Abstract

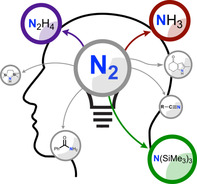

Dinitrogen (N2) is the most abundant gas in Earth's atmosphere, but its inertness hinders its use as a nitrogen source in the biosphere and in industry. Efficient catalysts are hence required to ov. ercome the high kinetic barriers associated to N2 transformation. In that respect, molecular complexes have demonstrated strong potential to mediate N2 functionalization reactions under mild conditions while providing a straightforward understanding of the reaction mechanisms. This Review emphasizes the strategies for N2 reduction and functionalization using molecular transition metal and actinide complexes according to their proposed reaction mechanisms, distinguishing complexes inducing cleavage of the N≡N bond before (dissociative mechanism) or concomitantly with functionalization (associative mechanism). We present here the main examples of stoichiometric and catalytic N2 functionalization reactions following these strategies.

Keywords: catalysis, coordination complexes, functionalization, mechanism, nitrogen

Dinitrogen (N2) is the most abundant gas in the Earth's atmosphere, but its inertness hinders its use as a nitrogen source in the biosphere and in industry. This review emphasizes the strategies for N2 reduction and functionalization using molecular transition metal and actinide complexes according to their proposed reaction mechanisms and presents the main examples of stoichiometric and catalytic N2 functionalization reactions.

1. Introduction

Atmospheric N2 is the primary source of all nitrogen atoms present on earth, but its assimilation by most living organisms requires its initial transformation into more reactive nitrogen species, all originating from ammonia. The conversion of molecular dinitrogen into ammonia is one of the most important chemical processes from both an industrial and a biological perspective. The biological fixation of dinitrogen occurs in the nitrogenase enzymes, which can effectively reduce N2 to NH3 under ambient conditions. However, the amount of dinitrogen fixed in such biological systems is not sufficient to replenish the reserves of nutrients needed in current agriculture practices. [1] The ground‐breaking discovery of artificial N2 reduction by Fritz Haber and its industrialization and optimization by Carl Bosch and Alwin Mittasch at the beginning of the 20th century,[ 2 , 3 ] allows to currently transform about half of the total reactive nitrogen available on Earth and is crucial to sustain the current 7.8 billion population. [4]

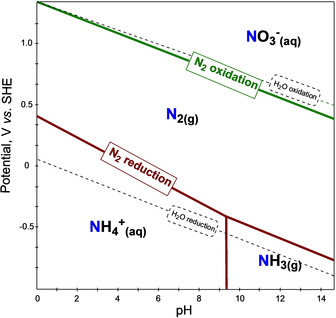

This process however requires reactors operating at high temperature and pressure and using highly purified N2 and H2. The use of H2 (mainly derived from fossil fuels steam reforming) as a reductant and the harsh conditions required result in a high CO2 footprint accounting for about 2 % of the world's CO2 emissions. [5] Industrial ammonia production can be carried out at very high energy efficiency, but the high temperature and pressure and the complex management of thermodynamic losses required render it only profitable at large scale, and therefore requires substantial capital investment. Consequently, a distribution infrastructure to ship from centralized sources to the local users is required, further increasing the overall environmental and energetic footprint of the process. More sustainable, delocalized and energy efficient alternatives to synthetic dinitrogen fixation are hence highly desirable in this context. [6] Nonetheless, energy‐efficient processes to reduce N2 under ambient conditions still face major challenges due to its chemical inertness, resulting from the thermodynamic strength of the N≡N bond (bond dissociation enthalpy of 944 kJ mol−1), the low proton affinity of N2 and its high kinetic stability towards reduction and oxidation. This high reduction stability of N2 originates from a poor electron affinity (calculated value of −1.903 eV) and a large LUMO‐HOMO gap (10.82 eV) resulting from strongly antibonding π* lowest unoccupied molecular orbitals (Scheme 2). [7] To overcome such high kinetic barriers requires energy along with an efficient catalyst.

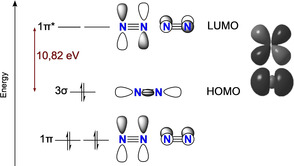

Scheme 2.

Molecular orbital diagram of free dinitrogen along with DFT‐computed HOMO and LUMO (B3LYP).

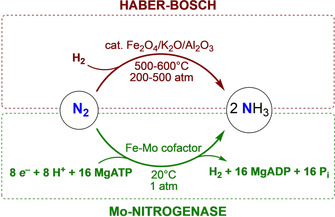

The Mo‐nitrogenase enzyme meets these challenges utilizing the energy of 16 equiv of ATP to transform one dinitrogen molecule, using water as the proton source (Scheme 1). The ability to mediate this reaction under mild conditions relies in that nitrogenases are effective promoters of multi‐electron and multi‐proton transfers, but the complete reaction mechanism is complex and still not completely uncovered today.[ 8 , 9 , 10 , 11 ] The Fe‐based heterogeneous catalysts currently used in the Haber–Bosch process rely on a very different strategy, using H2 as a source of electrons and protons (Scheme 1). [12] However, these require harsh conditions (>400 °C, >200 bar) to overcome the severe kinetic barriers to the dissociative nitrogen chemisorption on the catalyst surface. [13]

Scheme 1.

Comparative dinitrogen reduction to ammonia by the Haber–Bosch process (top) and in the Mo‐nitrogenase enzyme (bottom).

By providing a straightforward understanding of the reaction mechanisms and by allowing for the fine management of electron and proton transfer steps via the tuning of the active sites properties, molecular complexes have shown a strong potential to promote catalytic nitrogen reduction under mild conditions.[ 12 , 14 , 15 ] To date, dinitrogen metal complexes have been isolated with almost all metals from first to third row to rare‐earth metals,[ 16 , 17 ] but very few have led to the stoichiometric functionalization of dinitrogen and only a handful have been reported to enable catalytic functionalization.[ 18 , 19 , 20 ] Although recent reviews have surveyed dinitrogen activation by polynuclear complexes, [20] bond‐forming reactions from activated dinitrogen [19] and catalytic dinitrogen to ammonia formation using molecular complexes, [15] this Review will explore a complementary approach, encompassing aspects from all these reviews. We aim to provide an overview of the successful strategies utilizing molecular complexes to promote nitrogen reduction and functionalization with H, C and Si sources under mild conditions according to their proposed reaction mechanisms. For this purpose, we provide here two tools for a simple overview of the reactivity and performances of all complexes reported throughout this Review: the diversity of products obtained are compiled in Schemes 15, 19 and 47, while the performances of the complexes to mediate these transformations are summarized in Tables S1–S7 (Supporting Information). Other bond‐forming reactions with elements such as boron, phosphorous or with other Lewis acids are excluded from the scope of the current Review as their scarcity complicates the possibility to draw mechanistic conclusions. The interested reader may refer to the recent reviews from Chirik and co‐workers [19] and Simmoneau and Etienne, [21] which provide a good overview on the recent research in the field.

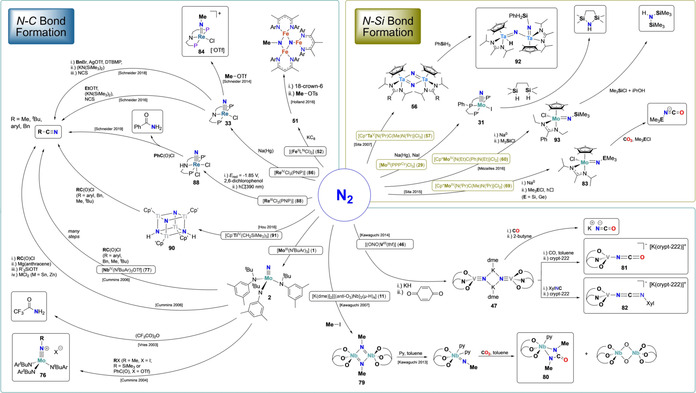

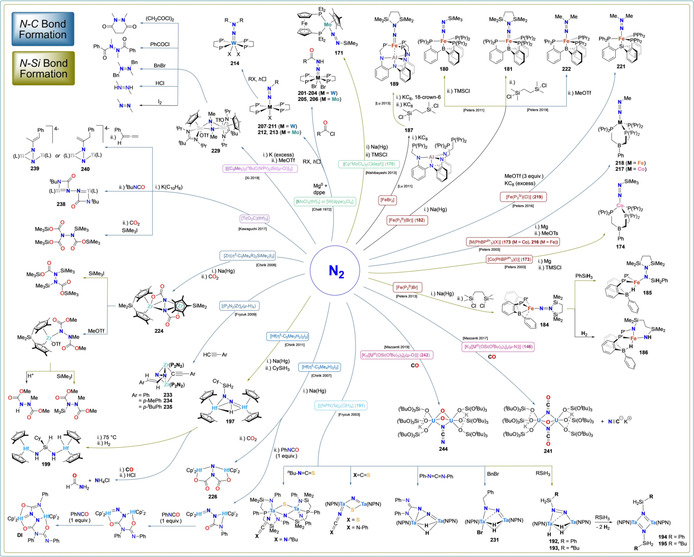

Scheme 15.

Stoichiometric functionalization of metal‐nitrides originating from N2 (N‐C and N−Si bond formation).

Scheme 19.

Stoichiometric functionalization of metal‐bound N2 (N−C and N−Si bond formation).

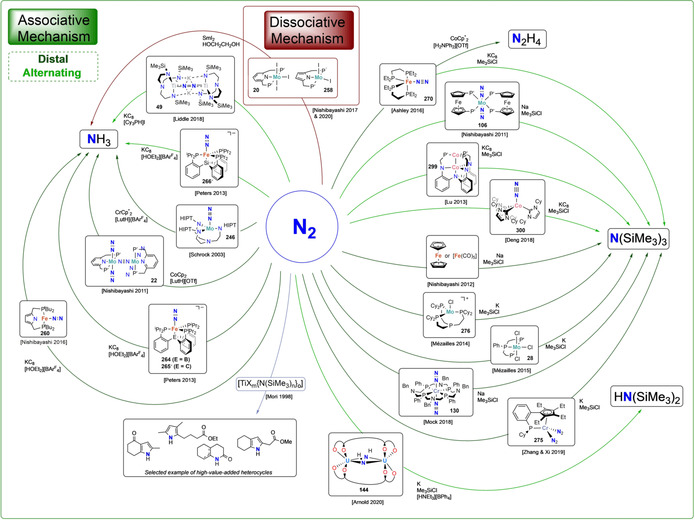

Scheme 47.

Catalytic systems for N2 functionalization (N−H, N−Si and N−C bond formation) and associated mechanism.

1.1. Molecular orbital considerations

Understanding the N2–metal interaction is key in rationalizing strategies for activating and functionalizing dinitrogen. Simple molecular orbitals models are a convenient way to simply illustrate and understand structural details and reactivity, and complementary to more in‐depth computational studies. [22] The free dinitrogen molecular orbital diagram is shown in Scheme 2.

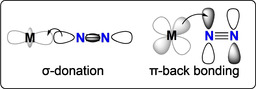

Most mononuclear d‐block metal complexes coordinate N2 in an end‐on fashion. Side‐on N2 bonding has been rarely observed in isolated mononuclear complexes,[ 23 , 24 , 25 ] but may occur for f‐block metal complexes or during the end‐to‐end rotation of mononuclear dinitrogen complexes. [26] In an end‐on coordination mode, the σ‐character of the HOMO and the π*‐character of the LUMO of N2 enable its coordination to the metal via a σ‐donation/π‐backbonding binding scheme, yet much less effective than for the more polarized isoelectronic CO molecule (Scheme 3). Such an interaction can weaken the triple bond of N2 by populating the π* molecular orbitals and by removing electron density from the bonding s‐orbital.

Scheme 3.

σ‐donation/π‐backbonding scheme of metal‐bound dinitrogen.

This binding scheme allows identifying optimal scenarios for N2 activation. Electron rich ligands have the potential to increase the electron density at the metal center and strengthen π‐backbonding. Following the same reasoning, metal complexes with a large number of valence electrons should lead to stronger activation. This effect may yet be limited by the decrease in energy of the d‐orbitals from left to right in the periodic table, lowering the overlap with dinitrogen's antibonding orbitals. For that reason, middle and group 8 transition metals often present the best compromise, as highlighted by the numerous complexes from these groups in N2 activation literature and the present review. [15]

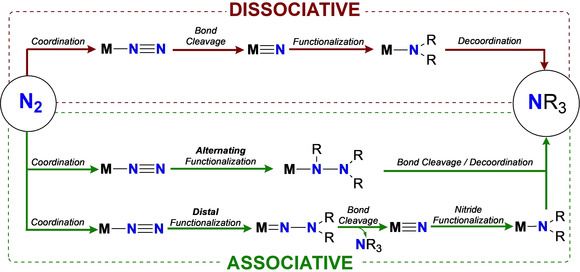

However, binding N2 to a single metal center in ambient conditions and in the absence of other reagents is not sufficient to induce N2 cleavage. The presence of a second metal center or of a Lewis or Brønsted acid is required to induce the scission of the N≡N bond. Two mechanistic paths can then be observed, involving either the initial cleavage of the triple bond to form metal nitrides functionalized in a second step by proton sources or electrophiles or the concomitant reduction and functionalization of the coordinated N2 molecule with proton sources or electrophiles. By analogy with the terms typically used to describe N2 mechanisms on heterogeneous catalysts, in this Review we will use the terms associative and dissociative to describe these two reaction paths. The terms may be over simplistic when describing activity of molecular complexes but are effective to identify common features in series of complexes. Within associative paths, the site of exogeneous substrate binding differentiates two mechanistic pathways depending on the distal or alternating functionalization of N2, as depicted in Scheme 4.

Scheme 4.

Dissociative and associative mechanisms for dinitrogen functionalization at a metal center M.

This Review will cover the most representative examples of N2 functionalization according to their proposed reaction mechanisms, highlighting first complexes reacting via a dissociative mechanism followed by associative pathway examples, to end on a brief exploration of reported catalytic systems.

2. Dissociative Mechanism

The major driving force in a dissociative mechanism is the formation of thermodynamically stable nitride complexes, while the later functionalization of the formed nitrides is the key parameter to envision a catalytic reduction of N2. Most complexes mediating N2 cleavage necessitate the use of external reducing agents and only a small number of compounds have been reported to cleave N2 without using reducing equivalents originating from an exogeneous electron source. Both possibilities will be distinguished here, further differentiating complexes forming terminal or bridging nitrides, summarized in Table S1. When reported, the functionalization of the formed nitrido ligands will be presented. An overview of all dissociative functionalizations is provided in Scheme 15 at the end of this section and summarized in Table S2.

2.1. Cleavage without external reducing agents

To date, only a limited number of complexes have been reported to split the dinitrogen triple bond without the use of exogeneous electron sources. In such a case, the complex is overall oxidized, the electrons being either provided by the metal center or from a concomitant reductive elimination step.

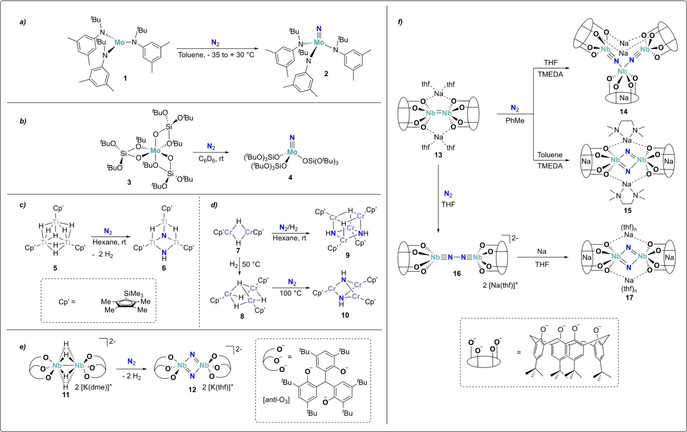

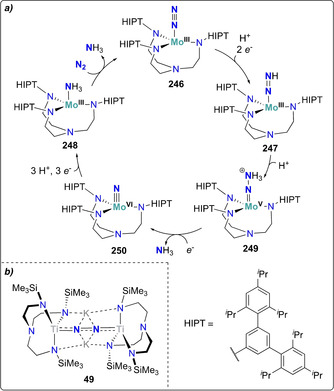

To our knowledge, only two examples of mononuclear metal complexes have been shown to cleave N2 into terminal nitrides, both being MoIII complexes. The first example is a MoIII‐trisamide complex introduced by Cummins in 1995. [27] Stirring a toluene solution of [MoIII(N(tBu)Ar)3] (1, Ar=3,5‐(CH3)2C6H3) under a dinitrogen atmosphere resulted in the successive binding and cleavage of the dinitrogen molecule to form the mononuclear MoVI‐nitride complex 2 (Scheme 5 a). The end‐on bridging intermediate (μ‐N2)[Mo(N(tBu)Ar)3]2 was observed and characterized by EXAFS [28] and later on by single crystal XRD. [29]

Scheme 5.

Dissociative N2‐splitting by mononuclear molybdenum complexes 1 (a) and 3 (b), trinuclear TiIII and CrIII hydride complexes 5 (c) and 7/8 (d) and dinuclear NbIII complexes 11 (e) and 13 (f).

This work, constituting the first example of full dinitrogen cleavage by a well‐defined transition metal complex, opened new perspectives for designing strategies for N2 reduction. The key feature for N2 activation is the presence of a highly reactive unsaturated trivalent MoIII species. In the case of C 3 symmetric [MoIII(N(tBu)Ar)3] (1), the three bulky amide ligands help to stabilize such species for example, by preventing them from dimerization. In addition, the MoL3 fragment is isolobal to a nitrogen atom by its three unpaired electrons populating the mainly d , dxz and dyz molecular orbitals, providing a significant thermodynamic stability to the corresponding Mo nitrides. A second MoIII complex displaying similar reactivity towards dinitrogen was reported more than 20 years later. [30] When the octahedral complex [MoIII(OSi(OtBu)3)3] (3) was exposed to dinitrogen, the corresponding mononuclear nitride complex (4) could be formed (Scheme 5 b). At the difference of the tris‐amide complex 1, the tris‐silanolate complex 3, is coordinatively saturated, but was shown to form a three‐coordinate MoIII complex in situ from the parent distorted octahedral complex thanks to the hemilabile character of the κ 2 coordinated silanolate ligands.

In addition to these two mononuclear examples, a few multimetallic complexes that react with dinitrogen in the absence of external reducing agents have been reported. In that case, N2 splitting results in the formation of multinuclear bridging nitride complexes. The trinuclear titanium(III) polyhydride complex 5 was shown to react with dinitrogen to form the bridging dinitride complex 6 with concomitant evolution of two equivalents of dihydrogen (Scheme 5 c). [31] In that complex, the electrons required for the reaction are formally not only delivered by the metal centers but also resulted from the reductive elimination of two equivalents of H2 per dinitrogen molecule. This system is relevant in the understanding of the biological dinitrogen fixation process, since bridging hydride ligands and analogous H2 elimination prior to N2 binding have been shown to be of key importance in the nitrogenase enzyme.[ 11 , 32 , 33 ] The cleavage of N2 by the related chromium(II) and chromium(III) hydride complexes 7 and 8 was demonstrated very recently (Scheme 5 d). [34] These compounds, which are the first well‐defined chromium hydride complexes capable of fixing N2, were shown to generate the corresponding bridging imide complexes 9 and 10 upon treatment with N2(/H2).

Reductive elimination of H2 as a strategy to provide electrons for the reduction of dinitrogen was also found for the niobium(IV) tridentate aryloxide bridging tetrahydride dimer [((anti‐O3)Nb)2(μ‐H)4][K(dme)]2 (11, anti‐O3, see Scheme 5 e). [35] Complex 11 was reported to react with N2 to afford the bridging dinitride, dinuclear NbV complex [((anti‐O3)Nb)2(μ‐N)2][K(thf)]2 (12). Among the six electrons required for the reduction of N2, four of them result from the reductive elimination of two equivalents of H2, while two electrons originate from the one‐electron oxidation of the two niobium centers. A very recent study demonstrated that the corresponding tetrahydride complexes with Na+ and Li+ counter cations showed a very different behavior. In both cases, reaction with N2 did not result in its full cleavage but lead to the elimination of only one equivalent of H2 and to the formation of corresponding side‐on/end‐on bridging dinitrogen complexes. [36]

Another low‐valent dinuclear NbIII complex 13, supported by a tetra‐anionic calix[4]arene ligand (Scheme 5 f), had been earlier reported by Floriani and co‐workers.[ 37 , 38 ] In toluene, this highly reducing species readily cleaved the N2 triple bond to yield a dimeric or a trimeric complex (14 and 15) with two bridging nitrido ligands. However, in more polar solvents such as THF, the corresponding dinitrogen bridged complex 16 was formed. The [N–N]4− unit could be further reduced for example, with sodium, again leading to full cleavage of the dinitrogen moiety and the formation of the bridging nitride complex 17.

2.2. In situ reduction under dinitrogen

The vast majority of complexes mediating dinitrogen reduction via a dissociative mechanism necessitate employing an external reducing agent concomitantly to N2 addition. This strategy avoids the challenging isolation of highly reactive reduced metal species, but implies that in most cases the reaction mechanism can only be proposed based on theoretical calculations and in situ spectroscopy. This should nevertheless not be seen as a drawback when targeting a catalytic system which requires dinitrogen and reducing agent to be present simultaneously.

2.2.1. In situ reduction under dinitrogen using alkali reducing agents

Frequently employed reducing agents such as sodium naphthalenide, sodium mercury amalgam, potassium graphite etc., contain alkali metal cations which may significantly contribute to the activation and cleavage of dinitrogen. Lewis acidic alkali metal cations can interact with coordinated dinitrogen molecules and further weaken their N−N bonds, as comprehensively reviewed by Holland in 2017. [39] We will focus here in two subsections on terminal and bridging nitride complexes formed by in situ N2 reduction using alkali‐metal reducing agents.

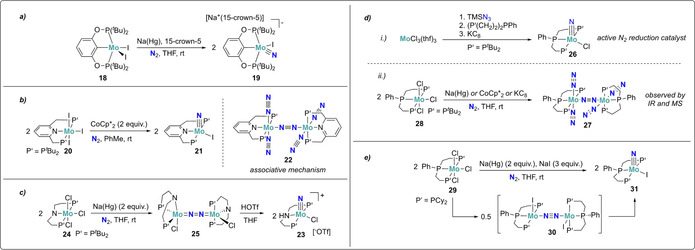

Formation of terminal nitrides: A significant number of transition metal complexes with pincer ligands were shown to cleave dinitrogen via both associative or dissociative mechanisms, depending on the ligand steric bulk and transition metal used. These bulky planar three‐coordinate neutral or mono‐anionic ligands are particularly suited for N2 activation: The T‐shaped geometry and tunable steric bulk of pincer ligands prevent the dimerization and deactivation of the corresponding complexes, of key importance to maintain reactivity of the formed nitride compounds. Molybdenum has been the most frequently studied metal in pincer complexes mediating dinitrogen activation, and Mo‐pincer catalytic systems with outstanding performances have been developed. Schrock and co‐workers reported dinitrogen cleavage by the MoIII PCP‐pincer complex 18 (Scheme 6 a). [40] Reduction with sodium mercury amalgam under dinitrogen afforded the corresponding terminal nitride complex [MoIVI(N)(PCP)]− (PCP=1,3‐[OP(tBu)2]2C6H3, 19) which was isolated as an ‐ate complex with a sodium‐crown ether counter cation. Surprisingly, attempts to selectively protonate the formed nitride with a variety of different acids only led to the undesired protonation of the phosphinite ligands.

Scheme 6.

Dissociative N2‐splitting by molybdenum complexes 18 (a), 20 (b), 24 (c), 28 (d), and 29 (e), all bearing pincer ligands.

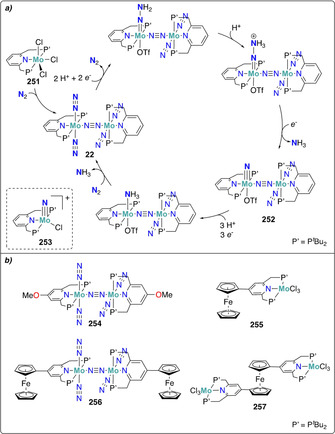

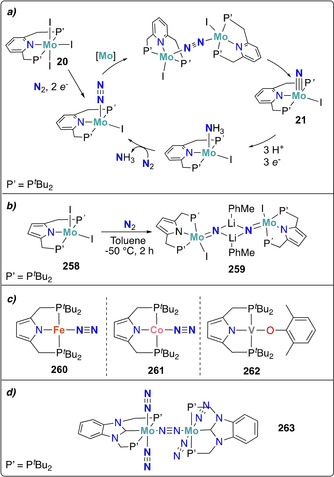

Furthermore, a variety of molybdenum pincer complexes with PNP and PPP scaffolds were shown to be able to cleave the dinitrogen molecule into nitrides. A pyridine‐based PNP‐pincer ligand scaffold was employed by Nishibayashi and co‐workers for the catalytic transformation of dinitrogen into ammonia. Stoichiometric reduction of the MoIII trisiodide complex 20 with either decamethylcobaltocene (CoCp*2) [41] or samarium diiodide [42] under dinitrogen yielded the corresponding terminal MoIV nitride complex 21 (Scheme 6 b). An end‐on bridging dinitrogen MoI intermediate was postulated as an intermediate based on synthetic experiments and theoretical calculations. Interestingly, a distinct mechanism was proposed for the corresponding Mo0 dinitrogen complex 22 supported by the same pincer ligand. This mechanism will be discussed in further details in Section 4.1.[ 43 , 44 ]

Molybdenum complexes bearing PNP‐pincer ligands for dinitrogen cleavage were studied by the group of Schneider. [45] In 2017, the formation of a MoV nitride complex [Mo(HPNP)(N)Cl][OTf] (HPNP=NH(CH2CH2PtBu2)2, 23) from the corresponding MoIV complex 24 and N2 was reported (Scheme 6 c). The two‐electron reduction of 24 with sodium mercury amalgam under a dinitrogen atmosphere yielded the end‐on bridging dinitrogen complex 25, in which, according to its N−N bond length and vibrational frequency, the N–N double bond was still intact. However, treatment of 25 with a Brønsted acid such as HOTf (−OTf=−OS(O)2CF3), induced full splitting of the dinitrogen unit into the corresponding nitride 23 (Scheme 6 d). While the reaction scheme may suggest an associative mechanism, the structure of 23 revealed that protonation took place at the amide ligand backbone. This proton‐assisted dinitrogen splitting was assigned to a lowering of the energy of the N–N anti‐bonding σ* orbital upon protonation of the amine in the pincer ligand backbone. Population of this N–N antibonding orbital subsequently promotes full dinitrogen cleavage. Dinitrogen scission was also demonstrated by the analogous tungsten complex. [46]

A catalytic system for dinitrogen reduction to ammonia based on PPP‐type Mo‐pincer complexes was developed. [47] There are two main advantages in the modulation of the ligand scaffold from PNP to PPP. Tridentate phosphine ligands are less Brønsted basic and thus more stable towards protonation, disfavoring the competitive hydrogen evolution reaction. The presence of acidic protons on the ligand scaffold may lead to undesired hydrogen evolution reaction under the reducing conditions applied during catalysis. Furthermore, their π‐accepting properties can stabilize a variety of molybdenum oxidation states during the catalytic cycle. Although independently synthesized from the corresponding azide, the MoIV‐nitride complex [Mo(N)Cl(PPP)] (PPP=PhP(CH2CH2PtBu2)2, 26) served as an active catalyst for nitrogen reduction, implying that catalysis proceeds through a dissociative mechanism (Scheme 6 d i). A bridging dinitrogen Mo0 complex 27 was identified as an intermediate species during catalysis and as a byproduct in the stoichiometric reduction of 28 under dinitrogen by IR spectroscopy and mass spectrometry (Scheme 6 d ii).

Another PPP Mo nitride complex [Mo(N)Cl(PPP)] (PPP=PhP(CH2CH2PCy2)2, 29) was prepared recently from dinitrogen cleavage by Mézailles and co‐workers. [48] The triphosphino molybdenum(I) iodide complex 30, generated in situ from the parent MoIII trischloride precursor, readily split N2 at room temperature to the corresponding terminal MoIV‐nitride 31 (Scheme 6 e).

Schneider and co‐workers investigated PNP pincer ligands as supporting scaffolds for rhenium complexes. [49] Reduction of [ReIIICl2(PNP)] (PNP=N(CH2CH2PtBu2)2, 32) with sodium‐mercury amalgam under dinitrogen led to the cleavage of the dinitrogen triple bond and to the formation of the ReV‐nitride complex [ReVCl(N)(PNP)] (33) (Scheme 7 a). [50] Complex 33 could also be prepared by using an outer‐sphere reducing agent or by electrochemical means, and will be discussed in Section 2.2.2. Mechanistic studies revealed that dinitrogen is activated via the formation of a bridging μ‐N2 dinuclear intermediate 34, which was isolated at low temperature and characterized by XRD. [50] The influence of backbone unsaturation on the pincer ligand was investigated in a follow‐up study (Scheme 7 b). [51] The ReIII complex 35 was shown to cleave N2 into the corresponding ReV nitride 36 either by chemical or electrochemical reduction, at less cathodic potentials but yet with lower yields than reported for complex 32 with a saturated ligand backbone.

Scheme 7.

(Electro)chemically induced N2‐splitting by rhenium complexes 32 (a) and 35 (b).

Formation of bridging nitrides: The high nucleophilicity of metal nitrides strongly favors their behavior as bridging ligands, resulting in the formation of di‐ or multinuclear complexes, reviewed in this section. Formation of such multinuclear assemblies was often shown to be further promoted by the presence of alkali cations originating from the reducing agents and acting as bridging groups between the nitride moieties and ligands scaffolds.

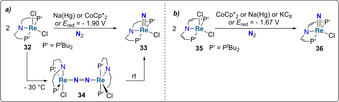

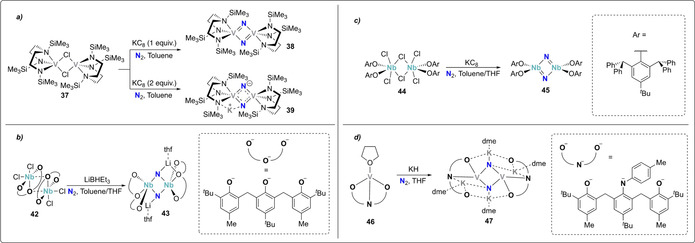

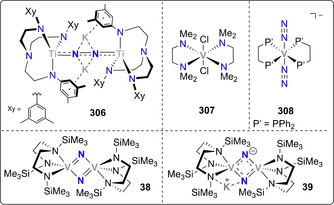

Reported in 1999, the vanadium(III) silylamino(disilylamido) complex 37 constituted of the earliest reported complexes capable of cleaving N2. The presence of one equivalent of potassium graphite afforded the bridging bis(μ‐nitrido) VV complex 38 upon N2 cleavage (Scheme 9 a). [52] When two equivalents of potassium graphite were used, the mixed valent VIV–VV complex 39 was obtained. Structural analysis of 39 revealed that one potassium cation was bridging between a supporting amide‐ and a nitride ligand, highlighting its potential role in the reaction of the calixpyrrole uranium(III) complex 40 with one equivalent of potassium naphthalenide under a dinitrogen atmosphere led to the formation of the dinuclear, μ‐nitrido UIV/UV mixed‐valent complex 41 (Scheme 8). X‐ray structural analysis revealed that each of the bridging nitride ligands of 41 were here also additionally coordinated to a potassium cation.

Scheme 9.

Dissociative N2‐splitting by group 5 transition metal complexes 37 (a), 42 (b), 44 (c), and 46 (d).

Scheme 8.

Dissociative N2‐splitting by uranium complex 40.

Analogous alkali ion incorporation was observed upon treatment of the tris‐aryloxide (chelating OOO ligand) NbV complex 42 with excess LiBHEt3 under a dinitrogen atmosphere, affording the bridging dinitride complex 43 (Scheme 9 b). [53] Two lithium cations are there bridging between a nitride and an aryloxide ligand. An analogous reactivity was observed using instead a monodentate but sterically more encumbered aryloxide ligand. The NbV dimeric complex 44 can cleave the N2 triple bond in presence of potassium graphite to form the dimeric niobium nitride complex 45 (Scheme 9 c). Protonolysis of 45 with anhydrous HCl resulted in the formation of ammonium chloride. [54]

Incorporation of four potassium ions coordinated to the nitride ligands and the ligand framework was observed upon treatment of the bis‐aryloxy‐amide (chelating ONO ligand) vanadium(III) complex 46 with potassium hydride under dinitrogen affording the bis(μ‐nitride) VIV dimer 47 (Scheme 9 d). [55]

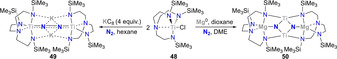

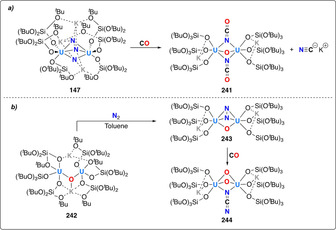

Using a triamidoamine ligand scaffold, Liddle and co‐workers further illustrated the influence of alkali or alkali‐earth reducing agents mediating the cleavage of dinitrogen by a TiIV complex 48.[ 56 , 57 ] When potassium graphite was used as the reductant, four‐electron reduction of N2 was observed (Scheme 10, left arrow). The dinuclear TiIV complex 49 with two potassium cations coordinating to the bridging [N–N]4− unit was then characterized. When performing the reduction with three equivalents of Mg0 instead, six‐electron reduction of N2 took place and afforded the bridging nitride complex 50 (Scheme 10, right arrow). The structure of 50 revealed that transmetallation from titanium to magnesium occurred. This work underlines the importance of cooperativity between the transition metal and the (earth‐)alkali cation used for dinitrogen reduction, since Mg2+ ions appeared to be necessary to induce full N2 cleavage. Treatment of the bridging nitride complex either with a strong acid (HCl) or with H2 in combination with a frustrated Lewis base pair (PtBu3+B(C6F6)3) led to the release of ammonia.

Scheme 10.

Dissociative N2‐splitting by titanium complex 48.

A whole series of low‐valent, three‐coordinate FeII complexes with β‐diketiminate supporting ligands were reported by Holland and co‐workers to bind and cleave N2 upon treatment with a variety of alkali metal based reducing agents.[ 58 , 59 , 60 , 61 ] Trinuclear and tetranuclear iron dinitrogen and nitride complexes were isolated and characterized. The degree of dinitrogen activation was observed to depend on the type and the amount of the reducing agent used as well as on the steric demand of the β‐diketiminate ligand substituents. The dinitrogen molecule was proposed to be cooperatively activated by π donation from the low‐valent iron centers as well as by the Lewis acidic activation of the alkali ions. Scheme 11 a displays the synthesis of the mixed‐valent tetranuclear FeII/FeIII nitride complex 51 from the corresponding dimeric FeII chloride complex 52. Interestingly, the solid‐state structure of 51 revealed that the potassium ions coordinate to the nitride and chloride ligands as well as to the aryl rings of the β‐diketiminate ligands. A fine tuning of the acid used to protonate the nitride ligands allowed identifying weak acids such as tBu3C6H2OH to selectively protonate the nitride to form ammonia in high yields. [61] When metallic Na as an external reducing agent was used instead of KC8, the formation of the trinuclear iron nitride complex 53 was observed. [62]

Scheme 11.

Dissociative N2‐splitting by iron complexes 52 (a) and 54 (b) bearing β‐diketiminate ligands.

Bridging of three β‐diketiminate moieties by two phenyl rings gave access to the trinuclear FeII bromide complex 54 which enabled reductive cleavage of the dinitrogen triple bond. This afforded the trinuclear complex 55 containing μ‐imide and/or μ‐amide bridging groups (abbreviated as NHx, x=1 or 2) between the iron centers (Scheme 11 b). [63] Mössbauer spectroscopy revealed that the iron centers in 55 were present as FeII and FeIII. In comparison to the iron nitride complexes supported by non‐bridging β‐diketiminate ligands (vide supra), no potassium cations were incorporated into the structure of 55. The origin of the protons bound to the bridging N‐containing ligands could however not be unambiguously assigned.

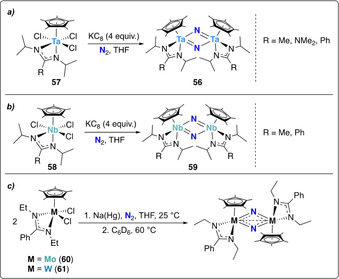

Sita and co‐workers reported the synthesis of the dinitride‐bridged tantalum dimer [{Cp*Ta[N(iPr)C(R)N(iPr)](μ‐N)}2] (56, Cp*=η 5‐C5Me5, R=Me, NMe2, Ph) obtained by reduction of the tantalum amidinate trichloride complexes [Cp*Ta[N(iPr)C(R)N(iPr)]Cl3] (57, Cp*=η 5‐C5Me5) with four equivalents of potassium graphite under a dinitrogen atmosphere (Scheme 12 a). [64]

Scheme 12.

Dissociative N2‐splitting by group 5 and 6 amidinate complexes, 57 (a), 58 (b), 60 and 61 (c).

The same ligand set was used to prepare a series of group 5 and 6 transition metals complexes.[ 65 , 66 , 67 ] Among those, only the niobium complex [Cp*Nb[N(iPr)C(R)N(iPr)]Cl3] (58, R=Me, Ph) presented the same dinitrogen cleavage activity in presence of potassium graphite, forming the bridging nitride complex 59 (Scheme 12 b). [67] Reducing the steric demand on the N substituents of the amidinate ligand (Et vs. iPr) allowed for homolytic cleavage of N2 promoted by the corresponding group 6 transition metal complexes 60 and 61 in presence of sodium amalgam (Scheme 12 c). [68]

2.2.2. N2 splitting induced by light or electrochemistry

As highlighted above, the use of alkali‐metal reducing agents may complexify the evaluation of their individual roles in the reaction mechanism, as potentially acting both as reducing agents and Lewis acids. In addition, the highly negative redox potential of alkali ions restrains their use for the development of catalytic systems, as large thermodynamic costs would be associated. Strategies allowing to separately investigate N2 cleavage and functionalization while being able to easily tune the energy provided to the system are hence highly desirable for both mechanistic analysis and the discovery of new catalytic systems. The following section aims at discussing the formation of metal nitride complexes from dinitrogen triggered by photo‐ or electrochemical means.

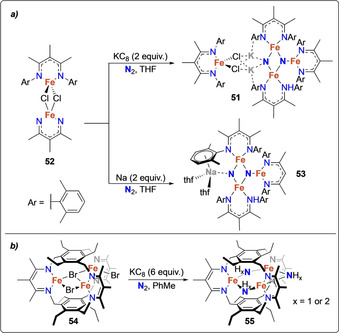

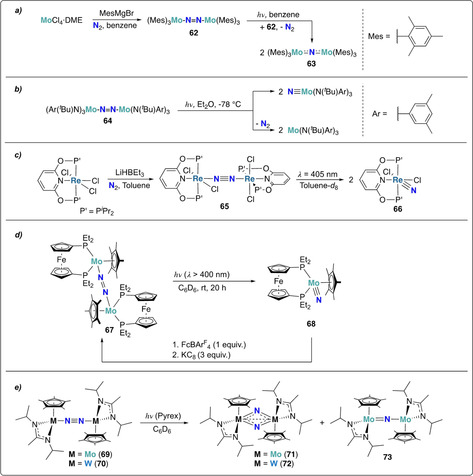

Photochemical activation of dinitrogen was described in few reports, taking advantage of potential MLCT transitions to the N–N π* orbital to promote N2 splitting.[ 69 , 70 ] The first example of photoactivation of N2 was reported by Floriani and co‐workers. The three coordinate complex [Mo(Mes)3] (Mes=2,4,6‐Me3(C6H2)), which was generated in situ by treatment of [MoCl4⋅dme] with four equivalents of mesitylene‐Grignard, reacted with dinitrogen by a four‐electron reduction under the formation of a dimeric MoV complex 62 with a bridging [N–N]4− unit (Scheme 13 a). [71] Compared to the tris‐amide complex 1 developed by Cummins (Scheme 5), [27] the mesitylene ligands in 62 are less electron donating than the anionic amide ligands and could not induce full cleavage of the dinitrogen moiety. 62 was reported to be stable in refluxing benzene, however, the formation of the bridging nitride complex 63 was observed upon exposure to UV light (λ=365 nm).

Scheme 13.

Photolytic N2‐splitting of dinitrogen bridged group 6 and 7 metal complexes 62 (a), 64 (b), 65 (c), 67 (d), 69 and 70 (e).

Transient absorption spectroscopy experiments revealed that the bridging dinitrogen complex 64 prepared by Cummins et al. could also be photoactivated, resulting in both Mo−N and N−N bond cleavage (Scheme 13 b).[ 29 , 72 ]

The photolytic cleavage of the rhenium bridging dinitrogen complex 65 was reported very recently (Scheme 13 c). [73] Similar to complex 62 (vide supra), 65 was found to be thermally stable, whereas irradiation with visible light (λ=405 nm) led to photolytic cleavage of the dinitrogen unit into the corresponding terminal nitride complex 66. Nitride functionalization to ammonia was achieved by a PCET‐type mechanism using SmI2 and H2O as reducing agent and proton source, respectively.

An additional example of photochemically triggered dinitrogen splitting was uncovered by Nishibayashi et al. [74] The ferrocenyl‐diphosphine and pentamethyl‐cyclopentadienyl supported dinitrogen bridged Mo‐complex 67, obtained from a molybdenum hydride complex and dinitrogen in two steps, was transformed to the corresponding Mo‐nitride 68 by irradiation with visible light (λ>400 nm) (Scheme 13 d). Note that the original dinitrogen‐bridging dinuclear Mo‐complex 67 could be regenerated by sequential oxidation with [FeCp2][BArF 4] and reduction with potassium graphite. Treatment of Mo‐nitride 68 with excess decamethylcobaltocene (CoCp*2) and [LutH][BArF 4] led to the formation of ammonia (0.37 equiv based on 68).

Sita and co‐workers disclosed the light mediated dinitrogen cleavage of group VI (M=Mo or W) bridging dinitrogen complexes (69 and 70) (Scheme 13 e). [75] Upon photolysis of 69 or 70, the respective bridging dinitride complexes 71 and 72 were obtained, together with small amounts of mono‐nitride complex 73 when Mo complex 69 was used. As mentioned in the previous section, modifying the steric demand of the supporting amidinate ligand from isopropyl to ethyl (Scheme 12 c) allowed for the conversion of the photochemically driven cleaving step into a thermally driven reaction. [68]

Electrochemical (or outer‐sphere) dinitrogen reduction to nitrides may represent a key step to the development of catalytic systems, however very few complexes have been reported to mediate dinitrogen cleavage in the absence of external functionalization agents such as protons or electrophiles. The first of such an example was reported by Schneider and co‐workers, showing that dinitrogen splitting and subsequent preparation of complex 32 could also be accomplished by controlled potential electrolysis under an N2 atmosphere (E red=−1.90 V vs. Fc/Fc+, 0.2 m nBu4N+PF6 − in THF) (Scheme 7 a), or by using an outer‐sphere reducing agent (CoCp*2). [50] The same behavior was observed for the analogous complex 35. [51]

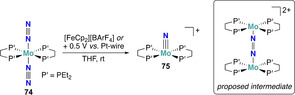

The one‐electron oxidation induced dinitrogen splitting reported by Masuda shortly after represents another rare example of nitride formation enabled by electrochemistry, yet with a very different strategy. [76] This approach relied on the oxidation of the Mo0 complex trans‐[Mo(depe)2(N2)2] (74, depe=Et2PCH2CH2PEt2) by chemical ([FeCp2][BArF 4]) or electrochemical means (E ox=+0.5 V vs. Pt‐wire), generating in situ [(μ‐N2)(MoII(depe)2)2]2+ with a MoII−N=N−MoII core followed by the formation of the MoIV nitride complex 75 (Scheme 14). Nevertheless, this protocol could not be easily exploited for catalytic N2 reduction as it operates under oxidative conditions, whereas the conversion of dinitrogen to ammonia requires an overall reduction of the substrate.

Scheme 14.

Electrochemical N2‐splitting by molybdenum complex 74.

2.3. Nitride functionalization

The previous section provided a significant number of metal complexes able to fully cleave dinitrogen to nitrides, but to date only very few catalytic systems were identified with such complexes (see Scheme 47 in Section 4). One of the main challenges to establish such catalytic system is to functionalize the formed nitrides. Transition metal nitrides that are formed upon dissociative N2 cleavage are often very stable and their functionalization hence requires strong electrophiles/proton sources. These harsh conditions could interfere with the low‐valent metal precursor. To overcome this limitation, a few synthetic cycles were developed, providing the reducing agents and functionalizing groups in a stepwise manner. [77] Following this strategy, most of the formed nitrides react with strong proton sources to generate ammonia, but in many cases destruction of the metal complex is observed simultaneously. These examples were treated together with the description of the nitride formation in the previous sections. The following section focuses on synthetic cycles enabling the formation of N−C and N−Si bonds from nitrides that originate from N2. Such reactions allow for the synthesis of fine chemicals with the N atom originating from dinitrogen. This can be especially interesting for the manufacture of value‐added products from N2 as well as for the synthesis of 15N labelled compounds (if using 15N2 as the nitrogen source). All nitride functionalization reactions reported here are summarized in Scheme 15 and Table S2. The reader is asked to refer to this scheme for all structures mentioned in this section.

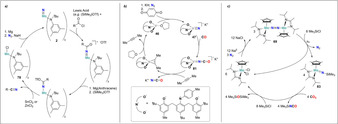

2.3.1. N−C bond formation

Many investigations have been performed on the MoVI trisamide nitride complex 2. [27] The weak nucleophilic character of this nitride allowed for functionalization with a variety of strong electrophiles such as methyl iodide, Me3SiOTf or PhC(O)OTf yielding substituted imido complexes 76 (Scheme 15). [78] Cummins and co‐workers developed a synthetic cycle consisting of the molybdenum‐ and niobium trisamide complex 1 and 77, which converted dinitrogen into nitriles. [79] The N−C bond forming reaction took place in between a NbV nitride and an acyl chloride species. The first well defined transfer of the nitride ligand from [MoVI(NtBuAr)(15N)] (2–15 N) to an organic molecule was achieved using trifluoroacetic anhydride as an acceptor. [80] Quantitative formation of CF3CO15NH2 was observed with concomitant decomposition of the molybdenum complex. A full synthetic cycle that converted dinitrogen into organic nitriles was later disclosed by Cummins (Scheme 16 a). Key step was the use of SnCl2 or ZnCl2 as strong Lewis acids and chloride donors to release the free nitrile and to form the MoIV trisamide chloride complex 78 which could be reduced back to the initial MoIII trisamide complex 1 and thus close the synthetic cycle. [81]

Scheme 16.

Synthetic cycles promoted by transition metal complexes 2 (a), 46 (b) and 68 (c) for the synthesis of isocyanates and nitriles utilizing N2 as a nitrogen source.

Similarly, Kawaguchi et al. reported the alkylation of the bridging μ‐nitrido niobium dimer 12 with methyl iodide to afford the corresponding imide bridged complex 79 (overview Scheme 15). [35] Subsequent addition of pyridine and reaction with CO2 afforded the NbV‐ureate complex 80. [82]

N−C bond formation, integrated into a synthetic cycle could also be accomplished from the VV nitride complex 47, which was obtained from the VIII complex 46 by reductive cleavage of N2 (Scheme 16 b). The nitride ligand of 47 was functionalized with CO to the corresponding isocyanate complex 81. Free potassium isocyanate precipitated upon addition of dimethylacetylene and dissolving in THF recovered the original complex 46. [55] Additional reactivity of 5 was observed with 2,6‐xylylisocyanide, which formed a carbodiimide complex 82.

Formation of isocyanates was also observed using the end‐on dinitrogen bridged dimer [(Cp*Mo[N(iPr)C(Me)N(iPr)])2(μ‐N2)] (69). Complex 69 was used in a chemical cycle producing isocyanates (R3ENCO) from N2, CO2 and R3ECl (R3E=Me3Si, Ph3Si, Me3Ge or Me3C) (Scheme 16 c). [75] Treatment of 69 with R3ECl under UV light afforded the corresponding terminal imido complexes 83. Reaction with CO2 and excess R3ECl followed by reduction under N2 led to the release of substituted isocyanate (R3ENCO) and regeneration of the original complex 69.

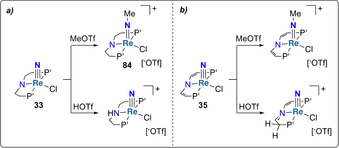

Organic nitriles were likewise obtained from PNP‐type pincer rhenium nitrido complexes in high yields. [83] While the nitride moiety in complex [ReV(PNP)Cl(N)] (33, PNP=((tBu2PCH2CH2)2N) could not be protonated with HOTf (which led to protonation of the ligand backbone), it could be functionalized to the methylimide complex 84 using MeOTf (Scheme 17 a). [49] The very same outcome was reported for functionalization of the nitrido complex 35 bearing a pincer ligand with an unsaturated backbone (Scheme 17 b). [51] Methylation of the nitrido ligand of the iron complex 51 was also achieved upon reaction with methyl tosylate (MeOTs, TsO−=p‐CH3‐C6H4‐SO3 −). [84]

Scheme 17.

Functionalization of metal‐nitride complexes 33 (a) and 35 (b).

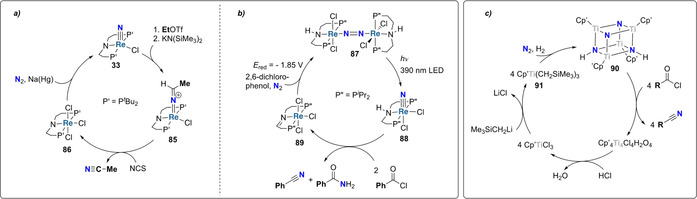

Analogously, reaction of 33 with ethyl triflate yielded a rhenium ethyl imido complex which was deprotonated with the strong base (KN(SiMe3)2) to afford the corresponding ReIII ketimide complex 85 (Scheme 18 a). Treatment with N‐chlorosuccinimide (NCS) led to the release of free acetonitrile and the rhenium(IV) trichloride complex 86. Reduction of this trichloride complex with sodium mercury amalgam under dinitrogen regenerated the putative rhenium nitride 33 and closed the chemical cycle which produced acetonitrile from ethyl triflate and N2. The very same protocol was applied for the synthesis of benzonitrile with in situ generated benzyl triflate as the carbon source. [85] Use of a sterically less demanding pincer ligand (isopropyl instead of tertiary butyl substituents on the phosphorous) enabled the formation of benzonitrile and benzamide from dinitrogen and benzoyl chloride (Scheme 18 b). [86] Interestingly, this synthetic cycle exploited for each step a different activation strategy: i) photochemical splitting of Re‐dinitrogen complex 87, ii) thermally induced reaction of benzoyl chloride with the formed nitride complex 88 and iii) electrochemical reduction of 89 under N2 to regenerate the dinitrogen bridged Re‐complex 87.

Scheme 18.

Synthetic cycles promoted by transition metal complexes 33 (a), 89 (b) and 91 (c) for the synthesis of organic nitriles utilizing N2 as a nitrogen source.

Multinuclear titanium complexes were also used as a platform to split dinitrogen followed by functionalization of the formed nitrides into organic nitriles (Scheme 18 c).[ 31 , 87 ] The tetranuclear bisimido/bisnitrido complex [(Cp′Ti)4(μ3‐NH)2(μ3‐N)2] (90, Cp′=C5Me4SiMe3) was obtained from [Cp′Ti(CH2SiMe3)3] (91) by hydrogenation under dinitrogen and heating under dinitrogen at 180 °C. Reaction with a variety of acyl chlorides yielded the corresponding organic nitrile compounds. The original titanium complex 90 could be obtained again upon treatment with HCl followed by Me3SiCH2Li.

2.3.2. N−Si bond formation

Alternatively, a few examples of electrophilic functionalization of metal nitride obtained by N2 reduction have been reported using silylation reagents such as silanes of silyl halides.

Mézailles and co‐workers used the bis(silane) HSiMe2(CH2)2SiMe2H to functionalize the PPP‐type pincer supported MoIV nitride complex 31. The use of a bis(silane) functionalizing group allowed the release of the N‐containing product as a cyclic silylamine in good yields (see overview Scheme 15). [48]

A different behavior had been disclosed by Sita and co‐workers using PhSiH3 to functionalize the bridging bis(μ‐nitrido)‐tantalum complex [{Cp*Ta[N(iPr)C(Me)N(iPr)](μ‐N)}2] (56). The functionalization product could not be released, affording the silyl substituted Ta‐imido complex 92. [64] However, as depicted in overview Scheme 15, using the Mo analogue [Cp*Mo[N(Et)C(Ph)N(Et)]Cl2] (60), quantitative formation of hexamethyldisilazane (HN(SiMe3)2) could be obtained upon reacting the terminal imido complex 93 with an alcohol X−OH (X=iPr, Me3Si) and Me3SiCl, allowing for the full cleavage of the metal nitride bond and release of the N‐containing product. [88]

The proposed mechanism for the generation of HN(SiMe3)2 involves the formal addition of HCl (generated from the reaction of X−OH with Me3SiCl) across the Mo=N double bond of the imido complex 93, generating a transient MoIV amido complex. This intermediates further reacts with a second equivalent of Me3SiCl to yield HN(SiMe3)2 and regenerate the initial MoIV dichloride complex 60.

2.4. Summary

The review of the complexes above highlights that, despite a significant number of molecular complexes are able to mediate the full cleavage of dinitrogen, only a few of them have been identified to mediate this cleavage in the absence of external reducing agents. In addition, the high stability of the formed nitrides is generally a key driving force of dissociative mechanisms. However, this high stability represents a challenge to be overcome when considering the functionalization of metal nitrides, which requires to utilize strong electrophiles and proton sources. The common incompatibility of such reagents with the metal complex precursors nevertheless constitutes one of the main limiting factors for the use of such complexes in catalytic conditions. Milder homolytic bond formation mechanisms, notably via PCET, may provide a promising strategy to utilize these metal complexes in a catalytic way, without the need of stepwise synthetic cycles.

3. Associative Pathways

The major driving force of associative reaction pathways relies on the activation of M−N2 species through the functionalization of the coordinated N2 moiety with electron deficient substituents, facilitating the transfer of electron density onto the N2 moiety and its subsequent reductive cleavage. We will distinguish in this section key associative N2 cleavage strategies based on the stepwise protonation and silylation of N2 or on the functionalization of N2 with carbon‐based electrophiles. This section will mainly focus on the stoichiometric transformation of N2, while systems enabling catalytic conversion of dinitrogen will be discussed in Section 4. Associative mechanisms typically involve the initial coordination of N2 without full cleavage: for most examples presented here we will hence not specifically focus on the N2 binding step but mainly on subsequent functionalization steps. An overview of all functionalization strategies towards N−H, N−Si and N−C bond formation reported in this section are compiled in Scheme 19 and Tables S3–S5.

3.1. N−H bond formation

Hydrogenation strategies of N2 require the provision of protons and electrons. Several strategies have been explored and will be reported in this section, differentiating mechanisms involving the separate supply of electrons and protons using Brønsted acid sources and reducing agents (that could be the complex itself) and reaction pathways providing protons and electrons via a sole source, namely dihydrogen or hydrides.

3.1.1. Protonation pathways

Direct protonation of the metal bound dinitrogen is one of the predominant criteria towards its conversion to ammonia. The key requirement for such protonation to occur relies on providing sufficient electron density to the bound dinitrogen moiety. [32] This often necessitates the use of low‐valent metal centers, which however typically display low Lewis acidity and N2 binding affinity while enhancing the risk of competitive proton reduction to dihydrogen. The Lewis acidity of the metal centers can yet be modulated by the ligand used. This allows for an advantageous N2 over H+ binding as well as furnishing substantial electron density on the N2 moiety for directed protonation via concomitant electron transfer in so‐called proton‐coupled electron transfer steps. Such strategies towards the protonation of metal ligated N2 species will be addressed in this section.

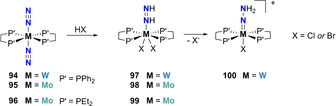

Bis‐diphosphine dinitrogen complexes of molybdenum and tungsten were early synthesized by the reduction under a N2 atmosphere of [MoCl3(thf)3] or [WCl4(thf)4] with sodium amalgam or metallic Mg [89] or of molybdenum tris‐acetylacetonate complexes with AlEt3. [90] This series of dinitrogen complexes enabled an extensive number of studies on N2 functionalization utilizing these species as starting N2 synthons. Chatt and co‐workers demonstrated as early as 1972 that such bis‐diphosphine dinitrogen complexes can undergo direct protonation using strong acids. Bis‐diphosphine complexes of tungsten, trans‐[(dppe)2W(N2)2] (94) (dppe=Ph2PCH2CH2PPh2), [91] and molybdenum, trans‐[(dppe)2Mo(N2)2] (95), trans‐[(depe)2Mo(N2)2] (96) can be protonated using strong inorganic acids (e.g. HBr or HCl) in toluene or THF to produce the corresponding diazene complexes [MX2(dppe)2NH=NH] (M=W (97), Mo (98), and X=Cl or Br) and [MoBr2(depe)2NH=NH] (99) in good yields (Scheme 20).[ 91 , 92 ] These seven coordinated diazene complexes further underwent proton reorganization to generate the corresponding hydrazido complexes, for example, 100, upon dissociation of an anionic halide ligand. The enhanced cationic character of the metal resulting from halide dissociation was attributed as a possible reason for this reorganization. Interestingly, Pickett and Talarmin demonstrated in 1985 that such hydrazido complexes could also be generated electrochemically but with a p‐TsO counterion. [93]

Scheme 20.

Associative N2 protonation using group 6 bis‐diphosphine complexes, 94–96 resulting in hydrazine complexes 97–99 and hydrazido complex 100.

This reactivity was shown to be maintained for a broad range of bis‐diphosphine complexes [M(N2)2(PP)2] that include redox active moieties such as ferrocenyl‐, ruthenocenyl‐, and chromobenzene‐based bis‐diphosphine ligands (PP) where the redox active moieties were incorporated in place of the ‐CH2CH2‐ group, as highlighted in Scheme 21 a. The formation of diazene intermediates trans‐[M(depf)2(=N‐NH2)(OTf)]OTf (M=W (101) or Mo (102), depf=bis‐diethylphosphinoferrocene) was also identified upon treatment with triflic acid (Scheme 21 c). At the difference of ethylene(bis‐diphoshine) complexes 94–96 presented above, formation of NH3 was observed upon treatment of complexes 103–107 with H2SO4.[ 94 , 95 , 96 ] This different behavior regarding the formation of NH3 was suggested to originate from the hemilabile character of the nonflexible metallocene ligands. Analogous complexes in mixed ligand environments with both bidentate and monodentate ligands such as 108–110 also showed similar reaction patterns, yet with an overall lower activity towards ammonia formation (Scheme 21 b). [96]

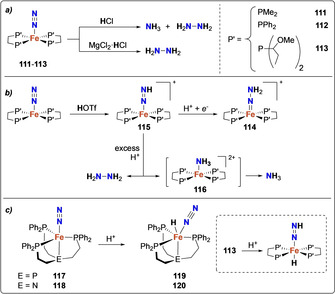

Scheme 21.

Associative N2 protonation using group 6 metal complexes, bearing metallocene diphosphine ligands 103–110 (a) and (b), and resulting hydrazido complexes 101–102 (c).

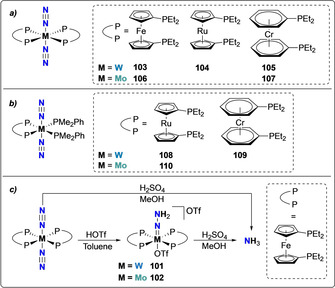

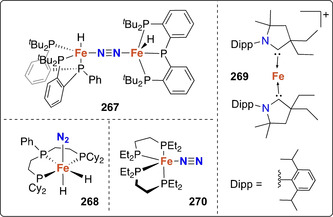

This behavior appeared to be characteristic of a broad range of bis‐diphosphine dinitrogen complexes, notably based on other transition metals such as Cr and Fe. Trans‐[Cr(dmpe)2(N2)2] (dmpe=Me2P‐CH2CH2‐PMe2) could be obtained by reduction of trans‐[Cr(dmpe)2Cl2] using sodium‐mercury amalgam, [97] Rieke magnesium [98] or nBuLi. [99] While ammonia or hydrazine were not released by protonation using a variety of proton sources, [100] the Cr hydrazido complex [Cr(OTf)(dmpe)2(=N‐NH2)][OTf], similar to the Mo and W analogues described before, was isolated. [101] Leigh et al. reported the stoichiometric activation of dinitrogen to ammonia using the iron(0)‐dinitrogen complex [Fe(dmpe)2N2] (111) (Scheme 22 a).[ 102 , 103 , 104 ] Interestingly, different reaction products could be observed depending on the protonation condition used: 0.12 equiv of NH3 and trace amounts of hydrazine were obtained upon reaction with HCl in THF whereas only hydrazine was formed when MgCl2 was added to the reaction mixture in presence of HCl.

Scheme 22.

Associative N2 protonation using iron complexes 111–113 supported by chelating diphosphines (a), and resulting hydrazido complex 114, diazenido complex 115 and ammonia complex 116 (b). Iron complexes 117–118 supported by chelating triphosphines and hydrides 119–120 (c).

Very similar type of reactivity was also encountered for other iron‐diphosphine complexes such as [(dppe)2Fe0‐N2] (112) [104] and water soluble trans‐[Fe(DMeOPrPE)2(N2)] (113). Formation of the [Fe=N‐NH2] species 114 in the presence of weaker acids, for example, HOTf or [Ph2NH2][OTf], and excess of [CoCp*2] further suggested the occurrence of a distal associative mechanism for N2 reduction. [105] It should be noted that in addition of the hydrazine complex 114 mentioned above, the other potential intermediates formed en route to NH3, for example, diazine 115 and ammonia complex 116 were isolated by ex situ reaction with the corresponding N‐containing synthons,[ 106 , 107 , 108 ] allowing to propose the reaction mechanism shown in Scheme 22 b.

The overall six electron reduction yielding to ammonia formation was proposed to occur via the participation of multiple Fe0 complexes acting as sacrificial reducing agents to provide the six electrons, as further suggested by the isolation of the bridging N2 dimer [{Fe(dmpe)2}2(μ‐N2)]. [109] In addition, product distribution was observed to be highly solvent dependent, as a consequence of the modulation of the acidity of the proton sources in different solvents: Complex 111 produced N2H4 in pentane, only NH3 in THF and a mixture of both N2H4 and NH3 in Et2O when treated with [H(OEt2)2][OTf]. [109]

The use of tetradentate tripodal phosphine ligands allowed to identify that iron hydrides were key reaction intermediates obtained upon protonation of the Fe dinitrogen complex: the protonation of tris‐(2‐diphenylphosphino)‐ethylene)phosphine (PPPh 3) iron dinitrogen complex [Fe(PPPh 3)(N2)] (117) [110] or tris‐(2‐diphenylphosphino)‐(ethylene)amine (NPPh 3) iron dinitrogen complex [Fe(NPPh 3)(N2)] (118) [111] resulted in the formation of stable iron hydride complexes 119 and 120 (Scheme 22 c). DFT calculations [107] and experimental [106] studies by Tyler and co‐workers allowed to demonstrate that such iron‐hydride species were also formed with the bis‐diphosphine complex 113 (Scheme 22 a). These studies suggested that protonation of the iron centre occurred first to generate hydrides trans to the N2 ligand, followed by protonation of the latter. The complete series of trans‐hydride dinitrogen, hydrazido‐, hydrazine‐ and amido‐complexes was characterized, highlighting the stability of these trans‐hydride species at all steps of ammonia generation. [106]

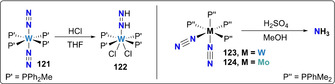

Essentially analogous reactivity to that observed with bidentate phosphine ligands was noticed with Mo and W complexes bearing monodentate phosphines. Protonation of trans‐[W(N2)2(MePPh2)4] (121) with HCl lead to the formation of the diazene complex trans‐[WCl(MePPh2)4NH=NH]Cl [112] (122). However, the cis‐isomer of [W(N2)2(Me2PPh)4] (123) showed significantly higher activity, leading to the quantitative formation of ammonia upon treatment with H2SO4 in methanol (Scheme 23).[ 113 , 114 ] Mixtures of ammonia and hydrazine were observed for the molybdenum analogue, cis‐[Mo(N2)2(Me2PPh)4] (124) under the same conditions.[ 115 , 116 ] These studies were key to identify the relatively lower reactivity of trans isomers towards NH3 formation [114] and constituted the first example of the use of H2SO4 in methanol as a proton source for ammonia generation, which inspired many following studies. [112] Direct coordination of methanol to the metal centers in these reaction conditions was early proposed as a key step for ammonia formation. [117] The difference of activity of complexes 123 and 124 with respect to their bidentate analogues 94 and 95 (Scheme 20, vide supra) towards NH3 formation (the latter two showing essentially no activity) was attributed to the easier dissociation of one of the monodentate PMe2Ph ligand upon protonation of N2. [114]

Scheme 23.

Associative N2 protonation using group 6 monodentate phosphine complexes 121, 123, 124 and resulting hydrazine complex 122.

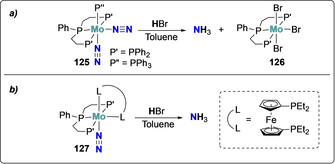

This behavior was exploited to design complexes bearing both tridentate and monodentate phosphine ligands. Protonation of the complex cis‐[Mo(N2)2(PPP)(PPh3)] (125) (PPP=PhP(CH2CH2PPh2)2) under milder conditions (HBr in Toluene) resulted in the quantitative formation of NH3 (Scheme 24 a).[ 118 , 119 ] This complex allowed the identification of the origin of the electrons required for N2 reduction: isolation of [Mo(PPP)Br3] (126) after NH3 formation suggested that each Mo center provided three electrons. The easier dissociation of monodentate PPh3 ligand provided access to the anionic Br−, leading to a further increase in electron density on the reaction center.[ 96 , 120 ] To circumvent the use of one equivalent of complex acting as a sacrificial electron donor, Mo complexes bearing redox non‐innocent ferrocenyl diphosphine ligands in combination with tridentate PPP ligands were investigated for N2 activation (Scheme 24 b) and exhibited the highest catalytic activity towards NH3 formation among a series of PPP Mo complexes with bidentate diphosphine ligands. [119]

Scheme 24.

Associative N2 protonation by molybdenum complexes 125 and 127 bearing chelating triphosphines.

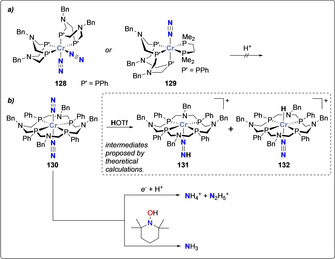

Inspired by active catalysts for H2 production replicating the proton relays found in the second coordination sphere of hydrogenase enzymes,[ 121 , 122 ] Mock and Bullock incorporated pendant amines to polydentate phosphine ligands for Cr dinitrogen complexes. Such ligands can act as proton relays and could mediate the challenging multiple protons transfers required for N2 reduction to ammonia. While Cr dinitrogen complexes bearing diphosphine [123] and triphosphine [98] ligands [Cr(N2)2(PBn 2NPh 2)2] (128) and [Cr(N2)(PBn 3NPh 3)] (129) with pendant amines were not reported to mediate N2 protonation (Scheme 25 a), the macrocyclic P4N4 chromium complex [Cr(N2)(PBn 4NPh 4)] (130) generates a mixture of N2H5 + and NH4 +, in presence of excess acid and reducing agent. The ratio between the two products being dependent of the reaction conditions: hydrazine is favored at low temperature while ammonia is obtained in quantitative yield at room temperature.[ 124 , 125 ] DFT calculations suggested that upon protonation, 130 generates the diazenido complex [Cr(N=NH)(PBn 4NPh 4)]+ (131), together with the hydride complex [CrH(N2)(PBn 4NPh 4)]+ (132) (Scheme 25 b, inset). [124] Most importantly, this complex was used to illustrate the first functionalization by hydrogen atom transfer of an end‐on bound dinitrogen ligand: NH3 was quantitively obtained from the reaction of 130 with TEMPOH (2,2,6,6‐tetramethylpiperidine‐1‐ol) (Scheme 25 b). [125]

Scheme 25.

N2 protonation by chromium complexes bearing macrocyclic phosphines ligands: no reactivity towards protonation of complexes 128–129 (a) and protonation of complex 130 using proton or hydrogen atom donors (b). Hydrazido complex 131 and hydride complex 132 proposed by DFT calculations are provided in inset.

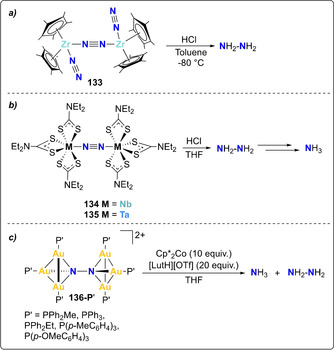

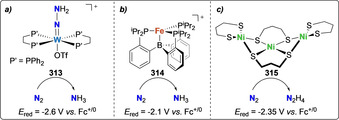

In addition to above described end‐on coordinated mononuclear N2 complexes, a few studies explored the protonation of complexes containing bridging end‐on M‐N2‐M cores (Scheme 26). Bercaw and co‐worker reported the preparation of [{(Cp*)2Zr(N2)}2‐(μ2‐N2)] (133) upon reduction of [Zr(Cp*)2Cl2] under a N2 atmosphere.[ 24 , 126 , 127 ] Addition of Brønsted acids to this N2‐bridged complex resulted in the formation of hydrazine and the release of two equivalents of dinitrogen. [126] End‐on bridging N2 dithioguadinate niobium and tantalum complexes 134 and 135 were reported,[ 128 , 129 , 130 , 131 , 132 ] and analogously afforded hydrazine as the main product upon stoichiometric protonation, whereas in presence of excess additional reducing agent, NH3 was generated instead.[ 133 , 134 , 135 , 136 ] Quantitative generation of NH3 and N2H4 was also observed for a series of dinitrogen bridged, phosphine (P′) supported dimeric gold clusters 136‐P′. [135] The presence of hydrazine as the main reduction product for this series of complexes suggested that N2 reduction occurred via an alternating associative pathway.

Scheme 26.

Associative N2 protonation by complexes 133 (a), 134 and 135 (b) and gold clusters 136‐P′ (c).

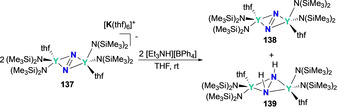

In 2011, Evans and co‐workers reported the first example of reductive protonation of a rare‐earth dinitrogen bridged complex using the bis‐yttrium complex {[(Me3Si)2N]2(thf)Y}2(μ‐η 2:η 2‐N2) (137). [137] Reduction of complex 137 with KC8 afforded the N2 3− bridging complex {[(Me3Si)2N]2(thf)Y}2(μ‐η 2:η 2‐N2[K(thf)6] (138). Upon treatment of 137 with one equiv of [Et3NH][BPh4], disproportionation to a 1:1 mixture of 138 and complex {[(Me3Si)2N]2(thf)Y}2(μ‐N2H2) (139) occurred (Scheme 27). Complex 139 had also been isolated in lower yields via the direct reduction of the precursor complex Y{[N(SiMe3)2}3 with excess KC8 in THF under N2. The hydrogen atoms in the latter case were hypothesized to originate from the methyl groups of the N(SiMe3)2 − ligand.

Scheme 27.

Protonation of the bridging N2 3− moiety in bis‐yttrium complex 137 to produce the corresponding hydrazido complex 139 via disproportionation.

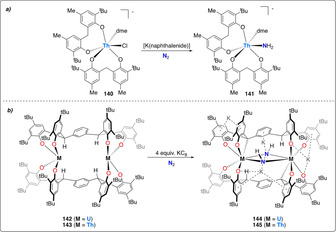

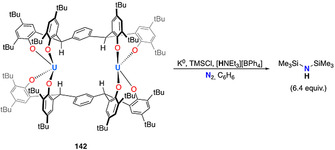

The potential of actinide complexes to mediate the reductive protonation of dinitrogen was first demonstrated using the thorium bis‐phenoxide complex 140, which formed the amide complex 141 upon treatment with excess potassium naphthalenide under a dinitrogen atmosphere (Scheme 28 a). [138] However, reaction intermediates in this reaction and the source of the protons could not be identified in this seminal study. Very recently, Arnold et al. further illustrated the potential of poly‐phenoxide actinide complexes for dinitrogen activation. The m‐tetraphenoxide‐arene ligated binuclear complex of UIV and ThIV (142 and 143) readily react with dinitrogen in presence of 4 equiv of KC8 to generate corresponding hydrazido (N2H2 2−) bridged dimeric dianionic complexex (144 and 145) (Scheme 28 b). [18] The source of protons was identified as the ligand benzylic C−H bond, resulting in the formation of a new metal‐carbon bond to each metal center. Subsequent protonation of the of the bridging hydrazido complex with weak acids (e.g. PyHCl or [HNEt3][BPh4]) afforded ammonia in yields up to 1.1 equiv with respect to complex 144 and 145.

Scheme 28.

(a) Activation of dinitrogen by mononuclear Th complex (140) with diphenoxide ligand. (b) Associative activation of dinitrogen with polyphenoxide complex of U (144) and Th (145) via ligand deprotonation.

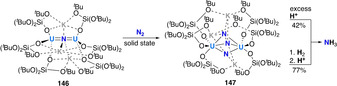

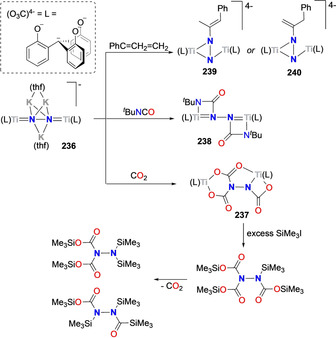

Last, the recent work of Mazzanti and co‐workers has illustrated the potential of actinides to mediate dinitrogen cleavage and hydrogenation. [139] The strongly reducing dinuclear UIII complex 146, which incorporates a bridging nitride ligand and the coordination of three potassium cations, was shown to react even in the solid state with one equivalent of dinitrogen (Scheme 29). Four electron reduction (2× UIII→UV) led to the formation of complex 147 with a side‐on bridging [N–N]4− unit. This side‐on bridging N2 4− moiety could be cleaved upon protonation with excess acid (e.g. HCl) to afford ammonia in 42 % yield. Higher ammonia yields of 77 % could be obtained upon initial treatment with H2 followed by protonation.

Scheme 29.

Associative N2 splitting and protonation/hydrogenation by uranium siloxide complex 146.

3.1.2. Hydrogenation pathways

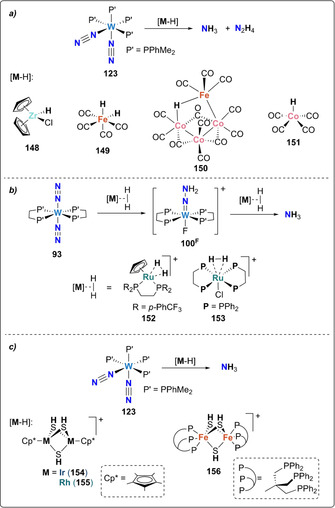

Reduction of N2 to hydrazine or ammonia necessitates the use of protons and electrons. All examples presented so far in this section involved the use of protons from Brønsted acids, the electrons being provided by the complexes themselves. Alternatively, protons and electrons can be both supplied using H2 or hydrides to hydrogenate N2, furnishing one or two electrons per proton added. In direct analogy with the Haber–Bosch process, early attempts of direct hydrogenation of end‐on bound terminal dinitrogen complexes were not successful.[ 90 , 140 ] Nevertheless, acidic transition metal hydrides [(η5‐C5H5)2ZrHCl] [141] (148), [H2Fe(CO)4] (149), [HFeCo3(CO)12] (150) or [HCo(CO)4] [142] (151) were shown to be effective at promoting the hydrogenation of cis‐[W(N2)2(PPh2Me)4] (123) to NH3 and N2H4 (Scheme 30). Morris and Hidai showed separately that the Ru‐H2 complex [η5‐C5H5Ru (η 2‐H2)(dtfpe)]BF4 (152) and in situ generated trans‐[RuCl(η 2‐H2)(dppe)2]X (153) are capable of hydrogenating the coordinated N2 molecule in trans‐[W(N2)2(dppe)2] (94) to produce the hydrazido complex 100F [143] and subsequently NH3.[ 143 , 144 ] Following the same strategy, hydrogen activation and transfer steps could also be realized via the coupling of polysulfido bridged iron, iridium or rhodium complexes, able to activate H2 to form polyhydrosulfido complexes 154–156, which were used to hydrogenate the dinitrogen tetraphosphine W complex 123 to yield NH3. [145]

Scheme 30.

Associative N2 hydrogenation by tungsten complexes 123 (a and c) and 93 (b) using various metal hydrides 148–156.

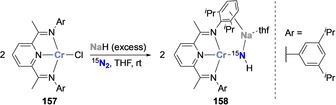

Budzelaar and co‐workers proposed an alternative strategy for N2 hydrogenation based on the use of sodium hydride as reducing agent and proton source and promoted by a Cr complex with redox non‐innocent diiminepyridine ligands. [146] Treatment of the formally monovalent CrI complex 157 with an excess of sodium hydride under a dinitrogen atmosphere afforded the high spin CrII imide complex 158 (Scheme 31). Interestingly, when sodium hydride was added in a stepwise manner, bridging dinitrogen intermediates either bearing a [N=N]2− or a [N−N]4− bridging unit could be isolated and fully characterized, indicative of an associative mechanism.

Scheme 31.

Associative N2 functionalization with sodium hydride mediated by the diiminepyridine Cr complex 157 and resulting amido complex 158.

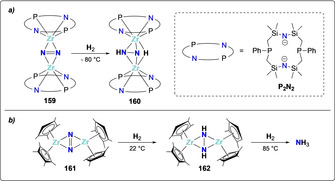

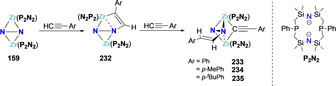

The first example of direct hydrogenation of dinitrogen was reported by Fryzuk and co‐workers upon treatment of a side‐on bridging N2 zirconium complex [(P2N2)Zr‐(μ‐N2)‐Zr(P2N2)] (159) (P2N2={(Ph‐PCH2SiMe2)2N}2) with dihydrogen, generating complex 160 with a singly protonated dinitrogen moiety [N‐NH]3− (Scheme 32 a).[ 147 , 148 ] Applying this strategy to the side‐on bridged N2 zirconocene complex [(CpMe4H)2Zr‐N2‐Zr(CpMe4H)2] (161) allowed the hydrogenative activation of N2 at 1 atmosphere of H2 at room temperature to afford complex [(CpMe4H)2Zr‐(μ‐NH‐NH)‐Zr(CpMe4H)2] (162) (Scheme 32 b). Further heating of complex 162 under H2 led to the cleavage of the N−N bond and formation of NH3.[ 149 , 150 ]

Scheme 32.

Associative N2 hydrogenation by zirconium complexes, 159 (a), 161 (b) and resulting hydrazine complexes 160 (a), 162 (b).

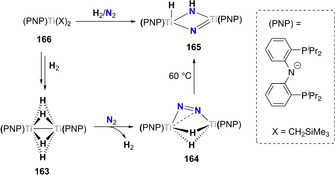

Alternatively, hydrogenation of N2 can be carried out using pre‐formed metal hydride complexes. Hou and co‐workers showed that the polyhydride bridged titanium PNP complex 163 readily coordinated N2 by releasing one equivalent of H2 and forming the side‐on/end‐on dinitrogen bridging complex 164. [151] Upon heating to 60 °C, complex 164 was transformed to the μ2‐imido/μ2‐nitrido/hydrido bis‐titanium complex 165. The same product was also isolated from the direct reaction of [(PNP)Ti(L)2] (166, X=CH2SiMe3) with H2 and N2 at room temperature (Scheme 33).

Scheme 33.

Associative N2 hydrogenation by titanium hydride complex 163 and resulting dinitrogen complex 164 and nitrido‐imido complex 165.

The molecularly‐defined silica‐supported tantalum bisneopentyl neopentylidene complex 167 showed analogous reactivity after initial treatment at 150 °C with molecular H2 to generate the tantalum hydride species 168 (Scheme 34). Upon exposure to N2, these complexes afforded the amido‐imido complex [(≡OSi)2Ta(=NH)(NH2)] (169). [152] In situ spectroscopic studies and theoretical analysis allowed proposing an associative distal mechanism and identifying several reaction intermediates (Scheme 34, dashed insert).[ 152 , 153 ]

Scheme 34.

Associative N2‐splitting and protonation by silica‐supported tantalum complex 167. The structures in the inset describe intermediates observed by in situ spectroscopy and theoretical studies.

3.2. N−Si bond formation

A significant number of complexes have been shown to mediate N2 silylation via associative pathways. Yet, the vast majority of silylation reactions were demonstrated to be catalytic in the presence of excess reducing agents and silylation reagents and will be reported in Section 4 on catalytic systems. Only examples of stoichiometric functionalization will be discussed in the present section.

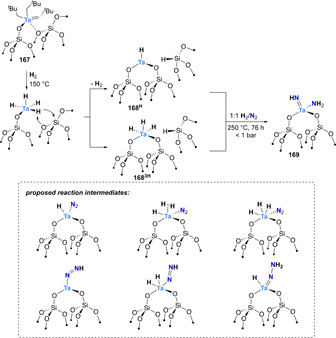

Stoichiometric distal N‐silylation was reported for the very stable complex [MoCp*(depf)(N2)] (170). [154] Reduction with excess sodium amalgam followed by silylation with trimethylsilyl choride afforded the corresponding [Mo−N=N−SiMe3] species (171) (Scheme 35 a).

Scheme 35.

Mono‐ and bis‐silylated N2 complexes: mono‐silylated complexes of molybdenum (171) (a), cobalt (174) and iron (180–181) (b), bis‐silylation of N2 coordinated by the iron dimer 183 (c), mono‐silylated complexes 177–178 (d) and of the bis‐silylated alumatrane complex 189 (e).

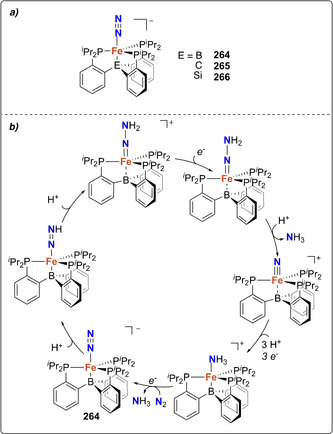

In 2003, Peters et al. showed that a cobalt‐dinitrogen complex bearing a phosphine borate ligand Mg(thf)4[Co(PhBPiPr 3)(N2)]2 (172) [PhBPiPr 3=PhB(CH2PiPr 2)3 ‐] could be silylated at the terminal nitrogen of the coordinated N2 ligand (Scheme 35 b). [155] Stepwise reduction of the complex [Co(PhBPiPr 3)I] (173) with metallic Mg in THF under N2 atmosphere allowed generating complex 172. Addition of trimethylsilyl chloride to 172 led to the formation of [(PhBPiPr 3)CoN=N‐SiMe3] (174). This activity was demonstrated to be preserved upon variation of the heteroatom in the triphos ligand. Reduction of the cobalt complexes [Co(EPPh 3)Cl] (175, E=N; or 176, E=CMe; EPPh 3=E(CH2CH2PPh2)3) under a dinitrogen atmosphere with excess reducing agent (e.g. Li, Na, Mg) followed by reaction with Me3SiCl also afforded the terminally monosilylated complexes [Co(XPPh 3)(N=N‐SiMe3)] (177, E=N; 178 E=CMe) (Scheme 35 b). [156] Analogous monosilylation was also shown later on for [Fe(P3 B)(N2)] (179) (P3 B=tris‐[2‐(diisopropylphosphino)‐phenyl]borane) which resulted in the formation of the N‐silylated complex 180 (Scheme 35 c). [157] The bis‐silylated product [(P3 B)Fe=N‐N(Me2SiCH2CH2SiMe2)] (181) could also be obtained from complex [Fe(P3 B)Br] (182) upon treatment with 1,2‐bis(chlorodimethylsilyl)ethane in presence of excess sodium mercury amalgam (see overview Scheme 19). Observation of the dissociation of one of the phosphines in presence of exogenous ligands (e.g. MeCN) motivated the investigation of diphosphino complexes such as [Fe2(P2 B)(μ‐1,2‐N2)]Fe2(P2 B)] (183) (P2 B=bis‐diphenylphosphinophenylborane) (Scheme 35 d). Complex 183 similarly showed the formation of [(P2 B)Fe=N‐N(Me2SiCH2CH2SiMe2)] (184), but also allowed for further functionalization using H2 or phenylsilane to afford complexes 185 and 186, respectively. [158]

An original approach involving an alumatrane ligand was investigated by Lu and co‐workers. [159] The ligand AltraPhos (AltraPhos=Al[N(o‐C6H4NCH2PiPr2)3]) allowed for the isolation of the zero‐valent iron complex [Fe(N2)AltraPhos] (187). Reduction of complex 187 with potassium graphite in the presence of 18‐crown‐6 yielded the reduced complex [K(18‐crown‐6)][Fe(N2)AltraPhos] (188) (Scheme 35 e). Treatment of complex 188 with 1,2‐bis(chlorodimethylsilyl)ethane at −78 °C afforded the FeII complex [Fe{N2(SiMe2CH2)2})AltraPhos] (189). Despite the difference in size between alumina and boron, 189 displays a similar iron‐imide bond distance to that of Peters’ metallaboratrane complex 181.

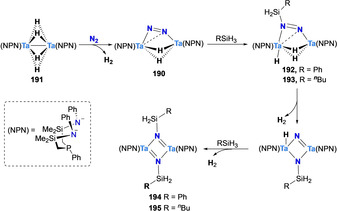

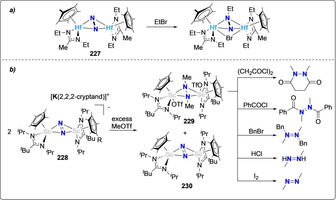

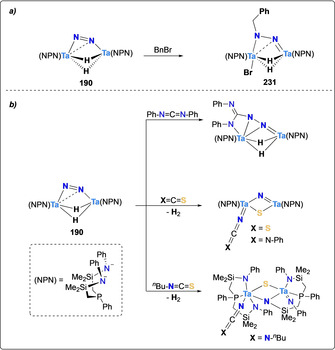

Fryzuk and co‐workers investigated the silylation of the Ta–N2 complex [(μ‐η1:η2‐N2){Ta(NPN)H}2] (190) obtained upon treatment of the tetrahydrido Ta dimer [{(NPN)Ta}2(μ‐H)4] (191) with N2. Unlike for previously presented complexes, the authors here used a reductive strategy utilizing silanes instead of chlorosilanes to functionalize the N2 synthon. Treatment of complex 190 with one equivalent of silane RSiH3 (R=Ph, nBu) led to the formation of the mono‐silylated complexes 192 (R=Ph) and 193 (R=nBu) respectively. In presence of excess silane, these monosilylated complexes reacted further with a second molecule of silane to produce the bis‐silylated complexes 194 and 195 via an unprecedented Si−H bond activation on a N2 complex (Scheme 36).[ 160 , 161 ]

Scheme 36.

Associative N2 silylation by tantalum hydride complex 191.

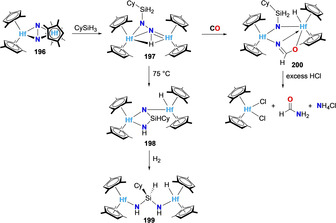

Chirik and co‐workers reported an original example of a stepwise dinitrogen functionalization via the intermediacy of a silylilated dinitrogen moiety. [162] Treatment of the dinitrogen complex [{(η 5‐C5H2‐1,2,4‐Me3)2Hf}2(μ 2,η2,η2‐N2)] (196) with cyclohexyl silane generated the mono silylated dinitrogen complex 197 (Scheme 37). Complete N−N bond cleavage was observed upon heating complex 197, inducing the isomerization to complex 198. Further hydrogenation of complex 198 afforded the ‐NH‐Si(HCy)‐NH‐ bridged dimetallic hafnocene hydride complex 199. This pre‐activation of the dinitrogen unit by silylation in complex 197 also enabled its reactivity with carbon monoxide to produce the amide complex 200, generating formamide and ammonia with excess hydrochloric acid.

Scheme 37.

Silylation of the bridging dinitrogen moiety in substituted dinuclear hafnocene complex 196 and further functionalization of the dinitrogen ligand.

3.3. N−C bond formation

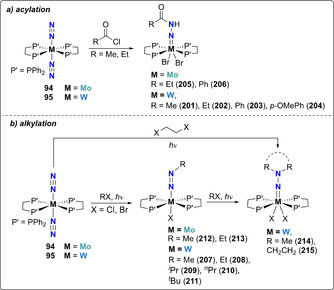

Chatt and co‐workers early reported the functionalization of bis‐diphosphino tungsten and molybdenum complexes 94 and 95 with acyl chlorides (RCOCl; R=Me, Et, Ph, or p‐MeOC6H4) in THF to form trans‐[WCl2(dppe)2(N‐NHC(O)R)] [163] (201–204) and trans‐[MoCl2(dppe)2(N‐NHC(O)R)] [164] (205–206) complexes (Scheme 38 a). The surprising presence of protons in the product was proposed to result from the presence of HCl generated by the reaction of acyl chlorides with traces of moisture. Using the same starting complexes 94 and 95, photochemical alkylation with various alkyl halides R‐X (R=Me, Et, nPr, iPr, tBu, ‐(CH2CH2‐)2, X=Cl, Br) led to the preparation of monoalkylated diazenido complexes [(dppe)2M‐N=NR] ((207–211, M=W) and (212 and 213), M=Mo)) [165] as well as of dialkylated hydrazido complexes [(dppe)2M=N‐NR2] (214–215), M=W) (R=Me, ‐(CH2CH2‐)2), depending of the alkyl moiety used (Scheme 38 b).[ 166 , 167 ] Transfer of the alkyl groups was suggested to occur in a stepwise manner on the distal nitrogen atom, and both diazenido [(dppe)2M−N=NR] and hydrazido [(dppe)2M=N‐NR2] species were isolated. [169] Similarly, acylation of the Re complex [(PhMe2P)3Re(N2)Cl2] with acetyl‐ and benzoylchloride resulted in the formation of the monoacylated diazenido complexes [(PhMe2P)3Re(N2COR)Cl2]+ (R=Me, Ph ). [165]

Scheme 38.

Associative N2 acylation (a) and alkylation (b) by group 6 diphosphine complexes.

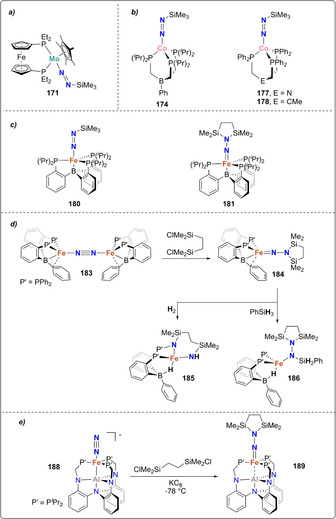

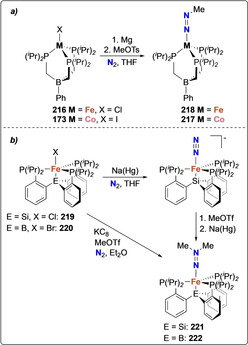

Peters and co‐workers further explored N−C bond formation on N2 using iron and cobalt complexes with phosphino borane and silane ligand scaffolds. The reaction of complex 173 and its iron analogue [Fe(PhBPiPr 3)(N2)][Cl] (216) with 1 equiv of MeOTs and in presence of excess Mg as a reducing agent afforded the monomethylated diazenido complexes [(PhBPiPr 3)CoN=NMe] (217) and [(PhBPiPr 3)FeN=NMe] (218) (Scheme 39 a). [155] Modification of the ligand, leading to a trigonal pyramidal coordination, allowed for bis‐methylation of the dinitrogen unit. Silylide (P3 Si=tris(2‐(diisopropylphosphino)phenyl)silylide)) and borane (P3 B) supported iron complexes 219 and 220 were used as starting materials to obtain the bis‐methylated diazenido complexes 221 and 222 upon treatment with excess MeOTf (Scheme 39 b).[ 169 , 170 ]

Scheme 39.

Associative N2 alkylation by cobalt complex 173 (a), and iron complexes 216 (a) and 219/220 (b).

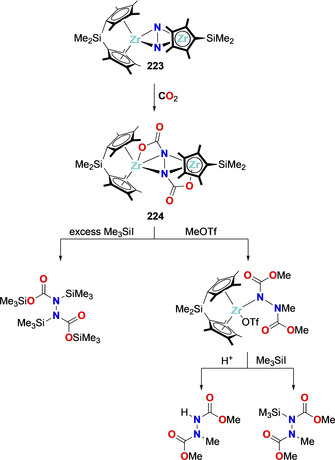

This early work triggered a significant interest for the functionalization of activated dinitrogen moieties with alkyl groups. Metallocene N2 complexes demonstrated a rich reactivity in that context. The complex [Zr((η 5‐C5Me4R)2SiMe2)]2(μ‐η2,η 2‐N2) (223), where a flanked SiMe2 moiety holds the Cp rings rigidly together, could be functionalized with CO2 to generate a trans‐(NCO2)2 bridged bis‐zirconium complex 224. Treatment of 224 with excess electrophiles (e.g. MeOTf or Me3SiI) allowed releasing the corresponding methylated or silylated organic synthons (Scheme 40). The rigid ligand framework was proposed to minimize the N2 loss via lowering its ligand exchange rate favoring the formation of more reactive dimeric ansa‐zirconocene dinitrogen complex. [171]

Scheme 40.

Associative N2 functionalization with CO2 and subsequent methylation/silylation by the ansa‐zirconocene complex 223.

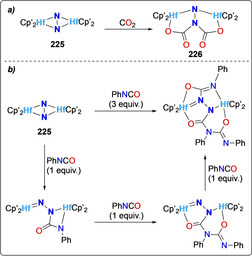

The hafnium analogues of side‐on bound [{Zr(η 5‐C5Me4R)2}2(μ‐η2,η 2‐N2)] were also explored for N−C bond formation using CO2 [172] or electrophiles such as organic isocyanates[ 65 , 172 ] and alkyl halides. [65] Unlike the Zr analogues, reaction of CO2 with the dimeric Hf metallocene N2 complex [{(η5‐C5Me4H)2Hf}2‐(μ2‐η2,η 2‐N2)] (225) revealed the formation of the N2C2O4 2− bridged Hf complex [(η5‐C5Me4H)2Hf]2(NCO2)2 (226), where both CO2 molecules reacted at the same nitrogen atom (Scheme 41 a). [172] The activated N2 ligand in complex 225 could be further functionalized by the stepwise addition of phenyl isocyanate in an alternating manner (Scheme 41 b). Three equivalents of isocyanate were necessary to functionalize both nitrogen atoms, as the second equivalent reacts on the N‐site of the isocyanate itself, to generate a N4C2O2 2− bridging dimeric Hf cluster. The bond distances of these species indicate a substantial imido character for the nitrogen atom bound to the Hf center.

Scheme 41.

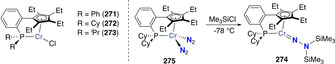

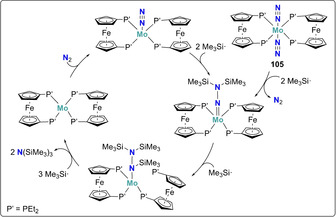

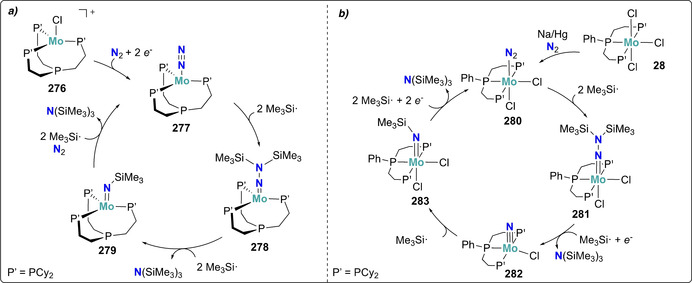

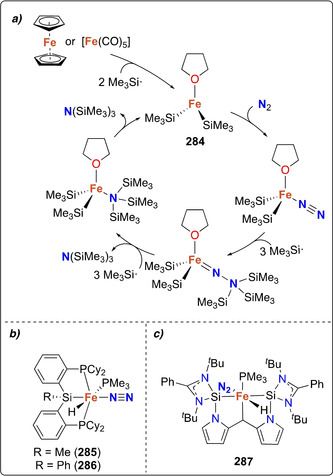

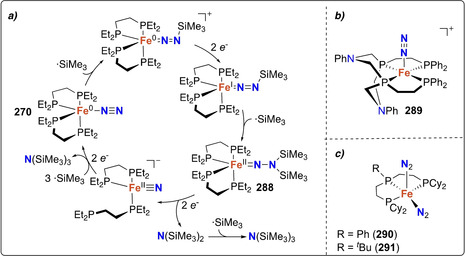

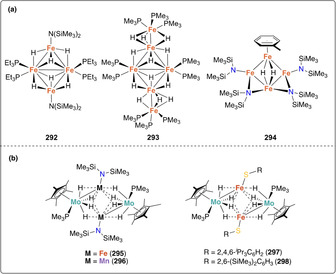

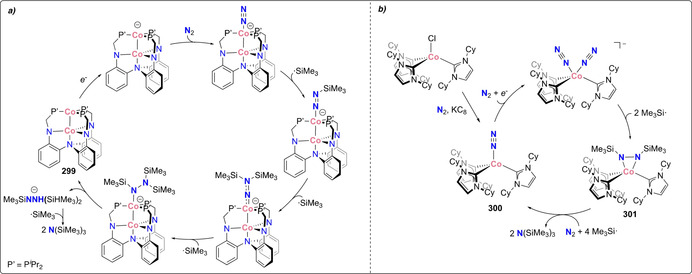

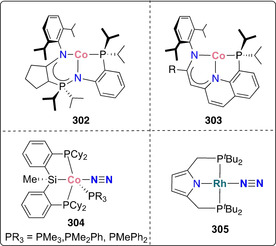

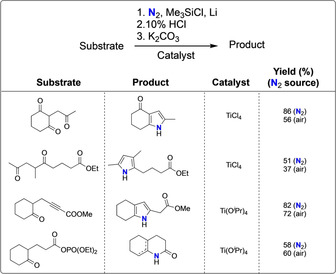

Associative N2 functionalization by hafnocene complex 225 with CO2 (a) and isocyanate (b).