Abstract

Neurological disorders such as Alzheimer's disease, stroke, and brain cancers are difficult to treat with current drugs as their delivery efficacy to the brain is severely hampered by the presence of the blood–brain barrier (BBB). Drug delivery systems have been extensively explored in recent decades aiming to circumvent this barrier. In particular, polymeric nanoparticles have shown enormous potentials owing to their unique properties, such as high tunability, ease of synthesis, and control over drug release profile. However, careful analysis of their performance in effective drug transport across the BBB should be performed using clinically relevant testing models. In this review, polymeric nanoparticle systems for drug delivery to the central nervous system are discussed with an emphasis on the effects of particle size, shape, and surface modifications on BBB penetration. Moreover, the authors critically analyze the current in vitro and in vivo models used to evaluate BBB penetration efficacy, including the latest developments in the BBB‐on‐a‐chip models. Finally, the challenges and future perspectives for the development of polymeric nanoparticles to combat neurological disorders are discussed.

Keywords: blood–brain barrier, drug delivery systems, microfluidic chips, neurological diseases, polymeric nanoparticles

This review highlights the development of polymeric nanoparticles for drug delivery to the central nervous system. The synthesis of promising polymeric nanoparticles is discussed with an emphasis on the effects of particle size, shape, and surface modification on blood–brain barrier (BBB) transfer. Moreover, current in vitro and in vivo models are discussed, including the latest advances in BBB‐on‐a‐chip models.

1. Introduction

1.1. Neurological Disorders

Neurological disorders that affect the brain and spinal cord are leading causes of morbidity and disability globally, with stroke being the second most common cause of death.[ 1 ] Common neurological disorders include Alzheimer's disease, Parkinson's disease, Huntington's disease, motor neuron disease, multiple sclerosis, traumatic brain injury, stroke, and brain cancers. A comprehensive study of the global burden of diseases, injuries, and risk factors in 2016 estimated that 276 million people are suffering from neurological disability and about 9 million deaths occur from neurological disorders each year.[ 1 ] With an aging and growing world population, there will be an even stronger demand for more effective management and treatment for neurological diseases.

Neurological disorders are predominantly associated with the central nervous system (CNS) that comprises the brain and spinal cord. Vital to the function and the regulation of the body, the CNS has three barriers: the cerebral microvascular endothelium (blood–brain barrier, BBB), the choroid plexus epithelium (blood–cerebrospinal fluid barrier), and the avascular arachnoid epithelium (cerebrospinal fluid–blood barrier). Due to these natural barriers, particularly the BBB, transporting pharmaceuticals into the CNS can be extremely difficult. Furthermore, neurons that harbor extensive cell–cell communication capabilities are key players in the CNS. Since neurons are extremely sensitive to temperature fluctuations, pathogens, and toxins, neurodegenerative diseases such as Parkinson's, Huntington's, and Alzheimer's disease that involve irreversable neuronal cell death are common.[ 2 ] The irreversible process of neurodegeneration can also develop after ischemic or hypoxic conditions like stroke, birth asphyxia, and traumatic brain injuries resulting in slow and progressive loss of neuron functions. Furthermore, brain cancers, such as glioblastoma, are driven by oncogenic transformation of genetic and cellular factors in neurons and glial cells. In addition to primary tumors, secondary brain tumors involving brain metastases occur in 9–17% of adults with cancer.[ 3 ]

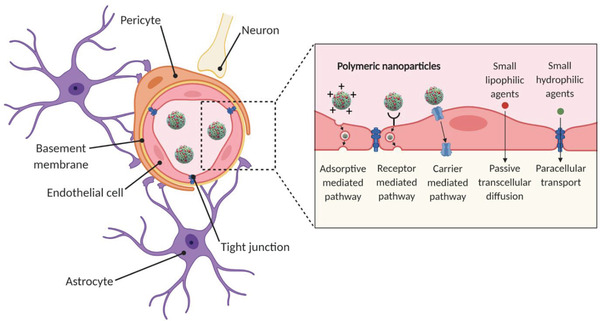

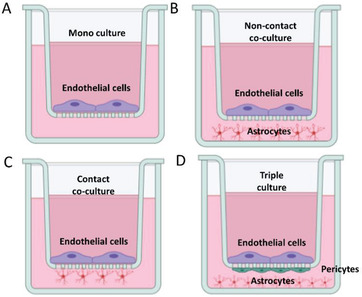

1.2. The Blood–Brain Barrier

The BBB is a structural, functional, and physiological barrier that intricately regulates the movement of ions, nutrients, and cells between the blood and the brain. Anatomically, the BBB consists of cerebral endothelial cells, pericytes, astrocytes, and basement membrane (Figure 1 ). The BBB acting together with neurons and glial cells forms the complete neurovascular unit (NVU) which is crucial for the function of the brain.[ 4 ] The cerebral endothelial cells are non‐fenestrated, contain a large number of mitochondria, and form tight junctions that highly regulate the molecule transport across the endothelium. The inter‐endothelial space is characterized by the presence of transmembrane protein complexes composed of occludin, claudin, and junction adhesion molecules. These specialized tight junction proteins undertake homophilic interactions to form an intricate tight barrier that is exclusive to the cerebral endothelial cells. The apical side of the endothelial cell is exposed to the blood flow in the brain capillaries, while the basolateral side is exposed to the cerebrospinal fluid and is supported by the basement membrane (30–40 nm thick) composed of collagen type IV, laminin, heparin sulfate proteoglycans, fibronectin, and other extracellular matrix proteins.[ 5 ]

Figure 1.

The neurovascular unit. Cross‐section schematic of a brain capillary depicting endothelial cells interconnected via tight junctions. On the brain side of the endothelial cells, the basement membrane surrounds the endothelial cells and embeds pericytes that span several endothelial cells. Astrocytic end‐feet are in contact with the endothelial cells. Neurons are present in the tissue of the brain. Polymeric nanoparticles are transported across the endothelium carrier via carrier‐mediated, receptor‐mediated, and adsorptive‐mediated pathways. Image is created with Biorender.

Aside from neurons, non‐neuronal cells (i.e., glial cells) also play an important role in the CNS. Pericytes are smooth muscle cells that span several endothelial cell lengths and form a discontinuous layer. They regulate the activity of endothelial cells and are likely to serve as macrophages during inflammation, thus providing a second line of defense after the tight junction of endothelial cells.[ 6 ] On the other hand, astrocytes have a characteristic star‐shaped morphology and play a crucial role in enhancing the BBB integrity. The astrocytes secrete soluble factors, such as β‐2 microglobulin and transforming growth factor beta (TGF‐β), which upregulate the expression level of tight junction proteins on endothelial cells. An intact BBB restricts the entry of more than 98% of small molecule drugs and ≈100% of large molecule drugs.[ 7 ] Under pathological conditions, such as neuroinflammation, traumatic brain injury, and brain cancers, the structural integrity and the function of the BBB can be compromised.[ 8 ] Therefore, in brain cancers, the BBB is referred to as the blood–brain tumor barrier (BBTB), which is highly heterogeneous and characterized by numerous distinct features, including non‐uniform permeability and active efflux of molecules. However, in most low‐grade brain tumors and in the tumor periphery, the BBTB strongly resembles the BBB.[ 9 ] Moreover, aging also contributes to dysfunctional barriers due to phenotypical changes of endothelial cells and decreased level of tight junction integrity.[ 10 ] Finally, the BBB can be temporarily disrupted using techniques such as focused ultrasound in combination with microbubbles, focused radiation therapy, or chemical modifications using hypertonic solutions such as mannitol.[ 11 ]

1.3. Transport Mechanisms

Transport of substances through endothelial cells can be broadly divided into two categories: paracellular and transcellular pathways. The paracellular pathway involves the transport of molecules through the intracellular space between the cells. Small lipid‐soluble agents of low molecular weight (<400 Da), such as hormones, alcohol, and gases (CO2, O2) can passively diffuse through the plasma membrane of the endothelial cells.[ 12 ] Although transport via the paracellular pathway is common in the peripheral capillaries, it is strictly limited in the BBB due to the presence of tight junctions which forces the majority of the transport through transcellular pathways.[ 12 ] For example, nutrients and macromolecules are transported through the BBB via one of the three following transcellular pathways: carrier‐mediated transcytosis, receptor‐mediated transcytosis, or adsorptive‐mediated transcytosis.

1.3.1. Carrier‐Mediated Transcytosis

Transporter protein carriers located on the luminal and basolateral sides of the endothelial cells are named nutrient and efflux transporter proteins, respectively. Nutrient transporter proteins are specific to solutes such as glucose, hormones, and amino acids. These solutes bind to their respective transporter proteins triggering a reversible conformational change. Upon cellular uptake of the solutes, they are transported to the basolateral side of the membrane, following high to low solute concentration gradient.[ 13 ] For example, glucose transport is facilitated by the glucose transporter, GLUT1. On the other hand, a diverse range of ATP‐binding cassette transporters or efflux pumps are employed to actively transport non‐specific substrates and drugs out of the endothelial cells. These efflux pumps, which include P‐glycoprotein (P‐gp), multi‐drug resistance proteins (Mrp), and breast cancer resistance protein (Brcp), are found on the luminal side of the brain capillaries and bind to a variety of substrates, and they effectively prevent drug accumulation in endothelial cells and hamper the transport of drugs to the brain.[ 14 ]

1.3.2. Receptor‐Mediated Transcytosis

Cerebral endothelial cells express highly specialized receptors for macromolecules such as hormones, enzymes, and plasma proteins. The three most‐studied ligands important for BBB transport are insulin, transferrin, and low‐density lipoprotein (LDL)‐cholesterol, which bind to insulin, transferrin (Tf), and LDL receptors on endothelial cells, respectively.[ 15 ] On the luminal side of the endothelium, ligands bind to the receptors on the plasma membrane and are internalized through the formation of vesicles. These vesicles are subsequently transported through the cytoplasm of the cells and then release the ligands on the basolateral side. The internalization of cargos through endocytosis can occur via clathrin‐ or caveolin‐dependent pathways. Transcytosis of most ligands, such as LDL‐1, transferrin, and insulin follows the clathrin‐dependent pathway.[ 12 ] This is a five‐step process that involves nucleation (binding of the cargo to the plasma membrane), cargo selection (initiation of clathrin‐coated pit formation), the assembly of the clathrin coat, membrane scission, and disassembly of the clathrin coat. Only a few compounds, such as folate, undertake the caveolin‐dependent pathway that is mediated by the caveolin protein and results in the formation of uncoated vesicles. However, this pathway is more relevant to leaky BBB in neurological diseases.[ 12 ]

1.3.3. Adsorptive‐Mediated Transcytosis

Drugs or substrates that are positively charged can undertake adsorptive‐mediated transcytosis. It is triggered by electrostatic interactions between the positively charged substrate surface, usually polycationic proteins (e.g., protamine) and the negatively charged heparin sulfate proteoglycans present on the plasma membrane surface of the endothelial cells.[ 16 ] This is a relatively slower process in comparison to carrier‐ or receptor‐mediated transport and has a lower transport capacity.

1.4. Strategies for BBB Transfer

Currently, the development of drugs for the treatment of neurological diseases is limited by the complex challenges that are posed by the neurovascular unit. One of the main obstacles is the presence of the BBB, which makes it difficult to transport the drugs to the brain tissue. The ability of drugs to penetrate the BBB depends on the drug size, hydrophilicity, lipid solubility, transport pathway, and degree of dissociation of the drug molecules.[ 17 ] Conventional approaches that use the drug molecules in their free form have demonstrated poor BBB penetration due to the presence of efflux pumps on the endothelial cells that strictly regulate the movement of drug molecules. This results in ineffective delivery of the drug molecules to the target cells in the brain.

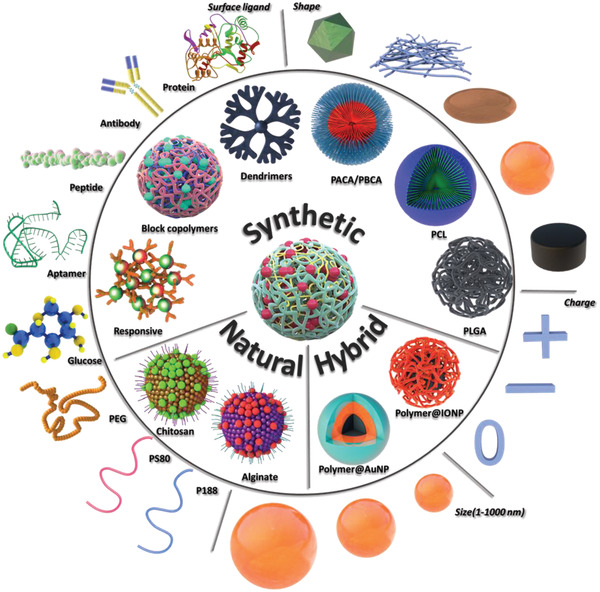

Nanotechnology has immense potential in addressing the complex needs for the treatment of neurological disorders, such as the penetration of the BBB and consequential drug delivery to cells of interest.[ 18 ] This can be achieved using nanosized drug delivery systems that can be specifically engineered (e.g., composition, size, shape, and surface ligands) to shuttle drugs across the BBB. For example, rational designs of nanoparticles can enhance circulation time in the brain capillaries and can take advantage of transcytosis pathways using different surface strategies (Trojan horse strategy). Furthermore, nanoparticles have the ability to escape the P‐gp efflux pumps owing to the presence of specific ligands engineered onto the particle surface.[ 19 ] Numerous drug delivery systems have been developed to improve drug delivery and are usually categorized as either organic or inorganic nanoparticles. The most common organic nanoparticles are the liposomes, polymeric nanoparticles, and lipid nanoparticles, while examples of inorganic nanoparticles are the iron oxide nanoparticles, gold particles, and quantum dots.[ 17 ] Polymeric nanoparticles, in particular, are a promising choice as drug delivery platform for CNS targeting, due to their tunable architecture (10 to 1000 nm), non‐toxicity, biocompatibility, and controllable drug release.[ 20 ] These polymeric nanoparticles can be easily modified with specific ligands that target the receptors on the endothelial cells, resulting in improved transcytosis efficiency (Figure 2 ).[ 18 ] Furthermore, polymeric nanoparticles have an increased circulation time and can be biodegradable.[ 21 ] After cellular uptake and internalization, the polymeric matrix can be triggered to release the drug, resulting in a protected, prolonged, and targeted therapeutic effect. Polymeric nanoparticles are versatile to be able to deliver a wide range of drugs, for example, via hydrophilic, hydrophobic, or electrostatic interactions, and via responsive covalent bonds.[ 22 ]

Figure 2.

An overview of polymeric nanoparticles developed for BBB penetration and their tunable parameters: surface (charge), size, and shape. PACA: poly(alkyl cyanoacrylate); PBCA: poly(butyl cyanoacrylate; PCL: poly‐ε‐caprolactone; PLGA: poly(lactic‐co‐glycolic acid); Polymer@AuNP: polymer‐coated gold nanoparticle; Polymer@IONP: polymer‐coated iron oxide nanoparticle; PEG: polyethylene glycol; PS80: polysorbate 80; and P188: poloxamer 188. Image is created with Biorender.

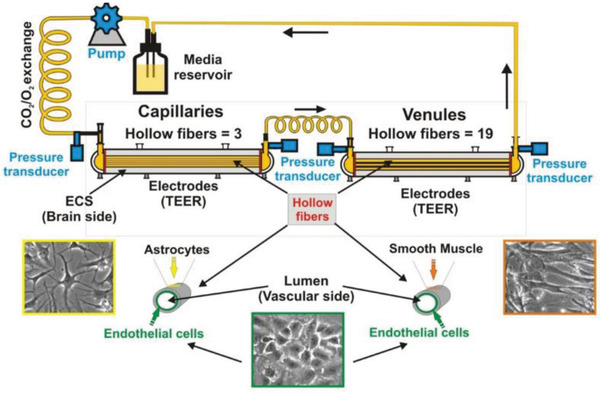

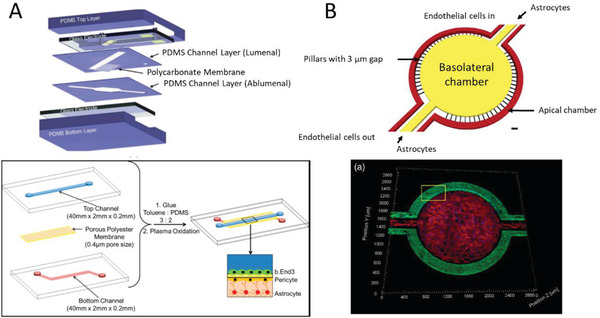

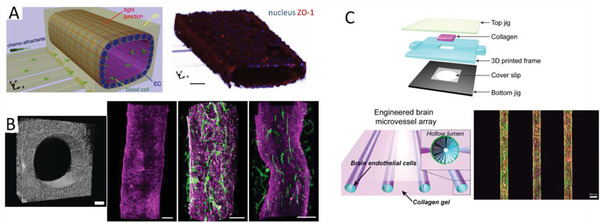

1.5. Testing Models

The first technique to isolate rat brain endothelial cells and culture them in vitro was pioneered by Ferenc Joό in 1996.[ 23 ] Since then, there has been substantial development in the understanding of the physio/pathological conditions of the brain and the mechanism of molecule transport to the brain. Choosing the right research model for drug (and drug complex) development is crucial because it provides valuable insights into translational research. Various in vitro, in vivo, and in silico models have been developed to study the transport of drugs and drug complexes across the BBB (Table 1 ). In vivo models offer physio/pathological conditions that can be evaluated for pharmacokinetics and pharmacodynamics (PK/PD) studies. However, they are costly and time consuming and do not translate directly into human conditions, due to species‐to‐species differences.[ 24 ] For example, differences in the capacity of plasma protein binding to the drug/substrate result in different barrier tightness. On the other hand, in vitro models are easy to set up, offer high throughput studies at a low cost, and are capable of real‐time microscopic measurements. Various BBB microfluidic models have been established to mimic the physiological conditions of the brain and to investigate therapeutic targets for penetrating the BBB to combat neurological diseases.[ 25 ] Although the majority of the in vitro BBB models are focused on the “non‐pathological” brain condition, in which the integrity of the BBB is maintained, some BBB models have been explored to simulate the “pathological” brain conditions with compromised BBB integrity.[ 26 ] In silico models reduce the cost of setting up in vitro or in vivo experiments by simulating the drug compound efficacy and predict its permeability across the BBB.[ 27 ]

Table 1.

Advantages and limitations of the various BBB models

| BBB models/features | 2D static models | Dynamic in vitro model | Microfluidic models | In vivo models |

|---|---|---|---|---|

| Ease of setup | Easy | Moderate | Moderate | Extensive skills required |

| Cost effectiveness | Minimal | Reasonable | Reasonable | Expensive |

| Co‐culture | Possible up to tri‐culture | Possible up to bi‐culture | Possible to setup entire neurovascular unit | Native |

| Geometry | 2D, flat morphology | 3D, cylindrical | 3D, cylindrical | Native |

| Permeability/TEER measurements a) | Low TEER values | Moderate TEER values | High TEER values | Invasive, difficult to measure |

| Imaging capability | Limited | Yes | Yes | Challenging, special instrument and skills required |

| 3D organization | No | Limited | Yes | Native |

| Mechanical stimulus | No | Yes, (shear stress induced by pulsatile flow) | Yes, (shear stress induced by interstitial and pulsatile flow) | Yes, biological |

| High‐throughput drug screening | Yes | No | Moderate | Highly expensive due to large number of animals required |

| Personalized medicine | Possible | No | Yes | No |

| Real‐time measurement | Limited | Limited | Yes | Yes |

| PK/PD profiling b) | No | No | No | Yes |

TEER, trans‐endothelial electrical resistance

PK/PD, pharmacokinetics/pharmacodynamics

In this review, we first discuss the polymeric nanoparticle systems that have been used for drug delivery to the CNS, including their synthesis methods and the latest advances. Next, we describe how their properties (i.e., surface, size, and shape) can be tuned to increase BBB penetration. Moreover, we critically review the in vitro and in vivo models used to evaluate BBB penetration efficacy of polymeric nanoparticles, including the latest developments in BBB‐on‐a‐chip models. Finally, we give an overview of the challenges and future perspectives for evaluating polymeric nanoparticles in clinically relevant BBB testing models.

2. Polymeric Nanoparticle Systems for BBB Transfer

Polymeric nanoparticles can be prepared from a plethora of monomers and using various polymerization techniques, and their properties can be tuned depending on their specific applications. In this section, we first discuss the most common polymeric nanoparticle systems that have been exploited for brain targeting, namely synthetic polymeric nanoparticles, natural‐based polymeric nanoparticles, and hybrid nanoparticles. We describe the synthesis methods of each polymer and its respective nanoparticle, drug loading, surface functionalization, and their suitability for drug delivery crossing the BBB. Thereafter, the effects of different nanoparticle parameters on BBB crossing are discussed: particle surface ligands, charge, size, and shape.

2.1. Synthetic Polymeric Nanoparticles

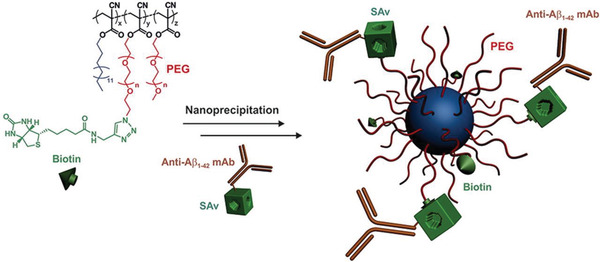

2.1.1. Poly(Alkyl Cyanoacrylate)

Poly(alkyl cyanoacrylate)s (PACA) are commonly known as superglues and have been commonly used as suture materials.[ 28 ] PACA nanoparticles were first developed by Couvreur et al. in 1972.[ 29 ] They have low toxicity[ 30 ] and are degraded by esterases from the pancreatic juice in the intestinal tract (oral administration) or by serum esterases in the blood.[ 31 ] The degradation time is in the order of hours and can be controlled by modifying the alkyl side chain length. For example, polymers with a longer side chain (e.g., octyl) degrade slower than shorter (e.g., butyl) side chain (PBCA).[ 32 ] Moreover, the choice of side chain also affects the toxicity profile.[ 33 ] PACAs can be synthesized via several polymerization techniques such as free radical, anionic, and zwitterionic polymerization,[ 34 ] and PACA nanoparticles are prepared either by polymerization in aqueous acidic phase or via interfacial emulsion polymerization.[ 28 ] PACA nanoparticles can be functionalized by esterification of cyanoacetic acid with, for example, polyethylene glycol (PEG)‐amine, folic acid, or drugs to create cyanoacetate esters that can then be polymerized. A variety of drugs have been loaded by encapsulation or adsorption including hydrophilic or poorly soluble molecules, peptides, proteins, and nucleic acids.[ 34 , 35 ] For brain delivery, PACA nanoparticles have been modified with PEG to escape macrophage uptake or with polysorbate 80 to improve their ability to penetrate the BBB.[ 36 ] In another study, PACA nanoparticles were decorated with anti‐Aβ1–42 antibody[ 37 ] and a significant increase in Aβ level was detected in the plasma, leading to memory recovery in an Alzheimer's disease mouse model (Figure 3 ).[ 38 ] These surface modifications will be discussed in more detail in Section 3.1. In fact, several PACA formulated nanoparticles have been investigated in clinical trials, although not yet for CNS diseases. For instance, PACA nanoparticles loaded with doxorubicin or mitoxantrone have been tested in patients with refractory solid tumors or hepatocellular carcinoma, respectively.[ 31 , 39 ] A phase II trial was discontinued due to severe acute respiratory distress events;[ 40 ] however, this was solved by changing the administration modality from the intra‐hepatic arterial route to a slow infusion by the intravenous route. Unfortunately, a phase III trial did not show any added survival benefit for patients compared to the best standard of care.[ 31 ] One of the reasons for the lack of clinical translation has been postulated by the variability in drug entrapment rate and release profiles.[ 39 , 41 ]

Figure 3.

Schematic overview of the synthesis of PACA nanoparticles for BBB crossing which were prepared by the nanoprecipitation of PEGylated PACA polymers functionalized with biotin. Thereafter, the nanoparticles were functionalized with monoclonal anti‐Aβ1–42 antibody. Reproduced with permission.[ 38 ] Copyright 2018, Elsevier.

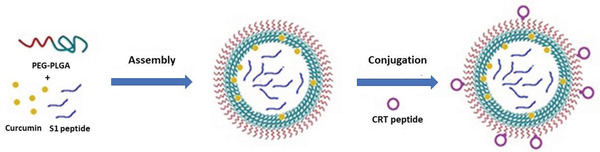

2.1.2. Poly(Lactic‐co‐Glycolic Acid)

Poly(lactic‐co‐glycolic acid) (PLGA) is a family of linear copolymers that can be prepared with different ratios of its constituent monomers, glycolic acid and lactic acid.[ 42 ] PLGA has been approved by the United States Food and Drug Administration (FDA) for medical uses such as sutures, drug delivery systems, and biomaterials (e.g., screws[ 42 ]). The PLGA copolymers are non‐toxic and biodegradable via hydrolytic de‐esterification followed by the clearance of their monomeric anions, glycolate and lactate.[ 43 ] The degradation rate, mechanical strength, degree of crystallinity, and thus drug loading and release kinetics can be precisely controlled by changing the lactic acid to glycolic acid ratio. Whereas poly(lactic acid) (PLA) is a crystalline hydrophobic polymer due to its methyl sidechains, poly(glycolic acid) (PGA) is a stiff and hydrophilic polymer with a low mechanical strength.[ 44 ] Consequently, PLGA copolymers with a higher PLA:PGA ratio are more hydrophobic and thus have a lower degradation and drug release rate. For example, the biodegradation rate of a 50:50 ratio is around 1 week (also dependent on molecular weight) as compared to a degradation rate up to 18 weeks for pure PLA.[ 45 ]

PLGA can be synthesized using several techniques: the polycondensation process,[ 45 ] ring opening polymerization,[ 46 ] and Segmer assembly polymerization.[ 47 ] PLGA nanoparticles can be obtained using methods such as emulsion, nanoprecipitation, solvent co‐evaporation, and spray‐drying from PLGA copolymer.[ 48 ] Non‐spherical nanoparticles (e.g., cylindrical shape) can also be prepared using soft lithography methods.[ 49 ] Surface modifications can be introduced via the terminal carboxylic acid groups, for example, creating diblock (PEG‐b‐PLGA) or triblock copolymers, PLGA‐b‐PEG‐b‐PLGA,[ 50 ] or introducing targeting moieties such as folic acid or antibodies.[ 51 ] Therefore, a wide range of drug molecules have been incorporated in PLGA nanoparticles including chemotherapeutics, antibiotics, anti‐inflammatory drugs, and proteins.[ 48 ] Numerous PLGA formulations have been studied for crossing the BBB.[ 52 ] For example, PLGA nanoparticles decorated with a cyclic transferrin‐targeting peptide and loaded with Aβ generation inhibitor peptide and curcumin showed improved spatial memory and recognition in transgenic mice (Figure 4 ).[ 53 ] Moreover, two non‐CNS targeting PLGA‐formulations have been clinically approved. Genexol‐PM was approved for the treatment of head and neck cancer and breast cancer in South Korea in 2006, while Nanoxel was approved for various cancers in India in 2007.[ 54 ] In addition, phase II clinical trials were successfully carried out using PGLA nanoparticles loaded with docetaxel (BIND‐014) and targeting a prostate specific membrane antigen in prostate cancer in 2016.[ 54 ]

Figure 4.

Preparation of PLGA nanoparticles. The PLGA nanoparticles were loaded with curcumin, S1 peptide (an Aβ generation inhibitor) and brain targeting peptide, CRT. Reproduced with permission.[ 54 ] Copyright 2017, Impact Journals.

2.1.3. Poly‐ε‐Caprolactone

Poly‐ε‐caprolactone (PCL) is a biodegradable, FDA‐approved polyester[ 55 ] and has been used among several applications: sutures (Monocryl), implants (e.g., 3D printed OsteoPlug for covering burr holes), contraceptive devices, and as drug delivery systems.[ 56 ] Chemically, PCL is composed of repeating units of hexanoate and can be degraded in the body by hydrolysis into 6‐hydroxycaproic acid,[ 57 ] which can be further transformed into adipate[ 58 ] and then catalyzed to CO2.[ 59 ] PCL is synthesized either by ring‐opening polymerization of ε‐caprolactone or via condensation polymerization of 6‐hydroxyhexanoic acid. Block copolymers containing PCL have been widely used, for example, PCL‐b‐PLGA (by grafting onto terminal di‐hydroxyl groups of PCL)[ 47 ] or PEG‐b‐PCL (by ring opening polymerization of ε‐caprolactone with methoxy‐PEG as initiator).[ 60 ] PCL‐based nanoparticles are predominantly synthesized using diblock PEG‐b‐PCL copolymers due to the insolubility of PCL in water. These nanoparticles can be prepared via standard methods such as solvent‐displacement, film dehydration, emulsion, and microfluidics.[ 61 ] PCL‐based nanoparticles have also been investigated for drug delivery for neurological diseases.[ 62 ] For instance, peptide‐functionalized PEG‐PCL micelles displayed significantly increased transport ratios in an in vitro BBB model and an enhanced accumulation in an intracranial glioma tumor‐bearing in vivo model.[ 63 ] However, the main limitation of PCL to be used as a drug delivery system is its low degradation rate (up to 1 year).[ 64 ] This drawback could potentially be overcome by modifying the molar mass or coating with other polymers such as copolymer with PLA.[ 65 ] Until now, no PCL‐based nanoparticles have been clinically approved.[ 66 ]

2.1.4. Polyamidoamine Dendrimers

Dendrimers are biocompatible 3D polymeric macromolecules that consist of tree‐like branches extending from a central core and have a corona with reactive functional groups.[ 67 ] Their size is measured in generations, based on the layer‐by‐layer structure by which they are synthesized.[ 68 ] Different types of dendrimers have been developed and the most prominent one is based on polyamidoamine (PAMAM). PAMAM can be synthesized using either a divergent or convergent method using Michael addition reactions followed by amidations. Other than amines, other surface functional groups such hydroxyl (−OH)[ 69 ] or carboxylic acid (−COOH)[ 70 ] can also be incorporated. These functional groups can render PAMAM dendrimers more water soluble, limit opsonization, and reduce clearance by the mononuclear phagocyte system (MPS).[ 71 ] Drugs are loaded to PAMAM via physical entrapment in the hydrophobic cavities or via conjugation to the surface functional groups.[ 72 ] As PAMAM dendrimers are usually smaller than 15 nm (depending on generation), they have been explored as another candidate drug delivery system for brain delivery.[ 73 ] For instance, dendrimers were shown to be able to cross the compromised BBTB of rodents with malignant glioma,[ 74 ] neuroinflammatory disease such as cerebral palsy,[ 75 ] and traumatic brain injury.[ 76 ] Moreover, PAMAM dendrimers (generation three) coated with a streptavidin adapter were shown to pass through the intact BBB via transcytosis, and slightly protonated G4 PAMAM dendrimers (10% amine) were able to reach the brain in healthy mice.[ 77 ] Despite the high medical expectations and research effort, clinical translation for dendrimers has been limited with only Starpharma's polylysine dendrimer‐based antimicrobial treatment approved for healthcare products.[ 67 ] Nevertheless, efforts have been made to significantly shorten dendrimer synthesis pathways and optimize the particle design, for example, amending multiple functional groups and incorporation of inner core functionalization to enable a higher drug loading.

2.1.5. Novel Synthetic Polymers

The aforementioned polymer‐based drug delivery systems have been investigated for several decades, however, with very limited clinical success. Therefore, recent research has been directed to other polymer systems to further enhance nanoparticle properties, such as drug loading, targeting, and controlled release kinetics. For example, pH‐responsive polymersomes based on the block copolymer poly(ethylene glycol) ethyl methacrylate‐block‐poly(2‐(diisopropylamino)ethyl methacrylate) (POEGMA‐b‐PDPA) have been shown to improve antibody delivery to the brain.[ 78 ] The polymersomes were conjugated with a peptide targeting the LDL‐related protein (LRP‐1). Interestingly, the study showed that LRP‐1 mediated transcytosis did not involve endocytic sorting and consequently pH‐driven degradation, and enabled intact nanoparticle transportation to CNS cells where the protein was released by endocytic acidification.[ 78 ] Drug loading efficiency can also be improved using other polymers. For example, transferrin‐coated nanoparticles consisting of the diblock copolymer PLA‐d‐alpha‐tocopheryl PEG 1000 succinate had a higher drug loading than PLGA nanoparticles,[ 79 ] and many other block copolymers have also been investigated. For example, a library of polymers based on (P(N‐(2‐hydroxypropyl)‐methacrylamide) (PHPMA) and P(laurylmethacrylate) (PLMA) were synthesized and were investigated for their BBB crossing capability. It was shown that a random copolymer containing 10% LMA was the most promising system due to the anchoring of the fatty acid‐like chains on the membrane.[ 80 ] Moreover, a dual targeting 2‐deoxy‐d‐glucose functionalized PEG‐co‐poly(trimethylene carbonate) also exhibited enhanced BBB crossing.[ 81 ]

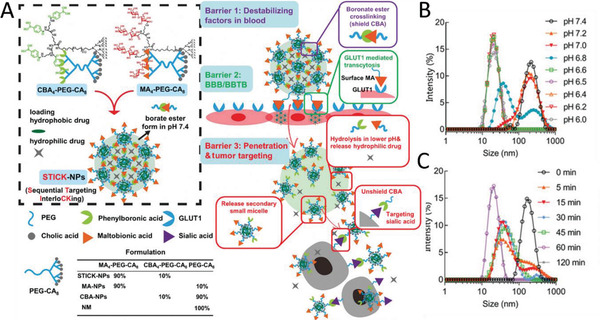

An interesting concept using a polymeric nanoparticle for sequential targeting based on cross‐linked telodendrimer micelles has been developed (Figure 5 ).[ 82 ] Maltobionic acid (a glucose derivative) was conjugated on the nanoparticle surface to promote GLUT1 receptor mediated BBB transcytosis. Upon exposure to an acidic extracellular pH (e.g., in solid tumors), the intrinsic boronate ester cross‐linkages are cleaved, transforming the nanoparticle into smaller secondary nanoparticles (Figure 5B,C) with newly unshielded surface carboxyphenylboronic that promoted tumor cell uptake.

Figure 5.

Sequential Targeting Interlocking (STICK) nanoparticles for BBB and blood–brain tumor barrier (BBTB) crossing. A) Synthesis scheme of STICK nanoparticles that consist of cross‐linked telodendrimer micelles functionalized with maltobionic acid as BBB targeting ligand. B) The size of the nanoparticles is pH‐dependent, and pH 6.8 appears to be the cut‐off value for triggering micellular transformation. C) Moreover, the size change is also time dependent (pH 6.5). Reproduced with permission.[ 82 ] Copyright 2020, John Wiley & Sons.

Positively charged polymeric nanoparticles have also been developed to enhance delivery of negatively charged gene therapeutics such as DNA and small‐interfering RNA (siRNA).[ 83 ] For example, poly(ethylene imine) (PEI)‐based nanoparticles were prepared and modified with glutathione to promote BBB penetration. The block copolymers, containing 80% primary or secondary amine groups, respectively, were investigated for penetration using a microfluidically perfused biochip, showing that secondary amines enhanced better BBB crossing performance.[ 84 ]

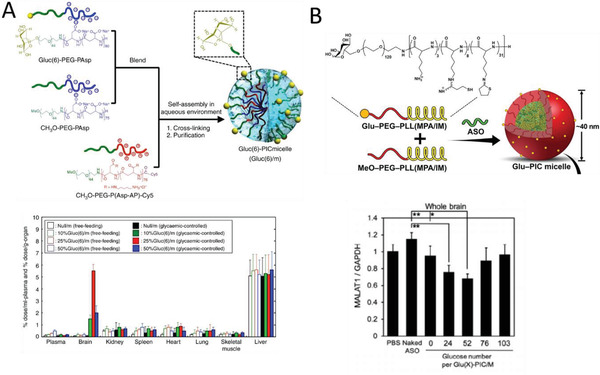

The Kataoka group explored polymeric micelles for BBB penetration (Figure 6 ).[ 85 , 86 ] These polymeric micelles were formulated using opposite charged pairs of PEG‐based block ionomers, that is, negatively charged PEG–poly(α,β‐aspartic acid) (PEG–PAsp) and positively charged PEG–poly([5‐aminopentyl]‐α,β‐aspartamide) (PEG–P(Asp‐AP)).[ 85 ] These ionomers were blended with glucose‐modified PEG‐PAsp to investigate the effect of the number of targeting moieties on BBB transfer efficiency (Figure 6A). Delivery of antisense oligonucleotides using a bespoke polymer system was further investigated.[ 87 ] A polyion complex (PIC) micelle self‐assembled from PEG‐b‐poly(l‐lysine) modified with 3‐mercaptopropyl amidine and 2‐thiolaneimine block copolymer was synthesized and the antisense oligonucleotides were immobilized through electrostatic interactions in the polymer core (Figure 6B). Disulfide crosslinking was introduced in the micelle core by partially derivatizing the side chain of the poly(l‐lysine) segment with sulfhydryl groups to improve its stability in the blood while stimulating release in the reductive condition in the brain. Finally, LDL receptor family‐targeted polymersomes were recently synthesized by blending PEG‐b‐poly(trimethylene carbonate‐co‐dithiolane trimethylene carbonate)‐b‐polyethylenimine (PEG‐P(TMC‐DTC)‐PEI) and apolipoprotein E peptide conjugated PEG‐P(TMC‐DTC). They demonstrated that these saporine‐loaded targeted polymersomes could cross the BBB in an in vitro BBB model and that systematic administration resulted in a complete growth inhibition in an orthotopic glioblastoma model.[ 88 ]

Figure 6.

A) Synthesis of polyion complex (PIC) micelles with different ratios of glucose on the surface (Gluc(6)/m) and their biodistribution in mice under different feeding conditions 48 h after injection. Open and closed bars show free‐feeding and glycemic‐controlled groups, respectively. Reproduced with permission.[ 85 ] Copyright 2017, Nature Publishing Group. B) PIC micelles for the delivery of antisense oligonucleotides (ASO) and the effect of glucose numbers on knock‐down. Reproduced with permission.[ 87 ] Copyright, 2020, Wiley‐VCH.

2.2. Natural Polymeric Nanoparticles

The use of synthetic polymers can sometimes be restricted due to their cost, purity, and undesirable toxicity profiles.[ 89 ] Therefore, nanoparticles based on naturally occurring polymers have also been explored as an alternative approach in brain drug delivery owing to their low toxicity, sustainability, low cost, and unique physicochemical characteristics including biodegradability.[ 90 ]

2.2.1. Chitosan

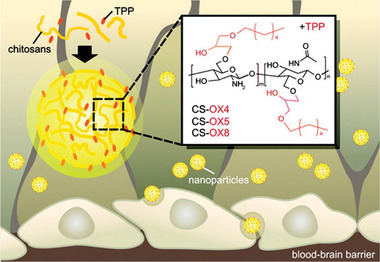

Chitosan is a cationic linear polysaccharide and is one of the most commonly used natural polymer‐based nanoparticles for drug delivery due to its low cost, biodegradability, and availability in a wide range of molecular weights.[ 91 ] It also has unique inherent biological properties, such as anti‐cancer, antimicrobial, and antioxidant characteristics.[ 92 ] Chitosan consists of randomly distributed β‐(1,4)‐linked d‐glucosamine and N‐acetyl‐d‐glucosamine units and is prepared by partial N‐deacetylation of chitin, a natural polymer extracted from crustaceans or fungi.[ 93 ] Chitosan has three types of functional groups (i.e., amine, primary and secondary hydroxyl) which can be exploited for various chemical modifications (Figure 7 ). Its biodegradability can be tuned by varying molecular weight, degree of deacetylation, and chemical modifications.[ 92 ] Chitosan nanoparticles can be prepared using a variety of methods including chemical cross‐linking, ionic gelation and microfluidic synthesis.[ 94 ] These natural nanoparticles have shown promise in brain delivery due to their positive charge, which enhanced cell uptake and suitable for loading with negatively charged therapeutics.[ 95 ] For example, antibody‐modified PEG‐chitosan nanoparticles showed a high brain uptake that was attributed to the synergy of the antibody and positive chitosan charge.[ 96 ] Nevertheless, chitosan nanoparticles have limitations such as a low drug loading efficiency of hydrophobic substrates[ 97 ] and poor control over molecular weight. In fact, drug loading efficiency has been shown to be improved using chemical modifications such as grafting palmitic acid.[ 90b ]

Figure 7.

Chitosan‐based nanoparticle for BBB crossing. O‐substituted alkyl‐glyceryl chitosan nanoparticles were prepared with systematically varied alkyl chain lengths (butyl‐OX4, pentyl‐OX5, octyl‐OX8) and sodium tripolyphosphate (TPP) to enhance BBB penetration. Reproduced with permission.[ 98 ] Copyright 2012, American Chemical Society.

2.2.2. Alginate

Alginate is an anionic linear unbranched polysaccharide and is extracted from brown seaweed (phaeophyceae). It is a random copolymer consisting of β‐d‐mannuronic acid and α‐l‐guluronic acid via 1,4‐glycosidic linkages.[ 99 ] Alginate is a non‐immunogenic substance that has been approved by the FDA[ 100 ] and has been used for wound healing, drug delivery, and tissue engineering applications.[ 101 ] Alginate has hydroxyl and carboxylic acid functional groups, which are exploited to introduce highly reactive functional groups (e.g., aldehyde groups) or introduce chemical (e.g., phosphate or sulfate) or biochemical (e.g., amino acids) groups that can increase its biointegration and bioaffinity properties.[ 102 ] Alginate nanocapsules and nano‐aggregates are prepared by complexation (using cationic compounds or divalent cations like Ca2+).[ 90b ] Alginate nanospheres are made using a water/oil emulsion method coupled with gelation.[ 103 ] Responsive alginate nanoparticles (pH or redox) can be synthesized by mixing with other polymers such as poly[(2‐dimethylamino) ethyl methacrylate][ 104 ] or employing disulfide cross‐links.[ 90 , 105 ] Brain delivery using alginate formulated nanoparticles have recently been reported. For example, alginate‐cholesterol micelles coated with lactoferrin were shown to be able to deliver a neuroprotective steroid to the brain,[ 106 ] and alginate nanoparticles cross‐linked with chitosan were shown to improve brain delivery of an anti‐depressant.[ 107 ] Furthermore, doxorubicin–alginate nanocomplexes with chitosan matrices showed enhanced uptake into the brain of rabbits.[ 108 ]

2.3. Hybrid Nanoparticles

Polymers have also been shown as a vital coating material for inorganic or lipid nanoparticles to form hybrid nanoparticles for brain delivery. For example, PEGylated liposomes (e.g., DaunoXome and Onivyde) and dextran coated Feridex iron oxide nanoparticles are FDA‐approved nanomedicines.[ 66 ] Foremost, PEG is used to improve blood circulation time and colloidal stability, including in CNS delivery. For example, an interesting system to improve magnetic resonance imaging (MRI) delineation of the periphery of brain tumors was recently published. The periphery of brain tumors has an intact BBB and therefore receptor‐mediated transcytosis is required to pass the BBB.[ 109 ] Gold nanoparticles were coated with PEG via a pH‐sensitive hydrazone bond and decorated with gadolinium‐chelates (click functional groups) and an LRP‐1 recognizing peptide. Upon BBB penetration, the hybrid nanoparticles aggregated in the acidic tumor environment after PEG cleavage, which resulted in increased MRI signals. PEGylated liposomes were also exploited to co‐deliver temozolomide and bromodomain inhibitor therapy, which showed a reduction in tumor burden and protection from the effects of systemic drug toxicity.[ 110 ] PEI is also used in hybrid nanoparticles to enhance drug loading, for example, for siRNA (gold nanoparticles)[ 111 ] and doxorubicin (iron oxide nanoparticles).[ 112 ] Natural polymers have been used in hybrid nanoparticles as well. Next to the ubiquitous dextran to coat, for example, iron oxide nanoparticles,[ 113 ] also other natural polymers such as chitosan have been exploited or combinations of above.[ 97 , 114 ] For example, hybrid nanoparticles consisting of an iron oxide core and an outer shell of chitosan–polyethylene glycol‐grafted polyethyleneimine copolymer were developed for the delivery of the cancer therapeutic, human tumor necrosis factor α‐related apoptosis‐inducing ligand, to glioblastoma and were able to cross the BBTB.[ 115 ]

3. Tunable Nanoparticle Properties for Enhanced BBB Transfer

Various factors can affect the performance of nanoparticles in BBB penetration such as surface ligands, charge, particle size, and shape. In this section, these features are discussed with an emphasis on polymeric nanoparticle systems.

3.1. Effect of Surface Ligands

The surface functionality of polymeric nanoparticles is the most important factor in BBB crossing efficiency. Specific ligands such as surfactants, antibodies, and peptides can be conjugated onto nanoparticles to promote recognition by receptors on the endothelial cells, leading to transcytosis and thus BBB crossing. Here, we provide an overview of the most promising ligands to enhance BBB penetration and their use in polymeric nanoparticles (Table 2 ).

Table 2.

An overview of ligands used to target the BBB, their specific targets, and examples of animal models and cell lines used

| Ligands | Receptors | Used animal models and cell lines | References |

|---|---|---|---|

| Surfactants | |||

| Polysorbate 80, Poloxamer 188 | LDL receptor |

Rats, mice Rat endothelial cells: RBE4 cells Bovine brain microvascular endothelial cell |

[ 116 , 117 , 118 , 119 , 120 , 124 , 125 , 126 ] |

| Natural proteins | |||

| Lactoferrin | LRP receptor and lactoferrin receptor | Rats, mice | [ 137 ] |

| Melanotransferrin | Unknown receptor | Bovine brain capillary endothelial cell: BBCEC | [ 139 ] |

| Transferrin | Transferrin receptor | Human brain endothelial cell line: hCMEC/D3 | [ 138 ] |

| Apolipoprotein | LDL receptor | Human brain endothelial cell line: hCMEC/D3 | [ 136 ] |

| CRM197 | Diphtheria toxin receptor | Mice | [ 140 ] |

| Antibodies | |||

| OX26, RI7217, 8D3 | Transferrin receptor |

Rats, mice Brain microvascular endothelial cells: BMECs Brain capillary endothelial cells: BCECs |

[ 144 , 145 , 146 , 149 ] |

| 83‐14 Mab, 29B4 | Insulin receptor |

Mice Human brain microvascular endothelial cells: HBMECs |

[ 147 , 148 ] |

| Peptides | |||

| Angiopep‐2, Apolipoprotein E peptide | LRP receptor |

Rats, mice Bovine brain capillary endothelial cell: BBCEC Rat endothelial cells: RBE4 cells Brain capillary endothelial cells: BCECs Mouse brain endothelial cells: bEnd.3 |

[ 88 , 157 , 158 , 159 , 161 , 162 ] |

| Peptide T7, Peptide B6, THR, CGGGHKYLRW, CRT, miR9, PQVGHL, TPL, TAT | Transferrin receptor |

Rats, mice Human brain capillary endothelial cells Mouse brain endothelial cells: bEnd.3 Bovine brain microvascular endothelial cells |

[ 54 , 163 , 164 , 165 , 166 , 167 , 168 , 169 , 175 ] |

| Leptin30 peptide | Leptin receptor |

Mice Brain capillary endothelial cells: BCECs |

[ 170 ] |

| Glycopeptide G7 | Unknown receptor | Mice | [ 171 ] |

| TGN, T‐T, TOL, CGN | Unknown receptor |

Mice, Mouse brain endothelial cells: bEnd.3 |

[ 172 ] |

| Rabies virus glycoprotein peptide | Acetylcholine receptor |

Mice Mouse brain endothelial cells: bEnd.3 |

[ 78 ] |

| Aptamers | |||

| RNA‐based aptamer A15 | Unknown receptor |

Mice Mouse endothelial cell line: bEnd.3 |

[ 183 ] |

| DNA homologue ‐aptamer | Transferrin receptor | Mice | [ 184 ] |

| Small molecules and other ligands | |||

| Maltobionic acid, glucose | GLUT receptor |

Mice Mouse endothelial cell line: bEnd.3 |

[ 82 , 85 , 185 ] |

| l‐Glutathione | Glutathione receptor | Human brain endothelial cell line: hCMEC/D3 | [ 84 ] |

| Adenosine | Adenosine G‐protein‐coupled receptors A2 |

Mice Mouse endothelial cell line: bEnd.3 |

[ 172 , 186 ] |

3.1.1. Polysorbate 80

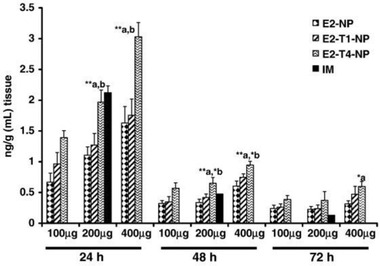

Polysorbate 80 (PS80, Tween 80) is a common surfactant used to enable drugs to pass through the BBB[ 116 ] and has been used for several pharmaceutical applications as an emulsifier. PS80 promotes BBB crossing due to the adsorption of apolipoprotein onto the nanoparticles, resulting in LDL receptor mediated transcytosis in epithelial BBB cells.[ 117 ] Polysorbates are derived from ethoxylated sorbitan, which is esterified with fatty acids. Tröster et al. investigated several surfactants and demonstrated that polysorbate‐coated poly(methyl methacrylate) nanoparticles had an increased brain uptake.[ 118 ] This was confirmed by other studies using polymeric nanoparticles with PS80 resulting in the highest CNS uptakes.[ 119 ] The amount of PS80 on a particle was shown to be an important parameter too as 4% of PS80‐coated PLGA nanoparticles displayed a higher uptake in the brain of an Alzheimer's disease rat model than 1% PS80‐coated PLGA nanoparticles or non‐coated nanoparticles (Figure 8 ).[ 120 ]

Figure 8.

PS80 coated PLGA nanoparticles increase the brain delivery of estradiol after oral administration. E2‐NP: estradiol‐loaded PLGA nanoparticle; E2‐T1‐NP: estradiol with 1% PS80 coated PLGA NP; E2‐T4‐NP: estradiol with 4% PS80 coated PLGA NP; IM: intramuscular administration. Reproduced with permission.[ 120 ] Copyright 2011, Elsevier.

3.1.2. Poloxamer 188

Poloxamers are non‐ionic triblock amphiphilic copolymers consisting of poly(ethylene oxide)‐poly(propylene oxide)‐poly(ethylene oxide).[ 121 ] The first two digits (e.g., 18 in poloxamer 188) indicate the approximate molecular mass of the polypropylene core (1800 g mol−1) and the last digit (e.g., 8 in poloxamer 188) multiplied by 10 gives the percentage of polyoxyethylene content (80%).[ 122 ] In particular, Poloxamer 188 has been used in the field of drug delivery and is approved by the FDA under the trade name of Pluronic F68.[ 123 ] Similar to PS80, Poloxamer 188 coated nanoparticles promote the adsorption of apolipoprotein on the surface of nanoparticles in plasma leading to LDL receptor‐mediated transcytosis.[ 124 ] Several polymeric nanoparticle systems have been successfully delivered to the brain using a poloxamer 188 coating, including PBCA[ 124 ] and PLGA.[ 125 ] In most studies, the BBB crossing efficiency for poloxamer 188 coating is similar to PS80, although the nanoparticle system seems to also have a minor influence.[ 126 ]

3.1.3. PEG

PEG is approved by the FDA for human intravenous, oral, and dermal applications.[ 127 ] Surface coating of nanoparticles with PEG results in a distinct reduction and modification of the protein corona that contains an abundance of clusterin proteins which limits non‐specific cell uptake,[ 128 ] and therefore clearance by the MPS. This results in a better biocompatibility, longer circulation time, and decreased aggregation.[ 129 ] Longer PEG chains (higher molecular weight), higher grafting densities, branched PEG chains, and methoxy termination can lead to longer circulation time.[ 127 ] Although PEG coatings do not directly increase BBB penetration, the longer circulation time increases the probability of decorated ligands on nanoparticles to interact with BBB receptors. Therefore, many polymeric nanoparticle systems have been coated with PEG: for example, PCL,[ 130 ] PLGA,[ 131 ] PACA,[ 132 ] chitosan,[ 96 ] and PAMAM.[ 133 ] Interestingly, the length of the PEG chain can also impact on polymeric nanoparticle penetration within the brain extracellular space. PLA nanoparticles (100 nm) coated with PEG chain lengths of 1 to 10 kDa and longer chain PEGs (5 and 10 kDa) resulted in the deepest brain parenchyma penetration.[ 134 ] Other polymers with enhanced circulation time are: polysulfoxides, poly(glycerol)s, poly(amino acid)s, poly‐(vinylpyrrolidone), poly(2‐oxazoline)s, and poly(N‐(2‐hydroxypropyl)methacrylamide).[ 135 ]

3.1.4. Natural Proteins

The natural ligands for receptors expressed on the BBB, such as the transferrin receptor, lipoprotein receptors, and diphtheria receptor, can also be used to improve the transcytosis of polymeric nanoparticles. Apolipoprotein,[ 136 ] transferrin,[ 137 ] lactotransferrin,[ 138 ] and melanotransferrin[ 139 ] have been successfully conjugated onto nanoparticles to improve BBB transcytosis. For example, PLGA nanoparticles coated with either transferrin or lactotransferrin showed a higher targeting efficacy (2.4 and 3.9 fold increase) in a mouse brain compared to non‐conjugated PLGA nanoparticles.[ 138a ] Moreover, PLGA nanoparticles modified with a mutated form of diphtheria toxin (CRM197) also exhibited an enhanced particle uptake.[ 140 ] However, a potential disadvantage for this approach is that protein‐conjugated nanoparticles encounter competition from endogenous proteins. Furthermore, it is important to tune the avidity of the nanoparticles, namely, natural ligand density, as nanoparticles with a high surface density of ligands remain strongly attached to brain endothelial cells, whereas those with less proteins are capable of binding to the relevant protein receptor on the luminal side of the BBB and detaching from the receptor on the brain side.[ 141 ] An alternative approach is to conjugate targeting ligands via responsive linkages to nanoparticles, which can be cleaved during transcytosis.[ 142 ] Moreover, cationized proteins can be used to exploit adsorptive‐mediated transcytosis. For example, albumin‐coated nanoparticles did not increase BBB penetration, while cationic albumin‐coated nanoparticles exhibited a significantly higher BBB crossing.[ 143 ]

3.1.5. Antibodies

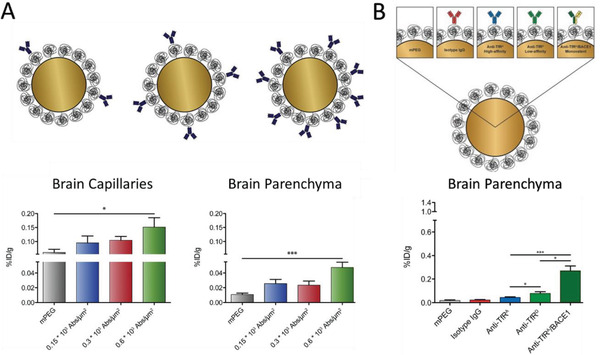

Antibodies recognize a unique motive in a receptor and are therefore well suited for receptor‐mediated transcytosis. Moreover, antibodies bind at different epitopes than endogenous ligands, such as proteins, preventing competitive binding. Therefore, antibodies have become a popular strategy to improve nanoparticulate brain delivery. Popularly used antibodies are the anti‐transferrin receptor antibodies (e.g., OX26,[ 144 ] RI7217,[ 145 ] and 8D3[ 146 ]) and anti‐human insulin receptor antibodies (83‐14 Mab[ 147 ] and 29B4).[ 148 ] For example, hyperbranched polyglycerol‐conjugated PLGA nanoparticles were functionalized with OX26 and loaded with endomorphins.[ 149 ] In an in vivo model, these antibody‐modified nanoparticles showed a pronounced analgesic effect compared to nanoparticles without OX26.[ 149 ] The antibody density on nanoparticles is also an important factor for the BBB penetration. For instance, the Moos group compared three low‐range densities of transferrin receptor antibodies (0.15, 0.3, and 0.6 x 103 antibodies µm−2) conjugated onto gold nanoparticles and liposomes for BBB transport in both in vitro model and in mice (Figure 9A).[ 145 ] They discovered that nanoparticle systems with higher antibody density increased the BBB transport after intravenous administration. On the other hand, too much antibody coverage on nanoparticles can actually limit BBB crossing as the antibodies remain associated with the receptor.[ 150 ] The brain uptake can also be improved by tuning the affinity of antibodies. Specifically, antibodies with high and low affinities mediate a low and intermediate uptake of nanoparticles into the brain, respectively, whereas a monovalent (bi‐specific) antibody with an intermediate affinity improved the uptake capacity remarkably (Figure 9B).[ 145 , 151 ]

Figure 9.

The effect of antibody density and affinity on the BBB penetration of nanoparticles. A) PEG‐coated gold nanoparticles with increasing low‐range transferrin antibody (RI7) surface densities showed increased brain uptake. Reproduced with permission.[ 145 ] Copyright 2019, Elsevier. B) Transferrin receptor antibodies (TfR) with different affinities (anti‐TfRA > anti‐TfRD, isotype lgG as control, and anti‐TfRA/BACE1 as bivalent antibody) were conjugated onto PEG‐coated gold nanoparticles and brain uptake was investigated. Reproduced with permission.[ 153 ] Copyright 2018, Ivyspring International Publisher.

3.1.6. Peptides

Peptides are short chains of amino acids that have shown great potential as conjugating ligands to promote BBB transcytosis due to their relatively low cost, reduced immunogenicity,[ 152 ] and versatility for conjugation.[ 153 ] BBB penetrating peptides, often called BBB shuttle peptides, are derived from neurotropic endogenous proteins, discovered by phage display or naturally occurring.[ 153 ] Like antibodies, most peptides do not compete in binding with endogenous counterparts. However, their medium‐to‐low binding affinity to receptors promote nanoparticle release into the brain parenchyma compared to high affinity antibodies.[ 153 , 154 ] BBB shuttle peptides have been used extensively to increase brain delivery of small molecules, macromolecules, and nanoparticles.[ 155 ]

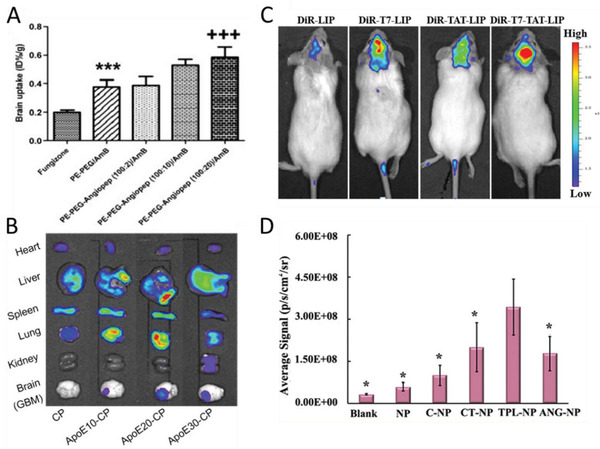

The most used BBB shuttle peptide, angiopep‐2, consists of 19 amino acids and was derived from the Kunitz domain of aprotinin, an LRP1 and LRP2 ligand.[ 156 ] Angiopep‐2 exhibits a higher transcytosis capacity than transferrin, lactoferrin, and avidin.[ 157 ] It can easily be modified with cysteine using solid phase peptide synthesis to enable conjugation to maleimide or epoxide functional polymeric nanoparticles. For example, PEG‐PLA nanoparticles were functionalized with angiopep‐2 using this method and displayed an increased brain uptake in mice.[ 157 , 158 ] The angiopep‐2 density on nanoparticles also affects BBB penetration.[ 159 ] 1,2‐Distearoyl‐sn‐glycero‐3‐phosphoethanolamine‐N‐[methoxy(polyethylene glycol)‐2000] (PE‐PEG) nanoparticles were prepared with a PE‐PEG to angiopep‐2 ratio of 100:2, 100:10, and 100:20. It was shown that a higher ratio (100:20) significantly increased the particle uptake in both brain capillary endothelial cells in vitro, as well as in a mouse brain (Figure 10A). Other LDL receptor family targeting peptides have shown some promising results too.[ 160 ] For example, apolipoprotein E peptide (ApoE) modified polymersomes had a 2.2‐fold higher BBB penetration in an endothelial cell monolayer compared to angiopep‐2 modified polymersomes.[ 88 ] This may be ascribed to its high affinity to multiple LDL‐receptors, including LDLR, LRP1, and LRP2.[ 161 ] The ApoE polymersomes also successfully delivered saporin to an orthotopic glioblastoma model resulting in complete tumor growth inhibition, although it must be stated that the BBTB is likely to have different penetration characteristics compared to a fully intact BBB (Figure 10B).[ 88 ] A synergic approach has also been explored by modifying PEG‐PCL nanoparticles with both ApoE and PS80.[ 162 ] Oral administration of this system resulted in an enhanced brain uptake of donepezil, an acetylcholinesterase inhibitor used for Alzheimer's disease.[ 162 ]

Figure 10.

Effect of peptide ligands on the BBB penetration of nanoparticles. A) Biodistribution of free amphotericin B(AmB) and AmB‐incorporated micellar formulations with different ratios of angiopep‐2. Reproduced with permission.[ 159 ] Copyright 2010, Elsevier. B) Ex vivo accumulation of chimeric polymersomes with varying ApoE peptide surface densities. Reproduced with Permission.[ 88 ] Copyright 2018, American Chemical Society. C) Representative in vivo images of tumor‐bearing mice injected with dye (DiR) labeled liposomes (LIP) with T7‐peptide, TAT‐peptide and both T7‐peptide and TAT‐peptide. Reproduced with permission.[ 163 ] Copyright 2014, American Chemical Society. D) The relative integrated fluorescence intensity in the brain of peptide conjugated nanoparticles: CGN peptide (C‐NP), CT peptide (CT‐NP), fusion peptide (TPL‐NP) or angiopep‐2 (ANG‐NP). Reproduced with permission.[ 164 ] Copyright 2020, Elsevier.

The transferrin receptor expressed on the endothelial cells of the BBB can be effectively targeted using BBB shuttle peptides. For example, the B6‐peptide was discovered by phage display and used to modify PEG‐PLA nanoparticles to enhance the brain delivery of a neuroprotective peptide.[ 165 ] Furthermore, the THR peptide also showed to improve the brain uptake of gold nanoparticles in mice.[ 166 ] Other transferrin receptor peptides that have been used for nanoparticle delivery are: CGGGHKYLRW,[ 167 ] CRT,[ 168 ] miR9,[ 169 ] and PQVGHL.[ 54 ] Peptide‐conjugated nanoparticles for targeting other receptors on the BBB have also been studied. This includes the leptin30 peptide to target the leptin receptor,[ 170 ] glycopeptide G7 for an unknown receptor,[ 171 ] TGN peptide for another unknown receptor,[ 172 ] and rabies virus glycoprotein peptide (RVG) for the acetylcholine receptor.[ 78 ] The latter enhanced DNA transport across the BBB using PEG‐PEI nanoparticles.[ 173 ] However, RVG modified pH‐sensitive polymersomes could not pass the BBB in an in vitro assay in contrary to angiopep‐2 modified polymersomes.[ 78 ] Glycopeptide and non‐toxic mutant of diphtheria toxin (CRM197) conjugated PLGA nanoparticles crossed the BBB to a similar extent, but higher than non‐peptide conjugated nanoparticles.[ 140 ] Furthermore, the BBB shuttle peptides RVG, rabies virus matrix protein fragment (RVMAT), or TGN were compared for the brain delivery of 90 nm sized PLGA‐DSPE‐PEG nanoparticles, and only TGN peptide modified nanoparticles showed a slightly higher uptake than unmodified nanoparticles.[ 172 ] Endogenous peptides have also been exploited. For example, insulin was conjugated onto human serum albumin nanoparticles using an NHS‐PEG‐maleimide linker and the loperamide‐loaded nanoparticles induced significant antinociceptive effects in the tail‐flick test in mice.[ 174 ] Nevertheless, these natural peptide‐conjugated nanoparticles need to compete with endogenous peptides for binding, and additionally the use of insulin could potentially affect the regulation of glucose homeostasis.

A different class of peptides to promote BBB crossing are the cell penetrating peptides (CPPs). These peptides mainly consist of amphipathic or cationic sequence that is able to cross cellular membranes.[ 153 ] Some common CPPs are model amphipathic peptide (MAP), transportan, antennapedia, and transactivator of transcription (TAT).[ 175 ] For example TAT peptide conjugated PLA nanoparticles were shown to have enhanced brain uptake of ritonavir, a protease inhibitor, and prevented the efflux action of P‐gp.[ 176 ] However, CCPs exhibit various levels of cytotoxicity.[ 177 ] CPPs can also be combined with BBB shuttle peptides to enable dual‐targeting. For instance, TAT was combined with a transferrin receptor targeted peptide (T7) to enhance the transport of doxorubicin‐loaded liposomes in an BBB in vitro model and a glioma mouse model where T7 enhanced brain selectivity and TAT increased uptake in the brain tumor (Figure 10C).[ 163 , 166 ] An alternative approach to achieve dual‐targeting is to use the so‐called fusion peptides in which both peptides are linked. For instance, a fusion peptide named TPL was synthesized that linked the BBB shuttle peptide, TGN, and the neuron binding peptide, Tet1, via a four‐glycine linker. Fusion peptide modified PEG‐PLA nanoparticles showed a 5.7‐fold higher fluorescence intensity in the brain of mice compared to control nanoparticles (Figure 10D).[ 164 ]

3.1.7. Aptamers

Aptamers are short single‐stranded chains of RNA or DNA oligonucleotides obtained via in vitro selection of randomized oligonucleotides using Systematic Evolution of Ligands by Exponential enrichment (SELEX) that bind to molecules such as peptides or proteins. Compared to antibodies, aptamers have a higher conformational stability and can reversibly refold to their native conformation.[ 178 ] Therefore, aptamers have been widely used to target and diagnose brain diseases such as Alzheimer's disease,[ 179 ] stroke,[ 180 ] brain tumors,[ 181 ] and Parkinson's disease.[ 182 ] Moreover, aptamers to facilitate BBB penetration have been developed, such as the RNA‐based aptamer, A15,[ 183 ] and a transferrin‐receptor aptamer liposomal delivery system exhibited a higher uptake in the rodent brain compared to control liposomes.[ 184 ] However, more research is needed to fully explore the potential of aptamers to enhance BBB crossing of nanoparticles.

3.1.8. Small Molecules and Other Ligands

Small molecules such as maltobionic acid,[ 82 ] glutathione,[ 84 ] glucose,[ 82 , 85 ] and natural polymers like chitosan have also shown to enhance the BBB and BBTB penetration of nanoparticles. Glucose‐conjugated nanoparticles can bind to the highly expressed BBB receptor GLUT‐1 to promote transcytosis with increased biocompatibility and tumor targeting. Similarly, 2‐deoxy‐d‐glucose modified poly(ethylene glycol)‐co‐poly(trimethylene carbonate) nanoparticles showed both enhanced BB(T)B crossing and uptake in glioma in mice,[ 82 ] and as previously mentioned, several glucose‐modified polymeric micelle systems were developed and the effect of the glucose density on the particle surface was investigated by blending different ratios of polymers with/without glucose (Figure 6). They showed an optimal BBB penetration when approximately half of the copolymer strands were modified with glucose (Figure 6D).[ 185 ] Interestingly, they were able to improve brain accumulation further by taking advantage of the rapid glycemic increase after fasting.[ 85 ] In addition, adenosine‐modified polymeric nanoparticle systems consisting of a block copolymer of polylactic acid and hyperbranched polyglycerol (PLA‐HPG) were also studied, and nanoparticles with 10% adenosine showed a higher brain uptake than particles with 0, 1%, or 5% adenosine.[ 172 ] Moreover, the 10% adenosine‐modified PLA‐HPG nanoparticles were compared to similar‐sized PLGA‐DSPE‐PEG nanoparticles conjugated with the BBB shuttle peptides RVG, RVMAT, or TGN, and exhibited a significantly higher brain uptake. However, it has to be noted that PLA‐HPG control nanoparticles showed a higher uptake than PLGA‐DSPE‐PEG nanoparticles. Adenosine is hypothesized to cross the BBB by carrier‐mediated transport through the concentrative nucleoside transporter type 2. Additionally, it also binds to G‐protein coupled receptor A2, producing a transient and controlled opening of the BBB.[ 186 ]

An alternative targeting ligand is chitosan which is often used as a stand‐alone nanoparticle system but can also be used as a surface coating as it is a cationic saccharide. For instance, chitosan‐modified PLGA nanoparticles loaded with carmustine showed a higher BBB penetration and anti‐tumor effect.[ 187 ]

3.2. Effect of Nanoparticle Size

The size of nanoparticles plays an important role in particle biodistribution, elimination, and CNS delivery.[ 188 ] Polymeric nanoparticles can be administered via different routes, such as oral, intranasal, intravenous, or intraperitoneal. In particular, the intravenous injection method is explored as nanoparticles bypass the gastrointestinal tract and thus improve the bioavailability. Once intravenously administered, nanoparticles enter the cardiovascular system and can be transported across the BBB under suitable conditions. Prolonged circulation time is advantageous as it increases the probability of nanoparticles interacting with the BBB leading to subsequent transcytosis to the brain parenchyma.

Small molecules and nanoparticles with diameters less than 5 nm are rapidly cleared by the kidneys via glomerular filtration.[ 189 ] Non‐continuous endothelia with vascular fenestrations are present in the liver, resulting in non‐specific accumulation of larger nanoparticles (50–100 nm). Furthermore, nanoparticles above 200 nm are retained in the spleen due to the 200–500 nm size range of splenic interendothelial cell slits.[ 190 ] Microparticles in the size range of 2–5 µm tend to accumulate in the capillaries of the lungs. It is important to note that particle–cell surface interactions play an essential role in particle biodistribution as the MPS that is associated with the liver, spleen, and lungs can eliminate nanoparticles from the circulation by phagocytosis. In short, nanoparticles above 5 nm in size can escape the renal clearance resulting in a longer blood circulation time, but larger particles will eventually be cleared by the liver and the spleen. Furthermore, the biodegradation rate of nanoparticles also affects particle distribution as particles that degrade too rapidly could be cleared by the kidneys limiting their circulation time.

Polymeric nanoparticles can be synthesized to a specific size range[ 191 ] and are therefore well suited to exploit the size effect on BBB interactions. For example, the effect of particle size on PLGA nanoparticle delivery in a brain injury model with a temporarily compromised BBB was studied.[ 192 ] PEG‐coated PLGA nanoparticles with various sizes (100, 200, and 800 nm) were conjugated to a targeting ligand. The smallest size of nanoparticles (100 nm) showed a deeper penetration into the brain than the larger ones (800 nm). Furthermore, the liver retention of the largest PLGA nanoparticles was also double that of the smallest size of PLGA, indicating that the smaller particles had a longer circulation time. Similarly, it was shown that smaller PLGA nanoparticles (<100 nm) not only enhanced the ability of the particles to cross an intact BBB but also could penetrate into the brain parenchyma.[ 193 ]

The size effect (20 to 500 nm) was also investigated for polystyrene nanoparticles coated with d‐α‐tocopheryl polyethylene glycol 1000 succinate (PEG‐vitamin E) for BBB penetration in rats.[ 194 ] It was observed that the smaller the nanoparticles the more pronounced the uptake into the brain (25 > 50 > 100 > 500 > 200 nm) and that the PEG‐vitamin E ligand was more effective in increasing BBB penetration for smaller particles than for larger particles. Interestingly, in a microfluidic model, a different non‐monotonic trend of particle dependence on size was observed where polystyrene particles of 200 nm in size exhibited the highest BBB transport than either smaller (100 nm) or larger (500 nm) particles.[ 195 ] However, it must be noted that microfluidic models cannot accurately modulate the effects of the MPS. In contrast, some reports showed that BBB penetration had no effect on particle size. For example, 75 nm antibody‐PEG coated gold particles had a similar BBB penetration as 135 nm antibody‐PEG liposomes[ 145 ] and the researchers concluded that particle size had no influence on BBB crossing.[ 196 ] Here, PBCA nanoparticles were prepared in the range of 87 to 464 nm and coated with surfactants such as Lutrol‐SDS (non‐BBB‐passage) or polysorbate 80 (BBB‐passage). The barrier penetration was examined using the blood–retina barrier as a substitute model for BBB, which has similarities in transport and permeation. Nevertheless, there are clear cellular, structural, and functional differences between the blood–retina barrier and the BBB.[ 197 ] Moreover, only limited quantitative analysis was performed and only a few sizes were investigated for each surfactant. However, the study did show that the nature of the surfactant was a more important determinant of uptake compare to particle size.

Apart from polymeric nanoparticles with a fixed size, size‐changeable nanoparticles have also been investigated to overcome multiple barriers including the BBB. An excellent example of this strategy is the earlier addressed study (Section 2.1.5), where 92 nm sized, cross‐linked telodendrimer micelles were able to cross the BBB, but were cleaved into smaller 14 nm secondary nanoparticles after exposure to the acidic tumor microenvironment to enhance transport to the brain tumor.[ 82 ]

3.3. Effect of Nanoparticle Shape

The most commonly explored nanoparticles in research have a spherical shape; however, nanoparticles can also be prepared with other shapes, for example, cubes, rods, discs, and stars. The shape of nanoparticles influences their behavior in blood flow, their interactions with endothelial cells, and the MPS, affecting circulation time, biodistribution, and cellular uptake.[ 198 ] For example, filamentous micelles (diblock copolymer of PEG and poly(ethylethylene)) were shown to have longer circulation times[ 199 ] than spherical micelles which could potentially be exploited to improve BBB interaction. This longer circulation time was also observed for PEGylated silica nanorods and was speculated to be aspect ratio dependent, which may be related to the uptake ability of the MPS[ 200 ] and behavior in dynamic flow.[ 201 ]

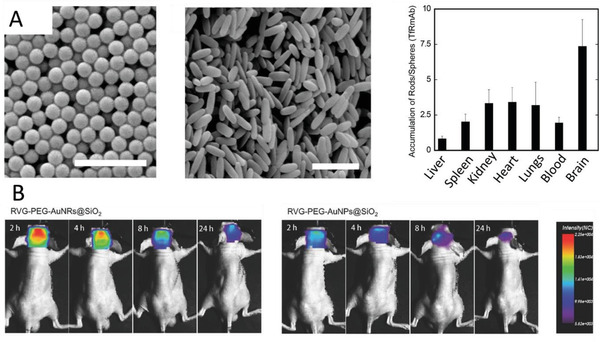

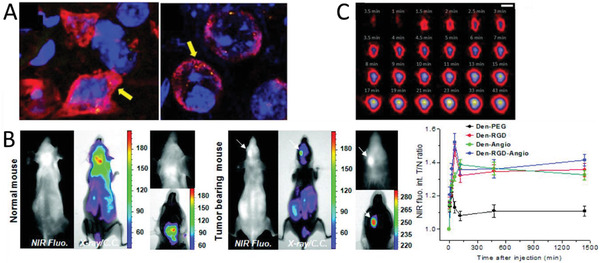

The specificity of endothelial targeting can also be enhanced by engineering the shape of ligand‐displaying polymeric nanoparticles.[ 202 ] Polystyrene nanospheres and nanorods with equivalent volumes were examined and their biodistribution in brain endothelium compared (Figure 11A). The polymeric nanoparticles were conjugated to an anti‐transferrin receptor antibody and rod‐shaped nanoparticles showed a sevenfold higher accumulation in the brain compared to spherical particles, while some uptake enhancement (two to three times higher) was also observed in kidney, heart, and lung. Moreover, rod‐shaped PEGylated polystyrene nanoparticles decorated with a vascular adhesion molecule‐1 (VCAM‐1) antibody showed a higher cell uptake in both static and flow conditions compared to spherical nanoparticles. However, no particle uptake differences were observed in vivo. The low aspect ratio (2:1) used, protein corona formation, or the lower number of antibodies on the surface of the rod‐shape nanoparticles could be potential reasons for the discrepancy in the results.[ 203 ] On the contrary, another study recently reported that that while rod‐shaped polystyrene nanoparticles exhibited lower affinity in a microfluidic model compared to spherical nanoparticles, they showed a higher BBB transport when normalized by endothelial association.[ 195 ] Similar shape effects were also observed for inorganic hybrid nanoparticles with a polymer shell. For example, gold nanorods coated with PEG and RVG (a BBB shuttle peptide) exhibited a higher brain accumulation in mice than the corresponding spherical nanoparticles[ 204 ] (Figure 11B). Other shapes such as nanodiscs, cubic nanocages, and nanostars are yet to be investigated for BBB penetration efficiency but have shown shape‐dependent biodistribution and cell association that could potentially also lead to enhanced BBB penetration. For instance, gold nanoparticles with a nanodisc shape were found to have higher tumor penetrations relative to nanorods and nanocubes in a tumor‐bearing mouse model.[ 205 ] Furthermore, gold nanostars had a higher tumor uptake compared to nanospheres that was attributed to an increased surface contact.[ 206 ]

Figure 11.

The effect of nanoparticle shape on BBB crossing. Scanning electron micrographs of transferrin antibody coated spherical and rod‐like nanoparticles, and their in vivo biodistribution (expressed as rods‐to‐spheres ratios). Scale bar 1 µm. Reproduced with permission.[ 202 ] Copyright 2013, National Academy of Sciences. B) In vivo fluorescence signal image of rabies virus glycoprotein (RVG) peptide‐PEG‐coated silica‐gold nanorods (RVG‐PEG‐AuNRs@SiO2) and RVG peptide‐PEG‐coated silica‐gold nanospheres (RVG‐PEG‐AuNPs@SiO2) in orthotopic glioma xenograft‐bearing mice. Reproduced with permission.[ 204 ] Copyright 2017, John Wiley & Sons.

3.4. Effect of Surface Charge

The surface charge of polymeric nanoparticles can also affect BBB penetration.[ 207 ] The luminal side of the BBB has a negative charge due to the presence of proteoglycans expressed on endothelial cells. As a consequence, positively charged nanoparticles can take advantage of adsorptive‐mediated transcytosis using either intrinsically positively charged nanoparticles[ 77 ] or by conjugating positively charged ligands such as cationic albumin or cell binding peptides onto nanoparticles.[ 208 ] Electrostatic interactions are triggered between the positively charged nanoparticles and negatively charged cell membrane, leading to endocytotic internalization of the nanoparticles.[ 209 ] However, particles with cationic surfaces also exhibit a higher macrophage uptake and clearance by the MPS compared to neutral surface charge nanoparticles (e.g., PEG).[ 210 ] Another potential drawback of using positively charged nanoparticles is that they may show a higher toxicity than anionic and neutral nanoparticles.[ 209 ] Charged particles can also have a negative effect on BBB integrity. One study demonstrated that while neutral or low concentrations of anionic nanoparticles had no impact on the BBB integrity, higher concentrations of anionic and cationic nanoparticles both disrupted the BBB and had immediate toxic effects on brain microvasculature endothelium.[ 211 ] The charge of nanoparticles also affects protein corona formation. While proteins are predominantly negatively charged, studies have shown that specific plasma proteins could also bind to some extent to various anionic and neutral nanoparticles,[ 212 ] which also affects receptor binding and BBB transcytosis.[ 213 ]

4. Testing Models for BBB Transfer

4.1. In Vivo Models for BBB

Prior to clinical trials, in vivo models (e.g., rodent models) are employed to test the efficacy, immune response, and toxicity of drug‐loaded polymeric nanoparticles.[ 214 ] Resulting data extracted from rodent models are often used to extrapolate to the human condition as comparable BBB permeability and the presence of efflux transporter proteins were reported in rodent and human brains.[ 24 , 215 ] Nanoparticle permeability and transport can be assessed using both invasive and non‐invasive techniques. Examples of invasive methods are compound permeation and product determination by intravenous injection and in situ brain perfusion, quantitative audiography, and microdialysis sampling.[ 216 ] Examples of non‐invasive techniques are positron emission tomography (PET), single‐photon emission‐computed tomography (SPECT), and in vivo fluorescence imaging.[ 216 ] Moreover, these imaging techniques, including magnetic resonance imaging (MRI), can also be used to assess disease progression.

The main challenge of drug delivery to the CNS is the rapid opsonization of the drug by the MPS. Different drug delivery routes, such as nasal, local, and systemic delivery have been developed in vivo aiming to transport drugs more efficiently to the brain.[ 217 ] Systemic delivery is the most common technique as it transports the drug through carrier‐mediated endocytosis or efflux pump transporters. In some in vivo models, the integrity of the BBB can be temporarily disrupted using mannitol and focused ultrasound waves[ 218 ] to deliver drugs into the CNS through the circulatory system. However, the intranasal delivery method is also gaining interest due to the rapid absorption of the drugs through the olfactory mucosa along the connective tissue surrounding the bundle of olfactory neurons.[ 219 ] The intranasal delivery bypasses the BBB, which in some cases can be advantageous in drug delivery in CNS diseases.

In vivo models have an added advantage of pharmacokinetic (PK) and pharmacodynamics (PD) profiling of administered nanoparticles. PK is the study of the fate of the drug‐loaded nanoparticle in the body (including accumulation in the brain), whereas PD investigates the response of the body to the drug‐loaded nanoparticle and involves dose‐response relationships. In vivo models are capable of testing the nanoparticle penetration across the BBB and provide reliable PK/PD profiles. In PK studies, the nanoparticle concentration in the blood plasma is measured at several time points after administration. The most widely determined PK parameters are C max (peak concentration), T max (time to reach peak concentration), and half‐life (time taken to eliminate 50% of the drug). The total nanoparticle amount in the brain and in the blood plasma is determined using the area under the concentration‐time curve (AUC) that reflects the actual body exposure of the nanoparticle after administration. The average time that the drug remains in brain or plasma is given by the mean residence time (MRT). Other than quantifying PK parameters, the ability to examine the biodistribution of the nanoparticles in the body and especially in the CNS is important as it provides an insight on evasion of the MPS, and the penetration of the BBB and brain parenchyma. Systemic organs such as heart, liver, spleen, lungs, kidney, and brain are collected by sacrificing the animals at specific or several time points to analyze the drug content. Moreover, the organs provide information about the toxicity of the nanoparticles, ability of the nanoparticles to reach the site of action, release the drug payload, and the ability to achieve a therapeutic effect.

Drug concentrations in tissue extracts can be determined ex vivo using analytic techniques such as high‐performance liquid chromatography (HPLC) or enzyme‐linked immunosorbent assays (ELISA). For example, PK/PD profile of PLGA nanoparticles loaded with bevacizumab administered demonstrated higher brain availability in comparison to the free bevacizumab administered for 7 days as determined using ELISA.[ 220 ] Similarly, HPLC studies of PEGylated albumin nanoparticles loaded with azidothymidine and decorated with transferrin demonstrated longer retention times in plasma and increased uptake in the brain compared to other organs.[ 221 ] The plasma AUC and MRT of transferrin‐modified nanoparticles were significantly higher in comparison to free azidothymidine drug administered in mice. However, as these methods cannot be used to study polymeric nanoparticles directly, more recent approaches exploit fluorescent probes and radioisotopes to assess nanoparticle biodistribution. Moreover, these modalities can facilitate non‐invasive real‐time imaging.

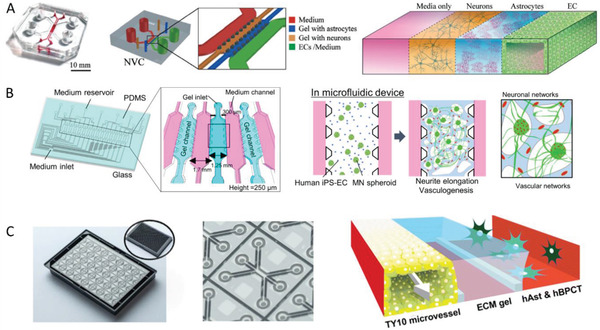

4.1.1. Fluorophore Labeling