Abstract

An experimental study of the ultrasonic compression moulding (UCM) to manufacture biobased composites made of semicrystalline starch powders and softwood fibres is described. The main objective was to assess the potential of using this fast and economical processing technique to elaborate a 100% biobased composite which might substitute more usual polymer materials for structural applications. The starch powder was chosen as raw material for the matrix while the reinforcement was made of softwood fibres. Tablets made of starch only and composite beams were processed under different conditions and characterised by several techniques. Three types of starch powders and two types of fibres were used as raw materials. A morphological and crystalline analysis was carried out by scanning electron microscopy (SEM) and X-ray diffraction (XRD). The native semicrystalline structure of starch granules was not totally preserved so as to obtain a homogeneous material. Diametral compression tests on tablets were performed to improve the processing route and obtain the materials with the best properties. Bending tests were used on composite beams to quantify the mechanical properties and study the effects of the processing parameters. The optimum processing parameters were defined and allowed obtaining a matrix for which the flexural strength reached 21 MPa. Mechanical properties were improved when fibres were added into the matrix: three-points bending tests showed a Young's modulus of 6 GPa, a flexural strength of 75 MPa and a flexural strain at break of 6% for a bulk density of 1.25. Considering these results, UCM appears to be a promising process to design a 100% biobased composite with mechanical properties comparable to those of classical discontinuous fibre composites.

Keywords: Ultrasonic moulding, Biobased composites, Starch granules, Wood fibres

Ultrasonic moulding; Biobased composites; Starch granules; Wood fibres

1. Introduction

Thanks to their specific mechanical properties, polymer matrix composites are more and more used in several domains for transport, packaging, energy and aeronautical applications. These materials allow reducing the weight of a product by preserving the mechanical properties as more classical materials. The polymer phase of composites is usually a petroleum-based material. However, the necessity to bring economic and sustainable developments together strongly encourages the development of biobased and easily biodegradable materials to develop a circular economy. This motivation explains why the development of a high added value composite with softwood fibres reinforcing starch powder is addressed. The process itself needs to be as environmentally-friendly as possible, and in order to satisfy all these requirements the ultrasonic compression moulding (UCM) was chosen. Indeed, this processing technique allows the raw material to be processed with a limited amount of energy (approximately 1 W h g−1) with a very short processing time of 1 s.

Ultrasonic welding is usually devoted to assemble components. Moreover, ultrasonic compression moulding has already been used to process polymer powders. Fairbanks [1] worked on acrylic and vinyl resin thermoplastic powders, and phenolic and allylic thermosetting powders. Paul and Crawford [2] worked with polypropylene (PP). Matsuoka [3] used polyamide (PA) and high-density polyethylene (HDPE) and Planellas et al. [4] incorporated clay particles to polylactide (PLA) and polybutylene succinate (PBS). Wu et al. [5] worked on metallic powders. However, to the best of our knowledge, this technique has still not been used to form biobased composite materials. In the previous studies, devoted to the processing of classical amorphous or semicrystalline polymers such as PP or PE, the physico-chemical properties of these powders were well known and the architecture of grains was quite simple (homogeneous spheres) unlike starch powders. Moreover, the thermo-mechanical properties of starch depend on several factors such as its botanical origin or its moisture content. In the same way, polymer phase transitions, such as gelatinisation, strongly depend on the environmental conditions.

Hence, in this study, samples like tablets and composite beams were characterised in order to understand the effects of several processing parameters on the microstructural as well as the physical and mechanical properties of the processed composite materials obtained using ultrasonic compression moulding.

2. Materials and methods

2.1. Materials

Maize starch

Three kinds of starches were studied. They were all from the same botanical origin but from different species and mainly differed by the ratio of their two constituting polymers, namely amylose and amylopectin: standard, amylopectin-rich (waxy) and high-amylose (amylose-extender) maize starches were chosen. Waxy maize (ref. C*gel 04201) and standard maize (ref. C*gel 03401) starch granules were supplied by Cargill (Saint-Nazaire, France) and had amylose/amylopectin ratios of 1/99 and 30/70, respectively. The amylose-extender starch (ref. N-460) granules were supplied by Roquette (Lestrem, France) and had a ratio of 60/40. The use of these three powders allowed the effect of amylose/amylopectin ratio on the final properties to be assessed.

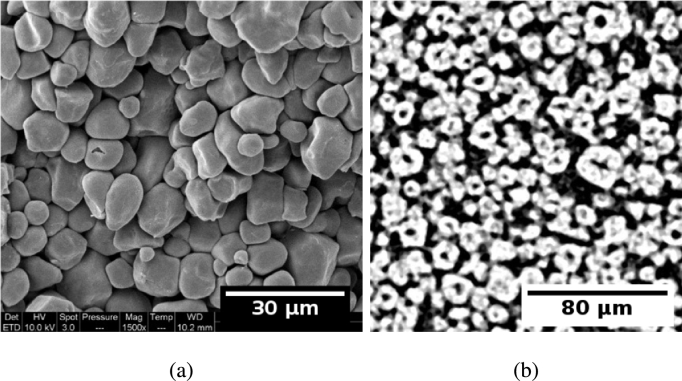

Scanning electron microscopy (SEM) images (Fig. 1-a) revealed the polyhedral shape of waxy maize starch granules of approximately 15 μm to 20 μm in diameter. Scans from X-ray tomography were performed on the 3SR-lab microtomograph (manufactured by RX Solution - France) with a Hammatsu L12161-07 source, and a Varian flat panel detector. The 2D reconstructions (Fig. 1-b) showed a porosity inside the granules which will be referred to as internal porosity in this study. Maize starch granules exhibited a central cavity of about 4 μm in diameter which was equivalent to approximately 20% of the granule volume.

Figure 1.

(a) Scanning electron microscopy image and (b) X-ray radiography of waxy maize starch powder.

Softwood fibres

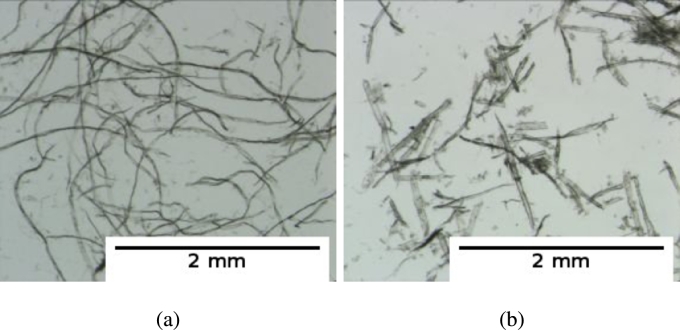

Fibres used as reinforcement were lignocellulosic fibres from softwood (pine). They were supplied by MetsäFibre (Joutseno mill, Finland). Two types of fibres, similar to those used in Regazzi et al. [6], were studied (Fig. 2):

-

•

a mechanical pulp which was produced by a chemithermomechanical pulping process (CTMP);

-

•

a chemical pulp which was produced by a chemical kraft process followed by a bleaching treatment (CB).

Figure 2.

Optical micrographs of (a) chemically bleached fibres and (b) mechanical fibres in aqueous suspensions.

Preparation of amylose-lipid complexes

Potato amylose (supplied by Sigma-Aldrich) was dispersed in water (0.1 wt%), bubbled with nitrogen and poured in a glass vial that was tightly sealed. The dispersion was heated at 140 °C for 30 min and cooled down to 90 °C. Palmitic acid (supplied by Sigma-Aldrich) was preheated at 90 °C and was added in the liquid state to the amylose solution. The mixture was kept at this temperature for 1 h and allowed to slowly cool down to room temperature in a Dewar container. After crystallisation, the solid residue was washed with diethyl ether to remove the excess lipid, concentrated by centrifugation and the pellet was equilibrated in a container maintaining a 95% relative humidity for a few days before XRD analysis.

2.2. Sample processing

Processing of starch alone

In order to study the behaviour of the matrix only and to improve the process, starch tablets without any fibres were fabricated. Altay and Gunasekaran [7] demonstrated that starch is highly sensitive to external conditions and is mainly affected by the presence of water [8]. When stored at room temperature of 20 °C and at a relative humidity (RH) of approximately 40%, the so-called “dry” starch powders had a moisture content of approximately 13 wt%. The moistening process was achieved by storing the so-called “hydrated” starch powders at 45 °C and 95% RH. This treatment resulted in a moisture content of approximately 18 wt%.

Biliaderis [8] showed that increasing the temperature with a small water content (smaller than 25 wt%) does not entail gelatinisation but induces an allomorphic transition in starch granules (from type B to type A). This should be kept in mind in order to explain the preservation of the semicrystalline structure of starch grains due to the small water content in the experiments.

To obtain starch samples in the form of tablets, the starch powder was introduced into a cylindrical mould and then processed by ultrasonic compression. The quantity of starch was the same for all experiments, i.e. 500 mg.

Processing of composites

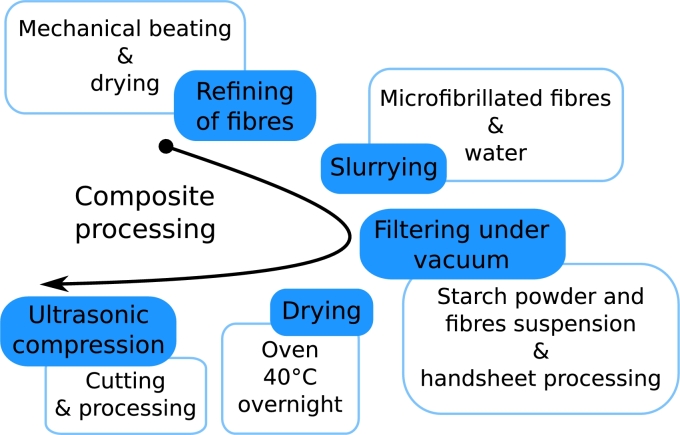

Fig. 3 shows the main steps used to fabricate composite materials from softwood fibres and starch powders.

Figure 3.

The main steps to process a composite material from fibres and starch powders.

1. First, fibres were refined using a PFI mill refiner. The refining efficiency and the effects of this treatment on fibres were assessed by using a fibre morphological analyser (MorFi, Techpap, Saint-Martin d'Hères, France). Table 1 gives the main morphological characteristics of fibres before and after refining. Refining induced a significant change in the morphology of fibres. This mechanical treatment resulted in a decrease in the length of fibres and induced a microfibrillation phenomenon. The index of fibrillation is defined by Udomkichdecha et al. [9] as the sum of the fibril lengths divided by the fibre length. After refining, the pulp was filtered (pore size: 1 μm) and dried in an oven at 40 °C overnight.

Table 1.

Morphological characteristics of fibres and effect of beating.

| Pulp | Average length (μm) | Average diameter (μm) | Linear density (mg m−1) | Index of fibrillation (%) | Residual remainder (Area %) |

|---|---|---|---|---|---|

| CTMP: mechanical pulp | |||||

| As received | 845 | 40.9 | 0.34 | 1.65 | 6.09 |

| Refined | 410 | 41.8 | 0.29 | 2.14 | 30.95 |

| CB: chemical pulp | |||||

| As received | 1359 | 33.0 | 0.17 | 0.30 | 2.21 |

2. Then, fibres were put in a blender (Philips HR2084) with 1 L of demineralised water. The mixture was stirred for 5 minutes in order to homogenise the suspension. After that, the right amount of starch was added to the suspension during blending for 20 minutes. The quantities of starch and fibres were chosen to obtain a complete dried mass of 10 g with a reinforcement of 30 wt% and 50 wt%.

3. The previously obtained mixture was put in a Rapid Köthen sheet former which allowed most of the water to be removed by vacuum filtration. A filter cloth with 1 μm pores was used to avoid losses. Depending on the weight fraction, this step could take from 5 to 20 min. Once filtering was completed, the handsheets were put in an oven and dried overnight at 40 °C to avoid gelatinisation of starch.

4. Handsheets were removed from the oven and cut to the desired oblong geometry (32 mm × 4 mm). Several layers were stacked into the mould of the ultrasonic welder. The number of layers by sample (usually 8) depended on their thickness, so as to obtain the same mass for each sample, i.e., mg. It was observed that one face of the layers showed an excess of starch, reflecting sedimentation of starch during the filtering process. Thus, each layer was put into the mould with the same orientation to achieve the best starch-fibres distribution as possible along the thickness.

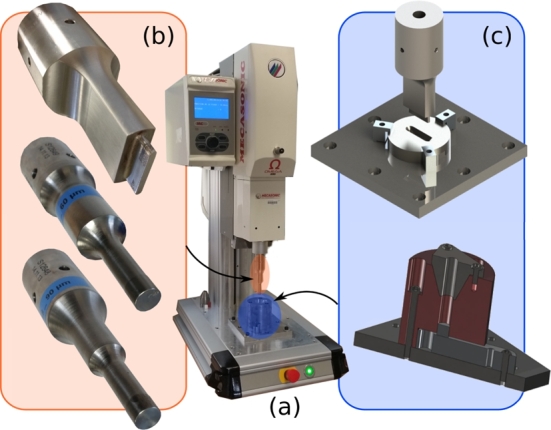

Ultrasonic welding machine and accessories

The next step consisted in welding the starch grains or starch/fibre layers altogether to obtain a continuous starch sample or a composite, respectively. The ultrasonic welder used in this work was an Omega 3 DG - MCX welder from Mécasonic (Juvigny, France), as shown in Fig. 4-a. This machine works with a 20 kHz and 2500 W electrical generator and allows a pressure of 7 bar on a 63 mm diameter pneumatic cylinder to be reached. Three different sonotrodes were used to produce starch tablets or starch-fibres composite samples. The geometry differed to control the shape of the fabricated samples and the amplitude of displacement transmitted to the sample. For starch powder tablets, two sonotrodes with a circular tip gave an amplitude of respectively 90 and 60 μm, whereas, for starch-fibres composite beams, a sonotrode with an oblong tip gave an amplitude of 60 μm (Fig. 4-b).

Figure 4.

(a) The ultrasonic welder with (b) the three sonotrodes and (c) the two moulds (CAD views) used to process starch powder (cylindrical mould) and composites (oblong mould).

The moulds are shown in Fig. 4-c. They were made of steel and were adapted to the geometry of the sonotrodes to manufacture tablet-shaped samples of 12.5 mm in diameter and beam-shaped samples with a 32 mm × 4 mm oblong top surface.

Fairbanks [1], Tolunay et al. [10] and Matsuoka [3] revealed that one of the most important parameters to weld polymeric powder by ultrasounds was the signal amplitude of the sonotrode, this amplitude being defined by the geometry of the sonotrode. However, using one single sonotrode, the machine was able to vary the displacement by about 20% by slightly changing the voltage when ultrasounds were applied. Within this interval, it was possible to study the effect of a variation in the amplitude during welding. The entire process consisted of several successive steps of application of both the mechanical pressure and the ultrasonic waves. Classically, one cycle began with setting up the mechanical pressure, then imposing the ultrasonic waves for a time period, maintaining the mechanical pressure during cooling (this time is called holding time in the following), and finally releasing it.

Moreover, when the powder or the composite layers were introduced into the mould, a compression phase at low pressure and without ultrasounds was applied (approximately 5 MPa at the sonotrode/material interface). This allowed the initial layout of the powder bed or layers to be enhanced. After that, the ultrasonic welding was performed at the wanted pressure and the ejection phase enabled the sample to be extracted from the mould.

2.3. Characterisation of the sample microstructure

Density and porosity measurements

To determine the absolute density of the processed material, the absolute densities of starch powders and fibres were determined using a helium pycnometre (Accupyc 1330, Micromeritics Instrument Corporation, USA). The densities of standard, waxy and amylose-extender maize starches were 1.493 g cm−3, 1.495 g cm−3 and 1.488 g cm−3, respectively, whereas CB and CTMP pulps exhibited densities of 1.542 g cm−3 and 1.486 g cm−3, respectively. All experiments were conducted three times.

Knowing , and the weight fibre content w, it was possible to determine the absolute density of the composite materials using Eq. (1):

| (1) |

The bulk density of samples, , was determined using mass and volume measurements. The mass m of sample was evaluated using a Mettler Toledo ME204 balance. The volume V was calculated assuming a plane-parallel geometry and taking length, width, thickness and diameter measurements using a Mitutoyo Digimatic 293-821 micrometre and a Mitutoyo Absolute Digimatic 500-181 calliper. The bulk density was obtained from the ratio of m over V.

Then, it was possible to characterise the porosity Φ of the processed samples as expressed in Eq. (2).

| (2) |

Diametral compression test

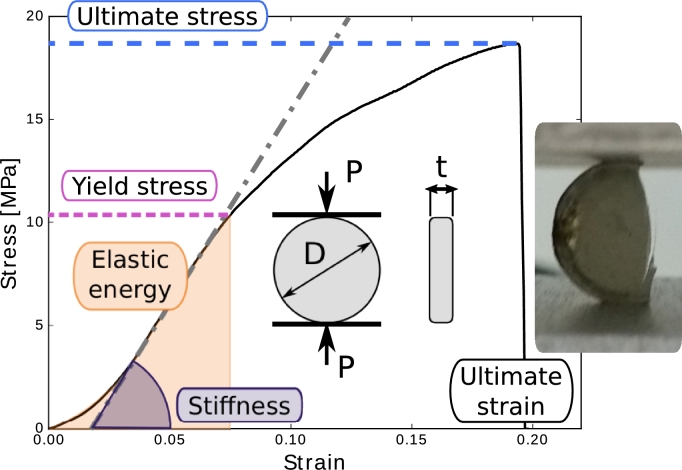

The diametral compression test or Brazilian test was used to characterise the ultimate strength of tablets made of starch powder only. This test, based on Hertz [11] and Michell [12], [13] works, provided the value of the tensile stress along the loaded diameter D of a cylindrical sample of thickness t as described in Eq. (3):

| (3) |

P being the applied load (Fig. 5). This equation is valid with the assumption that the material exhibits a brittle elastic behaviour. In addition, it has been shown by Fell and Newton [14] and Fahad [15] that the error in Eq. (3) is under 4% when the thickness t is not higher than . In this study, the diameter of the tablet was around 12 mm and its thickness was approximately 2 mm.

Figure 5.

Principle of the diametral compression test, typical curve definitions of the extracted properties.

Because of their mechanical behaviour and structure, starch tablets did not respect strictly the assumptions of the Brazilian test. However, results of this test enabled a qualitative comparison of the mechanical behaviour of each sample. A typical curve obtained by testing a starch tablet is shown in Fig. 5. One can also see how the different properties were measured. The mechanical tests were conducted using an Instron 5965 testing machine with a 50 N force sensor and a displacement velocity of 2 mm min−1. The samples were stored in the testing room at 23 °C and 50% RH. Each test was repeated five times.

It must be noted that the diametral compression test was the only suitable test, considering the shape of the samples made of starch only. Indeed, it was difficult to design a homogeneous oblong sample made of starch only. The size of defects that were induced in the samples with this processing route was close to the transversal dimensions of the samples themselves. For this reason, the sonotrode with a circular tip was used to obtain samples made of starch only and the mechanical properties could be determined.

Three-point bending test

The composite beams were obtained in the form of oblong samples (length of 2 mm, width of 4 mm, thickness around 2 mm). The thickness of the oblong samples depended on the processing parameters because the samples were always processed starting with a constant mass: mg.

The three-point bending tests were performed with the same testing machine as for the diametral compression tests. The displacement velocity was set to 2 mm min−1. The tests were conducted in triplicate and analysed considering the tensile stress and strain.

SEM

The starch granule powders were deposited on a metallic stub covered with carbon tape. The processed materials were first immersed in liquid nitrogen, then fractured. All specimens were then coated with Au/Pd in an Emitech K550X sputter coater. Images of the fracture surfaces were recorded using a FEI Quanta FEG 200 scanning electron microscope operated at 10 kV in secondary electron mode.

XRD

The crystallinity of native starch granules and the processed material ground to a fine powder was analysed by XRD. For this purpose, the powder was poured into a 1.5 mm outer diameter capillary which was then flame-sealed and exposed to X-rays in a vacuum chamber using a Philips PW3830 generator operating at 30 kV and 20 mA (). Fujifilm imaging plates were used to record the diffraction patterns. The plates were read off-line using a Fujifilm BAS 1800-II bio-imaging analyser. Diffraction profiles were obtained by radially averaging the two-dimensional ring patterns.

2.4. Preliminary testing and design of experiments

Preliminary tests were performed with the aim of obtaining an experimental design. Indeed, the number of setting parameters was substantial and it was necessary to understand and qualify the effects of each of them and the coupling between them.

Starch only

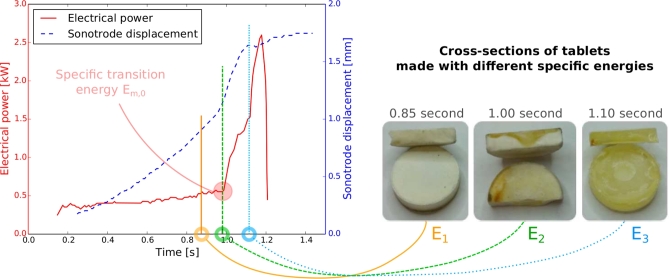

In order to determine the most influencing parameters for welding, some experiments - on starch powder only - were carried out while recording the evolution of the delivered electrical power and the displacement of the sonotrode. For all the processed samples, a correlation was observed between the visual aspect of samples and a sharp change in the electric power supplied to the sonotrode during welding (Fig. 6). This change was also visible on the evolution of the sonotrode displacement during the application time of ultrasounds. These behaviours can be explained by considering that the change in slope in the curves corresponds to the onset of a phase change in the sample. Indeed, below this point, the tablet was friable and fragile, its cohesion was weak; while beyond that point a yellowish translucent phase appeared and the tablet became more resistant and cohesive, as shown in the insets in Fig. 6. There was a specific energy (let us call it specific transition energy ), corresponding to this phase change. It was observed to depend also on the pressure applied and the amplitude of vibrations imposed by the sonotrode. For each value of pressure and amplitude investigated in the experiments, the transition energy measured is given in Table 2.

Figure 6.

Plots of the electrical generating power and displacement of the sonotrode and tablets appearance for different processing times. Here, E2 was chosen to be very close to Em,0.

Table 2.

Specific transition energy Em,0 observed according to the processing pressure and amplitude.

| Pressure∖Amplitude | ||

|---|---|---|

| 60 μm | 90 μm | |

| 7.6 MPa | 600 J g−1 | 440 J g−1 |

| 17.8 MPa | 465 J g−1 | 305 J g−1 |

The preliminary tests also enabled to choose the parameters to be evaluated: hydrothermal treatment, maize starch species (standard or waxy), sonotrode amplitude (60 and 90 μm) and applied pressure (7.6 and 17.8 MPa). The specific energy and the holding time 9.99 s were chosen as high as possible (before the material degradation and the limit of the machine, respectively). One last parameter was linked to a technological capability of the welding machine that allowed a slight variation of the amplitude of the waves (slightly increasing, constant, slightly decreasing) to be imposed.

The five parameters presented in the previous paragraph were assessed by using the table from the Taguchi method [16] which enabled every interaction between the parameters to be studied.

Composites

The processing of composites was evaluated following five parameters: fibre content (between 30 wt% and 50 wt%), maize starch species (amylose-extender and waxy), fibre species (CTMP and CB), sonotrode amplitude (around 40 μm) and the applied pressures (7.5 MPa and 15 MPa). The amplitude was chosen to decrease gradually (which was generally the best choice with starch only), the holding time was fixed at 9.99 s, there was no pre-compression, and the welding was time-controlled (energetically-controlled for starch only). The welding durations were 0.60 s, 0.65 s, 0.70 s and 0.75 s. These processing times allowed to cover a range of welding qualities from samples exhibiting unwelded regions (at 0.60 s) to samples exhibiting melted regions (at 0.75 s).

3. Results & discussion

3.1. Starch only

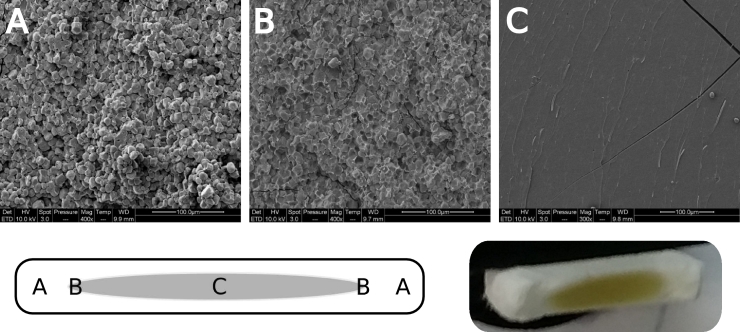

SEM. The morphology of the fracture patterns of the tablets was analysed using SEM. Three tablets processed with different energies were observed. The energies , and (respectively 250 J g−1, 300 J g−1 and 350 J g−1) were chosen so that (Fig. 6). Fig. 7 shows various zones of a tablet processed with the energy . The tablet was not homogeneous and the fracture pattern showed three distinct areas:

-

•

Area A; located near the edges of the tablet, showed a granular structure where grains and intergranular cracks could be clearly distinguished (Fig. 7-a);

-

•

Area B; adjacent to area A towards the centre of the tablet, showed a denser granular structure with intragranular cracks (Fig. 7-b);

-

•

Area C; in the middle of the tablet, was dense and grains were not visible (Fig. 7-c).

The samples processed with a low energy showed only the areas A and B (similar to the three insets in Fig. 6), while those produced with a higher energy where much more homogeneous and showed only one zone similar to the area C.

Figure 7.

Different kinds of morphology were observed by SEM for pure starch tablets on the breaking patterns depending on the location and the energy (A area for porous material; C area for dense and homogeneous material; and B area as transition between A and C areas). Similar results were observed in the work of Regazzi et al. [17] where thermal compression was studied on the same material.

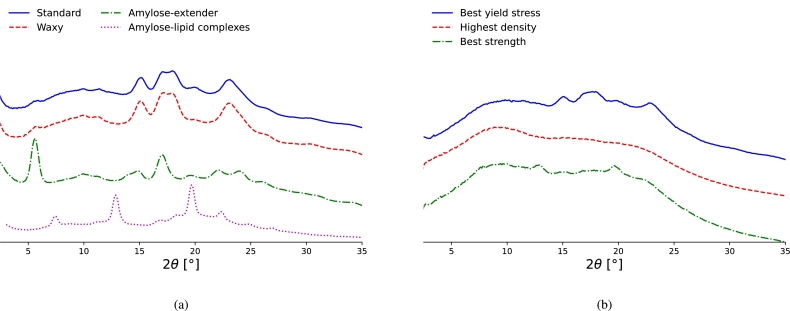

XRD. The evolution of crystallinity after processing was evaluated by X-ray diffraction. Fig. 8-a shows the diffraction profiles of the three native starches used in this study as well as that of amylose-lipid complexes prepared for comparison since a small fraction of lipids is present in cereal starch granules. As described by Cheetham and Tao [18], the allomorphic type varies with the amylose content. Standard and waxy maize starches correspond to type A and amylose-extender starch, to type B.

Figure 8.

X-ray diffraction profiles of (a) native and (b) processed starch samples presenting some of the best properties: best yield stress (standard dry maize starch - decreasing waves amplitude of 60 μm - pressure of 17.8 MPa), highest density (standard hydrated maize starch - decreasing waves amplitude of 60 μm - pressure of 17.8 MPa) and best strength (standard hydrated maize starch - decreasing waves amplitude of 60 μm - pressure of 7.6 MPa). These two graphs have the same vertical scale. The profile of amylose complexes with palmitic acid has been added in panel (a) for comparison.

For comparison purpose, we have recorded the XRD profile of inclusion complexes formed by crystallising pure amylose in the presence of palmitic acid. The profile corresponds to type V and contains three main peaks at diffraction angles 7.5, 12.8 and 19.7°. Fig. 8-b shows the diffraction profiles of the same starches after UCM. The analysed tablets were those having the best properties, considering parameters given in the next paragraphs (best strength, densest and best yield stress). The samples show little or no crystallinity. These results are in accordance with Biliaderis [8] who had shown that the granule structure could be preserved provided that its water content was low. Van Soest et al. [19] observed the same result by studying the residual and processing-induced crystallinities after compression moulding. Only the material showing the best yield stress seemed to have kept a small fraction of A-type crystallites. The densest tablet was totally amorphous, whereas the tablet with the best strength showed some peaks of V-type crystalline structures, likely indicating the formation of amylose-lipid complexes during the process.

Density. The bulk density was measured before every diametral compression test. The Taguchi method showed that the main process parameters to control the density are, in the order of efficiency, the applied pressure, the type of starch, the moisture content of the powder and the amplitude of the ultrasounds. To obtain the densest tablet, it was necessary to choose the largest pressure to apply on a hydrated standard maize starch with the smallest decreasing amplitude of the sonotrode. The Taguchi model was validated with experiments and the smallest measured porosity was 0.94% in the conditions described above.

Mechanical properties. The curves from diametral compression tests enabled the stiffness, the yield stress, the ultimate stress and strain, and the elastic energy to be assessed (Fig. 5). Each of these properties was more or less impacted by the parameters and the interactions between them. Table 3 gives the best properties allowing the validation of the experimental design for all properties excluding the stiffness. Even though the expected value for the stiffness was not reached, the measured value was significantly higher than the mean value measured in all the test program, i.e. 479 MPa.

Table 3.

Expected values from the design of experiments and best measured values for the starch only samples.

| Mechanical property | Expected value | Measured value | Maize starch - Processing parameters (type and water content) - (wave amplitude, pressure) |

|---|---|---|---|

| Stiffness (MPa) | 567 ± 17 | 505 | Standard hydrated - 60 μm decreasing waves, 7.6 MPa |

| Yield stress (MPa) | 8.7 ± 1.1 | 8.9 | Standard dry - 60 μm decreasing waves, 17.8 MPa |

| Ultimate stress (MPa) | 21.5 ± 0.6 | 21.2 | Standard hydrated - 60 μm decreasing waves, 7.6 MPa |

| Ultimate strain (%) | 12.7 ± 2.3 | 11.8 | Standard hydrated - 90 μm decreasing waves, 17.8 MPa |

| Elastic energy (kJ/m3) | 99.6 ± 19 | 99.6 | Standard dry - 60 μm increasing waves, 17.8 MPa |

More generally, the water content and the type of starch were the most influential parameters. A standard starch always gave the best mechanical properties. Hydrated powders globally improved the mechanical properties although the smallest water content seemed to improve the elastic properties. Regarding the machine parameters, the application of a small and gradually decreasing amplitude of vibration led to the best results. Applying a larger pressure did not have a great impact on the properties. Nevertheless, coupled with an increase of the ultrasound amplitude, it resulted in the highest deformation.

These results can be explained using the principles of polymeric welding with the reptation theory [20], which describes the random thermal motion of polymer molecules in concentrated solutions and melts. Choosing a small pair of pressure/amplitude resulted in increasing the required electrical energy and, thus, increased the duration of the process. With a longer processing time, the reptation time of amylose chains into the amorphous parts of the granules might be reached. Therefore, the welding is expected to be essentially due to the diffusion of molecular chains within amorphous structures. This idea is in line with the observation that the welding was easier for standard maize starch than for waxy maize starch since the amylose content is higher in the standard maize starch [21]. Since amylopectin is known to be more prone to crystallisation than amylose, a higher amylose content could be favourable to US welding. Similarly, because of the plasticising effect of water on starch [8], the glass transition temperature of hydrated granules was lower than for dry ones [7], the reptation time might be reached faster. Therefore, the presence of water could be also favourable to welding.

3.2. Composites

Welding. In the case of composites, it is natural to assume that the total energy was shared between the matrix and the fibres, and that interactions between matrix and fibres took a part. This could explain why it was more difficult to define a specific transition energy , like in Fig. 6. Indeed, the addition of fibres changed the power consumption of the welder due to several possible phenomena: vibrations damping, frictional dissipation and other endo- or exothermal phenomena.

The limits in terms of welding time were experimentally defined as the minimum time required to initiate adhesion between layers (≈0.60 s) and the time leading to the degradation of the sample (≈0.75 s). Thus, four values of processing times were chosen (0.60, 0.65, 0.70 and 0.75 s). The processed material showed good cohesion with a satisfactory visual appearance within this interval of welding time.

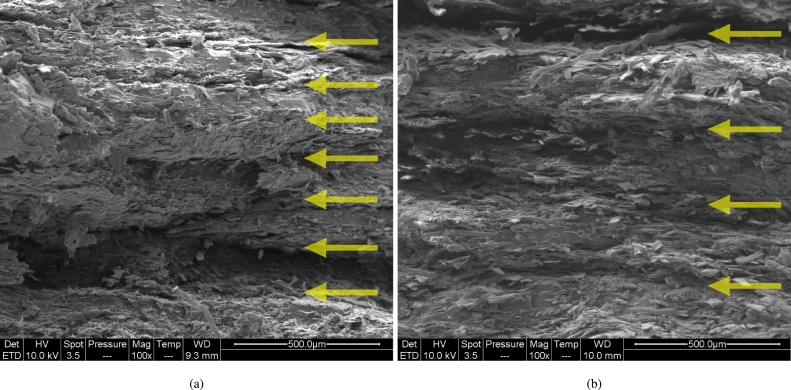

SEM. The SEM images of fracture patterns of CB and CTMP pulps with starch shown in Fig. 9 highlight the difference in the fracture behaviour of samples due to the fibre length of reinforcement. A layered structure is observed which is due to the processing method that involved the stacking up of several layers. Each layer can be observed in Fig. 9 (see arrows in Fig. 9-a: 8 layers, Fig. 9-b: 4 layers). The images show a clear heterogeneity in the structures of the composites. This phenomenon is more pronounced in the case of the CTMP pulp and is possibly due to the larger size of fibres and the heterogeneous distribution of starch within the composite layers themselves, as previously mentioned, leading to a larger thickness of each processed layer. This heterogeneity has a negative impact on the mechanical properties.

Figure 9.

SEM image of breaking patterns of 50 %wt reinforced (a) chemical fibres - waxy starch composite and (b) mechanical fibres - waxy starch composite (arrows show the interfaces between layers). The welding time is 0.70 s, pressure is 15 MPa with the highest amplitude.

Density. Due to the very close densities of the starches and fibres (around 1.5), the absolute density of the composite is supposed to be approximately 1.5. However, the results showed a bulk density for the composite beams of 1.25. This low density is certainly related to the presence of porosities inside the materials. The porosity was estimated to be approximately 17%, using Eq. (2).

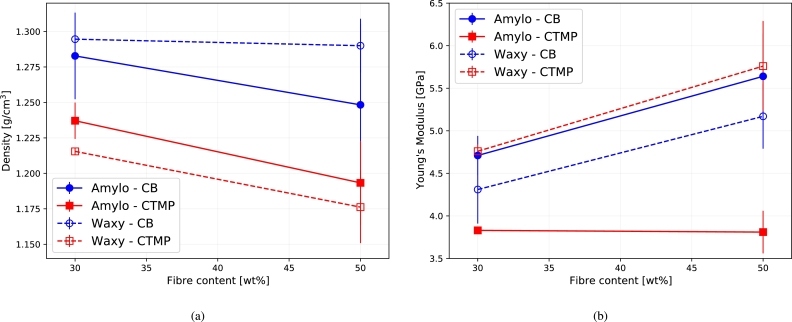

The porosity has two possible sources. On the one hand, the addition of fibres into the starch powder is a source of porosity at the scale of the fibres by intertwining mechanisms. On the other hand, porosity can also occur between layers. Fig. 10-a shows a drop in density with respect to the fibre content. This effect was related to the type of fibres: the use of the chemical pulp led to a denser material compared to the mechanical pulp. In the same way, the lower the fibre content the denser the material was.

Figure 10.

(a) Bulk density and (b) Young's modulus of composites as a function of the fibre content and the nature of starch and fibres. The welding time is 0.70 s, pressure is 15 MPa with the highest amplitude. “CB”, “CTMP” and “Amylo” refer to chemical pulp, mechanical pulp and amylose-extender starch, respectively.

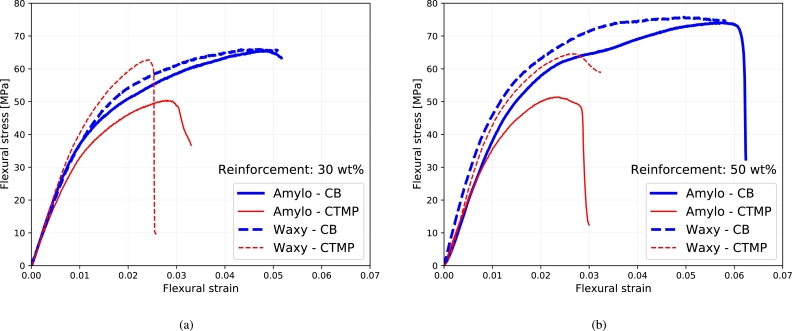

Mechanical properties. Three-point bending tests were performed on composite samples with different fibre contents ( or ) and various types of starches and pulps. Young's moduli are shown in Fig. 10-b and were determined from the curves of the flexural stress/strain shown in Fig. 11.

Figure 11.

Typical curves obtained from three-point bending tests for various composites and fibre contents of (a) 30 wt% and (b) 50 wt%. The welding time is 0.70 s, pressure is 15 MPa with the highest amplitude. “CB”, “CTMP” and “Amylo” refer to chemical pulp, mechanical pulp and amylose-extender starch, respectively.

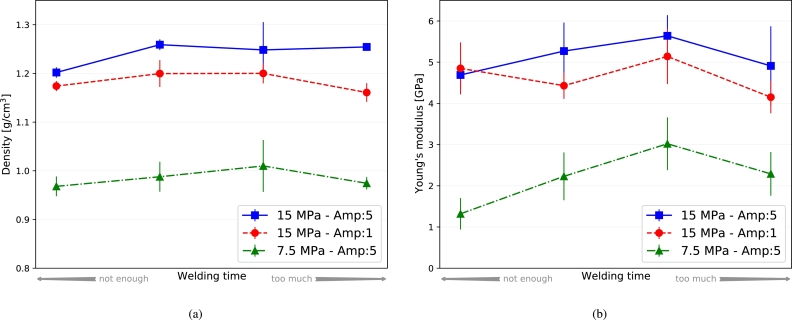

Fig. 12 shows the decrease of the density and Young's modulus near the limits of the interval of the welding time for three different processing parameters. In most cases, the best density and mechanical properties were obtained for a welding time of 0.70 s, with a pressure of 15 MPa and the highest amplitude of vibration. These processing parameters were chosen in the following.

Figure 12.

(a) Bulk density and (b) Young's modulus of composites as a function of pressure, amplitude and welding time. The composite is made of amylose-extender maize starch and chemical pulp with a reinforcement of 50%.

Generally speaking, the use of the chemical pulp improved the mechanical properties of the composites in terms of stiffness and strength (Fig. 11). The effect of the fibre content was mainly noticeable on Young's modulus. Increasing the fibre content raised the stiffness of the composite but the ultimate stress remained almost the same. Indeed, the maximum recorded values were approximately 6 GPa for Young's modulus and 75 MPa for the highest stress with 6% of flexural strain. The poor improvement in ultimate stress can be explained by the effect of adhesion between starch and fibres (note the phenomenon of fibre ravelling in SEM images). Concerning the effect of the various starch types, the waxy maize starch showed a better strength compared to amylose-extender starch (Fig. 11). The amylose/amylopectin ratio seemed to play a role on the mechanical properties of the composites, the best composite properties being reached for low amylose/amylopectin ratio. In fact, amylopectin presents a high crystallinity, which enabled to reach the largest strengths. Concerning starch only, it was the contrary: the lower the amylopectin content, the better the mechanical properties. An explanation of this effect might be that the structure of the starch granules has a direct effect on the quality of the adhesion between fibres and grains.

4. Conclusion

In this work, a new way to process a biobased powder made of starch granules was used to obtain a material with mechanical properties comparable to the most common polymers on the market. This process consists in applying an ultrasonic wave through a mass of starch powder compressed in a mould. The energy provided by the ultrasounds enables to activate dissipative phenomena resulting in a localised heating and welding between grains. The same process was used to produce composites made of wood fibres associated with a starch matrix. Several parameters affected the quality of the welding and therefore the mechanical properties of the processed materials. Considering starch only, the moisture content during processing and the type of starch were the most important parameters. Indeed, a hydrated powder with an amylose/amylopectin ratio of about 40% enabled to obtain a tablet exhibiting the best mechanical properties. This result was explained by considering the model of reptation of the polymeric chains. It was also shown that the ultrasonic compression moulding did not allow the initial crystallinity of the native grains to be preserved. Concerning the machine parameters, a relatively high pressure to density the material and a lower one for the welding are recommended, with a processing time of approximately 1 s. When adding pulp fibres, the optimised processing parameters changed because of the damping of ultrasounds. The quality of the adhesion between fibres and starch matrix seemed to be dependent on the types of fibres and starch. The use of short and chemically treated fibres with a waxy maize starch favoured the best mechanical properties. Due to the stacking up of layers to manufacture the sample, structural heterogeneities were observed in the samples in the perpendicular direction of the layers and caused the presence of weak areas. Despite that, the addition of fibres as reinforcement usually allows for the material to be more rigid and better resist to crack propagation. Thanks to the fibres, the obtained composites showed a Young's modulus of 6 GPa and a flexural ultimate stress of 75 MPa. As shown in the work of Regazzi et al. [6], such a material can be thought of as a substitute to more usual polymers for structural application. Looking at these results, UCM is a promising process to manufacture biobased composites. It would certainly be improved by optimising the design of the sonotrode [22] and the paper-making process to obtain homogeneous composite layers.

Declarations

Author contribution statement

M. Teil, A. Regazzi, B. Harthong, P.J.J. Dumont, D. Imbault, J.-L. Putaux, R. Peyroux: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Funding statement

This work was supported by Institut Carnot PolyNat (ANR-11-CARN-007-01).

Data availability statement

Data will be made available on request.

Declaration of interests statement

The authors declare the following conflict of interests: Pierre Dumont; [is an Associate Editor for the Materials Science section at Heliyon].

Additional information

No additional information is available for this paper.

Acknowledgements

The authors acknowledge the technical support of Bertine Khelifi (LGP2) for microscopy observations, as well as Romain Léger (C2MA - IMT Mines Alès) for helium pycnometry, and Cong Anh Khanh Le (CERMAV) for the gift of a sample of amylose-palmitic acid complexes. The laboratories LGP2 and 3SR are also part of the LabEx Tec 21 (Investissements d'Avenir - grant agreement n° ANR-11-LABX-0030).

References

- 1.Fairbanks H.V. Applying ultrasonics to the moulding of plastic powders. Ultrasonics. 1974;12(1):22–24. [Google Scholar]

- 2.Paul D.W., Crawford R.J. Ultrasonic moulding of plastic powders. Ultrasonics. 1981;19(1):23–27. [Google Scholar]

- 3.Matsuoka S.-I. Effects of ultrasonic vibration on the compaction molding of polymeric powders. J. Mater. Process. Technol. 1994;40(3–4):443–450. [Google Scholar]

- 4.Planellas M., Sacristán M., Rey L., Olmo C., Aymamí J., Casas M.T., del Valle L.J., Franco L., Puiggalí J. Micro-molding with ultrasonic vibration energy: new method to disperse nanoclays in polymer matrices. Ultrason. Sonochem. 2014;21(4):1557–1569. doi: 10.1016/j.ultsonch.2013.12.027. [DOI] [PubMed] [Google Scholar]

- 5.Wu S.-Y., Wu X.-Y., Xu B., Cheng R., Luo F., Ruan S.-C. A micro-ultrasonic powder moulding method to fabricate Sn–Bi alloy micro parts. J. Mater. Process. Technol. 2014;214(11):2668–2675. [Google Scholar]

- 6.Regazzi A., Teil M., Dumont P., Harthong B., Imbault D., Peyroux R., Putaux J.-L. Microstructural and mechanical properties of biocomposites made of native starch granules and wood fibers. Compos. Sci. Technol. 2019;182 [Google Scholar]

- 7.Altay F., Gunasekaran S. Influence of drying temperature, water content, and heating rate on gelatinization of corn starches. J. Agric. Food Chem. 2006;54(12):4235–4245. doi: 10.1021/jf0527089. [DOI] [PubMed] [Google Scholar]

- 8.Biliaderis C.G. Starch: Chemistry and Technology. third edition. Academic Press; 2009. Structural transitions and related physical properties of starch. (chapter 8) [Google Scholar]

- 9.Udomkichdecha W., Chiarakorn S., Potiyaraj P. Relationships between fibrillation behavior of lyocell fibers and their physical properties. Tex. Res. J. 2002;72(11):939–943. [Google Scholar]

- 10.Tolunay M.N., Dawson P.R., Wang K.K. Heating and bonding mechanisms in ultrasonic welding of thermoplastics. Polym. Eng. Sci. 1983;23(13):726–733. [Google Scholar]

- 11.Hertz H. Über die verteilung der druckkräfte in einem elastischen kreiszylinder. Z. Angew. Math. Phys. 1883;28 [Google Scholar]

- 12.Michell J.H. The stress in an æolotrophic elastic solid with an infinite plane boundary. Proc. Lond. Math. Soc. 1900;s1-32(1):247–257. [Google Scholar]

- 13.Michell J.H. The flexure of a circular plate. Proc. Lond. Math. Soc. 1901;s1-34(1):223–234. [Google Scholar]

- 14.Fell J.T., Newton J.M. Determination of tablet strength by the diametral-compression test. J. Pharm. Sci. 1970;59(5):688–691. doi: 10.1002/jps.2600590523. [DOI] [PubMed] [Google Scholar]

- 15.Fahad M.K. Stresses and failure in the diametral compression test. J. Mater. Sci. 1996;31(14):3723–3729. [Google Scholar]

- 16.Taguchi G., Yokoyama Y. American Supplier Institute; 1993. Taguchi Methods: Design of Experiments; p. 4. [Google Scholar]

- 17.Regazzi A., Dumont P., Harthong B., Imbault D., Peyroux R., Putaux J.-L. Effectiveness of thermo-compression for manufacturing native starch bulk materials. J. Mater. Sci. 2016;51(11):5146–5159. [Google Scholar]

- 18.Cheetham N.W.H., Tao L. Variation in crystalline type with amylose content in maize starch granules: an X-ray powder diffraction study. Carbohydr. Polym. 1998;36(4):277–284. [Google Scholar]

- 19.Van Soest J.J.G., Hulleman S.H.D., de Wit D., Vliegenthart J.F.G. Crystallinity in starch bioplastics. Ind. Crop. Prod. 1996;5(1):11–22. [Google Scholar]

- 20.De Gennes P.G. Cornell University Press; 1979. Scaling Concepts in Polymer Physics. [Google Scholar]

- 21.Pérez S., Baldwin P.M., Gallant D.J. Starch: Chemistry and Technology. third edition. Academic Press; 2009. Structural features of starch granules I; pp. 149–192. (chapter 5) [Google Scholar]

- 22.Grabalosa J., Ferrer I., Martínez-Romero O., Elías-Zúñiga A., Plantá X., Rivillas F. Assessing a stepped sonotrode in ultrasonic molding technology. J. Mater. Process. Technol. 2016;229:687–696. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.