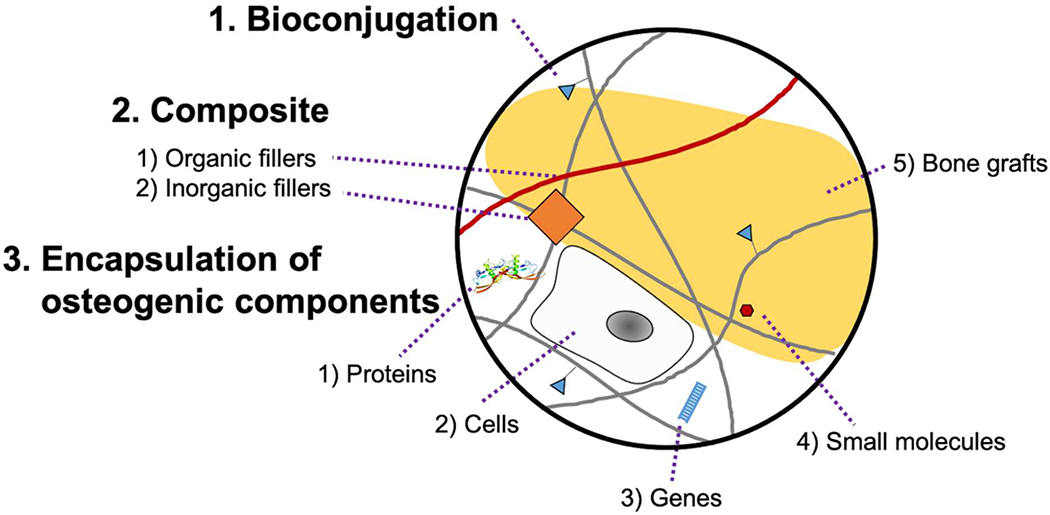

2. Biofunctionalization of hydrogels

Matrix remodeling is mediated by encapsulated cells, followed by the process of cell attachment, spreading, migration, differentiation, and ECM deposition86. Although a hydrogel already has advantages for providing a suitable microenvironment for cells because of its hydrophilic and three-dimensional organized nature, it is still necessary to present osteogenic microenvironments for applications in BTE (Figure 2). In the following sections, we will discuss the several strategies used to customize hydrogel microenvironments to specifically guide bone regeneration (Table 3 and Figure 3).

Figure 2.

Scheme of hydrogel biofunctionalization. The osteogenic properties of hydrogels are enhanced by various modifications including bioconjugation, composite formation, and encapsulation of osteogenic components. Bioconjugation enables covalent tethering of numerous functional groups. Composite hydrogel allows non-covalent incorporation of functional organic or inorganic fillers. Moreover, diverse osteogenic components (proteins, cells, genes, small molecules, or bone grafts) can be encapsulated into hydrogel network.

Table 3.

Biofunctionalization of hydrogel

| Biofunctionaliz ation | Function | Application |

|---|---|---|

| RGD peptide | - Binding ligand of integrin - Regulate cell attachment and spreading - Mediate osteoblast differentiation |

- Alginate91 - Chitosan31 - PEG134 |

| Catechol group | - Amino acid in mussel adhesive - Enhance cell adhesion - Adsorb hydroxyapatite and induce mineralization |

-HA95 - Alginate90 |

| Calcium-binding group | - Negatively charted PO43− or COOH - Nucleate minerals by capturing calcium ions |

- Chitosan31 - OPF98 - Poly acrylamide99 |

| Heparin | - High binding affinity on growth factors - Enhance BMP function by stabilization and protection from antagonists |

- Fibrin103, 104 - Chitosan105 |

| BMP/BMP-derived peptide | - Key regulating factor in osteogenesis - Various application in bone repair application |

- PEG-PCL107 - Fibrin-HA108 - Alginate109 |

| Nucleic acids | - Modulate cellular function in gene level - siRNA, miRNA, DNA etc. - Carrier free delivery of genes by direct hydrogel conjugation |

|

| Calcium phosphate | - Precursor of hydroxyapatite crystal | - Chitosan-gelatin114 - PEG116 - Gellan gum118 |

| Nanoclay | - 2D silicate sheets adsorbing biomolecules - MMT, LAPONITE® etc - Induce osteogenesis by enabling osteogenic signaling |

- MMT-chitosan121 - Laponite-HA122 - Laponite-chitosan123 |

| Bioactive glass | - Osteoinductive glass-ceramic surfaces - Possess numerous silicon-OH groups |

- Gelatin124 - Chitosan-silk fibrin125 |

| Bone cement | Contain tricalcium silicate and calcium sulfate hemihydrate - Enable apatite mineralization |

- Alginate127 |

| Polymeric fillers | - Incorporate biomolecules mimicking polymers - Can form a stable IPN structure for better mechanical support |

- Fibrin-HA129 - Chitosan-polysulfonate29 - PEG-PLGA132 |

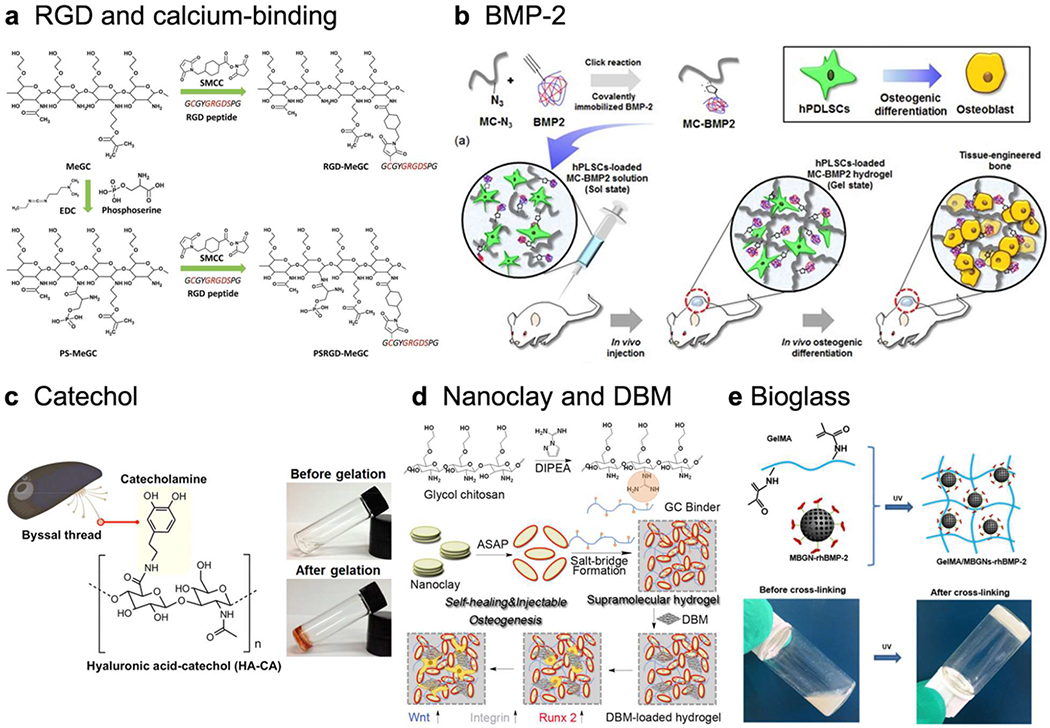

Figure 3.

Biofunctionalization of hydrogel, a) Chitosan hydrogel modified with both cell RGD peptide, a cell binding site, and phosphoserine, a calcium binding group. Adapted with permission from 31. Copyright 2016 The Royal Society of Chemistry, b) BMP-2 immobilized hydrogel inducing osteogenesis of human periodontal ligament stem cells. Reprinted with permission from 107 without changes under the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/). Copyright 2017 Springer Nature, c) Mussel-inspired catechol functionalized HA hydrogel and its gelation. Adapted with permission from 95. Copyright 2016 American Chemical Society, d) Supramolecular chitosan hydrogel functionalized with guanidine group, nanoclay, and DBM activating Wnt/β-catenin signaling. Adapted with permission from 123. Copyright 2020 American Chemical Society, e) Gelatin hydrogel incorporated with rhBMP-2 grafted mesoporous bioglass nanoparticles and its crosslinking. Adapted with permission from 124. Copyright 2020 American Chemical Society.

2.1. Bioconjugation

Bioconjugation covalently couples functional groups onto the polymer backbone to fabricate novel cell-responsive hydrogels. Because of strong covalent bonds, it can stably deliver bioactive molecules to the localized area. These functional groups can be a variety of peptides, proteins, polysaccharides, specifically charged moieties, and genes.

2.1.1. RGD peptide

The arginine-glycine-aspartic acid (RGD) peptide is an integrin binding ligand, which regulates cell attachment and spreading87. While some biopolymers like collagen or fibrin already contain abundant RGD groups in their structure, many other polymeric materials such as hyaluronic acid, alginate, chitosan, and PEG lack this ligand. RGD peptide also triggers intracellular signaling, which mediates osteoblast differentiation88, 89. Therefore, RGD conjugation significantly improved cell attachment, spreading, and osteogenesis in these hydrogels31, 90–92.

2.1.2. Catechol group

Catecholic amino acid present in mussel adhesive is an attractive functional moiety for enhancing cell adhesion. The role of catechol in wet-adhesion is well known through the mechanism of π-π stacking, coacervation, or oxidation93. The catechol group can be adsorbed onto hydroxyapatite, which is a key component of matrix mineralization94. Therefore, catechol-functionalized polymeric hydrogels such as hyaluronic acid95 or alginate96 have high potential in BTE.

2.1.3. Calcium-binding groups

Matrix mineralization is a unique process in bone tissue that fills the organic matrix with calcium-based nanocrystals. Negatively charged PO43− or COOH groups can attract calcium ions, which are appealing candidates for bioconjugation97. Phosphate groups containing phosphoserine conjugated chitosan hydrogel could nucleate minerals on the hydrogel surface and support bone repair in a mouse calvarial defect31. Oligo[poly(ethylene glycol) fumarate] hydrogel functionalized with phosphate groups also allowed calcium uptake and exhibited osteoconductivity98. Carboxyl group functionalized polyacrylamide hydrogel could capture calcium ions by decreasing its diffusion rate and initiating chelate formation99.

2.1.4. Heparin

Heparin is a highly sulfated ECM molecule with great binding affinity for growth factors, such as BMPs. It forms a stable complex with growth factors to increase their bioactivities, and also regulates BMP function by interacting with its antagonists, such as noggin100–102. By conjugating heparin onto a hydrogel backbone, it is possible to achieve a specific interaction with BMP to demonstrate the overall osteogenic ability of the hydrogel. Heparin conjugated fibrin hydrogel was studied for the sustained delivery of BMP-2 and improved bone regeneration in a mouse calvarial defect103, 104. Heparin conjugated chitosan hydrogel enhanced BMP bioactivity by protecting BMP from physiological stressors and its antagonist, noggin105.

2.1.5. BMP or BMP-derived peptides

BMP is a key regulating factor in osteogenesis, which is commonly used with various delivery strategies for bone repair106. However, a high dose application of BMP-2 because of its short half-life and poor vehicle ability produces many side effects4. Therefore, direct immobilization of BMP-2 in a hydrogel scaffold is an appealing strategy to prolong BMP-2 stability and release. BMP immobilized methoxy polyethylene glycol-polycaprolactone block copolymer hydrogel could mineralize calcium and induce osteogenic differentiation in a mouse subcutaneous implant107. BMP conjugated fibrin-hyaluronic acid hydrogel showed no side effects, such as heterotopic bone formation in a goat mild intervertebral disc degeneration model108. However, direct conjugation of BMP is costly. Therefore, a peptide that mimics BMP is an alternative strategy to keep the osteogenic potency of BMP protein with a simpler conjugation. BMP-2 mimicking peptide conjugated alginate hydrogel could initiate BMP-2 signaling and increase mineral deposition of murine MSCs109.

2.1.6. Nucleic acids

Nucleic acids can modulate cellular function at the gene level by enabling specific protein expression with the addition of DNA and mRNA, or knocking down target genes with the incorporation of siRNA and miRNA. Delivery of nucleic acids using nanoparticles is an extensively studied field. In comparison to nanoparticle-based delivery, carrier-free delivery of genes is not a typical strategy because of its low cellular uptake. However, lipophilic modification of genes could effectively improve siRNA uptake110, such that it enables direct delivery of naked genes by conjugation in a hydrogel network. Recent studies showed that covalently tethered siRNA in a dextran hydrogel could control and prolong its localized release and improve RNA bioactivity111.

2.2. Composite-hydrogel

Beside chemical conjugation of hydrogels, a composite strategy driven by non-chemical interactions is also beneficial for hydrogel functionalization. Composite-hydrogels can exhibit synergistic effects by counterbalancing the drawbacks of each of the combined materials112. A hydrogel network provides a continuous phase in composite-hydrogels, and a dispersed phase created by other incorporated molecules can add bioactivities as well as reinforcement113.

2.2.1. Inorganic fillers

Inorganic substance in bone tissue plays a role in supporting and protecting the structure of the organic portion. A composite hydrogel constructed with inorganic fillers and an organic hydrogel mimics native bone structure.

1). Calcium phosphate

The main organic and inorganic composition of bone is collagen and hydroxyapatite, a crystal form of calcium phosphate. Therefore, direct incorporation of calcium phosphate in various hydrogels is a common fabrication method for BTE applications. This approach is seen in diverse hydrogels, such as chitosan-gelatin114, whey protein isolate-gelatin115, PEG116, polyacrylic acid-polyaspartic acid117, and methacrylated gellan gum118. Calcium phosphate can be self-assembled in a hydrogel network by incorporating calcium intriguing molecules, such as poly-L-glutamic acid119 or 2D black phosphorus nanosheets120. These hydrogels have increased mechanical strength with better mineralization compared with the unmodified hydrogels.

2). Nanoclay

Clays and clay minerals, such as montmorillonite and laponite, are 2D silicate sheets with large surface area, which can adsorb biomolecules such as proteins, peptides, or protons. A montmorillonite-chitosan nanocomposite hydrogel could induce osteogenic differentiation of the encapsulated cells and enhance bone healing in a mouse calvarial defect model without additional therapeutic agents or stem cells121. Laponite-bisphosphonate functionalized HA hydrogel could facilitate self-assembly of hydrogel and BMP-2 localization in vivo122. Laponite-guanidylated chitosan hydrogel induced osteoinductivity by enabling osteogenic differentiation via activation of the Wnt/β-catenin signaling pathway123. Addition of nanoclay molecules in hydrogels enhanced stiffness and released biochemical cues for osteogenesis over time during degradation.

3). Bioactive glass

Bioactive glass is an osteoinductive glass-ceramic surface decorated with silicon-OH groups. The surface of bioactive glass can deposit calcium phosphate and lead hydroxyapatite formation. The functional groups on the surface of bioactive glass can be used in grafting BMP-2 and form a composite hydrogel with methacrylate gelatin to promote bone regeneration in a rat calvarial defect124. It can form a composite hydrogel with chitosan-silk fibrin-glycerophosphate and support bone repair in a rat calvarial defect125. Bioactive glass can be mixed with other ceramic powders to produce bonelike granules and combined with a dextrin hydrogel for application in goat tibial fractures126.

4). Others

Bone cement consisting of tricalcium silicate and calcium sulfate hemihydrate in an alginate hydrogel enabled apatite mineralization with excellent cytocompatibility of rat bone marrow stem cells127. Another inorganic filler, such as eggshell, was also able to form a composite with a gelatin hydrogel and successfully regulate osteogenic differentiation of human dental pulp stem cells128.

2.2.2. Organic fillers

Composite-hydrogels can be fabricated using not only inorganic but also organic fillers, such as various polymers. A polymer-based composite-hydrogel has an entangled network because of the elongated structure of the polymer, which can support physical stiffness, and influence the swelling and deswelling response.

A polymer-based composite-hydrogel can be fabricated with a simple mixture of different polymers. Usually polymers with different surface charges can be stably incorporated because of electrostatic binding leading to stable network formation. A composite-hydrogel of fibrin and HA minimized cell-contractile forces, which accelerated fibrin degradation and maintained a three-dimensional structure that supported cell proliferation129. Another composite-hydrogel of chitosan and heparin-mimicking sulfonated polymers, such as poly-vinylsulfonic acid or poly-4-styrenesulfonic acid, were stably incorporated in a chitosan network with homogenous distribution29. These polysulfonate fillers were also able to stabilize and enhance BMP activity similar to heparin. There are also other examples of polymer-polymer composite hydrogels in BTE, such as chitosan-collagen71 or chitosan-alginate70 composites.

Polymer-based composite-hydrogels can be diversified using various fabrication techniques, such as electrospinning or self-assembly. Electrospinning is a typical method for generating nanofibers, with a high aspect ratio, greater than 50130, in comparison to bulk native polymer chains, with an aspect ratio of 2-3131. Therefore, nanofiber incorporation in hydrogels can be a reinforcing material, which enhances the mechanical properties of the composite-hydrogel. Poly (lactic-co-glycolic acid) (PLGA) stiffened PEG hydrogel could improve the mechanical strength of the hydrogel compared with unmodified hydrogel and support cell viability and proliferation132. A nanofiber is also able to form a porous structure, which is favorable for cell adhesion and migration. Chitosan nanofiber incorporated PEG hydrogel could provide mechanical strength and support osteoblast attachment and growth133.

2.2.3. Interphase in composite-hydrogels

A composite-hydrogel has two or more heterogenous phases, and the interaction of hydrogel and fillers at the interphase determines the long-term stability and mechanical support of the composite-hydrogel. The nature of the interphase depends on the two inorganic and organic filler types. There are three types of interphase between hydrogel and inorganic filler, 1) filler dispersed in hydrogel network, 2) filler acting as a crosslinker, and 3) filler adsorbed on the hydrogel surface. There are two types of interphase between hydrogel and organic filler, 4) interpenetrating network (IPN) and 5) semi-IPN.

Inorganic fillers in a composite-hydrogel can support mechanical stiffness by providing additional crosslinking points in the polymer network. It is possible to have no interactions with the polymer network in 1) or hinder crosslinking between polymer chains by changing polymer dispersion by adsorbing onto the surface corresponding to 3). Nanoclay121 or hydroxyapatite135 are good examples that can provide additional anchoring points in a hydrogel network corresponding to 2) by intercalation chemistry. However, when the addition of hydroxyapatite increased, it decreased the elasticity of the hydrogel network and showed heterogenous mechanical properties at mesolength and macroscopic range scale136.

Organic fillers in a composite-hydrogel can also stiffen mechanical strength by presenting additional conflicting points in the hydrogel network. IPN structure is generated by two independently crosslinked networks corresponding to 4), or entrapping a linear polymer in a crosslinking network corresponding to 5). Two independent networks can be formed by different crosslinking technologies, such as a combination of chemical and physical crosslinks. A mixture of gelatin methacrylamide and alignate successfully formed a double-crosslinked IPN structure using step by step UV irradiation and calcium ion absorption137.

2.3. Hydrogels as delivery vehicles for bioactive molecules

Multiple bioactive molecules including growth factors (large proteins, cytokines, hormones), genes, and small molecule drugs play an important role in cellular signaling and tissue development. Each category of molecules has its own physicochemical characteristic and requires an accurate delivery system. A hydrogel could be a candidate for a delivery carrier, but many molecules still need additional vehicles for maintaining a proper release profile138.

An osteoinductive growth factor, BMP-2, was tactically integrated in a hydrogel via various vehicles including liposomes139, microfibers140, nanofibers141, poly(phosphazene) nanoparticles142, coacervates, and gelatin microparticles143. These BMP-2 incorporated hydrogels showed great osteoinductive potentials in vitro and in vivo. Parathyroid hormone (PTH) is an FDA approved anabolic treatment of osteoporosis, which can improve bone mineral density in female patients144. A PTH-PEG hydrogel coated onto a poly(propylene fumarate) scaffold supported bone healing in rat femoral defects by bridging full bone or a combination of bone and cartilage145.

Gene transfection is an attractive strategy for inducing osteogenesis. Both viral and non-viral vectors, which help effective transfection, incorporate homogenously in a hydrogel network for osteoinductive functionalization. RNAi strategy using siRNA or miRNA to downregulate a BMP antagonist, such as noggin or chordin, could enhance osteogenic differentiation in vitro and in vivo146, 147. There are several studies that integrate these siRNAs in a bulk hydrogel to promote osteogenesis including siNoggin-chitosan-calcium phosphate in a chitosan hydrogel148, siNoggin-sterosome in a chitosan hydrogel149, siNoggin-PEI in a PEG hydrogel150, and miRNA-20a-PEI in a PEG hydrogel151. Additionally, siRNA152 or miRNA153 sequestration could be carried out by hydrophobic moieties in RNA and HA hydrogel, which successfully control and prolong its release.

Multiple small molecule drugs have been studied for applications in bone repair, such as dexamethasone, phenamil, simvastatin, purmorphamine, and hydroxycholesterol. Many small molecule drugs are hydrophobic, which makes it difficult to directly integrate them in a hydrophilic hydrogel network, therefore, appropriate carriers are required to disperse these molecules homogenously in a hydrogel. These drugs could be applied in various forms with great osteogenic properties like nanodiamond-dexamethasone in a gelatin hydrogel154, liposome-phenamil in a chitosan hydrogel155, maltodextrin based micelle-simvastatin in a maltodextrin hydrogel156, mesophorous silicate nanoparticle-purmorphamine in a HA hydrogel157, and sterosome formed with hydroxycholesterol and sterylamine in a chitosan hydrogel158.

Demineralized bone matrix (DBM) is an allograft processed to remove the mineral of native bone to better expose osteoinductive factors such as BMP-2. However, the use of DBM is limited because of its handling issues and batch-to-batch variability in osteoinductivity159, 160. Although commercially available DBM products commonly use HA, sodium alginate, glycerol, and calcium sulfate as delivery carriers, these are still easily dispersed in the body and can potentially induce inflammation and lower the osteogenic effects161, 162. Several studies have investigated a new carrier hydrogel to deliver DBM and improve its osteogenic efficacy such as pentenoate-modified hyaluronic acid163, heparinized chitosan105, and laponite-chitosan hydrogel123.

3. Strategic approaches to improve osteogenic capacity

A conventional hydrogel provides a homogenous and steady microenvironment, which enables the stable incorporation of cells and bioactive molecules initially. However, actual tissue growth is not a static but dynamic process involving surrounding tissue architecture, cells, and bioactive molecules. Therefore, hydrogels reflecting these physicochemical dynamics are required for advanced BTE. Various strategies to improve osteogenic capacity will be discussed in the following section (Figure 4).

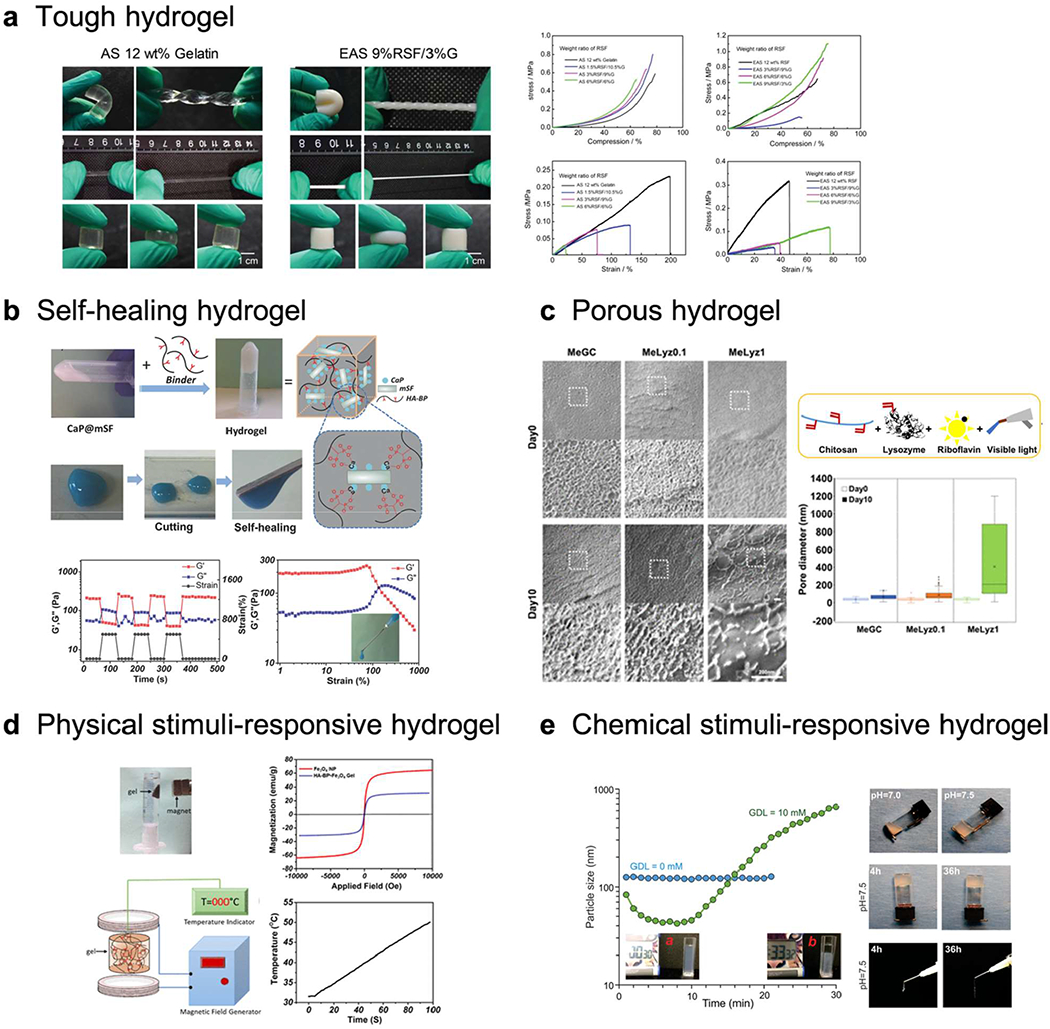

Figure 4.

Various strategies to improve the osteogenic potentials of hydrogels, a) Tough hydrogel. Double-crosslinked (physical and chemical) regenerated silk fibroin/gelatin (RSF/G) hydrogel with enhanced mechanical properties (AS: ammonium sulfate, EAS: enzyme-treated AS). Adapted with permission from 164. Copyright 2019 Wiley-VCH. b) Self-healing hydrogel. Silk fibroin-calcium phosphate-HA hydrogel and its self-healing property. Adapted with permission from 165. Copyright 2017 Wiley-VCH. c) Porous hydrogel. Lysozyme conjugated hydrogel with tunable degradation to generate porous hydrogel. Adapted with permission from 166. Copyright 2018 American Chemical Society, d) Magnetic-responsive hydrogel. HA hydrogel incorporating FesCE nanoparticles and its heat generation under magnetic stimulus. Adapted with permission from 167. Copyright 2019 American Chemical Society, e) pH-responsive hydrogel. Carboxymethyl chitosan (CMCh)-amorphous calcium phosphate (ACP) hybrid hydrogel demonstrating pH triggered self-assembly. Adapted with permission from 168. Copyright 2019 American Chemical Society.

3.1. To enhance mechanical performance

3.1.1. Tough hydrogels

A hydrogel typically has low mechanical strength, which makes it difficult to apply in load-bearing tissues like bone. Mechanical strength of tissues vary from 0.01-1.0 kPa for fat, brain, or natural ECM, 1-10 kPa for skin, lung, or kidney, 10-100 kPa for muscle, 100-1,000 kPa for cartilage, and over 1,000 kPa for bone169. Many hydrogel matrices can diversify their mechanical properties to 0.1-100 kPa by simple modification169. Although it is impractical to achieve over 1,000 kPa of initial mechanical strength in a hydrogel environment, the fate of stem cells could be modulated by relatively soft tuning of mechanical properties of the hydrogel.

Multiple studies have already demonstrated that neurogenesis, myogenesis, and osteogenesis of stem cells varied by mechanical strength of the 2D hydrogel surface, 0.1–1 kPa, 8–17 kPa, and 25–40 kPa170–173. In a 3D environment, matrix stiffness also influenced the fate of stem cells such that hMSCs are likely differentiated to neuronal cells at 1 kPa, while they are transformed to a glial lineage at 10 kPa174. Murine MSCs also differentiated to an adipogenic lineage at 2.5-5 kPa and an osteogenic lineage at 11-30 kPa, respectively175. In general, softer hydrogels are favorable for the differentiation of soft tissues, such as brain, fat, and muscle, while stiffer hydrogels are favorable for the differentiation of hard tissues, such as cartilage and bone175.

Many studies have investigated various strategies to overcome the mechanical weakness176 of hydrogels by enhancing homogeneity of the hydrogel network, dissipating energy, or a combined approach. Homogeneity of a hydrogel network can evenly distribute the stress and is achieved by various functionalization techniques. Energy dissipation can prevent macrocrack propagation and is acquired by network entanglement, such as with an IPN structure. A double-network hydrogel composed of both rigid-brittle and soft-stretchable materials is tough-rigid177. A brittle network dissipates energy during deformation, and the elastic network allows it to return to its original form. A combined approach can be carried out by various composite-hydrogel forms.

An alginate hydrogel functionalized with RGD, methacrylate, and dopamine has shown enhanced tensile strength and great bone repair capacity in a rat peri-implantitis model178. A silk fibroin and gelatin hydrogel with dual crosslinking network also showed great improvement in compressive and tensile strength with promising bone healing ability in a rat calvarial defect. A composite-hydrogel of acrylamide and urethacrylate dextran with hydroxyapatite mineralization exhibited strengthened mechanical properties with osteoconductivity179. A ternary composite-hydrogel with chitosan, graphene oxide, and hydroxyapatite provided an oriented microstructure with high mechanical strength and good biocompatibility180.

3.1.2. Self-healing hydrogels

Self-healing hydrogel recovers its mechanical properties upon destruction, which is beneficial for preserving the structure in a dynamic tissue healing environment. Briefly, the self-healing mechanism depends on crack closure ability mediated by mass transfer and reconnection of broken networks in a hydrogel matrix. Various mechanisms that mediate self-healing properties are studied including noncovalent and dynamic covalent bonds181.

A silk fibroin-calcium phosphate-HA composite-hydrogel exhibited self-healing properties by metal-ligand coordination and supported bone healing in a rat calvarial defect165. Laponite nanosilicate is a well-known thixotropic modulator and showed self-healing properties by forming composite-hydrogels with gelatin182, chitosan123, and HA122. A DNA-alginate composite-hydrogel with laponite provided two self-healable links, a dynamic imine bond and electrostatic interactions with nanosilicate183. Both Diels-Alder and cyclodextrin-adamantane interactions provide dynamic covalent bonds that support self-recovery of hydrogels. A chondroitin sulfate-PEG hydrogel with both Diels-Alder and guest-host interactable moieties could form a dual crosslinked network and support bone repair in a mouse limb defect61 and a rat cranial defect184.

3.2. To mimic the tissue architecture

Native bone tissue is a highly complex structure composed of nanofibrous entanglement and microporous channel arranged in a macroscopic network. The defined structure of hydrogels can affect cell-matrix interactions in the presence of soluble cues at nano-, micro-, and macro-scales for bone repair and regeneration.

3.2.1. To mimic nanoscale tissue structure

Polymeric hydrogels often incorporate linear nanofibers but the simple linear structure is not sufficient to provide a stable hydrogel network for cell encapsulation or growth factor delivery. Therefore, self-assembling peptides were widely used to create stable 3D hydrogels driven by physicochemical crosslinking of amphiphilic peptides185. In addition, their 3D structure could be easily modulated by altering the sequence of peptides. A recent study has shown that the nanofiber hydrogel made by synthetic D-form and L-form self-assembling peptides formed stable hydrogels and facilitated the release of growth factors to promote the rat femoral bone repair186. Additionally, various electrospinning techniques have been applied to improve the alignments, orders, and structure of nanofibers in the hydrogels187. Another study reported an electrospun organic-inorganic hybrid hydrogel that could constantly mineralize on its surface and promote osteogenic differentiation188.

3.2.2. To mimic microscale tissue structure

Tissue reformation requires mass transport to support cell migration, infiltration, and proliferation which lead to differentiation and vascularization over time. However, a traditional nano-porous hydrogel network interferes with these activities because of restricted room for cell movement. Modulation of a conventional nanoporous hydrogel with various functionalizations or recent progress to fabricate hydrogel microparticles are widely applied to produce microporous structures.

The conventional method to generate a porous hydrogel is the use of freeze-drying technology or the incorporation of a porogen. A hybrid hydrogel of silk fibroin and organosilane fabricated by unidirectional freeze-drying showed high porosity and bone-type anisotropic structure. It could trigger osteoblast proliferation and exhibited successful osseointegration in rat femur189. An alginate hydrogel incorporating hydrolytically degradable porogens could deliver MSCs and recruit endogenous cells to regenerate a critical-sized rat femoral defect34.

A nanoporous hydrogel network was able to enlarge its pore size by degradation of the hydrogel network. A lysozyme conjugated chitosan hydrogel could increase its pore size by degradation and induce cell migration throughout the bulk hydrogel166. It was also able to increase osteogenic differentiation and bone healing in a mouse calvarial defect. A nanocomposite-hydrogel also enables the generation of a microporous structure by changing network orientation. A chitosan-MMT hydrogel-composite exhibited an interconnected microporous network by intercalation chemistry and the presence of nanosilicates also successfully promoted bone healing in a mouse calvarial defect121. A composite-hydrogel including chitosan, HA, and hydroxyapatite also exhibited porous structure associated with hydroxyapatite aggregation in a hydrogel network with good cytocompatibility190.

3.2.3. To mimic macroscale tissue structure

3D printing is an emerging technique to construct BTE hydrogels. It allows fabricating a precise, complex, and highly customizable architecture mimicking native bone microstructure, and provides great cell support and infiltration191. The physicochemical properties of hydrogels can be readily controlled by different 3D printing processes and the selection of bioinks. The current printing techniques are based on laser, nozzle, or inkjet. Hydrogel inks can be prepared by polymer composite or reinforced filler192, which are beneficial to improve mechanical properties of the final products. The hydrogel consisting of chitosan and hydroxyapatite could be successfully 3D printed and supported the osteogenic differentiation of preosteoblasts193.

Moreover, 3D printing enables the construction of more complicated structures such as layered, graded, multicellular, or even customized shape of hydrogels. For example, bone defects in the subchondral region requires a sophisticated approach to treat the complex osteochondral tissue with appropriate mechanical loading. A 3D printed tri-layered hydrogel with diverse gelatin and hydroxyapatite ratio was successfully integrated with the surrounding tissue and enhanced the osteochondral regeneration in a rabbit osteochondral defect model194. A 3D printing of thermosensitive copolymerized N-acryloyl glycinamide, and N-[tris(hydroxymethyl)methyl] acrylamide could prepare a gradient hydrogel due to rapid sol-gel transition of the materials195. The 3D printed gradient hydrogels promoted cartilage and subchondral bone regeneration in a rat model195. Additionally, the hierarchical haversian bone structure could be built up by 3D printing196. A recent study exhibited great potential of 3D printing to arrange the spatial distribution of different types of cells and create multicellular tissue, thereby increasing bone repair with blood vessel formation196. Lastly, cell-laden-hydrogels can be an ideal candidate for bioinks to be used in 3D bioprinting due to its highly cell-friendly nature. Bioinks with different properties can readily be obtained by blending different biopolymers. Although 3D bioprinting enables fabrication of customized bone grafts, many challenging points still remain to obstruct the clinical translation; the restricted size of printed constructs, a lack of long-term stability, and slow host tissue integration, among others197.

Recent advances in 3D printing technology also open the field of 4D printing. 4D printing incorporates the fourth dimension, time, by facilitating stimuli-responsive smart hydrogels. The 4D printed constructs transform their shapes and orientations by responding to the external stimuli, which is also beneficial to on-demand biomedical applications such as drug delivery198.

3.3. To enhance the release of bioactive molecules

A hydrogel implanted in bone tissue encounters diverse stimuli derived from physical, chemical, and biological cues. Without proper response to these stimuli, the hydrogel might undergo unexpected consequences, such as fast degradation or burst release of encapsulated cells and bioactive molecules. Additionally, because of the dynamic remodeling environment, a hydrogel sustains defects, which may disrupt the structure and lead to failure of the implant. Therefore, an optimal stimuli-responsive hydrogel must be engineered and advances made in engineering hydrogels have provided a number of potential candidates. Lastly, these stimuli-responsive hydrogels also enable 4D cell culture mimicking the dynamic heterogeneity of an in vivo environment199.

3.3.1. Physical stimuli-responsive hydrogels

Physical stimuli include various signals including light, temperature, and magnetic field. Photoresponsive hydrogels usually incorporate photoreactive molecules or functional groups in the hydrogel backbone. A variety of photo-crosslinkable hydrogels modified with vinyl groups are good examples200. Photodegradation is also a common mechanism used to modulate hydrogel structure. For instance, black phosphorous nanosheet incorporated gelatin hydrogel could enhance the phosphate release profile with light activation, including natural and near infrared light, and improved bone healing in a rabbit calvarial defect201. An azobenzene derived crosslinker reversibly changed its chemical isomerization with UV and visible light activation to act as a photo-switchable crosslinker and modulated hydrogel stiffness by light activation202.

A thermo-responsive hydrogel is also very commonly used in bone tissue engineering. PNIPAM based thermal gel is a well-known thermo-crosslinkable hydrogel40. PNIPAM conjugated HA hydrogel exhibited reversible gelation203, and effectively delivered bioactive microvascular fragments with enhanced vascularization in a mouse femur defect model204, 205. Alginate conjugated with temperature-responsive poly(ε-caprolactone-co-lactide)-b-poly(ethylene glycol)-b-poly(ε-caprolactone-co-lactide) and O-phosphorylethanolamine transformed to a stable hydrogel at 37 °C and showed in situ mineralization in a rat subcutaneous injection with BMP-2 loading206.

A magnetic-responsive hydrogel incorporates paramagnetic or ferromagnetic molecules in a hydrogel network. A super paramagnetic Fe3O4 nanoparticle incorporated hydrogel of methoxy(polyethylene glycol)-polyalanine and hydroxyapatite could enhance osteogenic gene expression under both static and moving magnetic fields207. Iron oxide, Fe3O4, incorporated bisphosphonate modified HA hydrogel exhibited heat-generation controlled by a magnetic field and showed good biocompatibility167. In addition, a recent study has shown that a ferrogel loaded with BMP-2 could successfully control the timing of the protein release using remote magnetic stimulation in an immediate or delayer manner208.

3.3.2. Chemical and biological stimuli-responsive hydrogels

Chemical and biological stimuli involve alterations in pH or enzymes. A pH-responsive hydrogel contains functional moieties, which can accept or donate protons with pH alteration. A composite hydrogel of chitosan and PEG reinforced with bone ash could modulate incorporated amoxicillin release at different pH 1.2 and 7.4, which are close to the gastric and intestinal environment pHs, respectively because of the polyelectrolyte properties of chitosan209. A chitosan-calcium phosphate-glucono δ-lactone composite-hydrogel demonstrated pH-triggered self-assembly and induced ectopic bone formation in mouse with BMP incorporation168.

Enzyme-responsive hydrogels containing substrates are triggered by endogenous enzyme activity in the human body. Chondroitin sulfate-PEG hydrogel modified with transglutaminase factor XIII specific substrate sequences could tune hydrogel network properties by altering transglutaminase concentration210. It also exhibited controlled release of BMP-2 and promoted the osteogenic differentiation of BMSCs. Matrix metalloproteinase (MMP) cleavable crosslinker is also a well-known enzyme-sensitive group widely used in BTE. MMP-sensitive PEG hydrogels could support cell maturation from osteoblast to osteocyte and bone ECM deposition211.

4. Evaluation of osteogenic hydrogels

Osteogenic potential of the newly developed hydrogel can be evaluated under diverse conditions including in vitro, ex vivo, in vivo, and clinical settings. However, direct translation to the clinical assessment costs hugely, and it is sometimes difficult to understand the results because of the complexity of the system. Therefore, researchers have investigated various preclinical models to assist the clinical studies. In this section, we will discuss the characteristics of each evaluation model.

4.1. In vitro evaluation

The intimate interaction of hydrogels with bone tissue is critical to the success of implantation. Therefore, it is necessary to evaluate molecular and cellular level phenomena in the immediate environment of bone forming cells212. Bone tissue possesses a variety of cells including osteoblasts, osteoclasts, mesenchymal stem cells, and different types of immune cells. Osteoblastic cell lines are well-established and available for in vitro investigation. It usually begins with a typical characterization of cell adhesion and growth, followed by the analysis of osteogenic differentiation phenotype markers. However, true bone regeneration is not a one-pot reaction, but followed by a dynamic sequential order or crosstalk between different cell types.

Bone response to implanted biomaterials is a highly concerted process involving blood clotting, secretion of inflammatory cytokines, initiation of vascularization, and woven bone formation. To simulate these complex dynamic environments in vitro, recent studies have tested biomaterials with co-cultures of immune cells, osteoclasts, and endothelial cells, or step-by-step inclusion of stimulating factors213. The effect of a periosteal ECM derived hydrogel on the different stages of bone healing was evaluated in vitro by demonstrating its ability to promote the M1-to-M2 transition of macrophages and induce angiogenesis and osteogenesis214. The bioactivity of a silica-collagen hydrogel was characterized in a human co-culture model by evaluating its ability to control the ratio of osteoblasts and osteoclasts215. A collagen-fibrin gel was tested in the co-culture system of endothelial cells and MSCs to recapitulate vascular formation in vitro216.

Additionally, advances in nano- and pico-technology provide new methods to characterize the surface and internal morphology of hydrogels in vitro. Conventional methods to characterize materials are occasionally not appropriate for hydrogels due to their high-water content or soft nature. Cryo-imaging has been adopted to observe the hydrated hydrogel network and its mesh size, which is difficult to detect after dehydration166, 217. Additionally, the development of spectroscopy such as Brillouin or Raman enabled nondestructive observation of nanostructured hydrogel networks in a noninvasive manner136. Diverse nanoindentation methods including atomic force microscopy could measure poroelastic properties of hydrogels218, 219.

4.2. Ex vivo evaluation

Even though both in vitro and ex vivo models represent the tests conducting outside of the living body, in vitro is usually related to the test tube experiments and ex vivo covers more broad range. Traditionally, ex vivo bone organ culture was accompanied by the retrieval of bone tissue and treatment with biomaterials, cells, or stimulating factors220. The cytoarchitecture and intercellular connections are well retained in ex vivo systems, which can mimic and replace ethically challenging in vivo models221. For instance, an organotypic chick femur defect culture system was adopted as a critical size defect model to evaluate bone augmenting abilities of hydrogels releasing osteogenic growth factors222, 223. Human ex vivo bone defect model prepared by cylinder-cut of femoral heads also remained viable for 28 days and exhibited bone repair processes with the incorporation of collagen hydrogels224. Moreover, recent development of microfluidics systems create the organs-on-a-chip models which bridge the gap between traditional ex vivo and in vivo studies225. Bone-on-a-chip enables the spontaneous growth of miniaturized bone and periodic sampling in a physiologically relevant model226. The ex vivo bone models allow rapid screening of therapies, high reproducibility, and low cost, which are beneficial in comparison to in vivo studies. However, ex vivo models are not appropriate for long-term culture and do not completely mimic the in vivo state in the perspective of nutrients supply or missing mechanical stimulation.

4.3. In vivo evaluation

In vivo models have been the long-established sources to elucidate safety and activity of biomaterials in a living organism prior to human clinical trials. The in vivo bone repair ability of osteogenic hydrogels can be studied using diverse animal models. Animal studies are more suitable for estimating results before translating them to clinical settings in comparison to in vitro experiments. Animal models are selected using multiple criteria including size, cost, handling, surgery resistance, infection, biological similarity to humans, and bone structure and composition etc. Diverse animal models to assess bone healing capacity will be discussed in the following section (Table 4).

Table 4.

In vivo evaluation of various hydrogels

| Animal | Defect | Hydrogels | Size | Time | Outcome |

|---|---|---|---|---|---|

| Mouse | Calvarial | ciiitosan-MMT121 | 3 mm | 6 weeks | - Recruited native cells - Bone volume increased to 46% |

| Calvarial | PEG-RGD-Lys-glutamine receptor237 | 4 mm | 12 weeks | - Recruit mesenchymal progenitor cells - Bone volume increased to 1 mm3 |

|

| Femur | Decellularized adipose tissue-hydroxyapatite238 | 3 mm | 12 weeks | - Increased collagen I and osteopontin expression - Bone volume increased to 5 mm3 |

|

| Ectopic | Gelatin239 | N/A | 4 weeks | - Coated with cells in osteogenic media - Increased collagen I and osteopontin expression |

|

| Ectopic | FIA-Laponite122 | N/A | 6 weeks | - Sustained retention of BMP-2 in vivo | |

| Rat | Calvarial | Pentonate-HA-devitalized tendon240 | 7.5 mm | 8 weeks | - Enhanced compressive modulus and calcium - Bone volume increased to 42% |

| Calvarial | Gelatin-PEO-PPO-PEO241 | 8 mm | 12 weeks | - Comparable with autologous bone graft - Bone surface area increased to 80% |

|

| Femur | Gelatin-Alginate242 | 3 mm | 3 weeks | - Mg particle as a foaming agent induced vascularization - Bone volume increased to 60% |

|

| Mandible | PNFPAM-PLGA-PEG-mesoporous silica nanoparticles243 | 5 mm | 10 weeks | - Incorporated with miRNA222 and aspirin - Bone volume increased to 22% |

|

| Ectopic | HA244 | N/A | 8 weeks | - Acidic F1A enhance BMP-2 sequestering and improve bone formation in vivo | |

| Rabbit | Mandible | Chitosan-Collagen245 | 8 mm | 12 weeks | - Incorporated with BMP-2 in gelatin microsphere - Bone volume increased to 55% |

| Femur | Polyacrylamide-Dextran-Flydroxyapatite179 | 5 mm | 12 weeks | - Inorganic-organic interaction in hydrogel enhanced mechanical properties - Bone volume increased to 8 mm3 |

|

| Pig | Mandible | Alginate-HA240 | 10 mm | 9 weeks | - Delivered BMP-2 and hBMSCs, and enhanced bone healing |

| Femur | Polyhydroxyethyl methacrylate-Collagen-DBM247 | 10 mm | 8 weeks | - Collagen stimulated bone healing by changing biological properties of synthetic polymer and enhanced mineralization | |

| Sheep | Iliac crest | ROD-Alginate-HA248 | 15 mm | 12 weeks | - Incorporated with ovine MSCs - Bone volume increased to 40% |

| Femur | Keratin-Hydroxyapatite249 | 10 mm | 4 weeks | - Dental implant coated with hydrogel was implanted - Bone-implant contact increased to 58.1% |

4.3.1. Choice of animals

Various animal models ranging from small animals, such as rodents and rabbits, to large animals, such as dog, goat, sheep, and pig, are employed to evaluate the osteogenic properties of hydrogels. Rodent models are preferred because of their numerous advantages in mouse and rat species, respectively. A mouse model is commonly used in biological research because of the diversity in the available strains and ease of use with relatively high cost efficiency227. However, it has a size limitation, which presents challenges for surgery and makes it difficult to perform experiments and create proper load-bearing defects. A rat model may overcome the size issue of mice with similar organ proportions to humans. However, it has limited strain diversity compared with mice, and it is less cost efficient to maintain because of its larger size. A rabbit model has a larger bone structure but is still limited in size compared with a dog, sheep, or pig. Large mammals have a much larger skeleton which resembles the high load-bearing human bone environment, but each model also has limitations in the existence of gaps between human bone composition and healing rate.

4.3.2. Bone regeneration models