Abstract

Hydrogels prepared via self-assembly offer scalable and tunable platforms for drug delivery applications. Molecular-scale self-assembly leverages an interplay of attractive and repulsive forces; drugs and other active molecules can be incorporated into such materials by partitioning in hydrophobic domains, affinity-mediated binding, or covalent integration. Peptides have been widely used as building blocks for self-assembly due to facile synthesis, ease of modification with bioactive molecules, and precise molecular-scale control over material properties through tunable interactions. Additional opportunities are manifest in stimuli-responsive self-assembly for more precise drug action. Hydrogels can likewise be fabricated from macromolecular self-assembly, with both synthetic polymers and biopolymers used to prepare materials with controlled mechanical properties and tunable drug release. These include clinical approaches for solubilization and delivery of hydrophobic drugs. To further enhance mechanical properties of hydrogels prepared through self-assembly, recent work has integrated self-assembly motifs with polymeric networks. For example, double-network hydrogels capture the beneficial properties of both self-assembled and covalent networks. The expanding ability to fabricate complex and precise materials, coupled with an improved understanding of biology, will lead to new classes of hydrogels specifically tailored for drug delivery applications.

Keywords: Biomaterials, Molecular Engineering, Peptide Self-Assembly, Supramolecular Chemistry, Block Copolymers

1. Introduction

A number of hydrogel biomaterials have been explored for various applications in tissue engineering, regenerative medicine, and drug delivery.[1, 2] Hydrogels are commonly used in a variety of biomedical applications, including as topical or oral drug formulations, injectable drug depots, in situ forming biomaterials, and contact lenses.[3-6] This class of materials is characterized by an ability to imbibe water or physiologic fluid in quantities which may be upwards of 1000 times the dry weight of the material.[6] Many common hydrogels are constructed from hydrophilic polymers which are held together by some type of crosslinking to yield a percolated network.[7] Of the different modes of crosslinking, chemical crosslinks are characterized by typically permanent, non-reversible covalent bonds between polymer chains. Meanwhile, physical crosslinks are characterized by transient and reversible interactions which give rise hydrogel networks often exhibiting these same dynamic properties.[8, 9] Regardless of the specific mode of crosslinking, the material comprising the hydrogel is itself rendered insoluble; this is in spite of its construction from highly soluble polymeric precursors as well as typically a high degree of favorable hydrogen bonding or ion-dipole interactions between water and the polymer backbone.

Due to their highly hydrated and porous architecture, these materials have been extensively explored for the encapsulation and controlled release of therapeutic drugs and proteins. Both small molecules and macromolecules can be modified with a range of chemistries that enable interaction with drugs, either through covalent linkages or non-covalent binding. The delivery of drugs can be controlled using strategies which leverage diffusion, swelling, and/or erosion-based release mechanisms.[10, 11] The soft and compliant mechanics of hydrogels, combined with their extensive hydration, enables uses in soft tissue regeneration as cell-supporting scaffolds which match the typical mechanics of native tissue and enable facile nutrient and waste transport.[12-14] These features are often enhanced by strategies to facilitate minimally invasive (e.g., syringe-injectable) administration through in situ gelation mechanisms or mechanically responsive and self-healing interactions.[15-18] In their applications for drug delivery, it may furthermore be desirable for these hydrogels to respond to environmental stimuli with changes in their chemical, microscopic, or bulk mechanical properties.[19-21]

The phenomenon of self-assembly, defined as the autonomous organization of components into patterns or structures without intervention, is a powerful tool to create a diversity of functional materials.[22-24] Examples from the living world support the many uses of self-assembly as a bio-inspired design tool.[25, 26] A variety of biomaterials have thus been designed to leverage self-assembly phenomena in their formation and stability.[27-29] While a subset of self-assembling biomaterials include specific motifs rooted in supramolecular chemistry which give rise to molecular-scale organization,[30] non-specific hydrophobic association is the prevailing underlying mechanism by which order is realized for self-assembly in a water environment. The use of hydrophobic association as a directive cue in the formation of self-assembled hydrogels is primarily an entropically driven phenomenon. Whereas the dispersal of typically non-polar hydrophobic building blocks may have long-range impact on the mobility and free orientation of bulk water molecules, the association of these same building blocks so as to limit the surface area available for unfavorable contact with the bulk water phase affords significant increase in solvent entropy.[31, 32] Hydrophobic domains within hydrogels can thus serve a dual role to both stabilize the network, while offering a favorable environment to solvate and sequester hydrophobic drugs. This same phenomenon underlies many structures in nature; the lipid bilayer of a cell forms a semi-permeable barrier through the association of long aliphatic tails and outward solvent presentation of polar/charged head-groups, while the native tertiary structures of many proteins arise spontaneously and reliably in part by preferentially concealing amino acids with non-polar side-chains. It is furthermore important to note that self-assembly is a dynamic and concentration-driven phenomenon. Accordingly, many building blocks which are designed to self-assemble exhibit concentration-dependent association, whereby assemblies arise above a critical concentration (e.g., a critical micellar concentration). Self-assembled building blocks also exhibit dynamic exchange between associated and free conformations, the nature of which is often tunable as a function of molecular design or environmental parameters such as temperature, pH, or osmolarity. Importantly, the spontaneous and non-covalent nature of self-assembly typically enables reversibility and “healing” of these interactions in response to a disruptive force.

Self-assembly is a useful tool for forming hydrogels. Utilizing self-assembly for the non-covalent organization of small molecules generates hydrogels which exhibit traits consistent with a physically crosslinked network. Namely, these materials form by reversible and dynamic associations of certain constituents, allowing the material to respond to mechanical forces by reorganizing to dissipate stress, and to self-heal in response to destructive mechanical insult. The transition from liquid to gel can be done using only chemical moieties found on native biomolecules, and doesn’t require unnatural functional groups. In certain cases, self-assembly drives formation of high aspect-ratio structures, which themselves can physically entangle and/or bundle to form hydrogel networks. Herein, a variety of different self-assembly strategies are discussed which have used molecular and/or macromolecular building blocks to create hydrogels for drug delivery. Routes based on molecular-scale self-assembly have been explored from both hydrophobic association and/or supramolecular interactions to yield hydrogels prepared from molecular or oligopeptides building blocks. Oligopeptides in particular offer opportunities to include enzyme-responsive functionality in their use for drug delivery. Macromolecular building blocks such as block (co)polymers and proteins have also been designed to self-assemble and form hydrogels through hydrophobic interactions, which in many cases are also supplemented by supramolecular or electrostatic interactions. For added control of properties, the covalent character of self-assembled materials can be subsequently modulated. One such route would seek to couple both self-assembled and covalent networks, wherein covalent bonding imbues a hydrogel with elasticity and resistance to permanent deformation, while dynamic non-covalent bonds increase hydrogel toughness and allow for energy dissipation within the material. With these many varied approaches, new materials have been realized which afford function as new tools for drug delivery as well as enable more accurate structural mimicry of viscoelastic biological matrices.

2. Self-Assembly of Low Molecular Weight Gelators

The controlled assembly of small molecules proceeds through non-covalent intermolecular interactions between adjacent molecules.[33] In many systems the concentration of a gelator is less than 10 milligrams per gram of water (<1% by weight).[34] A variety of intermolecular forces have been explored to drive association of molecules, and the balance of these interactions serves to not only dictate the properties of the assemblies but also their functional utility in the context of both sequestering and releasing bioactive molecules.

2.1. Motifs in Small-Molecule and Peptide Self-Assembly

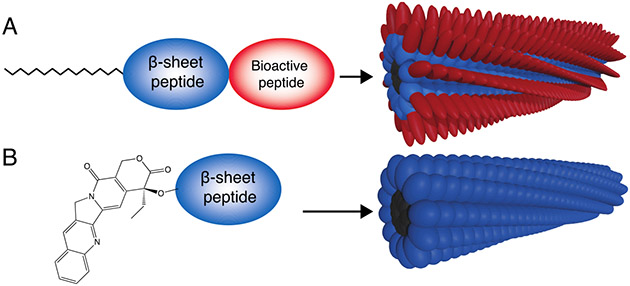

Small molecule self-assembly is often driven through the incorporation of groups which initiate hydrophobic association in aqueous environments and, in doing so, effectively reduce the entropic penalty entailed in adopting defined conformations (Figure 1).[35] Hydrophobic modification of peptides and other biomolecules is used in a native biological context to control their circulation half-life and localization.[36] Some of these moieties, such as palmitoyl groups, have been used to drive self-assembly of synthetic small molecules.[37] For instance, peptide amphiphiles are a class of supramolecular polymers in which an alkyl tail is appended to a peptide, giving rise to high aspect-ratio assemblies which form physically entangled hydrogel networks under physiological conditions.[37] Other hydrophobic moieties, such as fluorenylmethyloxycarbonyl (Fmoc) protecting groups common in peptide synthesis, can also be easily added to small molecules to induce self-assembly.[38] Finally, hydrophobic drugs may be covalently coupled to the peptide to induce hydrophobic collapse while also possessing therapeutic capabilities.[39]

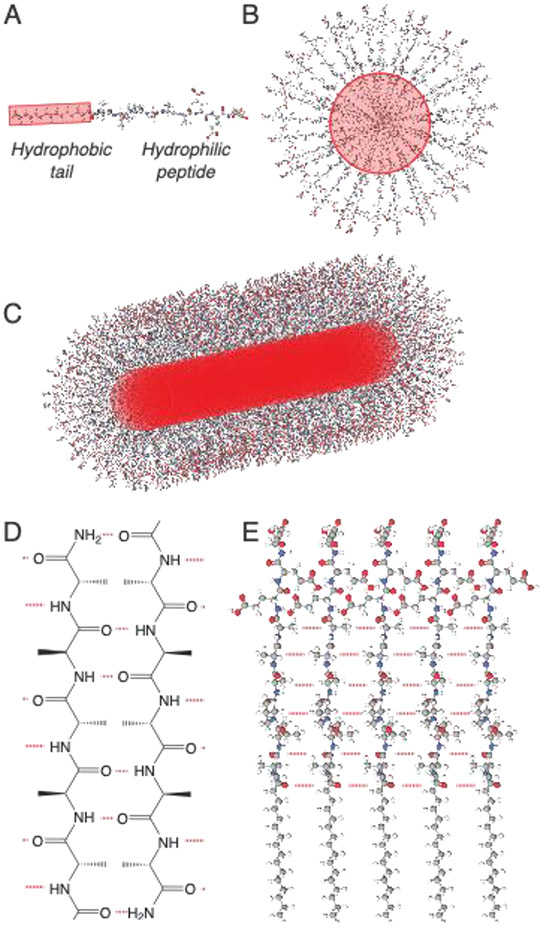

Figure 1:

(A) Non-polar motifs can be coupled to peptides to (B) drive self-assembly through hydrophobic association. (C) Directional non-covalent interactions between adjacent molecules, such as the formation of β-sheet hydrogen bonding networks, drives the formation of high-aspect ratio nanostructures. (D) Peptides can form ordered arrangements of hydrogen bonds (in red), most often resembling β-sheet secondary structures, by positioning adjacent proton donors and acceptors on their amide backbone. (E) Hydrogen bond networks drive axial organization are are a common driving force for the formation of high-aspect ratio nanostructures.

Beyond hydrophobic interactions, non-covalent hydrogen bonds, which typically form between a carbonyl group and a hydrogen coupled to either a nitrogen or oxygen, are also useful in driving self-assembly in an aqueous environment. Hydrogen bonding is especially prevalent in self-assembly arising from peptides due to the presence of hydrogen bond donors and acceptors in the peptide backbone (Figure 1D).[40] Unlike hydrophobic interactions, hydrogen bonds are directional and are often a primary driving force underlying the formation of high-aspect ratio structures from molecular self-assembly.[41] Fortunately, a common secondary structure found in proteins, the β-sheet, features extensive hydrogen bonding between adjacent strands. As such, β-sheet interactions are often incorporated into self-assembling peptides, serving to template axial assembly into high aspect-ratio structures (Figure 1E).[40, 42, 43]

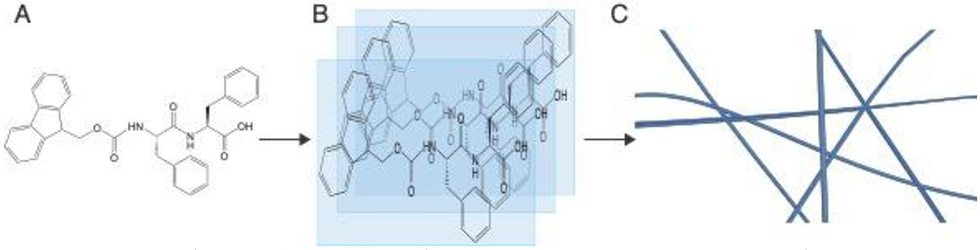

Another directional non-covalent force which is common in molecular self-assembly is the π-π stacking of aromatic groups. This special class of electrostatic interaction arises most commonly from conjugated ring structures which are hydrophobic, enabling these motifs to serve a dual role by both inducing hydrophobic association in water and driving axial assembly through stacking with adjacent moieties.[44] Aromaticity can be added through the use of specific amino acids, including phenylalanine,[45] as well as with non-peptidic motifs including Fmoc protecting groups,[38] to aromatic fluorophores,[46] and hydrophobic drugs (Figure 2).[39]

Figure 2:

(A) Peptides can be modified with hydrophobic aromatic groups both as terminal prosthetic groups and through the inclusion of aromatic amino acids like phenylalanine. (B) This design enables directional π-π stacking, (C) leading to axial organization and nanofibril formation.

Though many chemistries have been used to develop self-assembling small molecule gelators, peptides are pervasive in the use of such systems for drug delivery.[47] Peptides are composed of amino acids which offer both a diversity of chemical functionalities to drive self-assembly as well assembling the opportunity to encode biological functionality in the peptide sequence. For these reasons, peptides offer many advantages from a pharmaceutical, drug delivery, and biomaterials perspective. Peptides are also synthesized by economical automated methodologies to yield high purity products with minimal synthetic expertise required.[48] There are 20 canonical amino acids found in nature, yet solid-phase peptide synthesis is compatible with an array of non-natural amino acids and functional groups to enable stimuli-responsiveness or afford sites for specific bioconjugation.[49] The backbone of peptides contains repeating amides, each of which can participate in two hydrogen bonds, once as an acceptor and once as a donor. Interestingly, converting the amide bond to a urea increases backbone rigidity and hydrogen bond propensity and leads to a significant increase in mechanical properties of materials prepared from self-assembling peptide gelators.[50] While individual hydrogen bonds are weak, peptides offer a very high density of hydrogen bonds; proteinaceous materials in nature such as silk fibroin[51] and collagen[52] offer inspirational examples for the exceptional mechanical properties possible from hydrogen bonding of a peptide backbone.

Peptides undergo proteolytic degradation into their amino acid substituents; as these are already present in the body, degradation typically does not yield toxic side products. Many self-assembling peptides do not generate a significant immune response,[53] and are primarily excreted through kidney clearance.[54] Since proteins and peptides are involved in many natural biological processes, peptide-based biomaterials can be harnessed to recreate such functions through binding proteins or activating cell surface receptors.[55] Peptides are also the substrates for a variety of enzymes, including proteases which cleave specific peptide sequences,[56] or kinases which transfer phosphate groups to hydroxyl-containing amino acids.[57]

2.2. Mechanisms in Small-Molecule and Peptide Hydrogel Formation

Self-assembling molecules can undergo gelation, transitioning from a solution to a solid hydrogel. Early hydrogel theory described the behavior of highly hydrated covalently crosslinked polymer networks which do not flow once equilibrated.[58] Hydrogel networks featuring only covalent crosslinks are elastic and the mechanical properties are not typically dependent upon shear rate.[59] Non-covalent self-assembled hydrogels are both capable of flowing under high shear (e.g., shear-thinning) and generally have an observed storage modulus (stiffness) which is non-linear and increases with oscillatory frequency.[60] For these systems, rheological gelation is often defined as the point at which the measure of “elastic” portion of the modulus (G’, storage modulus) is greater than the viscous component (G”, loss modulus).[61] The specific values for storage and loss moduli will depend upon both the magnitude and frequency at which the strain is applied. However, a gel should have a storage modulus that is greater than the loss modulus for a range of frequencies relevant to biomedical applications, such as 0.1-100 Hz. Furthermore, the strain at which rheology is performed should be within the linear viscoelastic region to ensure mechanical properties of the hydrogel are not compromised during measurement.

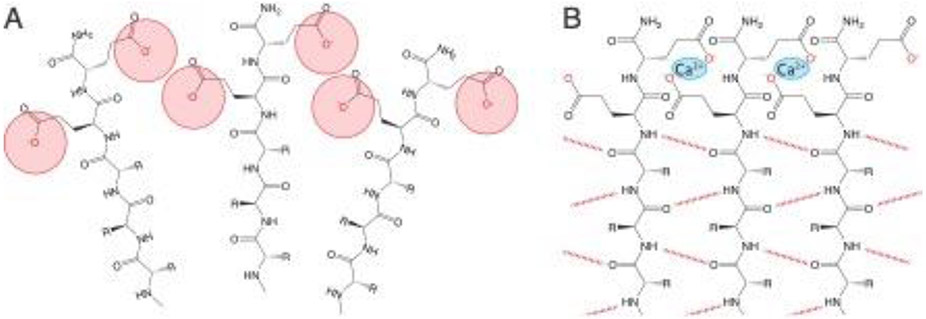

Hydrogels typically arise in molecular-scale self-assembly through one of two routes. In the first route, small molecules or oligomers transition into larger elongated aggregates known as supramolecular polymers which form entanglements and contribute to a network with elastic behavior.[62] The second route by which gelation is induced arises from an increase interactions between nanostructures which lead to an enhancement in the density of physical crosslinks and often drive increased nanostructure bundling.[63] In both of these gelation mechanisms, forces within and between self-assembled structures becomes more attractive (or less repulsive). Often, such a phenomenon is induced by modulating charge states, either by adjusting the pH or by adding counterions, such as calcium, to screen repulsive electrostatic interactions (Figure 3). Interactions between self-assembled nanostructures can be tuned at the molecular level through controlling surface charge,[64, 65] introducing host–guest interactions between fibers,[66] or adding multivalent binding groups to non-covalently crosslink multiple fibers simultaneously.[67]

Figure 3:

(A) Self-assembling peptides typically contain hydrophilic domains comprised of charged amino acids, leading to electrostatic repulsion which may disfavor self-assembly under physiological conditions. (B) These repulsive forces can be overcome to drive self-assembly and/or stabilize assembled nanostructures by changing pH or adding ions, like calcium, to screen and/or bridge charged groups.

The pH of the body is typically around 7.4, though there are regions where pH may be significantly higher or lower. pH can also be dependent on specific pathologies , as a hallmark of cancer is an increase in metabolic activity which can decrease the local pH below 7.0.[68] Accordingly, pH presents a useful and biologically relevant trigger to induce gelation. Molecules which are designed to be sensitive to a relevant pH change often present functional groups with pKa values near those of the physiological scenario where gelation is desired. The side-chain of the amino acid histidine, for example, is mostly uncharged at physiological pH, but becomes positively charge as pH drops below 6. This has been used to induce a transition from sheet-like nanostructures at pH 4.5 to short, twisted fibers at pH 7.4.[69] Another key challenge in drug delivery arises in transitioning therapeutic payloads from the extracellular space into the cytoplasm, and this often requires escape from an endosome/lysosome.[70] In one example, a β-sheet forming peptide coupled to an oligoarginine was designed to be in an unassembled monomeric state at pH 7 but form nanostructures in the acidic pH of the lysosome to promote intracellular escape.[71]

2.3. Controlling Hydrogel Properties in Self-Assembling Peptides

Self-assembly results from a balance of both attractive and repulsive intermolecular forces. Amphiphilic molecules that lack axial directives such as hydrogen bonding or π-π stacking will form a variety of nanostructures, from spherical micelles to sheets, depending on the ratio of their hydrophilic and hydrophobic components.[72] For most systems, the nanostructure will depend upon the molecular architecture and composition of the molecule. The alkyl tails on peptide amphiphiles are capable of crystallizing within nanostructures,[73] which promotes the formation planar structures, while β-sheets are naturally curved,[74] and have a propensity to form cylindrical micelles. Supramolecular peptide assemblies prepared from shorter peptide domains are more likely to form flat or belt-like structures,[75, 76] while those with longer β-sheet sequences typically form cylindrical micelles.[73]

The structure of amphiphilic peptide gelators can also be tuned by modifying the length and order of amino acids in the β-sheet domain, while keeping the composition the same. Since β-sheets are naturally curved, molecules with a higher propensity to form β-sheets typically result in cylindrical assemblies in which the β-sheets twist around a central axis, while those in which the β-sheet domains are weaker form flat structures.[77-79] The resulting nanostructure has also been controlled through incorporation of multiple hydrophobic components within a single nanostructure. This approach has been utilized in peptide-drug conjugates, for example by placing between 1-4 camptothecin groups per molecule as a way to both modulate the drug loading capacity and afford control of nanostructure from filaments, to fibers, to tubes.[80] In self-assembling systems which don’t rely on hydrophobic domains, hierarchical structures can form in which the twisted β-sheets stack to form high aspect-ratio fibers.[81] While most self-assembled structures form on the nanometer length scale, a challenge in the field of biomaterials is to recapitulate the function of human tissues which have structures organized across multiple length scales.[82, 83] Heating peptide amphiphile solutions can lead to the formation of highly aligned monodomain gels by strengthening β-sheet interactions and inducing liquid-crystalline behavior and nanostructure bundling;[84] these massively aligned fibrillar hydrogels are able to guide the growth of encapsulated neurons.[85]

A benefit of using peptides is that the common β-sheet secondary structures offers extensive intermolecular hydrogen bonding between adjacent strands. As a result, many self-assembled peptide systems have rheological properties that are surprisingly stiff, with storage moduli that can exceed 100 kPa for gels that are less than 2% peptide by weight.[73] This affords a variety of different features which can be tailored to modify the mechanical properties of hydrogels arising from self-assembled peptide materials. The control of self-assembled structures can lead to a diversity of morphologies which can then influence the mechanical properties of a material,[86] its cellular or biologic response,[87] or even its in vivo circulation time.[88] Even within a specific morphology, the mechanical properties can be tuned through molecular design. The number of hydrogen bonds between peptides will largely depend upon the length of the peptide sequence, with each additional amino acid being capable of providing two hydrogen bonds (Figure 5). The β-sheets themselves can have varying degrees of twisting within nanostructures, which can lead to sub-optimal hydrogen bond distances and hydrogels with lower storage moduli.[73] In another example, native chemical ligation has been used to form covalent bonds between self-assembling peptides in situ, leading to a five-fold increase in hydrogel stiffness.[89] Independent of added bioactivity, self-assembled hydrogels exhibit “plug flow” which shields cells from shear forces experienced during injection or other high-shear operations, improving cell viability.

Figure 5:

Self-assembled nanostructures are able to sequester drugs through (A) encapsulation due to hydrophobic partitioning or (B) covalent conjugation to the peptide sequence.

2.4. Peptide Self-Assembly in Drug Delivery

Among the simplest ways to endow self-assembling peptide materials with therapeutic action is to use peptide sequences which can signal cells (Figure 4A). Supramolecular peptide hydrogels can thus be modified with amino acid sequences that improve cell adhesion,[90-93] mimic growth factors,[94, 95] selectively differentiate stem cells,[96] inhibit angiogenesis,[97] act as an immune adjuvant,[98] bind growth factors,[99] or provide anti-inflammatory signals.[100] The process of making materials via self-assembly affords an added benefit of co-assembling multiple bioactive peptides into a single nanofiber,[101, 102] while the spacing of these presented cues can be controlled to improve selectivity in binding to cell-surface proteins.[103] Peptide self-assembly has been used to present epitopes at defined density to tune both T-cell response[104] and humoral antibody response.[105] The surface of peptide nanofibers can also be conjugated to full length protein antigens.[106]

Figure 4:

Bioactivity can be incorporated into self-assembled hydrogels by (A) the addition of cell-signaling peptides on the exterior of nanostructures or (B) the inclusion of binding sequences for bioactive proteins.

Protein-mimetic oligopeptide sequences typically have inferior binding compared to the use of full-length proteins.[107] However, supramolecular systems can compensate for this effect by leveraging polyvalent ligand display with tunable and high density.[91, 103] The presentation of bioactive sequences on an assembled nanostructure, which dictates the efficiency of binding, can also be controlled by changing of the length and flexibility of the linker.[108] Ligand concentration and orientation are thus tunable parameters that can control cell signaling.[109]

The hydrophobic domains present in many self-assembled peptides can serve a dual role by both inducing self-assembly and acting to solubilize and/or sequester hydrophobic drugs (Figure 5A).[110] Compared to direct drug conjugation, this approach is compatible with the delivery of unmodified drugs and does not require the drug possess specific chemical groups amenable to functionalization. The chemotherapeutic camptothecin has been loaded into self-assembling peptides, where the nanofiber-encapsulated drug was found to inhibit tumor growth.[111] Low molecular weight peptide gelators featuring Fmoc protecting groups and a single phenylalanine were used to deliver the non steroidal anti-inflammatory drug diclofenac.[112] Self-assembling peptides that do not contain hydrophobic protecting groups, such as the β-hairpin peptide assemblies, have also been used as injectable depots for the delivery of hydrophobic drugs like curcumin.[113] More recently, multifunctional delivery systems have been reported, for example by encapsulating the anti-cancer drug paclitaxel in the interior of nanofibers while presenting cell-targeting sequences on the periphery of the assembly.[114]

Non-covalent encapsulation of drugs within self-assembled peptides via hydrophobic partitioning has challenges in terms of encapsulation of drug and leakage once introduced to the body, where the drug may be just as likely to partition into other hydrophobic regions.[115] Covalently coupling a drug to the gelator provides a useful way to obtain consistent loading and ensure that the drug remains stably encapsulated in the self-assembled delivery material (Figure 5B). Gelator design is a crucial feature in this regard, as the release of a hydrolyzable drug from a peptide assembly was found to be dependent on the location within the nanostructure in which the drug was tethered.[116] The loading efficiency is also readily tuned through controlling the number of drugs coupled per molecule. Self-assembling nanofibers have been made from gelators with up to four camptothecin units per monomer.[117] This general strategy to design self-assembling systems which contain drugs as explicit components of their design has been termed as “one component nanomedicine.”[118]

The percolated mesh arising from self-assembled nanostructures can also be used for controlled release of encapsulated proteins or other macromolecular payloads. For instance, a hydrogel explored for the repair of periodontal bone defects released was designed to release both stromal cell derived factor-1 (SDF-1) to attract stem cells and bone morphogenetic protein 2 (BMP-2) to differentiate these cells into osteoblasts.[119] Generally, the hydrogels which arise from peptide self-assembly are capable of tunable protein release, with rates controlled by varying the concentration of the hydrogel.[120] An alternate route to the controlled release of biological drugs has sought to present binding sequences on the surface of assemblies. This approach can be tailored towards a specific biomedical application, and binding sequences have been explored for active agents including BMP-2,[121] fibroblast growth factor (FGF),[122] and transforming growth factor beta-2 (TGF-β2).[123] These bioactive factors do not have to directly bind to a signal presented directly on the assembly, as several designs have utilized an intermediate tether to simultaneously bind both the self-assembling peptide and the molecule of interest. For instance, tetravalent streptavidin can bind biotin molecules presented from a self-assembled nanostructure and appended to biomolecules.[124] Many biomolecules of interest have native binding sites for biopolymers, like heparin. Accordingly, nanofibers have been designed to bind heparin, which can then in turn bind growth factors including vascular endothelial growth factor (VEGF) and FGF for their prolonged release from a hydrogel.[125-127] Release systems have also been designed in which proteins are covalently tethered to self-assembling peptide, which can be fabricated into gradients within the hydrogel.[128]

2.5. Stimuli-Responsive Self-Assembly for Drug Delivery

The delivery of active therapeutics often leverages pharmacologically inactive prodrugs with sensitivity to a particular stimulus in order to trigger therapeutic activation at the desired site of drug action.[129] The mechanism by which this transformation occurs depends on the linkage used, with the availability of such linkages dependent on the presence of certain functional groups on the therapeutic, and require specific conditions to cleave this covalent bond. For instance, pH responsive linkers have been incorporated to release drugs at acidic pH in several systems.[130] Disulfide bonds are also common in prodrug designs, since this bond is stable in the extracellular space, but is ruptured through disulfide reduction in the cytoplasm due to millimolar quantities of glutathione.[131] Reduction-sensitive bonds have thus been used in a variety of self-assembled delivery systems wherein cleavage of the disulfide bond induces disassembly of the hydrogel or coverts a pro-drug to the active form upon internalization into the cell.[80, 132, 133]

A key goal of drug delivery is to increase the targeting specificity to desired cells or tissues within the heterogenous body environment. Targeted cells may differ in many features, including size, shape, metabolic rate, and/or protein expression. Enzyme expression is particularly useful as a trigger for drug delivery as enzymes-catalyze chemical reactions can be utilized to locally release bioactive payloads or convert non-active molecules to active drugs.[134] Enzymes catalyze a range of reactions, many of which have been used to both convert a pro-drug to its active form, as well as modulate the properties of the self-assembled systems. In one example ascorbyl palmitate, which is generally regarded as safe (GRAS) by the FDA, forms self-assembled hydrogels in which the corticosteroid dexamethasone can be loaded.[135] These gels are degraded by enzymes released as part of inflammatory bowel disease, locally releasing the drug to reduce inflammation. Esterases have been leveraged as the target stimuli to release the non-steroidal anti-inflammatory drug naproxen from self-assembling peptide amphiphile nanofibers.[136]

2.6. Enzyme-Responsive Self-Assembly for Drug Delivery

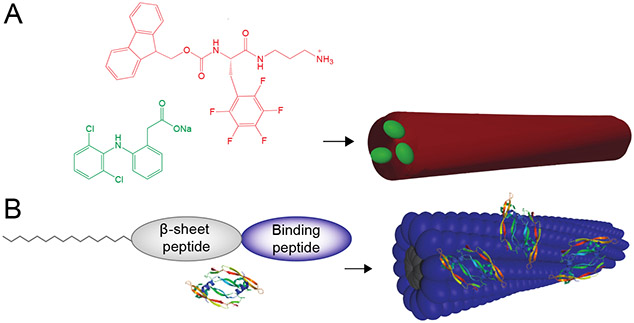

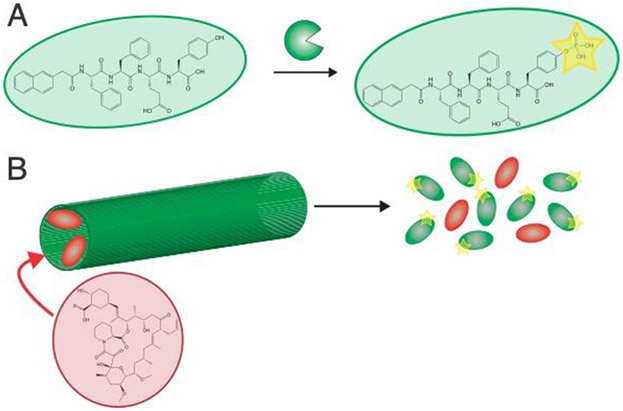

A benefit of molecular self-assembly is that modification at a single site can trigger significant nanostructural transformations. Enzyme-induced self-assembly (EISA) often utilizes phosphatases in their role as biological catalysts to convert charged phosphate-containing amino acids to uncharged alcohols.[137] Drug-containing low molecular weight gelators have the added benefit that enzymatic catalysis rates can depend upon the self-assembled structure, with molecules in the assembled state being shielded from enzymatic activity.[138] Self-assembling peptide systems have therefore been designed as substrates for both phosphates and kinases, which convert alcohols to phosphates. These systems undergo enzyme-reversible sol-gel transformations in the presence of physiologically relevant enzymes.[139] One phosphatase, alkaline phosphatase (ALP), has also been used to simultaneously trigger gelation and induce chemiluminescence in a dual-responsive system.[140] Immune cell-secreted protein tyrosine kinase (PTK) has also been used to locally deliver tacrolimus, a drug used to prevent organ rejection after transplantation (Figure 6).[141]

Figure 6:

(A) Self-assembling peptides can be designed as substrates for cell-secreted enzymes such as kinases, (B) which enables these enzymes to be cues for disassembly and drug release from peptide-based carriers. This figure illustrates concepts from reference 129.

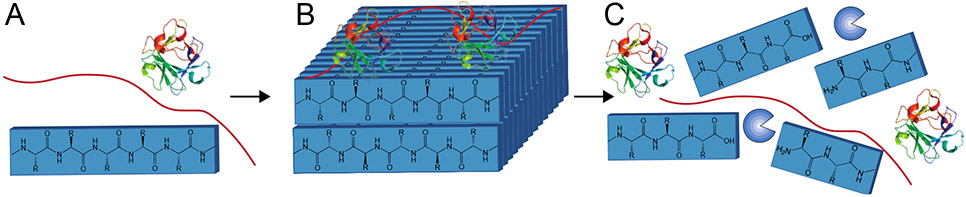

Proteases are subset of enzymes that cleave peptide bonds and constitute a class with over 580 members.[56] These proteins play important roles in many physiological processes, including cell migration,[142] tissue regeneration,[143] and cancer progression.[144] MMP-2, for example, is over-expressed in a variety of cancers,[145] and peptide sequences containing MMP-2 substrates have been incorporated into several self-assembling peptide systems to afford either proteolytically induced degradation[146, 147] or conversion from high aspect-ratio nanofibers into micelles.[87] The rate at which proteases hydrolyze peptide bonds depends on the peptide sequence, and incorporating specific peptides can both dictate the proteases which cleave the sequence and tune the degradation rate.[148] Supramolecular chemistry offers another level of control, as using the same sequence in different self-assembled geometries significantly influences enzyme kinetics.[149, 150] Proteolytic degradation of MMP-2 sensitive peptide have been used to deliver the chemotherapeutic agents cisplatin,[151] paclitaxel,[152] and release growth factors to improve the regeneration of dental tissue (Figure 7).[153] Interestingly, the enzyme enteropeptidase has been used to remove a branch from a self-assembling peptide which converts the self-assembled structure from spherical micelles to a nanofibrillar hydrogel.[154] A challenge in using protease-sensitive linkers to covalently couple drugs to self-assembling moieties is that most substrate sequences will leave some amino acids attached the drug after cleavage. To overcome this challenge and realize the release of the authentic and unmodified drugs, self-immolative linkers have been developed such that a proteolytic cleavage initializes a reaction which releases a drug coupled to the molecule by a primary amine.[155] For example, a tri-phenylalanine peptide gelator was designed with a boronic acid-phenyl group on the N-terminus such that removal of the boronic acid from the aromatic ring by hydrogen peroxide cleaved the phenyl ester from the N-terminus, leading to dissolution of the hydrogel.[156] Hydrogen peroxide can be generated in situ with localized glucose oxidase such that these hydrogels disassemble in the presence of glucose.

Figure 7:

(A) Self-assembling peptides can be mixed with biopolymers and biopolymer-binding growth factors. (B) Self-assembly of these components creates protein-loaded nanofibrous hydrogels. (C) These peptides contain a substrate for MMP-2, with this protease promoting hydrogel degradation and growth factor release. This figure illustrates concepts from reference 138.

3. Self-Assembly of Macromolecular Gelators

Macromolecules, typically consisting of polymeric or biopolymeric constructs, offer an alternate design paradigm by which to achieve self-assembling building blocks for the creation of hydrogels. The design space for macromolecular gelators is quite broad and largely under-explored, owing to the plethora of synthetic approaches and commercially available reagents for polymerization, as well as a variety of bio-derived or bio-inspired sources of natural biopolymeric materials. Herein, we describe generally the creation and use of hydrogels based on self-assembling macromolecules for various possible applications in drug delivery.

3.1. Mechanisms and Motifs in Synthetic Polymer Self-Assembly

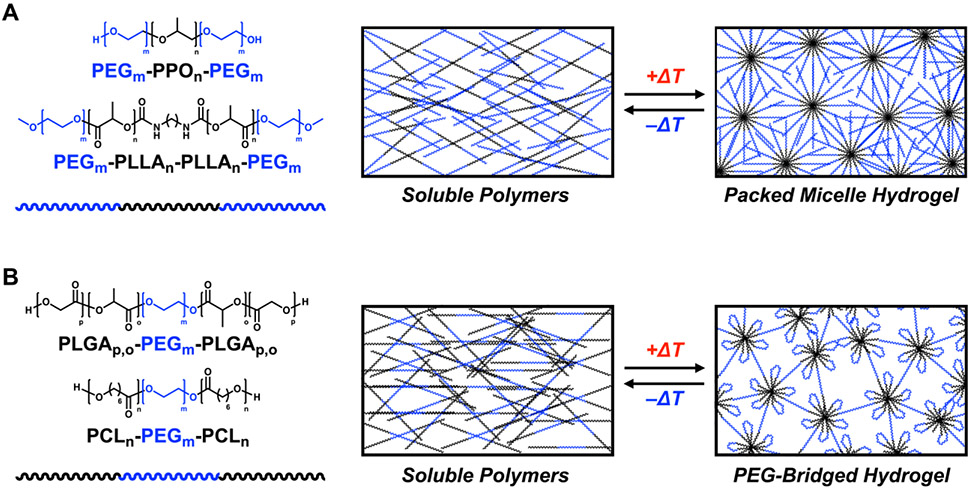

While various synthetic polymers have been explored for the design of self-assembled materials (e.g., micelles) and hydrogels, the majority fall into the category of block copolymers which bear hydrophilic and hydrophobic blocks.[157-163] A prevailing class of block copolymers with a long history of biomedical and pharmaceutical use is poly(ethylene glycol)-b-poly(propylene oxide)-b-poly(ethylene glycol) triblock copolymers (PEG-PPO-PEG), marketed as Pluronic® or Poloxamer® surfactants (Figure 10A).[164, 165] Different variations of PEG-PPO-PEG copolymers are used for an assortment of biomedical applications including as solubility enhancers or as stabilizers for protein drugs, earning these a place on the US FDA GRAS list for their role as excipients. A key benefit of PEG-PPO-PEG materials is temperature-dependent micelle formation, with the PPO mid-block desolvating and transitioning from hydrophilic to hydrophobic at temperatures experienced when traversing a transition from ambient to physiologic conditions.[166, 167] Above a critical concentration of ~15-20 wt% in water, these thermally induced micelles can pack to form hydrogel networks (Figure 8A).[168, 169] At lower concentrations, these micelles can still be induced to form temperature-responsive hydrogels by synthetic end-modification with recognition motifs to facilitate micelle crosslinking.[170, 171] Pluronics have been modified with a variety of polymer functionalizations to control both their thermoresponsive behavior and drug release. Poly(PEG/PPG/PCL urethane) materials were shown to have thermogelling behavior above 3 wt% and sustain paclitaxel delivery for several weeks.[172] Other modifications, including poly(polytetrahydrofuran carbonate) blocks[173] and polyhedral oligomeric silsesquioxane (POSS) blocks[174] indicate that pluronic-based hydrogels are a robust platform whose properties can be tailored with a variety of polymer chemistries.

Figure 10:

Hydrogel networks with coupled covalent and non-covalent interactions have exceptional mechanical properties, including stretchability and fracture toughness. Figure based on concepts from reference 352.

Figure 8:

(A) Example of thermoresponsive ABA block copolymer gelators which feature two hydrophilic PEG blocks flanking a midblock prepared from a polymer which transitions to hydrophobic according to a temperature stimulus. Shown are the structures of PEG-PPO-PEG and PEG-PLLA-PEG copolymers. These polymers transition from a soluble sol state to a hydrogel state characterized by packed micelle structures. (B) Example of thermoresponsive BAB block copolymer gelators which feature a PEG midblock flanked by two blocks prepared from a polymer which transitions to hydrophobic according to a temperature stimulus. Shown are the structures of PLGA-PEG-PLGA and PCL-PEG-PCL copolymers. These copolymers transition from a soluble sol state to a hydrogel state characterized by self-associating aggregates of the ‘A’ blocks which are bridged by soluble PEG chains.

A related family of block copolymers explored for hydrogel formation and drug delivery are PEG/polyesters, and like with the Pluronics these materials also frequently take the form of an ABA triblock copolymer (Figure 8A).[175] Early work on self-assembling hydrogel variants of these materials for uses in drug delivery explored diblock and triblock copolymers prepared from a hydrophilic PEO block and a hydrophobic poly-L-lactic acid (PLLA) block.[176] Unlike with the Pluronics, these PEG-PLLA copolymers are a sol at an elevated temperatures of 45°C where they can be loaded with drug, and immediately gel upon introduction into the reduced temperature of the body. Features of this system, including the balance and lengths of the PEG and PLLA blocks and the hydrophobicity of the hydrophobic polyester block were found to be useful parameters to tune the sol-gel transition temperature.[177, 178] A similar design replacing the polyester mid-block with polylactide (PLA) has been shown,[179] along with others replacing the hydrophobic mid-block with poly(D,L-lactide-co-glycolide) (PLGA).[180] The hydrophobic block can also be comprised of poly(ε-caprolactone) (PCL) which can be combined with PEG to form diblock or PEG-PCL-PEG triblock copolymers.[181-183] In each of these systems, gelation arises from close packing of micelles which assemble due to temperature-governed hydrophobicity of the polyester mid-blocks upon heating, with some variations even able to achieve a sol-gel transition upon reaching body temperature. Self-assembling PEG/polyester diblock copolymer hydrogels, which typically arise from packing of PEG-coated micelles, have also been extensively explored for applications in drug delivery.[184, 185]

Another PEG/polyester block copolymer motif has explored BAB triblock designs where instead two hydrophobic blocks flank a hydrophilic PEO mid-block (Figure 8B). Designs based on this general motif include PLGA-PEG-PLGA triblocks.[186, 187] This motif self-assembles via the formation of close-packed bridged micelles upon temperature-induced increase in hydrophobicity of the PLGA blocks, with associated PLGA chains forming the micelle core and PEG mid-blocks bridging these aggregates to form a network. The PLGA-PEG-PLGA design results in hydrogel formation which is very sensitive to the chemistry of the terminal groups (e.g., hydroxyl, acetyl, propionate, or butanoyl) on the PLGA blocks.[188] PLGA-PEG-PLGA hydrogelation is also sensitive to the block ratio, and mixtures of copolymers with different blocks can be prepared to control the gelation temperature.[189] These systems also exhibit gelation which which can be controlled by stereocomplexation of triblocks prepared from different enantiomeric hydrophobic blocks.[190] PCL-PEG-PCL triblocks have also been reported to form thermo-sensitive hydrogels.[191] In this case, the design based on PCL-PEG-PCL results in ~100x increase in the storage modulus (G’) of the hydrogels compared to PEG-PCL-PEG designs due to the altered network topology which arises from intra-micellar association of PCL end blocks and micelle bridging by PEG chains.[182, 191]

Polymers based on poly(N-isopropylacrylamide) (NIPAAm) constitute another commonly explored class of synthetic polymeric materials which have been used to create hydrogels via temperature-induced self-assembly.[192] This polymer has a particularly well-defined lower critical solution temperature (LCST) wherein it undergoes a hydrophilic to hydrophobic transition upon heating from (nominally) ambient to physiologic temperatures, though the precise transition temperature can be tuned by copolymerization and control of polymer molecular weight.[193] Accordingly, this polymer has been routinely used for numerous biomedical applications as a component of thermosensitive materials and coatings.[194, 195] Though a majority of uses for NIPAAm have explored this moiety within crosslinked polymer networks to afford temperature-responsive swelling, systems arising from self-assembly have also been reported. For example, copolymerization of NIPAAm with acrylic acid monomers succeeded in fusing hydrophilic carboxylate groups with NIPAAM to achieve thermoresponsive hydrogels via physical entanglements of aggregated structures above the LCST.[196] Subsequent work instead copolymerized NIPAAm with propylacrylic acid and enabled pH-responsive gelation owing to the elevated pKa for the propylacrylic acid sidechain relative to acrylic acid.[197]

Self-assembled hydrogels have also been prepared via interactions between synthetic polymers and colloidal particles, as well as from electrostatic interactions among networks of colloidal particles themselves.[198-201] Many examples in this class have relied on inorganic nanoparticles which either interact with other similar colloids to form networks or are fused by surface-adsorbed polymers bridging multiple colloids; the reader is encouraged to also explore this body of literature. In the specific context of amphiphilic macromolecules which self-assemble in water, a class of polymer-colloid materials has been created from PEG-PLA block co-polymer assemblies through interaction with surface-adsorbed hydrophobically modified polymers.[202] In this system, crosslinking of PEG-PLA assemblies by bridging of a modified cellulose polymer requires a strong interaction greater than or equal to that of thermal fluctuation (i.e., kT), while the creation of a percolated network requires polymer persistence length in excess of the particle diameter to enable the polymer to bridge ≥2 particles rather than wrapping around a single particle. The hydrophobic association in this system can be replaced with electrostatic associations between polymer and PEG-PLA colloid to also achieve a hydrogel.[203] A related class of materials has been created from cylodextrin-mediated bridging of PEG-PLA diblock co-polymer assemblies.[204]

A broad array of hydrogels have also been prepared from ordered supramolecular interactions and crosslinking within hydrogel networks.[8, 9] Supramolecular interactions of this sort form spontaneously, driven by a mixture of hydrophobic interactions, hydrogen bonding, and ion-dipole interactions. Synthetic polymers can thus be designed to present supramolecular motifs to facilitate dynamic associations which serve to crosslink a percolated hydrogel network. The nature of these supramolecular interactions means that they are equilibrium-governed, concentration-driven, and temperature-dependent and can furthermore be engineered to respond to a variety of stimuli.[205-208] Thus, when these motifs are present at concentrations around or above the KD for the motif being used, the spontaneous organization of these motifs yields a dynamic physical crosslink that can give rise to a hydrogel network. For example, multi-arm PEG macromers and other synthetic polymers have been modified with macrocyclic host molecules and their corresponding guests to form dynamic points of crosslinking in a hydrogel.[209-217] Similarly, multi-dentate hydrogen bonding motifs which form complementary or self-complementary interactions can also be incorporated within a synthetic polymer backbone or at its termini to facilitate crosslinking via motif dimerization.[218] The design of such polymeric materials from a varied and extensive number of supramolecular motifs could be the topic of its own review of this sort; the reader is encouraged to explore the number of reviews cited herein for more detailed discussion of supramolecular hydrogels prepared from synthetic polymers and specifically designed recognition motifs.

3.2. Drug Delivery from Synthetic Macromolecular Hydrogels

There are specific considerations for this class of synthetic macromolecular materials which are important to keep in mind when envisioning their use in drug delivery applications. It has been thought desirable to use designs which afford in situ gelation for ease of injection-based administration; this avoids the high pressure or large needle required to extrude a pre-formed hydrogel through a syringe. In this regard, temperature, pH, or osmolarity are useful triggers to promote a rapid hydrophobic transition once the polymer is introduced into the body.[163] The kinetics of gelation for an in situ triggered process introduce risk of a burst release if the delivered payload is not encapsulated quickly enough by the hydrogelation event. In the case where hydrogelation is triggered upon delivery to the body, the often high molecular weight of many macromolecular precursors may still present a high viscosity sol which may prove difficult to integrate with facile injection-based administration. Finally, wherein small molecule gelators afford a discrete molecular entity, synthetic polymeric building blocks are characterized by some degree of molecular weight dispersity which can lead to batch-dependent variability and may complicate regulatory approval in terms of the thorough characterization required for both the desired polymer and its degradation products.

There are many examples of synthetic block-copolymer hydrogels for applications in drug delivery. The Pluronic/Poloxamer class of block copolymers has seen extensive use in the context of drug delivery applications.[219, 220] While in their more dilute form these polymers serve the role of excipients to stabilize and solubilize pharmaceutical and biopharmaceutical agents, gels prepared from these materials have also been explored. Applications have included the use of injectable thermosensitive hydrogels for localized release of bioactive proteins from within the hydrated polymer mesh of the hydrogel,[221, 222] as well as release of hydrophobic antibiotic and chemotherapeutic drugs from within hydrophobic micellar cores of the hydrogel network.[223-225] The rapid formation of these gels upon introduction in the body has also been explored clinically, for example, using and FDA-approved Poloxamer-407 gel marketed as LeGoo® to achieve rapid clampless vascular occlusion during surgery.[226] Variants of these materials have shown bioactivity on their own; Vepoloxamer is a purified Poloxamer-188 which has been explored for a variety of clinical applications due to its anti-inflammatory and cytoprotective function resulting from native activation of tissue plasminogen.[227] Materials based on dynamic crosslinking of Pluronic micelles also have been used as easily injectable hydrogel depots which can encapsulate a payload of interest for controlled release,[171] or alternatively localize systemically administered small molecule drugs to the hydrogel site through drug affinity for a presented macrocycle.[170]

Hydrogels prepared from PEG/polyester ABA block copolymers have also been extensively explored for applications in drug delivery.[228] PEG-PLGA-PEG has been shown to be a useful hydrogel depot for controlled release, persisting for a tunable timeframe of up to 2 months upon subcutaneous injection.[229, 230] As an injectable depot, the release of both small molecule drugs and larger therapeutic proteins has been explored,[231] with the controlled delivery of TGF-β demonstrating enhanced wound healing.[232] The delivery of plasmid DNA has also been explored with this thermoresponsive hydrogel platform.[233] Compared to Pluronic hydrogels, which typically exhibit short tissue retention and rapid clearance, technology based on PEG-PLGA-PEG offers a more sustained presence in tissue.[234] Systems based on PLGA-PEG-PLGA and related BAB polyesters have also been used to deliver a variety of small molecule and protein drugs, with these systems typically encapsulating a hydrophobic drug within the associated its phase and proteins within its hydrated mesh.[235-238] One particular example of clinical use is found in a product, OngoGel™, which was explored in clinical trials for the delivery of paclitaxel to inoperable solid tumors.[239]

Hydrogels prepared from polymer-mediated crosslinking of self-assembled PEG-PLA diblock copolymers have likewise been explored for drug delivery applications. Multi-modal drug release is possible from such a system, wherein a protein encapsulated within the hydrophilic mesh and a small molecule encapsulated within the PLA core can be simultaneously released with differential rates.[202] The polymers used to create these nanoparticle assemblies can also be varied to control release rate of encapsulated therapeutics.[240] These materials have been explored for applications as shear-thinning supports for injectable delivery of cells in tissue engineering applications,[241-243] as well being applied to tissue in order to prevent pericardial adhesions following surgical intervention.[244] Recent work has furthermore explored the release of chemotactic proteins and immune-stimulating adjuvants for applications in immune cell recruitment and vaccination.[245-248]

Hydrogels formed through spontaneous recognition of supramolecular motifs appended from synthetic polymers also offer a useful approach to the creation of injectable biomaterials and drug delivery devices.[249, 250] These materials afford three-dimensional networks which can encapsulate and control the release of bioactive macromolecules, with the porosity offering a size-selective control over release.[251] The nature of these dynamic supramolecular recognition groups may themselves give rise to specific function, with the release of an encapsulated model macromolecule therapeutic and the rate of immune cell infiltration following injection both dictated by the dynamics of supramolecular crosslink exchange in these materials.[215] Likewise, the dynamic and reversible formation of supramolecular interactions enables synthetic hydrogels to be injected by minimally invasive catheter delivery into deep tissue sites such as the myocardium, where interactions can rapidly self-heal to afford tissue retention and controlled release for bioactive signals encapsulated within the gel.[252-255]

3.3. Mechanisms and Motifs in Biomacromolecular Self-Assembly

Nature achieve remarkable structure and concomitant function through organized assemblies of biological macromolecules. Proteins constitute a prime example of self-assembling building blocks found in nature, underlying both structure and function in the formation of extracellular matrices and cytoskeletal components. In this regard, naturally sourced collagen is one of the most commonly explored biomacromolecular hydrogels for applications in tissue engineering and drug delivery.[256] Type-1 collagen has a primary sequence that consists predominantly of tripeptide repeats of Proline–Hydroxyproline–Glycine, enabling the extended chains to present an interface which can register with two other primary sequences to form triple-helical bundles.[257] Isolates of native type-1 collagen also self-assemble into triple-helical fibrils which further bundle to form long fibers of 12-120 nm in diameter and which then entangle to form a physically crosslinked hydrogel network upon heating. This gel formation is typically irreversible on relevant timescales with temperature cycling. However, thermoresponsive collagen hydrogels can be realized by methacrylation of lysine side-chains in the protein to enable hydrogels which form at physiological temperatures and revert to a sol upon cooling.[258] Efforts to engineer synthetic replicates of collagen structures from synthesized or recombinant building blocks have likewise been explored for the creation collagen-mimetic assemblies which can give rise to self-assembled fibrils that bundle to form hydrogels.[259, 260]

Silk is another self-assembling protein which has been extensively explored as hydrogels for biomedical applications.[261, 262] Silk is typically derived from the cocoons of the Bombyx mori silkworm, though spider silk and recombinant silk proteins have also been explored. Like with collagen, silk also arises from primary chains with significantly repeating amino acid sequences which encodes efficient β-sheet formation between chains.[263] These β-sheets form highly aligned domains yielding a crystalline character which contributes to silk having a remarkable combination of strength and toughness.[264] The crystalline nature of these β-sheet assemblies makes silk typically insoluble in water, and thus the process of making hydrogels from silk protein extracts can be challenging. However, with control over the concentration, temperature, pH, and osmolarity of silk processing, hydrogels can be realized by enabling the random coil to β-sheet transition in the protein to be controlled.[265, 266] The high stability and crystallinity of the β-sheets which underly the structure of silk lead to self-assembled hydrogels which have effectively irreversible formation.

Elastin inspires another class of biopolymer-based materials which have been used to form self-assembling materials and hydrogels for biomedical applications.[267, 268] Elastin-like polypeptides (ELPs) consist of pentapeptide repeats of Valine–Proline–Glycine–X–Glycine, where X is a guest residue that can be any amino acid other than proline. ELPs undergo an inverse temperature phase transition, similar to that described above for NIPAAm, transitioning from a soluble state to a water-excluding coacervate phase upon heating.[269] This transition temperature can be tuned by varying the guest residue, controlling the chain length, varying concentration, or altering the concentration or identity of ion species.[270] The creation of ELP diblock copolymers by altering the guest residue in each block can be used to vary the transition temperature in each block to afford micelle assemblies.[271] While most uses of ELPs have explored their temperature transition in the context of chemically crosslinked networks, uncrosslinked ELPs can also form networks with rheological properties similar to a collagen hydrogel upon reversible hydrophobic association arising above its transition temperature.[272]

Other bio-inspired materials have been explored in a similar context. For example, natural resilin is found in specialized compartments of most arthropods and gives rise to rubber-like properties of low stiffness, high resilience and effective energy storage; this has likewise motivated exploration of polypeptide hydrogels possessing similar properties.[273] Several works have also evaluated hybrid engineered proteins consisting of multiple different naturally inspired motifs. For example, multistimuli-responsive hydrogels can be realized from silk-elastin-like polypeptides, coupling the thermal sensitivity of elastin motifs to induce association of the polypeptides with the β-sheet propensity of silk motifs to stabilize these assemblies and resist phase separation.[274-277] Recombinant silk-collagen hybrids have also been explored which couple the self-association of each motif to yield hydrogels.[278, 279] Another class of protein-based hydrogel materials has been demonstrated from the use of naturally derived recognition motifs, resembling synthetic supramolecular interactions in their use to physically crosslink polymer or biopolymer precursors.[30, 280] By this way, self-associating motifs derived from protein binding pairs have been used to form dynamic hydrogel materials with useful shear-thinning and self-healing character, using either fully recombinant or peptide-polymer conjugates as building blocks.[281-284] The creation of synthetic or recombinant polypeptides thus has proven as powerful strategy to capture one or a number of protein-based assembly motifs for creation of functional hydrogel materials.

Polysaccharides constitute a broad class of biomacromolecules — including common biomaterials like alginate, chitosan, hyaluronic acid, cellulose, dextran, and carrageenan — which have been extensively explored in the creation of hydrogels.[285] Some of these, such as alginate and chitosan, are able to self-assemble into hydrogels through ionic crosslinking with certain oppositely charged multivalent ions.[286, 287] However, their chain flexibility and often hydrophilic character means that most polysaccharides must be synthetically modified in order to self-assemble and form hydrogels. Early work in this regard explored hydrophobic modification of polysaccharides with groups such as cholesterol to enable physical crosslinking mediated by self-association of the prosthetic groups.[288-290] In another approach, polysaccharides may be modified with supramolecular (e.g., host–guest) recognition motifs to facilitate physical crosslinking and hydrogel formation.[291] As such, the modification of polysaccharides constitutes another rich and biologically relevant design strategy to fabricate self-assembling hydrogels for drug delivery applications.

3.4. Drug Delivery from Biomacromolecular Hydrogels

Hydrogels arising from association and self-assembly of isolated collagen have a long history of clinical use, with several examples approved for use as wound dressings.[292] Hydrogels prepared from pure isolated collagen, recombinant collagen analogues, and collagen blended with other material components have also been used in various applications for the encapsulation and controlled release of therapeutics.[293-296] For example, the encapsulation and controlled release of growth factors from in situ-forming collagen hydrogel assemblies has been explored in the context of cardiovascular regeneration.[297] In another common use, the natural origins of collagen present a logical choice as a support matrix in the context of injectable cell-based therapies.[298] Self-assembling hydrogels prepared from synthetic collagen mimics and analogues have also been explored for biomedical applications, including one demonstration of inherent platelet activation and homeostasis for applications in controlling bleeding.[299]

Silk-based materials and hydrogels have also been readily explored for applications in drug delivery.[300] Like with collagen, the material itself may serve to activate regenerative processes following administration.[301] While processing to produce self-assembled hydrogels from silk can be laborious, their compact network structure and high extent of hydrophobic regions afford many opportunities to deliver both molecular-scale and protein payloads. For example, silk-based hydrogels have been explored to encapsulate a small molecule drug and control its release with zero-order kinetics over a period of weeks to drive vascularization at an injection site.[302] Others have demonstrated the use of sonication-induced self-assembly and hydrogel formation of silk for the controlled release of antibiotics.[303] Protein drug delivery has also been achieved using silk-based hydrogels, for example in preparing materials for neural regeneration through the delivery of active signaling proteins,[304] or for the encapsulation and controlled release of antibodies.[305]

Recombinant ELPs are also of great interest as self-assembling materials for injectable drug delivery applications.[306-308] The formation of hydrophobic domains upon exposure to body temperatures serves as both a rapid trigger for hydrogelation and affords the ability to partition certain drugs for controlled release.[309, 310] For example, these materials may be used as injectable localized depots for the controlled release of antibiotics or anti-inflammatory agents.[311, 312] Peptide and protein therapeutics may also be encapsulated for sustained release from within these in situ gelling materials.[313] Hydrogels prepared form self-assembly of ELPs have also been explored for the support of cells useful for cartilage regeneration.[314]

There are also a number of examples of recombinant hybrids combining multiple protein-derived assembly motifs being used for drug delivery. Silk-elastin hydrogels have been extensively explored in this regard.[315, 316] One of the most explored directions for these materials has been in gene therapy applications for hydrogel-mediated delivery of plasmid DNA and related genetic cargo.[317-319] These hydrogels have also been evaluated for the encapsulation and controlled release of small molecule drugs, with one example exploring an ophthalmic formulation for use in addressing glaucoma.[320] Silk-elastin hydrogels have also been explored as cell supports for applications in tissue regeneration.[321] In terms of engineering materials with protein-derived associating domains to form physical hydrogels via motif association, there are a variety of examples using these injectable materials to encapsulate therapeutic cells and bioactive molecules for tissue regeneration applications.[322-326]

Hydrogels based on polysaccharide self-assembly have also been widely studied, with a plethora of examples from the ionic crosslinking of alginate and chitosan to prepare hydrogels with encapsulated drugs, cells, and other therapeutic cargo.[327, 328] In this regard, the breadth of this topic extends beyond the scope of this review. However, materials prepared through self-assembly arising from designed interactions of modified polysaccharides have also been explored. Hydrophobic modification of certain polysaccharides offers one route to create hydrogels via self-assembly.[290] The gelation of hydrophobically modified polysaccharides has been explored for the encapsulation and controlled release of a variety of small molecule and protein drugs.[329-331] Supramolecular interactions used to crosslink modified hyaluronic acid (HA) have also been used for a range of application as injectable drug-releasing depots.[332-334] For example, modified HA crosslinked by a macrocyclic ternary complex was used for controlled delivery of active therapeutics upon depot injection into tumors.[335] Modified cellulose which was designed to form hydrogels via a similar crosslinking mechanism has also been explored for the oral delivery of active agents to address ulcerative colitis.[336] As such, the engineering of associative interactions on polysaccharide offers a tool to enable the use a variety of abundant and compatible biopolymers as hydrogels for drug delivery.

4. Manipulating Covalent Bonds to Modulate Self-Assembled Hydrogels

Human tissues, such as cartilage, have exceptional mechanical properties with an ability to withstand cyclic loads orders of magnitude better than most single component hydrogel systems.[337] It is likewise well understood that cells are able to sense their local mechanical environment.[338] Accordingly, there is significant interest in developing hydrogels with mechanical properties that more closely mimic those of the local matrix microenvironment. In this section we will describe how a combination of covalent and non-covalent interactions can be coupled to influence the material properties of hydrogels prepared through self-assembled components.

4.1. Covalent Stabilization of Self-Assembled Hydrogels

Underlying self-assembled systems are an array of dynamic non-covalent interactions which give rise to an assortment of nanostructures. This process of material fabrication offers many benefits, such as the ability to control the properties of resulting hydrogels, reliably include bioactive components, and controllably release drugs through a variety of previously described mechanisms. However, these hydrogels are derived from extensive non-covalent interactions which serve to promote axial elongation or dynamic physical crosslinking. These features result in networks which are more dynamic than covalently bound polymers. Moreover, hydrogels arising from one-dimensional self-assembly of low molecular weight gelators can also be significantly more rigid than covalent polymer networks,[339] leading to materials that are unable to deform like crosslinked polymer networks with significant degradation of mechanical properties often occurring above only 2% strain.[73, 340, 341] The interactions present in self-assembled systems, comprising non-covalent hydrophobic interactions, hydrogen bonds, and electrostatic interactions, are also susceptible to competition from species existing within the body. Thus, their mechanical properties and stability in vitro may not be representative of how these materials behave in vivo. While While covalently crosslinked hydrogels can persist in the body for years,[342] self-assembled hydrogels have typically degraded within months in vivo.[343] Materials which contain both covalent and non-covalent interactions thus offer an opportunity to couple the desirable properties of both classes of materials to realize exceptional properties.

Systems combining covalent and non-covalent interactions can broadly be divided into two different classes: those which feature non-covalent/supramolecular crosslinks of polymeric systems, and those which have two distinct networks. Non-covalently crosslinking of covalent polymers can be achieved by attaching chemical recognition motifs as pendants or terminal groups. For example, reports have explored polymers which are terminated with self-complementary ureidopyrimidinone (UPy) groups,[344, 345] host–guest chemistries,[346-348] coiled-coil peptide motifs,[349, 350] and complementary nucleic acid sequences.[351, 352] Since many of these interactions can be tuned, such as by the length of the nucleic acid sequence[353, 354] or the affinity of host–guest motif,[355] these non-covalent crosslinks not only stabilize the resulting hydrogels but can used to endow the material with the desired mechanical properties.

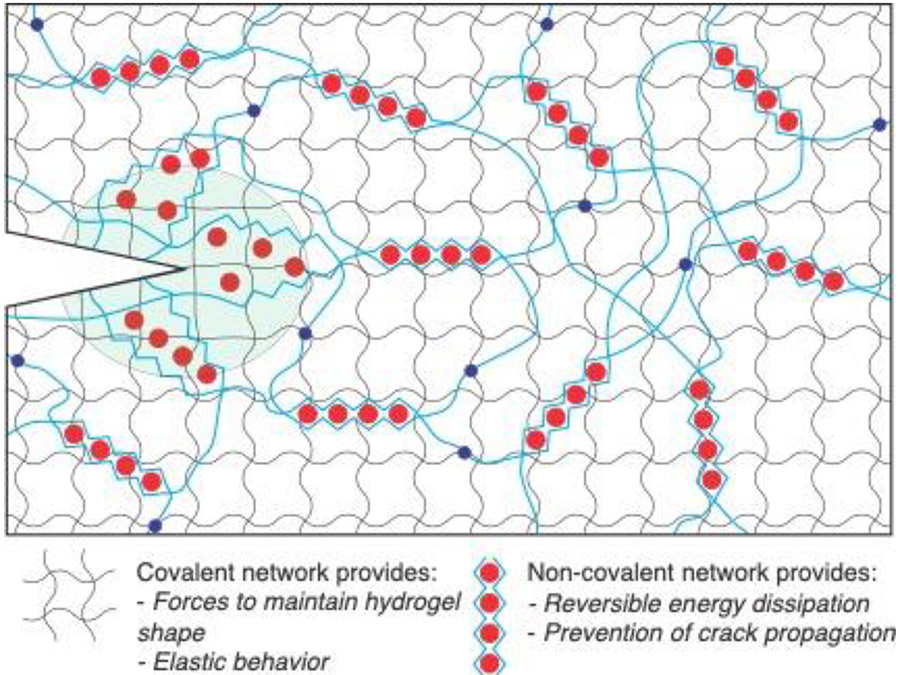

Another route to combine covalent/non-covalent systems would seek a hybrid material comprised of two separate interpenetrating networks. Such materials are inspired by work in double-network hydrogels, wherein the presence of two discrete polymers systems leads to hydrogels with exceptional mechanical properties.[356] The ability of the non-covalent network to dynamically break and reform allows these materials to dissipate energy without inducing permanent deformation.[337] Hybrid hydrogel systems with both covalent and non-covalent networks arise from a variety of polymer architectures, to include systems with distinct supramolecular and polymer networks,[357] systems which engineer non-covalent interactions between the networks,[358] and systems in which the self-assembling molecule is covalently bound to the polymer network (Figure 9).[359, 360] The myriad of design choices in these systems, such as whether the polymer network itself is cross linked,[361] enables a more tailored approach to achieving desired mechanical properties for a variety of biomedical applications.[362]

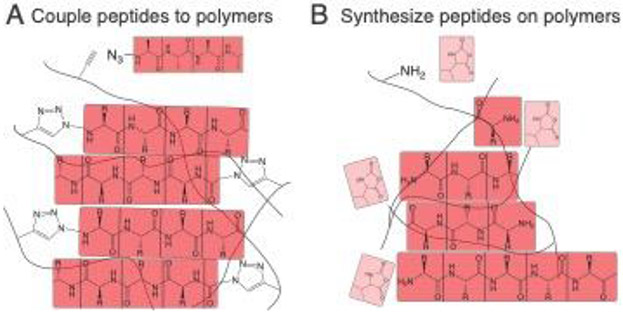

Figure 9:

The mechanical properties of self-assembling hydrogels can be improved through conjugation to a covalent polymer network. These hybrid-hydrogel networks and be made through (A) direct conjugation of peptides to the polymer network or (B) growing peptides from functional groups on the polymer backbone. Panel A is based on concepts from reference 340 and Panel B is based on concepts from reference 341.

4.1.2. Bioconjugation and Double-Network Formation

A number of polymers have been utilized as hydrogels and drug delivery, including those based on PEG, hyaluronic acid, poly(acrylic acid), and others.[363] These polymers are typically not capable of inherent non-covalent bonding that is sufficient to induce gelation at reasonable concentrations. As such, these are typically modified with other chemical groups to afford addition interactions and drive hydrogel formation.[8] One route to combinine these common biomedical polymers with additional bonds is to create two distinct networks within the resulting material. For instance, hydrogel-forming Fmoc-FF dipeptides have been mixed with unmodified polymers including hyaluronic acid,[357] alginate,[364] konjac glucomannan,[365] poly-L-lysine,[366] and dextran.[367] The Fmoc-FF peptides have a negatively charged carboxylate on their C-terminus, affording some opportunity for electrostatic interaction between the peptide assembly and a positively charged polymer such as poly-L-lysine. However, many of the polymers which have been combined with self-assembling peptides do not introduce electrostatic interactions. Other self-assembling peptides, such as peptide amphiphiles, have also been mixed with polymers including alginate[368] and PEG,[369] to modulate their mechanical properties.

The covalent polymer component in double-network hydrogels can be modified with a range of chemistries.[370] Moreover, supramolecular recognition motifs can often be coupled for polymer presentation.[371] In systems utilizing biopolymers the most widely used bioconjugation route for modification is to form an amide bond between a primary amine and a carboxylic acid using a standard coupling agent.[372] This approach has been used to couple self-assembling Fmoc-FF gelators to polymer backbones.[373] Combining biopolymers with oppositely charged self-assembling peptides can lead to strong interfacial interactions and the formation of a peptide-polymer membrane.[374] The mechanical properties and nanostructure of these membranes can be tuned by both modulating the concentration of the negatively charged hyaluronic acid biopolymer and the time at which the membranes are incubated in a solution of positively charged self-assembling peptide amphiphiles.[375] More complex systems can be made in which a second negatively charged biopolymer, heparin, is added to release growth factors.[376] This system demonstrates multiple biopolymers can be incorporated with distinct roles, from increasing mechanical properties to improving bioactivity.

Many biopolymers and peptide gelators present groups that can participate in unwanted side reactions; various “click” reactions have been explored which occur under mild conditions and offer greater selectivity for these conjugations.[377] Accordingly, a variety of different chemistries have been used to couple biomolecules to polymers,[378] including thiol-maleimide,[379] thiol-vinyl sulfone,[380] copper catalyzed azide-alkyne cycloadditions,[359] and copper-free azide-alkyne cycloadditions.[381] Technologies have also been developed to enable local hydrogel modification through the use of photo-reactive chemistries.[382-384]

The formation of self-assembled materials can also be used to template the synthesis of covalent polymer networks. For instance, diacetylene groups have been included in gelator design to localized to the interior of self-assembling peptide systems and these can be subsequently polymerized.[385, 386] Modifying self-assembling peptides with polymerizable groups and adding free polymer can be used to create networks in which supramolecular assemblies are covalently coupled, a useful approach for reinforced 3D-printed gels.[387] Biopolymers such as hyaluronic acid can also be modified with both supramolecular host–guest chemistries to stabilize the hydrogel during 3D printing, and acrylate groups for post-printing covalent crosslinking.[388] The templated polymer networks can have functions beyond improving the mechanical properties of the hydrogels; including light-activated spyropyran molecules enables the use of these hydrogels as stimuli-responsive mechanical actuators.[389]

4.1.2. Impact on Properties and Function in Drug Delivery

The mechanical properties of double-network hydrogels are often greater than the sum of their parts, with properties often greatly surpassing either network in isolation.[390] Synthetic hydrogel materials typically lack the fracture toughness of human tissues, as covalent bonds at the tip of propagating cracks are highly strained which focuses the stresses on a small area and reduces resistance to fracture.[391] Pioneering efforts in 2003 demonstrated the use of a second interpenetrating network, or “double-network” which was lightly crosslinked and coupled to the first network, significantly increasing the energy required to propagate cracks through the hydrogel compared to single-network hydrogels.[356] These initial double-network hydrogels were purely covalent, but in 2012 significant progress was realized by using an alginate network to introduce reversible non-covalent crosslinks.[371] In this system, these non-covalent interactions dissipate energy, while the covalent network provides a force to restore the hydrogel to its original shape (Figure 10).[337, 392] Double-network hydrogels have been developed for a range of biomedical applications,[393] and their combination of stretchability, wet adhesion, and transparency have made double network materials promising candidates for hydrogels that interface with skin.[371, 394]

While most interpenetrating network (IPN) hydrogels are composed of two distinct covalent polymer networks, other systems have also been developed in which one or both networks are supramolecular. An advantage of this approach is that the formation of an optimized covalent network generally requires multiple polymerization steps,[356] while small molecule self-assembly is orthogonal to most covalent polymerizations or crosslinking reactions. A self-assembling peptide was used to synthesize a one-pot IPN in combination with PEG-crosslinked chitosan.[395] These IPN hydrogels had superior mechanical properties and promoted increased expression of type-2 collagen in culture chondrocytes. Other self-assembling molecules have also been mixed with polymers to improve hydrogel mechanical properties. A non-covalent structure consisting of the nucleic acid guanosine, boronic acid, and potassium hydroxide was formed with an interpenetrating covalently cross-linked poly(N,N′-dimethyacrylamide) network.[340] These hydrogels exhibited impressive mechanical properties in tension, and were rapidly self-healing. The covalent polymer can also contribute to enhanced mechanical properties through electrostatic interactions with the surfaces of self-assembled structures. For instance, the introduction of heparin bound to the surface of a peptide nanostructure, intended to bind and release growth factors, at the same time was found to increase the storage modulus of the resulting heparin-binding peptide-amphiphile hydrogels.[396]

The Fmoc-FF hydrogelator is the most widely used self-assembling peptide system explored for double network systems. Adding alginate to Fmoc-FF hydrogels increased the storage modulus several fold, even without the addition of calcium to gel the alginate.[364] The Fmoc-FF peptide has also been modified with a negatively charged C-terminal phosphotyrosine (Fmoc-FFpY) and co-assembled with a positively charged polymer poly(allylamine hydrochloride) (PAH).[358] Whereas the Fmoc-FFpY, does not form a hydrogel on its own, the addition of PAH resulted in hydrogels with superior mechanical properties to Fmoc-FFY by both increasing the storage modulus and increased maintenance of mechanical properties upon induction of strain. In some cases double-network hydrogels themselves can elicit a biological response in vivo without any added bioactivity. Self-assembling Fmoc-FF monomers were mixed with sulfhydryl-modified poly-L-lysine and injected into the tumors of mice to activate a T-cell response and reduce tumor volume.[366]