Abstract

Despite the boom in biologics over the past decade, the intrinsic instability of these large molecules poses significant challenges to formulation development. Almost half of all pharmaceutical protein products are formulated in the solid form to preserve protein native structure and extend product shelf-life. In this review, both traditional and emerging drying techniques for producing protein solids will be discussed. During the drying process, various stresses can impact the stability of protein solids. However, understanding the impact of stress on protein product quality can be challenging due to the lack of reliable characterization techniques for biological solids. Both conventional and advanced characterization techniques are discussed including differential scanning calorimetry (DSC), solid-state Fourier transform infrared spectrometry (ssFTIR), solid-state fluorescence spectrometry, solid-state hydrogen deuterium exchange (ssHDX), solid-state nuclear magnetic resonance (ssNMR) and solid-state photolytic labeling (ssPL). Advanced characterization tools may offer mechanistic investigations into local structural changes and interactions at higher resolutions. The continuous exploration of new drying techniques, as well as a better understanding of the effects caused by different drying techniques in solid state, would advance the formulation development of biological products with superior quality.

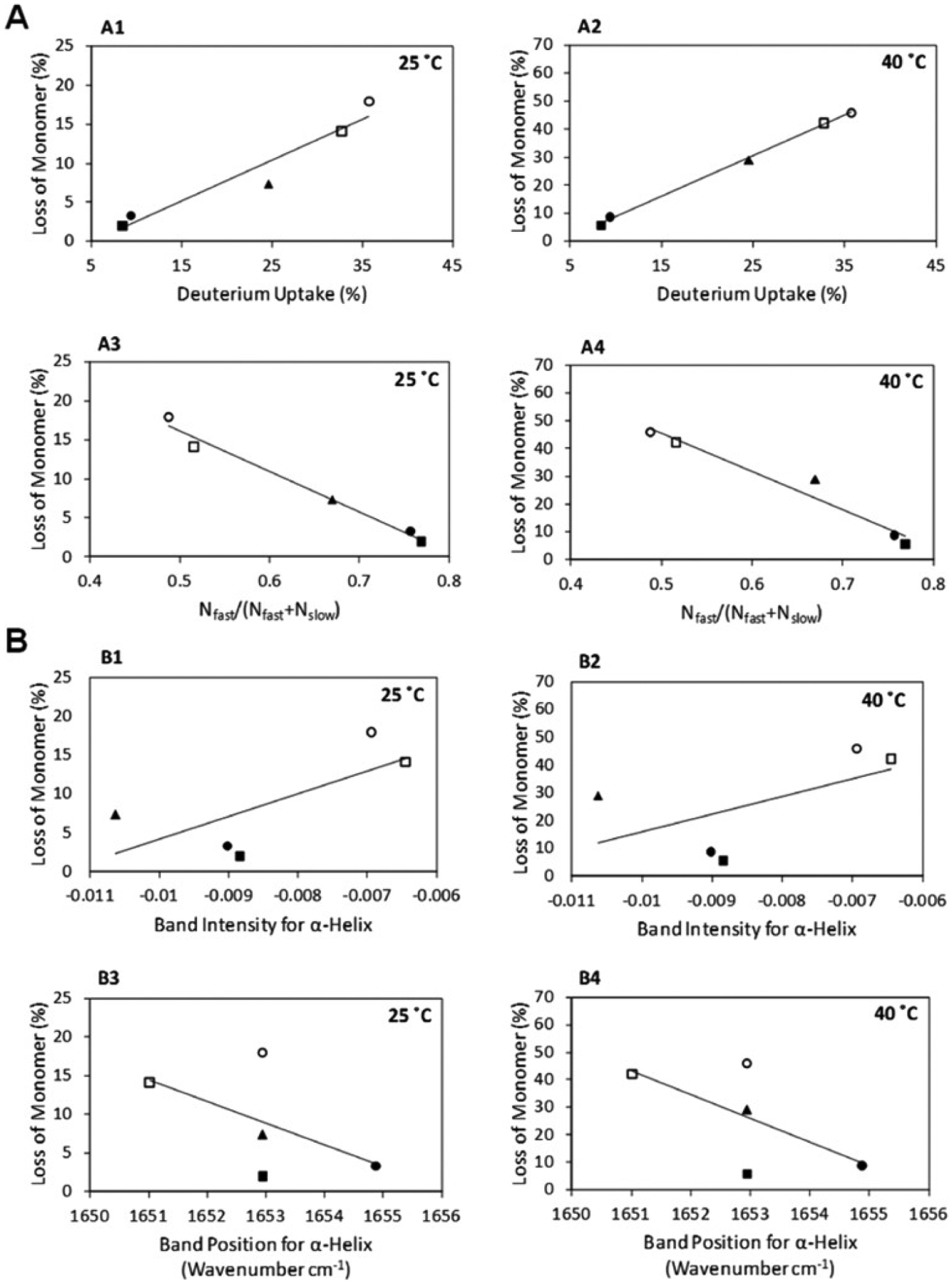

Keywords: protein solids, drying technology, solid-state characterization, process stress, physical stability

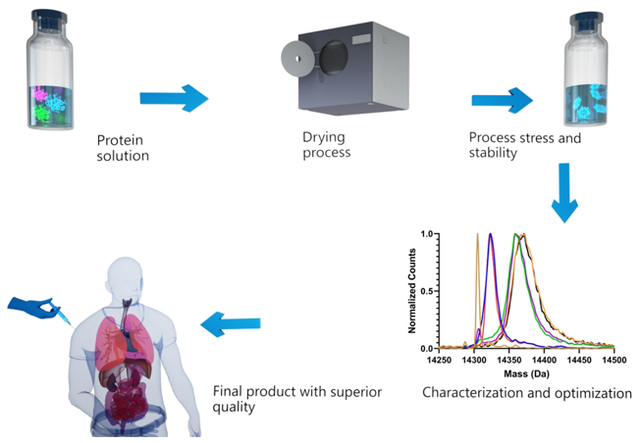

Graphical abstract

1. INTRODUCTION

The rapid growth in development of biopharmaceuticals, particularly protein products, in recent decades has been accompanied by challenges in their formulations [1–4]. Most biopharmaceuticals are introduced into the human body through parenteral administration [5]. However, biomolecules are generally less stable in the liquid state than in the solid. The preservation of biopharmaceuticals in solid state has proved to be effective in maintaining molecule stability and extending product shelf-life [6]. The removal of water also facilitates the transportation process. In solid products, the biomolecules are usually dried with disaccharide excipients to protect the structure and ensure stability. The stabilizing mechanisms of excipients are commonly explained by either water replacement theory or vitrification theory [7]. The type of excipient has a great impact on the stability of biomolecules [7–9]. There are multiple drying techniques with assorted drying stresses and efficiency available for solid biopharmaceutical development. Direct solid-state characterization methods for biopharmaceuticals are limited. It can be challenging to fully understand the large biomolecule and the matrix in solids because most characterization techniques are developed for liquids. In general, the development process for the dried biopharmaceuticals is more complicated than for solution products [10]. In this review, we will discuss various aspects regarding manufacturing of biological solids, with a focus on pharmaceutical protein solids.

Lyophilization, or freeze drying, has been used for a long time in the development of biopharmaceuticals in solid state [11]. It is a mature drying method compared to others such as spray drying. However, lyophilization is a time-consuming batch process with extensive energy use. Technologies such as spray drying and spray freeze drying are potential new processing methods to be applied on biologics. It is important to understand their drying efficiency as well as the physico-chemical properties of the dried molecules. In this review, we will discuss the advantages and disadvantages of different types of drying techniques and their suitability for protein products.

One of the key purposes for developing biopharmaceuticals in solid state is to maintain the stability and extend shelf-life. However, the drying process can generate various stresses which promote aggregation and lead to visible and sub-visible particles in the final products [12]. For example, improperly controlled freezing steps in lyophilization could affect drying efficiency and final product quality. High drying temperature in spray drying may induce protein denaturation. The stresses affecting the stability of protein solids are discussed here.

A combination of various solid-state characterization methods is usually necessary to understand the stability of protein solids since different methods provide various aspects or levels of information. Differential scanning calorimetry (DSC) can be used as a routine method for Tg detection of the solid matrix while it does not provide information on protein structure. Solid-state Fourier Transform Infrared Spectrometry (ssFTIR) detects the change of protein secondary structure but its quantitation capability is limited. More detailed information of protein conformation and dynamic could be obtained from advanced approaches such as Solid-state Hydrogen Deuterium Exchange (ssHDX) and Solid-state Nuclear Magnetic Resonance (ssNMR); nevertheless, these methods generally require extra sample preparation or extensive data analysis. The characterization methods for the structure and conformation of protein in the solid state as well as the properties of solid matrix are introduced here.

2. DRYING TECHNOLOGY

2.1. Lyophilization/Freeze Drying (Lyo/FD)

Lyophilization, or freeze drying, is the process of dehydrating under vacuum at low temperatures. The word “lyophilization” is derived from the ancient Greek and means “to make solvent-loving”. The method originated during prehistoric times when it was used by the Eskimo and Aztecs to preserve food [13]. It wasn’t until the 1880s that lyophilization was used in a laboratory setting. The advancement of refrigeration and vacuum technologies and the increased necessity to process heat sensitive antibiotics and blood products in the 1930s enabled the production of the industrial scale freeze dryer to be used in both the food and pharmaceutical industries. Proteins were one of the earliest substances to be lyophilized and the demand for bulk preparations of plasma proteins during World War II paved the path for lyophilization of biomolecules at an industrial scale [13, 14]. Lyophilization has since evolved as the most widely used technique for manufacturing biomolecules with therapeutic and diagnostic applications.

2.1.1. Description of Process

The lyophilization process involves multiple steps. First, sample freezing immobilizes the solution components, reduces the thermal denaturation, and prevents foaming of the product when vacuum is applied. It also creates an ice-crystal matrix in the sample that facilitates the drying of the product. Sample freezing is generally followed by primary drying, where the principle of drying is sublimation of ice. Primary drying is followed by secondary drying, where the moisture adsorbed on the dried sample structure is removed by desorption at the ambient or higher temperature. Sealing the samples in a vacuum or under an inert gas takes place after the secondary drying. The use of vacuum or inert gas excludes reactive and destabilizing atmospheric gases like oxygen or carbon dioxide and prevents the adsorption of moisture [15, 16].

2.1.2. Design of Lyophilization Process

Lyophilization is a batch process that is time-consuming and energy-intensive. A non-optimized freeze drying cycle may lead to even longer drying time and cause damage to the product [17–20]. In order to design an optimized freeze drying cycle, it is important to understand the critical properties of the sample. The critical properties of lyophilized formulations are the stability of the drug and the properties of the excipients used as well as the collapse temperature of the final formulation [21]. The role of the stabilizing excipients will be discussed elsewhere in this theme issue.

The temperature above which the macroscopic structure of the lyophilized product collapses during lyophilization is known as the macroscopic collapse temperature (Tc) [22]. Tc in general is about 2 °C higher than the glass transition temperature (Tg’) of the formulation in the frozen state [23]. If the solute is crystallized in the frozen state then the Tc is about 2 °C higher than the eutectic temperature (Teu). If the frozen solute contains a mixture of amorphous and crystalline matrix then the amorphous matrix will collapse if the product temperature (Tp) is above the Tg’. A macroscopic collapse occurs if both Tg’ and Teu are below the product temperature. If Tg’ is below Tp and Teu is above Tp, then the crystalline matrix provides mechanical support to the amorphous matrix, thereby preventing macroscopic collapse [24]. Tc is close to Teu in a formulation containing amorphous and crystalline matrices while dominated by the crystalline matrix. Therefore, it is important to lyophilize a formulation at a temperature less than Tc [17].

Every step in the lyophilization process takes a different amount of time to finish but all have a significant impact on the final product. For this reason, it is important to understand the freezing, primary drying and secondary drying steps in order to design a process where each of the steps are optimized for a specific formulation.

2.1.2.1. Freezing

Freezing is the first step in the lyophilization process. This step often induces stresses on the protein such as protein-protein interactions which lead to aggregation due to an increase of protein concentration, crystallization of buffer salts leading to pH change, and protein degradation at the ice-water interface. These stresses can be minimized with formulation changes and by designing a proper freeze drying cycle. In the freezing step, numerous freezing methods such as nitrogen freezing, ramped cooling, or loading vials onto a precooled shelf may result in differences in the cooling effect and ice crystal growth size [25]. It has been reported that slower cooling rates (0.5°C/min) led to a larger super-cooling effect and loading vials onto pre-cooled shelves reduces the super-cooling effect but increases the heterogeneity in super-cooling among the vials [25]. Another study indicated that the slower cooling rate increased the potential of phase separation in formulations that were susceptible to phase separation, and led to protein damage and longer freezing times [26]. A moderate cooling rate (1°C/min) that allows moderate levels of supercooling and ice surface area along with fast freezing times to be observed has been suggested [21]. The final freezing temperature of the formulation is dependent on the Tg’ and/or Teu of the formulation and is generally 2°C less than the Tg’ or Teu [21]. Annealing is a step where the product is held at a temperature higher than the final freezing temperature for a certain amount of time [27]. It is usually applied when the freeze drying cycle is designed for formulations with components that could crystallize, such as the bulking agent mannitol [21]. The purpose of annealing is to ensure the crystallizing components can completely crystallize before the primary drying step, as crystallization during the primary drying may lead to vial breakage, and partially crystalized material may fully crystalize during storage [28].

2.1.2.2. Primary Drying

Primary drying is the longest step in the lyophilization process. In this step it is important to optimize the product temperature (Tp) as an increase in the product temperature leads to a decrease in the primary drying cycle time. It is reported that a 1°C increase in Tp can decrease the primary drying time by 13% [17]. Therefore, a balance in Tp should be considered between drying cycle time and product stability. Tp depends on multiple factors such as the formulation, the freeze dryer’s shelf temperature and the chamber pressure. Tp should be below the Tc in order to prevent the product from collapsing. The chamber pressure (Pc) is another crucial parameter in designing the primary drying cycle because it influences the sublimation rate. Generally, a Pc well below the vapor pressure of the ice as the sublimation rate can be represented by the equation

| (1) |

where dm/dt is the rate of ice sublimation (g/hour per vial), Pc is the chamber pressure, Pice is the equilibrium vapor pressure of ice at the sublimation interface temperature (Torr), and Rp and Rs are the resistance to water vapor transport from the sublimation interface (Torr·h/g) due to the dry layer and stopper, respectively [29]. This suggests that the smallest chamber pressure results in the highest sublimation rate. However, it has also been observed that very low chamber pressure may result in greater heterogeneity in the heat transfer among the vials, thereby resulting in larger Tp differences between the vials [30]. An optimum chamber pressure can be calculated using the equation below to obtain a target product temperature (Tp) [21].

| (2) |

where Pc is the chamber pressure (Torr) and Tp is the product temperature (°C).

Developing a shelf temperature - time profile for efficiently achieving the product temperature during primary drying is another important factor in designing an optimized lyophilization cycle. The end point of primary drying can be detected using several methods [30], such as with thermocouples within the vials. However, it has been reported that the vials containing the thermocouples usually have lower levels of super-cooling than the vials without thermocouples, leading to larger ice crystals and faster ice sublimation and therefore, a faster primer drying cycle [31]. Dew point sensors have also been used to detect the vapor composition change and can indicate the end of the primary drying cycle [31].

2.1.2.3. Secondary Drying

The next step in the process is secondary drying, where the adsorbed water is removed through desorption. Depending on the formulation and the primary drying cycle, the primary dried product may contain 5–20% w/w residual water. Secondary drying is performed to reduce the residual water content to the preferred amount, generally less than 1–2 % [21]. To prevent the solid product from collapsing, a slow ramp rate (0.1 – 0.15°C/min) of temperature is preferred. For crystalline products, a slightly higher ramp rate (0.3–0.4°C/min) is suggested. It is reported that the chamber pressure does not affect the desorption rate if the chamber pressure is maintained under 200 mTorr [21]. Secondary drying time is also dependent on the type of solid matrix as it takes more time to desorb water in an amorphous matrix than in a crystalline matrix. It is suggested that the secondary drying should be done at higher temperatures for shorter periods of time rather than lower temperature for longer periods of time [32], as long as higher temperatures do not jeopardize stability.

2.1.2.4. Use of Mathematical Modelling in Lyophilization

In the past, optimization of the lyophilization process was approached empirically through trial and error [21]. Mathematical models based on partial differential equations (PDE) [33–36] and model predictive control (MPC) [37–39] were some of the earlier predictive tools used to optimize the lyophilization cycle. However, determining the values of the many parameters involved was experimentally difficult [40]. Another approach to understanding the lyophilization process and optimizing the cycles is the use of computational fluid dynamics (CFD). Some studies have been recently conducted using CFD to understand the mass and heat transfer within various sections of the lyophilizer such as the drying chamber and the condenser [41, 42]. The parameters of different cycles in lyophilization might differ even for the same product when the operation takes place in a lab-, pilot- or production-scale lyophilizer [40]. This is due to the position of the vials, and change in the mass and heat transfer from the vials in the lyophilizer at different scales. Therefore, an optimized process obtained in the lab- or pilot-scale equipment often may not be transferred directly to production-scale equipment without modifications. Mathematical models based on the dominant parameters in the lyophilizer have been developed to facilitate the scale-up of the process [43–45]. It has been observed that at a higher product temperature there is a reduction in frost layer thickness that offers less resistance to vapor flow within the vial, resulting in greater primary drying efficiency. This observation led to the development of a scale-up theory that focuses on the primary drying [40, 46, 47].

While the use of mathematical models to optimize lyophilization has been helpful, there has also been a development of the in-situ process parameters monitoring technology that can help in modifying and improving these models. The technology is known as process analytical technology (PAT). It can be used to study the temperature and pressure data in the lyophilizer. Some of the PAT tools currently used in lyophilization are listed in Table 1.

Table 1.

PAT for monitoring freeze drying process.

| PAT method | Parameter measured | Integrated into the system | Reference |

|---|---|---|---|

| Thermocouple | Product temperature (Tp) | Yes | [31] |

| Resistance thermal detectors (RTD) | Product temperature (Tp) | Yes | [31] |

| Temperature remote interrogation system | Product temperature (Tp) | Yes | [48] |

| Manometric temperature measurement (MTM) | Sublimation interface temperature (Tice) and Product temperature (Tp) | Yes | [49–52] |

| Valveless monitoring system (VMS) | Product temperature (Tp) | Yes | [53] |

| Temperature measurement by sublimation rate (TMbySR) | Product temperature (Tp) | Yes | [54] |

| Capacitance Manometer | Chamber Pressure (Pc) | Yes | [55, 56] |

| Pirani Gauge | Chamber Pressure (Pc) | Yes | [55] |

| Lyotrack | Vapor saturation in chamber | Yes | [57] |

| Residual gas analyzer | Analysis of gas and vapor in the chamber | Yes | [55, 57–59] |

| Karl Fischer | Moisture content measurement | No | [60] |

| Thermogravimetric analysis (TGA/LOD) | Moisture content measurement | No | [60] |

| Computrac® Vapor Pro® XL | Moisture content measurement | No | [61] |

| Near IR spectroscopy (NIR) | Moisture content measurement | Yes | [62] |

| Raman Spectroscopy | Moisture content measurement | Yes | [62] |

| Tunable diode laser absorption spectroscopy (TDLAS) | Water vapor concentration | Yes | [63] |

2.1.3. Advancements and Future of Lyophilization

2.1.3.1. Microwave-assisted Freeze Drying

Several new technologies are being developed to improve lyophilization. Although currently being tested at a smaller lab-scale level, microwave-assisted freeze drying (MFD) is one such technology. In MFD, freeze drying is assisted with a microwave heat source to increase the drying rate while improving the product quality [64]. In a recent study, the application of MFD in a modified laboratory scale vacuum dryer reduced drying time by over 75%. The study also showed that samples produced by MFD have shown similar stability during accelerated stability studies when compared to conventional freeze drying for monoclonal antibody formulations used in the study [65]. However, more studies are needed before this technology can be used in an industrial scale lyophilizer.

2.1.3.2. Continuous Freeze drying

Continuous manufacturing is gaining popularity in the pharmaceutical industry due to advantages such as operation flexibility, improved manufacturing efficiency, real time quality monitoring and reduction in investment and operating costs [66]. In biopharmaceutical products, around 50% of the FDA and EMA approved drugs are lyophilized solid products despite the high operating costs and long processing time of the lyophilization process [67]. The current lyophilization process is a batch operation with several disadvantages, such as uneven heat transfer causing vial to vial inhomogeneity even within a single batch, and batch to batch product quality variability [68]. While continuous freeze drying in the food industry dates back to the 1960s, the transition of the technology to pharmaceutical products has not prevailed due to strict requirements in regards to the sterility, product quality and accurate dosage at a large-scale industrial production level. The principles behind the operation and current use of these continuous freeze dryers have been discussed in a recent review article by Pisano et al. [69].

Continuous freeze dryers that work on single dosage units appear favorable for biopharmaceutical products. As it is not straightforward for the transition from the existing batch freezer dryers to the continuous freeze dryers, there are only a limited number of concepts that have been developed over the years for continuous freeze drying of unit doses. Shell/spin freezing followed by vacuum drying is one example. During this process, the vial with the solution is rotated while freezing, causing a thin layer to form on the surface and then dry [68]. Becker’s concept [70], Broadwin’s process [71], and Oughton’s freeze dryer [72] all use the shell/spin freezing concept. A recent patent by Corver [73] looks at a new approach to shell/spin freezing followed by continuous drying. Another new continuous freeze drying concept has been proposed in which the vials are suspended over a track that moves through chambers with different temperatures and pressure conditions [74]. This method uses vacuum-induced surface freezing to produce controlled nucleation, thereby reducing vial to vial variability. Overall, continuous freeze drying on single dose units offers a promising way forward to reduce the processing time and the operating cost with potential capability to incorporate process analytic technology (PAT).

2.2. Spray Drying (SD)

Spray drying is a process in which the atomization of a solution, suspension or emulsion into a high-temperature gaseous medium produces dried powders [75]. The dairy [76] and the food [77, 78] industries were among the first to employ this technique at an industrial-scale. In the pharmaceutical industry, producing dried powders through spray drying offers advantages such as consistent powder quality, continuous and controllable processes with high drying efficiency, the availability of a wide range of dryers, and scale-up capability with high output.

2.2.1. Description of the Process

For a laboratory-scale spray dryer, there are four main components: drying chamber, atomizer/nozzle, aspirator, and particle collection cyclone [79]. In a typical spray drying process, a feed stock is pumped through the atomizer/nozzle to produce droplets with a desired size range. The droplet size can be altered with different types of atomizer/nozzles, solution concentration and feed rate of the liquid through the atomizer. The atomized droplets then enter the drying chamber where a high temperature gas stream evaporates the solvent and solid particles are formed. The temperature and the gas for the gas stream should be selected depending on solvent type, material degradation temperature, and glass transition temperature. The dried particles are then collected in a cyclone. The physical properties of the final product, such as particle size, density and morphology, can be altered by changing the process and formulation conditions.

2.2.2. Spray Dryer Setup

Atomization is a critical step in the spray drying process because the particle size, morphology, and residence time of the droplets/particles in the drying chamber are dependent on the atomization of feed solution. While the type of atomizer used has an effect on the atomization process, other factors such as shearing and inertial stresses, viscosity and size distribution of the droplets also influence the angle and velocity of the atomization [80]. There are several atomizer/nozzles available to be used in the spray drying process, including the rotary atomizer, single-fluid nozzle, multi-fluid nozzle, and ultrasonic nozzle. The rotary atomizer comes in two types: atomizer wheel and atomizer disc. The atomization occurs when the feed liquid passes through or across the rotating disc/wheel, where centrifugal forces of the disc break the feed liquid into droplets [81, 82]. The rotary atomizer is favored for viscous solutions because it can produce relatively uniform droplet size for viscous feed liquid. Rotary atomizers also have high feeding capacities, making them suitable for industrial-scale operations [80].

For the single-fluid nozzle, the fluid is pressurized and passed through an orifice, causing the fluid to break into droplets [82]. In a multi-fluid nozzle, the solution feed is atomized by a gas stream (generally air or inert gas) which breaks the feed into droplets at the nozzle tip. These multi-fluid nozzles usually produce fine droplet size (10–100 μm) and are widely used in the pharmaceutical industry [82]. The multi-fluid nozzles include 2-fluid nozzles, where the solution feed is atomized by the gas stream, and 3- or 4- fluid nozzles, [83] where the nozzle can atomize two different feed solutions either for microencapsulation [84] or multifunctional layered microparticles [85]. The ultrasonic nozzle generates droplets by vibrating at high frequency [86], which can produce a relatively larger droplet size range (5–1000 μm) [82]. Another advantage of the ultrasonic nozzle is the minimized risk of nozzle clogging, which can occur with the multi-fluid nozzles [82].

The drying gas flow pattern in the drying chamber of a spray dryer differs depending on design. The flow patterns that are commonly used in a spray dryer system are counter-current, co-current, and mixed flow. In a counter-current setting, the gas enters from the bottom of the chamber and leaves from the top, while the feed solution enters from the top and the dried particles settle at the bottom [87]. In this arrangement, the residence time of the droplets/particles in the drying chamber is more than in the other two arrangements, allowing for higher heat transfer and resulting in better drying. However, this arrangement is not preferred for materials that are heat sensitive. In a co-current setup, both the feed solution and drying gas enter from the top of the drying chamber and the particles are collected at the bottom using a cyclone. This drying gas flow arrangement is common for most pharmaceutical products, especially biopharmaceuticals. Mixed flow is a combination of counter-current and co-current flow patterns. In this setup, the atomization of the feed takes place in the central part of the drying chamber with the atomized feed solution sprayed upwards or downwards based on the thermal sensitivity of the material, while the drying gas enters from the top of the drying chamber [88, 89].

2.2.3. Spray Drying of Biopharmaceutics

Many biopharmaceutical products such as protein- and peptide-based formulations show less stability in the liquid state than in the solid state at the ambient temperature [90]. Lyophilization has been used to produce solid state biopharmaceuticals for a long time. With the development of novel drug delivery systems such as long acting microspheres [91], powders for transdermal delivery [92], and for pulmonary delivery [93], lyophilization can no longer satisfy the product requirements that are necessary for these new delivery methods; thus, the demand for alternative drying techniques increases. Spray drying provides significant control on powder properties and is feasible to scale-up. However, the use of relatively high temperatures for solvent evaporation is a limitation when it comes to drying thermo-sensitive biopharmaceutical products. Mezhericher et al. [94] gave a detailed description of the drying process for a droplet in a spray dryer. While spray drying eliminates some of the stresses in lyophilization, such as ice formation, freeze concentration of solute and pH imbalances, it introduces air-liquid interface and thermal stress. These stresses and their impacts on the stability of biological solids will be discussed in detail in the following section.

Recent work has shown that the influence of drying methods on physical stability (or protein aggregation) of protein solids is highly correlated with protein type and excipient choice [95, 96]. The use of excipients that can preserve hydrogen bonds during the drying process has been extensively studied. Excipients that are expected to satisfy the hydrogen bonding requirements to preserve the secondary structure of the proteins include sugars such as sucrose [97], trehalose [98], and polyols (sorbitol) [99]. Other excipients such as surfactants [100], polymers [101], antioxidants [102], and amino acids [103] also improve the stability of the proteins during spray drying. However, one should be cautious about the potential negative effects of such excipients on the stability of protein solids, especially for those which crystallize during drying. Mannitol is a commonly used excipient for lyophilization formulations due to its ability to form a crystalline matrix that prevents macroscopic collapse of the lyophilized cakes. Use of mannitol by itself as an excipient has been shown to cause phase separation, resulting in poor protein stability [95].

Powder properties are affected by type of excipient, protein/excipient ratio, total solid concentration in the feed solution, inlet/outlet temperature, solution feed rate, atomizer type, and atomizing pressure. Yield, physical and chemical stability, morphology, therapeutic efficiency, and powder flow characteristics are some of the parameters that need to be optimized for spray drying [79]. Often these parameters are inter-related, and optimization of these parameters becomes complicated. Models based on single droplet drying have been used in tandem with experimental setups to understand the heat and mass transfer within a droplet [104, 105]. DoE, CFD, heat and mass transfer modelling have also been used by various research groups to understand the impact of formulation and process in both the lab- and industrial-scale spray dryers [106–108].

In the pharmaceutical industry, spray drying has been used to manufacture biological solids for inhalation and topical products. Insulin, owing to its high thermal stability and fast absorption, is one biopharmaceutical product that has been developed for pulmonary drug delivery. Exubera® spray-dried insulin received FDA approval for pulmonary delivery. The Exubera® formulation consisted of recombinant insulin (60%), mannitol, sodium citrate, glycine and small amounts of sodium hydroxide (for pH adjustment) [109]. While the product was considered to be technically successful in terms of the drug delivery, it was withdrawn from the market within a year due to poor sales [110]. Another pharmaceutical product, Raplixa®, is the first FDA-approved sterile spray drying solid protein product [111].

2.3. Spray Freeze Drying (SFD)

Spray freeze drying is a relatively new drying technique [112] used to manufacture thermo-sensitive food products like whey protein, coffee, maltodextrin, and milk powder [113]. Although spray freeze drying has not been widely adopted to manufacture commercial pharmaceutical products, there is increasing interest in applying spray freeze drying for manufacturing thermo-sensitive biopharmaceutical solids.

2.3.1. Description of Process

In SFD, the feed solution is sprayed into a cold vapor phase or a cryogenic liquid. The atomized droplets freeze either during their movement through the cold vapor phase or upon contact with the cryogenic liquid. The frozen droplets are dried under the same principle as freeze drying. SFD offers the advantage of producing particles for products that are thermo-labile. Various setups have been explored on how to handle the frozen droplets [93, 114–116]. Atmospheric freezing, spray freezing into liquid (SFL) and spray freezing with compressed carbon dioxide are some examples of this process [117–119].

2.3.2. Spray Freeze Drying of Biopharmaceutics

Factors such as the chemical composition, atomization rate, feed rate, and temperature of the cryogenic fluid play crucial roles in ensuring the stability and controlling the density and particle size distribution of the particles [117]. Moreover, the super-cooling phenomena due to the use of a cryogenic liquid may mitigate ice crystallization effects and pH shifts that can be observed in freeze drying. The production of porous spherical particles during SFD increases the surface area and thereby reduces the time for sublimation and secondary drying. The spherical shape of SFD particles results in relatively satisfactory flowability. The porous structure generally leads to low particle density, which contributes to better aerosolization behavior for inhalation products [120].

In a study of the effects of atomizing conditions and variability in formulations containing bovine serum albumin (BSA) on the particle size and stability, particle size was found to be inversely related to the specific surface area and the amounts of BSA aggregates [114, 115]. In a study of spray-dried and spray freeze dried anti-IgE Mab and rhDNase formulations, it was shown that the spray freeze dried powders had better aerosol performance than the spray-dried powders, likely owing to the porous structure of the particles [93]. Other studies on salmon calcitonin [121] and parathyroid hormone [122] also showed that SFD resulted in products with good flow properties. In a recent study conducted by our lab group, we found that the spray freeze dried formulations of lysozyme and myoglobin showed similar stability results to freeze dried formulations in the formulations containing non-crystallizing cryoprotectants (sucrose) as excipient [123]. In another study, insulin with/without tylopaxol and lactose was spray freeze dried [124]. Irrespective of the presence of lyoprotectants, spray freeze dried insulin showed minor to no degradation, suggesting that spray freeze drying is capable of delivering stable solid product [124]. Spray freeze dried influenza vaccines showed better stability compared to the liquid formulations [125]. A study evaluating enzyme activity of trypsinogen after SFD found an [126] approximately 15% loss from initial activity, with an aggregation of 1.4%.

Spray freeze drying is promising in terms of particle morphology control and flow property optimization, making it a favorable drying method for pulmonary delivery. It offers advantages such as rapid freezing and short drying time when compared to freeze drying for biopharmaceutical production. Nevertheless, more research is warranted to fully understand the impact of the process on the physical and chemical stability as well as the therapeutic efficacy of the products.

2.4. Other Emerging Drying Techniques

In addition to the drying techniques mentioned above, other emerging drying techniques for biopharmaceutical solids include super critical fluid drying (SCFD), foam drying and electrostatic spray drying.

In SCFD, materials like carbon dioxide, ethylene or methanol are used above their critical temperature and pressure in order to facilitate dehydration. Compared to ethylene and methanol, carbon dioxide is a non-toxic and non-inflammable material with a critical temperature of approximately 31°C and critical pressure of approximately 73 bar. Two approaches have been proposed to use the SCFD process for biopharmaceutical products [127]. The first is to use a super critical fluid (SCF) as an anti-solvent for water extraction, leading proteins to be concentrated and precipitated, followed by spray freezing and drying to remove the remaining water before obtaining the final product. In the second approach, the SCF dissolved at high pressure is used as a propellant to atomize the feed solution in a two-fluid nozzle. Results have shown that SCFD is capable of generating particles with adjustable sizes and uniform spherical features with acceptable flow properties [128–130]. Additional research is necessary to understand the long-term storage stability and therapeutic efficacy of SCFD-produced products.

Foam drying is another relatively new process for producing biopharmaceutical solids, in which the solution is converted to dried foam [131]. The solution is boiled or foamed under reduced vapor pressure, followed by water evaporation that leads to a solidified foam structure [132]. Foam drying offers the advantage of drying at near-ambient temperatures without ice formation. In a study with Ty21a vaccine, foam drying demonstrated a stability of 42 weeks at 25 °C [133]; while a commercial freeze dried Ty21a vaccine, Vivotif™, showed stability of only 2 weeks at the same temperature [134]. In another study, foam drying of an IgG1 mAb formulation with varying levels of sucrose showed better storage stability than freeze drying and spray drying [135]. The increased storage stability is ascribed to creating products with lower specific surface area and surface accumulation of the protein, [135] as lower surface area is related to lower monomer loss in protein formulations [114]. Although foam drying appears to exhibit better stability, it presents several challenges such as surface tension stresses leading to cavitation of the dried product, reduced water desorption rate resulting in longer drying time, and the risk of freezing due to evaporative cooling. The process usually takes days to complete. The drying kinetics are not fully understood and research of this topic is required to optimize the drying cycle and improve product stability. Scale-up of this process for manufacturing warrants further investigations.

Recently, electrostatic spray drying has been developed as an alternative to traditional spray drying. In this process, an electric charge is applied to the feed solution before spray drying. Within these charged droplets, solvent (usually water) possesses a higher proportion of electrons and attains a greater charge density due to its high-polar nature, while the solute molecules that are generally less polar in nature than the water have fewer electrons. Such an effect leads to a solute-rich core and a solvent-rich shell within the droplet, which improves drying efficiency and facilitates drying at low temperature [136]. Spray dryers with these technologies are commercially available with varied scales from bench-top lab equipment to full-scale for industrial manufacturing [137].

The concept of electrostatic spray drying has been previously evaluated to produce nanoparticles [138], nanosuspensions [137], and microspheres for encapsulation [139]. Commercially available electrostatic spray dryers have been used to study the process of encapsulation for modified food starch, vitamin C, strawberry flavor and sunflower oil [140]. An emulsion containing non-polar active ingredient, polar solvent and carrier material are spray dried using the electrostatic spray dryer. The non-polar active ingredient has fewer electrons and forms the core, while the carrier and solvent pick up more electrons and form the shell through droplet formation, enabling encapsulation of the active ingredient inside the carrier. Since it is relatively new, publications on its use for biologics are rare. More research is warranted to provide a clearer understanding on the mechanisms of how charging affects drying efficiency of pharmaceutical related materials.

Although traditional lyophilization is still the mainstay drying technique for the production of biopharmaceutical solid products for now, alternative technologies have been employed to circumvent key shortcomings of lyophilization. Spray drying appears to be a viable alternative to lyophilization in producing biopharmaceutical solids, particularly for developing inhalation products. FDA-approved sterile spray-dried biologic products are already on the market [109], which eases some concerns on the sterility of spray-dried products. In addition, the emergence of new drying technologies that are specifically designed for biological products will facilitate the development of commercial solid biopharmaceutical products in the future; while there is an urgent demand in research to obtain the fundamental understanding on how the process and formulation affect product quality.

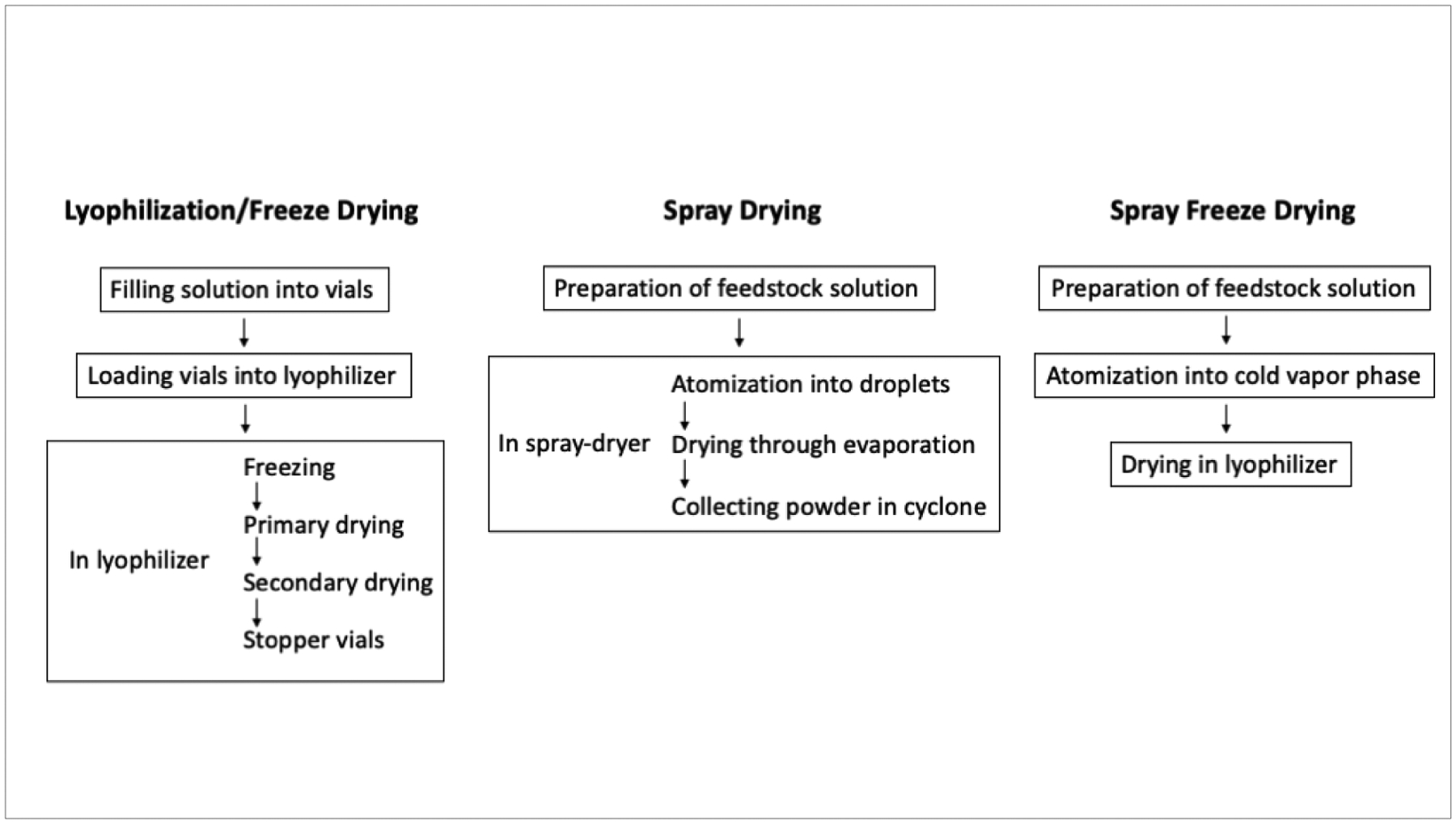

A simplified workflow illustration of lyophilization, spray drying and spray freeze drying is presented in Figure 1.

Figure 1.

Illustration of lyophilization, spray drying and spray freeze drying processes.

3. STRESSES IN DRYING PROCESS

Proteins undergo a complicated process from the raw material to the end user, including synthesis, purification, formulation, storage and handling [141]. The time needed for the formulation step is largely impacted by the desired dosage form, with different challenges associated with formulations in aqueous solution and solid state [142]. Lyophilization, or freeze drying, is the most common approach to produce dried biologic product [143]. Recently, more drying methods are being explored for biologics, such as spray drying, spray freeze drying, and foam drying [144].

With the rapid growth of protein products in the pharmaceutical industry, understanding how the processing stresses affect protein stability and function is vital for formulation design. The native structure of protein is maintained by different interactions including hydrogen bonds, van der Waals forces, electrostatic interactions, and hydrophobic interactions [145]. These interactions are critical for protein functions such as binding and solubility. It has been a challenge in the development of protein products to protect the native conformation of protein from the processing stresses [142].

The stresses induced by drying processes could alter the native conformation of proteins. The interactions among proteins, or between the protein and its surrounding environment, can be affected by these stresses, resulting in an energetically unfavorable state which leads to further structure disruption [145]. Processing stresses can disrupt the secondary, tertiary, or quaternary protein structure [146], and thus cause protein denaturation.

The manufacturing process exposes proteins to various types of stresses simultaneously that can destabilize the molecules. The final effect to the biologic product is a combination of the exposure time and strength, as well as the selection of the formulation composition [127]. This section presents common stresses from drying methods that induce physical denaturation of the protein structure as well as formulation strategies for preventing protein unfolding and aggregation.

3.1. Temperature

One of the most common causes for protein denaturation is the exposure to extreme temperature changes. The thermodynamics of a protein unfolding process in a two-state model can be described by an equilibrium between a folded native state (N) and an unfolded, denatured state (D) [145]. The equilibrium constant (K) of the equilibrium is represented by the following equilibrium equation:

| (3) |

with K representing the equilibrium constant; [D] and [N] representing the concentrations of denatured and native proteins respectively. Furthermore, the Gibbs free energy between the unfolded and native states, ΔGu can be given by the equation:

| (4) |

where R is the ideal gas constant, T is the temperature, ΔHu is the enthalpy change of unfolding, and ΔSu is the entropy change of unfolding.

The free energy for the globular protein in its folded state is 5–20 kcal/mol higher than its unfolded state [147]. The activation energy needed for unfolding to occur is within the range of 25–150 kcal/mol, which is typically weaker than covalent or ionic bonds [127]. The free energy of protein varies with exposure to temperature changes, the degree of which corresponds with the non-covalent interactions stabilizing the protein structure. The induction of unfolding can be highly temperature-dependent, and is accompanied by a large increase in the heat capacity (given by ΔCp) [148]. Since the changes in enthalpy and entropy of unfolding are both temperature-dependent, these properties can be described as:

| (5) |

| (6) |

where Tm is the midpoint of the thermal unfolding curve; ΔHm and ΔSm are the values of the changes in the enthalpy and entropy of unfolding, respectively, at Tm. These parameters can be inserted into Equation (4) to give:

| (7) |

Furthermore, a modified Gibbs-Helmholtz equation can be used to describe the free energy of unfolding by its dependence on temperature [149]. This theory is derived from the assumption that as the free energy of unfolding approaches zero, the midpoint of the change in entropy approaches ΔHm/Tm, which can be given by the following equation:

| (8) |

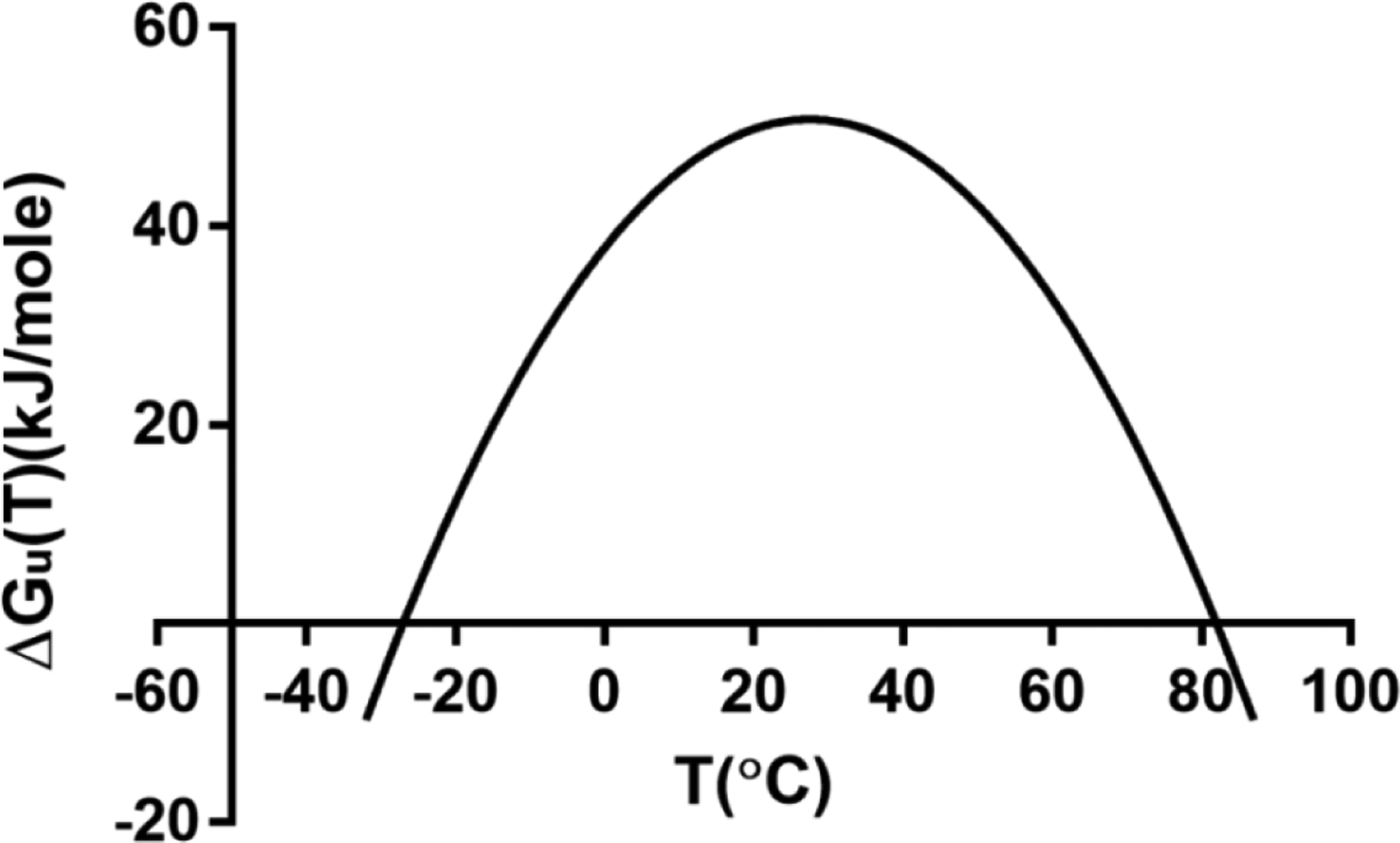

Following equation (8), the free energy of unfolding can be plotted as a function of temperature (Figure 2). As shown, the kinetics for protein unfolding is parabolic, with the free energy of unfolding reaching zero at around −30°C and 80°C. When the free energy is negative, protein unfolding is energetically favorable, which can lead to aggregation. The two-state model is not applicable for all the protein folding states. Proteins in intermediate states with partially unfolded structures have been identified [150–152]. These intermediates could act as the initial states for denaturation and aggregation before the environment temperature reaches the calculated unfolding point.

Figure 2.

A protein stability curve for the Gibb’s free energy of unfolding as a function of temperature, given in Equation (8). Repurposed from [148].

3.1.1. High Temperature Denaturation

High temperatures during the drying process pose a significant risk to the stability of biologics, including proteins [129]. Drying methods such as spray drying [144] and convective oven drying [153] utilize high temperature. In spray drying, the solution formulation is atomized by air into droplets. After brief exposure to a hot drying gas, water is removed and dry solid particles form. In a convective oven dryer, solutions or dry solids are exposed to elevated temperatures for a set period of time to reach a desired moisture content. The temperature settings used for these drying methods are significantly higher than the denaturation temperature, or melting point, of most proteins, which usually begin to unfold in a range between 40–80°C [154].

As indicated in Figure 1, the unfolding process is energetically favorable at temperatures above 80°C. The kinetic energy of the non-covalent bonds maintaining the protein structure increases with an elevated temperature. The increasing heat from the environment leads to the disruption of intramolecular hydrogen bonding, resulting in protein denaturation [145]. Various intermediates can form through the unfolding process upon drying, which is associated with the drying rate as well as the formulation composition [150]. For example, β-lactoglobulin showed decreased α-helical and β-sheet content and increased disordered structure above 50°C. Aggregation was observed above 60°C with an increase in intermolecular β-sheet content [155]. For thermally-sensitive proteins, irreversible aggregates tend to form quickly upon unfolding due to high temperature.

In spray-dried protein solids, thermal denaturation may not be observed even at the inlet temperature above 100°C because of self-cooling in droplets induced by solvent evaporation [141]. The droplet temperature typically does not exceed the wet bulb temperature, which is the lowest temperature present on the droplet surface through solvent evaporation. The wet bulb temperature increases as the drying process continues, while the temperature inside the droplet maintains at 10–15°C lower [156]. Once the critical concentration on the droplet surface is achieved, secondary drying occurs until it reaches the dry bulb temperature, which is close to the outlet temperature of the spray dryer [141].

The extent of exposure time and high temperature is critical to the level of denaturation observed on the protein molecules. For spray drying, a lower outlet temperature is preferred. It has been well-documented that outlet temperature has a greater impact on protein denaturation and aggregation than inlet temperature [157–159]. The protein primary structure could affect the stability against the effect of high temperature. It has been reported that molecules containing higher content of hydrophobic amino acid residues tend to have an increased stability against thermal stress than those with more hydrophilic residues [141]. Additionally, selecting excipients capable of forming strong hydrogen bonding with the protein also provides protection against denaturation induced by high temperature and improves the overall protein stability [99].

3.1.2. Cold Denaturation

Exposure to low temperatures could lead to protein denaturation with the free energy of unfolding, comparable to that induced by high temperature [160]. Cold denaturation can be induced by the freezing step of lyophilization, or through product storage at temperatures below 0°C. Proteins unfold at low temperatures through different mechanisms than at high temperatures. In an study of β-lactoglobulin, it has been reported that the intermediates forming from thermal stress varied at different temperatures, which indicates that the unfolding mechanism at lower temperature differs from that at a higher temperature [151]. Though not fully understood, it is proposed that unfolding in cold denaturation results from changes in the interactions between water and the nonpolar residues on the protein [161–163]. As the temperature drops below a certain point, it is entropically favorable for water to interact with the hydrophobic amino acids. Consequently, the hydrophobic residues are hydrated, weakening the hydrophobic interactions stabilizing globular protein structure. Such changes in hydrophobicity can lead to the collapse of tertiary structure. In a study of apomyoglobin, protein stability was affected by its hydrophobic core at lower temperatures. Below the denaturation temperature, the helices in the hydrophobic core of apomyoglobin became detached, followed by protein unfolding [152].

The effects of cold denaturation are not fully understood because it is difficult to analyze it at below 0°C in the partially-frozen solution. Even without protein denaturants such as urea, cold denaturation can be found below the freezing point of water [164]. However, the effects of cold denaturation on proteins can be reversible [165]. Structure changes caused by low temperature denaturation can be recovered by thawing the frozen solutions at a higher temperature or reconstituting the lyophilized solids back to aqueous solution. Dried protein solids can be stored at low temperature with the removal of water. With the use of a cryoprotectant such as sucrose or trehalose, protein stability can be further improved to protect against the effect of low temperature in the process [166].

3.2. Surface-induced Denaturation

During processing of protein formulations, it is inevitable that solutions will be exposed to some type of foreign interface, whether by filtration, filling, or drying methods [167]. Exposure to these interfaces can result in interactions of the protein by adsorption, which can lead to shearing conditions and unfolding in relation to its environment. This is due to the amphipathic nature of proteins, which leads to high concentrations orienting at the surface because of their polar and nonpolar side chains [168, 169]. There are two hypotheses regarding the underlying principles of surface-related stresses that lead to unfolding: (1) surface-induced denaturation due to surface adsorption, aggregation of intermediate states, and/or recycling of unfolded proteins into solution; (2) shear-induced denaturation by structural changes of proteins in bulk solution by shear force, aggregation of intermediate states, or solid surface adsorption [127]. In recent studies, it has been found that shear alone is not significant enough to induce protein structural changes, even at conditions higher than those that would be found in traditional manufacturing processes [170]. For unfolding, a force of 20–150 pN is generally required for proteins such as a monoclonal antibody. Shear alone is only capable of generating a force of 0.06 pN, far lower than what is required for protein unfolding [171]. This indicates that another foreign interface in tandem with shear may be critical in generating stress high enough to cause denaturation. Three types of surface-induced stresses found in manufacturing are solid-liquid, air-liquid, and liquid-liquid interfacial stresses.

3.2.1. Solid-liquid Interfacial Stress

During all phases of processing, protein formulations will be exposed to solid surfaces, either in a vial or storage device used for the drug product [172], in membranes during dialysis [173], or the equipment used in the manufacturing process [174]. Whether proteins adsorb to a surface depends on the surface interacting with the protein, and the state of the protein’s bonding interactions, in particular its electrostatic and hydrophobic interactions [170]. If the protein favorably interacts with the solid surface it is being processed in, the protein can adsorb onto the surface. During this adsorption the protein may be folded or partially unfolded, with a higher probability of adsorption for a partially unfolded protein, as the exposure of the hydrophobic residues increases the number of possible interactions with the surface [169, 175]. The initially adsorbed proteins act as nuclei on the interface, whereby additional molecules passing through the solid can attach to these sites, increasing the size of the aggregates.

The stability of the protein structure plays an important role. There are two classes of proteins, based on their stability, that determine which types of surfaces will lead to adsorption: “hard” and “soft” proteins [169]. Hard proteins have a high internal stability, or strong hydrophobic interactions, which help to maintain the protein structure against adsorption. For these types of molecules, adsorption at the solid interface is unlikely on a hydrophilic surface unless there is a strong electrostatic interaction disrupting the protein structure, or unless there is a strong hydrophobic surface. For example, lysozyme has a higher amount of aggregation due to adsorption that occurs on a more hydrophobic surface, polytetrafluoroethylene, than on glass [176]. Soft proteins have a low internal stability, or weaker hydrophobic interactions, which allows for adsorption on any surface with an increase in conformational entropy by unfolding and attaching to a solid interface. For example, a monoclonal antibody has been found to unfold during adsorption to stainless steel [177].

The ionic strength in the solution can affect solid-liquid interfacial stress in the formulation. Increasing the ionic strength can weaken the repulsion interactions found between the protein and solid during processing, leading to aggregation [178]. In addition, it has been found that catalase can bind to hydroxyapatite when protein and surface are both negatively charged due to the high ionic strength of the buffering agent [179].

Interfacial stress caused by proteins or solid breaking off into the solution leads to additional aggregation [168]. Denatured proteins may desorb from the surface and move back into solution, serving as additional nuclei for aggregation or unfolding. The manufacturing equipment can introduce particulates into solution by leaching or shedding of sub-visible particles through regular usage [180]. These particulates can further promote aggregation and denaturation.

Interfacial stress can be limited by choosing materials unfavorable to adsorption for hard proteins, or by controlling the solution pH and ionic strength to prevent electrostatic attractions. For soft proteins, sugars and surfactants can prevent aggregation by reducing the amount of protein interacting with the solid surface, such as preventing interactions with the ice interface during lyophilization [181, 182]. Reducing the flow rate of the material passing through a pump or filtration unit can limit the combined effects of shear with solid-liquid interfacial stress and reduce adsorption[170].

3.2.2. Air-liquid Interfacial Stress

The air-liquid interface is present in nearly all types of processing methods. For example, air atomizes solution into small droplets to control particle size during spray drying and protein solution is exposed to air-liquid interface [183, 184]. Stress at the air-liquid interface can also be induced upon completion of unit operations such as filling, which introduces air headspace [185] and leads to agitation during shipping and handling [186].

When exposed to the air-liquid interface, proteins tend to adsorb at the surface due to their amphiphilic nature. A higher concentration of protein can be found at the interface than in solution [184]. As the protein moves from solution to the surface, unfolding can expose its hydrophobic core to equally align at the air-liquid interface. More denaturation and protein damage can be found at the surface, which increases the tendency for aggregation as protein crowding occurs [79]. Additionally, the increase in protein concentration at the air-liquid interface leads to more interactions among protein molecules with a decrease in free volume, causing additional conformational dissociation and alteration of the tertiary structure. An increase in atomization air flow rate in spray-freeze drying of bovine serum albumin has been found to decrease particle size. However, higher amounts of aggregates were observed with increased protein interactions at the air-liquid interface [114].

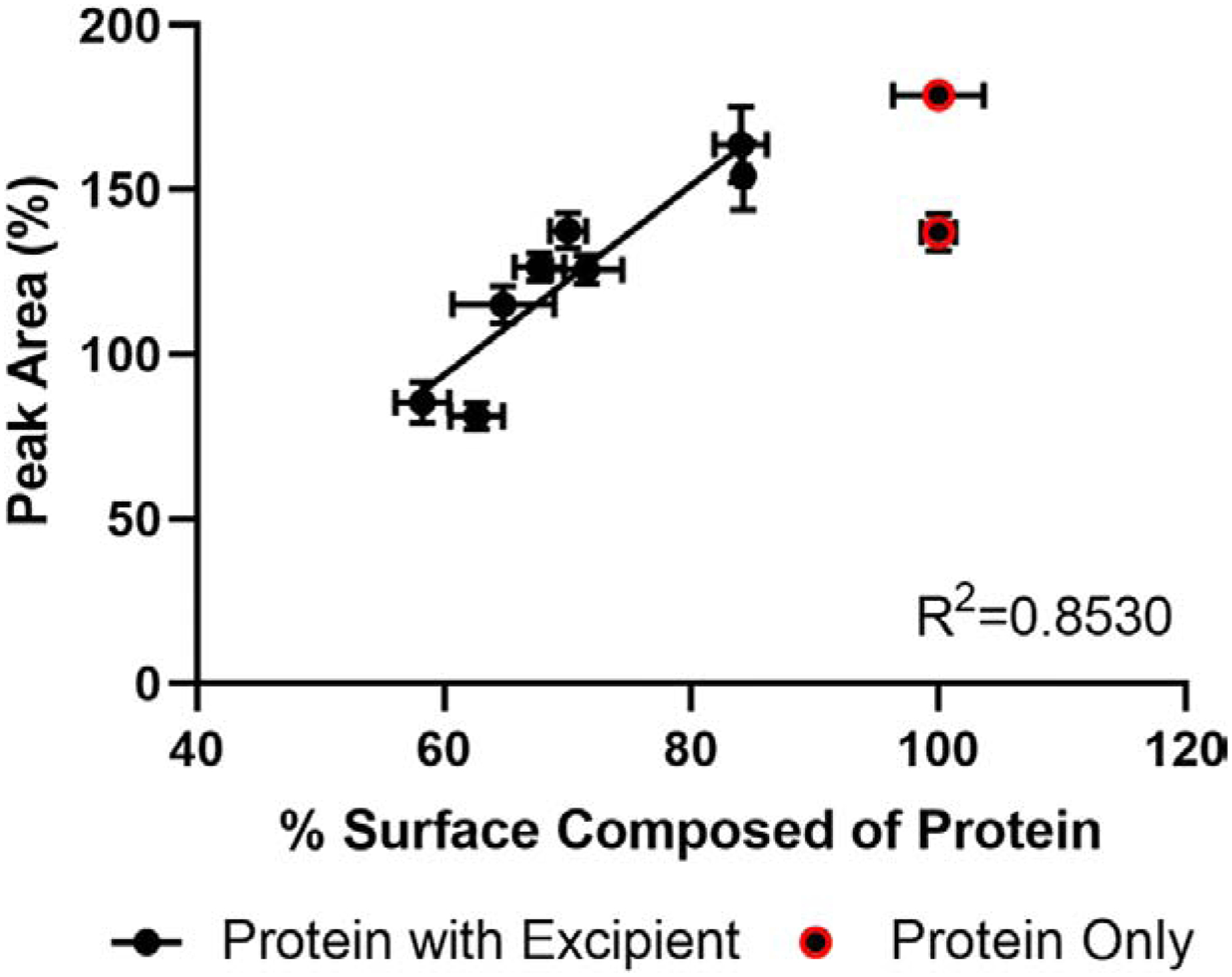

Proteins exposed at the particle surface tend to have greater heterogeneity, as suggested by a study of spray-dried bovine serum albumin on its heterogeneity and particle surface composition (see Figure 3) [96]. The effect of the stress from air-liquid interface can be minimized by reducing the air exposure time during the drying process, or by decreasing exposure area by reducing vial headspace [167]. Surfactants can be used to alleviate the stress effect from air-liquid interface in manufacturing [115, 187, 188]. Surfactants are amphipathic, which compete with proteins for adsorption at the surface, decreasing the presence of proteins at the air-liquid interface.

Figure 3.

Correlation of percentage surface composition of protein to peak area of the deconvoluted mass envelope relative to an experimentally fully-deuterated sample (Reprinted from [96, 189] with permission from Springer Nature).

3.2.3. Liquid-liquid Interfacial Stress

Proteins can be adsorbed to the interface in a two-fluid system and denatured. Such stress can be found in purification [190], encapsulation with emulsion-based methods [191], or through contamination by foreign liquids [192]. Protein molecules orient themselves at the liquid-liquid interface to reduce surface tension. Proteins will rearrange their native structures and expose hydrophilic and hydrophobic residues in order to reduce free energy at the surface and stabilize the solution [193].

Adsorption at the liquid-liquid interface depends on the properties of the two fluids, particularly when there are significant differences in solubility [194]. In several enzymes, it has been shown that the difference in solvent exposure area and interfacial tension in an aqueous-organic solvent system affects the extent of denaturation [195]. Compared to the solid-liquid and air-liquid interface, higher molecular mobility can be found at the liquid-liquid interface [193]. It promotes aggregation formation with the recycling of denatured proteins from the interface back into the bulk solution.

Excipients can reduce denaturation induced by liquid-liquid interface. Surfactant has been shown to prevent the adsorption of proteins from liquid-liquid interface [196]. Solvents can be carefully selected to prevent unfolding and structure loss. For example, the use of polyethylene glycol-dextran solutions should be avoided in lyophilization because it introduces phase separation in freezing [197]. Moreover, avoiding contamination from silicon oil during manufacturing prevents the formation of liquid-liquid interface and preserves protein structure [192].

3.3. Dehydration/Moisture Content

Proteins in aqueous solutions are hydrated with a fluid hydration shell [198]. The surface area of protein in contact with the hydration shell decreases as water is removed by high temperature drying or sublimation. Drying reduces the number of water molecules interacting with the protein. At the same time, protein molecules tend to be exposed to excipients at a higher extent as the solution becomes more concentrated, and thereby intermolecular interactions between protein and excipient that can stabilize the drug product are increased [145, 199].

Nevertheless, the drying process itself can be detrimental to protein structure. With moisture removal, the free energy of the protein changes, which causes the protein to be less stable. To compensate for the energy difference, protein molecules can rearrange themselves, or aggregate by forming intermolecular interactions with other protein molecules [198]. The increased interactions result in destabilization of protein structure, especially when there is a lack of stabilizing excipients to replace the hydrogen bonding formed by water [200]. Typically, dried protein products exhibit reasonable long-term storage stability when stored appropriately [201]. Increased moisture uptake introduces phase separation of different components in the solid [202]. Extra moisture exposure prior to reconstitution of solids could induce precipitation and aggregation of solid components and decrease protein efficacy [203]. The effect of residue moisture on protein stability needs to be further explored. In a study of a lyophilized monoclonal antibody formulation, the physical stability was compromised in the solid with higher moisture content as Tg decreased and aggregation formation increased. Moderate increase in moisture level of lyophilized solids might have a negligible impact on the chemical stability of proteins based on aspartate isomerization rate [204].

Disaccharide excipients such as sucrose and trehalose are commonly used to stabilize proteins in solid state [205]. The stabilizing effect can be explained by their ability to serve as hydrogen bond replacements for water [205]. In solution, excipients are preferentially excluded from the protein surface. Protein molecules can form strong hydrogen bonds with excipients upon depletion of the hydration shell [206, 207]. The protein structure can be stabilized as unfolding is avoided to reach a thermodynamically favorable state. Ideally, both excipients and protein remain amorphous in a stable solid state [158]. With excess excipient concentration, increased interactions among excipient molecules lead to nucleation or small crystals. These crystals may not have any deleterious effects upon formation in minute amounts [208, 209]. However, they can act as nuclei for other excipient molecules, which can lead to phase separation and could remove available hydrogen bonds for proteins.

3.4. pH

Solution pH is important in determining the interactions of formulation components. pH shifts through manufacturing steps. pH dictates the charge state of exposed amino acids of protein molecules and changes their electrostatic interactions by altering the total charge of the molecule. It affects local and global protein structures as well as solubility [154, 210, 211].

At the isoelectric point (pI), proteins have a net neutral charge and the lowest solubility [210]. Decreasing (more acidic) or increasing (more basic) pH can alter the net charge and increase protein solubility, which can destabilize the protein structure. At higher charged state, there are more electrostatic interactions with nonspecific repulsions among amino acid residues [212]. This causes amino acid sidechains to move apart, which leads to protein unfolding to maintain a state with lower free energy. However, increased electrostatic charges can introduce the formation of salt bridges. Ion pairing between amino acid sidechains with opposite charges forms a strong electrostatic bond stabilizing protein conformation [213].

Highly charged protein molecules develop repulsive interactions among themselves, which stabilize proteins and make aggregation energetically unfavorable in a colloidal solution. However, at pH closer to pI, proteins possess an anisotropic distribution of charges with both negative and positive charges. Dipoles exist and favorably interact with other protein molecules, leading to the formation of aggregates [213].

Solution pH affects protein structures. As mentioned previously, the accuracy of the two-state model of folded and unfolded protein is limited as intermediate states are not included. At extreme pH conditions, proteins can undergo conformational changes where they exist in a partially folded state called the “molten globule” state [214]. The protein molecules maintain their secondary structure similar to their natively folded state, while the overall shape tends to be slightly larger. The tertiary structure cannot be detected. It is assumed that the hydrophobic core of proteins is exposed to the solvent. The molten globule state is useful in understanding the protein folding mechanism. However, it is undesirable in a formulation. Proteins such as staphylococcal nuclease, α-lactalbumin, and β-lactamase have demonstrated pH dependence on the change of secondary and tertiary structure [215–217].

Buffer component and solution pH is critical to ensure reasonable solubility and minimize repulsive interactions. Ideally, solution pH should be far from the pI [210]. At low concentrations of salt, it reduces electrostatic interactions. When there is an excess of salt, it can bind to the protein surface and disrupt protein native conformation [218]. Higher concentration of salt is capable of salting out of the protein from solution. In addition, the processing steps such as freezing in lyophilization affects the pH and ionization strength of the solution [219]. pH shift was observed by freezing phosphate buffered saline (PBS) solution with the crystallization of disodium hydrogen phosphate dodecahydrate (Na2HPO4•12H2O) [220]. Such change has contributed to protein aggregation formation in the formulations of bovine serum albumin and β-galactosiase [221]. In addition, it has been reported recently that protonation and tautomeric states of histidine varied in solids lyophilized from solutions ranging from pH 4.5 to 11.0 as identified by 13C and 15N NMR spectra. The change of histidine was used as a probe to investigate the microenvironmental acidity change in an HPV vaccine [222].

3.5. Freezing

Drying techniques such as lyophilization and spray-freeze drying involve freezing of solutions. Freezing involves a combination of different stresses destabilizing proteins, including cold denaturation, stress at interfaces, phase separation, and changes induced by concentrated components [26, 143, 181, 209]. Freezing a solution follows the steps of super-cooling, ice nucleation, and crystal growth [223]. Super-cooling is a state when the solution maintains liquid below the ice formation temperature. Super-cooled solution solidifies quickly upon the release of latent heat [224]. As super-cooling leads to formation of ice crystals, the proteins and excipients are excluded from the sites of ice nucleation as the solubility decreases, leading to increased interaction among components in the matrix as they are concentrated. The ice nuclei begin to increase in size as the lower temperature is maintained until the water in the system has been crystallized.

Cooling rate dictates the number of ice nuclei and the size of the crystals, which is affected by the formulation composition [225]. A faster cooling rate results in greater nuclei formation and smaller crystals. A fast-freezing step used for lactate dehydrogenase demonstrated larger extent of structural damage and lower activity recovery than for a slow-freezing rate [225]. As smaller ice crystals have a larger surface area for proteins to be adsorbed, formulations with smaller ice crystals tends to lose their secondary and tertiary structures.

Differences in solubility of formulation composition causes phase separation in freezing, and certain components crystallize instead of maintaining in the amorphous matrix [226]. Crystallization of stabilizing excipients reduces stabilizing interactions with proteins, exposing them to cold denaturation stresses and increasing intermolecular interactions. The ionization strength and pH of the solution change in freezing. When the frozen solution loses moisture through drying, hydrophobic interactions decrease and the ionization strength of the solution as well as the charge on the protein increases. Additionally, buffer components can crystallize at different temperatures, leading to significant pH changes. For example, in a phosphate buffer solution, the pH with dibasic sodium salt solution will drop from 7 to 4 between −0.5°C to −9.9°C, whereas only a minor pH shift can be observed in potassium salt solution [219, 227].

Controlling the nuclei size can minimize the negative effects from freezing on protein structure, which can be achieved with controlled ice nucleation in lyophilization [228]. This promotes the formation of larger ice crystals and reduces the overall surface area, resulting in less aggregation formed at ice interfaces. Surfactants such as polysorbate 80 can also be used to reduce the adsorption of proteins at ice interfaces [181].

3.6. Pressure

Proteins are elastic in order to bind to specific sites and adapt to environmental changes [142, 229]. The volume of the protein can be altered with high pressure, resulting in conformational changes. The change in volume as a result of the change in free energy due to pressure can be described in the following equation:

| (9) |

where ΔV is the change in volume, ΔG is the change in Gibbs free energy, and p is the pressure of the system.

The volume change is affected by the space occupied by the atoms of the protein, the volume of the excluded solvent (such as the hydrophobic core), and the volume difference from the interaction between the protein and solvent [230]. High pressures have an effect on all the factors mentioned above and induce protein disassociation or unfolding. The rate of denaturation or disassociation due to pressure can be given by the equation:

| (10) |

where Kd is the equilibrium constant for dissociation or denaturation at pressure p, and Kd0 is the equilibrium constant for structural destabilization at atmospheric pressure [231].

Stabilizing interactions with protein molecules such as ionic and hydrophobic bonding can be disrupted with high pressures. For oligomeric proteins primarily connected by electrostatic and hydrophobic interactions, moderate pressures (0.5–2 kbar) are required for dissociation [232]. Protein unfolding leads to cavitation, exposing the hydrophobic core to the solvent. The formation of these denatured species under high pressures is favorable due to volume reduction, as unfolded protein have higher compressibility than those in the folded state [233].

The pressure required to impact protein stability is typically 2–4 kbar [234], which is not common in standard manufacturing processes. High pressure can be used to concentrate proteins in solution and reduce aggregation through dissociation oligomers. In protein synthesis, increased pressure has been shown to improve the recovery of properly folded proteins from non-native aggregates with and without chaotropic agents [235, 236]. Similarly, proteins have been stabilized at the pressure between 1–3 kbar by dissociating oligomers into monomers [237].

In summary, protein solid products are exposed to various stresses in development and manufacturing, which can cause detrimental effects on protein structure and further promote irreversible damage and aggregation. By understanding the origin and impact of these stresses in manufacturing, strategies in formulation and process design can be utilized to minimize the effects and achieve stable products. In the next section, we will discuss the solid-state characterization techniques that can detect and evaluate stress-induced damage on protein during the drying process.

4. SOLID STATE CHARACTERIZATION TECHNIQUES

Today, monoclonal antibodies (mAb) are popular biotherapeutics [238], and other new biotherapeutics such as mRNA [239] and Cart-T cells [240] are emerging. Due to the unique nature of proteins, their manufacturing process is much more complicated than that of smaller molecules [241]. As we discussed in the previous sections, proteins can be exposed to various stresses throughout the manufacturing process, which can lead to chemical and physical changes [241]. Protein drugs are usually formulated with disaccharide excipients and must be manufactured in solid dosage forms in order to have a reasonable shelf-life [10]. It is critical to ensure that the protein structure remains stable during manufacturing and storage. Understanding the properties of solid matrix containing excipients as well as understanding the interactions between protein and excipients will improve the formulation development process.

Some techniques can be used to detect protein structure changes in the solid samples. For example, solid state Fourier transform infrared spectrometry (ssFTIR) and solid-state fluorescence spectroscopy can be used to measure the secondary and tertiary structure of a protein. There are also methods to characterize the global properties of solids. Differential scanning calorimetry (DSC) measures the glass transition temperature (Tg) of the solid matrix. Tg is routinely determined in formulation development, since protein formulations are expected to remain stable while the storage temperature is below Tg [242]. These techniques can easily be applied on solid samples without extra sample preparation. However, it is difficult to examine solid matrix at the molecular level with these traditional analytical methods. Traditional methods used for small molecules and newly emerging techniques have been applied on biopharmaceutical solids for characterization purposes. Solid-state magnetic resonance (ssNMR) has been used to analyze protein dynamics and phase separation in solid matrix [243, 244]. In addition, solid-state hydrogen deuterium exchange (ssHDX) coupled with mass spectrometry (MS) has been used to study the disruption of protein conformation in solid state, and the results have been correlated with long-term physical stability of proteins in formulations [245]. Unconventional methods such as photolytic cross-linking have also emerged to study the interactions between excipient and protein in the solid state [246]. The choice of characterization technique usually depends on instrument resolution and the information needed. A combination of various analytical tools is commonly used to characterize proteins and the solid matrix [247, 248]. This section focuses on analytical techniques that have been applied on the characterization of protein formulations in the solid state. Their principles as well as advantages and disadvantages are discussed.

4.1. Differential Scanning Calorimetry (DSC)

Pharmaceutical products are often formulated as solids to achieve desired stability [249]. Such protein solids are often amorphous; when they are heated, the system undergoes a transition from amorphous to a rubbery condition [250]. The heat flow between the sample and reference can be used to quantitatively characterize the change in enthalpy and heat capacity. This works well for solids of a pure material when heated at a constant rate, but not for pharmaceutical solids containing several components [251]. There are reversible (e.g. glass transition) and non-reversible (e.g. crystallization) heat events involved when heating amorphous pharmaceutical solids. Thus, modulated DSC (mDSC) has been introduced by adding a temperature modulation to the constant heating rate. The response to multiple heating rates is recorded simultaneously, which helps to separate the thermal events of each component [252]. The state transition from amorphous to rubbery shows as a discontinuity on the diagram of heat-capacity versus temperature, which exhibits as a base line shift. The midpoint of such a shift is defined as the glass transition temperature (Tg) [253].

Most lyophilized products exist in glassy state below the Tg value. A high Tg value is desirable when considering the storage condition of pharmaceutical solids. In the powders of a model protein alkaline phosphatase spray dried with either inulin or trehalose, optimal protein stability was maintained when the storage temperature was 10 °C to 20 °C below Tg [254]. Tg is one of the most important criteria in the development of the lyophilization cycle because it is closely related to determining storage temperature. In a mAb formulation lyophilized with only sucrose, a Tg of ~43 °C was achieved. When different levels of the combination of 2-hydroxypropyl-beta-cyclodextrin (CD), recombinant human albumin, PVP and dextran 40 kDa were added to the formulation, Tg values of 96~200 °C could be obtained. Formulations with sucrose/CD and sucrose/CD/PVP in 9-month storage at 40 °C were better compared to the formulation with only sucrose in characterization tests such as visible/subvisible particles and monomer content [255].