Abstract

The human body offers a template for many state-of-the-art prosthetic devices and sensors. In this work, we present a novel, sensorized synthetic skin that mimics the natural multi-layered nature of mechanoreceptors found in healthy glabrous skin to provide tactile information. The multi-layered sensor is made up of flexible piezoresistive textiles that act as force sensitive resistors (FSRs) to convey tactile information, which are embedded within a silicone rubber to resemble the compliant nature of human skin. The top layer of the synthetic skin is capable of detecting small loads less than 5 N whereas the bottom sensing layer responds reliably to loads over 7 N. Finite element analysis (FEA) of a simplified human fingertip and the synthetic skin was performed. Results suggest similarities in behavior during loading. A natural tactile event is simulated by loading the synthetic skin on a prosthetic limb. Results show the sensors’ ability to detect applied loads as well as the ability to simulate neural spiking activity based on the derivative and temporal differences of the sensor response. During the tactile loading, the top sensing layer responded 0.24 s faster than the bottom sensing layer. A synthetic biologically-inspired skin such as this will be useful for enhancing the functionality of prosthetic limbs through tactile feedback.

I. INTRODUCTION

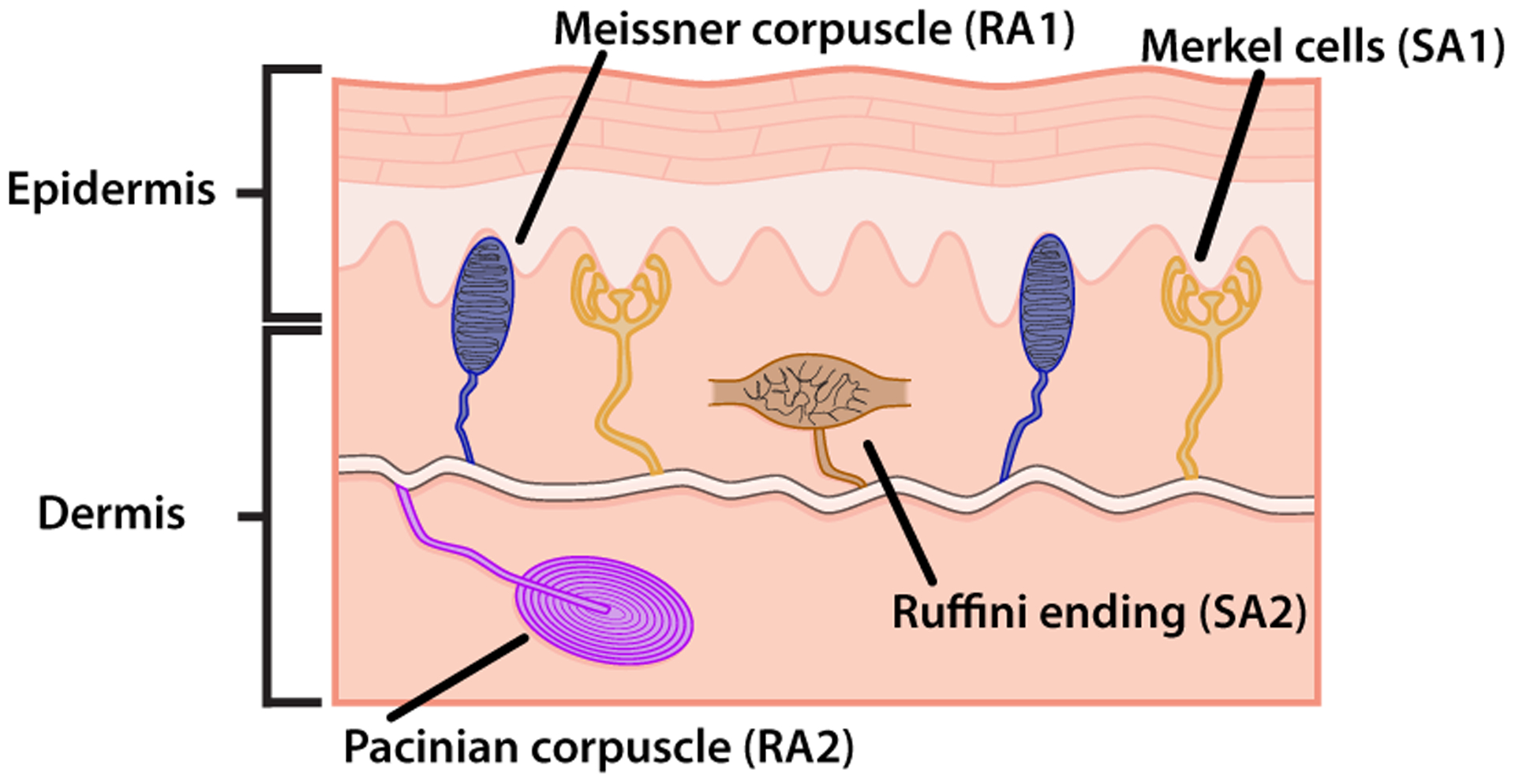

One of the primary functions of the somatosensory system is to provide exteroreceptive sensations to help us perceive and react to stimuli from outside of our body [1]. Our sense of touch is a crucial aspect of the somatosensory system and provides valuable information that enables us to interact with our surrounding environment. Tactile feedback, in conjunction with proprioception, allows us to perform many of our daily tasks that rely on the dexterous manipulation of our hands [2]–[4]. There are 4 types of primary mechanoreceptors in the glabrous skin that convey tactile information: Merkel cells, Meissner corpuscles, Ruffini endings, and Pacinian corpuscles. The Merkel cells and Ruffini endings are classified as slowly adapting (SA) and the Meissner and Pacinian corpuscles as rapidly adapting (RA) [1], [5]. SA mechanoreceptors respond to sustained tactile loads while RA responds to the onset and offset of tactile stimulation. It is through the function of these mechanoreceptors in our skin that we are able to perceive tactile sensation.

Unfortunately for the nearly 50,000 people living in the U.S. with a major upper limb amputation, prosthetic limbs rarely provide the tactile sensation that has been lost [6]. Prosthetic arm technology has improved significantly in recent years with advances in myoelectric (EMG) control [7], [8], closed-loop grip control [9], [10], and even tactile sensors [11]–[13]. Recently, novel tactile sensors have been designed to mimic the response behavior of healthy mechanoreceptors [14]. To further these advancements, we investigate the design and functionality of a novel, multi-layered, sensorized synthetic skin for prosthesis applications. While recent work attempts to mimic the output behavior and function of natural mechanorecptors [10], [14], the sensorized synthetic skin presented in this work is modeled in a biomimetic fashion and takes into account the natural layering of SA and RA mechanoreceptors in the human hand, which has potential for improving the resolution and sensing capabilities of tactile sensors for prosthetic limbs. We hypothesize that a multi-layered approach will help exploit temporal differences in sensor response during loading.

II. SENSOR DESIGN

The sensorized synthetic skin is modeled after healthy glabrous skin, which contains mechanoreceptors located at various depths within the skin. Fig. 1 shows a simplified diagram of the mechanoreceptors and their approximate locations within the epidermis and dermis layers of glabrous skin. It is important to note the different depths of the receptors, which plays a key role in the type of tactile information they convey. The Merkel cells (SA1) are located in the basal layer of the epidermis and respond to sustained loading. The Meissner corpuscles (RA1) are found in the dermal papillae, which leads to their sensitivity to tactile stimulation, and respond to skin movement and the onset/offset of tactile stimuli. Ruffini endings (SA2) and Pacinian corpuscles (RA2) are found in the dermis and deep dermis, respectively, which leads to their decreased sensitivity to tactile stimuli [1].

Fig. 1.

A simplified schematic of the mechanoreceptors found in healthy glabrous skin. Meissner’s corpuscles (SA1) and Merkel discs (RA) lie closer to the skin surface and offer higher sensitivity to touch sensation than the Ruffini endings (SA2), which lie deeper within the dermis layer [1].

The goal with the synthetic skin is to create sensing elements at different depths to model the SA1 and RA1 mechanoreceptor as a “top layer” of sensing elements while the SA2 and RA2 mechanorecptors act as the “bottom layer”. The idea being that the top layer of sensing elements will provide higher sensitivity to tactile stimuli, which is important for light touch as well as the onset/offset of touch. The bottom layer, because of its depth, provides a larger sensing range for tactile events with larger loads.

A. Materials

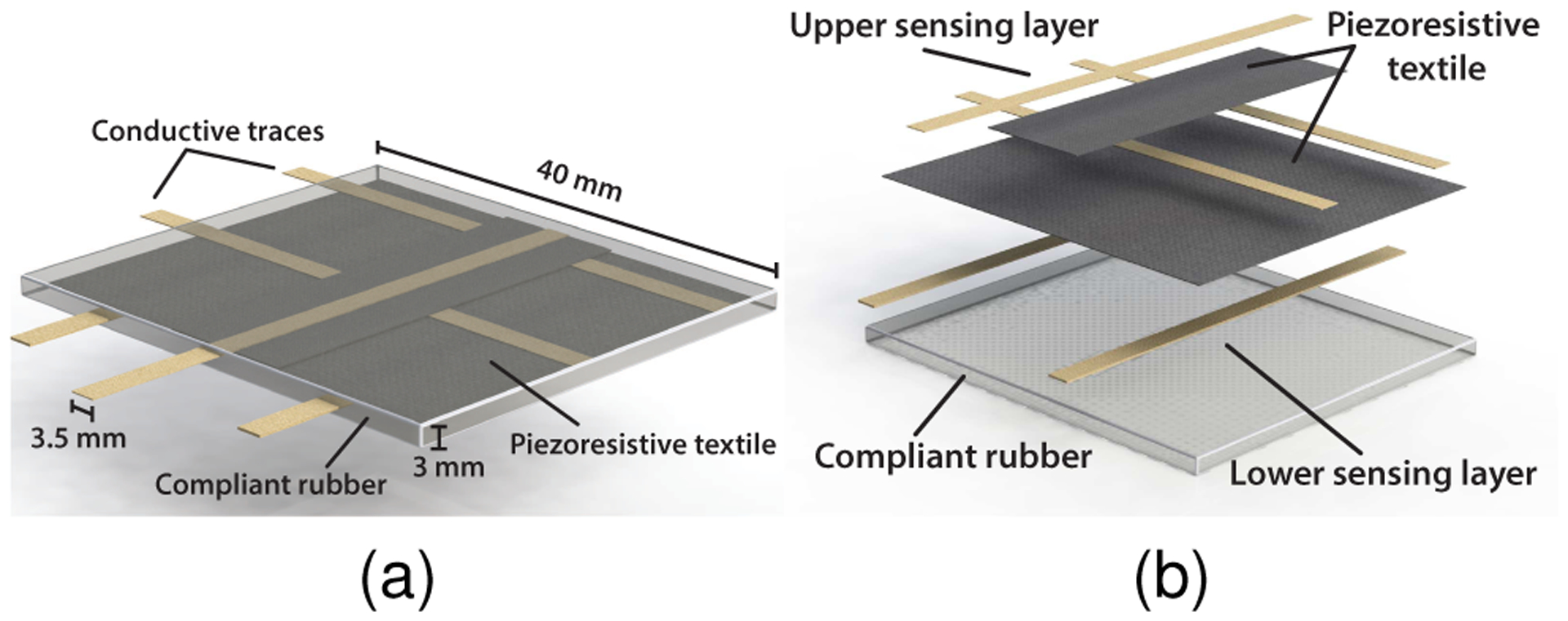

Each sensing element of the synthetic skin is constructed with a piezoresistive transducing fabric (Eeonyx, Pinole, USA) placed between crossing conductive traces (stretch conductive fabric, LessEMF, Latham, USA). The piezoresisitve material is pressure sensitive and decreases in resistance with increased loading. The intersection of the conductive traces creates a sensing taxel, a tactile element. The sensors are embedded within a silicone rubber (Dragon Skin 20, Smooth-On, Easton, USA), which provides the skin-like compliance of the device. The synthetic skin sensor is 40 × 40 mm2 with a rubber thickness of 3 mm. Each conductive trace is approximately 3.5 mm in width. The piezoresisitve material and the conductive traces are 0.4 mm and 0.5 mm thick, respectively. The sensor is shown in Fig. 2a.

Fig. 2.

The multi-layered synthetic skin sensor. (a) The sensing elements are created by the crossing of the conductive traces across the piezoresistive textile. A silicone rubber is used to encase the sensing elements, lending to its skin like flexibility and compliance. (b) An exploded view of the multi-layer synthetic skin sensor. The top layer serves as the highly sensitive RA1 and SA1 tactile receptors while the lower layer is more similar to the RA2 and SA2 receptor found deeper in the dermis of healthy glabrous skin

To accomplish the layering effect of natural mechanorecptors, two layers of the piezoresisitve material are utilized in the synthetic skin, as seen in Fig. 2b. A total of five conductive traces are used in the sensor, one trace is placed above the upper piezoresistive layer and two more traces are placed perpendicular to the top trace in between the upper and lower piezoresistive layers. Two more conductive traces, parallel to the top trace, are placed below the lower piezoresistive layer. The layering of the piezoresistive textile creates a top layer of sensors which are sensitive to light touch and small tactile loads as well as a bottom layer of taxels, approximately 1 mm deeper, that are primarily responsive to larger loads.

B. Characterization

The textile force sensitive resistors (FSRs) were characterized by mounting the synthetic skin on a flat surface. A normal force was applied directly to the sensing areas of the synthetic skin with a probe the size of a single taxel. Data was collected using an NI USB-6001 DAQ (National Instruments, Austin, USA) and processed using LabView and MATLAB on a PC. Each taxel was tested multiple times and the results averaged.

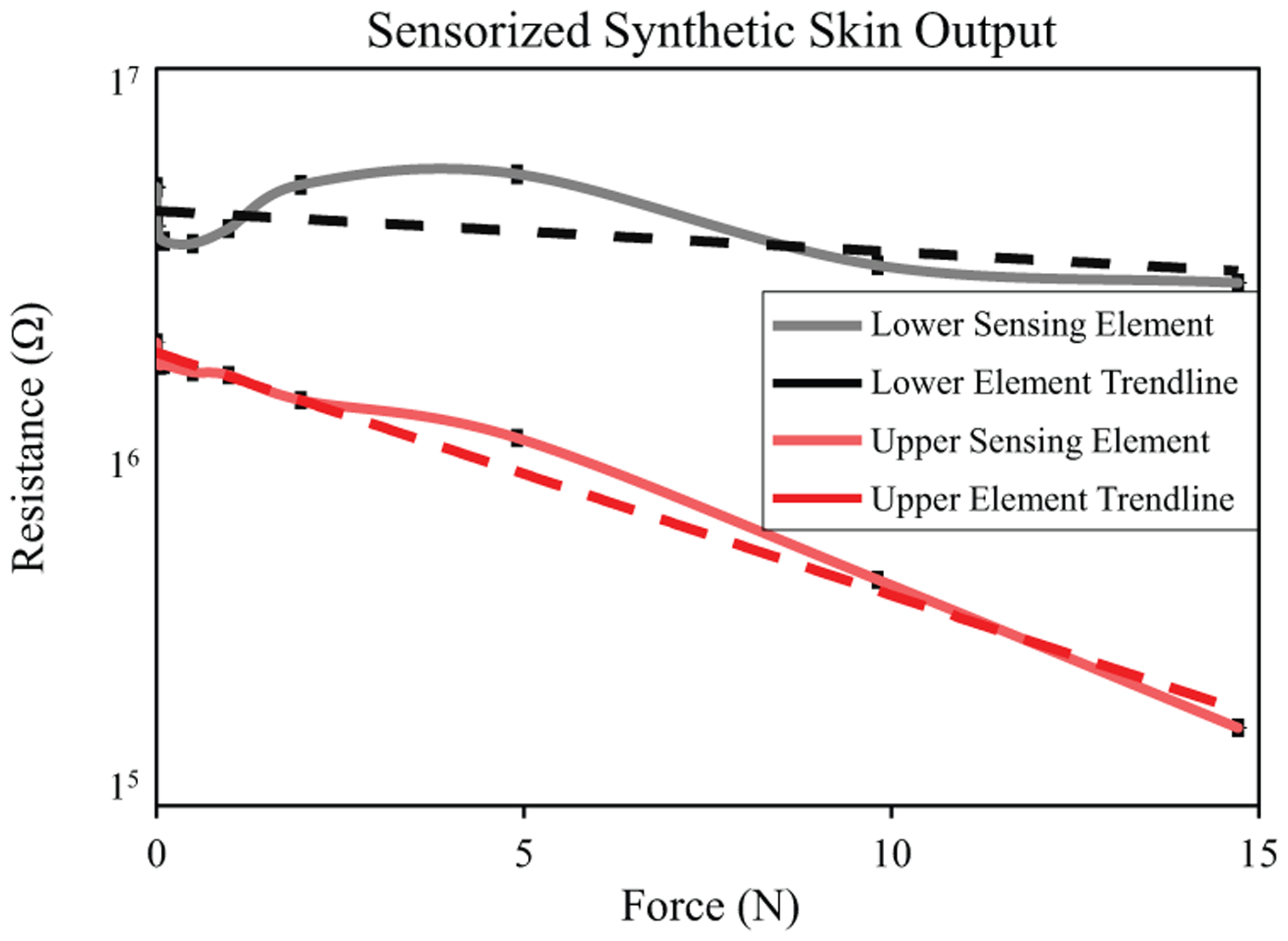

The results from the synthetic skin sensor characterization are shown in Fig. 3 with exponential trendlines fit to the data. The standard error of the mean at rest (i.e. no loading) is 8 kΩ and 162 kΩ for the top and bottom layers, respectively. These values corresponds to 0.13% and 0.79% of the resting resistance value for the top and bottom sensing layers, respectively. It should be noted that the upper sensing element is noticeably more sensitive to applied loads than the lower sensing element. This can be attributed to the superficial nature of the upper taxels compared to the deeper location of the lower sensing elements within the rubber. It should be noted that the resting resistance is different for the upper and lower sensing elements shown in Fig. 3. This is most likely caused by small differences in the cross sectional areas of each taxel, which could affect the output of the sensor.

Fig. 3.

Resistance output of sensing elements from the upper and lower layers of the biologically-inspired synthetic skin during loading. The top sensing element offers greater sensitivity to small loads, not unlike the SA1 and RA receptors in healthy skin. The bottom layer responds to increasingly larger loads, offering a larger dynamic range for the sensor. The error bars represent the standard error of the mean.

III. MODELING & METHODS

A series of simulations and experiments were performed to evaluate the functionality of the synthetic skin. The goals are 1) to investigate the performance of the synthetic skin compared to human skin and 2) to assess the ability of the synthetic skin to measure tactile events for a prosthetic limb.

A. Finite Element Analysis

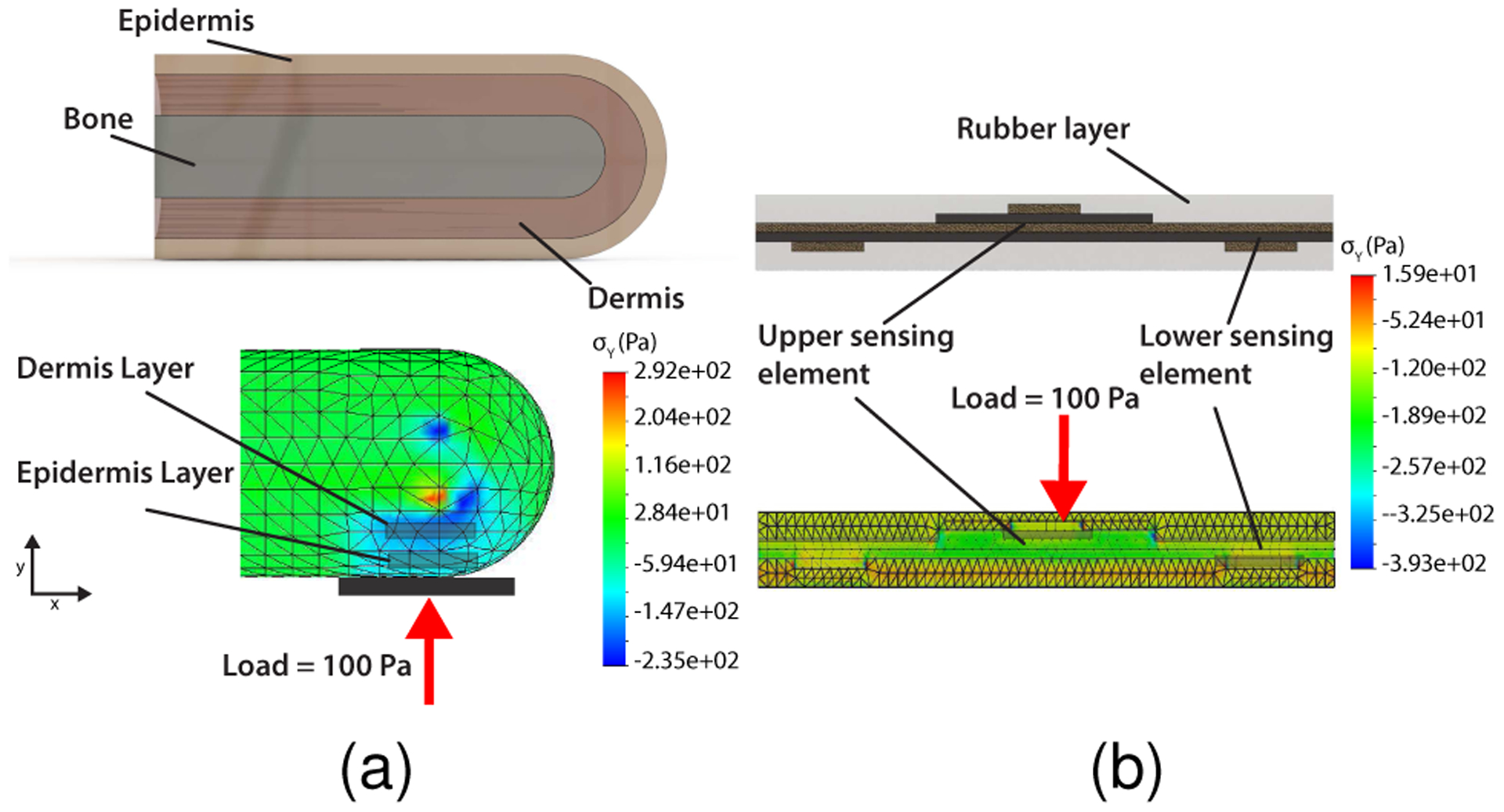

A computational model was employed for understanding the behavior of a human fingertip under loading. Finite element analysis (FEA) was performed on a simplified 3D model of a human fingertip using SolidWorks Simulation (Dassault Systémes, Vélizy-Villacoublay, France). The simplified fingertip was designed as a two-layered skin system, made up of a epidermis and dermis layers, surrounding an internal bone structure, as seen in Fig. 4a. Young’s modulus was taken to be 5 kPa, 600 kPa, and 11 GPa for the epidermis, dermis, and bone models, respectively. These values were chosen from current literature [15]–[18]. The sensorized synthetic skin was modeled in a similar fashion with multiple layers. A Young’s modulus of 8 GPa was used for the textile components of the synthetic skin [19]. A simulated load of 100 Pa was cycled on the 3D models at 4 Hz for 1 sec. A snapshot of the normal stress during loading of the models is shown in Fig.4 for the models.

Fig. 4.

FEA results showing the normal stress component in the y-direction, σy, of (a) the 3D modeled human fingertip with bone, dermis, and epidermis layers and (b) the synthetic skin with the upper and lower sensing elements. The results show the varying response from the different layers of both the human fingertip and the synthetic skin model.

B. Experimental Procedure

The synthetic skin was mounted on the palm of a bebionic v3 prosthetic hand (Steeper, Leeds, UK). The prosthetic limb was oriented with the palm facing upwards. Similar to the simulations, a load of approximately 10 N was applied to the synthetic skin and released. This experiment is used to emulate a natural tactile loading event that may occur during normal use of a prosthetic hand. During offline processing, a numerical derivative of the sensor response is taken and used to indicate tactile loading and unloading. A simulated neural spike train is activated for the layers during tactile loading and is subsequently truncated upon release of the applied load. To simulate a spiking neural output from the synthetic skin tactile signal we use an estimated firing rate, F, to drive a Poisson process. The estimated probability of a spike firing is proportional to F and each time step, dt. Methods such as this have been used in the past to generate neural spiking activity [20], [21].

IV. RESULTS & DISCUSSION

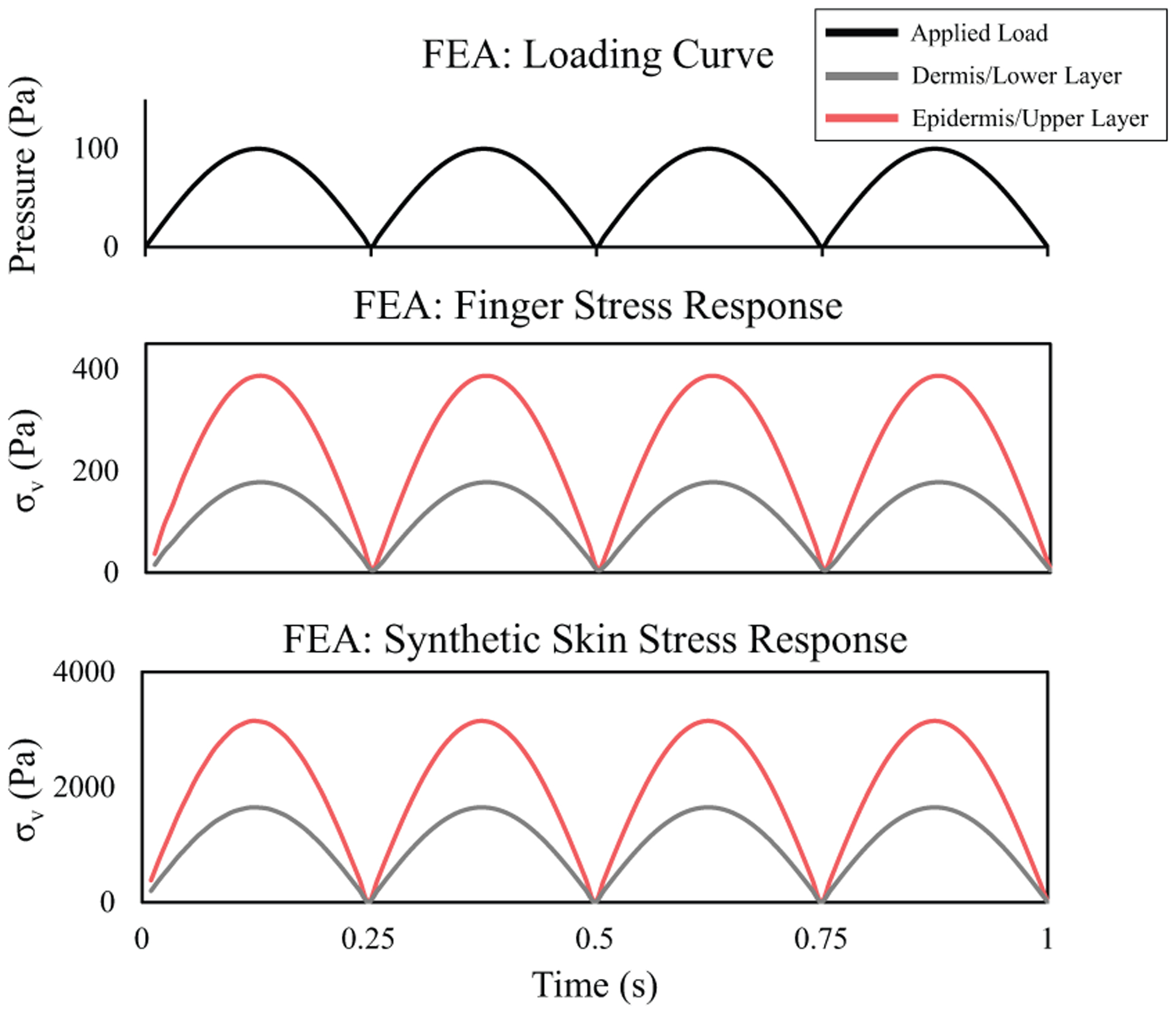

Results from the FEA are shown in Fig. 5. The von Mises stresses, σv, of nodes from the different layers of the 3D models are plotted in time against the loading curve. It should be noted that the relative stress between the upper and lower layers of the synthetic skin matches the behavior of the fingertip model. The epidermis on the simplified fingertip exhibits higher sensitivity and overall stress levels compared to the lower dermis layer for the same loading. Similarly, the synthetic skin exhibits a similar response for the upper and lower sensing elements.

Fig. 5.

Cyclic pressure loading over time for the FEA on the 3D models (top) with single node stress responses for the epidermis and dermis layers of the 3D modeled human fingertip (middle) and the corresponding upper and lower sensing layers of the synthetic skin (bottom). The relative stress between the upper and lower layers of the synthetic skin matches that of the epidermis (upper) and dermis (lower) of the simplified fingertip model.

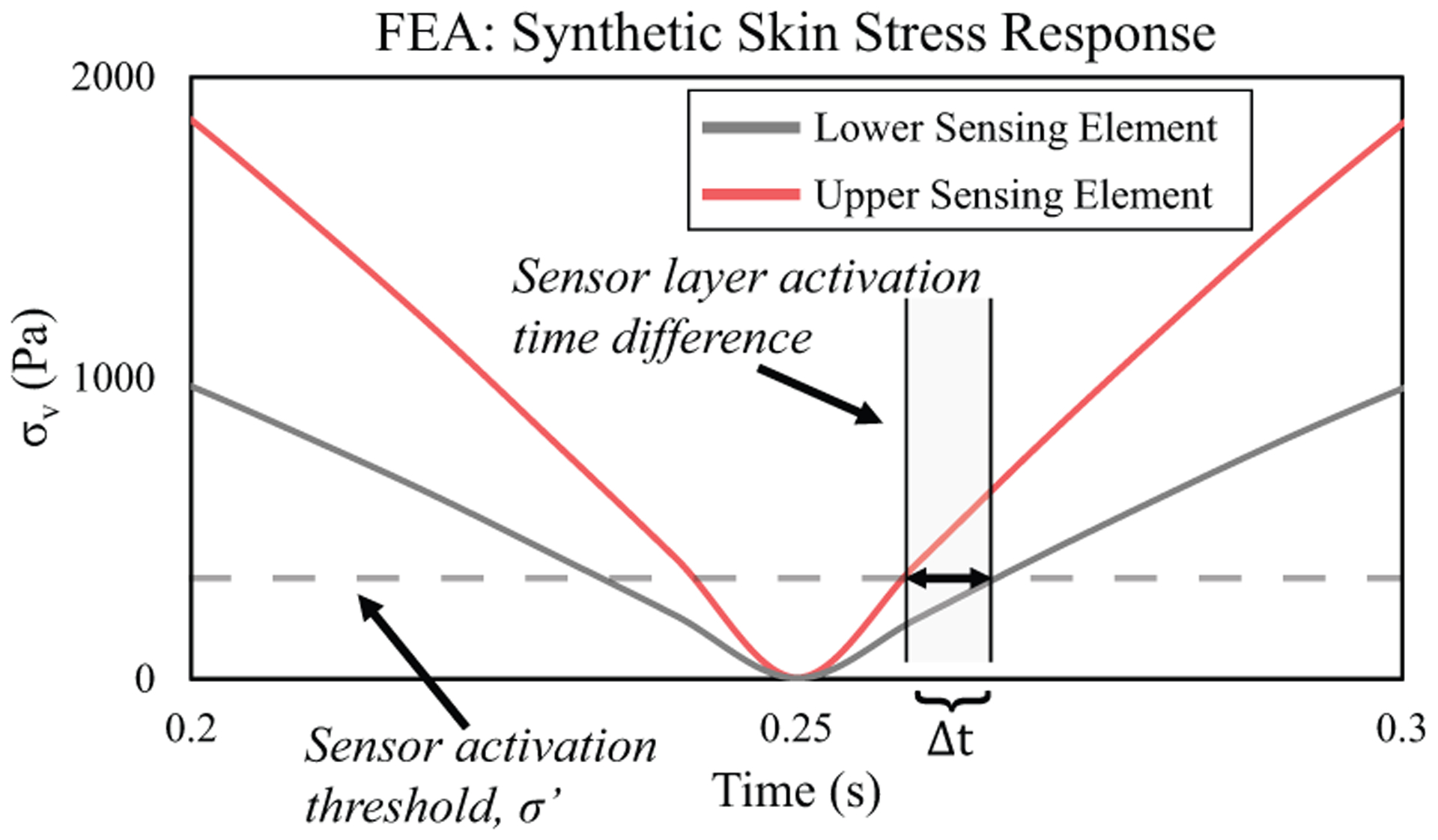

The relative timing between activation of the two sensing layers of the synthetic skin is shown in Fig. 6. A threshold of 10% of the maximum von Mises stress, σv,max, is used to indicate activation of each sensing layer. The temporal difference between the two layers is given by

where tLowerσ′ and tUpper,σ′ are the times at which σv = σ′ for the lower and upper sensing layers of the synthetic skin, respectively. For this simulation Δt = 0.01 s, indicating the slightly faster response of the upper sensing layer compared to that of the lower sensing layer.

Fig. 6.

Zoomed in section of the synthetic skin stress response during cyclic loading.The activation threshold is 10% of the maximum von Mises stress, σv,max. The timing between layer activation is given by Δt.

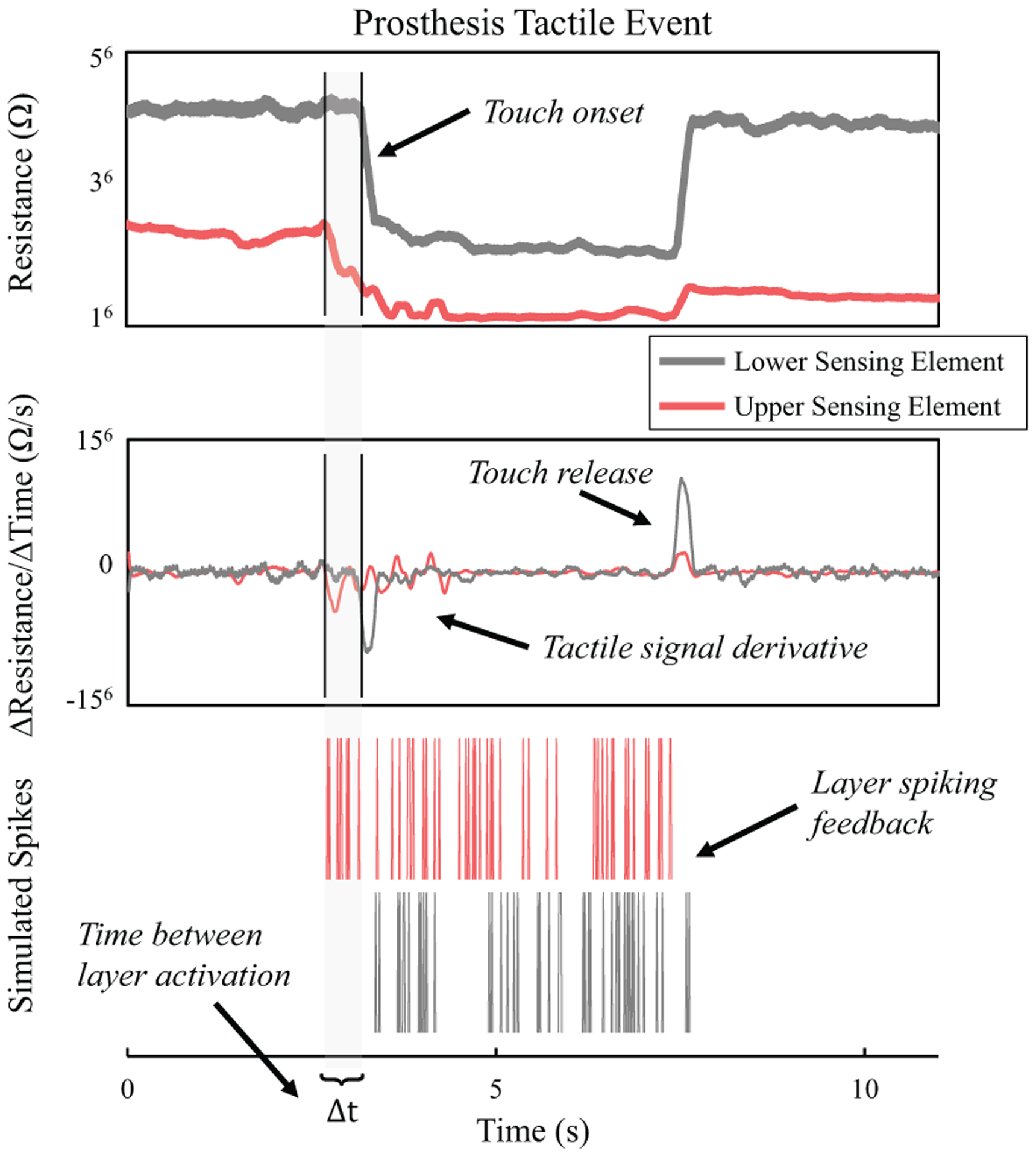

Fig. 7 shows the synthetic skin output for a tactile loading and release event with an applied load of approximately 10 N distributed evenly across the sensor. The synthetic skin was placed on a prosthetic hand to simulate a potential use for this biologically inspired multi-layered sensor. The numerical derivative of the sensor response highlights rapid changes in the tactile signal, primarily the onset and release of touch. One important feature to note is the relative differences between the time of sensor response, Δt, during the loading event. For this experiment Δt = 0.24 s. It should be noted that this value is significantly larger than the temporal difference in the simulation. This is could be due to the idealized simulation that ignores many physical properties such as friction or sensor imperfections as well as differences in loading rate between the computational model and physical tactile experiment. Regardless, the sensorized synthetic skin portrays similar behavior to the FEA results in the upper sensing layer responds first to the onset of touch followed by the lower sensing layer after a short duration Δt.

Fig. 7.

Sensor output during the prosthesis loading task (top). A numerical derivative of the sensor response highlights the onset and release of touch (middle). The onset of touch triggers the simulated spike train for the duration of the tactile event (bottom). The time of activation for the multiple sensor layers during the tactile event is noticeable different with the top layer responding first followed by the upper layer after a short time Δt = 0.24 s. This could play an important role for providing feature rich tactile feedback to prosthetic limbs

Activation of a sensor layer triggers the simulated neural spike train for the corresponding sensing element. The upper sensing layer of the synthetic skin responds first to the tactile loading, as seen by the Δt delay between the layers’ spiking. The temporal response of a mechanoreceptor plays a key role in our sensory perception [2], [22]. Using this biological phenomenon as a template, the simulated spiking response from the synthetic skin could play a useful role for providing tactile information to a prosthetic limb. Recent work with neuromorphic tactile feedback systems suggests the benefit of using a spike-based approach for providing tactile information to a prosthetic limb [10] or even directly to peripheral nerves to elicit sensory percepts [23].

The synthetic skin designed in this work can be expanded to cover an entire prosthetic hand and arm to provide a full map of tactile information for the limb. The flexible and stretchable nature of the materials used to make the sensor provide the unique benefit of easy customization for placing the sensor in any location on the prosthesis. This would allow the synthetic skin to effectively sensorize key parts of the prosthesis while still allowing it to operate unimpeded due to the nature of the materials used in the sensors.

Acknowledgments

This work is supported by the grant R44NS065495 from the National Institutes of Health.

REFERENCES

- [1].Abraira VE and Ginty DD, “The sensory neurons of touch,” Neuron, vol. 79, no. 4, pp. 618–639, 2013. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [2].Johansson RS and Flanagan JR, “Coding and use of tactile signals from the fingertips in object manipulation tasks,” Nat. Rev. Neurosci, vol. 10, no. 5, pp. 345–359, 2009. [DOI] [PubMed] [Google Scholar]

- [3].Johansson RS, “Dynamic Use of Tactile Afferent Signals in Control of Dexterous Manipulation”, Adv. Exp. Med. Biol, vol. 508, pp. 397–410, 2002. [DOI] [PubMed] [Google Scholar]

- [4].Johansson RS, “Sensory and Memory Information in the Control of Dexterous Manipulation”, in Neural Bases of Motor Behavior, Springer Netherlands, vol. 85, pp. 205–260, 1996. [Google Scholar]

- [5].Vallbo A and Johansson R, “Properties of cutaneous mechanoreceptors in the human hand related to touch sensation,” Hum. Neurobiol, vol. 3, no. 1, pp. 3–14, 1984. [PubMed] [Google Scholar]

- [6].Ziegler-Graham K, MacKenzie EJ, Ephraim PL, Travison TG, and Brookmeyer R, “Estimating the prevalence of limb loss in the united states: 2005 to 2050,” Arch. Phys. Med. Rehabil, vol. 89, no. 3, pp. 422–429, 2014. [DOI] [PubMed] [Google Scholar]

- [7].Powell MA, Kaliki RR, and Thakor NV, “User training for pattern recognition-based myoelectric prostheses: Improving phantom limb movement consistency and distinguishability,” IEEE Trans. Neural Syst. Rehab. Eng, vol. 22, no. 3, pp. 522–532, 2014. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [8].Smith LH, Kuiken TA, and Hargrove LJ, “Real-time simultaneous and proportional myoelectric control using intramuscular emg,” J. Neural Eng, vol. 11, no. 6, pp. 1–13, 2014. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [9].Engeberg ED and Meek SG, “Adaptive sliding mode control for prosthetic hands to simultaneously prevent slip and minimize deformation of grasped objects,” IEEE Trans. on Mechatronics, vol. 18, no. 1, pp. 376–385, 2013. [Google Scholar]

- [10].Osborn L, Kaliki R, Soares A, and Thakor N, “Neuromorphic event based detection for closed-loop tactile feedback control of upper limb prostheses,” IEEE Trans. Haptics, vol. PP, no. 99, pp. 1–10, 2016. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [11].Cotton DPJ, Chappell PH, Cranny A, White NM, and Beeby SP, “A novel thick-film piezoelectric slip sensor for a prosthetic hand,” IEEE Sens. J, vol. 7, no. 5, pp. 752–761, 2007. [Google Scholar]

- [12].Fishel JA, Santos VJ, and Loeb GE, “A robust micro-vibration sensor for biomimetic fingertips,” in 2nd IEEE Int. Conf. Biomed. Robot. Biomechatronics (BioRob), 2008, pp. 659–663. [Google Scholar]

- [13].Osborn L, Lee WW, Kaliki R, and Thakor NV, “Tactile feedback in upper limb prosthetic devices using flexible textile force sensors,” in 5th IEEE Int. Conf. Biomed. Robot. Biomechatronics (BioRob), 2014, pp. 114–119. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [14].Tee BCK, Chortos A, Berndt A, Nguyen AK, Tom A, McGuire A, Lin ZC, Tien K, Bae W-G, Wang H, Mei P, Chou H-H, Cui B, Deisseroth K, Ng TN, and Bao Z, “A skin-inspired organic digital mechanoreceptor,” Science, vol. 350, no. 6258, pp. 313–316, 2015. [DOI] [PubMed] [Google Scholar]

- [15].Pailler-Mattei C and Zahouani H, “Study of adhesion forces and mechanical properties of human skin in vivo,” J. Adhes. Sci. Technol, vol. 18, no. 15–16, pp. 1739–1758, 2004. [Google Scholar]

- [16].Geerligs M, “Skin layer mechanics,” M.Sc thesis, Biomed. Eng., Tech. Univ. Eindhoven, Eindhoven, NLD, 2009. [Google Scholar]

- [17].Pailler-Mattei C, Bec S, and Zahouani H, “In vivo measurements of the elastic mechanical properties of human skin by indentation tests,” Med. Eng. Phys, vol. 30, no. 5, pp. 599–606, 2008. [DOI] [PubMed] [Google Scholar]

- [18].McCloskey C and Furnival T, “Mechanical properties of bone,” DoITPoMS, 2011. [Google Scholar]

- [19].Lin J-J, Prediction of elastic properties of plain weave fabric using geometrical modeling. INTECH Open Access Publisher, 2010. [Google Scholar]

- [20].Vázquez Y, Salinas E, and Romo R, “Transformation of the neural code for tactile detection from thalamus to cortex,” P. Natl. Acad. Sci, vol. 110, no. 28, pp. 2635–2644, 2013. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [21].Dayan P and Abbott LF, Theoretical Neuroscience: Computational And Mathematical Modeling of Neural Systems. MIT Press, 2005. [Google Scholar]

- [22].Hsiao SS and Gomez-Ramirez M, “Neural mechanisms of tactile perception,” in Comprehensive Handbook of Psychology: Volume 3: Behavioral Neuroscience, 2nd ed., Gallagher M and Nelson R, Eds. John Wiley and Sons, Inc, 2012. [Google Scholar]

- [23].Oddo CM, Raspopovic S, Artoni F, Mazzoni A, Spigler G, Petrini F, Giambattistelli F, Vecchio F, Miraglia F, Zollo L, Pino GD, Camboni D, Carrozza MC, Guglielmelli E, Rossini PM, Faraguna U, and Micera S, “Intraneural stimulation elicits discrimination of textural features by artificial fingertip in intact and amputee humans,” eLife, vol. 5, pp. e09148, 2016. [DOI] [PMC free article] [PubMed] [Google Scholar]