Abstract

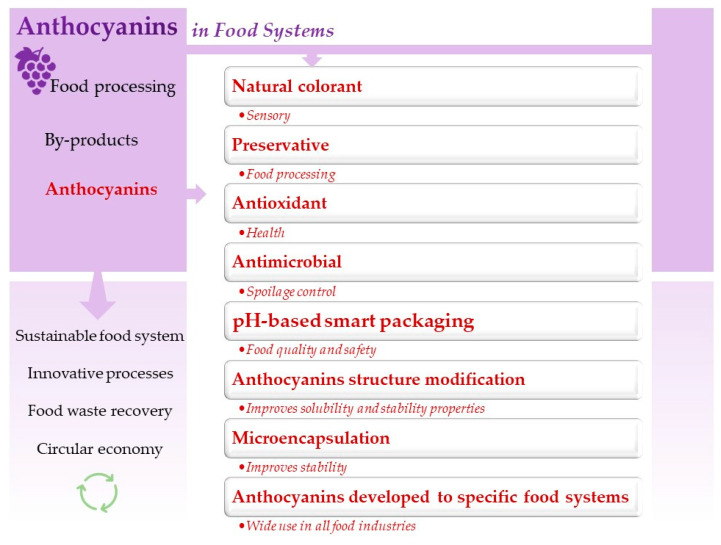

Anthocyanins are naturally occurring phytochemicals that have attracted growing interest from consumers and the food industry due to their multiple biological properties and technological applications. Nevertheless, conventional extraction techniques based on thermal technologies can compromise both the recovery and stability of anthocyanins, reducing their global yield and/or limiting their application in food systems. The current review provides an overview of the main innovative processes (e.g., pulsed electric field, microwave, and ultrasound) used to recover anthocyanins from agri-food waste/by-products and the mechanisms involved in anthocyanin extraction and their impacts on the stability of these compounds. Moreover, trends and perspectives of anthocyanins’ applications in food systems, such as antioxidants, natural colorants, preservatives, and active and smart packaging components, are addressed. Challenges behind anthocyanin implementation in food systems are displayed and potential solutions to overcome these drawbacks are proposed.

Keywords: phenolic compounds, bioactive compounds, waste valorization, emerging technologies, green chemistry, non-thermal processes, pulsed electric field, microwave, ultrasound

1. Introduction

Sustainable development plays a crucial role in improving the social, technical, and economic fields, aiming to create a circular economy and meet society’s needs. Therefore, the implementation of sustainable food production systems is essential to ensure the future needs of safe, healthy, and nutritious foods for the growing human population. In this way, the proper use of natural resources, zero food wastes, and the adoption of food production systems with high efficiency and low energy consumption are critical parts of sustainable food production [1].

Food and agricultural industries generate millions of tons of wastes and by-products annually, resulting in a significant financial burden to the processors and causing and/or contributing to immense environmental problems [2]. However, wastes and by-products derived from food processing are rich sources of potentially valuable bioactive compounds. Their sustainable use to produce value-added products/ingredients could reduce environmental issues, improve economic growth, and promote human health benefits through foods enriched with bioactive compounds [3,4]. Thereby, agri-food by-products (e.g., wastewaters, peel and seeds of fruits and vegetables, pomaces, straws, shells, brans, leaves, and other derivative by-products) have emerged as potential sources for obtaining bioactive compounds (e.g., phenolic compounds, anthocyanins, carotenoids, fiber, bioactive peptides, fatty acids, etc.) and enzymes of great interest for the food, pharmaceutical, and cosmetical industries [5,6].

Among the various value-added molecules obtained from agri-food by-products, anthocyanins have attracted special attention from people, researchers, and industries due to their multifaceted technological and biological properties. Anthocyanins are phytopigments and bioactive compounds belonging to the flavonoid class of phenolic compounds found in plant tissues (especially flowers and fruits). These water-soluble pigments provide a broad color spectrum ranging from red to blue, depending on pH [7]. This feature has been exploited to develop natural colorants [8,9] and active/smart packaging for foods [10,11]. Moreover, anthocyanins are natural antioxidants and antimicrobials that have been used as food preservatives [12,13]. In addition to their technological applications, anthocyanins have been shown to possess protective and promoting effects on human health by preventing and mitigating the onset and/or progression of neurodegenerative diseases, metabolic syndromes, cancers, etc., due to their multiple biological properties [14,15,16].

Despite the high technological, functional, and economic potential, anthocyanins’ application as food additives in food systems is still limited. Prior steps of obtaining these molecules condition it (e.g., extraction, purification, and stabilization) [17]. Anthocyanins are highly unstable compounds and easily susceptible to several factors, such as temperature, oxygen, enzymes, light (UV-visible), pH, ascorbic acid, and other substances (e.g., copigments and metals) [17,18]. Consequently, anthocyanins can be degraded by one or more of the factors mentioned above during their extraction process. Therefore, the choice of extraction technology and extraction conditions are key steps in the recovery and purification of anthocyanins for food purposes. These choices should be based on simplicity, versatility, cost, and ability to extract and preserve the target compounds [19].

The food industry is increasingly interested in innovative mild/non-thermal processing technologies (e.g., ultrasound (US), pressurized liquid extraction (PLE), supercritical fluid extraction (SFE), high hydrostatic pressure extraction (HHPE), pulsed light (PL), pulsed electric field (PEF), high voltage energy discharge (HVED), microwave (MW), enzyme-assisted extraction (EAE), and instant controlled pressure drop-assisted extraction (DIC)) for anthocyanin extraction due to their ability to enhance the extraction yield, increase the extraction rate, operate at room or low temperature, minimize the loss for thermal degradation during processing, reduce the detrimental effect on the extracted compounds, improve energy efficiency, and prioritize the use of “recognized as safe” organic solvents as compared to conventional thermal processing [2,20]. Therefore, the combination of agri-food by-products with innovative extraction techniques for obtaining anthocyanins can contribute to the achievement of high-quality products and the sustainable development of food systems.

The current review provides an overview of the main innovative processes (e.g., pulsed electric field (PEF), microwave (MW), and ultrasound (US)) used to recover anthocyanins from agri-food waste/by-products and the mechanisms involved in anthocyanin extraction, as well as their impacts on the stability of these compounds during the extraction process. Moreover, human clinical trials showing the potential beneficial health effects of anthocyanins, trends, and perspectives of anthocyanins’ applications in food systems and the challenges behind their implementation are also addressed. This review can be handy for scientists and food manufacturers from the point of view of commercial exploitation. It compiles and shows the main agri-food by-products sources of anthocyanins and the best processing conditions for their recovery using different innovative extraction technologies.

2. Anthocyanins

2.1. Chemical Structure and Properties

Anthocyanins (derived from Greek anthos = flower and kyáneos = blue) are natural plant pigments widely found in foods and beverages. These compounds are responsible for the red-orange to blue-violet colors in many fruits, vegetables, flowers, and leaves, and they are found in high quantity in the pigmented leaves, followed by fruits and flowers [21,22].

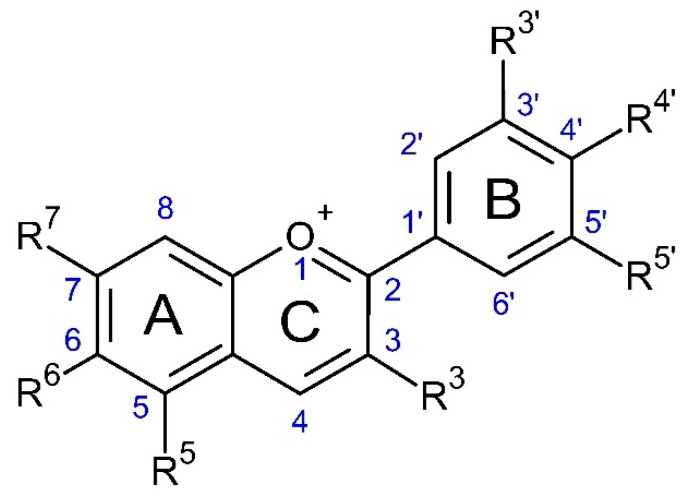

Anthocyanins are water-soluble antioxidants pigments that belong to a polyphenol-based flavonoids family due to their characteristic C15 skeleton based on C6-C3-C6 core structure [17]. Chemically, anthocyanins are polyhydroxylated and/or polymethoxylated glycosides derived from the 2-phenylbenzopyrilium ion (flavylium cation). As can be seen in Figure 1, the basic anthocyanin structure consists of an aromatic ring (A-ring) bonded to an oxygenated heterocyclic ring (C-ring) which, in turn, is also linked through its C3 to the C1’ of a second aromatic ring (B-ring). The flavylium cation gives anthocyanins the red color that distinguishes them from other types of flavonoids [23,24].

Figure 1.

Basic anthocyanin structure.

The anthocyanin molecule is formed of an aglycone (anthocyanidin) with the presence or not of sugars (glycosylated anthocyanins) and organic acids groups (acylated anthocyanins). They can be divided into different groups based on the types of aglycones; those most commonly found in plants are cyanidin (reddish-purple color, 50%), delphinidin (red-blue color, 12%), pelargonidin (red-orange color, 12%), peonidin (magenta color, 12%), malvidin (purple color, 7%), and petunidin (red color, 7%) [25,26].

There is a wide variety of anthocyanins found in nature. Estimates point to the existence of more than 500 anthocyanins and 23 anthocyanidins [24]. The main differences between them are due to their chemical structure features, such as the number of hydroxyl groups and/or methoxyl groups present; the nature, number, and position of sugars groups linked to the anthocyanin backbone; and the presence of aliphatic or aromatic acids bonded to the sugar molecule [27,28]. The intensity and hue of the color of anthocyanins depend on the number of hydroxyl and methoxyl groups. In general, blueness increases with the degree of hydroxylation, while redness rises with the degree of methylation. Anthocyanins’ color is also influenced by copigmentation; for example, copigmentation of anthocyanidins with flavonoids improves their color intensity [26].

Anthocyanins have a positive charge on their C-ring (ionic nature) that favors the appearance of different colors in response to pH variations [29]. Polymerization, cleavage, and derivatization are mainly reactions that occur with anthocyanins according to pH changes and are related to their color stability, resulting in browning compounds, colorless, and colored molecules, respectively [18]. In general, highly acidic conditions favor redness color and the stability of the anthocyanins due to a higher formation of flavylium cations. In contrast, alkaline conditions reduce stability, increase blueness color, and promote the chemical degradation of the anthocyanins [25].

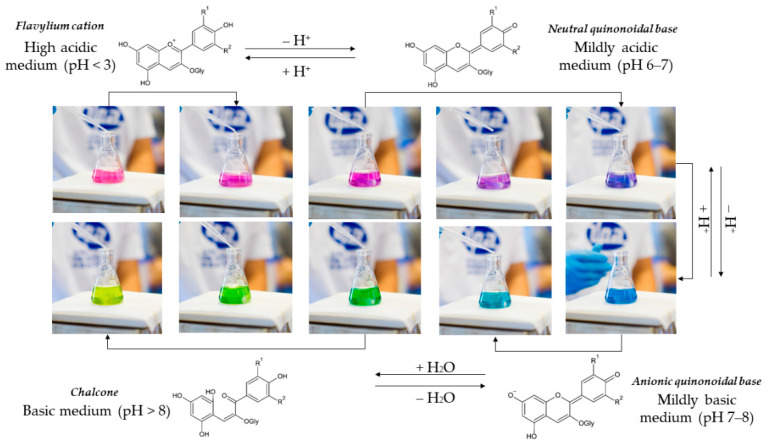

In superacid conditions (pH < 3), the flavylium cation is the majority species and favors reddish-purple color. At increasing pH conditions (pH 4–5), colorless carbinol pseudo base predominates, and anthocyanin solution become very little colored due to the small number of other colored species (flavylium cation and quinonoidal anion). At mildly acidic conditions (pH 6–7), the blue-violet neutral quinonoidal species are predominant. As the pH increases (pH 7–8), the neutral quinonoidal species’ deprotonation forms anionic quinonoidal bases that promote an intense blue color. In superalkaline conditions (pH > 8), yellowish chalcone is formed and, subsequently, anthocyanins undergo breakdown according to their substituent groups and structure (see Figure 2) [25,26]. Figure 2 shows the pH-dependent structural and color changes of anthocyanins from a red cabbage aqueous extract.

Figure 2.

pH-dependent chemical structures and color changes of anthocyanins from red cabbage. Experiment performed by Gustavo Araujo Pereira and registered by Karla Ferreira Nery Martins (photos). HCl and NaOH (0.1 M) were employed to alter the pH of the red cabbage aqueous extract.

2.2. Natural Sources

Anthocyanins are naturally found in a wide number of foods, including fruits and vegetables. They are predominantly found in berries, currants, grapes, tropical fruits, red to purplish blue-colored leafy vegetables, grains, roots, and tubers. The berries are the wealthiest and most well-known sources of anthocyanins, such as blackberries, blueberries, strawberries, blackcurrants, cherries, chokeberries, elderberries, and gooseberries. Furthermore, there are other anthocyanin sources, such as red grapes, eggplant, acai, jabuticaba, oranges, purple corn, red wine, red cabbage, apples, radishes, pomegranate, black carrots, purple potatoes, and edible flowers (e.g., red hibiscus, red rose, red pineapple sage, red clover, pink blossom, cornflower, blue chicory, blue rosemary, purple mint, purple passionflower, purple sage, common violet, and lavender) [25,26]. In addition to being widely consumed in fresh and frozen forms, anthocyanins-rich fruits/vegetables are also found in several processed and derived products, including wine, dried and canned fruits, yogurts, beverages, jams, and jellies [30]. Anthocyanin profile and content varies between the foods due to external and internal factors, such as biotic and abiotic stress, cultivation practices, genetics, intensity and type of radiation, temperature, processing, and storage [30,31,32].

Various phenolic compounds remain trapped in the food matrix during food processing, resulting in high value-added agri-food by-products discarded as natural waste in the environment or used for composting. This generates great economic losses and environmental problems that could be avoided using an agri-food by-product recovery system. In general, the agri-food by-products are mainly constituted of skin/peel and seeds, and they are generated mainly from fruits and vegetable processing [33]. The main and best-known agri-food by-product is the grape pomace that results from grape juice and winemaking processing, consisting mainly of skin, seeds, stems, and remaining pulp. Grape pomace stores many phenolic compounds. It is the most-used raw material for anthocyanin extraction by the food industry [33,34].

Although anthocyanin content varies according to the cultivation techniques and species, the malvidin was the major anthocyanin (0.29 to 3.33 mg/g skin) in all studied grape cultivars, followed by petunidin, delphinidin, peonidin, and cyanidin [35]. Thirteen anthocyanins were identified from grape pomace by HPLC-MS/MS, whose results also confirmed that malvidin is the predominant anthocyanin. The most intense chromatographic signals observed were for malvidin-3-O-glucoside, malvidin-3-O-acetylglucoside, and malvidin-3-O-p-coumaroylglucoside [36]. Meanwhile, grape seeds showed only two anthocyanins that were found in low concentrations, namely malvidin-rutinoside (0.024 µg/g extract) and malvidin-hexoside (0.010 µg/g extract) [37]. Another anthocyanin source resulting from the winemaking industry is the wine lees that, according to some authors, could be alternative that is cheaper and more easily extracted than the traditional sources [38].

Other agri-food by-products have been exploited for anthocyanin extraction, such as black carrot pomace [39], eggplant by-product [40,41], black soybean seed coat [42], purple corn cob and corn husk [43], onion peel [44], black rice bran [45], and some berry by-products (e.g., blueberry [46], red raspberry [47], sweet cherry [48], sour cherry [49], bilberry [50], blackcurrant [51], blackberry [52], jabuticaba [53], black chokeberry [54], and mulberry [55], among others). Nonetheless, they are less explored and less known when compared to grape pomace. Therefore, research should be intensified and driven towards the less exploited agri-food by-products to obtain high added-value anthocyanin extracts.

2.3. Chemical Stability

Anthocyanins are highly unstable and susceptible to degradation, which varies widely according to their chemical structure and food concentration. This strongly influences the anthocyanin content in the final product and their benefits to human health [56]. Several environmental factors affect anthocyanin color and stability. The most important and studied of them are temperature, pH (see Section 2.1), enzymes, light, oxygen, metallic ions, sulfites, and interaction with other food components (e.g., other flavonoids and phenolics, ascorbic acid, sugars, etc.) as well as other factors [18,32].

Anthocyanins are largely unstable during food processing, in which the temperature can reach around 50–150 °C [57]. Thermal processes are one of the main and most well-known factors that influence the anthocyanin stability rate. They are extremely sensitive to thermal treatment. When exposed to high temperatures and prolonged heating, the anthocyanins undergo oxidation and structure breakdown characterized by successive reactions of deglycosylation, nucleophilic attack of water, cleavage, and polymerization. These structural changes result in the loss of sugar moieties, color, stability and, consequently, considerably reduce anthocyanin content in the final product [32]. Anthocyanin stability is maintained at temperatures up to 60 °C. High processing temperatures (>60 °C) promote the anthocyanin molecules’ breakdown into colorless compounds. Therefore, prolonged exposure to high temperatures should be avoided to reduce the chalcone formation and losses of anthocyanin stability [58]. The lower the processing temperature, the greater the accumulation and stability of anthocyanins (flavylium cation).

Anthocyanins are enzymatically degraded in foods due to glycosidases and polyphenol oxidases that promote their decolorization. The β-glycosidases hydrolyze glycosidic bonds between the glycosyl residue and an anthocyanins aglycone, releasing their less stable counterpart, anthocyanidins. On the other hand, in the presence of oxygen, polyphenol oxidases catalyze the hydroxylation of monophenols to o-diphenols and the oxidation of o-diphenols to o-quinones compounds promoting anthocyanin degradation and catalyzing the formation of brown-colored compounds. Furthermore, peroxidases have also been reported to promote anthocyanin degradation [59,60]. Therefore, the inactivation of these enzymes can be a good strategy to improve anthocyanin stability.

The accumulation of anthocyanins is also directly influenced by their exposure to light. In plants, this exposure favors their biosynthesis, resulting in colored pigments, while over food processing/storage, light accelerates their degradation. Light intensity and spectrum influence the anthocyanin biosynthetic genes, improving their production. In contrast, light irradiation promotes anthocyanin molecule excitation, leading to the formation of carbon-centered radicals that can generate peroxyl radicals in the presence of oxygen, accelerating anthocyanin degradation [61,62].

Oxygen is another major environmental factor influencing anthocyanin stability, and that can result in some undesired outcomes. Anthocyanins undergo decomposition under aerobic conditions. The molecular oxygen promotes harmful effects in the anthocyanin molecule [60]. In the presence of oxygen, ascorbic acid-induced degradation of anthocyanin results in the formation of hydrogen peroxide and oxidative cleavage of the C-ring, producing brown pigments that are undesirable changes in food, especially in juices [63]. Moreover, the synergism between oxygen and high temperatures is the factor that most accelerates anthocyanin degradation [64]. The removal of oxygen protects the anthocyanins against oxidative degradation and slows down thermal degradation.

The interaction between anthocyanins and sulfites leads to the formation of colorless adducts because of the interruption of the conjugated π-electron system [18]. As a consequence, sulfite addition should be avoided in anthocyanin-rich processed products.

On the other hand, anthocyanin association reactions can improve their stability and color by protecting C2 of the flavylium chromophore from the nucleophilic attack of water. These associations can occur in three ways: (1) self-association (anthocyanins are associated with each other via hydrophobic interactions that occur between their aromatic nuclei), (2) copigmentation (anthocyanins are associated with other compounds, such as other phenolic compounds), and (3) metal complexing (anthocyanins are associated with metals, such as magnesium and aluminum, via interactions of their o-hydroxy groups). Meanwhile, copigmentation can be intramolecular or intermolecular. Intramolecular copigmentation is characterized by stacking the hydrophobic acyl moiety covalently bound to sugar and the flavylium nucleus. In contrast, intermolecular copigmentation occurs when anthocyanins interact with some colorless compounds (e.g., aurones, flavones, and flavanols) through van der Waals interactions between the planar polarizable nuclei of the anthocyanin with these compounds [17,32]. Therefore, the copigments approach can be a promising tool for improving anthocyanins color and stability.

As a general remark, food processing should minimize these aforementioned undesirable changes to obtain high-quality anthocyanins-rich foods/extracts.

2.4. Biological Activities

Anthocyanins are widely studied as bioactive agents to manage and/or prevent the onset/development of several diseases, such as chronic degenerative diseases including cardiovascular diseases, cancers, type 2 diabetes mellitus, neurodegenerative diseases, and dyslipidemias [28]. Several biochemical parameters have been related to the prevention or development of these diseases. Some biochemical parameters, such as tumor necrosis factor-alpha (TNF-α), interleukins (ILs), nuclear factor-kappa B (NF-kB), and cyclooxygenase 2 (COX-2), are involved in the inflammatory responses. In contrast, the increase in reactive oxygen species (ROS) and malonaldehyde, and the reduction in the activity/expression of antioxidant enzymes, such as superoxide dismutase (SOD), catalase (CAT), etc., are related to oxidative processes [65,66,67].

The biological activities of anthocyanins are dependent mainly on their structure and chromatic features. For example, the three hydroxyl groups in the B-ring in the molecular structure of the delphinidin increase their efficiency against cancer cells compared with other anthocyanins, such as cyanidin [28].

Beneficial effects for human health related to anthocyanins have been demonstrated in human clinical trials. Daily intake of anthocyanins improved glycemia, insulin sensitivity, lipids and lipoproteins profiles, memory function, cardiovascular health, antioxidant status, gut microbiota composition, etc. (for more details, see Table 1).

Table 1.

A summary of human trials showing the potential health beneficial effects of anthocyanins.

| Anthocyanin | Anthocyanin Dose | Time | Subject Profile | Study Type | Major Findings | Reference |

|---|---|---|---|---|---|---|

| MEDOX® (Purified anthocyanins) a | 320 mg/day | 12 weeks | 160 subjects with prediabetes or early untreated T2DM (40–75 years; 54 males and 106 females) | Randomized, double-blind, placebo-controlled trial |

|

[68] |

| MEDOX® (Purified anthocyanins) a | 320 mg/day | 12 weeks | 138 subjects with prediabetes or newly diagnosed T2DM (40–75 years; 45 males and 93 females) | Randomized, double-blind, placebo-controlled trial |

|

[69] |

| MEDOX® (Purified anthocyanins) a | 320 mg/day | 12 weeks | 121 patients with fasting hyperglycemia (average age: 61 years old; 42 males and 79 females) | Randomized controlled trial |

|

[70] |

| MEDOX® (Purified anthocyanins) a | 320 mg/day | 4 weeks | 14 healthy (35.2 ± 3.16 years old; 8 males and 6 females), 14 T2DM at-risk (50.1 ± 3.15 years old; 8 males and 6 females), and 12 T2DM (57.7 ± 2.5 years old; 8 males and 4 females) individuals | Open-label design |

|

[71] |

| MEDOX® (Purified anthocyanins) a | 20, 40, 80, 160, and 320 mg/day | 14 days | 111 healthy adults (18–35 years old; 39 males and 72 females) | Randomized, double-blind, placebo-controlled trial |

|

[72] |

| MEDOX® (Purified anthocyanins) a | 40, 80, and 320 mg/day | 12 weeks | 169 dyslipidemic subjects (35–70 years old; 45 males and 124 females) | Randomized, double-blind, placebo-controlled trial |

|

[65] |

| MEDOX® (Purified anthocyanins) a | 40, 80, and 320 mg/day | 12 weeks | 176 dyslipidemic subjects (35–70 years old; 46 males and 130 females) | Randomized, double-blind, placebo-controlled trial |

|

[73] |

| MEDOX® (Purified anthocyanins) a | 40, 80, and 320 mg/day | 12 weeks | 176 dyslipidemic subjects (57.41 ± 7.95 years old; 46 males and 130 females) | Placebo-controlled, double-blind, randomized trial with multiple doses |

|

[74] |

| MEDOX® (Purified anthocyanins) a | 320 mg/day | 24 weeks | 150 hypercholesterolemic subjects (40–65 years old; 63 males and 87 females) | Randomized, double-blind, placebo-controlled trial |

|

[75] |

| MEDOX® (Purified anthocyanins) a | 320 mg/day | 4 weeks | 12 lean (33.0 ± 3.2 years old; 6 males and 6 females), 9 overweight (49.9 ± 4.2 years old; 5 males and 4 females), and 8 obese (43.3 ± 4.5 years old; 4 males and 4 females) participants | Clinical trial |

|

[76] |

| MEDOX® (Purified anthocyanins) a | 320 mg/day | 4 weeks | 51 subjects (25 normal subjects (38.2 ± 2.7 years old; 13 males and 12 females) and 26 MetS subjects (56.6 ± 2.6 years old; 14 males and 12 females)) | Clinical trial |

|

[77] |

| MEDOX® (Purified anthocyanins) a | 320 mg/day | 4 weeks | 35 subjects (15 normal subjects (37.3 ± 2.9 years old; 10 males and 5 females) and 20 MetS subjects (56.2 ± 2.9 years old; 11 males and 9 females)) | Clinical trial |

|

[78] |

| MEDOX® (Purified anthocyanins) a | 320 mg/day | 4 weeks | 26 pro-thrombotic overweight and obese individuals (39 ± 11 years old; 9 males and 17 females) | Randomized, double-blind, placebo-controlled, crossover design dietary intervention trial |

|

[79] |

| MEDOX® (Purified anthocyanins) a | 320 mg/day | 4 weeks | 16 sedentary pro-thrombotic individuals (38 ± 12 years old; 3 males and 13 females) | Randomized, double-blind, placebo-controlled, cross-over design dietary intervention trial |

|

[80] |

| MEDOX® (Purified anthocyanins) a | 320 mg/day | 16 weeks | 27 individuals with MCI (n = 8) or stable non-obstructive coronary artery disease (n = 19) (55–70 years old; 18 males and 9 females) | Open-label study |

|

[81] |

| Anthocyanins-rich blackcurrant extract | 150, 300, and 600 mg | Acute | 14 men and 9 postmenopausal women (46 ± 14 years old) consuming a high-carbohydrate meal | Randomized, double-blind, crossover trial |

|

[82] |

| Anthocyanins-rich blackcurrant extract | 3.2 mg/kg/day (~240 mg/day) | 5 weeks | 34 healthy individuals (38 ± 11 years old; 21 males and 13 females) | Double-blind placebo-controlled trial design |

|

[66] |

| Anthocyanins-rich black soybean testa extract | 31.45 mg/day | 8 weeks | 63 overweight or obese individuals (30.59 ± 9.25 years old; 50 males and 30 females) | Randomized, double-blinded, placebo-controlled clinical trial |

|

[83] |

| Anthocyanins-rich Queen Garnet plum juice | 200.8 mg/day | 4 days | 16 overweight subjects (65.9 ± 6.0 years old; 3 males and 13 females) consuming a high-fat high energy meal | Crossover, randomized, controlled, double-blind clinical trial |

|

[84] |

| Anthocyanins-rich Queen Garnet plum juice | 47 and 201 mg/day | 8 weeks | 31 subjects with MCI (75.3 ± 6.9 years old; 12 males and 19 females) | Randomized, controlled, double-blind clinical trial |

|

[85] |

| Anthocyanins from blueberry | 258 mg/day | 16 weeks | 37 older adults with MCI (≥68 years old; 17 males and 20 females) | Randomized, double-blind, parallel groups, placebo-controlled trial |

|

[86] |

| Anthocyanins-rich black rice extract | 19.08 mg/day | 12 weeks | 48 subjects with subjective memory impairment (63.88 ± 7.59 years old; 16 males and 32 females) | Double-blind randomized, placebo-controlled trial |

|

[87] |

| Anthocyanins-rich cherry juice | 138 mg/day | 12 weeks | 49 older adults with mild-to-moderate dementia (≥70 years old; 25 males and 24 females) | Randomized controlled clinical trial |

|

[88] |

| Anthocyanins-rich bilberry extract | 840 mg/day | 6 weeks | 13 patients with current mild-to-moderate ulcerative colitis (19–61 years old; 10 males and 3 females) | Open, prospective, non-blinded, and non-controlled pilot trial |

|

[67] |

| Anthocyanins-rich blackcurrant extract | 210 mg/day | 7 days | 14 older adults (73.3 ± 1.7 years old; 6 males and 8 females) | Randomized, double-blind, placebo-controlled, crossover design study |

|

[89] |

| Anthocyanins-rich red fruit juice b | 205.5 mg/day | 8 weeks | 57 healthy male volunteers (20–50 years old) | Prospective, randomized, placebo-controlled parallel design |

|

[90] |

| Anthocyanins-rich aronia extract | 30 mg/day | 12 weeks | 66 healthy male volunteers (18–45 years old) | 3-arm, randomized, double-blind, placebo-controlled, parallel trial |

|

[91] |

| Anthocyanins-rich bilberry extract | 88.5 mg/day | 12 weeks | 109 healthy adults (20–60 years old; 34 males and 75 females) | Randomized, double-blind, placebo-controlled, parallel-group comparison trial |

|

[92] |

| Delphinol® (Purified anthocyanins) c | 60 mg/day | 8 weeks | 16 healthy female subjects (27–57 years old) | Randomized, double-blind, placebo-controlled pilot study |

|

[93] |

Where: ↓ indicates reduction; ↑ indicates increase; 8-iso-PGF2α, 8-iso-prostaglandin F2α; 8-OHdG, 8-hydroxy-2′-deoxyguanosine; ADP, adenosine diphosphate; Apo, apolipoproteins; BD2, beta-defensin 2; COX-2, cyclooxygenase 2; ENA-78, epithelial neutrophil-activating peptide; FBG, fasting blood glucose; GIP, glucose-dependent insulinotropic polypeptide; HbA1c, glycated hemoglobin A1c; HDL-c, high-density lipoprotein cholesterol; HFC-1, high-frequency component 1; HO-1, heme oxygenase 1; hs-CRP, high-sensitivity C-reactive protein; IFN-γ, interferon-gamma; IgA, immunoglobulin A; IGFBP-4, insulin-like growth factor binding protein 4; IL, interleukins; LDL-c, low-density lipoprotein cholesterol; MCI, mild cognitive impairment; MCP-1, monocyte chemoattractant protein 1; MDA, malonaldehyde; MetS, metabolic syndrome; NAP-2, neutrophil-activating peptide 2; NF-κB, nuclear factor-kappa B; NQO-1, NAD(P)H quinone oxidoreductase 1; PAC-1, procaspase 1; PECAM-1, platelet endothelial cell adhesion molecule 1; PPAR-γ, peroxisome proliferator-activated receptor gamma; RANTES, regulated on activation, normal T-cell expressed and secreted; ROS, reactive oxygen species; SDF-1α, stromal cell-derived factor 1-alpha; SOD, superoxide dismutase; STAT1, signal transducer and activator of transcription 1; T2DM, type 2 diabetes mellitus; TC, total cholesterol; TG, triglycerides; TNF-α, tumor necrosis factor-alpha. a The MEDOX® food supplement capsules (Medapalett Pharmaceuticals, Biolink, Sandnes, Norway) contain purified anthocyanins isolated from bilberries (Vaccinium myrtillus) and blackcurrant (Ribes nigrum) (33.0% of 3-Ο-β-glucosides, 3-Ο-β-galactosides, and 3-Ο-β-arabinosides of cyanidin; 58.0% of 3-Ο-β-glucosides, 3-Ο-β-galactosides, and 3-Ο-β-arabinosides of delphinidin; 2.5% of 3-Ο-β-glucosides, 3-Ο-β-galactosides, and 3-Ο-β-arabinosides of petunidin; 2.5% of 3-Ο-β-glucosides, 3-Ο-β-galactosides, and 3-Ο-β-arabinosides of peonidin; 3.0% of 3-Ο-β-glucosides, 3-Ο-β-galactosides, and 3-Ο-β-arabinosides of malvidin; and 1.0% of 3-Ο-rutinoside of cyanidin and delphinidin). b The anthocyanins-rich red fruit juice (Eckes-Granini GmbH, Niederolm, Germany) was produced from red grape juice, lingonberry juice from concentrate, apple, blueberry, and strawberry puree, Aronia juice from concentrate, and acerola puree (100% fruit content). The total anthocyanin content of red fruit juice was 274 mg/L, comprising 33% of malvidin-3-glucoside, 14.3% of cyanidin-3-galactoside, 11.6% of peonidin-3-glucoside, 10.3% of petunidin-3-glucoside, 7.7% of delphinidin-3-glucoside, 6.8% of cyanidin-3-arabinoside, 6.4% of cyanidin-3-glucoside, 3.8% of delphinidin-3-arabinoside, 2.5% of malvidin-3-galactoside, 2% of petunidin-3-galactoside, and 1.6% of delphinidin3-galactoside. c The Delphinol® food supplement capsules (Oryza Oil & Fat Chemical Co., Ltd., Aichi, Japan) contain purified anthocyanins isolated from maqui berry (Aristotelia chilensis). Each capsule contains ≥ 35% anthocyanin glycosides and ≥25% delphinidin glycosides.

After daily intake of 320 mg of purified anthocyanins for 12 weeks, diabetics and prediabetic subjects showed improvement in insulin secretion, insulin sensitivity, and lipid profile. The results showed a reduction in glycated hemoglobin A1c level (HbA1c), low-density lipoprotein cholesterol (LDL-cholesterol), and apolipoprotein B (ApoB), while increasing ApoA1. These effects may be attributed to the molecular mechanisms of glycolipid metabolism, such as activation of adenosine monophosphate-activated protein kinase (AMPK) that inhibit 3-hydroxy-3-methylglutaryl-coenzyme A (HMG-CoA) reductase (limiting enzyme of cholesterol synthesis), or by regulating transcriptional factor Forkhead box O1 (FoxO1) of adipose triglyceride lipase (main lipase involved in triglycerides breakdown in adipocytes), inhibiting cholesterol synthesis and adipocyte lipolysis [68,69].

Human clinical trials further support that purified anthocyanins may improve adipocyte dysfunction by regulating adipokines expression (e.g., adipsin and visfatin). Adipsin plays an important role in maintaining the pancreatic β-cell function, whose failure in the human system promotes the deficiency in adipsin and, therefore, results in insulin resistance and the progression of type 2 diabetes mellitus. Meanwhile, increased visfatin expression is associated with obesity and type 2 diabetes mellitus. The daily administration of 320 mg purified anthocyanins for 12 weeks increased the serum adipsin and reduced the serum visfatin in diabetic patients. Besides that, it significantly improved the HbA1c and ApoA1 and decreased C-peptide, C-peptide index, and ApoB [69].

Previous human clinical studies have suggested that patients with metabolic syndrome showed significatively reduced inflammation and improved lipid profile, evidenced by decreased serum cholesterol, LDL-cholesterol, triglycerides, fasting blood glucose, and inflammatory biomarkers after daily intake of 320 mg of purified anthocyanins for 4 weeks. These beneficial effects have been associated with anthocyanins’ capacity in regulating the expression/activation/activity of pro-inflammatory mediators, such as NF-κB signaling pathways, pro-inflammatory cytokines (e.g., TNF-α, IL-6, and IL-1A), and pro-inflammatory enzymes (e.g., COX-2). The anthocyanins also inhibited the production of pro-inflammatory molecules, such as high-sensitivity C-reactive protein (hs-CRP), the best validated inflammatory biomarker, while increasing SOD expression. Moreover, anthocyanin supplementation upregulated proliferator-activated receptor-γ (PPAR-γ) expression. PPAR-γ plays a crucial role in lipid and glucose homeostasis by modulating dietary fats and glucose metabolism, adipocyte differentiation, and inflammatory responses [77,78].

Dietary supplementation studies have shown that intake of increasing anthocyanin concentrations for 12 weeks significantly improved the antioxidant status in patients with dyslipidemia through the reduction in oxidative stress-related biomarkers, such as malonaldehyde, urine 8-iso-prostaglandin F2α (8-iso-PGF2α), and urine 8-hydroxy-2′-deoxyguanosine (8-OHdG) and promoted the increase in the total SOD activity. Furthermore, anthocyanin supplementation also improved the anti-inflammatory capacity through decreased inflammatory cytokines expression (e.g., IL-6 and TNF-α), improved lipids profile, and cholesterol efflux capacity due to the reduction in ceramide species levels [65,73].

The consumption of anthocyanins-rich cherry juice (about 138 mg of anthocyanins/day) for 12 weeks has been shown to attenuate cognition losses in older adults with mild-to-moderate dementia Alzheimer’s type by improving cognitive tasks, such as verbal fluency and short and long-term memory [88]. Daily intake of purified anthocyanins (320 mg/day for 16 weeks), anthocyanins-rich black rice extract (19.08 mg of anthocyanins/day for 12 weeks), and blueberry anthocyanins (258 mg of anthocyanins/day for 16 weeks) also improved the cognitive performance in subjects with subjective memory impairment or mild cognitive impairment [81,86,87]. Anthocyanins can eliminate and block the action of free radicals in the brain, protect neurons susceptible to inflammatory processes, enhance existing neuronal function, increase cerebrovascular blood flow, and stimulate neurogenesis in areas of the brain related to cognition, among other mechanisms [15,88]. However, there is no evidence that anthocyanins can halt disease progression [88].

Clinical trials have also demonstrated that anthocyanin supplementation can improve cardiovascular function [79,80,84,89,91], modulate gut microbiota composition [90,91], alleviate ulcerative colitis symptoms [67], enhance exercise recovery effectiveness [66], reduce ocular fatigue [92], and maintain a healthy skin facial condition [93]. Therefore, the consumption of anthocyanins-rich fruits/extracts showed beneficial effects on glucose and lipid metabolism, oxidative stress, inflammatory cascade, and gut microbiota profile and, thereby their daily intake may have a key role in the prevention or treatment of type 2 diabetes mellitus, obesity, dyslipidemias, metabolic syndrome, neurodegenerative disorders, cardiovascular diseases, cancers, and other chronic degenerative diseases, as well as in maintaining overall health and wellbeing. Nevertheless, further research is required to elucidate the effective anthocyanin concentrations required to perform their biological effects and action mechanisms of anthocyanins in the body.

3. Innovative Processes for Anthocyanin Extraction from Agri-Food By-Products

3.1. Pulsed Electric Field

Pulsed electric field (PEF) is an innovative non-thermal processing technology regarded as environmentally friendly due to its low energy expenditure water depletion [1]. PEF technology has been successfully used to extract anthocyanins from different matrices [94,95,96,97,98]. As shown in Table 2, PEF technology improved anthocyanin extraction from different agri-food by-products compared to conventional extraction technologies or even other innovative extraction technologies (e.g., US and high voltage electrical discharges). The potentiation of anthocyanin extraction promoted by PEF technology is due to the increase in mass transfer and, consequently, anthocyanins release into the medium, caused by the formation of temporary (reversible) or permanent (irreversible) pores in the cell membranes, a phenomenon known as electroporation [17].

Table 2.

Summary of the main recent findings showing the effects of the pulsed electrical field (PEF) technology on anthocyanin extraction from agri-food by-products.

| Waste/By-Product | Extraction Process Parameters | Major Findings | Reference |

|---|---|---|---|

| Raspberry by-product |

Electric field intensity: 1 and 3 kV/cm Specific energy input: 1, 6, and 12 kJ/kg Frequency: 20 Hz Pulse width: 20 μs |

|

[47] |

| Sweet cherry by-product |

Electric field intensity: 0.5, 1, and 3 kV/cm Specific energy input: 10 kJ/kg Frequency: 5 Hz Pulse width: 20 μs |

|

[48] |

| Sour cherry by-product |

Electric field intensity: 1, 3, and 5 kV/cm Specific energy input: 10 kJ/kg Frequency: 10 Hz Pulse width: 20 μs |

|

[99] |

| Blueberry by-product |

Electric field intensity: 10–35 kV/cm Pulse number: 2–14 Pulse width: 2 μs |

|

[100] |

| Blueberry by-product |

Electric field intensity: 3 kV/cm Specific energy input: 1, 5, and 10 kJ/kg Frequency: 10 Hz Pulse width: 20 μs |

|

[46] |

| Blueberry by-product |

Electric field intensity: 1, 3, and 5 kV/cm Specific energy input: 10 kJ/kg Frequency: 10 Hz Pulse width: 20 μs |

|

[101] |

| Blueberry by-product |

Electric field intensity: 1, 3, and 5 kV/cm Specific energy input: 10 kJ/kg Frequency: 10 Hz Pulse width: 20 μs |

|

[102] |

| Blueberry pomace |

Electric field intensity: 10, 15, and 20 kV/cm Specific energy input: up to 41.03 kJ/kg Pulse number: 10, 50, and 100 Pulse width: 2 μs |

|

[103] |

| Peach pomace |

Electric field intensity: 0.8–10 kV/cm Specific energy input: 0.02–20 kJ/kg Frequency: 0.1 Hz Pulse width: 4 μs |

|

[98] |

| Grape pomace |

Electric field intensity: 1.2, 1.8, and 3.0 kV/cm Specific energy input: 18 kJ/kg Pulse number: 200–2000 Pulse width: 100 μs |

|

[104] |

| Grape pomace |

Electric field intensity: 13.3 kV/cm Specific energy input: 0–564 kJ/kg Frequency: 0.5 Hz |

|

[105] |

| Grape peel |

Specific energy input: 289.8 (PEF-I) and 37.8 W (PEF-II) Pulse number: 25.2 (PEF-I) and 9.7 (PEF-II) Frequency: 10 Hz Pulse width: 6 μs |

|

[106] |

| Plum peel |

Specific energy input: 228 (PEF-I) and 17.8 W (PEF-II) Pulse number: 25.2 (PEF-I) and 9.7 (PEF-II) Frequency: 10 Hz Pulse width: 6 μs |

|

[106] |

Cell membranes are the cell barriers that govern the target compounds’ extraction yield. Thus, extraction rate depends on the cell membrane permeability [107]. The cell membrane acts like a capacitor with a low dielectric constant, in which the cell membrane conductivity is extremely lower than that of the surrounding medium and cytoplasm. However, when the cell is exposed to a strong external electric field, ions migrate from the fluid and accumulate at the cell membrane interface, forming free charges of opposite sign at the two interfaces (inner/outer) of the membrane itself that increases transmembrane potential on the cell surface. Due to the very low thickness of a typical plant cell membrane (approximately 5 nm), electrostatic attraction of opposite charges occurs along the cell membrane, inducing cell membrane compression, reducing the membrane thickness. When the electric field strength exceeds a certain critical limit (Ec), usually around 0.2–1 V/m for plant cells, the elastic properties of the cell membrane does not resist the electrostatic attraction that leads to reversible (E ≈ Ec) or irreversible (E >> Ec) formation of micropores in weaker areas of the cell membrane, increasing cell permeability. Thereby, PEF treatment enhances the migration of target compounds located in the cytoplasm across the cell membrane, which boosts mass transfer and, consequently, increases the extraction rates and yield [108,109].

Plant cell membrane permeabilization is easier to reach than in microbial cells due to their larger cell size, requiring lower critical electric field strengths (0.5–2 kV/cm) for electroporation and, consequently, lower energy consumption [1,108]. The PEF extraction process is based on the direct application of very short duration pulses (usually micro to milliseconds) of current high-electric voltage to a matrix placed between two electrodes [2]. Electric field strength, treatment time, specific energy input, pulse number, and temperature are the main parameters that affect the performance of PEF extraction. Overall, electroporation intensifies as the intensity of these parameters increases and, thereby enhancing the target compounds extraction [107,110]. Indeed, some studies have shown an increase in anthocyanin extraction from agri-food by-products as these parameters are intensified. When evaluating the PEF treatment effect on blueberry by-product, Pataro et al. [46] reported that anthocyanin extraction enhances (up to 75%) as specific energy input increases (1–10 kJ/kg). In this study, PEF technology did not affect the number and type of anthocyanins extracted and did not induce any degradation/modification of individual anthocyanins [46]. Similar findings were obtained by Bobinaitė et al. [102]. They demonstrated that the higher the electric field intensity (1–5 kV/cm) applied, the greater the anthocyanin extraction from the blueberry by-products (up to 95% higher than conventional extraction). In particular, malvidin and peonidin glycosides extraction were not significantly affected by electric field intensity, while delphinidin, cyanidin, and petunidin glycosides significantly increased when higher electric field intensities were applied. Moreover, it is worth pointing out that the authors did not report PEF technology’s effect on the number, type, and stability of individual anthocyanins extracted [102]. In another study, Lončarić et al. [103] verified that the intensification of electric field intensity (10–20 kV/cm) and pulse number (10–100) enhances anthocyanin recovery from blueberry pomace. Moreover, PEF technology was more efficient at extracting anthocyanins from blueberry pomace than other innovative technologies (US and high voltage electrical discharges) [103]. Likewise, Zhou et al. [100] reported enhanced anthocyanin recovery from blueberry by-product by PEF technology compared to US extraction. In this study, anthocyanin extraction improved as pulse number (up to 10 pulses) and electric field intensity (up to 20 kV/cm) increased [100]. Similarly, PEF technology was more effective for anthocyanin extraction from grape pomace than conventional (up to 430%), US (up to 22%), and high voltage electrical discharges (up to 55%) extraction. This study evidenced that the higher the specific energy input applied, the greater the total and individual anthocyanins (delphinidin-3-glucoside, petunidin-3-glucoside, peonidin-3-glucoside, and malvidin-3-glucoside) extraction [105]. These findings agreed with Medina-Meza and Barbosa-Cánovas [106] and Corrales et al. [95]. They indicated higher anthocyanin yields from grape pomace using PEF treatment than control, US, and high hydrostatic pressure extractions. Moreover, PEF treatment of higher intensity (289.8 W and 25.2 pulses) resulted in better extractability of anthocyanins from grape pomace [106].

Nonetheless, the PEF extraction process intensification does not always improve anthocyanin extraction yields. Lamanauskas et al. [47] observed that the PEF treatment of red raspberry by-products increased anthocyanin extraction up to 25.7% compared to conventional extraction. However, the intensification of electric field intensity (1–3 kV/cm) and specific energy input (1–12 kJ/kg) did not promote any significant modification in the content of anthocyanins extracted. PEF treatment of sweet cherry by-product increased anthocyanin extraction by up to 38.4%, with no effect on the number and type of anthocyanins extracted. Moreover, the anthocyanin yield remained unchanged as the electric field intensity increased (0.5–3 kV/cm) [48]. PEF-treated sour cherry by-product had an anthocyanin yield 44–54% higher than conventional extraction and electric field intensity (1–5 kV/cm) did not significantly influence anthocyanin extraction [99]. Likewise, PEF treatment improved total and individual anthocyanins (delphinidin-3-glucoside, petunidin-3-glucoside, peonidin-3-glucoside, and malvidin-3-glucoside) extraction from grape pomace by up to 18.9%, but electric field strength intensification (1.2–3 kV/cm) did not allow for any significantly higher anthocyanin extraction yield [104].

Depending on the PEF extraction process intensity, there may be a reduction in anthocyanin extraction yields with the PEF process intensification. Increasing the intensity of some PEF extraction process parameters (e.g., electric field intensity and specific energy input) showed a tendency to reduce anthocyanin recovery from red raspberry by-product [47] and sweet cherry by-product [48]. When evaluating the PEF treatment effect on blueberry by-product, Zhou et al. [100] reported that anthocyanin extraction enhances up to a certain point as pulse number (up to 10 pulses) and electric field intensity increases (up to 20 kV/cm). However, the application of higher electric field intensity (>20 kV/cm) and pulse number (>10 pulses) drastically and progressively reduced anthocyanin extraction [100]. PEF application increased anthocyanin extraction from peach pomace by up to 11.8-fold compared to conventional thermal extraction. However, intensification of specific energy input (0.02–20 kJ/kg) drastically and progressively reduced anthocyanin extraction yields in PEF technology. These findings suggest that anthocyanins from peach pomace are highly sensitive to degradation by PEF treatment intensification with a degradation constant equal to 8.2 kg/kJ [98]. In another study, Pataro et al. [48] noticed that the cyanidin-3-glucoside content extracted from sweet cherry by-product decreases as the electric field intensity increases (0.5–3 kV/cm).

In general, the intensification of PEF extraction process parameters promoted higher anthocyanin extraction yields from blueberry and grape by-products. At the same time, it did not affect anthocyanin recovery from red raspberry, sweet cherry, and sour cherry by-products. On the other hand, PEF intensification had negative effects on anthocyanin extraction from peach pomace. Overall, electric field intensity and specific energy input applied to the agri-food by-products ranged from 0.5–20 kV/cm and 0.02–20 kJ/kg, respectively. Nevertheless, the behavior of anthocyanin extraction greatly differed according to the matrix as mentioned above. The influence of PEF treatment on anthocyanin extraction depends on distinct factors, such as the relative location in the plant cell, cell size distribution between peel and pulp, ability to bind to the matrix, chemical structure, stability, etc. [46,99]. Peel cells are lower than pulp cells. Thus, it is likely that a lower degree of cell disintegration occurs in peel cells, making anthocyanin extraction from peels more difficult [46]. Monoglucosides anthocyanins are more easily extracted than acylated glucoside anthocyanins since the latter seems to be physically entrapped within the matrix or form hydrogen bonds with cell wall polysaccharides [95]. When evaluating the effect of PEF treatment (10 kV/cm electric field intensity, 5 μs pulse width, and 10 Hz pulse frequency) on individual anthocyanins, Sun et al. [111] verified that cyanidin-3-glucoside was more susceptible to PEF degradation than cyanidin-3-sophoroside. In addition to sugar moieties and phenolic groups bonded to the C-ring, anthocyanin stability depends on -OH and -OCH3 groups at position R1 and C3′ and R2 and C5′ from the B-ring. The anthocyanin stability enhances as the number of -OH, -OCH3 and acyl groups increases (stability order: malvidin > peonidin > petunidin> cyanidin > delphinidin) [95]. Electrode materials from PEF devices have also been shown to influence anthocyanin recovery. Sun et al. [111] noticed that stainless steel was the electrode material that allowed greater anthocyanin retention after PEF treatment. In contrast, pure titanium and titanium-based alloy materials led to greater anthocyanin degradation. Moreover, PEF technology can show a very distinct effect in different fruit varieties of the same species [112]. Furthermore, the critical electric field strength required to promote electroporation in cell membranes can differ for each agri-food by-product. As discussed previously, the closer the electric field strength values to the critical value (Ec), the greater the extent of the electroporation phenomenon and, consequently, higher compounds release into the extraction medium [108,109]. However, when the electric field strength values overcome the critical value (Ec), the excess energy can promote structural changes and/or degradation of organic molecules [100]. Thereby, the use of excessively high electric field strengths can lead to drastic and progressive anthocyanin degradation.

The results compiled here demonstrate that high electric field strengths are demanded to promote complete electroporation of cell membranes from blueberry and grape by-products. In contrast, moderate electric field strengths are required for red raspberry, sweet cherry, and sour cherry by-products, and low electric field strengths for peach pomace. Anthocyanins are mainly located in peels of blueberry and grape, and there is a great difference in peel and pulp cell size. Therefore, anthocyanins from smaller and denser cells of peels are released more difficulty than those from larger and juicer cells of pulp [46]. As blueberry and grape by-products are mainly composed of peels, higher electric field strengths are required to promote peel cell disintegration and consequent anthocyanin release. Zhou et al. [100] showed that very high electric field strengths are needed to cause anthocyanin degradation from blueberry by-products. In contrast, increasing extraction yields were reported by Barba et al. [105] for grape pomace anthocyanins even when a high electric field intensity (13.3 kV/cm) was applied together with increasing specific energies input (0–564 kJ/kg). Meanwhile, moderate PEF treatment can affect anthocyanin stability from sweet cherry by-product during extraction since cyanidin-3-glucoside content progressively reduced as the electric field intensity increased (0.5–3 kV/cm) [48]. On the other hand, Plazzotta et al. [98] proved that low electric field strengths (<0.8 kV/cm) are needed to extract anthocyanins from peach pomace since the application of electric field strengths higher than 0.8 kV/cm drastically degraded its anthocyanins. Studying the anthocyanin degradation kinetics, the authors found a high degradation constant (8.2 kg/kJ), showing that peach pomace anthocyanins are very sensitive to PEF treatment intensification [98]. Similarly, previous studies demonstrated that degradation constants of cyanidin-3-glucoside exposed to PEF treatment were boosted as electric field strength increased [113,114]. When the electric field strength is high enough, electrochemical reactions can occur (particularly electrolysis of solvent and electrode corrosion), leading to the production of high concentrations of metallic ions and reactive oxygen species (especially hydroxyl radicals and hydrogen peroxide). Metallic ions, it turns, can catalyze the decomposition of hydrogen peroxide into hydroxyl radicals via the Fenton reaction. Hydroxyl radicals have been identified as the main reactive oxygen species related to benzene ring cleavage in phenolic compounds [107,111]. Indeed, increased hydroxyl radicals formation has been observed after PEF treatment [111,115]. Sun et al. [115] proposed a mechanism for the PEF-induced cyanidin-3-sophoroside degradation based on the action of reactive oxygen species formed by electrochemical reactions at the electrode-medium interface during PEF treatment. According to the authors, hydrogen peroxide promotes a nucleophilic attack at the C2 of the C-ring leading to the cleavage of the heterocyclic ring between C2 and C3 through the Baeyer–Villiger oxidation reaction and consequent formation of benzoyloxyphenylacetic acid ester of cyanin type (called cyanone). Then, cyanone is oxidized by other oxidants (e.g., hydroxyl radicals) at either of two phenolic hydroxyl groups on A-ring forming several quinonoid cyanone isomers. Zhang et al. [113] verified that protocatechuic acid, 2,4,6-trihydroxybenzoic acid, and eight other unknown compounds were the main degradation products of cyanidin-3-glucoside exposed to PEF treatment. Protocatechuic acid, phloroglucinaldehyde, a dimer, chalcone-3-sophoroside, and four quinonoid cyanone isomers were identified by Sun et al. [115] as the main PEF degradation products of cyanidin-3-sophoroside. These studies also pointed out that the degradation mechanism and pathways of anthocyanins by PEF treatment were different from thermal treatment [113,115]. Therefore, the reactive oxygen species’ action on anthocyanins could explain their degradation during PEF processing, particularly when high electric field strengths are employed.

In addition to enhancing the anthocyanin recovery from agri-food by-products without affecting the number and type of anthocyanins extracted [46,48,102,103,104], PEF technology can be used to improve the extraction of individual anthocyanins selectively. For example, the PEF treatment of grape pomace remarkably enhanced the monoglucoside anthocyanin extraction compared to acylated glucoside anthocyanins [95]. Bobinaitė et al. [102] observed that higher PEF treatment intensities particularly increased the extraction of delphinidin, cyanidin, and petunidin glycosides from blueberry by-products. Barba et al. [105] found PEF treatment intensification remarkably enhanced malvidin-3-glucoside extraction compared to the content of other individual anthocyanins. Moreover, PEF technology can be more selective to extract anthocyanins rather than other phenolic compounds. Brianceau et al. [104] noticed that PEF treatment increased the total anthocyanins/total flavan-3-ols ratio regarding the non-treated sample in grape pomace. Likewise, Barba et al. [105] verified that PEF-treated grape pomace had a higher total anthocyanins/total phenolic compounds ratio than reference extraction.

Finally, the application of high-intensity PEF technology to extract anthocyanins from agri-food by-products can lead to some anthocyanin degradation. Nevertheless, low/moderate-intensity PEF treatments improved anthocyanin recovery without inducing any anthocyanin degradation/modification. Therefore, PEF is a promising innovative technology to extract anthocyanins from agri-food by-products.

3.2. Microwave

Microwave (MW) is another innovative and green extraction technology considered to be more advantageous than conventional extraction technologies due to its high extraction rate, less use of solvents, and shorter extraction time [109]. Anthocyanins from different plant sources have been successfully extracted by using MW technology [116,117,118,119,120]. MW technology enhanced anthocyanin extraction from various agri-food by-products compared to conventional extraction technologies or even other innovative extraction technologies (e.g., US) (for more details, see Table 3). MW technology improves anthocyanin extraction due to its ability to increase mass transfer rates and, consequently, anthocyanins release into the extraction medium because of the cell interruption caused by internal overheating [17].

Table 3.

Summary of the main recent findings showing the effects of the microwave (MW) technology on anthocyanin extraction from agri-food by-products.

| Waste/By-Product | Extraction Process Parameters | Major Findings | Reference |

|---|---|---|---|

| Blueberry peel |

Microwave power: 500 W Temperature: 40–100 °C Irradiation time: 2–40 min Solvent: Choline chloride:lactic acid (1:1) containing 25% (v/v) water |

|

[121] |

| Blueberry bagasse |

Microwave power: 525 and 700 W Irradiation time: 3 min Solvent: Acidified water |

|

[122] |

| Fig peel |

Microwave power: 400 W Temperature: 40–115 °C Irradiation time: 5–35 min Solvent: Acidified hydroethanolic mixtures (0–100% ethanol) |

|

[123] |

| Eggplant peel |

Microwave power: 100–300 W Irradiation time: 5–15 min Solvent: Acidified hydroethanolic mixtures (55–95% ethanol) |

|

[40] |

| Black soybean seed coat |

Microwave power: 340–680 W Irradiation time: 2.5–7.5 min Solvent: Hydroethanolic mixtures (20–60% ethanol) |

|

[42] |

| Grape pomace |

Microwave power: 600–1000 W Irradiation time: 5–10 min Solvent: Acidified water |

|

[124] |

| Grape pomace |

Microwave power: 300–600 W Irradiation time: 1–3 min Solvent: Water |

|

[125] |

| Grape pomace |

Microwave power: 100–300 W Irradiation time: 10–15 min Solvent: Choline chloride:citric acid (2:1) containing 10–50% (v/v) water |

|

[126] |

| Bilberry pomace |

Microwave power: 300–600 W Irradiation time: 1–16 min Solvent: Solvent-free |

|

[50] |

| Sour cherry peel |

Microwave power: 350–500 W Irradiation time: 0.5–1.5 min Solvent: Acidified hydroethanolic mixtures (20–80% ethanol) |

|

[49] |

| Blackcurrant bagasse |

Microwave power: 385–700 W Irradiation time: 10–20 min Solvent: Acidified hydroethanolic mixtures (0–90% ethanol) |

|

[51] |

| Peach pomace |

Microwave power: 180–900 W Irradiation time: 10–50 s Solvent: Hydroethanolic mixture (70% ethanol) |

|

[127] |

| Onion peel |

Microwave power: 700–1000 W Irradiation time: 3–5 min Solvent: Hydroethanolic mixtures (40–75% ethanol) |

|

[44] |

| Black rice bran |

Microwave power: 298–800 W Irradiation time: 13–147 s Solvent: Acidified water |

|

[45] |

| Black carrot pomace |

Microwave power: 340–680 W Irradiation time: 5–15 min Solvent: Hydroethanolic mixtures (10–30% ethanol) |

|

[39] |

As discussed earlier, cell membranes are the cell barriers that control solute permeability and, therefore, extraction yields. Thus, cell rupture is needed to boost anthocyanin extraction from plant matrices. When microwave irradiation is applied to a matrix or extraction medium, microwave energy is absorbed by polar compounds causing ion conduction and dipole rotation [109]. In ionic conduction, the electric field produced by the microwaves induces electrophoretic migration of charge carriers (e.g., ions and electrons), generating friction between the moving ions and the medium that causes heating. Meanwhile, in dipole rotation, heating occurs due to the collision between dipolar molecules and surrounding molecules caused by the dipolar species’ oscillation when they attempt to align themselves with the alternating electric field produced by microwaves [128]. In plant matrices, the water naturally present inside their structure selectively absorbs the microwave energy favoring localized heating above or near the boiling point of water. This internal overheating causes the expansion and rupture of cell structures (especially cell walls and cell membranes) by disrupting the dipole attractions, hydrogen bonds, and van der Waals forces, which facilitates the release of target compounds bound to the matrix and solvent penetration into the plant materials, resulting in the improved mass transfer of these compounds into the extraction medium [17,109]. Moreover, MW-induced temperature rise modifies the solvent properties, reducing its viscosity and surface tension while increasing its diffusivity and molecular mobility, improving the mass transfer rates [19].

MW extraction process is based on the focused or non-focused application of non-ionizing electromagnetic waves of frequency ranging from 300 MHz to 300 GHz on a sample [17]. Solvent type is a crucial parameter in MW extraction since its ability to solubilize the target compounds and absorb microwave energy is critical for recovering these compounds. Regarding the solubility, it is preferable to use solvents that have the Hildebrand solubility parameter (measure the cohesion (interaction) energy of the solvent-solute mixture) similar to those of the target compounds [128]. On the other hand, the ability of a solvent to absorb electromagnetic energy and dissipate heat depends on its dielectric constant (ε′) and dielectric loss factor (ε″). The dielectric constant is a parameter proportional to the amount of energy absorbed. Meanwhile, the dielectric loss factor denotes a solvent′s ability to dissipate input dielectric energy as heat. Polar solvents with a high dielectric constant (e.g., water and ethanol, ε′ = 78.5 and 24.3 at 25 °C, respectively) have a better capacity to absorb electromagnetic energy and reemit it as heat, whereas apolar solvents with a low dielectric constant (e.g., hexane, ε′ = 1.87 at 25 °C) are almost insensitive to this energy, besides not being considered green solvents [128,129]. Thereby, solvents with a high dielectric constant are recommended for MW extraction purposes. Nevertheless, the relationship between dielectric properties from the plant material and solvent is also essential. When plant material has better dielectric properties than solvent, that is, when the dielectric loss tangent (δ = ε′/ε″) of plant material is higher than the solvent, the plant material better absorbs the microwave energy than the solvent. This allows plant material to reach higher temperatures than the solvent, increasing the inside cell pressure that results in the cell membrane’s rupture and the release of target compounds into the extraction solvent [128]. This factor can be managed by changing the extraction temperature. Lee et al. [130] reported that the dielectric loss tangent of plant material (okra) raised as temperature increased, while for the solvent (water), this parameter reduced as temperature increased. Similar outcomes were found by Mao et al. [131] for orange, apple, and mango pomaces. Therefore, higher extraction temperatures can improve the dielectric properties of plant material regarding the solvent.

In addition to solvent, microwave power, irradiation time, and extraction temperature also significantly impact the performance of MW extraction [132]. Overall, cell structure disintegration intensifies as the intensity of these parameters increases, thereby improving the extraction yields of target compounds [119]. Indeed, several studies conducted with MW have shown an increase in anthocyanin extraction from agri-food by-products as these parameters are intensified. When evaluating the MW treatment effect on eggplant peel, Doulabi et al. [40] reported that the anthocyanin extraction enhances as the microwave power increases (100–300 W). Şahin et al. [49] verified that anthocyanin recovery from sour cherry peels gradually enhanced as the microwave power (350–500 W) and irradiation time (0.5–1.5 min) increased. Similarly, the intensification of microwave power (600–1000 W) and irradiation time (up to 7 min) progressively increased anthocyanin recovery from grape pomace [124]. Likewise, the higher the microwave power (300–600 W), the greater the anthocyanin extraction from bilberry pomace [50]. Grape pomace also had higher anthocyanin yields as the microwave power increased (100–300 W) [126]. Meanwhile, longer irradiation times gradually improved anthocyanin recovery from wine lees (30–90 s at 300 W) [133], sour cherry pomace (30–90 s at 900 W) [134], and saffron floral bio-residues (0.5–5 min at 800 W) [135].

Although the MW intensification generally enhances the anthocyanin extraction, a decreased anthocyanin recovery can occur depending on the intensity of the process parameters. Grillo et al. [121] reported that anthocyanin extraction from blueberry peel enhances up to a certain point (up to 62.7% higher than conventional extraction) as extraction temperature (up to 60 °C) and irradiation time (up to 15 min) increases and decreases afterward. Similar behavior was observed by Backes et al. [123] for fig peel anthocyanins, where the extraction yields enhanced (38% and 16.73% compared to the US and conventional thermal extractions, respectively) as the extraction temperature was increased (up to 64.21 °C), but begins to decrease with the rise of extraction temperature (>64.21 °C) and irradiation time (>5 min). In another study, Kumar et al. [42] showed that anthocyanin recovery from black soybean seed coat progressively raised (up to 4.72-fold compared to conventional solvent extraction) with increasing microwave power. However, it diminished at microwave powers greater than 510 W. Likewise, anthocyanin yields from blackcurrant bagasse were boosted as the microwave power (up to 551 W) and irradiation time (up to 16.4 min) increased and, then, it begins to decrease [51]. The anthocyanin extraction from grape pomace also improved as the microwave power and time extraction increased. However, when it was applied microwave powers and irradiation times higher than 428 W and 2.23 min, respectively, anthocyanin extraction gradually decreased [125]. Similar behavior was obtained by Halee et al. [45] for anthocyanins from black rice bran, in which enhanced anthocyanin yields were achieved as the microwave power (up to 648 W) and irradiation time (up to 83 s) increased and subsequently declined. Meanwhile, Ferreira et al. [122] pointed out that an increase in microwave power (from 525 to 700 W) led to lower anthocyanin recovery from blueberry bagasse. Increased microwave power (from 700 to 1000 W) also caused a reduction in anthocyanin extraction from onion peel, while longer irradiation time (5 min) improved it [44]. MW application increased anthocyanin extraction from peach pomace by up to 26-fold compared to control extraction. However, the intensification of microwave power (180–900 W) drastically and progressively reduced anthocyanin extraction yields, while irradiation time (10–50 s) had the opposite effect [127]. Higher anthocyanin yield was also found in MW-treated black carrot pomace compared to conventional (133%) and US (24.12%) extractions. Nevertheless, it was noted that increasing microwave powers (340–680 W) and irradiation times superior to 9.86 min harmed anthocyanin recovery [39]. Doulabi et al. [40] and Backes et al. [136] noticed that the longer the irradiation time, the lower the anthocyanin recovery from eggplant peel and fig peel, respectively. Likewise, excessively long irradiation times beyond optimal point can also result in a reduction in the anthocyanin extraction from grape pomace [124,125], blueberry peel [121], blackcurrant bagasse [51], black rice bran [45], black carrot pomace [39], and corn husk [43].

In general, the excessive intensification of MW extraction process parameters resulted in reducing anthocyanin extraction yields from agri-food by-products due to their degradation. In the literature, it is well established that anthocyanins are thermolabile compounds [115,137]. Several studies have shown that anthocyanins’ degradation rate augments as the temperature increases [138,139,140]. Thus, it is recommended to use non-thermal MW processes to extract anthocyanins, that is, extraction temperatures below 60 °C, to minimize losses due to thermal degradation. In addition to extraction temperature, extraction time also significantly impacts MW extraction. Overall, increased extraction times lead to a progressive release of target compounds from the sample matrix into the extraction solvent [19]. Nevertheless, longer extraction times do not always favor anthocyanin recovery. On the contrary, it can even cause their reduction. After a certain extraction time, the analyte concentrations in the sample and solvent reach a final equilibrium [19]. The excess time after this equilibrium can cause anthocyanin degradation due to higher exposure of these extracted compounds to severe conditions of the extraction procedure, such as high temperatures and microwave powers. However, anthocyanin degradation can occur even when non-thermal MW processes are employed and the irradiation times are optimized, mainly if high microwave powers are applied. When the microwave power is excessively high, internal overheating can occur, leading to carbonization and other reactions such as isomerization and/or degradation of sample components [129]. Indeed, high temperatures can be reached when samples are subjected to MW treatment. For example, extraction mixtures of coffee cherry peel by-product, bilberry pomace and orange peel, grape pomace, and wine lees achieved up to 89, 90, 93.5, and 117 °C during MW extraction, respectively [50,124,131,133,141]. Zhao et al. [137] reported that malvidin-3-glucoside and malvidin-3,5-diglucoside exposed to thermal and MW treatments shared some degradation products, demonstrating that the thermal pathway has a key role in the degradation of MW-treated anthocyanins. Sun et al. [115] and Zhao et al. [137] have deduced the thermal degradation pathways of anthocyanins. According to the authors, anthocyanins’ thermal degradation pathway occurs through the successive loss of sugar moieties (for anthocyanins with two or more sugar moieties) and subsequent opening of the C-ring, forming a carbinol pseudo base. Next, chalcone is formed by hydrolysis of the remaining sugar moiety and later cleaved between C2 and C3. Then, intermediate products from A-ring and B-ring are oxidized into different compounds depending on the anthocyanin. Other parallel thermal degradation pathways of anthocyanins are also described [115,137]. The thermal degradation pathway seems to be the main phenomenon related to anthocyanin degradation in MW-treated samples. However, anthocyanin degradation during MW extraction can be at least partially explained by oxidative phenomena. When extreme MW processing conditions are applied, decomposition reactions of water molecules can occur, leading to the increasing production of reactive oxygen species, especially hydroxyl radicals [137]. Indeed, it has been reported that the hydroxyl radicals formation is boosted as the microwave power and irradiation time increases [142]. Quan et al. [142] postulated that the oxidative degradation pathway of anthocyanins under MW treatment is given by the Baeyer–Villiger-type oxidation (for more details regarding this pathway, see Section 3.1). Therefore, the action of high temperatures together with reactive oxygen species on anthocyanins could explain their degradation during MW extraction, particularly when high microwave powers are employed.

In addition to MW process parameters, anthocyanins’ structural features also significantly impact their recovery from plant matrices. Herrman et al. [143] noticed that 3-deoxyanthocyanins (anthocyanin analogs that are unsubstituted at C3 of the C-ring) are more stable to MW treatment than common anthocyanins. The authors also pointed out that acylated anthocyanins were more stable than non-acylated ones [143]. Similar behavior was reported by Liazid et al. [144] in grape skin anthocyanins, in which MW treatment remarkably enhanced the acylated glucoside anthocyanin recovery regarding monoglucoside anthocyanins compared to the solid-liquid maceration classical method. Wang et al. [145] observed that delphinidin was more stable than petunidin under MW treatment. Meanwhile, Sivamaruthi et al. [146] verified that petunidin was more stable than cyanidin after MW exposure.

Finally, the employment of high-intensity MW technology to extract anthocyanins from agri-food by-products can lead to drastic anthocyanin degradation. However, in general, non-thermal MW treatments associated with low/moderate microwave powers result in higher anthocyanin yields without inducing any anthocyanin degradation/modification. Therefore, non-thermal MW treatment is a promising innovative technology to recover anthocyanins from agri-food by-products.

3.3. Ultrasound

The use of acoustic energy for recovering phytochemical compounds from plant matrices has strongly increased in the past decade due to its versatility in developing non-thermal extraction processes [147,148]. In this way, several thermolabile bioactive compounds such as phenolic compounds may have their biological activity maintained after this high-energy extraction technique [149]. Extracts obtained from ultrasound-based extraction processes have a high potential for developing nutraceuticals and functional food products. Furthermore, extraction processes based on ultrasound (US) technology enable low-cost industrial manufacturing lines, mainly due to the reduction in solvent used and extraction time, contributing to the lower energy expenditure [150]. US technology also meets one of the most critical demands from modern consumers to develop sustainable green processes [151,152]. Therefore, the combination of US-based extraction techniques using agri-food by-products is a promising approach for obtaining extracts rich in phenolic compounds such as anthocyanins.

US technology is based on the acoustic cavitation phenomenon observed in a liquid medium subjected to sonication treatment. The application of a low-frequency (16 to 100 kHz) and high-power (>10 W) ultrasound into liquid systems promotes the generation of acoustic fields which are associated with the occurrence of mechanical waves and vibrations [150,153]. The formation and subsequent collapse of microbubbles characterize the acoustic cavitation phenomenon. The acoustic cavitation microbubbles convert acoustic energy provided by the acoustic field into mechanical and thermal energies. The implosive collapse of microbubbles produces punctual zones of very high temperature (approximately 10,000 K) and pressure (about a few tens of GPa) [154]. Thus, during their collapse, shock waves and microjets are observed in the sonicated liquid system, resulting in turbulence and temperature rise. The acoustic cavitation shear stress effect on the surface of cells and particles is known as sonoporation [155,156]. Acoustic cavitation enables the formation of micropores and even the disruption of cellular structures. Therefore, the sonoporation effect is a powerful mechanism for extracting bioactive compounds from plant matrices because it favors the release of phytochemicals found inside plant cells into the extraction solvent [157]. Likewise, the sonication treatment also favors phytochemicals diffusion into the liquid medium due to the temperature increase and turbulence provided by acoustic cavitation [20,152]. However, US processing can generate free radicals such as hydroxyl radicals, promoting the degradation of bioactive compounds extracted from plant matrices [158]. The greater formation of these radicals is associated with the US process intensification. In this way, US-based extraction processes must be designed considering the opposite effects of acoustic energy on the recovering and degrading of target compounds concerning the generation of free radicals. On the other hand, the number of free anthocyanins can be reduced after US processing due to the formation of protein/carbohydrate-polyphenol conjugates induced by acoustic energy [159,160,161,162]. Xue et al. [163] induced the formation of conjugates between soy protein isolate and cyanidin-3-galactoside using an ultrasound intensity of 105.86 W/cm² for 20 min. However, the antioxidant capacity of proteins can be enhanced due to the formation of covalent conjugates with polyphenols [160].

Table 4 summarizes some interesting recent studies regarding the application of US technology to recover anthocyanins from agri-food by-products. Acoustic energy-based extraction processes are promising extraction techniques for phenolic compounds. Compared to conventional exhaustive extraction techniques based on solid-liquid extraction principles such as percolation, Soxhlet, and others. US-assisted extraction processes are more energy efficient regarding the shorter processing time. Another critical issue is related to green solvents, making these processes more sustainable and greener [164]. Grillo et al. [121] tested different natural deep eutectic solvents for the US-assisted recovery of anthocyanins from blueberry peels, the main by-product of blueberry fruit industrial processing. The authors emphasized the importance of developing new, environmentally friendly bio-based solvents to enhance the efficiency and selectivity of innovative extraction processes.

Table 4.