Abstract

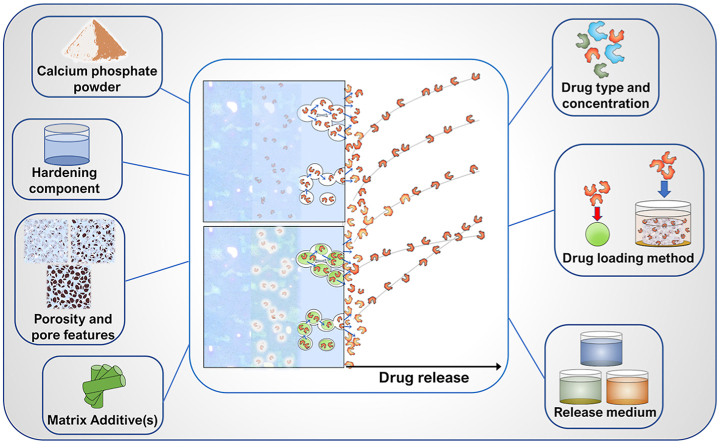

Thanks to their biocompatibility, biodegradability, injectability and self-setting properties, calcium phosphate cements (CPCs) have been the most economical and effective biomaterials of choice for use as bone void fillers. They have also been extensively used as drug delivery carriers owing to their ability to provide for a steady release of various organic molecules aiding the regeneration of defective bone, including primarily antibiotics and growth factors. This review provides a systematic compilation of studies that reported on the controlled release of drugs from CPCs in the last 25 years. The chemical, compositional and microstructural characteristics of these systems through which the control of the release rates and mechanisms could be achieved have been discussed. In doing so, the effects of (i) the chemistry of the matrix, (ii) porosity, (iii) additives, (iv) drug types, (v) drug concentrations, (vi) drug loading methods and (vii) release media have been distinguished and discussed individually. Kinetic specificities of in vivo release of drugs from CPCs have been reviewed, too. Understanding the kinetic and mechanistic correlations between the CPC properties and the drug release is a prerequisite for the design of bone void fillers with drug release profiles precisely tailored to the application area and the clinical picture. The goal of this review has been to shed light on these fundamental correlations.

Keywords: Calcium phosphate cements, Drug release, Release rate, Antibiotics release, Bone fillers

Graphical abstract

Highlights

-

•

Drug release from calcium phosphate cements (CPCs) for bone healing and regeneration.

-

•

Release of antibiotics, anti-inflammatories, chemotherapeutics, growth factors, and metallic ions.

-

•

Influence of different CPC formulations, matrix porosity, structure, and crystallinity.

-

•

Influence of matrix additives and the release medium.

-

•

Influence of the drug type, concentration and loading method.

1. Introduction

Bony tissues count among the least accessible ones in the human body. When pathological conditions such as osteoporosis, osteomyelitis, osteosarcoma, fracture or trauma occur, invasive surgery is required to remove the pathological tissue [1] and/or insert the prostheses or regenerative scaffolds [2,3]. Bone regeneration represents an essential step on the way to full postoperative recovery [[4], [5], [6]]. During the last 30 years, the paradigm of Bone Tissue Engineering has come to embrace an approach consisting of the following four key factors: (1) a biocompatible scaffold that closely mimics the extracellular matrix niche of the natural bone; (2) morphogenic signals that help to direct the cells to the phenotypically desirable types; (3) recruitment of osteogenic cells to lay down the bone tissue matrix; and (4) sufficient vascularization to meet the growing tissue nutrient supply and clearance needs [7]. According to this paradigm, an ideal material for bone regeneration consists in a scaffold made of biocompatible, bioresorbable material(s) that deliver morphogenic molecules such as bone morphogenetic proteins (BMPs) [8], transforming growth factor β (TGF-β), and/or others [9,10]. Furthermore, the first stage of a postoperative or posttraumatic event implies the inflammation of the tissue, which begins within the first 12 h, and should be completed by the approximately 7th day after the injury [11]. Moreover, the possibility of the surgical site contamination by pathogenic bacteria must always be accounted for [[12], [13], [14], [15], [16]], from which arises the need for the local and sustained delivery of anti-inflammatory and antibiotic molecules by the biomaterial. Starting from this assumption, it comes natural that during the last 30 years there have been countless studies devoted to the development of suitable biomaterials able to meet the mechanical and biological requirements for in-vivo implantation and also to be able to host and successively release drugs or molecules aiding the regenerative process.

Bone is an organ with widely varied mechanical properties and metabolic rates across different regions of its tissues, for which reason different release profiles prove to be ideal for each of these regions [17]. Long bones, for one, display a functionally gradient nature, shifting from the soft marrow in the centre to the relatively porous cancellous bone around it and the harder and less porous cortical bone near and on the surface. With the clearance rate of the released drug consequently decreasing with the distance from the central axis of long bones, the need for the tuning of the release rate to the exact implant location arises as imperative [17]. The goal of this review has been to describe the way different structural and compositional features of a particular class of materials known as calcium phosphate cements (CPCs) affect drug release characteristics. It is assumed that with such correlations established, the field of drug delivery to the bone would be brought closer to a state where biomaterials could be in situ adjustable to produce an ideal release kinetics for the physiological niche of the bone defect.

Among all the investigated materials falling into the category of bone void fillers [18,19], CPCs have been one of the most studied due to their exceptional biocompatibility and bioresorbability, but also due to their ability to host and release a variety of atomic and molecular substances, as exhaustively reviewed by Ginebra et al. [20]. Their injectability and ability to adapt to the geometry of the bone void defect site, allowing for a minimally invasive reconstructive surgery, presents another one of the exceptional traits of CPCs [21]. CPCs are synthesized in situ by mixing a powder and a liquid phase, after which they harden within minutes.

All CPCs belong to one of the two categories depending on the composition of their powder phase: 1) single-phase ones or 2) two-phase ones [22]. In the first case, a single calcium phosphate (CP) phase is mixed with a liquid phase to trigger the setting reaction, leading to the formation of either hydroxyapatite (HAp) as the most thermodynamically stable of all CP phases under the physiological conditions or dicalcium phosphate dihydrate (DCPD), a.k.a. brushite. Precursor phases in this case are metastable under the chemical conditions provided by the liquid phase and include CPs such as amorphous CP (ACP), α- or β-tricalcium phosphate (TCP) or tetracalcium phosphate (TTCP). The following reactions apply in this scenario for the stoichiometries of ACP and TCP (Eqs. (1), (3))) and of TTCP (Eq. (2)), forming either HAp (Eqs. (1), (2))) or DCPD (Eq. (3)):

| 10Ca3 (PO4) 2 + 6H2O → 3Ca10-x (HPO4) x (PO4) 6-x (OH) 2-x + 2H2PO4− + 2H+ | (1) |

| 3Ca4 (PO4) 2O + 3H2O → Ca10-x (HPO4) x (PO4) 6-x (OH) 2-x + 2Ca(OH) 2 | (2) |

| Ca3 (PO4) 2 + H3PO4 + 6H2O → 3CaHPO4 x 2H2O | (3) |

For the second type of CPCs, two concomitant CP phases are used in the powder phase, one of which is alkaline and another one acidic. The two typical combinations of such phases are that of TTCP and brushite (Eq. (4)) or α/β-TCP and monocalcium phosphate monohydrate (MCPM) (Eq. (5)), although other combinations are possible [22]. While the former combination yields HAp as the final product of the setting reaction, the product of the latter reaction is brushite.

| 2Ca4 (PO4) 2O + 2CaHPO4 → Ca10-x (HPO4) x (PO4) 6-x (OH) 2-x | (4) |

| Ca3 (PO4) 2 + Ca(H2PO4) 2 x H2O + H2O → 4CaHPO4 x 2H2O | (5) |

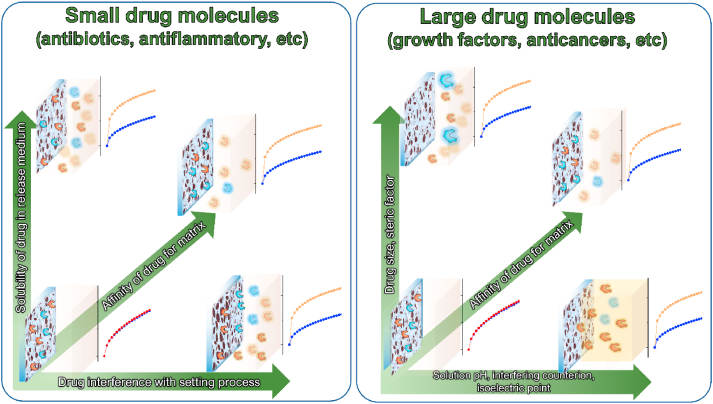

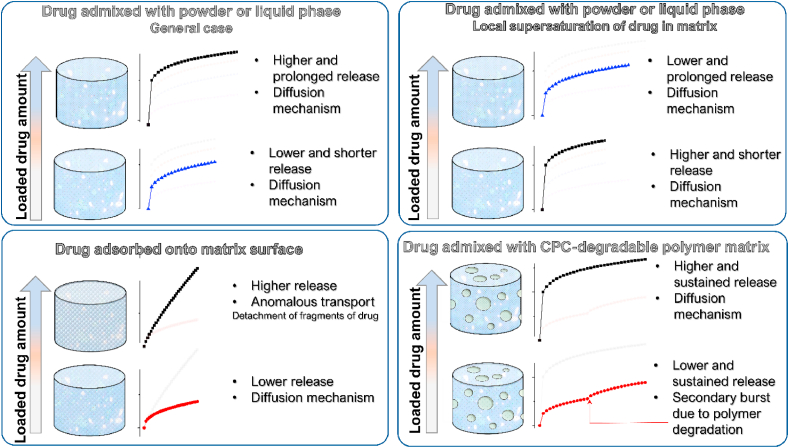

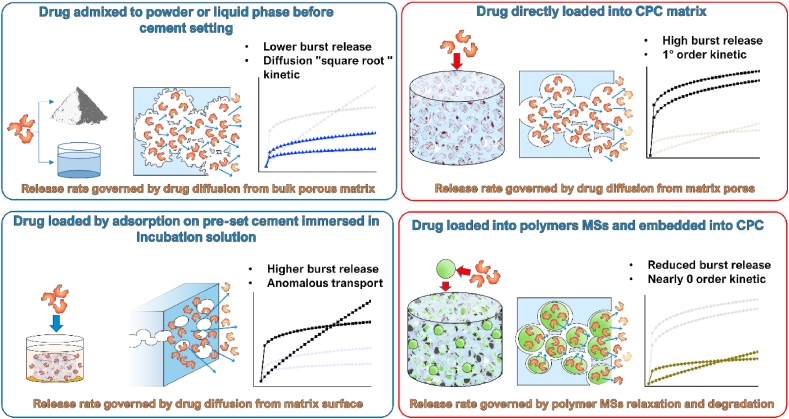

Since the first pioneering studies in the early 1990s, a number of works have been focused on drug release from CPC matrices and every successive study usually led to a more in-depth comprehension of drug release mechanisms and conditions. In order to provide a proper interpretation of the obtained results, theoretical and semi-empirical models were borrowed from the pharmacokinetic field [23,24] and successfully applied to CPC-drug release systems as tools for the qualitative and quantitative analysis of drug release from CPC matrices. Once the basic characteristics of the release mechanisms were established, numerous formulations of different CPCs were proposed as host matrices for different drugs. Several combinations of powder and liquid components of CPCs, their relative quantities, the use of additives, the large repertoire of drugs, drug loading methods and many other aspects of matrix-drug systems were experimented with in search of the most satisfactory release kinetics for a specific drug under the conditions relevant for its clinical application. The optimality of the drug release has been defined by different parameters, such as the initial burst release, the minimal and maximal released amounts, the total release period, the release rate and the release curve profile, which, in turn, are all derivatives of the overall release kinetics and mechanisms. The majority of literature reports have been focused on two main aspects of the drug release from CPC scaffolds: 1) the matrix component characteristics, including the chemical composition, porosity, crystallinity, and degradability, with or without the incorporation of supplementary phases or other additives; 2) drug-related studies, where different aspects of the drug have been investigated and the release effects of parameters such as the drug type, the loaded amount and the loading method have been considered. In addition to these two main aspects, some reports have been dedicated to the study of the effect of various environmental conditions, such as the release medium or in-vivo release, on the drug release kinetics.

Within this frame, this systematic review aims to collect the contributions to the specific field of drug release from CPC matrices in the timespan of the last 25 years. Due to the methodological difficulty of comparing different matrix-drug release systems, the inclusion of different scientific contributions to the present work was accomplished by selecting only papers that meet specific requirements: 1) the included work must show quantitative release data with at least 4 experimental points (except for Sec.8, which is focused on in vivo release) in order to properly define the release profile; 2) nearly all included articles include comparative results showing changes to the release curves due to variations in one or more characteristics of the release system, such as the drug type, the structural features of the CPC matrix (e.g., porosity, microcrystallinity, the additive concentration, etc.), the drug loading method, and/or others. In the present work, a lot of effort has been made to provide a clear division between the different characteristics of CPC-drug systems. This was done in the attempt to isolate individual structural or compositional effects on the release behaviour and to find a systemic and logical rationale as to what drives the different aspects of the release process. Despite all the effort, these variables defining the structure of the CPC matrix are always interrelated. Because it is not possible to draw distinct boundaries between these different, but intrinsically interconnected variables, some doubts are bound to remain with respect to what the key features defining the release kinetics are in each discussed case. This is especially true for systems where these key parameters are multiple, working in synergy. One example with respect to the matrix composition is that of the frequent impossibility of clearly demarcating the main component of the matrix from its extra component or an additive. Endless considerations could be made in this regard, but the final decision would depend on the chemical nature of the introduced extra component (such as a secondary CP precursor powder or a biodegradable polymer), its relative quantity and the homogeneity of its distribution within the cement matrix. Even after all these considerations and rationalizations, a very thin and rather blurred line will separate these individual aspects and the decision as to which of them is dominant will be, more or less, arbitrary.

Another question that is difficult to address is that of the classification of drug release systems to tailorable and tunable depending on their physicochemical makeup and release characteristics. In a study from 2016 [17], Uskoković et al. provided an etymological and functional classification of these terms. Nevertheless, doubts still persist when it comes to classifying a complex, multicomponent system into one of these categories based on the way their drug release kinetics has been reported in the relevant literature. One example comes from the release from CPC matrices with and without the inclusion of polymeric additives, such as chitosan or a polyester. Here, a hypothetic CPC with a fixed composition can be classified as a matrix for tailorable release, but the addition of a polymer in continuously varied amounts with, say, five different concentrations in the 1–5 wt% range, would render the system tunable. In this case, however, the tunability is due to the variations pertaining to an additive component of a CPC rather than to the core matrix, producing a sense of uncertainty as to whether the system is intrinsically tailorable or tunable. Despite all the unaddressed questions and ambiguities, the structure of this work is divided to sections individuating contributions of specific compositional and structural characteristics to the drug release process. These individual characteristics stand out as the most investigated aspects of CPC-drug release systems and the in-depth understanding of their contribution to the release rates can be a way of helping the researchers engage in the rational design of release kinetics for particular medical applications. In fact, the design of a bioactive CPC for use as a ubiquitous bone void filler requires comprehensive understanding of the factors governing the drug release, both alone and in synergy. Elucidation and elaboration of these factors from a qualitative standpoint and based on a complete survey of the relevant literature presents the central topic of this article.

1.1. Kinetic equations and the semiempirical model

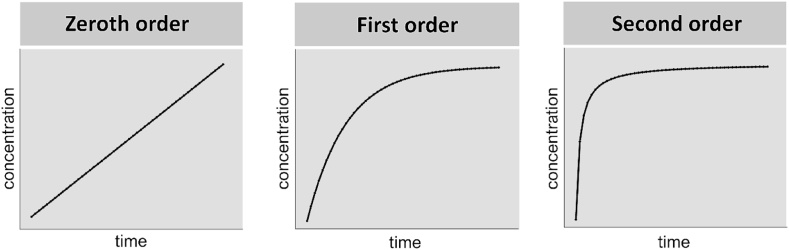

Works reported in this review make use of different equations and semiempirical mathematical models to quantitatively interpret the release outcomes. Fig. 1 schematically illustrates the three most common reaction orders of the physical release of drug molecules from the matrix, namely the zeroth, first and second.

Fig. 1.

Schematic illustration of the drug release profiles corresponding to the zeroth, the first and the second order of the reaction of release.

The zero-order kinetic equation is applicable when the dissolution of the drug is only the function of time and proceeds with irrespective of the concentration of the drug at any given time point. Mathematical representation of the zero-order equation is as follows:

where χi is the fraction of the dissolved drug at a given time t, and K0 represents the constant release rate that remains unchanged throughout the entire dissolution process.

The first-order kinetics describes the absorption/release of drugs, where the rate of the reaction linearly depends on drug concentration:

where m is the amount of adsorbed/released drug and k is the first-order rate constant. The integrated form of this equation from time t = 0 to a generic time t can be expressed as:

where m0 is the initial amount of the drug dispersed in the matrix and mt is the quantity of the drug released by time t.

The second-order kinetics implies a dependency of the drug release/adsorption rate on the squared value of the drug amount or concentration:

That could be represented in the integrated form as:

where k is a second-order rate constant and m0 and mt stand respectively for the initial amount of the drug and the amount of the drug released by time t.

Although the above-reported equations could provide accurate numerical solutions for many unidimensional and simple systems, they are of limited use for real, three-dimensional cases where the complexity and variety of environmental variables must be taken into account for the investigated systems to be modelled correctly. Moreover, there is never a straightforward and unambiguous way to extrapolate the information indicative on the release mechanism from these numerical solutions. To this end, a series of empirical and semi-empirical models and equations have been proposed for application on drug-release systems, as able to provide more realistic indications on the release kinetics and mechanism.

The Higuchi model was originally proposed in 1963 [25] to describe the rate of the drug dissolution from an ointment film. Afterwards, it was applied in a more extensive context, such as the drug release from tablets. The Higuchi equation is given as follows:

where χi is the fraction of the released drug by time t, A is the surface area of the tablet, D is the diffusion coefficient in the given medium, ε is the porosity of the matrix, τ is the tortuosity factor, C is the initial loaded amount of drug, and CS is the solubility of the drug in the release medium.

The Higuchi equation is often referred to as the “square-root” law due to the fact that the graphical representation of this relation can be linearized by reporting the fraction of the dissolved drug as a function of the square root of time (χi vs. t1/2). The Higuchi equation can be correctly applied only in systems that meet specific requirements and boundary conditions, including the following:

-

1)

The matrix contains an initial drug concentration much higher than the solubility of the drug;

-

2)

The diffusion is unidirectional because the edge effects are negligible;

-

3)

The thickness of the dosage form is much larger than the size of the drug molecules;

-

4)

The swelling or dissolution of the matrix is negligible;

-

5)

The diffusivity of the drug is constant;

-

6)

The perfect sink conditions are attained in the release environment.

Because of these abundant of requirements, this relation is often incorrectly applied in systems that do not strictly meet all of them. For this reason, all the deviations from the ideal conditions must be evaluated for a correct interpretation of the results to be reached.

A different semiempirical model was proposed by Korsmeyer et al. [26]. It is commonly called the Korsmeyer–Peppas or power law model:

The Korsmeyer–Peppas equation is a semiempirical model able to describe the drug release from polymeric or monolithic systems. In this equation, k is a parameter descriptive of all the geometrical and structural characteristics of the matrix, while n is related to the mechanism that governs the release kinetics. The value of the n factor generally indicates the release regime and for specimens with the cylindrical shape, as described in Table 1.

Table 1.

Interpretation of the Korsmeyer-Peppas exponent for cylindrical samples.

| Korsmeyer–Peppas model | ||

|---|---|---|

| n exponent value | Release regime | Release kinetic and mechanism(s) |

| 0<n < 0.45 | Hindered Fickian diffusion | Representative of systems characterized by diffusive regime with hampered release |

| n = 0.45 | Fickian diffusion (Case I) | Representative of first-order kinetic where diffusion is the main release mechanism |

| 0.45<n < 1 | Anomalous transport | Characteristic of those cases where in addition to the diffusion, other mechanisms contribute to the release of the drug |

| n = 1 | Non-Fickian transport (Case II) | Corresponds to a zeroth order kinetic and is typical of kinetics governed by phenomena of polymer degradation and relaxation or degradation/dissolution of monolithic systems (tablets, cements blocks) |

| n > 1 | Super case II | Extreme form of transport that usually occurs where severe modifications in the matrix take place |

2. General matrix features

2.1. General matrix features of pre-set CPCs

A very common approach utilized to adjust the drug release from CPC matrices consists in modifications of the powder phase, the liquid phase or both of them in the cement formulation. Several articles focused on this aspect of the control of the drug release, albeit with different objectives and results. Since the drug release rate is directly proportional to the rate of dissolution of the hardened cements, the control of this dissolution rate has been one of the methods to control the release rate, too.

In 1998, Otsuka et al. [27] investigated the effect of the geometrical features of the matrix on release characteristics. CPC tablets of the same thickness (2 mm), but different diameter (2, 4, 15 mm) were fabricated for this purpose. In vitro and in vivo release of indomethacin at different drug loadings from HAp-forming TTCP/DCPD cements set for 1 h was examined. Here and elsewhere in the text, the term “in vitro” refers to abiotic release conditions only occasionally supplemented by biomolecular species, but without containing any cells. In the case of the release of indomethacin, the release rate followed a linear relationship with the tablet surface area, indicating a diffusion-controlled release (at least during the first stage of the experiment), as confirmed by the solid fit with the Higuchi equation.

Several works investigated the direct or the indirect effect on drug release originating from the use of the liquid phase obtained by or with the addition of components known to have a retarding effect on the CPC setting process, such as the compound class of carboxylic acids [22]. In a work from 2007 [28], Alkhraisat et al. aimed to elucidate factors that determine the superficial degradation of brushite under conditions simulating the highly blood-perfused regions in bone. In order to improve the brushite stability, different cements were prepared using different aqueous solutions of phosphoric, glycolic, tartaric, and citric acids at adequate concentrations. The specimens were immersed in the incubation solution for either 1 min (phosphoric solution) or 2 min (carboxylic acid based solutions) after the start of the setting reaction. The weight loss was measured by comparing the direct weights of the dried particles before and after the release. The experimental evidence indicated that the weight loss was dependent on the liquid phase used: phosphoric > tartaric > glycolic > citric acid. Degradation behaviour of the cement obtained with citric acid was further investigated after the addition of 0.5% hyaluronic acid and 0.5% chondroitin-4 sulphate. Superficial disintegration was noticeably reduced for the cement prepared with hyaluronic acid. An analogue approach was used in a work from 2010 by Khasaba et al. [29] where several aspects of CPC obtained with the use different liquid phases were explored. Cements were prepared using the same powder phase (a mixture of monocalcium phosphate monohydrate [MCPM], CaO and synthetic HAp), but different liquids, namely the aqueous solutions of polyacrylic acid (PA), polyalkenoic acid or 35% (w/w) polymethyl vinyl ether maleic acid. While the former two cements exhibited an intense release of calcium during the first day of incubation, the latter cement was characterized by the controlled release for the entirety of the incubation period of 8 weeks.

Hemmati et al. in a work from 2014 further evaluated the role of ascorbic acid (AA) in the release behaviour of CPCs [30]. Different CPC matrices were obtained, containing different amounts of AA: 0, 50, 100 and 200 mg/ml. Release patterns of ascorbic acid in the simulated body fluid (SBF) solution were fitted with the power law model. The calculated k parameter decreased as the AA amount increased, indicating the formation of more compact microstructures within cements obtained at 100 and 200 mg/ml of AA. On the other hand, the n factor for the cement with 50 mg/ml AA was more than twice higher than the value obtained for higher concentrations of AA (0.38 vs. 0.15). The hindered diffusional release of AA from samples with 100 and 200 mg/ml AA could be ascribed to the strong interaction of AA with CPC, being more pronounced at high concentrations of the released species.

Akashi et al. in 2001 published a work [31] where CPC based on α-TCP was selected as a carrier for antimicrobial agents. Different powders (α-TCP, α-TCP + BaSO4) and liquids (water + sodium carboxymethyl cellulose, water + citric acid + tartaric acid + polycarboxylic acid) were mixed to obtain two different cements named type I and type II, respectively. Upon mixing, the cement cylinders were kept for 1 h in a humid environment and then immersed in the release medium. The release of metronidazole, cefaclor and ciprofloxacin from these systems was investigated. Cement I consisted of needle-like crystals of HAp, characterized by a higher porosity which allowed for a faster release of the drug. On the other hand, cement II was found to have formed mainly amorphous calcium salts, with tighter particle aggregates, entailing a slower release during the early time of incubation, albeit with the propensity to disaggregate dramatically at later time points, inducing a drug release driven by matrix degradation. Results achieved in this work, along with the ones presented by Alkhraisat et al. [28], provided an interesting insight into the role played by the chemical nature of the liquid phase of the cements and how they affect the setting process and, in turn, the drug release behaviour. First, they confirmed that carboxylic acids act in general as retardants of the setting reaction. As a consequence, due to an extended setting reaction, cements retain for a longer period their state of a mouldable paste. For drug release experiments, cement pastes were immersed in incubation solutions a few minutes after the mixing. Cement pastes could be considered as highly porous systems where constituent nanoparticles are weakly entangled to each other; hence, the incubation medium can easily diffuse within the matrix, enhancing the sink and consequently allowing for a burst effect and an increased drug release as long as the setting process is retarded. Nature of the liquid components can also affect the solubility of the matrix in the release medium. Ca release, one of the markers of cement degradation, can be explained in terms of the cement solubility, which is, in turn, dependent on the inner solubility of the carboxylic acid used in the liquid phase. It could be concluded that the higher the solubility, the higher the cement degradation and, consequently, the higher amount of the drug can be released from these systems. Finally, the influence of the liquid component on the final pH of the cement can be addressed. As reported by Khashaba et al. [29], the cement pH, especially at the initial stages of the setting process, can play an important role in drug dissolution. Thus, a more acidic environment achieved with the use of the modified polyacrylic acid tends to increase the release rate, whereas cements at a more neutral pH achieved with the use of polymethyl vinyl ether maleic acid in the liquid phase are characterized by a more controlled drug release.

The group of Irbe et al. in their work from 2012 [32] followed a similar protocol by creating cements with combinations of different powders with different liquids in order to clarify the effect on the release of lidocaine. They obtained 3 different cements, namely HAp-B, HAp-A and DCP/HAp, where DCP stands for dicalcium phosphates either in the anhydrous (DCPA) or dihydrate (DCPD) form, which were mixed with two different loads of lidocaine (30 and 50 mg). The DCP/HAp cement was characterized by a strong burst desorption with 80% of the loaded drug being released within the first 10 h. In contrast, for HAp-A and HAp-B cements, a sustained linear release allowed only 40% of the drug to be released during the first 24 h, ending with a complete exhaustion that occurred by the 3rd day. A parallel experiment confirmed that pH increased over time for all the matrices except for HAp/DCP, in which case it retained a relative high acidic level. This acidic environment was responsible for the higher solubility of the cement, which explains the faster release of the drug as its corollary.

A biphasic α-TCP/HAp cement was proposed in a work of Su et al. from 2013 [33] and studied as a carrier for gentamicin. Different gentamicin loadings (4, 8, and 16%) were included in the cement. Release experiments revealed two distinct stages in the release profile. During the first stage, a burst release was observed, with the dissolution of a relatively large amount of the drug. This phase was followed by the second stage with a slower and more sustained release. The authors explained this behaviour through the influence of the drug on the structural evolution of the cement matrix during the setting stage. It was deemed that sulphate group contained in gentamicin molecules hindered the phase transformation from α-TCP to HAp, as evident from the consequent lack of formation of needle-like or plate-like crystals, which, in turn, blocked the release of gentamicin. Therefore, a comparatively large amount of the drug was released during the first hours of the reaction, before this transformation had been completed. As gentamicin and, consequently, the sulphate ion, got released, the formation of needle-like structure was boosted, slowing down the release process.

2.2. General matrix features of in-situ setting CPCs

Several articles attempted to assess the effects that different stages of the setting/hardening process of the cements have on the release behaviour. In two works by Rau et al. from 2017 to 2019 [34,35], the releases of Cu and Fe ions, respectively, were considered. In particular, in Ref. [34], the authors investigated the release of the Cu ion from the Cu-TCP precursor powder and the corresponding Cu-TCP cement forming more soluble brushite. Unexpectedly, the release of Cu from the TCP powder was higher than that from the brushite cement at all the time points except the earliest, 1 h one. When the Cu content was normalized to the amount of the actively releasing phase in the material, the released amount continued to be higher for the precursor powder than for the cement, but the difference was no longer statistically significant. Both profiles were characterized by a comparatively intense burst release and a nearly zeroth order kinetic. Two articles by the group of Ginebra et al. focused on the comparison of fresh mixed CPC with pre-set CPC in terms of the release rate. In their work from 2013 [36], doxycycline (DOXY) was loaded inside both fresh CPC and 7 days old pre-set CPC and the release behaviour was investigated. The pre-set CPC was characterized by the diffusion-controlled release. The Korsmeyer-Peppas fit provided the k parameter that remain unchanged for the duration of the release experiment, serving as the evidence that no modifications of the microstructure occurred during incubation. The non-Fickian diffusion was defined by the calculated parameter n, which ranged between 0.49 and 0.58. For the fresh CPC, a different scenario was observed, with two distinct regions of release as a function of the incubation time. The initial stage showed a burst release and was followed by a second stage with a marked rate decrease, levelling to a zeroth order kinetic with sustained release of the drug. A correlation was found between the transition time between the two different kinetic regimes and the final setting time. The authors suggested that this correlation indicated the influence of the evolution of the CPC microstructure on the release pattern. It was hypothesized that during the setting reaction, precipitation of calcium-deficient HAp (CDHA) nanocrystals occurs, filling the space previously occupied by the liquid containing the drug molecules. This resulted in an increase of tortuosity, which hampered the drug mobility, hence decreasing the release rate.

The use of the cement at different setting times can allow for modelling the release behaviour of clinically applicable injectable cements at different stages of setting and hardening. Therefore, in the follow-up work from 2015, Mestres et al. [37] focused their attention on a brushite cement matrix prepared at different times: 3 min (fresh cement) and 1 h and 15 h as pre-set cements. Simvastatin was selected as the model drug and loaded onto the abovementioned cements. The release curves were fitted by the Korsmeyer-Peppas model. The release of the drug from the 3 min and the 1h set cements showed a burst release during the first 8 h and a slower dissolution for the remaining 4 days, while the 15h cement was able to provide a sustained elution for the whole incubation period. Fitting parameters allowed to conclude that the transport mechanism was anomalous, with the corresponding n value of 0.77. By knowing the n value, it was possible to calculate the k parameter for all the examined CPCs and their evolution with time. The initial k values (k3min > k1h > k15h) were inversely related to the tortuosity factor, as could be expected from the difference between the fresh, yet-to-be-set cements and the pre-set ones. Plotting k values as a function of time highlighted the fast change occurring to the microstructure of the 3min cement with a concomitant increase of tortuosity. The 1h cement showed a slower evolution of the k value with time. Interestingly, all the k values of different cements converged at almost the same value at the end point of the release experiment, confirming the similar structural nature of the same cement investigated at different elapsed setting times.

In a work from 2016, the Uskoković group [38] showed the possibility to obtain an injectable cement with an adaptive drug release. For this study, two basic powders, HAp1 and HAp2, were taken as basic components of the cement formulations and were combined in different proportions, including HAp1:HAp2 0:100, 50:50, 85:15, and 100:0. HAp1 was prepared by the slow precipitation, while HAp2 was precipitated abruptly. The peculiarity of these two main components was that HAp2 was able to retain its amorphous state after being mixed with a liquid and before reprecipitation in a crystalline form. On the other hand, HAp1 tended to return fast to its original crystalline state. The release experiments were carried out by loading the cements with vancomycin and ciprofloxacin as model drugs. The drug dissolution patterns demonstrated that HAp2 was characterized by the high burst release and fast drug exhaustion. An opposite behaviour was observed for HAp1. Mixed component cements possessed hybrid behaviours and the release rate was directly proportional to the fraction of HAp2 used. Explanations given by the authors referred to a number of thermodynamic considerations, such as the surface energy and solubility of precursor powders with respect to their crystalline or amorphous conditions. The follow-up article from 2019 [39] focused on elucidating the characteristics of this mechanism of drug release in the same system of cements comprising HAp1 and HAp2 at different proportions. Basic considerations for the investigated cements were the same as in the previously described work [38]. This time, however, the kinetic analyses aimed to decipher the key aspects of the mechanism involved in the release process. The Korsmeyers-Peppas model was employed and the author demonstrated that by plotting the k parameter vs. HAp1/HAp2 ratio in the cements, a strong increase of the k value is observed, suggesting that the microstructure of HAp2 allows for a faster and in many scenarios more favourable release. The analogue plots of n values for the release of vancomycin demonstrated a decrease of this exponent with the HAp2 content, indicating a transition from the anomalous transport to a more common Fickian diffusion. The opposite occurred in the case of ciprofloxacin, with the n exponent increasing with the HAp2 content, suggesting that the nature of the drug can influence not only the release rate, but also the mechanism of release.

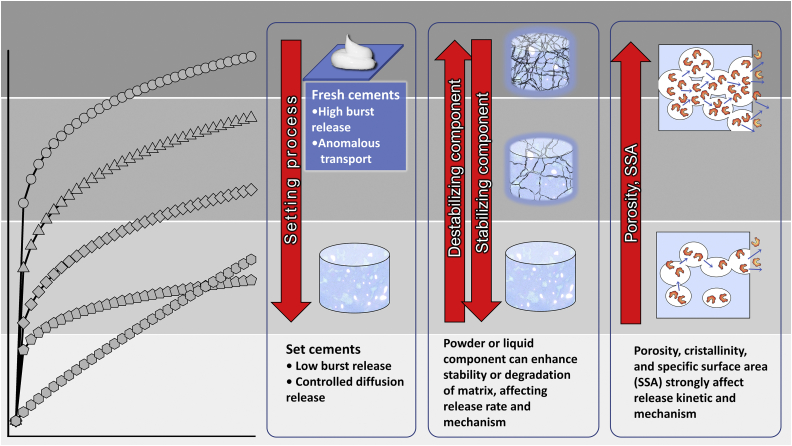

In a work from 2018 by Uchida et al. [40], a comparison between the release of vancomycin from CPC and from non-biodegradable poly(methyl methacrylate) (PMMA) was reported for both in vitro and in vivo conditions. In the in-vitro experiment, the drug release was consistently more copious from the CPC carrier than from the PMMA one and this difference in release increased constantly with time for 56 days. A comparison of the release from TCP and HAp granules was the objective of a work from 2019 by Son et al. [41]. Gentamicin sulphate was used as the model drug and its dissolution was studied using a matrix obtained from granulated TCP or a mixture of HAp and TCP particles. Three release systems were studied, where gentamicin sulphate was dispersed inside: 1) TCP granules, 2) TCP-HAp granules, and 3) the setting agent, i.e., water. The most optimal release rate was obtained when the drug was dissolved within the matrix composed of a mixture of TCP and HAp. This system showed a constant and sustained release for a period of 140 h. The authors supposed that the presence of HAp granules, which are characterized by a remarkably reduced solubility in comparison to TCP, makes the cement less prone to degradation during the setting reaction. The intrinsic stability of HAp granules helped to protect the loaded gentamicin, allowing for a more prolonged and sustained release of the drug over 144 h. Moreover, the presence of HAp granules can lead to the formation of DCP, which is characterized by an increased porosity and consequently enhanced release. In general, notwithstanding the ever-present physical effects, the drug release rates are expected to be directly proportional to the solubility of the CP phase(s) that the CPC evolves into. This conclusion can be drawn in spite of the fact that studies specifically comparing the phase-dependent kinetics of drug release from CPCs have not been conducted to date, with the exception of studies indirectly addressing this issue that were mentioned here. Considering all the effects summed in this section, Fig. 2 schematically represents the inducible trends, referring specifically to the effects of matrix degradability, freshness and microstructural properties on the kinetics and the mechanism of drug release.

Fig. 2.

Schematic description of the effect of the cement matrix features on the drug release rate and mechanism: in the first panel from the left, a fresh cement (higher release rate with possible anomalous transport) is compared with a set cement (lower rate and diffusional transport). In the second panel in the centre, a degradable matrix (higher release rate with possible anomalous transport) is compared with a non-degradable matrix (lower rate and diffusional transport). In the third panel from the left, the effects of porosity, crystallinity, and specific surface area, all of which increase the release rate, are reported.

3. Porosity and pore features

Porosity and pore features clearly represent one of the most important properties of CPC matrices, along with their chemical nature. Suitable porosity of carriers allows to host a relatively large amount of the drug within the cement, assuring at the same time the possibility of unhindered adsorption and desorption of the hosted molecules. Many authors have attempted to gain an insight into the specificity of the influence of porosity of the host matrices on the release process and several works reported possible methods for inducing, enhancing and tailoring the pore features for an optimal release. In a work from 2010 by Haghbin-Nazarpak et al. [42], the release of gentamicin sulphate from a biphasic cement (β-TCP and MCPM) was investigated. The release profile showed that the process proceeded in two different stages: in the first stage, lasting for approximately 10 days, the drug distributed along the cement surface was released at a relatively high rate. Degradation of the cement occurred in parallel with this initial release stage. Cracks and macropores with dimensions ranging in microns appeared across the cement matrix volume, causing a sudden burst release of about 15% of the drug load. From day 10 to day 15, no further release of the drug was observed, determining the end of the release.

In their work from 1997 [43], Otsuka et al. investigated the effect of sodium bicarbonate addition on the release behaviour of indomethacin from a carbonated apatite cement. Four samples were prepared by increasing the amount of NaHCO3 porogen (0%, 2%, 5%, 10%). A microporosity distribution study revealed that the pore size increased after the drug release. The amount of NaHCO3 strongly influenced the pore dimensions and, thus, the release process, with larger pore radii corresponding to the higher amounts of NaHCO3. The authors explained this effect by an augmented solubility of carbonated apatite, producing increasing amounts of pores at higher NaHCO3 contents within the matrix. However, the sublimation of the dissociated carbonates in the form of CO2 must have also been responsible for the pore formation. Variations in the pore size distribution strongly affected the release rate, which increased together with the pore size. The release curves indicated a diffusion-controlled process characterized by a sustained release with an increasing rate in direct proportion with the amount of NaHCO3 introduced. In the case of 10% NaHCO3, however, the enlargement of pores was so pronounced that it led to a burst release of nearly 100% of the loaded drug within the first 10 h. A similar approach was used in a work from 2009 by Girod-Fullana et al. [44]. In this case, the release system consisted of pectin-microspheres loaded with ibuprofen as the model drug. The microspheres were incorporated within the CPC matrix at different ratios, namely 2%, 4%, and 6% w/w, in order to explore the influence of the amount of microspheres within the composites on the release process. The total porosity and microporosity were measured for all the composite samples and it was found out that they both increased with the microsphere content, from 0% macropore volume fraction for 0% microsphere content to 29% at 6% microsphere content. Results from the release experiments showed a Fickian diffusion regime from all the composites, with the release lasting for at least 45 days. Unexpectedly, the release rates were higher for composites with the lower amounts of microspheres and, consequently, lower porosities. The authors proposed two possible explanations of this phenomenon: 1) the confinement of the drug could have induced local concentration pockets exceeding the solubility level, resulting in a slowed release; 2) the ability of pectin to form a gel, as a result of which some microspheres could have undergone swelling and filled some of the intrinsic pores of the CPC, thus reducing the real porosity.

Different groups have investigated the influence of the powder-to-liquid (P/L) ratio used during the mixing process on porosity and the possibility of using this parameter to tailor the drug release rate. In their work from 2009 [45], Hofmann at el. aimed to investigate the possibility to produce a near zero porosity matrix in order to prevent the burst release of antibiotics from CPC matrices. They studied the release of vancomycin and ciprofloxacin from CPC formulations created with different P/L ratios (2.5 g/ml and 4.0 g/ml). The porosities for these two formulations were 18% and 38%, respectively. Cumulative drug release curves demonstrated that for both drugs, the release rate was greater for the P/L ratio of 4.0 than for that of 2.5, with no apparent modification of the diffusion regime. Therefore, these results conform to the notion that the release rates should increase with the total porosity of the matrix. In a paper from 2011 [46], Schnieders et al. examined the effect of the CPC porosity on drug release by varying the drug loading method, that is, by either directly loading the drug onto the CPC matrix or by encapsulating it into a biodegradable poly(lactic co-glycolic acid) (PLGA) copolymer subsequently incorporated into the CPC matrix. In order to modulate the sample porosity, different P/L ratios were employed and five different CPC formulations were created, with the P/L ratios of 2.0, 2.4, 2.7, 3.0, and 3.3 g/ml. The porosity increased almost linearly with the liquid content, i.e., reciprocally with the P/L. In the case of a system with the drug directly dispersed into the CPC, the release rate and the initial burst release increased inversely with respect to the P/L ratio. Results from the system with the drug loaded via PLGA microspheres showed a prolonged release and a decreased burst release for all the formulations as compared to those involving the direct drug loading. A more interesting insight was provided when the Higuchi model was used to fit the experimental data. While in the case of the direct loading of the drug, a good correlation was found between the Higuchi coefficient and the CPC porosity, in the case of the drug encapsulated in PLGA microspheres, no correlation could be established, suggesting that in the latter case the drug release was kinetically controlled by diffusion from the microspheres, drastically reducing the dependence of the drug release rate on the matrix porosity. Similar conclusions were drawn in the 2013 paper by the group of Ginebra [36]. In this work, a series of experiments was designed and conducted to determine how different variables affect the drug (DOXY) release, either singularly or in a synergetic manner. Focusing on the porosity factor, the authors investigated the characteristics of two CPC matrices with different liquid-to-powder (L/P) ratios: 0.35 and 0.65 ml/g. Open porosity measurements showed a greater mean pore size for samples richer in liquid (L/P of 0.65). As expected, a higher release rate was found for cements with a higher L/P ratio.

The group of Otsuka reported many works which share the same approach to induce the porosity in a CPC matrix. In these works, pre-set CPC blocks containing drugs were used as matrices and series of macropores were mechanically created in the blocks with the use of several stainless steels needle-like male dies arranged in a multi-cross manner in a regular 3D pattern along the blocks and then removed. In these papers [[47], [48], [49]], an identical methodology was used to investigate the effect of mechanically induced macropores (radii of 300, 500 or 600 μm) on drug release. Different cement blocks with an increasing number of cross-arranged macropores (0, 20, 40, 60) were used for the release experiments. Each block contained the same amount of the drug. The release patterns brought to light a direct relation between the number of macropores and the release rate. All the release patterns showed the diffusional trend, for which reason a Higuchi plot was used for fitting and relative Higuchi constants were calculated from these analyses. The calculated Higuchi constants were plotted as a function of the number of macropores or the corresponding specific surface area. In all cases, the experimental data were fitted well by a linear regression with a high regression coefficient, thus establishing the possibility to obtain CPC blocks loaded with different drugs with a desired release rate. In two articles from 2013 [50,51], Hesaraki et al. evaluated the possibility of inducing macroporosity in a CPC matrix by the addition of sodium dodecyl sulphate (SDS) as a surfactant. In Ref. [50], the release systems were obtained by the combination of different amounts of SDS (0, 20 and 100 mM) with different doses of cephalexin monohydrate (CMH) loaded into the cement as the drug (0, 1, 5, 10 wt%). The release was observed for over 300 h. The release curves of different systems revealed an interesting influence of the induced macroporosity on the release patterns. During the first 10 h of the release, a diffusion-controlled regime was observed and the release rate was higher when larger amounts of SDS were added to the system and more macropores were produced. Fitting these results with the Higuchi model yielded a good correlation. In the time interval of 24–300 h, deviation from this behaviour was observed, with the release being linearly dependent on time, following zeroth order kinetic profile. This deviation was attributed to the degradation of the CPC matrix, the regimen under which the release rate was no longer related to the matrix porosity. In the second work by the same group [51], the authors explored the release behaviour of demaxothasone (DEX) from porous CPCs. The experimental setup was similar to the previous one, involving the fabrication of porous CPC matrices by the addition of SDS (0 mM and 100 mM) combined with different drug dosages (0, 10, 50, 100 nM). It was observed that the addition of SDS led to an increase in macroporosity by 13–16%, with a concomitant reduction of the micropore volume relative to the SDS-free CPC. Release profiles of all the systems showed a diffusion-controlled release, with the higher rate of release corresponding to the higher amount of SDS and DEX. The release curves were fitted with both the Weibull equation and the Korsmeyer-Peppas model. The fitted parameters suggested that while macro- and micro-porous matrices shared the same release mechanism, (the differences between n values or d values were not statistically significant), a significant difference was observed for the k and t constants, which are dependent on the geometrical and physical characteristics of the matrix. The authors inferred that these differences could be attributed to the matrix modifications induced by porosity. Based on the results of this study, it could be concluded that the introduction of macropores into a microporous CPC can be a route to increasing the release rate in direct proportion with the concentration and the average size of the macropores introduced. In a work from 2013 by Vorndran et al. [52], the authors proposed an injectable, ready-to-use CPC paste as a bone filler with drug carrier properties. CPC pastes were created using an oil-based compound as the liquid phase. Characteristics of this oil-based cement were compared with its water-based analogue. The water-based CPC reference showed a total porosity of 42%, which was higher than the oil-based porosity of about 20%. The average pore diameter was 15 nm for the water-based cement vs. 25–30 nm for the oil-based one. The release profiles demonstrated a faster release for all the oil-based CPCs despite their lower total porosities, while the Korsmeyer-Peppas fit indicated that the dissolution of the drug occurred under a diffusion or diffusion/degradation regime. This was attributed to the larger pores that characterized the oil-based cements. The pore enlargement was related either to the dispersion of the aqueous solution within the cement or to the dissolution of the solid drug contained in the cement.

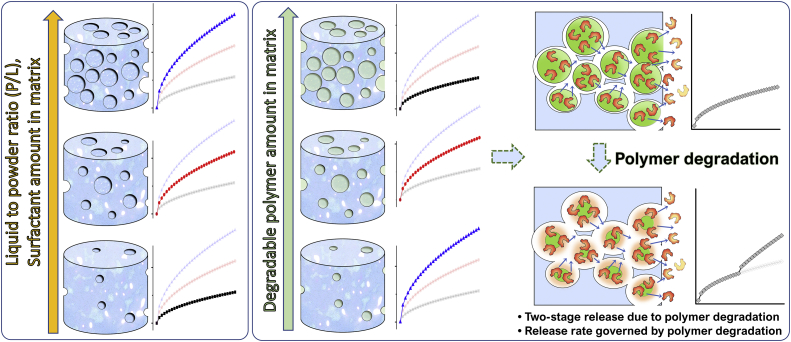

In the aforementioned article by the group of Uskoković from 2016 [38], which was focused on the preparation of a CPC matrix with a tunable release profile, several parameters were taken into account in order to discern the role of each in defining the release behaviour of two different antibiotics: vancomycin and ciprofloxacin. The investigated systems consisted of various combinations of two different HAp powders: HAp1, with higher crystallinity, relatively low porosity (42%) and a lower release rate; and HAp2, mostly amorphous, but with a higher porosity (55%) and a strong propensity for drug release. The experimental evidence revealed a parallel increase in the release rate for both drugs and the porosity, which increased with the relative amount of HAp2 in the hybrid cements. In a recent work from 2020 by Lucas-Aparicio et al. [53], a TCP-based CPC with an extensive accommodation of Si in the matrix was studied as a potential carrier of drugs able to provide a constant release with the minimal burst effect. Characterizations were conducted on the cements with different amounts of Si: 0, 40 and 80% of the stoichiometric Si substitution. It was observed that the total porosity and the average pore size decreased with the introduction of Si, while the specific surface area increased with the Si content. The increment in the Si content led to substantial changes in the release profiles: from the first-order release in the cases of 0% and 40% Si to the zeroth order release in the case of 80% Si. Furthermore, the cement with 80% Si substitution showed a negligible burst release. The authors ascribed this interesting result to the nanometric nature of the pores, which is capable of producing a greater tortuosity and becoming a key control factor for the drug diffusion. Clearly, when the dimensions of the pores are comparable to the dimensions of the drug molecules, the effect of the pore size is more intense than when the pores are significantly larger than the drug molecules, in which case the latter can freely diffuse out of the pores and the release is controlled more by diffusion than by the structural factors [54]. It could be concluded that the drug transport mechanism is strictly related to the relation existing between drug molecules and pore dimensions. Properly tuning the pore size to drug dimensions (i.e., few nanometers for small-drug molecules and tens of nanometers for large-drug molecules) makes it possible to establish a non‐Fickian diffusion driven regime at the molecular scale, where suitably sized pores allow for a single molecule release at a time, resulting in a concentration-independent, zeroth-order kinetic. Conversely, when pore sizes largely exceed the drug molecule dimensions, the stream release of the drug can occur, giving rise to the Fickian diffusion regime and the burst effect [55]. Fig. 3 schematically summarizes the different effects through which the porosity in CPCs affects the drug release rate and mechanism.

Fig. 3.

Schematic illustration of the effect of porosity on the release rate. In the left panel, the general case is represented, where increasing porosity (tunable with different approaches) corresponds to higher release rates. In the right panel, the case of porosity induced by the inclusion of a polymer in the matrix is reported. In this case, the release rate is governed by the polymer relaxation and degradation and by the subsequent drug diffusion from within the bulk of the cement, with lower release rates corresponding to the higher contents of the included polymer. When the polymer undergoes degradation, the second stage of sustained drug release takes place.

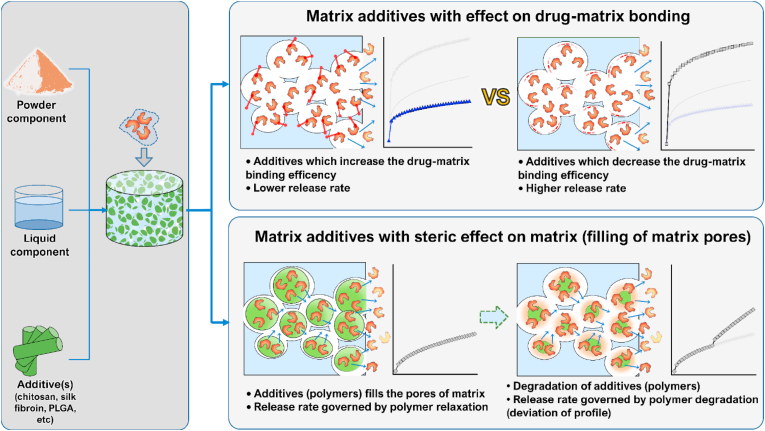

4. Matrix additive

A relatively easy method to control the drug release by the addition of polymers into the CPC matrix was reported by Wang et al. [56]. In this paper, a CPC powder was mixed with different polymers, such as mannitol crystals or salicylic-acid crystals. These additives induced macropores in the matrix and were used to enhance the release rate of growth factors. A curve showing the release of TGF-β1 from the CPC/(salicylic acid) composite was presented. Dissolution of the drug occurred with the first-order kinetic and a sustained release for over 800 h was observed.

In a work by Takechi et al. from 2002 [57], the release of an antibiotic, flomoxef sodium, from a CPC matrix modified with anti-washout chitosan was observed. Different amounts of the polymer were added to the cement to decipher its effects on the release of the drug. The release curves were obtained from cements containing 0%, 0.5% and 1% of chitosan. In the first stage, which lasted 24 h, the release was higher for the cement with the lowest amount of chitosan. After 24 h, the saline buffer was fully replenished and the release started again with diminished magnitude but inverse behaviour, specifically with a higher release rate from cements containing higher concentrations of chitosan. All profiles at both stages were characterized by a diffusion-controlled profile. The authors explained that in the first stage chitosan might have filled the pores of the cement matrix, thus promoting the retention of the drug. When the saline buffer was substituted, however, the cements with higher amounts of chitosan, now containing larger amounts of the retained drug, began to release the drug at a higher rate.

A brushite-chitosan matrix system was presented in a work from 2009 by De la Riva et al. [58] as a carrier for growth factors, specifically vascular endothelial growth factor (VEGF) and platelet-derived growth factor (PDGF). A small cylindrical chitosan sponge was first synthesized and PDGF and VEGF were included in it as components of either the liquid phase or alginate microspheres, respectively. The sponge was, in turn, incorporated inside a brushite cement, resulting in two variants of the drug-containing brushite-chitosan scaffold. Both drugs were released with a diffusion-controlled kinetic. During the first 24 h, 45 and 13% of PDGF and VEGF was released, respectively. After this initial burst release, the release of PDGF reached 70% after two consecutive weeks, while 64% of VEGF was delivered during the following 3 weeks. These results confirmed the ability of chitosan to slow down the drug release. Whereas the drug molecules adsorb mostly onto the surface binding sites on brushite grains, they get incorporated deeper into the carbonaceous network of chitosan, explaining its ability to lower the release rate by extending and complicating the escape path for the drug molecules.

The development of chitosan/HAp scaffolds was accomplished for the delivery of basic fibroblast growth factor (bFGF) and reported in an article by Tığlı et al. [59]. Two scaffolds were prepared, with 2% and 3% (w/v) of chitosan in the reaction solution and 1.25% (w/v) of HAp granules. bFGF was inserted into the scaffolds using the solvent sorption method. The release curves for both formulations indicated a hindered release rate and extended dissolution process due to the presence of HAp in the matrix, but also the faster release from the scaffold prepared at the higher concentration of chitosan. This has hinted at the possibility of controlling the release rate from CPCs through modulation of the concentration of the polymer in the reaction solution. Experimental data were fitted with the power law model. The anomalous transport characterized the release of bFGF from these HAp/chitosan scaffolds, indicating that the absorption of water and swelling-controlled diffusion were the key mechanisms of bFGF release.

In a study reported in by Lode et al. [60], the release kinetic of a CPC functionalized with VEGF was explored. The modified CPC matrices were obtained through the use of different combinations of additives. Namely, the precursor powder was mixed with 2.5% (w/w) mineralized collagen I (BioD/coll) and either 48 g/g trisodium citrate (BioD/coll/cit) or 25 mg/g O-phospho-l-serine (BioD/coll/PS). A total of three modified cement matrices were thus obtained and the release profiles for VEGF under abiotic cell culture conditions (37 °C, 5% CO2) were investigated. The profiles for each of the three different formulations showed a diffusion-controlled kinetic. Also, all the variants that included collagen (coll) showed an increased initial burst. Collagen stands for one of the most used organic additives in CP composites. Its addition into CPC precursors induces the formation of complexes with Ca2+ ions [61] and a slight delay in the setting time [62]. The tendency of collagen to increase the burst release can be explained by the ability of this macromolecule to decrease the binding efficiency of CPC for VEGF, with a consequently higher amount of unbound VEGF molecules free to diffuse out of the matrix. This stage was followed by a slower release for the remaining 7 days. The BioD/coll/PS formulation did not show a significant change with respect to the pure collagen variant. On the contrary, a decrease in the release rate was observed for the variant with trisodium citrate (BioD/coll/cit). The authors suggested that trisodium citrate could enhance the negative surface charge of the cement, thus leading to an increased electrostatic affinity for VEGF and its stronger binding to the CPC. However, for all the formulations, a markedly slowed release was registered after 7 days, with the cumulative release of 25% in the case of BioD/coll and BioD/coll/PS and 15% in the case of BioD/coll/cit.

Li et al. [63] studied the release of the salmon calcitonin (S-CT) from a CPC modified with organic phases such as chitosan oligosaccharide (CO) and collagen polypeptide (CP). Four different cements were prepared with different amounts of the CO-CP organic phase: 0%, 5%, 10% and 15% w/w. The release of S-CT from these composites was observed for 60 days. For all the formulations, two stages of the release, characterized by different rates, could be individuated. While the unmodified cement displayed a higher release rate during the first 7 days, after this time point the CO-CP modified cement showed an increased rate, where the magnitude was proportional to the CO-CP content. This is thought to be due to the filling of the matrix pores by the organic phase in the first stage of the release. During the incubation period, polysaccharides tended to dissolve, leaving open channels inside the cement matrices and allowing for a higher release of the drug. A nearly zero-order kinetic was observed, with a constant and sustained release for both stages during the whole duration of the experiment.

A CPC composite modified by the addition of 0.5% of alginate was tested as a drug carrier for gentamicin by Chen et al. [64]. The release profiles of unmodified and modified cements were compared. The addition of alginate strongly mitigated the initial burst release, which changed from 70% during the first 24 h in the unmodified cement to 51% in the modified cement. In general, a slower and more controlled release of the drug was obtained with the modified cement. According to the previous literature data, this could be explained by the selective interaction of gentamicin with the mannuronic residues of alginate. For both variants, a complete depletion of the drug was observed after one week. Finally, the addition of alginate did not modify the shape of the release profiles, which were in both cases kinetically controlled by diffusion.

Colpo et al. in their work from 2018 [65] aimed to elucidate the mechanisms governing the in-vitro release of different drugs from two different CPC matrices: 1) a cement obtained from the pure α-TCP precursor and 2) a cement obtained from the α-TCP powder with the addition of 10 wt% acrylamide polymer (α-TCP DS powder). Four different molecules were selected as model drugs for release experiments: gentamicin sulphate, lidocaine, bupivacaine, and levobupivacaine hydrochloride. A total of 2 (matrices) x 4 (drugs) = 8 experiments were carried out. Firstly, XRD results for all the investigated systems allowed to conclude that the drugs did not interfere with the setting process and that the final composition of all the cements consisted of a mixture of α-TCP, β-TCP and CDHA. The release experiments were carried out by immersion of cement cylinders in 10 ml phosphate buffer saline (PBS) solution at pH 7.0 and 37 °C for a total duration of 90 days. Similar profiles characterized all combinations of matrix/drug systems, with a burst effect occurring within the first 200 h followed by a reduced and sustained release rate. Except for the lidocaine case, all other systems showed a higher release from the matrix obtained with the 10 wt% acrylamide addition. Three different mathematical models were applied to the release experimental profiles in order to determine the release kinetics and mechanism: 1) Higuchi equation, 2) Korsmeyer–Peppas equation and 3) Peppas–Sahlin equation. The best fit with the experimental data was achieved with the use of the Peppas–Sahlin model. Comparison of n exponents of the Peppas–Sahlin equation for the same released drug and different matrices revealed that higher n values (within the 0.33–0.51 range) characterized the release from the α-TCP DS cement, indicating that the Fickian diffusion was the prevalent mechanism, with a minor contribution of the anomalous transport. The authors concluded that the latter contribution can be attributed to the chain relaxation of acrylamide and the consequent formation of hydrogel, which explains the higher release rate.

Multi-walled carbon nanotubes (MWCNTs) with carboxylic moieties were employed in a work by Lin et al. [66] to reinforce a monetite-based cement and develop a suitable carrier system for MG132, a small peptide molecule used for the inhibition of NF-κB-mediated osteoclastic resorption. Indirect measurements of the MG132 release were extrapolated from the luciferase assay conducted for a period of 28 days. It was observed that the MWCNT introduction decreased the burst release of MG132 and induced a more sustained release as compared to the unmodified CPC cement. Moreover, the pharmacological activity of MG132 was preserved for up to 28 days.

Wang et al. [67] investigated the reinforcement of an α-TCP-based cement by the introduction of silk fibroin. Semaphorin 3A (Sema3A) was loaded inside chitosan microspheres (Sema3A/CMs). Thus loaded microspheres were incorporated inside the cement/silk fibroin composite, yielding Sema3A CMs/SF/α-TCP. The release of Sema3A from this delivery system was investigated. The initial burst effect was observed during the first days of incubation. Thereafter, a continuous and sustained release of Sema3A was observed with a nearly zero-order kinetic. The authors did not provide any evidence of polymer (chitosan) degradation, for which reason the low burst effect along with a controlled zeroth order kinetic release could be considered to be in agreement with other results where the release kinetics of the drug encapsulated in polymeric microspheres is governed by the polymer relaxation.

In a work from 2016 by Zhang et al. [68], experimental orthodontic cements were prepared and characterized. To prepare these cements, the particles of ACP were incorporated at 40% in: 1) a mixture of pyromellitic glycerol dimethacrylate (PMGDM) and ethoxylated bisphenol A dimethacrylate (EBPADMA) at the mass ratio of 1:1, 2) polyethylene (PE) + 10% 2-hydroxyethyl methacrylate (HEMA) and 5% bisphenol A glycidyl dimethacrylate (PEHB), leading to the formation of two distinct composites: PE+ 40ACP and PEHB+40ACP, respectively. Two cements which did not include ACP (PE and PEHB) were also analyzed for their release of calcium and phosphate ions. Three rounds of release (recharge) and re-release were conducted. During the first round, high levels of release from PE+40ACP and particularly PEHB+40ACP were detected, indicating the importance of the resin phase formulation. The authors attributed the higher release propensity of PEHB+40ACP relative to that of PE+40ACP to the HEMA component present at 10 wt%, specifically to its hydrophilic nature, which can explain the higher water sorption by this formulation. This HEMA characteristic could promote an enhanced water diffusion within the matrix, allowing for a higher calcium and phosphate ion dissolution and release in a pH-adjusted medium. Further rounds of recharge and re-release demonstrated the capacity of PE+40ACP and PEHB+40ACP to provide a superior release compared with the cements without ACP. Every successive round was characterized by decreasing release rates for all the formulations. Further, all the release profiles for all of the cements in each of the release rounds were characterized by the diffusional regime.

In a work by Uskoković et al. from 2017 [69], a HAp-forming CPC was supplemented with silica and gelatin, which endowed the cement with thermosetting properties. The volume of the cement that would take around 45 min to set at room temperature would thus set in a matter of minutes at physiological 37 °C. These additional components also increased the surface porosity of the hardened product owing to the controlled dissolution of gelatin, which left voids in the solid material. The release of vancomycin was studied for two different cement formulations, which contained 19.4 and 26.5 wt% of the additive phases. No burst release was detected for any of these two cements and for both of them the total release was slower and more sustained than that from the additive-free CPC. The drug release kinetic was independent on the content of gelatin, suggesting that the release was controlled mainly through the affinity of vancomycin for HAp. The parallel increase in vancomycin loading efficiency and the weight percentage of HAp in the set cement supported the idea that vancomycin was not predominantly entrapped by gelatin, but that it rather got bound to the surface of HAp through electrostatic attraction and was released by overcoming this attraction with the help of the hydration force. Gelatin here, however, still played a key role by coating HAp grains and hindering the desorption of vancomycin molecules, thus promoting their slow and sustained release.

In a work from 2017 [70] by Schumacher et al., a delivery system for VEGF and lysozyme (Lyz) proteins from a matrix consisting of CPC and mesoporous bioactive glass (MBG) based on calcium silicate was proposed and investigated. Mesoporous calcium silicate was added at different ratios to the precursor α-TCP powder and the formulation containing 10 wt% MBG was selected as suitable for the drug release assessment. The cement was obtained by mixing the precursor powder with a Na2HPO4 aqueous solution. Two different loading routes were applied for the Lyz inclusion: 1) dissolving Lyz in the Na2HPO4 aqueous solution and 2) incubation of MBG particles in a Lyz-enriched buffer solution. Experiments assessing the individual release of the two proteins from the pure CPC matrix and from the CPC/MBG composite cement pre-set for 3 days were carried out. Comparison of the profiles of release from the two matrices showed a higher release rate from the CPC pure matrix than from the CPC/MBG composite. A diffusive profile characterized the release of VEGF and Lyz from the two different matrices, indicating that the diffusion from the matrices is the main involved mechanism. The lower released amount of proteins from the CPC/MBG matrix can be ascribed to the antagonistic effect induced by mesoporous silica. Namely, on one hand, MBGs are known to possess an intrinsic porosity and a high propensity for degradation in solution through the formation of hydrated silica species. This factor would theoretically induce an increase in the drug release rate. On the other hand, mesoporous silica possesses a high bioactivity, which is able to promote the deposition of a layer of CDHA on the cement surface and hinder the leaching of the drug. In this study, the dominance of the latter factor could explain the reduced release from the CPC/MBG system.

Jani et al. in their work from 2018 [71] proposed a mesoporous silica (MCM-41) and HAp composite (MCM/HA) as a delivery matrix for ibuprofen (IBU). The release behaviour of this matrix was compared with a system made of pure MCM-41. The release test was conducted under an in vitro condition in the PBS solution with a pH of 7.4. The most important conclusion drawn from the comparison of the curves of the release of IBU from MCM-41 and MCM/HA was the greater amount of the released drug from the MCM-41 matrix. The mesoporous silica-based system also displayed a higher burst release that caused the faster depletion of the contained drug during the first 10 h. An almost negligible release was observed for the remaining 60 h. On the other hand, MCM/HA showed a more contained release with a minor burst effect, followed by a decreased but sustained release. The observed burst release can be attributed to the presence of IBU molecules on the matrix surface. FTIR analysis revealed a high concentration of SiOH groups along the pore walls and OH− and COO− groups of IBU could interact with SiOH via hydrogen bonding. Furthermore, the carboxyl group of IBU could interact with the Ca2+ of HAp. The authors suggested that these factors could cause a diminished mobility of IBU within the matrix, with a consequently slower release from the MCM/HA system.

An article from 2013 by Su et al. [72] reported on calcium silicate (CS) modified β-TCP cement as a drug carrier. Formulations with different ratios of CS to β-TCP were taken into account, namely 0:100, 30:70, 50:50, 70:30, and 100:0. In vitro release of fibroblast growth factor-2 (FGF-2) from these matrices was investigated. Degradation of the matrix cement itself, when immersed in SBF solution for predetermined durations of time, was monitored for all the formulations. Inhibition of the degradation rate was found for matrices incorporating higher amounts of CS. It is well known that the accommodation of the silicate group within the CP lattice decreases the surface charge [73] due the formation of Si–OH species at the surface, which in turn enhance the dissolution rate of superficial Si [74]. Further, the formation of a SiO2-rich layer induced the precipitation of Ca2+ and PO43− from the solution, leading to the formation of a HAp layer that partially shields the matrix from the solution [75]. However, the release of FGF-2 over 12 weeks showed desorption rates that increased steadily with the CS content. Interestingly, while the curves retained a similar shape during the first stage of the release, indicating a diffusion-controlled regime, the difference between them began to accrue at longer periods of incubation and the release kinetics changed from the first order to the zeroth order in inverse proportion with the CS content. This result was in agreement with the CPC degradation evidence, suggesting that at lower amounts of CS, liberation of the drug due to a higher dissolution of the cements becomes more prominent. The more controlled drug release from the CS-rich cement is in agreement with the aforementioned process of formation of superficial HAp.

Doping the powder phase with ions presents another strategy for controlling the release rate from CPCs. Many ions capable of accommodating themselves inside the CP lattice deform it and render it more soluble, which, in theory, should make the drug load less stable and more prone to a faster release. A work from 2006 by Ito et al. [76], for example, reported on the results of the experiments aiming to explore the possibility to vary the dissolution rate of β-TCP ceramic by the addition of Zn in amounts ranging between 0 and 10 mol.%. In order to quantify the dissolution fraction of the ceramic, the Ca2+ concentration in the acetate buffer was measured. All samples showed decreased dissolution at higher contents of Zn. Dissolution flux plots suggested that the mechanism governing this process is polynucleation, whereas the equilibrium solubility decreased with the zinc content due to a decrease in the free energy of formation (equivalent to an increase in stability due to the presence of Zn). Strontium is another common cationic dopant in CPs that, like Zn, increased the solubility of TCP-based CPCs [77] and, thus, made them prone to exhibit faster drug release kinetics than pure CPCs.

The effect of strontium doping on the loading and the release of DOXY hyclate from a CPC was investigated in a work from 2009 by Alkhraisat et al. [78]. Three different CPC formulations were selected for this study: β-TCP CPC containing 0, 13.3 or 26.6% of Sr. The pore size and the specific surface area were measured for all the formulations, showing their enhancement in Sr-containing matrices as compared to the Sr-free controls. CPCs were left ageing for 24 h in different drug-containing solutions at low (5 mg/ml) and high (24 mg/ml) concentrations of DOXY. It was observed that the pore size and the specific surface area had a direct effect on drug loading, which was more efficient in Sr-containing cements due to the augmented binding sites and the accessibility of the drug molecules to them. Desorption curves confirmed the efficiency of permeation of the Sr-containing cements with the liquid medium. Saturation of the binding sites occurred for drug concentrations ≥10 mg/ml, with the excess drug molecules oversaturating the cement surface. Higher release was registered during the first 40 h of incubation for samples with 13.3% and 26.7% of Sr relative to the Sr-free control. Release curves were fitted with the power-law equation and the calculated fitting parameter suggested a Fickian transport for the low drug loadings (5 mg/ml) and the anomalous transport for the high drug loadings (24 mg/ml) of DOXY. This could be attributed to the uneven distribution of DOXY molecules across the oversaturated binding sites on the cement surface at high loadings.

The effects of strontium doping on the degradation of a α-TCP bone cement and its release of Sr ion were also the aims of a study reported by Shi et al. [79]. Different Sr-substituted cements were prepared starting from different sources of Sr: Sr-OCP powder (Sr-CPC-O), Sr-αTCP powder (Sr-CPC-S), SrCO3 powder (Sr-CPC-C), and SrCl2 solution (Sr-CPC-L). The cements had the final Ca-to-Sr substitution ratios of 0.2%, 1.0% and 1.5%. Experiments on the release of Ca2+ and Sr2+ ions from all the cements were carried out. Concentrations of the Ca ion in the ageing solution indicated a constant and slow release during the first 14 days followed by a rapid increase in the release throughout the remaining 14 days of monitoring. This was observed for all the cements, with no regard to the Sr content in the cements. The Sr release rate was primary defined by the Sr substitution degree in the CPC. Sr-CPC-C had the least concentration of Sr and it is likely that it contained SrCO3, which decomposed and got reincorporated in the matrix, contributing to the mass gain, as indicated by the experimental results. Sr-CPC-S showed a noticeable increase in the Sr release, probably due to the presence of weakly alkaline compounds in the hydrated cements containing impure β-TCP. Here, β-TCP, which is more soluble than HAp, could promote the ionic uptake and the release of Sr. Fig. 4 schematically summarizes the different effects through which the additives in CPCs affect the rate and the mechanism of drug release.

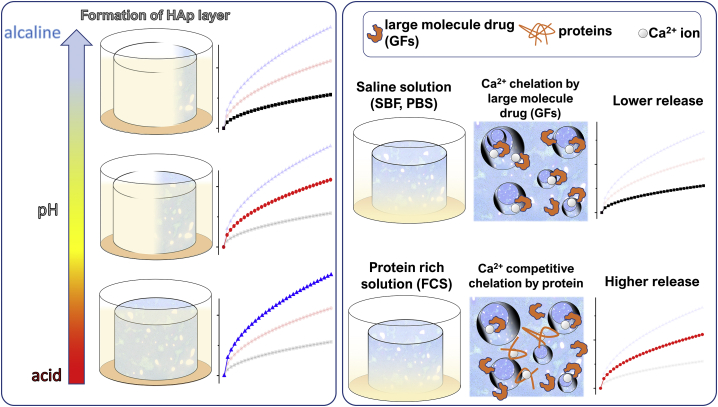

Fig. 4.