Abstract

Background

Pulses are the dried seeds of the Leguminosae family that serve as cheaper proteins, particularly in developing countries. They contain proteins ranging 20–25%. Pulses play important roles in the farming systems and in the diets of poor people. They are ideal crops for simultaneously achieving three key developmental goals: reducing poverty, improving human health, and enhancing ecosystem sustainability. The year 2016 was declared as the year of pulses by the United Nations. These growing global attentions given to legumes has resulted in increasing their nutritional and economic desirability.

Objectives

This review presents the potential of pulses processing in Ethiopia for enhanced nutritional and economic outcomes. Pulses are important foods and export commodity in Ethiopia, which are exported in unprocessed form, fetching low returns.

Data and discussions

There are advanced but simple pulses processing technologies that include concentrating or isolation of proteins for nutritional and other uses. Pin milling of legumes and air classification of the flour helps to obtain protein concentrate of 60–75% purity. Protein isolation by alkaline extraction and isoelectric precipitation results in proteins of 90–95% purity. Legume proteins are mainly globulins and albumins that are nutritionally of great quality. The protein products are being texturized by thermal and mechanical means to make meat analogues, substitutes and extenders.

Summary and conclusion

Ethiopia being one of the significant legume producers, can benefit from this growing market by adopting the processing technologies and exporting premium quality plant proteins. This help Ethiopia satisfy domestic protein needs for child nutrition. This review summarizes the potentials for developing pulses processing technologies in Ethiopia for better economic and nutritional benefits.

Keywords: Pulse proteins, Plant proteins, Protein concentrates, Protein isolates, Texturized proteins, Meat analogues, Meat extenders

Pulse proteins, plant proteins, protein concentrates, protein isolates, texturized proteins, meat analogues, meat extenders

1. Introduction

Food legumes are the second largest category of food grains next to cereals. They are the vital sources of protein, calcium, iron, phosphorus and other minerals and hence form a significant part of the diet of vegetarians since the other food items they consume don't contain much protein [1]. Food legumes complement cereal crops as a source of protein and minerals while agronomically they serve as rotation crops with cereals, reducing soil pathogens and supplying nitrogen to the cereal crops [2]. The edible part of food legumes in most cases are the dried seeds also known as pulses [3].

Ethiopia is one of the major producers of pulses in Africa, although the processing of these crops are limited to small scale baltinas that produces some intermediate ingredients of traditional dishes and the exports are also limited to neighboring countries such as Sudan, Kenya and Djibouti [4]. Pulses rank second among ingredients in staple dishes in Ethiopia and are integral parts of culinary practices [5]. However, the processing is still limited to time consuming and health damaging traditional methods that are gender biased, giving all the responsibilities of food processing and preparations to only women.

Although pulses are the major sources of dietary proteins in developing countries for billions of people [6], the utilization is based on rudimentary traditional processing technologies which limits their values and functionalities [7]. The trades of pulses in developing countries like Ethiopia is limited to neighboring markets that is more complicated and ineffective. This paper reviews the opportunities for development and transformation of the Ethiopian pulses sector to gain better economic and nutritional outcomes at national and regional levels.

2. Importance of legumes

2.1. Economic importance

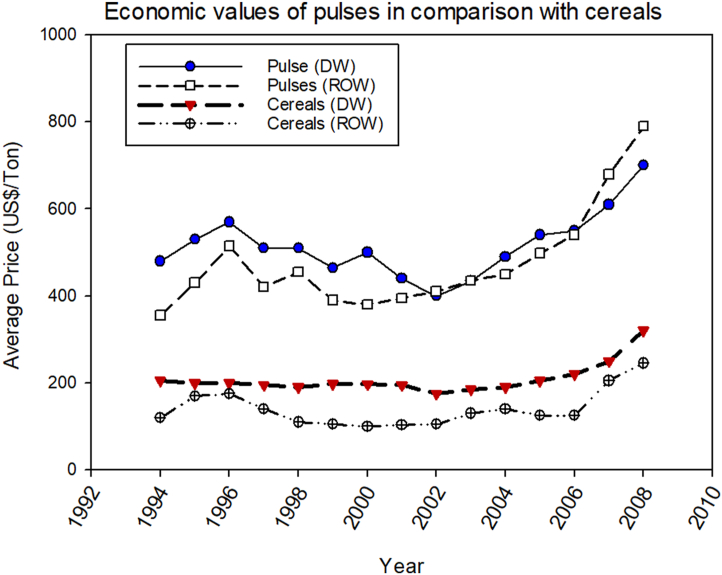

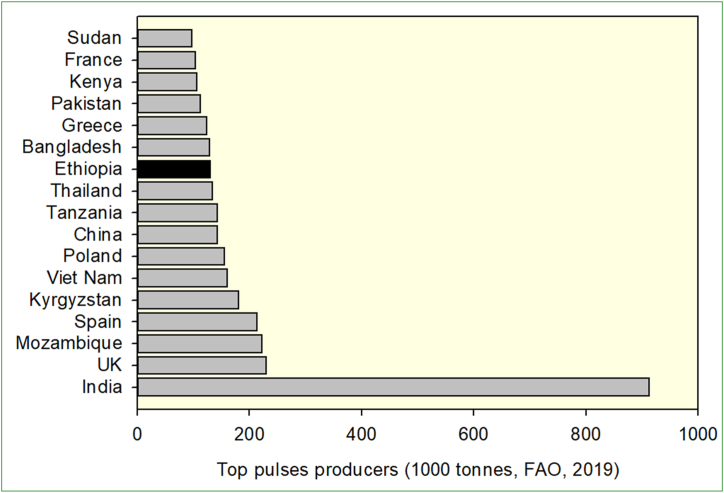

Pulses are known to have higher market values compared to cereals and other categories of food crops. Price data of pulses (Figure 1) were more than double of that of cereals in both developing (DW) and the rest of the world (ROW) between 1994 and 2008 [2]. The average produce price of the 15 years was 495.77 and 174.10 US$ for pulses and cereals, respectively, showing that the economic importance of pulses is almost three folds of that of cereals. In the year 2014, it was reported that about 77 million tons of pulses were produced globally [8]. This volume of pulses would generate 61.6 billon US$ considering the maximum price of 800 US$ shown in the Graph (Figure 1) [2]. The major global producer countries for pulses in 2019 were presented in Figure 2 and Ethiopia was one of the top contributors [7, 9], ranking the third in Africa (next to Mozambique and Tanzania). However, technological advancements for processing and converting pulses into premium products like proteins is yet in its infancy stage, which limits the economic return for the actors of the pulses value chains. The limitations in technology supplies and research and development are more severe in the developing world, including Ethiopia.

Figure 1.

Economic values of pulses in comparison with cereals in both developing countries and the rest of the world.

Figure 2.

Global top pulses producers in 2019 [9]; Ethiopian is among the list.

2.2. Nutritional roles

Pulses are important sources of cheaper proteins (compared to meat) for billions of people around the world [6]. Majority of food pulses contain approximately 21–25% protein; but having limiting amount of essential amino acids such as methionine, tryptophan and cystine [6]. Some underutilized species like lupin (which is also grown in Amhara and Benishangul Gumuz Regions of Ethiopia [10]), have even higher proteins (~46%) with higher dietary fibers (~30%) that makes it extremely important in adult nutrition [11]. Pulses are also known to complement cereal crops as a source of proteins (limiting essential amino acids such as lysine) and minerals while agronomically they serve as rotation crops with cereals, reducing the buildup of specific categories of pathogens, disease agents (pests) and also supplying nitrogen nutrients [2].

The high contents of proteins in pulses (Table 1) are known to have the highest solubility and digestibility compared to the proteins obtained from other foods like cereals. The reason for the improved digestibility is because pulses have mainly (70–80%) albumins (water soluble protein fractions) and 20–30% globulins (salt soluble fractions) [12]. However, due to slow development of pulse processing technologies, the crops are not fully utilized and protein-energy malnutrition is still challenging significant proportions of the populations in developing countries, including Ethiopia. Although, Ethiopia is producing significant tonnage of faba bean, field pea, chick pea, haricot beans and lentils [7], the sluggish development in the value addition aspect is hindering the country from gaining enough.

Table 1.

Protein levels (ranges and averages) for major pulses commonly produced and consumed in Ethiopia.

| Pulses types | Protein levels (%, db) |

Reference | Major food uses | |

|---|---|---|---|---|

| Range | Mean | |||

| Faba beans (Vicia faba) | 18–31 | 24 | El-Sherbeeny and Robertson, 1992 [13] | Stews, snacks, mixing with cereal based foods |

| Field peas (Pisum sativum) | 20.2–26.7 | 23.3 | Wang and Daun, 2004 [14] | Stews, snack, |

| Chick pea (Cicer arietinum) | 18.8–28.0 | 25.8 | Kharkwal, 1998 [15] | Snacks, stews, textured pieces |

| Haricot beans (Phaseolus vulgaris) | 22.5–27.1 | 25.7 | Siddhuraju et al., 2002; Mengistu, 2020 [16, 17] | Snack, main dish with routs and cereals |

| Lentils (Lens culinaris) | 18.1–32.7 | 22.4 | Kumar et al., 2016 [18] | Stews, soups, snacks |

2.3. Environmental sustainability

Legumes (pulses) are known to play multiple roles in environmental and agricultural sustainability [19]. The most popular role of legumes (pulses) is its natural ability in nitrogen-fixation (converting atmospheric nitrogen into plant nutrient) with the help of microorganisms in the soil [20, 21, 22]. The use of pulses as rotation crops with cereals is therefore, a natural and cheap method of maintaining soil fertility in a sustainable farming systems. This will cut the heavy application of chemical fertilizers that would have inflated the production cost and also have negative consequences on the environmental sustainability. The rotation of pulses with cereals also helps in preventing buildup of pests that attack certain group of crops and this also helps us avoid heavy application of chemical pesticides. The production of pulses in agriculture for both human foods and animal feeds is both nutritionally, economically and ecologically appealing.

3. Opportunities for legumes research and development in Ethiopia

Pulses production for food, feed and industrial raw materials in Ethiopia is done in a comprehensive way, where specialized varieties suiting best to the different purposes are yet to be developed. There are some researches that reported canning quality of some pulses in Ethiopia [23], which should be given due attention and worked on intensively. Some experiences, reports and biological resources might be obtained from neighboring African countries like Kenya, where the canning varieties of beans are excelled and established [24, 25, 26, 27, 28]. The fact that Ethiopian pulses are not yet developed for different processing applications, presents a great opportunity for research and development for the national legumes and pulses program.

3.1. Improving varieties

Researches on the development and release of new varieties in Ethiopian breeding programs are focused largely on the enhancement of the agronomic performances and yield targeting household consumption and export markets for the unprocessed grains [29, 30, 31, 32]. Researches on pulses breeding should focus on traits relevant to food processing and applications to complete the value chain packages. Pulse Breeders and Food Scientists should design research goals and work together to achieve impactful results. Canning varieties of different beans and green peas; roasting varieties of chickpea, field peas and broad beans for the application of shiro stews, and splits (kik); fast cooking types of lentils for whole as well as split application in traditional Ethiopian misir kik stew and soup making should be lines of specialization, all with improved protein and mineral levels as traits of focus for future breeding endeavors. The combined breeding and value addition research programs should also focus on such traits as kernel softness (fast cooking, [33]) and reduced hardening on storage (hard to cook phenomena, [34]) for application in dry milling in extraction as well as concentration of proteins as premium commercial ingredients for the healthy food industry (detail is presented under section 4.2).

3.2. Selection of processing technologies and optimizations

Most pulses-based staples in Ethiopia are almost exclusively processed at home or at a cottage level small industry usually known as baltinas [35]. For instance, the preparation of intermediate ingredients like plain (nech/alicha) or seasoned (mitin) shiro flours [36]; splits (kik) from either lentils and peas are made either at every household level or by small scale women or youth groups at a very small scale with inefficient energy, labor and time utilization, resulting in substandard and sometimes unsafe products, with insufficient returns. There are no ready-to-eat foods prepared from pulses except few snacks mixed with micronized/roasted and dehulled barley kollo, which are usually dry and hard to chew. Researches focusing on developing and or testing processing technologies to improve the cost of production and product desirability need to be encouraged. Indigenous technologies need to be mechanized into an effective mass production set ups to save time, energy and minimize cost of doing businesses, hence maximizing economic return to encourage the players.

3.3. Setting standards and specifications

Many pulses-based traditional dishes in Ethiopia do not have specifications and standards and quality control is extremely challenging. Researchers in the universities and research institutes need to work closely with the Ethiopian standards agency to characterize traditional foods and set specifications for commercial level production and marketing. Out of many traditional staples in Ethiopian food culture, only injera from tef has a specification on ingredients, processing, composition and microbial safety aspects [37]. Other important main and side dishes as well as snacks need to be adequately characterized and standardized for commercial scale production and marketing. This would benefit the country by creating additional jobs, making it easier for nutritional enrichment (fortifications) and safety control activities. The mechanization of making traditional foods and commercial level production will also save the time and health of our women [38], and help them do more economical activities like petty trade, field works and schooling for young girls. This in turn helps achieve better gender equality and equity by freeing women from routine responsibilities of cooking family foods.

4. Processing technologies for legumes

4.1. Primary and secondary processing techniques

Primary processing techniques for food pulses include cleaning (wet or dry), drying, husking (dehulling), splitting, winnowing, separation and packaging for use as intermediate ingredients in either home prepared or industrially processed ready-to-eat (RTE) foods. Secondary processing operations may also be applied for various reasons either at industry or household processing scales. Some of the popular secondary processing unit operations include [39]:

-

•

Sorting by screening to classify seeds based on physical parameters like size, density, color and soundness for separation of defective and broken kernels or for better and uniform processing [39].

-

•

Soaking pulses in either plain water, acid or alkaline solutions [40] can be used to either soften the seeds for further processing (cooking, roasting, wet milling), or accelerate sprouting or dehulling processes, leaching out of antinutritional agents or multiple of these effects.

-

•

Blanching or wet heating to inactivate lipoxygenase enzymes that causes undesirable beany flavor when used in foods [41].

-

•

Cooking (boiling) to soften the kernels and enhance its palatability is done either at commercial or home preparation levels. Th cooking of pulses is usually used as a mean of preparing RTE products and should be done with the application of sensory improving spices and some application of oils like in the case of the preparation of hummus in the Mediterranean food cultures.

-

•

Roasting is also done for the same effect as in the case of cooking but when a richer flavor and other sensorial attributes like texture and mouthfeel are of higher importance.

-

•

Germination and Fermentation are also used in certain Asian food cultures (as in the Korean bean sprouts [42] and African fermented bean preparations such as afitin, iru and sonru [43].

-

•

Milling and screening are also common unit operations in the productions of pulses based raw or roasted flours like in the preparation of shiro, an intermediate powder for the preparation of popular Ethiopian staple sauce (stew).

-

•

Canning is probably the oldest and the single most common commercial processing and preservation techniques for pulses (cooked or green beans and peas) [44]. Canned pulses make important part of all meals as side dishes in western food cultures.

All sorts of pulses processing (primary and secondary) for either commercial or household utilizations are at a scale of non-existence in Ethiopian scenario [38]. Grain pulses are exported to neighboring countries like Sudan, Yemen, South Africa, and United Arab Emirates (UAE) without processing with minimal return to the producers, traders and the country [7]. If Ethiopia has to benefit from the pulse production, processing technologies like canning and other advanced value addition operations (Section 4.2) are of paramount importance, sooner than later.

4.2. Advanced processing techniques

Advanced processing technologies developed for pulse grains includes the extraction of premium components like proteins and their application in novel food products. Production of other byproducts of economic importance including hydrocolloids such as locust bean gums, starch and edible oil are also included. The following sections present the details of advanced pulses processing, their major products and their applications in food industries, nutraceuticals and pharmaceuticals.

4.2.1. Processing technologies for producing protein concentrates

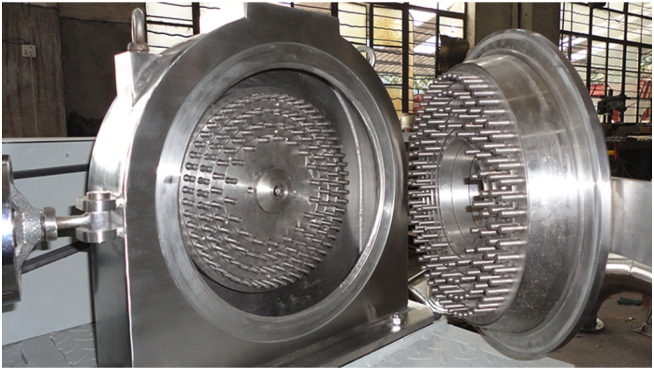

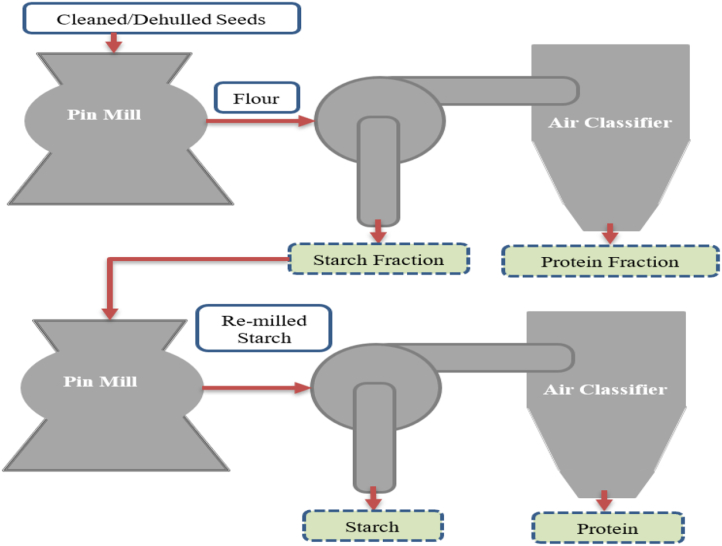

Pulses are known to have higher kernel hardness than cereals and require special types of mills for converting them into flours. Impact milling types such as hammer and pin mills are suitable technologies for milling pulses [45]. Protein concentrate production makes use of pin mill (Figure 3) followed by air classification (Figure 4) of the flour into fine/lighter components (proteins) and coarser/denser components (starch) [46]. The process may follow a double milling stages (Figure 5) to maximize the protein recovery. Protein concentrates produced using this technology gives commercially viable products (Figure 6), with protein contents ranging from 60 – 75%, with the remaining portions being starches [46]. The protein recovery rate may depend on the type of pulses and efficiency of milling as well as that of air classification.

Figure 3.

Medium capacity pin mill for pulse grinding.

Figure 4.

Air classifier with a tea pulverizing mill on the left.

Figure 5.

Production of protein concentrates using pin mill followed by air classification; based on information from: [51].

Figure 6.

Pea protein concentrate with 80% pure plant protein as a direct supplement or bulk ingredient in healthy food preparation.

The technology required for the production of pulse protein concentrates makes use of pin mill and cyclone type air classifier (Figure 4), both of which do not require heavy investment. This means that the pin mill and air classifiers of medium capacity can be purchased by small businesses and run with minimal cost in Ethiopia. For instance, a medium pin mill (Figure 3) costs about 25,000 to 30,000 USD [47] and a simpler cyclone air classifier often with a simple mill (Figure 4) costs less than 20,000 USD [48]. Pea protein concentrates extracted from Canadian yellow pea (from Prescribed for Life Co., Figure 6) [49], having 80% pure plant protein on amazon costs about 27 USD per kilo. There have been growing demands for animal-based proteins with increasing world population, but due to the potential of intensified animal breading to increase greenhouse gas (GHG) emission, which is resulting in increased demand for plant-based proteins [50]. This presents great opportunities for Ethiopia (one of significant producers of pulses), to benefit from the increasing global demand, if the agro-processing sector for pulses can be given due attention and development is achieved.

There are numerous research outputs on the production and characterization of plant protein concentrate [46, 52, 53]. It is also believed that many studies are underway to optimize processing conditions and costs for proteins from different plant sources. It is therefore, recommended that Ethiopian pulses development program have strategies in place to benefit from these ample opportunities.

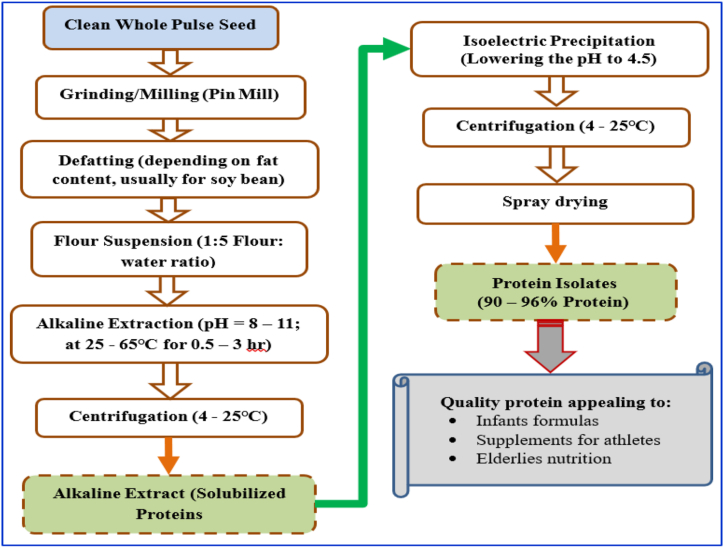

4.2.2. Processing for protein isolate production

The pin milling technology discussed under section 4.2.1 above can also be coupled with other chemical techniques and produce a more concentrated protein product, also known as protein isolates. The milled flour is defatted (oil separated for food or other industrial uses) and the flour is made to suspend in water (1:5, flour: water ratio (Figure 7). The suspension is allowed to soak in alkaline solutions of a pH ranging from 8 to 11 for a period of 30 min to 3 h [46]. Since majority of the proteins dissolve in the alkaline pH ranges [54], the alkaline soaking helps in dissolving majority of the albumin and globulin proteins to separate from the starch matrix. The solution is centrifuged to separate the starch and then the pH is changed to acidic range (<4.5) to bring the proteins to their isoelectric points to precipitate from the solution. The precipitated proteins are separated from the solution by centrifugation, which can also be completed by a spray drying to give fine protein powder of 90–96% protein purity [46]. This protein products are of high value and commercially available as sports supplements (Figure 8).

Figure 7.

Production of protein isolates using alkaline extraction followed by isoelectric precipitation.

Figure 8.

Pure protein isolates available commercially for various applications.

Protein isolates obtained from pulses are known to have undesirable beany flavors that limits their uses for consumption as such in supplements and food ingredients [55, 56]. There are opportunities for research on improving the sensorial properties of plant proteins and increase their relevance as premium food ingredients. The improvement of pulse flavors might be part of the national pulses research and development in Ethiopia.

4.2.3. Uses of protein concentrates and isolates

Pulse proteins obtained either from pin milling and air classifications (section 4.2.1) or as pin milled alkaline solubilized and centrifugally separated from starch and isolated by isoelectric precipitation are well characterized [57, 58, 59, 60] and used as premium ingredients in the production of novel food products by further processing into meat analogues from wet extrusion (protein texturization) [61, 62] as vegan and vegetarian meat. Meat extenders [63, 64] to increase the protein body of some skeletal muscles of chicken were also of popular applications which have shown promising results. Texturized (heated and extruded) soy protein products like Tasty® and Sossi® Soya (Figure 9) are becoming popular in Ethiopian food cultures as vegetarian meat substitutes during fasting seasons for the Christian families. Protein concentrates and isolates from different pulses, usually soy bean are extruded and cut into pieces of different sizes and shapes to give dried textured proteins that can be used as meet substitutes [65, 66, 67, 68, 69]. This processing technology is already in Ethiopia, but this sector needs to be given attention and support to develop and produce for export markets.

Figure 9.

Texturized soy protein pieces becoming popular in Ethiopian market: Tasty Soya® (left) and Sossi Soya® (right).

The textured proteins are marketed as dried pieces that are readily hydrated and converted to different meet analogue-based products, some of which include vegetable meat extenders in burger patties improving textures and flavors as well as health of consumers [70]. The textured pulse proteins can also be used in any application mixed with or totally substituting beef or chicken meats. Textured pulse protein pieces, can for instance, be instantly hydrated, seasoned and applied on pizza as toppings [71].

4.2.4. Non-conventional pulses processing technologies

Non-conventional (advanced non-thermal processing) technologies have great potential to improve the shelf life and sensory acceptance of pulse-based food products. Advanced processing technologies that employ high pressure (HP), pulsed electric field (PEF) and ultrasound are being extensively investigated for use in food processing (preservation) applications [72] and can be considered for pulses processing. Lipoxygenase is an enzyme responsible for strong beany and/or grassy flavor in pulse-based foods. Alhendi et al. [73] demonstrated that effective lipoxygenase inactivation in soy beans by pulsed light was achieved, that also improved the sensory acceptability of the products [74]. Gamma irradiation applications were also used to inactivate lipoxygenase, trypsin inhibitors and raffinose family oligosaccharides, while improving the sensorial acceptance and nutritional quality of beans [75, 76]. Microwave treatments were also shown to destroy lipoxygenase enzymes in beans [77, 78].

Application of pulses in diverse food uses might also be innovated as a non-convential means to increase the nutritional benefits of pulses in the community. Coupling of pulses with fermentation and other food preparations with known health beneficial outcomes is of high priority to add values to pulse-based products. Fermentation of beverage milk from chickpea and faba beans was characterized to be acceptable, presenting an alternative to soy bean milk replacers [79]. The non-conventional processing technologies could be adopted in the efforts of value addition to pulses and pulse products (protein isolates and concentrates) focused on in this review article. The new technologies would change the production and utilization of pulses in Ethiopia for a better nutritional and economic outcomes.

4.2.5. Effects of processing on nutritional quality of pulses

Pulses are known for their supplies of proteins and dietary minerals. The major importance of pulses is generally, their protein contents, which is also the focus of this review. Conventional processing technologies, such as thermal treatments as in cooking, is known to improve the solubility and digestibility of proteins, but may result in leaching out of the mineral constituents. Starch digestibility is also increased as a result of the different processing techniques, but no change is expected on the other proximate components of pulses. Comparing the conventional and advanced (non-conventional) technologies, it is recommended that the advanced technologies are known to result in better nutrient retentions [80], but the effect on the protein digestibility and bioavailability is yet to be discovered [81]. Differences in the protein quality of pea was reported as a result of processing methods (conventional heating versus microwaving) [82]. Many research showed the positive effect of advanced processing technologies on reducing the levels of antinutrients (trypsin inhibitors) [75, 77, 78], but more research are required to establish the effects on the digestibility and biological values of pulse proteins. The effects of the non-conventional processing techniques on the yield and quality of protein concentrates and isolates, as well as their processed ready-to-eat products require research focuses.

5. Economics of pulses processing in Ethiopia

5.1. Economic analysis of pulse protein isolation and concentration

Pulse's production is a cost-effective activity for it requires less agronomic inputs (nitrogen fertilizers), because pulses are nitrogen fixers by nature. The non-food biomass residues of pulses are rich protein supplements for farm animals, which is of great economic benefits. Processing of pulses into proteins is a cost-effective technology that requires only a medium sized pin mill and air classifier with no sophisticated mechanical or chemical technologies. Production of pulse protein isolates (premium quality plant proteins) requires additional but cheap chemicals for pH adjustment together with containers (vats or tankers) and a medium-sized centrifuge. Other equipment sets for cleaning and packaging might also be needed, all of which require fairly low capital investment, compared to the expected high return from the global demand for the final products. The major focus of this review article is to introduce the pulses value addition (processing), which is the major missing element in Ethiopian setting. The economic benefits of pulses protein isolation and concentration is promising [83], which is a real potential for significant producer countries like Ethiopia. Both the milling and air classification require electric energy that is from hydroelectric generations, in the case of Ethiopian scenario, which in relation to the Grand Ethiopian Renaissance Dam (GERD) is expected to boost the economy, while still ensuring environment friendly energy alternative [84]. The increasing global demand for plant protein concentrates and isolates will also present great opportunity for Ethiopia as one of the top three producers in Africa and top ten globally [9]. The development of pulses processing sector is also expected to influence the employment of many youths in the country and stabilize the economic progress and peace. Value addition to pulses will also benefit the small holder farmers and traders. The investment in the pulse's protein production is expected to be a successful venture as some products such as meat analogues are already in the market (Figure 9) for over a decade now.

5.2. Investment modalities for Ethiopian pulse

In order to excel the pulses business and the businesses to create capacities to support research and development in their favor, there are multiple ways the sector can be transformed into. One of the models is the small and medium businesses development where government and non-governmental development agents can present financial and technical supports to youth and women groups as an employment opportunity. Another modality could be capacitating farmers associations and unions to work in the pulses production and processing export marketing. Private companies could also invest in the sector at large scale either by obtaining financial resources from local banks or by mobilizing monetary funds via selling shares. The commercial level production and processing of pulses for export markets is a viable and promising venture as there has been a growing global demand for plant-based protein ingredients in the diets of the millennial consumers. Ethiopia cannot afford to waste ample opportunities at hand, waiting for international investment to come and develop the pulses sector.

6. Challenges and opportunities for advanced and feasible pulses processing in Ethiopia

The major challenges in adopting the advanced processing technologies are limited experiences of mechanized level of production of pulses-based staples and commercial products in Ethiopia [38]. Availability of seeds and development of new ones with desirable end-use traits is already challenging [35, 85] and development of new ones will definitely take time. The commitment and attention of the government and the private investment sectors is also of importance. Development projects by development partners and NGOs should also focus on the development of processing technologies for pulses and other grains.

It is expected also that fragmented land tenure in Ethiopia presets challenge to mass production of pulses with consistent quality traits at reasonably stable prices. Other socio-economic challenges related to gender balance and equity was reported by [86] in Ethiopian pulses development as part of the experience of Ethio-Canadian development project focusing on chickpea value chains. The recommendation is that all the stakeholders in the pulses values (researchers, government, private sectors) pay attention to the pulses to better serve the income and nutrition objectives.

7. Summary and conclusions

Legumes are important sources of cheaper but quality proteins for the populations of developing world. Pulses are also increasingly becoming important and preferable sources of proteins for the populations of the developed world. This presents great development opportunities for pulses producing countries like Ethiopia. By improving the varieties in terms of nutritional and processing functionalities of the different species of pulses and adopting advanced, but feasible value addition technologies, Ethiopia can benefit from the expanding global markets of pulse proteins. Production of protein concentrate simply by mechanical means and protein isolates using a combination of mechanical and chemical procedures for export markets is a promising investment opportunity for Ethiopia. This can also contribute to the national effort of irradicating protein-energy malnutrition in young children by supplying cheaper proteins from domestic markets for the production of good quality complementary foods. Improvement of traditional dishes and their processing technologies to enable a mechanized scale of commercial production can also come along the pulses research and development endeavor. It is therefore, recommended that researchers in the breeding programs and processing for value addition areas come together and work hand in hand to redefine the focuses of the national pulse development programs for a greater national goal.

Declarations

Author contribution statement

Tadesse Fikre Teferra: All authors listed have significantly contributed to the development and the writing of this article.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability statement

Data will be made available on request.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- 1.Nedumaran S., Abinaya P., Jyosthnaa P., Shraavya B., Rao P. Working Paper Series No 60. ICRISAT Research Program, Markets, Institutions and Policies. Patancheru 502 324. International Crops Research Institute for the CGIAR; Telangana, India: 2015. Grain legumes production, consumption and trade trends in developing countries. [Google Scholar]

- 2.Akibode C.S., Maredia M. Global and regional trends in production, trade and consumption of food legume crops. Staff Pap. 2012:1–87. [Google Scholar]

- 3.Havard T.H. Chan school of public health, cholesterol | the nutrition source | harvard T.H. Chan school of public health. Nutr. Source. 2018 https://www.hsph.harvard.edu/nutritionsource/legumes-pulses/ [Google Scholar]

- 4.Koroma S., Molina P.B., You N. Promoting regional trade in pulses in the Horn of Africa. Food Agric. Organ. 2016:29. www.fao.org/contact-us/licence-request [Google Scholar]

- 5.Kabata A., Henry C., Moges D., Kebebu A., Whiting S., Regassa N., Tyler R. Determinants and constraints of pulse production and consumption among farming households of Ethiopia. J. Food Res. 2016;6:41. [Google Scholar]

- 6.Singh N. Pulses: an overview. J. Food Sci. Technol. 2017;54:853–857. doi: 10.1007/s13197-017-2537-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Rashid S., Yirga C., Behute B., Lemma S. Pulses value chain in Ethiopia constraints and opportunities for enhancing exports with significant contributions – a working paper, IFPRI. Int. Food Policy Res. Inst. 2010:1–44. [Google Scholar]

- 8.Varma P. Book review: vikas rawal and dorian kalamvrezos. In: Navarro, editor. Vol. 2020. SAGE PublicationsSage India; New Delhi, India: 2019. (The Global Economy of Pulses). [Google Scholar]

- 9.FAO . FAOSTAT; 2019. Top Global Pulses Producers in 2019 FAOSTAT.http://www.fao.org/faostat/en/#data/QC (accessed June 7, 2021) [Google Scholar]

- 10.Azeze H., Mekbib F., Dessalegn Y., Tadele Z., Megersa N. Challenges on production and utilization of white lupin (lupinus albus L.) in Ethiopia: a strategic orphan crop. Am. J. Exp. Agric. 2016;13:1–14. [Google Scholar]

- 11.Tamayo Tenorio A., Kyriakopoulou K.E., Suarez-Garcia E., van den Berg C., van der Goot A.J. Understanding differences in protein fractionation from conventional crops, and herbaceous and aquatic biomass - consequences for industrial use. Trends Food Sci. Technol. 2018;71:235–245. [Google Scholar]

- 12.Kenmoe L., Kotue T., Chandra K., Djouhou F., Pieme A., Kansci G., Fokou E., Arumugam N. Albumin and globulin fractions from black bean seeds (Phaseolus vulgaris L.) used in the management of sickle cell disease (SCD) in the west region of Cameroon have antisickling and antioxidant properties. J. Biotechnol. Biomed. 2020;3 [Google Scholar]

- 13.El-Sherbeeny M.H., Robertson L.D. Protein content variation in a pure line faba bean (Vicia faba) collection. J. Sci. Food Agric. 1992;58:193–196. [Google Scholar]

- 14.Wang N., Daun J.K. Effect of variety and crude protein content on nutrients and certain antinutrients in field peas(Pisum sativum) J. Sci. Food Agric. 2004;84:1021–1029. [Google Scholar]

- 15.Kharkwal M. Induced mutanons for improvement of protein in chickpea (Cicer arietinum L.) Indian J. Genet. Plant Breed. 1998;58:61–68. www.IndianJournals.com [Google Scholar]

- 16.Siddhuraju P., Becker K., Makkar H.P.S. Chemical composition, protein fractionation, essential amino acid potential and antimetabolic constituents of an unconventional legume, Gila bean (Entada phaseoloides Merrill) seed kernel. J. Sci. Food Agric. 2002;82:192–202. [Google Scholar]

- 17.Mengistu D.K. Effects of combined application of phosphorus and sulfur fertilizers on agronomic traits and protein content of supplementary irrigated haricot bean (Phaseolus vulgaris) varieties. Artic. African J. Food. 2020 [Google Scholar]

- 18.Kumar J., Singh J., Kanaujia R., Gupta S. Protein content in wild and cultivated taxa of lentil (Lens culinaris ssp. culinaris Medikus) Indian J. Genet. Plant Breed. 2016;76:631–634. [Google Scholar]

- 19.Stagnari F., Maggio A., Galieni A., Pisante M. Multiple benefits of legumes for agriculture sustainability: an overview. Chem. Biol. Technol. Agric. 2017;4:1–13. [Google Scholar]

- 20.Atienza S.G., Rubiales D. Legumes in sustainable agriculture. Crop Pasture Sci. 2017;68:i–ii. [Google Scholar]

- 21.Meena R.S., Lal R. Legum. Soil Heal. Sustain. Manag. Springer Singapore; 2018. Legumes and sustainable use of soils; pp. 1–31. [Google Scholar]

- 22.Vanlauwe B., Hungria M., Kanampiu F., Giller K.E. The role of legumes in the sustainable intensification of African smallholder agriculture: lessons learnt and challenges for the future. Agric. Ecosyst. Environ. 2019;284:106583. doi: 10.1016/j.agee.2019.106583. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Teshome D.M., Emire S.A. Canning quality evaluation of common bean (Phaseolus vulgaris L.) varieties grown in the central rift valley of Ethiopia. East African J. Sci. 2012;6:65–78. https://www.ajol.info/index.php/eajsci/article/view/103441 [Google Scholar]

- 24.Chemining’wa G.N., Kitonyo O.M., Nderitu J.H. Status, challenges and marketing opportunities for canning navy bean in Kenya. African J. Food, Agric. Nutr. Dev. 2014;14:2072–2087. https://www.ajol.info/index.php/ajfand/article/view/107904 [Google Scholar]

- 25.Karuri E., Kimani P. University of Nairobi; 2014. Canning Quality of New Advanced Canning Bean Lines Developed in Kenya.http://erepository.uonbi.ac.ke/handle/11295/77584 [Google Scholar]

- 26.Warsame A.O., Kimani P.M. Canning quality of new drought-tolerant dry bean (Phaseolus vulgaris L.) lines. Am. J. Food Technol. 2014;9:311–317. [Google Scholar]

- 27.Njau S.N. 2016. Selection for Yield Potential, Disease Resistance and Canning Quality in Runner and Snap Bean Lines and Populations.http://erepository.uonbi.ac.ke/handle/11295/97736 [Google Scholar]

- 28.Kimani P. 2017. Role of Universities in Development of Improved Crop Varieties, Seed Production, Dissemination and Impacts: Case Studies of Dry, Canning, Snap and Runner Beans, Pigeonpea and Onions.http://erepository.uonbi.ac.ke/handle/11295/103439 [Google Scholar]

- 29.Yirga C., Rashid S. DIIVA; 2010. Diffusion and Impact of Improved Varieties in Africa (DIIVA) View Project Diffusion and Impacts of Improved Varieties in Africa. 2010–2013. [Google Scholar]

- 30.Amsalu B., Tumsa K., Negash K., Ayana G., Fufa1 A., Wondemu M., Teamir M., Rubyogo J.C. Agric. Res. Ethiop. Renaiss. Challenges, Oppor. Dir. Ethiopian Institute of Agricultural Research, EIAR; 2016. Lowland pulses research in Ethiopia: achievement,... - google scholar; pp. 40–60.https://scholar.google.com/scholar?hl=en&as_sdt=0%2C5&q=Lowland+Pulses+Research+in+Ethiopia%3A+Achievement%2C+Challenges+and+Future+Prospect&btnG= [Google Scholar]

- 31.Jarso M., Keneni G., Wolabu T. Enhancing the technical relevance of pulses and oilseed crops through target oriented breeding. In: Derso E., Kirub A., Alemu D., Assefa G., editors. Agric. Res. Ethiop. Renaiss. Challenges, Oppor. Dir. 2017. pp. 41–60. [Google Scholar]

- 32.Amsalu B., Negash K., Shiferaw T., Tumssa K. Progress of common bean breeding and genetics research in Ethiopia. Ethiop. J. Crop Sci. Spec. 2019;6:115–128. https://www.researchgate.net/profile/Gemechu_Keneni2/publication/328760031_Crenate_broomrape_Orobanche_crenata_Forsk_problem_and_its_management_in_food_legumes/links/5c3d8b25a6fdccd6b5ada468/Crenate-broomrape-Orobanche-crenata-Forsk-problem-and-its-manage [Google Scholar]

- 33.Wiesinger J.A., Cichy K.A., Tako E., Glahn R.P. The fast cooking and enhanced iron bioavailability properties of the manteca yellow bean (Phaseolus vulgaris L.) Nutrients. 2018;10:1609. doi: 10.3390/nu10111609. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Mubaiwa J., Fogliano V., Chidewe C., Linnemann A.R. 2016. Food Reviews International Hard-To-cook Phenomenon in Bambara Groundnut (Vigna Subterranea (L.) Verdc.) Processing: Options to Improve its Role in Providing Food Security. [Google Scholar]

- 35.Setotaw F., Asnake F., Seid A. Assessing the competitiveness of smallholders chickpea production in the central highlands of Ethiopia. Ethiop. J. Crop Sci. 2018;6:51–65. http://oar.icrisat.org/10635/ (accessed June 7, 2021) [Google Scholar]

- 36.Olika E., Abera S., Fikre A. Physicochemical properties and effect of processing methods on mineral composition and antinutritional factors of improved chickpea (Cicer arietinum L.) Varieties Grown in Ethiopia. Int. J. Food Sci. 2019;2019:7. doi: 10.1155/2019/9614570. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.ESA . 2018. Teff Injera Specifications by Ethiopian Standards Agency, Ethiopian Standards, Addis Ababa. [Google Scholar]

- 38.Kuyu C.G., Bereka T.Y. Review on contribution of indigenous food preparation and preservation techniques to attainment of food security in Ethiopian. Food Sci. Nutr. 2020;8:3–15. doi: 10.1002/fsn3.1274. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Subuola F., Widodo Y., Kehinde T. Processing and utilization of legumes in the tropics. In: Eissa A.A., editor. Trends Vital Food Control Eng. 2012. p. 72. [Google Scholar]

- 40.Autónoma U., Mérida Y., Yucatán M., Wanjekeche E., Wakasa V., Mureithi J.G. Effect of germination, alkaline and acid soaking and boiling on the nutritional value of mature and immature Mucuna (Mucuna pruriens) beans. Trop. Subtrop. Agroecosyst. 2003;1:183–192. http://www.redalyc.org/articulo.oa?id=93911288019 [Google Scholar]

- 41.Wang W.Q., Yang C.Y., Li D.P., Wang H.Q., Rong R.F. Effects of different heat treatments on lipoxygenase activity and the oxidative stability of walnut oil. Acta Hortic. 2014;1050:249–256. [Google Scholar]

- 42.Han K.-S., Pyo S.-H., Lee E.-J., Lee H.-A. Korean Society of Food and Cookery Science; 2008. Standardization of the Recipe for the Large-Scale Production of Korean Cooked Rice Varieties-Bibimbab, Bean Sprout Bab, and Fried Rice. [Google Scholar]

- 43.Azokpota P., Hounhouigan D.J., Nago M.C. Microbiological and chemical changes during the fermentation of African locust bean (Parkia biglobosa) to produce afitin, iru and sonru, three traditional condiments produced in Benin. Int. J. Food Microbiol. 2006;107:304–309. doi: 10.1016/j.ijfoodmicro.2005.10.026. [DOI] [PubMed] [Google Scholar]

- 44.Rockland L.B., Radke T.M. 1986. Process for Canning Dry Beans and Other Legumes. US4729901A. [Google Scholar]

- 45.Vitelli M., Rajabzadeh A.R., Tabtabaei S., Assatory A., Shahnam E., Legge R.L. Effect of hammer and pin milling on triboelectrostatic separation of legume flour. Powder Technol. 2020;372:317–324. [Google Scholar]

- 46.Klupšaitė D., Juodeikienė G. Legume: composition, protein extraction and functional properties. A review. Chem. Technol. 2015;66 [Google Scholar]

- 47.Alibaba.com/Medium_pin_mill . 2020. Factory Price Pulverizer New Stainless Steel Pin Mill - Buy China Pin Mill,Pin Grinding Mill,Hammer Mill Product on Alibaba.Com.https://www.alibaba.com/product-detail/Factory-Price-Pulverizer-New-Stainless-Steel_60784510615.html?spm=a2700.7724857.normalList.1.5f67312fkMUTa5 [Google Scholar]

- 48.Alibaba.com/air_classifier, Brightsail Air Classifier Mill Acm Grinder Ultra Fine Powder Grinder - Buy Acm Grinder,Air Classifier Mill, Ultra Fine Powder Grinder Product on Alibaba.Com. 2020. https://www.alibaba.com/product-detail/Air-Classifier-Brightsail-Air-Classifier-Mill_62405325798.html?spm=a2700.galleryofferlist.topad_creative.d_image.76413eaeIUPdFw [Google Scholar]

- 49.Amazon.com/pea_protein, Amazon.Com: Prescribed for Life Pea Protein - Natural Non-GMO Canadian Yellow Pea Protein Concentrate Powder - 80% Protein, 2 Kg: Health & Personal Care. 2020. https://www.amazon.com/Pea-Protein-Natural-Canadian-Concentrate/dp/B07CZ3P4YN/ref=sr_1_3?crid=JWUE9KNNEQB7&dchild=1&keywords=pea+protein+concentrate&qid=1603194361&sprefix=Pea+Protein+Concent%2Caps%2C427&sr=8-3 [Google Scholar]

- 50.Henchion M., Hayes M., Mullen A., Fenelon M., Tiwari B. Future protein supply and demand: strategies and factors influencing a sustainable equilibrium. Foods. 2017;6:53. doi: 10.3390/foods6070053. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 51.Boye J., Zare F., Pletch A. Pulse proteins: processing, characterization, functional properties and applications in food and feed. Food Res. Int. 2010;43:414–431. [Google Scholar]

- 52.Peter R. University of Saskatchewan; 2018. Properties of Aqueous-Alcohol-Washed Protein Concentrates Prepared from Air-Classified Pea Protein and Other Air-Classified Pulse Protein Fractions.https://harvest.usask.ca/handle/10388/11054 [Google Scholar]

- 53.Toews R., Wang N. Physicochemical and functional properties of protein concentrates from pulses. Food Res. Int. 2013;52:445–451. [Google Scholar]

- 54.Görg A., Obermaier C., Boguth G., Csordas A., Diaz J.J., Madjar J.J. Electrophoresis. John Wiley & Sons, Ltd; 1997. Very alkaline immobilized pH gradients for two-dimensional electrophoresis of ribosomal and nuclear proteins; pp. 328–337. [DOI] [PubMed] [Google Scholar]

- 55.Xu M., Jin Z., Gu Z., Rao J., Chen B. Changes in odor characteristics of pulse protein isolates from germinated chickpea, lentil, and yellow pea: role of lipoxygenase and free radicals. Food Chem. 2020;314:126184. doi: 10.1016/j.foodchem.2020.126184. [DOI] [PubMed] [Google Scholar]

- 56.Ma Z., Boye J.I., Simpson B.K. Preparation of salad dressing emulsions using lentil, chickpea and pea protein isolates: a response surface methodology study. J. Food Qual. 2016;39:274–291. [Google Scholar]

- 57.Gorissen S.H.M., Crombag J.J.R., Senden J.M.G., Waterval W.A.H., Bierau J., Verdijk L.B., van Loon L.J.C. Protein content and amino acid composition of commercially available plant-based protein isolates. Amino Acids. 2018;50:1685–1695. doi: 10.1007/s00726-018-2640-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 58.Chew P.G., Casey A.J., Johnson S.K. Protein quality and physico-functionality of Australian sweet lupin (Lupinus angustifolius cv. Gungurru) protein concentrates prepared by isoelectric precipitation or ultrafiltration. Food Chem. 2003;83:575–583. [Google Scholar]

- 59.Stone A.K., Karalash A., Tyler R.T., Warkentin T.D., Nickerson M.T. Functional attributes of pea protein isolates prepared using different extraction methods and cultivars. Food Res. Int. 2015;76:31–38. [Google Scholar]

- 60.Wani I.A., Sogi D.S., Shivhare U.S., Gill B.S. Physico-chemical and functional properties of native and hydrolyzed kidney bean (Phaseolus vulgaris L.) protein isolates. Food Res. Int. 2015;76:11–18. [Google Scholar]

- 61.Malav O.P., Talukder S., Gokulakrishnan P., Chand S. Meat analog: a review. Crit. Rev. Food Sci. Nutr. 2015;55:1241–1245. doi: 10.1080/10408398.2012.689381. [DOI] [PubMed] [Google Scholar]

- 62.Kumar P., Chatli M.K., Mehta N., Singh P., Malav O.P., Verma A.K. Meat analogues: health promising sustainable meat substitutes. Crit. Rev. Food Sci. Nutr. 2017;57:923–932. doi: 10.1080/10408398.2014.939739. [DOI] [PubMed] [Google Scholar]

- 63.Asgar M.A., Fazilah A., Huda N., Bhat R., Karim A.A. Nonmeat protein alternatives as meat extenders and meat analogs. Compr. Rev. Food Sci. Food Saf. 2010;9:513–529. doi: 10.1111/j.1541-4337.2010.00124.x. [DOI] [PubMed] [Google Scholar]

- 64.Vatansever S., Tulbek M.C., Riaz M.N. Low- and high-moisture extrusion of pulse proteins as plant-based meat ingredients: a review. Cereal Foods World. 2020;65 [Google Scholar]

- 65.Applewhite T.H. 1989. Proceedings of the World Congress on Vegetable Protein Utilization in Human Foods and Animal Feedstuffs; p. 575.https://books.google.com/books?hl=en&lr=&id=CuARGRnPGKUC&oi=fnd&pg=PP14&dq=Proceedings+of+the+World+Congress+on+Vegetable+Protein+Utilization+in+Human&ots=JU8onTeQtF&sig=Rl8_ICOmlU3eS5n_BPK8OasjqiQ [Google Scholar]

- 66.Lusas E.W., Riaz M.N. Soy protein products: processing and use. J. Nutr. 1995 doi: 10.1093/jn/125.3_Suppl.573S. [DOI] [PubMed] [Google Scholar]

- 67.Brabin B.J., Hakimi M., Pelletier D. Imported from. J. Nutr. 2001;131:604S–615S. doi: 10.1093/jn/131.2.604S. https://academic.oup.com/jn/article/148/suppl_1/1001S/5033576 [DOI] [PubMed] [Google Scholar]

- 68.González-Pérez S., Arellano J.B. Handb. Hydrocoll. second ed. Woodhead Publishing; 2009. Vegetable protein isolates; pp. 383–419. [Google Scholar]

- 69.Riaz M.N. Handb. Food Proteins. Elsevier; 2011. Texturized vegetable proteins; pp. 395–418. [Google Scholar]

- 70.de Carvalho G.R., Milani T.M.G., Trinca N.R.R., Nagai L.Y., Barretto A.C. da S. Textured soy protein, collagen and maltodextrin as extenders to improve the physicochemical and sensory properties of beef burger. Food Sci. Technol. 2017;37:10–16. [Google Scholar]

- 71.Qammar G., Mohy-ud-Din G., Huma N., Sameen A., Issa Khan M. Textured soy protein (TSP) as pizza topping. Nutr. Food Sci. 2010;40:551–556. [Google Scholar]

- 72.Mota M.J., Lopes R.P., Koubaa M., Roohinejad S., Barba F.J., Delgadillo I., Saraiva J.A. Fermentation at non-conventional conditions in food- and bio-sciences by the application of advanced processing technologies. Crit. Rev. Biotechnol. 2018;38:122–140. doi: 10.1080/07388551.2017.1312272. [DOI] [PubMed] [Google Scholar]

- 73.Alhendi A., Yang W., Goodrich-Schneider R., Sarnoski P.J. Total inactivation of lipoxygenase in whole soya bean by pulsed light and the effect of pulsed light on the chemical properties of soya milk produced from the treated soya beans. Int. J. Food Sci. Technol. 2018;53:457–466. [Google Scholar]

- 74.Alhendi A., Yang W., Goodrich-Schneider R., Sims C., Marshall S., Sarnoski P.J. Sensory evaluation and flavour analysis of soymilk produced from lipoxygenase-free soya beans after modified processes and pulsed light treatment. Int. J. Food Sci. Technol. 2018;53:1434–1441. [Google Scholar]

- 75.Kumar Dixit A., Kumar V., Rani A., Manjaya J.G., Bhatnagar D. Effect of gamma irradiation on lipoxygenases, trypsin inhibitor, raffinose family oligosaccharides and nutritional factors of different seed coat colored soybean (Glycine max L.) Radiat. Phys. Chem. 2011;80:597–603. [Google Scholar]

- 76.de Barros É.A., Broetto F., Bressan D.F., Sartori M.M.P., Costa V.E. Chemical composition and lipoxygenase activity in soybeans (Glycine max L. Merr.) submitted to gamma irradiation. Radiat. Phys. Chem. 2014;98:29–32. [Google Scholar]

- 77.Vagadia B.H., Vanga S.K., Singh A., Gariepy Y., Raghavan V. Comparison of conventional and microwave treatment on soymilk for inactivation of trypsin inhibitors and in vitro protein digestibility. Foods. 2018;7:6. doi: 10.3390/foods7010006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 78.Kubo M.T.K., dos Reis B.H.G., Sato L.N.I., Gut J.A.W. Microwave and conventional thermal processing of soymilk: inactivation kinetics of lipoxygenase and trypsin inhibitors activity. LWT. 2021;145:111275. [Google Scholar]

- 79.Nawaz M.A., Tan M., Øiseth S., Buckow R. An emerging segment of functional legume-based beverages: a review. Food Rev. Int. 2020:1–39. [Google Scholar]

- 80.Nosworthy M.G., Franczyk A.J., Medina G., Neufeld J., Appah P., Utioh A., Frohlich P., House J.D. Effect of processing on the in vitro and in vivo protein quality of yellow and green split peas (pisum sativum) J. Agric. Food Chem. 2017;65:7790–7796. doi: 10.1021/acs.jafc.7b03597. [DOI] [PubMed] [Google Scholar]

- 81.Sá A.G.A., Moreno Y.M.F., Carciofi B.A.M. Food processing for the improvement of plant proteins digestibility. Crit. Rev. Food Sci. Nutr. 2019 doi: 10.1080/10408398.2019.1688249. [DOI] [PubMed] [Google Scholar]

- 82.Hefnawy T.H. Effect of processing methods on nutritional composition and anti-nutritional factors in lentils (Lens culinaris) Ann. Agric. Sci. 2011;56:57–61. [Google Scholar]

- 83.Kim T., Riaz M.N., Awika J., Teferra T.F. The effect of cooling and rehydration methods in high moisture meat analogs with pulse proteins-peas, lentils, and faba beans. J. Food Sci. 2021;86:1322–1334. doi: 10.1111/1750-3841.15660. [DOI] [PubMed] [Google Scholar]

- 84.Khan B., Singh P. The current and future states of Ethiopia’s energy sector and potential for green energy: a comprehensive study. Int. J. Eng. Res. Afr. 2017;33:115–119. [Google Scholar]

- 85.Atilaw A., Alemu D., Bishaw Z., Kifle T., Kaske K. Early generation seed production and supply in Ethiopia: status, challenges and opportunities. Ethiop. J. Agric. Sci. 2017;27:99–119. https://www.ajol.info/index.php/ejas/article/view/150369 [Google Scholar]

- 86.Geleta E.B., Henry C., Elabor-Idemudia P. “The pluses of pulses”: haricot beans and women’s empowerment in Ethiopia. Dev. Pract. 2018;28:311–317. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.