Abstract

In spite of the considerable achievements in the field of regenerative medicine in the past several decades, osteochondral defect regeneration remains a challenging issue among diseases in the musculoskeletal system because of the spatial complexity of osteochondral units in composition, structure and functions. In order to repair the hierarchical tissue involving different layers of articular cartilage, cartilage-bone interface and subchondral bone, traditional clinical treatments including palliative and reparative methods have showed certain improvement in pain relief and defect filling. It is the development of tissue engineering that has provided more promising results in regenerating neo-tissues with comparable compositional, structural and functional characteristics to the native osteochondral tissues. Here in this review, some basic knowledge of the osteochondral units including the anatomical structure and composition, the defect classification and clinical treatments will be first introduced. Then we will highlight the recent progress in osteochondral tissue engineering from perspectives of scaffold design, cell encapsulation and signaling factor incorporation including bioreactor application. Clinical products for osteochondral defect repair will be analyzed and summarized later. Moreover, we will discuss the current obstacles and future directions to regenerate the damaged osteochondral tissues.

Keywords: Osteochondral tissue engineering, Cartilage tissue engineering, Gradient scaffold, Bioreactors

Graphical abstract

Highlights

-

•

Building materials are summarized: polymers, bioceramics, metals and ECM-based ones.

-

•

The advancing gradient scaffolds include multiphasic and continuous gradient ones.

-

•

Signaling factors are sorted into biochemical, and physiochemical and physical ones.

-

•

The commercially available products are introduced and categorized into three types.

-

•

Four biggest challenges are proposed followed by some possible future directions.

1. Introduction

Osteoarthritis, a long-term chronic disease, is the most common degenerative musculoskeletal disorder affecting diarthrodial joints worldwide [1]. It can affect an estimated 9.6% of men and 18% of women aged more than 60 years [2] and cause a great physical and psychological burden on individuals as well as a considerable socioeconomic burden on the whole world [3,4]. Growing life expectancy and aging populations are expected to witness a consequent rise in the prevalence of such a chronic disease [5,6]. The clinical manifestations of osteoarthritis include pain, transient morning stiffness and impaired joint movement. Apart from age, osteoarthritis is associated with numerous risk factors such as obesity, occupational injury, and trauma [1]. Although it is now known to be a complex condition affecting the whole joint involving the cartilage, subchondral bone, synovium and ligaments, the early recognized mechanical degradation of articular cartilage and the alternation of subchondral bone play a pivotal role in its pathogenesis [7].

As an avascular and aneural tissue, the degenerated articular cartilage lacks the capability to self-heal after damaged. Without appropriate and timely intervention, the chondral defect may extend deep into the subchondral bone and require a joint replacement at the end stage [5,8]. The defects associated with articular cartilage can be classified into three different types based on the lesion depth, partial thickness chondral defect, full thickness chondral defect and osteochondral defect. To prevent and treat the early osteoarthritis indicated by the loss of articular cartilage, a wide range of clinical treatment methods have been developed and applied including palliative, reparative and regenerative treatments [9]. Palliative treatments intended to relieve the knee pain and improve the functional status are incapable to prevent the progression of further chondral defects [10]. In terms of reparative approaches such as bone marrow stimulating techniques, the chondral defect can be thoroughly filled, but the filled tissue made up of fibrocartilage is deficient in biomechanical and viscoelastic features comparable to the natural hyaline cartilage [11]. The later appeared osteochondral transplantation using autografts or allografts provides appealing opportunities for the treatment of even the most severe osteochondral defects. Nonetheless, autografts are faced with disadvantages like a limited origin of the donor, unmatched mechanical properties, and the morbidity of the donor site. Shortcomings of allografts include difficulties in graft preservation and management, risks of disease transmission, and immunogenicity [12]. Autologous chondrocyte implantation (ACI) is the first explored regenerative treatment which potentiates the production of mechanically and functionally stable hyaline cartilage and it has evolved with several generations to achieve optimization of the surgical process and cartilaginous restoration [13,14]. Whereas, its potential to regenerate osteochondral defect involving both articular cartilage and subchondral bone remains challenging [12].

In early 1990s, the emergence of tissue engineering field broadened new horizons for the improvement of the traditional regenerative treatments [15]. To repair the cartilage defects, cartilage and osteochondral tissue engineering have been proposed with three key components, scaffolds, cells and signaling factors [16,17]. Given that the study of both cartilage and bone has all come a long way over the past decades, we will focus on the recent development in osteochondral defect repair in this review. The regeneration of osteochondral defect which involves cartilage, cartilage-bone interface and subchondral bone is largely based on the knowledge advances of the two separate tissues and more importantly, the understanding of osteochondral interface. In designing the osteochondral scaffold, a variety of materials are available in tissue engineering and regenerative medicine fields, including polymers, inorganic materials, extracellular matrix (ECM)-based materials, and metals. Also, the architectures of the grafts have experienced a tremendous improvement from the simplest monophasic scaffolds to biphasic, triphasic, multiphasic, and most recently, gradient ones to better mimic the complex hierarchy of native osteochondral units. The incorporation of tissue forming cells and/or signaling factors is acknowledged to improve the ECM deposition and restoration efficacy by influencing the interaction between the adjacent native tissue and the artificial scaffold [18,19]. Among the molecular factors, there are biochemical, physiochemical and physical ones, the first of which are represented by growth factors, while the last physical ones are always shown in various bioreactors [20]. Although the options of the cells and signaling factors are relatively limited compared to those of the scaffolds, the importance cannot be ignored. Despite the considerable progress in the osteochondral tissue engineering, only a few have been translated into clinical products.

In this review, we will first present the basic anatomical stratified structure of osteochondral tissues, including articular cartilage, calcified cartilage and subchondral bone. Later, the defect classification and several clinical treatments as well as their corresponding advantages, disadvantages and development will be introduced. Furthermore, recent advances of cartilage and osteochondral tissue engineering will be overviewed from aspects of the three critical components, highlighting the compositions and architectures of the scaffolds. The architectures of the scaffolds are classified into four categories and four separate focuses are included. Summary is also conducted for the bioreactor related physiochemical and physical signaling factors. We then summarize the current clinical products for articular cartilage and osteochondral defect repair by sorting them into three types and finally, the four biggest challenges are proposed and corresponding future development directions in regenerating the damaged osteochondral tissues are envisioned (Fig. 1).

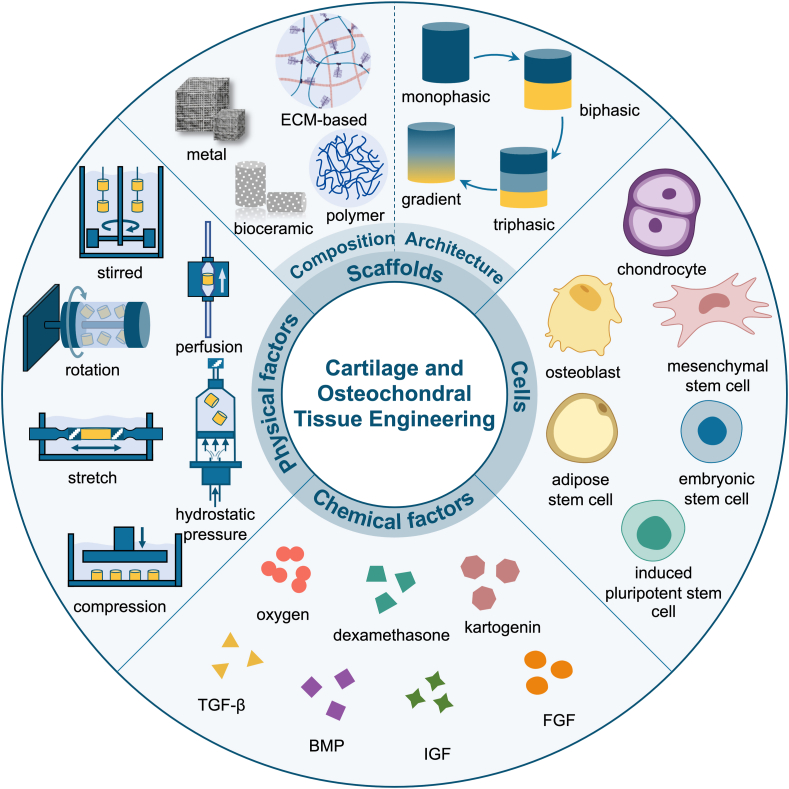

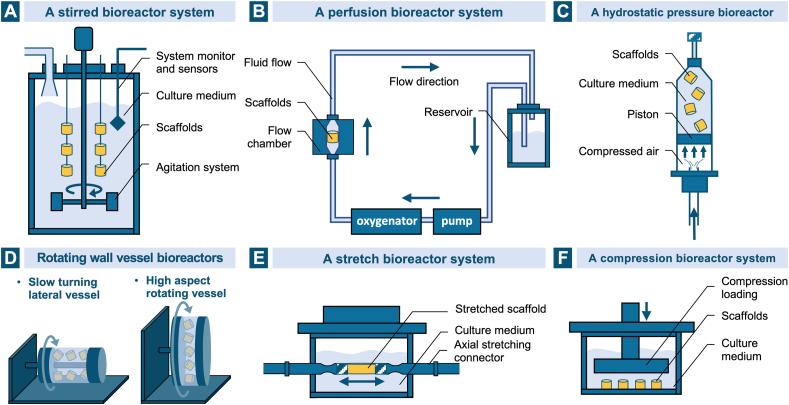

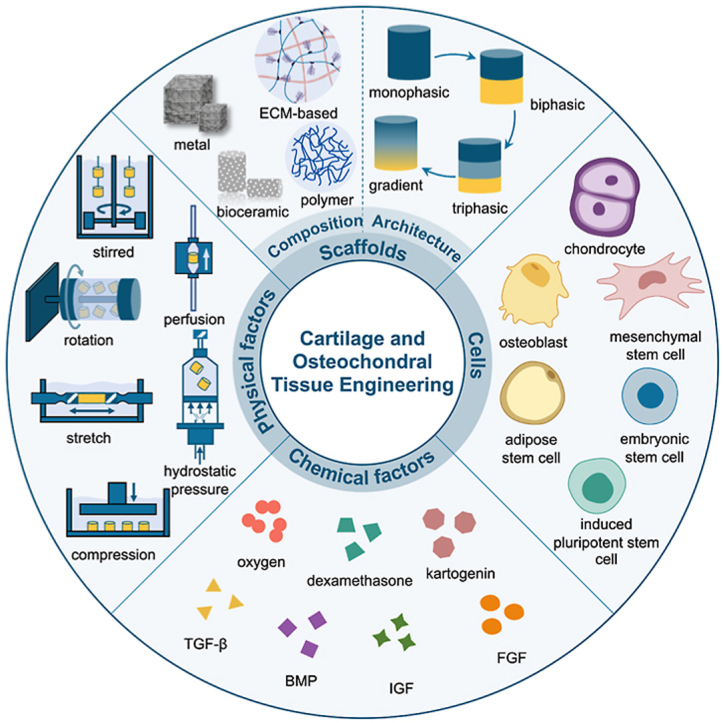

Fig. 1.

The schematic illustration of the key elements in cartilage and osteochondral tissue engineering including scaffold design from perspectives of composition and architecture, cell encapsulation and signaling factors which consist of chemical factors and physical factors (bioreactors).

2. Anatomical structure of the osteochondral unit

2.1. Articular cartilage

As a tough, durable and flexible form of the supporting connective tissue, cartilage plays the supportive and protective roles in the musculoskeletal system. Devoid of any blood and lymphatic vessels and nerves, it consists of a dense extracellular matrix and the embedded chondrocytes, the primary cell type within. According to the composition of the matrix especially the fibers, cartilage can be classified into three main types: hyaline cartilage, elastic cartilage and fibrocartilage, among which the first is the most common one found in the human body with a semitransparent appearance at fresh state and constitutes the articular cartilage [21,22]. Located on the surface of movable joints, articular cartilage is superficially lubricated and serves as the cushion to lower the friction between adjacent bones, transmit the mechanical loads into the deep subchondral bone plate and facilitate the bone movement. As the primary cell type in the articular cartilage, chondrocytes (<10% of total cartilage volume) are responsible for the synthesis, organization and maintenance of all ECM components. The articular cartilage ECM principally consists of water (68–85% of total wet weight, the main fluid phase), collagen (60–86% of dry weight), proteoglycan (15–40% of dry weight) and some other minor noncollagenous proteins and glycoproteins [23]. The water flow through the cartilage can not only transport the nutrients to chondrocytes but also provide lubrication on the articular surface [24]. The most abundant collagen in articular cartilage is type II collagen (90–95%), forming microfibrils, fibrils and later collagen fibers intertwined with proteoglycan aggregates [[25], [26], [27]]. Other collagens including type I, IV, V, VI, IX and XI are also present in minor proportions and can help increase the structural and elastic strength of cartilage along with type II collagen fiber network [24,28]. Proteoglycans are glycosylated protein monomers composed of a protein core and the covalently bonded negative glycosaminoglycans (GAGs) chains. They can then interact with hyaluronan chains via link proteins to form larger proteoglycan aggregates possessing different GAG compositions and functions [29]. The main proteoglycan type in articular cartilage is aggrecan, while the key GAGs are hyaluronic acid, chondroitin sulfate, keratan sulfate and dermatan sulfate. The GAGs with a high density of sulfate anions in the aggrecan can attract cations in water and offer the articular cartilage with osmotic properties [30]. The collagen fiber network and the attached proteoglycan aggregates collaboratively give rise to the compression resistance of the cartilage, as was biomechanically studied and systematically analyzed by Prof. Mow, who is the first bioengineer proposed the biphasic theory (a solid matrix phase and an interstitial fluid phase) of articular cartilage [31,32]. (Fig. 2).

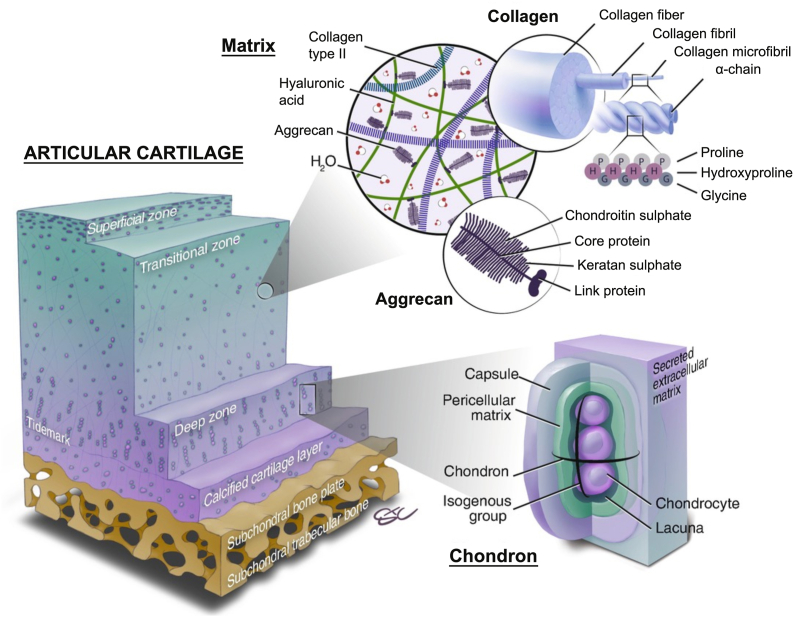

Fig. 2.

The schematic presentation of the extracellular structure of osteochondral unit and its main individual components including the collagen and aggrecan in matrix, and chondron. Reproduced with permission [8]. 2019, Springer eBook.

Despite the same basic constituents throughout the entire articular cartilage, there are obvious regional variations in the structure and composition concentrations of the matrix as well as the morphology of the chondrocytes along the perpendicular direction: the superficial/tangential zone, the middle/transitional zone and the deep/radial zone (Fig. 2). These three zones make up approximately 10–20%, 40–60% and 30–40% of the articular cartilage thickness separately [33]. From the surface to the depth of the articular cartilage, the content of the proteoglycan aggregates undergoes an increasing trend, the content of the water and the chondrocytes decreases while the collagen fibrils' concentration remains nearly constant [34,35]. In the superficial zone, the type II collagen fibrils are tenuous, tightly packed and parallel to the articular surface, and the chondrocytes exhibit a flattened shape in the interstitial of the fibrils. In contact with the synovial fluid, this zone is vital in maintaining the lubrication and tensile properties of the tissue. Immediately beneath the superficial zone is the largest zone, the middle zone, where the collagen fibrils are thicker and randomly oriented, and the cells are rounder. As an anatomic and functional transition between the other two zones, the middle zone is the first line of defense in resisting the compressive forces imposed on the articulating surfaces. In the deep zone, the collagen fibrils are bunched into tough fibers with the largest diameter perpendicular to the cartilage's surface. The interstitial chondrocytes are oriented parallel to the collagen fibers in a columnar direction and may appear in groups of several cells. This radial zone contributes most of the compressive resistance during body movements [24].

2.2. Calcified cartilage

At the bottom of the deep zone in the articular cartilage, there is a thin wavy basophilic border distinguishing the non-calcified zones from the calcified cartilage below, which is known as the tidemark with a complex three-dimensional structure. The collagen fibers across this junction are continuous with those in the non-calcified and calcified zones. From a biomechanical perspective, the undulating shape of the tidemark provides a geometric pattern to resist the articular shearing. This junction in mature cartilage can also protect the relatively flexible fibers from being sheared at their anchoring point on the subchondral bone beneath the calcified cartilage [36,37]. As a result of endochondral ossification, the calcified cartilage combining both the characteristics of cartilage and bone provides an excellent structural integration to transfer and distribute mechanical loadings between the flexible uncalcified cartilage and the rigid subchondral bone during joint motion [38,39]. Chondrocytes in this zone express a hypertrophic phenotype and can produce type X collagen to calcify the ECM [22]. This chondro-osseous interface including the tidemark and the calcified cartilage is permeable to small nutritional solutes of low molecular weight and plays an important role in maintaining the microenvironment of the two distinct tissues [40].

2.3. Subchondral bone

The subchondral bone, the last region of the osteochondral tissue, is separated from the calcified cartilage by the cement line. Anatomically, it consists of the subchondral cortical bone and subchondral cancellous (or trabecular) bone. The former, also called the subchondral bone plate, is a thin lamella lying immediately beneath the calcified cartilage with low porosity and limited blood vessels. The latter containing randomly aligned supporting trabeculae is more porous, highly vascularized and metabolically active [41,42]. Detailed information on subchondral bone's morphology, function, pathology and its relationship with osteochondral diseases has been comprehensively reviewed by Prof. Madry [41]. The bone tissue is mainly composed of the extracellular bone matrix and three major cells including osteoblasts, osteocytes and osteoclasts. The organic contents in the calcified bone matrix are primarily the collagen fibers, 90% of which is type I collagen, and the amorphous interfibrillar matrix, mostly proteoglycans and their composites such as osteonectin, osteopontin, and osteocalcin. For the inorganic components, nearly 50% of the dry weight of the matrix, calcium hydroxyapatite (HAp, Ca10(PO4)6(OH)2) in the form of needle-like crystal is the most abundant, others including biocarbonate, citrate, magnesium, potassium and sodium ions are also present [21]. Associated with the inorganic minerals that are arranged in a complex hierarchical structure, the collagen fibers are responsible for the ultimate hardness and resistance of the bone tissue [43,44]. As a crucial part of the osteochondral junction, the stiffened and less pliable subchondral bone is shock-absorbing with supportive functions of transmitting the mechanical loads and providing the nutrient supply for the overlaying cartilage [45]. Although it has been long recognized that the degradation of articular cartilage is the primary hallmark of osteoarthritis, microstructural and histopathological changes of the subchondral bone are attracting increasing attention in the progression and pathogenesis of these osteochondral diseases like osteoarthritis. Besides, the highly innervated subchondral bone is probably the main contribution of the pain in disease [7,41].

3. Osteochondral defect classification and clinical treatments

Conducting an epidemiological survey in the general population is faced with a great challenge since that part of the patients with cartilage or osteochondral defects won't consult the doctors because of the lack of obvious clinical symptoms. Although difficult to acquire a thorough knowledge about the overall prevalence of the lesions in articular cartilage, it can be estimated that about 60–70% of all the patients submitted to an arthroscopic procedure are diagnosed with chondral or osteochondral lesions [[46], [47], [48]].

3.1. Defect classification

According to the depth of the lesion, articular osteochondral defects can simply be divided into three types: partial thickness chondral defect, full thickness chondral defect and osteochondral defect. For the first partial thickness chondral defect, the damage is confined only to the articular hyaline cartilage zone without affecting the calcified cartilage. The full thickness chondral defect will cause damage to the calcified cartilage layer, while the defect can be then defined as an osteochondral defect when the subchondral bone is totally exposed and the structure of the whole osteochondral tissue is destroyed [49].

To evaluate the severity of the articular cartilage lesions correctly for appropriate clinical treatment and scientific study, several classification systems have been developed, including the most accepted Outerbridge classification score and the evaluation score system recommended by the International Cartilage Regeneration & Joint Preservation Society (ICRS). The location, depth, size, area of the defects as well as the status of the surrounding cartilage are the primary defect parameters in classification [47]. Outerbridge first described a four grades’ classification system in 1961 according to the macroscopic aspects, depth and extension of the cartilage injury. In Grade I, the softening and swelling of the articular cartilage are present. Grade II denotes the fissuring or fragmentation of the cartilage surface in an area up to half an inch in diameter. Lesions with the same fissuring and cracks as Grade II, but an area more than half an inch are classified as Grade III. Finally, the cartilage lesions eroded down to the subchondral bone would be considered as Grade IV [50,51]. Another five grade classification system recommended by ICRS mainly takes the depth and extent of the lesions into consideration [47,52]. Different classification systems can be proposed with the development of newer imaging technologies, as Prof. Kennedy et al. has summarized for the osteochondral lesions of the talus [53].

3.2. Clinical treatment methods

Focusing on the level of the repair for the chondral or osteochondral lesions, clinical treatment methods can be categorized to palliative treatments, reparative treatments and regenerative/restorative treatments. Palliative treatments strive to alleviate the symptoms of the patients like articular pain and usually the replacement of the injured tissue does not happen. Reparative treatments aim at repairing the defect area by stimulating the blood in the subchondral bone to recruit the cells or replacing with some biological materials. However, regenerative methods are the ideal ones that can help restore the defective osteochondral tissue [9]. (Fig. 3).

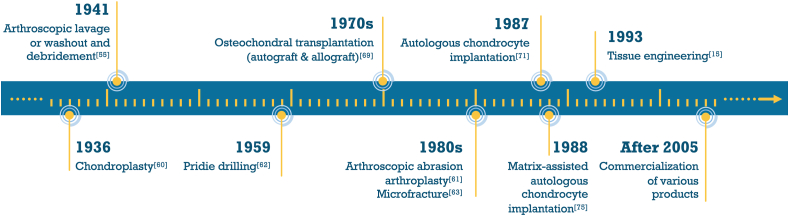

Fig. 3.

Major milestones in articular cartilage and osteochondral defect treatments.

3.2.1. Palliative treatments

Arthroscopic lavage or washout and debridement are the typical palliative treatments for chondral and osteochondral defects to relieve the knee pain and improve the functional status. As the least invasive surgical technique, arthroscopic debridement needs to wash and suck out all the cartilage or bone debris in the damaged area first and then remove the degenerated meniscus, ligament loose bodies, chondral fragments and the redundant synovia [[54], [55], [56]]. Although arthroscopic washout and debridement were considered to provide a short-term symptomatic relief by reducing the inflammatory response and resecting the pathological structures [57,58], the clinical usage of those procedures is in decline over the last decade since that weak support could be found for the benefit of arthroscopic lavage and debridement [54,59]. With the intent to produce a macroscopically smooth edge without damaging the surrounding cartilage by utilizing mechanical tools or radiofrequency energy, chondroplasty is thought to be palliative as well. Side effects include risks of osteonecrosis, damage to the surrounding cartilage and progression of the partial-thickness lesions [10,60].

3.2.2. Reparative treatments

Reparative procedures including arthroscopic abrasion arthroplasty, Pridie drilling and microfracture seek to realize a spontaneous and natural cartilage repair by promoting the hemorrhage from the subchondral bone, blood clot formation and consequent recruitment of bone marrow cells and fibrocartilage filling. The primary difference between the abrasion arthroplasty and subchondral bone drilling is the extent of the bone and vascularity exposure. As an extension of the debridement, the arthroplasty emphasizes the superficial abrasion and exposure of the viable bone and vascularity [61]. Pridie drilling, first introduced by Dr. Pridie K. H. in 1959, is a modification of debridement to create multiple deep holes into the subchondral bone marrow by a quarter-inch drill [62]. Inspired by the self-healing potential after drilling, microfracture was initially developed by Dr. Steadman in 1980s and then quickly gained ubiquitous clinical applications for patients with full-thickness chondral defects [63,64]. In the procedure, multiple perforations, approximately 3–4 mm apart and 2–4 mm in depth, are made on the exposed subchondral bone plate by a specially designed arthroscopic awl after thorough removal of the overlaying calcified cartilage. Despite the popularity of microfracture as the gold standard for knee cartilage repair and the fact that it is advocated by the FDA and many clinicians for the effective short-term functional improvement, less supportive data are found in the long-term treatment when possible deterioration happened [[65], [66], [67]]. Besides, the common shortcoming of these bone marrow stimulating techniques is the lack of the biomechanical and viscoelastic features of the filled fibrocartilage compared to the natural hyaline cartilage [11].

First introduced in 1970s, the osteochondral transplantation, consisting of autograft and allograft transplantation with various origins of the donor grafts, gained widespread attention in 1990s [68,69]. The donor of the autograft is the lesser-weight-bearing on the same joint or another joint of the patient himself/herself, while that of the allograft is from another person [12]. Both types can be further applied as mosaicplasty utilizing more than one cylindrical graft. Disadvantages of the autografts include the limited origin of the donor, the unmatched mechanical properties and the morbidity of the donor site. Allografts also present serious shortcomings like difficulties in graft preservation and management, risks of disease transmission and immunogenicity [12]. Problems in these technically demanding methods have accelerated the development of new procedures to restore the damaged articular cartilage.

3.2.3. Regenerative treatments

As the clinically recognized regenerative treatment method for cartilage defect, autologous chondrocyte implantation has evolved with several generations. The earliest animal trials for the homotransplantations of isolated chondrocytes in the orthopedic use can date back to 1960s [70]. More than 30 years ago in Sweden, Dr. Peterson and Dr. Brittberg introduced the first cell-based biological approach for full-thickness chondral defect treatment and opened a new era in cartilage repair [14,71]. In this procedure, healthy autologous chondrocytes from the cartilage biopsy samples are isolated from the injured knee during arthroscopy and then cultured in the laboratory, followed by injection into the lesion under a periosteal cover. The long-term results 10–20 years after the surgery of ACI have shown positive outcomes that the mechanically and functionally stable hyaline-like cartilage can be produced and shows integration into the adjacent cartilage and subchondral bone [13,14].

Complications associated with the first-generation ACI like periosteal hypertrophy, complexity of the operation, large-area joint exposure and long recovery time prompted the emergence of the second-generation ACI, when the periosteal patch was substituted by the synthetic collagen membrane to cover the treated defect [72,73]. However, the maintenance of the chondrocyte phenotype in the two-dimensional culture is still critical since that the chondrocyte may dedifferentiate into fibroblasts without the capacity for hyaline cartilage regeneration [74]. For the third-generation ACI, a matrix made of porcine type I/III collagen is used for the in vitro growth of the isolated autologous chondrocytes before the cell seeded matrix is transplanted into the lesion. The so-called matrix-assisted autologous chondrocyte transplantation (MACI) allows for not only the reduced operating time and surgical exposure, but also the enhanced proliferation, phenotype and the even distribution of the chondrocytes [74,75]. Nevertheless, a secondary operation is always necessary for ACI and the high expense warrants further investigation [17]. Moreover, the regenerative efficacy for osteochondral defect where the damage of the subchondral bone is involved is still challenging [12].

Later in the early 1990s, ACI are further improved with the emergence of tissue engineering. Combining the principles of engineering and biology for the functional regeneration, maintenance and improvement of the damaged tissue, tissue engineering consists of three principal components: scaffolds, cells and signaling factors [15]. In 2011, Brian J. Cole et al. reported the first clinical experience treating focal chondral defects in using cartilage autograft implantation system (CAIS), which combined an absorbable scaffold with autologous cartilage fragments based on ACI, and demonstrated its safety, feasibility, and possible effectivity in improving the long-term clinical outcomes [76]. The past few decades have witnessed the booming development in the study of both bone and cartilage tissue engineering [17,77]. In the following parts, a comprehensive summary of the tissue engineering advances in articular cartilage and osteochondral defects will be discussed from different aspects of the three components.

4. Strategies of the scaffolds for cartilage and osteochondral tissue engineering

As a temporary three-dimensional construct to fill the osteochondral defect, the scaffold can structurally and functionally imitate the native osteochondral tissue and provide an appropriate microenvironment for the restoration of the complex tissue. Generally, several requirements from different perspectives need to be considered in designing and fabricating the osteochondral scaffold: (1) Compositionally, the scaffold should be biocompatible with no or little immune rejection and stable physicochemical properties when implanted into the body, and at the same time, be biodegradable with harmless degradation products and a comparable degradation rate to the growth rate of the osteochondral tissue. (2) In regard to the structure, a stratified orientation, a continuous gradient interface as well as a porous structure with an appropriate pore size and porosity are required for the transit of nutrients and wastes, providing an optimal reticular skeleton to maintain a suitable environment for the cell attachment, proliferation and in-growth, and eventual establishment of the damaged tissue. (3) From a functional viewpoint, the ability to maintain the morphology and phenotype of chondrocytes, the biomechanical properties (such as tensile strength, compressive strength and superficial lubrication) to withstand the local stresses and forces, and the integration with the surrounding cartilage and bone should all be taken into consideration. (4) In terms of the preparation, the manufacturing techniques, which are convenient and versatile enough to support the individualized design of the scaffold with a patient-customized geometry, would render the widest acceptance [[78], [79], [80], [81], [82]].

The scaffold is the key factor in osteochondral tissue engineering and at the same time the paramount research focus for material scientists. Since the application of tissue engineering in osteochondral repair, the scaffolds have experienced deeper and more comprehensive research in aspects like compositions, structures, functions and preparation methods. In this review, we will mainly summarize the recent advances of the scaffolds from their compositions and structures.

4.1. Choices for the fundamental material composition

Types of scaffolds’ compositions applied in osteochondral tissue engineering include polymers, inorganic materials, ECM-based materials, metals and the composites of several kinds of the aforementioned materials, among which polymers are the most widely studied ones for biomedical applications because of the largest diversity and unique characteristic similarity to the natural ECMs [83].

4.1.1. Polymers

Polymers, usually presented in the form of hydrogels composed of ECM-mimicking networks, can be further divided into natural polymers, synthetic ones and their corresponding derivatives. The chemical structures, origins, advantages and limitations for cartilage and osteochondral tissue engineering of the commonly used polymers are summarized in Table 1.

Table 1.

Overview of some commonly used natural and synthetic polymers for cartilage and osteochondral tissue engineering.

| Polymer Type | Polymer Name | Chemical Structure | Existence in Osteochondral Tissue and/or Origin | Advantages | Limitations | References |

|---|---|---|---|---|---|---|

| Natural polymers: Polysaccharide | Hyaluronic acid (HA) |  |

Yes. The most abundant GAG in native cartilage | ECM component (vital in the structural and functional maintenance of cartilage: the morphogenesis and proliferation of chondrocytes, formation of proteoglycans and collagen II, water adsorption and retention, lubrication and compression bearing, immune system modulation), easy to be functionalized | Poor mechanical properties, rapid degradation, week cell adhesion | [[84], [85], [86], [87]] |

| Chondroitin sulfate |

|

Yes. A sulfated GAG ubiquitous in native cartilage ECM | ECM component (beneficial in reducing pain and functional limitation associated with knee osteoarthritis, anti-inflammatory activity, role in cell recognition and signaling), easy to be functionalized | Poor mechanical properties, rapid degradation | [[88], [89], [90], [91], [92]] | |

| Alginate |  |

No. A natural unbranched negative polysaccharide obtained from brown algae and bacterial sources |

High functionality, fast cross-linking, low cost, injectable for bioprinting, structural similarity to GAGs | Poor mechanical strength, low cell-matrix interaction, varying levels of purity due to source variability, immunogenicity | [83,[93], [94], [95], [96], [97]] | |

| Agarose |  |

No. A natural neutral polysaccharide found in red algae |

High functionality, thermoreversible gelation, low cost, structural similarity to GAGs | Limited mechanical performance, low bioactivity, poor cell attachment | [[98], [99], [100], [101]] | |

| Chitosan |  |

No. A chemically partial deacetylated derivative of chitin, mainly exploited from two marine crustaceans, shrimps and crabs |

Intrinsic antibacterial ability, pH and temperature responsiveness, cationic characteristic for the electrostatic interactions with the anionic GAGs in ECM, low cost, structural similarity to GAGs | Poor water solubility in physiological conditions, potential allergenic risks, inferior mechanical properties, low cell-matrix interaction | [[102], [103], [104], [105], [106]] | |

| Gellan gum | No. A linear negatively charged polysaccharide produced by the Sphingononas group bacteria |

pH and temperature responsiveness, structural similarity to GAGs | Weak mechanical strength, poor stability, low bioactivity, relatively high gelation temperature, small temperature window | [[107], [108], [109], [110]] | ||

| Natural polymers: Protein based materials | Collagen |

type II collagen type II collagen |

Yes. The most prevalent protein component constituting the ECM | ECM components, good cell-matrix interaction | Potential of immunogenicity, relatively low mechanical strength, high cost, religious issues, limited sterilizability | [25,[111], [112], [113]] |

| Gelatin |  |

Yes. A derivative of collagen by partial hydrolysis with much lower antigenicity | Biologically active for cellular interaction, low immunogenicity in comparison to collagen, ease of processing and functionalization | Poor mechanical properties, rapid degradation, low thermal stability | [98,[114], [115], [116]] | |

| Silk fibroin |  |

No. The major protein component of natural silk |

High mechanical strength, low immunogenicity, structural similarity to collagen, morphologic flexibility, good sterilizability | Source variability, low biodegradability of the β-sheet crystals | [[117], [118], [119], [120]] | |

| Synthetic polymers |

Poly(ethylene glycol) (PEG) Poly(ethylene oxide) (PEO) |

|

No | Good biocompatibility, versatility in processing and functionalization, mechanical adjustability, low immunogenicity | Biologically inert for cellular interaction, non-biodegradability | [[121], [122], [123], [124]] |

|

Polylactic acid (PLA) Polyglycolic acid (PGA) Poly(lactic acid-co-glycolic acid) (PLGA) |

|

No | Good biocompatibility and biodegradability, ease of functionalization, low immunogenicity | Low bioactivity, acidic degradation products eliciting inflammatory response | [[125], [126], [127], [128]] | |

| Polycaprolactone (PCL) |  |

No | Relatively low melting temperature for 3D printing, long-term mechanical stability, ease to manufacture | Poor bioactivity, hydrophobicity | [[129], [130], [131], [132]] | |

| Poly(vinyl alcohol) (PVA) |  |

No | Good water adsorption and retention ability, chemical resistance, good mechanical properties, ease of aqueous processing | Biologically inert, non-degradability | [[133], [134], [135], [136]] | |

| Poly(l-glutamic acid) |  |

No. But its degradation product, l-glutamic acid, is the most abundant amino acid in articular cartilage |

No antigenicity or immunogenicity, good biological and physio-chemical properties, hydrophilicity. | Non-injectability | [[137], [138], [139], [140]] | |

| Poly(propylene fumarate (PPF) |  |

No | High mechanical strength, good degradability, biocompatible degradation products, injectability, thermal and photochemical crosslinkability | Deficient bioactivity | [[141], [142], [143], [144]] | |

| Poly(N-isopropyl acrylamide) (PNIPAAm) |  |

No | Thermoresponsiveness over a wide range of ionic strengths and pH, ease of modification | Poor cell affinity | [[145], [146], [147], [148]] |

Natural polymers including polysaccharide (typically hyaluronic acid (HA), chondroitin sulfate, alginate, agarose, chitosan and gellan gum) and protein-based materials (commonly collagen, gelatin and silk fibroin) have acquired widespread explorations due to the structural similarity to native GAGs and the consequent biocompatibility, biodegradability and little inflammatory response. Nevertheless, problems like the difficulty in purification, poor mechanical properties, uncontrollable degradation time and batch-dependent performances remain to be resolved. As the most abundant GAG in native cartilage, HA plays a pivotal role in the structural and functional maintenance of cartilage. To overcome its disadvantages for cartilage and osteochondral regeneration like inadequate mechanical properties and degradability, much effort has been taken through the incorporation of additional polymer networks [149] or by chemical modifications at the hydroxyl and carboxyl functional groups using methacrylate [86], thiol [150], enzyme [151] and amino acid [152]. Chondroitin sulfate is similar with hyaluronan in fundamental structural and biological processes. It has been reported to be beneficial in reducing pain and functional limitation associated with knee osteoarthritis [89] and improving the mechanical and signaling properties in composite materials for cartilage engineering [88,153,154]. Alginate, agarose, chitosan and gellan gum are all natural polysaccharides with similar structures to GAGs and thus have been widely explored in cartilage and osteochondral tissue engineering. Their inferior mechanical strength and low bioactivity are always addressed by combining with other polymers and encapsulating some bioactive molecules [93,100,104,108]. Collagen, as the main protein component constituting the ECM, and its derivative gelatin, are biologically active but are faced with the same drawback of poor mechanical properties. Another popular protein based natural polymer for cartilage and osteochondral restoration that is worth mentioning is silk fibroin. Apart from the structural similarity to collagen, it can be processed into reinforcing fibers and then incorporated into hydrogels to improve the mechanical strength [120,155].

Scaffolds based on synthetic polymers such as poly(ethylene glycol) (PEG) [121], polylactic acid (PLA) [128], polyglycolic acid (PGA) [126], poly(lactic acid-co-glycolic acid) (PLGA) [126], polycaprolactone (PCL) [130], poly(vinyl alcohol) (PVA), poly(l-glutamic acid) [139], poly(propylene fumarate) (PPF) [141] and poly(N-isopropyl acrylamide) (PNIPAAm) [145] have also been extensively reported in osteochondral tissue engineering for their better controllability and reproducibility over the molecular weight, degradation rate as well as industrial scale production. However, the synthetic polymers are faced with challenges like limited bioactivity and complicated structural design and preparation processes. Based on star-shaped PLA, nanofibrous hollow microspheres were fabricated by the group of Prof. Peter Ma as the injectable chondrocyte carriers for knee cartilage repair. The microspheres were designed to mimic the structure of collagen fibers in ECM for cell-material interactions and showed channels/pores at multiple scales with a high porosity for cell migration, proliferation and tissue regeneration [156]. Zhao et al. fabricated an ultra-tough PVA-based hydrogel under physiological conditions through a self-reinforcing mechanism, which exhibited effective cartilage regeneration inducement results through the in vivo evaluation on a rabbit model [136]. PPF-based materials with appropriate mechanical strength, degradation rate and bioactivity are capable of promoting the cell proliferation and differentiation, the mineralization for bone healing and remodeling [143]. Moreover, composites of two or more natural and synthetic polymers have gained an increasing interest in cartilage and osteochondral regeneration because of the advantages of the different polymers can be combined in the composites to achieve comprehensive superiorities that no single biopolymer is comparable to. Gao et al. introduced a hydrogen bond-strengthened supramolecular polymer into the methacrylated gelatin hydrogel and realized a significant improvement in the mechanical properties of the hydrogel. This biohybrid hydrogel scaffold showed positive results in concurrent regeneration of cartilage and subchondral bone in a rat model [114].

4.1.2. Bioceramics

The above-mentioned polymers are mostly designed to mimic the natural hyaline cartilage tissue environment to facilitate cartilage tissue regeneration. Nevertheless, in an attempt to optimize the full chondro-osseous tissue restoration in osteochondral defects where the lesion of subchondral bone is involved as well, the successful engineering of the underlying bone is another key that cannot be neglected. As the most ubiquitous and widely acknowledged type of materials for the replacement and reconstruction of damaged bone tissues, bioceramics have been extensively reported to be incorporated with natural or synthetic polymers and serve as the components in promoting subchondral bone regeneration for their biocompatibility, bioactivity and mechanical strength. They include both crystalline and amorphous inorganic biomaterials from a general perspective such as hydroxyapatite (Ca5(PO4)3(OH)), tricalcium phosphate (TCP, Ca3(PO4)2), calcium silicate and amorphous bioactive glass (BG) [[157], [158], [159]]. Studies on the bioceramics with the simultaneous promotion for restoring cartilage and subchondral bone are rare but still available [160,161].

HAp, the major component of the natural bone tissue, is particularly attractive and beneficial as an additive material for engineering of bone and bone-related tissues including the articular osteochondral unit for its intrinsic bioactivity [108,129,[162], [163], [164]]. Zhou et al. generated a stratified graft composed of collagen upper layer and collagen/HAp lower layer. The different promotion superiority on mesenchymal stem cells (MSCs) of the two layers was demonstrated that the lower collagen/HAp layer was more efficient in promoting the osteogenic induction than either the collagen layer or pure HAp [165].

TCP is another common member of calcium phosphate, among which β-TCP is the most popular in bone tissue engineering because of its lower formation temperature and better structural, mechanical and biological performances [158]. With the similar chemical composition, structure and bioactivity to the natural bone mineral component, TCP is also popular as the osseous compartment in the osteochondral scaffold [[166], [167], [168], [169], [170]]. Deng et al. incorporated the manganese (Mn) into β-TCP for regenerating osteochondral defects, and found that the Mn-doped TCP scaffolds promoted not only the proliferation and differentiation of the embedded chondrocytes and MSCs, but also the regeneration of both cartilage and subchondral bone tissues from in vivo results [171].

Calcium silicate is a simple silicate bioceramic with osteogenic and angiogenic abilities and the released silicon ions were recognized to play a vital role [172,173]. Most other silicate ceramics which have been explored in bone and osteochondral tissue engineering are complex in chemical compositions containing various ions besides Ca2+ and Si4+ [174,175], for instance, Li+ [160], Sr2+ [161,176,177], Mg2+ [[178], [179], [180]]. Chen et al. 3D printed an osteochondral scaffold using pure-phase lithium calcium silicate bioceramic. In addition to the good mechanical strength and biodegradability, dual bioactivities for the regeneration of both cartilage and subchondral bone simultaneously in rabbit osteochondral defects were demonstrated [160].

BG has experienced an expanded development in the compositions, hierarchical structures, synthesis and performance for orthopedic applications since the first discovery by Hench in 1971, and the well-known 45S5 Bioglass® is composed of SiO2, CaO, Na2O and P2O5 [[181], [182], [183]]. Able to bound rapidly with the living bone and stimulate the osteoprogenitor cells at a genetic level, BG is attracting growing interest in regenerating bone and subchondral bone tissues [[184], [185], [186], [187]]. Zhu et al. reported a continuous stratified sodium alginate construct in which the BG was blended as the subchondral bone layer. The osteoblast differentiation of bone marrow mesenchymal stem cells (BMSCs) in this layer was proved from the upregulated gene expression results of the alkaline phosphatase and collagen I [187].

4.1.3. Metals

Metals and their alloys are another suitable candidate as bone implants with a long application history, the mostly used ones of which include titanium, titanium alloy, tantalum and cobalt based alloys on account of their good mechanical strength and biocompatibility [[188], [189], [190], [191]]. Porosity is often introduced, not only for a better ingrowth of the bone tissue, but also to alleviate the bone resorption and even implant failure caused by the stress shielding as a result of the much larger stiffness than native bones [192]. Bearing the recognition that the mechanical support from the subchondral bone plays an essential part in articular cartilage protection [193], researchers have investigated the effects of employing the metallic materials as the bony phase on osteochondral regeneration [[194], [195], [196], [197], [198]]. Bal et al. compared the in vivo chondral defect repairing outcomes of porous tantalum, bioglass and allograft bone cylinders and found that the tantalum was superior to the allograft in host bone integration, hyaline-like tissue regeneration and type II collagen expression [194]. Whereas, the lack of biodegradability of metals has been one of the main obstacles on their way to a wider acceptance and application [195]. Besides, metals can hardly mimic the articular cartilage tissue in osteochondral units.

4.1.4. ECM-based materials

Despite the tremendous progress that has been achieved to fabricate tissue engineering scaffolds with biomaterials simulating the native osteochondral tissue in the field of materials science, these materials can hardly mimic the tissue's microenvironment in full. Extracellular matrix, the natural template for the biomaterials with a complex 3D environment, offers another possibility [199,200]. Composed of various collagens, proteoglycans and the incorporated multiple biochemical and biophysical signal factors, ECM not only serves as a physical framework to support the structural integrity of the organism, but also delineates specific microenvironment for the survival, organization and differentiation of the resident cells [201]. Given the complexity and difficulty in totally mimicking the highly sophisticated native ECM with comparable composition and architecture, decellularization of whole tissues or organs by removing all cells and genetic material while maintaining the physical and biochemical characteristics has emerged as a possible alternative method for cartilage and osteochondral repair [[201], [202], [203]]. The resulting decellularized extracellular matrix (dECM) can be further processed to serve as a whole scaffold [[204], [205], [206], [207], [208]], a solubilized hydrogel component [123,[209], [210], [211]], a bioink for additive manufacturing [[212], [213], [214], [215], [216]] or pulverized particles for composite scaffold fabrication [205,[217], [218], [219]]. Lin et al. produced a biphasic decellularized osteochondral ECM scaffold by combining physical freezing-thawing methods and chemical treatments. The rabbit model results after 12 weeks surgery demonstrated that the scaffold with low immunogenicity and high bioactivity promoted the osteochondral regeneration dependent on the stratified constituents [208]. Limited standards and guidelines for the decellularization procedures and poor reproducibility are the primary challenging problems that remain to be solved in the future.

4.2. Architectures of the scaffolds

To successfully construct an ideal scaffold for the regeneration of cartilage or osteochondral defects, the architecture is another crucial factor in addition to the materials’ composition. The past decades have witnessed the development of osteochondral scaffolds in tissue engineering from the simplest monophasic scaffolds to biphasic, triphasic and multiphasic ones. In recent years, gradient scaffolds have attracted increasing attention in order to achieve a more sophisticated mimicry of the natural heterogeneity found in native osteochondral tissue.

4.2.1. Monophasic scaffolds

Containing a uniform material composition and structure, single phased scaffold is one of the first explored strategies for its simplicity in processing [78]. Although consistent throughout the whole scaffold, different component combinations of varying natural and synthetic materials mentioned in the sections before [179,220,221] as well as the structural designs including macroscopic shapes (hydrogels, fibers et al.), pore size and pore topology [[222], [223], [224], [225], [226]] can induce distinct efficacy for tissue restoration. Chen et al. designed two kinds of monophasic collagen scaffolds with radial and random orientation separately and measured the effects on in vitro MSCs migration and in vivo osteochondral defect regeneration. The radially oriented scaffolds with aligned channels horizontally and vertically performed better in both cell migration promotion and osteochondral defect healing results [222]. (Fig. 4A).

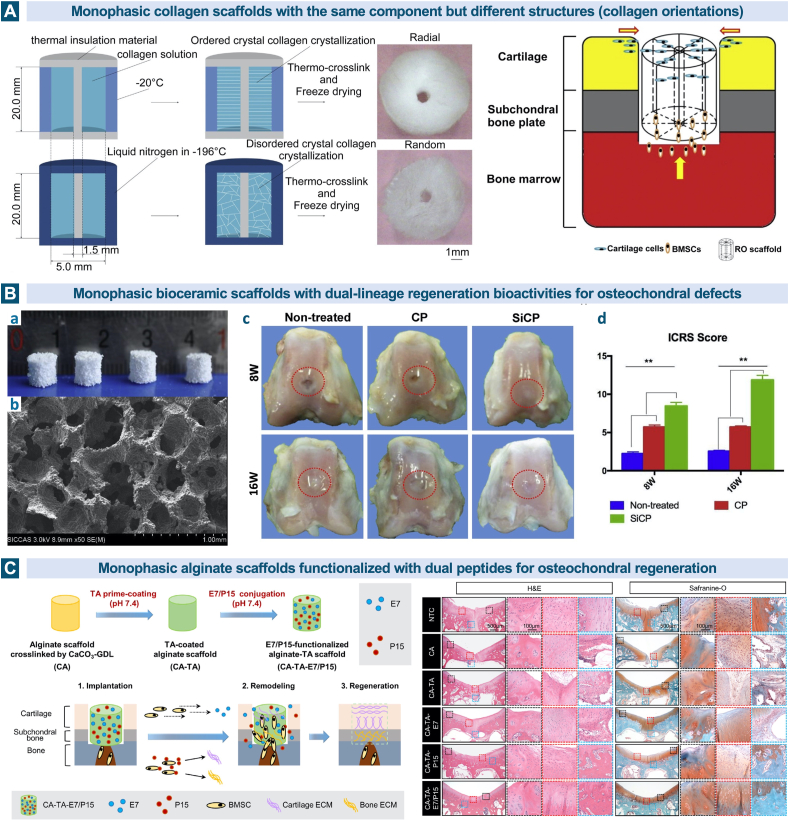

Fig. 4.

Monophasic scaffolds in osteochondral tissue engineering. A. The radially oriented monophasic collagen scaffolds with aligned channels horizontally and vertically can promote the cell migration and osteochondral defect healing. Reproduced with permission [222]. 2015, Elsevier. B. The silicon-based bioceramic monophasic scaffold has dual-lineage regeneration bioactivities for osteochondral defects. (a) Optical images of the SiCP scaffolds, (b) Scanning electron microscope (SEM) image of the SiCP scaffold, (c) gross images of the osteochondral defects in the three groups at 8 and 16 weeks post-operation, (d) ICRS scores for the three different groups. Reproduced with permission [174]. 2019, Elsevier. C. The dual E7/P15 peptide-functionalized monophasic scaffolds mediated by tannic acid (TA) enhanced the recruitment of BMSCs and promote simultaneously the regeneration of cartilage and subchondral bone. Reproduced with permission [228]. 2020, Elsevier.

In spite of the universally accepted recognition about the poor structural similarity between monophasic scaffolds and the native stratified osteochondral tissues, several recent studies have reported appealing findings about the concurrent regeneration of cartilage and subchondral bone in the rabbit model using these seemingly simple scaffolds [160,161,171,174,177,184,227,228]. The released ions of Mn2+, Sr2+, Si4+, Li+, Cu2+ from the bioceramics were demonstrated to play an important role in the related inflammatory and regeneration process [160,161,171,174,177,184]. Bunpetch et al. fabricated a silicon-based bioceramic (silicon-calcium-phosphate, SiCP) monophasic scaffold with dual-lineage regeneration bioactivities for osteochondral defects. To investigate the efficacy and underlying mechanisms, micro-CT, qPCR, western blot and pathway analysis of RNA-sequencing were conducted, and the significant role of Si ions was ultimately validated [174]. (Fig. 4B) Zhang et al. prepared the dual peptide-functionalized monophasic scaffolds mediated by tannic acid and also presented the satisfactory biological performance in MSCs recruitment and simultaneous regeneration of cartilage and subchondral bone [228]. (Fig. 4C) Although the study of monophasic scaffolds can provide useful information about the effect of a specific composition or structure on tissue reconstruction, the majority of these attempts are far from the requirements to regenerate osteochondral lesions efficaciously.

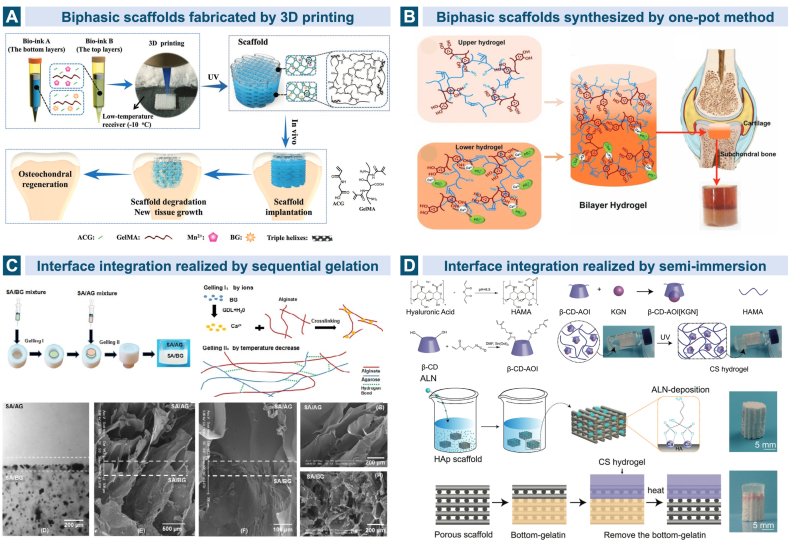

4.2.2. Biphasic scaffolds

The natural coexistence of the articular cartilage and subchondral bone as the two major lineages in the osteochondral unit accounts for the widely acknowledged bioinspired strategy of biphasic scaffolds with two different regions resembling the stratified anatomical architecture. Numerous biphasic scaffolds have progressed into the preclinical animal studies and a few are even commercially available for clinical utilization now [49]. Getgood et al. compared the in vivo morphological, histological and mechanical performance of a collagen-GAG-calcium phosphate biphasic scaffold (now commercially available as ChondroMimetic®) and a PLGA/PGA/calcium sulfate bilayered scaffold (commercially known as TruFit™). The early stage data after 26 weeks implantation in the osteochondral defects in goats revealed that the former scaffold based on collagen-GAG showed a better environment for tissue regeneration [229]. Generally speaking, the upper cartilaginous layer prefers hydrogels based on natural or synthetic polymers due to their hydrated nature and viscoelastic similarity to the native ECM, while the lower calcified subchondral layer favors more strengthened materials such as bioceramics, metals and harder polymers. A complex mixture of several kinds of biomaterials along with varying resident cells and biological molecules is common in designing both layers [165,170,187,[230], [231], [232], [233], [234]]. Cell-free scaffolds which can promote the chondrogenic and osteogenic differentiation of BMSCs and ECM deposition are popular as well [108,114,166,[235], [236], [237], [238], [239]]. (Fig. 5A and B).

Fig. 5.

Biphasic scaffolds for osteochondral tissue regeneration. A. The bilayered cell-free gelatin scaffold was reinforced by high-strength supramolecular polymer and the top and bottom layers were separately loaded with Mn2+ and bioglass [114]. B. Gelatin methacryloyl was mixed with polydopamine (PDA) in the upper layer, while in the lower layer the HAp was mineralized in situ for subchondral bone repair. Reproduced with permission [236]. 2019, Wiley. C. The stratified biphasic scaffold based on sodium alginate (SA), agarose (AG) and bioglass (BG) formed a continuous interface integration by utilizing the common SA network. Reproduced with persmission [187]. 2018, Elsevier. D. Two stem cell differentiation inducers, kartogenin and alendronate, were incorporated separately into the hyaluronic acid-based cartilage layer and the HAp-based bone layer in order to promote the differentiation of MSCs into chondrocytes and osteoblasts. The two layers were bound by semi-immersion. Reproduced with permission [234]. 2020, Wiley. Triphasic and multiphasic scaffolds involving the calcified cartilage simulation.

Interface integration between the chondral and bony layers in the engineered osteochondral unit is of importance in designing the bilayered but monolithic scaffold. Poor integration may lead to the delamination and final failure in tissue regeneration [169,240]. Zhu et al. used the sodium alginate (SA)/agarose composite hydrogel containing BMSCs and articular chondrocytes as the layer for cartilage reconstruction while fabricated SA/bioglass hydrogel with only BMSCs for subchondral bone regeneration. The continuous SA phase provided a stable integration in the stratified structure through crosslinking. Hyaline cartilage and subchondral bone were observed to be stimulated simultaneously after the injection of the stratified scaffold into the rat model [187]. (Fig. 5C) Liu et al. incorporated two stem cell differentiation inducers, kartogenin and alendronate, separately into the HA-based cartilage layer and the HAp-based bone layer which were bound by semi-immersion. The MSCs in the biomimetic biphasic scaffold can differentiate into both chondrocytes and osteoblasts, promoted by the layer-specific release of the two drugs [234]. (Fig. 5D) However, the calcified cartilage, the natural chondral-osseous interface which is a primary determinant in maintaining the microenvironment of the two distinct tissues is ignored in biphasic scaffolds.

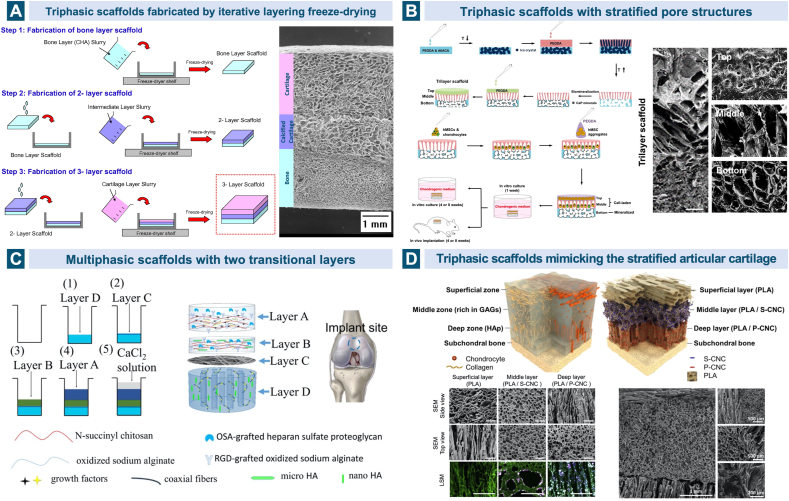

4.2.3. Triphasic and multiphasic scaffolds involving the calcified cartilage simulation

Taking the significance of the calcified interface in native osteochondral tissue into account, researchers have made considerable advances in fabricating scaffolds with a closer resemblance to the osteochondral physiological structure. Over ten years ago, Tampieri et al. developed a biomimetic mineralization process of nucleation of HAp nanocrystals onto the collagen fibers during their self-assembling and then generated a trilayerd scaffold based on HA, type I collagen and HAp. Apart from the upper cartilaginous layer made of hyaluronan-charged collagen and the lower subchondral bone layer composed of the biomineralized collagen (70 wt% HAp), an intermediate region with the same biomineralized collagen but a lower percentage of mineral (40 wt% HAp) was incorporated to resemble the calcified zone [241]. The nano-composite triphasic scaffold was later demonstrated to exhibit good mechanical and biological behavior in treating the chondral and osteochondral lesions in horse and sheep models as well as clinical trials, which is now commercially available as MaioRegen® for clinical applications [[242], [243], [244], [245], [246]]. Levingstone et al. fabricated a triphasic scaffold through a “iterative layering” freeze-drying technique using similar basic materials of HA, type I collagen and HAp, but type II collagen was added in addition in the intermediate and upper layers, imitating the native cartilaginous components. Macroscopic, micro-computed tomographic and histological observations showed that the scaffold was able to restore the osteochondral defects in a relatively long term, 6- and 12-months post implantation in caprine joints [112,247,248]. (Fig. 6A).

Fig. 6.

Triphasic/multiphasic scaffolds in cartilage and osteochondral tissue engineering. A. A triphasic scaffold was fabricated through a “iterative layering” freeze-drying technique using similar basic materials of hyaluronic acid, type I collagen and HAp, but type II collagen was added in addition in the intermediate and upper layers to imitate the native cartilaginous components. Reproduced with permission [247]. 2014, Elsevier. B. The single-unit scaffold based on PEGDA consists three layers with depth-varying pore architecture, mineral and cell environment: the hydrogel top layer, the cryogel middle layer with anisotropic pore structure and the biomineralized bottom layer. Reproduced with permission [250]. 2018, Elsevier. C. Based on composite materials of SA, chitosan and HAp with different micro and nano sizes, an intermediate calcified cartilage layer as well as a subjacent electrospun fibre membrane for cell migration prevention was designed in the four-layered scaffold to repair osteochondral defects. Reproduced with permission [162]. 2018, Elsevier. D. Multiphasic scaffold fabrication strategy was applied in mimicking the complex stratified architecture of articular cartilage structurally, chemically and mechanically. Reproduced with permission [253]. 2015, Elsevier. Multiphasic gradient and continuous gradient scaffolds.

The impact of the intermediate layer in the osteochondral scaffold on tissue regeneration has been studied by Da et al. both in vitro and in vivo. Compared with the biphasic scaffold without the compact intermediate layer fabricated from PLGA and β-TCP, the compact layer-containing scaffold exhibited significantly higher anti-tensile and anti-shear properties as well as better in vivo regeneration results including macroscopic scores, the content of GAG and collagen and the histological properties of the neo-tissue [249]. The compact layer mimicking the calcified cartilage functioned as not only a connector to withstand the stresses within the joint and enhance the integration between the other two zones, but also an insulator to inhibit the adverse infiltration and provide the optimal independent microenvironment [249]. The bone-cartilage interface has developed to be one of the major research projects in designing a biomimetic scaffold for osteochondral tissue engineering, and the adopted materials are always a combination of those used in chondral layer and bone layer with a specific proportion. Stratifications in the content of minerals, and porosity and pore size are common approaches [129,162,[250], [251], [252]]. (Fig. 6B) Chen et al. fabricated a single integrated scaffold with a multi-layered functional structure, concentrating on the transitional zone between the uncalcified cartilage and the subchondral bone. Based on composite materials of SA, chitosan and HAp with different micro and nano sizes, the four-layered scaffold contained an intermediate layer simulating the calcified cartilage as well as a subjacent electrospun fiber membrane to prevent the cell migration and vascular invasion [162]. (Fig. 6C).

Given the fact that the articular hyaline cartilage consists of three distinct zones (the superficial, the middle and the deep zones) with varying structures and compositions, the strategy of triphasic scaffold has also been employed in cartilage tissue engineering [[253], [254], [255]]. Camarero-Espinosa et al. designed a trilayered scaffold that can mimic the mature articular cartilage structurally, chemically and mechanically. PLA was selected as the same basic biopolymer for all three layers but in various pore orientations, while the middle and deep layers were incorporated with sulfated and phosphated cellulose nanocrystals (CNCs) respectively on account of their mechanical reinforcement and cell growth promotion capabilities. The sulfated CNCs in the isotropic porous middle layer were thought to be well representing the native sulfated GAGs and the phosphate modification groups were chosen to promote the localized formation of HAp [253]. (Fig. 6D).

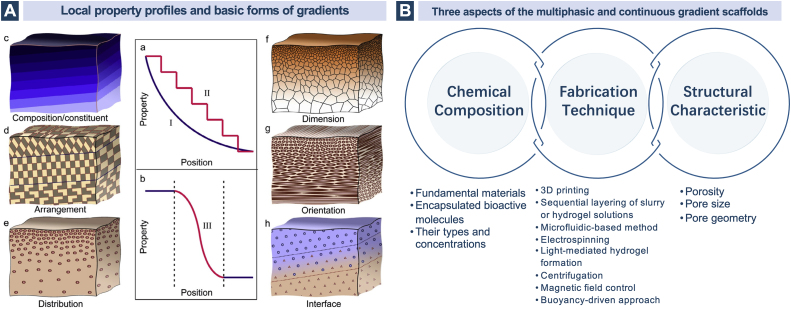

4.2.4. Multiphasic gradient and continuous gradient scaffolds

The native osteochondral tissue possesses a much more complicated gradient heterogeneity instead of a straightforward stratification of three separate regions. To imitate this natural paradigm and translate such design motif into bioinspired applications in osteochondral tissue engineering, multiphasic discrete gradient (more than three layers in this section) and continuous gradient scaffolds in a stepwise mode and a gradual manner respectively have been exploited to achieve gradients in a broad scale throughout the entire construct or within a limited interface region. Gradient scaffolds consistently perform superior to monophasic and biphasic ones in regenerating osteochondral defects [256,257]. The gradients can be described in terms of the variations of the basic units in chemical compositions and structural characteristics which further include several basic forms in arrangement, distribution, dimension and orientation [258]. (Fig. 7) The combined incorporation of different patterns of chemical and structural gradients in a monolithic osteochondral scaffold have been explored in orthopedic research as well.

Fig. 7.

A. The local property profiles and basic forms of gradients. Reproduced with permission [258]. 2017, Elsevier. B. The three aspects of the multiphasic and continuous gradient scaffolds.

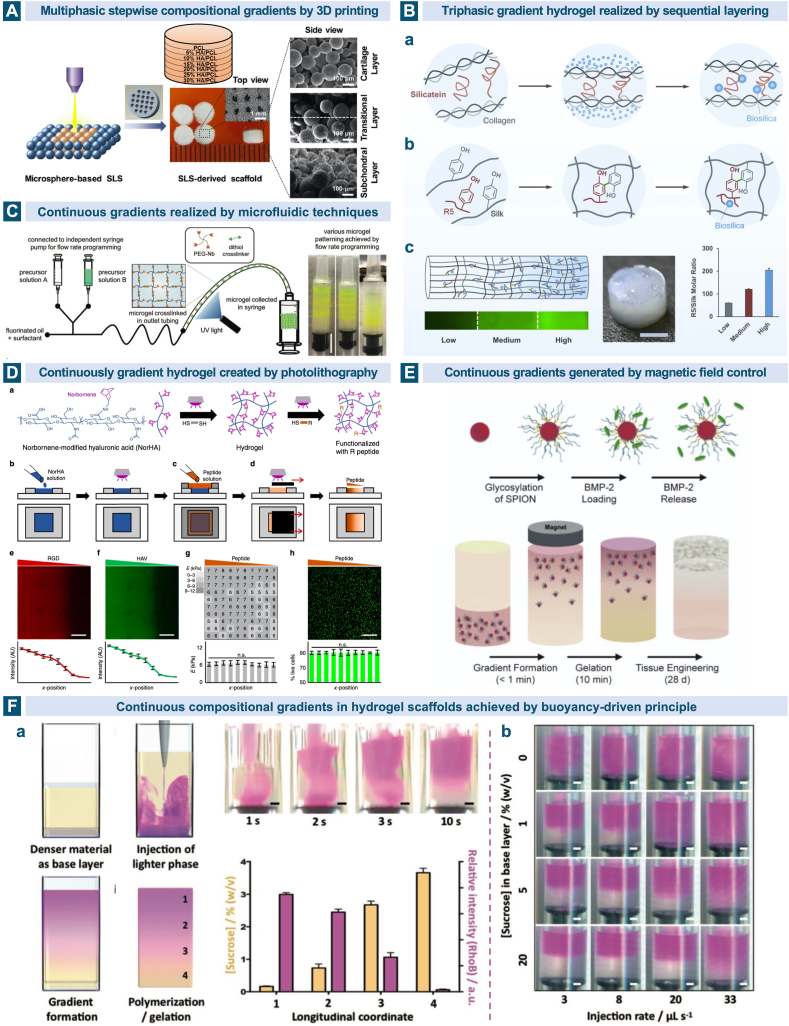

Various techniques have been developed to incorporate multiphasic and continuous gradients into the cartilage and osteochondral scaffolds such as 3D printing especially extrusion printing and selective laser sintering [130,224,259,260], sequential layering of slurry or hydrogel solutions at partial gelation [257,[261], [262], [263]], microfluidic-based method [[264], [265], [266], [267], [268], [269], [270], [271]], electrospinning [272,273], light-mediated hydrogel formation [274,275], centrifugation [[276], [277], [278]], magnetic field control [279] and buoyancy-driven approach [280]. Chemical compositional gradients involve the changes in the fundamental materials and the encapsulated bioactive molecules. An acellular seven-layered gradient scaffold consisting of basic building blocks of PCL and HAp microspheres was prepared through selective laser sintering technique. From the top cartilage layer to the bottom bone layer, the content of HAp was increased from 0 to 30% with 5% increments. The in vitro cellular evaluation and in vivo implantation results verified its capability in inducing the formation of articular cartilage and subchondral bone tissues [130]. (Fig. 8A) With regard to the hydrogel-based scaffolds, sequential addition of different solutions into a cylindrical container layer by layer before the complete gelation allows for the formation of a gradient interface. Utilizing the silk protein-based composites coupled with biosilica selective peptide-R5, Guo and coworkers fabricated a bioinspired gradient protein/biosilica analog by layering three regions with high, medium and low concentrations of the R5 peptide along the longitudinal direction. This gradient silicified silk/R5 system showed continuous transitions in composition, structure and mechanical properties, and could promote the osteogenic differentiation of MSCs in vitro in a gradient manner [262]. (Fig. 8B) Microfluidic techniques for the synthesis of gradient materials on a miniaturized scale rely on their precise control of the fluid flow. Xin et al. produced continuous physicochemical gradients in the microporous annealed particle hydrogels by combining the microfluidic mixing and droplet generator modules. The flow rates of two distinct precursor solutions through two syringe pumps were program-controlled and the continuous gradient profiles were detected in the fluorescent images when the layer thickness was adjusted to 1, 3 and 6 microgels. The findings that MSCs embedded on the hydrogels exhibited differential spreading and proliferation trends along the gradient provided a potential for the hydrogels to facilitate repair of osteochondral defects when a smooth transition from osteogenic to chondrogenic regulations were designed [270]. (Fig. 8C) Gradients created by photolithography can be realized through the manipulation of cross-linker concentration, applied wavelength and duration of irradiation [256]. By moving the opaque sliding mask below the UV light across the exposed hydrogel at a constant rate, continuous peptide gradients were achieved through the thiol-norbornene chemistry in the photocrosslinked HA-based hydrogel. Chondrogenesis of the encapsulated MSCs indicated by the Sox9 and aggrecan expressions showed a spatial variation along the hydrogel's concentration gradient [275]. (Fig. 8D).

Fig. 8.

Multiphasic gradient and continuous gradient scaffolds for osteochondral tissue regeneration. A. Through selective laser sintering technique, multilayered gradient scaffold was prepared from the building blocks of PCL and HAp microspheres, with the HAp content increasing from 0 to 5%, 10%, 15%, 20%, 25% and 30% from the top to the bottom. Reproduced with permission [130]. 2017, Elsevier. B. Design strategies of the gradient composite scaffold. (a) The formation of biosilica particles on the fibrous network of collagen, also known as the in vivo silicification, is mediated by the self-assembled silicatein, (b) biosilica selective peptide R5 was utilized to mimic the natural biomineralization process and deposit biosilica particles on the silk templates, (c) the gradient composite scaffold with gradually increasing concentration of the R5 peptide from the top to the bottom. Reproduced with permission [262]. 2017, Elsevier. C. A microfludic device with a Y-shaped mixing module and a T-junction droplet generator module was used to create different patterns of microgels including the continuous physicochemical gradient one. Reproduced with permission [270]. 2019, Wiley. D. Biochemical peptide gradients in the HA based hydrogel was achieved by controlling the UV light exposure time using an opaque sliding mask [275]. E. The glycosylated superparamagnetic iron oxide nanoparticles conjugated with heparin can sequester and release growth factors and finally create a gradient biochemical pattern under an external magnetic field in the agarose hydrogel to form the gradient engineering osteochondral tissue [279]. F. The casting process of the buoyancy-driven gradient scaffold. (a) After the injection of the purple phase at a controlled rate, the system was allowed to equilibrate and form a gradient by polymerization. (b) By changing the injection rate and the sucrose concentration in the base layer, the pattern of the gradient could be easily modulated [280].

Magnetic field has also been exploited as a facile strategy for generating functional gradients in hydrogels. Under the mediation of the external magnetic fields above the mold, the glycosylated superparamagnetic iron oxide nanoparticles loaded with growth factors aligned gradient in the agarose hydrogel in less than 1 min, accounting for the smooth longitudinal gradients of the growth factor concentration. The engineered osteochondral tissue constructs cultured in vitro presented a tidemark transition separating the mineralized subchondral bone/calcified and non-mineralized hyaline cartilage and an interface rich in hypertrophic chondrocytes indicated by type X collagen [279]. (Fig. 8E) Later, the same group of Li et al. developed a more universal approach based on the fundamental physical principle of buoyancy to generate gradient materials in several different systems including gelatin methacryloyl, gellan gum, agarose and acrylate polymers, and a wide range of cargos such as liposomes, nanoparticles and small molecules. A gradient distribution of bone morphogenetic protein 2 in a gelatin methacryloyl hydrogel was then produced as an example to realize integrated osteochondral tissue constructs [280]. (Fig. 8F).

The structural characteristics including porosity, pore size and pore geometry have widely been recognized as important parts of the environmental cues that influence the migration and differentiation of cells as well as the tissue growth within the scaffolds [281,282]. Designing scaffolds with a structural gradient imitating the native osteochondral units is also an appealing strategy for osteochondral defect treatments. By using a centrifugation method, PCL scaffolds with a pore size gradient from 90 μm to 400 μm approximately along the longitudinal direction were prepared. The in vitro study revealed that the sectioned scaffold with the pore size ranging from 370 to 400 μm were more appropriate for the chondrogenic differentiation of adipose stem cells [276]. Di Luca et al. 3D printed a multiphasic pore size gradient scaffold and evaluated the effect on the proliferation and differentiation of the seeded MSCs and the ECM deposition. As the pore size decrease in the gradient scaffold, the gradual increases of chondrogenic markers and ECM deposition were found [259]. They later fabricated the 3D scaffolds presenting a stepwise pore shape gradient by changing the fiber deposition patterns of two consequent layers. Among the four various patterns with separate angles of 15°, 30°, 45° and 90°, squared pores were observed to provide a more favorable environment for chondrogenic differentiation of the embedded MSCs whereas the pores with a rhomboidal shape support a better osteogenic differentiation when the constructs were cultured under osteochondral conditions in vitro [224]. Despite the difficulty in achieving continuous structural variations, the creation of those multiphasic structural gradient scaffolds offers another strategy to obtain an accurate mimicry of native tissues and also serves as a great tool for improving our understanding of the interactions between cells and biomaterials with different pore structures.

The multiphasic gradient and continuous gradient scaffolds fabricated by emerging new technologies and traditional methods have been achieved both in chemical compositions and structural characteristics, as have been summarized in this part. However, the studies on developing gradient scaffolds mimicking the osteochondral heterogeneities in anatomical, biological, physicochemical and mechanical properties are still limited and in the infancy.

5. Other key elements in cartilage and osteochondral tissue engineering

5.1. Tissue forming cells

The addition of cells with the potential of chondrogenic and/or osteogenic differentiation in the scaffolds is ubiquitous in the field of tissue engineering for the creation of an engineered osteochondral unit. By influencing the interaction between the adjacent native tissue and the artificial scaffold, the incorporated cellular components are universally considered to improve the outcome of ECM deposition and tissue regeneration. Unlike the diversity of biomaterials used to build a biomimetic 3D architecture in osteochondral tissue engineering, limited cell populations are available, including those existed in the host tissue such as chondrocytes, chondroprogenitor cells and osteoblasts, and stem cells with multipotency or pluripotency especially BMSCs, adipose stem cells (ASCs), embryonic stem cells (ESCs) and induced pluripotent stem cells (iPSCs).

As the main cell type resident in articular cartilage and responsible for its structural and functional maintenance, chondrocytes are one of the most widely used cell types in restoring chondral and osteochondral defects. It has been observed that chondrocytes embedded in a wide range of biomaterials could maintain their morphology and phenotype and promote hyaline cartilage formation [107,117,217,283]. The proliferation and differentiation of chondrocytes not only vary in scaffolds with different compositions, but also can be influenced by the architecture of the scaffolds [284,285], including structural form [286], pore size [287,288], pore geometry [289], fiber orientation [290] and fiber dimensionality [291]. On the other hand, the encapsulation of chondrocytes can also alter the properties of the hydrogel scaffold by interacting with the precursors and then reducing the crosslink density [121]. Nevertheless, chondrocytes are faced with several notable challenges like low isolation efficiency, limited proliferation potential and common dedifferentiation phenomenon in culture [18,292]. For osteochondral defect repair, chondrocytes in the cartilage layer have been used in combination with preosteoblasts in the subchondral layer to mimic the different environment in the two regions [251]. In an effort to solve the limitation of cell isolation from the non-load bearing region of articular cartilage in traditional strategy, nasal septum and auricle have been reported to be alternative cell sources of chondrocytes for articular surface reconstruction in osteochondral lesions [[293], [294], [295]]. Apart from culturing the cells in a three-dimensional scaffold, other effective methods to improve the proliferation capacity and maintain the chondrogenic phenotype in vitro include the addition of bioactive molecules and the utilization of bioreactors, which will be introduced in the following sections.

The use of stem cells is another potential solution to avoid the drawbacks associated with articular chondrocytes. Among the various types of stem cells, MSCs especially those derived from the bone marrow are the most widely studied ones in osteochondral tissue engineering due to their advantages like relative ease of isolation and proliferation, ability to differentiate into cells of both chondrogenic and osteogenic lineages, properties of low immunogenicity and no ethical concerns [296,297]. It is worth mentioning that Caplan, the author of the paper first using this term, and some other researchers have recently called for a name change of mesenchymal stem cells to more precise labels in order to reflect the function more accurately and clear up the mess [298,299]. The encapsulation of BMSCs in the scaffolds have been broadly studied in various materials for cartilage and osteochondral regeneration [149,154,174,190,234,270]. Zhou et al. have evaluated the proliferation and differentiation of BMSCs into chondrocytes and osteoblasts on the two separate layers of the collagen-HAp biphasic scaffold in the presence of chondrogenic and osteogenic chemical factors [165]. The chondrogenesis and hypertrophy of BMSCs are dependent on the type of material [105], and the induced lineages can also be influenced by the scaffold's architecture with different pore sizes, interconnectivities, and the engendered different metabolic environments [300]. Co-culture of BMSCs and chondrocytes in tissue engineering scaffolds has also been explored to enhance the cartilage regeneration, when the chondrogenic phenotype of chondrocytes can be maintained and the chondrogenic differentiation of BMSCs can be promoted [187,301]. Other sources of MSCs include adipose tissue, muscle, umbilical cord and etc. [297], among which ASCs isolated from lipoaspirates are the most readily accessible ones. They possess higher proliferation potential and larger abundance than BMSCs [302] and have showed the ability of both chondrogenesis and osteogenesis in a variety of biomaterial environments in increasing reports [98,[303], [304], [305], [306]]. However, their chondrogenic potential is relatively lower than BMSCs and the optimal culture system as well as the effect of scaffold architectures on the cell differentiation remain to be identified in the future [18,307].