Highlights

-

•

Ultrasound osmotic pretreatment improved vacuum freeze-drying of strawberry slices.

-

•

Dual-frequency ultrasound shortened drying time more than single-frequency.

-

•

Dual-frequency ultrasound in sequential mode exhibited the best quality attributes.

-

•

Pretreatment improved the physical properties and biological activity of strawberry.

Keywords: Ultrasonic, Strawberry, Vacuum freeze-drying, Water migration

Abstract

The effects of osmotic pretreatment assisted by ultrasound in different frequency modes before vacuum freeze-drying (VFD) on moisture migration and quality characteristics of strawberry slices were investigated. The frequency modes are single-frequency modes under 20, 40 kHz (SM-20, SM-40), and dual-frequency under 20/40 kHz including sequential mode (SeDM) and simultaneous mode (SiDM). The quality characteristics of dried strawberry products including rehydration, hardness, color, flavor, total anthocyanins, total phenols, vitamin C content, and active antioxidant components (DPPH and –OH) were determined. Results showed that drying time of the strawberry slices irradiated by ultrasound was reduced by 15.25%–50.00%, compared to the control samples. Besides, dual-frequency ultrasound shortened the drying time more than single-frequency ultrasound. The drying time of SeDM was the shortest. In addition to vitamin C content, the quality characteristics including rehydration, hardness, color, flavor, total anthocyanins, total phenols, and antioxidant activity of dried strawberry products pretreated by SeDM were significantly (p < 0.05) better than those of control and other pretreated samples. It can be concluded that the SeDM was an effective pretreatment method to produce high-quality vacuum freeze-dried strawberry products.

1. Introduction

Strawberry is a perennial herb with bright color, tender and juicy, rich in anthocyanins, polyphenols, vitamin C, and other nutrients [1]. Unfortunately, strawberries are not resistant to storage and transportation, and suffer severe losses after harvest. They are highly perishable and deteriorate, and the red pulp will quickly soften and become brown [2]. These undesirable characteristics limit the development or storage of processed products from strawberries to a great extent.

Drying is an important processing method to lengthen the shelf-life of fruits. However, improper drying methods can lead to a decline in dried products’ quality, including color deterioration, shape changes, and nutrient loss [3]. Vacuum freeze-drying (VFD) has been widely studied in recent years and considered as an appropriate drying method, maximizing the retention of color, aroma, taste, shape, and nutrients of dried products. However, VFD is energy-intensive and costly. In order to overcome this problem, pretreatment is usually carried out before drying, such as ultrasonic [4], osmotic [5], high pressure [6] and microwave [7] pretreatment methods.

In recent years, ultrasound (US) has attracted widespread attention due to its numerous advantages over traditional methods. It has been widely used in the food processing, such as extraction [8], freezing [9], drying [10], [11], thawing [12], fermentation [13], as well as cleaning [14], [15], [16]. As a pretreatment method prior to drying, ultrasonication, makes the material shrink and expand continuously, forming a spongy structure, which affects the damage of cell wall and the formation of micro channels [17]. It has been confirmed that the total drying time of okra can be shortened by 10–30% by flat sweep frequency ultrasound [18]. Besides, the hardness and brittleness of sweet potato were increased by ultrasonic pretreatment, and the β-carotene content was increased by 42% [3]. Osmotic dehydration is a method to remove water from fruit tissue by immersing fruit in a hypertonic solution [19]. Due to the slow soaking process, additional force is needed to increase the mass transfer process. The combination of ultrasonic and osmotic dehydration can enhance the mass transfer. Many researchers have studied the ultrasonic-assisted osmotic dehydration pretreatment of fruit drying and obtained a shorter drying time [20].

In the process of ultrasound, the frequency is a significant indicator for the sonochemical reaction [21]. It is directly related to the intensity of the ultrasonic cavitation. In addition, it also affects the bubble activity caused by the bubble rupture, and further affects the product quality [22]. Generally speaking, not all bubbles can have a significant bubble effect on the ultrasonic cavitation. When the natural resonance frequency of the bubble is commensurate with the ultrasonic frequency, the coupling of ultrasonic energy reaches its peak [23]. Dual-frequency ultrasound is one of the forms of ultrasound technology, which is helpful to produce higher cavitation effect than single frequency ultrasound, and it has been studied in starch and protein now. Xu et al. [24] studied the effect of ultrasonic mode on the degradation of gelatinized waxy corn starch (GWCS). The results showed that compared with native starch, GWCS in all frequency modes was significantly degraded, and dual-frequency ultrasound decreased more. Wen et al. [25] investigated the dual-frequency ultrasound (DFU, 20 / 28 kHz) pretreatment on watermelon seed protein structure. The results showed that the antioxidant activities and stability of watermelon seed protein hydrolysates were increased significantly after DFU pretreatment. To the best of our knowledge, the effect of ultrasound-assisted osmotic dehydration pretreatment with different frequency modes on VFD process and quality characteristics of dried strawberry has not been studied.

In consequence, the present study aimed to: (1) evaluate the effect of ultrasound-assisted osmotic pretreatment with different frequency modes on moisture migration and microstructure change of strawberry; (2) investigated the effect of ultrasound-assisted osmotic pretreatment on drying characteristics during VFD; (3) determine the quality attributes including color, texture, flavor, total phenolic content, VC and oxidation resistances of vacuum freeze-dried strawberry slices pretreated by ultrasound-assisted osmotic pretreatment.

2. Materials and methods

2.1. Raw materials

Fresh strawberries (Fragaria × ananassa Duch, cv. HongYan) were obtained from a strawberry farm (Danyang, Jiangsu, China). Ripe strawberries with uniform size and color and without mechanical damage were selected as the experimental object. After cleaning, the pedicels were removed, and the middle part of the strawberry was selected for transverse slicing, with a thickness of 5.0 ± 0.5 mm. The initial moisture content of fresh strawberries was measured as 92.65 ± 0.83% (wet basis) in a hot air oven at 105 °C until the sample reached a constant weight.

2.2. Ultrasound-assisted osmotic pretreatment

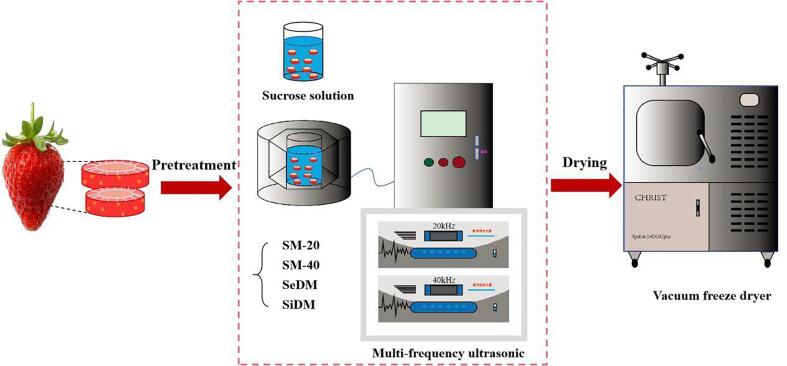

The strawberry slices (50 ± 1 g) were soaked in 10% (W/V) sucrose solution with the ratio of 1:4 (W/V), and ultrasonic treatment was carried out at the same time. As shown in Fig. 1, the beaker containing strawberry slices and sucrose solution was put into the ultrasonic bath with the hexagon cylinder ultrasonic bath equipment independently developed by Jiangsu University (Zhenjiang, Jiangsu, China). There were three different modes of ultrasonic processing: single-frequency mode, dual-frequency in sequential and simultaneous mode. In the single-frequency mode, the ultrasonic processing was carried out at 20 kHz (SM-20) and 40 kHz (SM-40). The sequential dual-frequency mode (SeDM) signifies that the ultrasonic processing was proceeded at alternate 20/40 kHz frequency, and the simultaneous dual-frequency mode (SiDM) means that the ultrasonic processing was proceeded at the same time at 20 and 40 kHz frequency [24]. During the ultrasonic pretreatments, the power density, pulse switching time and duration were 30 W/L, 5 s/5 s, and 30 min, respectively. The ultrasonic temperature (25 ± 1 °C) was kept constant by water bath circulation. After pretreatment, the water on the sample surface was removed with absorbent paper, and then VFD was carried out. Strawberry slices without ultrasonic pretreatment were labelled as control samples, and each treatment was repeated three times.

Fig. 1.

The schematic diagram of experiments.

2.3. Vacuum freeze-drying (VFD)

The VFD process of strawberry slices were performed using a vacuum freeze dryer (Epsilon 2-6D LSC+, Martin Ltd., Germany). Firstly, the strawberry slices were pre-frozen at − 40 °C, then the temperature of main drying was set at 25 °C with the vacuum degree of 0.518 Mbar and cold trap temperature of −90 °C. The temperature of final drying was 35 °C [26]. Until the moisture content was less than 5%, drying process was stopped [27].

2.4. Analysis of drying characteristics

2.4.1. Mass transfer determination

The mass transfer phenomenon of strawberry slices in different ultrasonic pretreatment process was evaluated by water loss (WL) and solid gain (SG), which were calculated according to the Eqs. (1), (2) [28].

| (1) |

| (2) |

where X0 is the mass of the initial fresh strawberry (g); Xt is the mass of strawberry after pretreatment (g); x0 is the initial dry basis mass of strawberry (g); xt is the dry basis mass of strawberry after pretreatment (g).

2.4.2. Moisture content on dry basis

The formula for calculating the initial moisture content on wet basis is shown in Eq. (3). Where m represents the initial mass, and n represents the mass after drying to constant, [18]:

| (3) |

So, the initial dry basis moisture content is according to Eq. (4) [18]:

| (4) |

The dry basis moisture content calculation formula at time t can be expressed as follows [19]:

| (5) |

where Mt is the moisture content of strawberry at t time (dry basis, g/g), m0 means the initial mass (g), mt means the mass at time t (g), and Wg means the mass of dry matter (g/g).

2.4.3. Moisture ratio (MR)

Drying kinetics usually expressed by the change of moisture ratio over time. The equation of moisture ratio (MR) is given below [29], [30]:

| (6) |

where M0 is the initial moisture content of strawberry (dry basis, g/g), Mt is the moisture content of strawberry at t time (dry basis, g/g), Me is the moisture content at equilibrium (dry basis, g/g). Since Me is much smaller than M0 and Mt, it can be ignored.

2.4.4. Drying rate (DR)

The drying rate (DR) during drying process is expressed by Eq. (7) [2]:

| (7) |

where DR is the drying rate between t1 and t2 (g/ (g∙min)), Mt1 and Mt2 are the moisture content (dry basis, g/g) of strawberry at t1 and t2.

2.5. Microstructure analysis

The microstructure images of different groups of dried strawberry samples were obtained by scanning electron microscopy (S-3400N, Hitachi Ltd., Japan). The sample section is pasted on the sample table by conductive adhesive. The scanning electron microscopy (SEM) imaging was performed at an acceleration voltage of 20 kV [31].

2.6. Low-field nuclear magnetic resonance (LF-NMR) and magnetic resonance imaging (MRI) analysis

The moisture status and distribution of strawberry samples pretreated by different ultrasonic methods and after VFD were determined by low-field nuclear magnetic resonance analyzer (Niumag Corporation, Suzhou, China). About 3 g strawberry samples were put in a cylindrical glass tube (diameter 2 cm, height 4 cm), and then inserted into the NMR test room. The CPMG pulse sequence measured the T2 (transverse relaxation time), and the image information of the sample was collected by SE pulse sequence.

The parameters of CPMG sequence: SF = 21 MHz, O1 = 136363.3 Hz, P1 = 7 μ s, P2 = 14 μs, SW = 200 kHz, TW = 6000 ms, PRG = 3, RG1 = 20 db, DRG1 = 1, NS = 64, TE = 0.1 ms, NECH = 15,000.

The parameters of SE sequence: TR = 2000 ms, TE = 3.02 ms, DRG1 = 5, NS = 16, Slice Width = 20 mm, Slice Size = 1, FOV Read = 50 mm, FOV Phase = 50 mm

2.7. Quality characteristics of strawberry slices

2.7.1. Rehydration ratio (RR)

The determination of rehydration ratio was achieved by soaking 1.5 g of VFD strawberry slices into 200 mL distilled water at 25 °C for 30 min. After rehydration, the sample was taken out to drain the water, and the surface water was wiped with absorbent paper and then weighed. The ratio of the sample’s mass after rehydration to that of the initial sample was the rehydration ratio [32].

2.7.2. Hardness analysis

Freeze-dried strawberry samples with similar size were selected and the hardness was determined by a texture analyzer (TA-XT2i Stable Micro Systems Ltd., Vienna 153Court, Surrey, UK). The same sample was repeatedly measured for 5 times with the unit of g. Parameter settings were as follows [6]: probe model: shear probe P/2; test mode: compression; target mode: strain; operation type: return to start; trigger mode: stress; pre-experimental speed: 2.0 mm/s; experimental speed: 1.0 mm/s; post-experimental speed: 10.0 mm/s; test distance: 3 mm; trigger stress: 5 g.

2.7.3. Color analysis

The color parameters of strawberry slices were measured by a hand-held color difference meter (CR-400, Konica Minolta, Inc., Japan). Then the color parameters namely L* (brightness), a* (red/green) and b* (yellow/blue) of dried strawberry samples were evaluated at room temperature. For each pretreatment method, 3 samples were selected, and measured 5 times, and the average value was taken. The total color difference (ΔE) was calculated according to Eq. (8) [33], where L0, a0 and b0 are the values of fresh strawberry samples.

| (8) |

2.7.4. Electronic nose analysis

An electronic nose system (PEN3.5, AIRSENSE Analytics GmbH, CITY, Germany) equipped with 10 sensors was used to analyze the flavor changes of dried strawberry samples. 2.0 g of VFD strawberry slices grounded to a coarse powder and put into a 20 mL vial. After capping, the vials were incubated in a 40 °C water bath for 30 min. For the determination of the flavor profile: the chamber flow rate was 400 mL/min, the initial injection flow rate was 400 mL/min, the flushing time was 180 s, and the measurement time was 120 s. 3 parallel tests were performed for each sample [26]. The sensors' analytes includes: W1C: aromatic, W5S: broadrange, W3C: aromatic, W6S: hydrogen, W5C: arom-aliph, W1S: broad-methane, W1W: sulfur-organic, W2S: broad-alcohol, W2W: sulph-chlor, W3S: methane-aliph.

2.7.5. Determination of total anthocyanin content, total phenolic content and vitamin C in strawberry slices

The freeze-dried strawberry powder was weighed (2 g) into a 50 mL beaker, and then 20 mL 70% ethanol solution (V/V) was added. Then it was extracted using an ultrasonic water bath (KQ-300DE Ultrasound Cleaner, Kunshan Instrument Co., Ltd, Kunshan, Jiangsu, China) for 30 min (100 W, 40 kHz), centrifuged at 6000 rpm (Eppendorf 5084 R centrifuge, CITY, Germany) for 15 min, and the supernatant was collected. The filter residue was added with 70% ethanol solution and centrifuged in water bath under the same conditions. The supernatant was mixed twice, and the strawberry extract was obtained by constant volume of 70% ethanol solution to 50 mL.

2.7.5.1. Total anthocyanin content (TAC)

The content of total anthocyanins in dried strawberry was determined by pH differential method [34]. First, 2 mL of extraction solution was mixed in 8 mL of pH 1.0 buffer solution (0.1 M KCl) and pH 4.5 buffer solution (0.5 M NaAc). Then the absorbance values were determined at 510 nm and 700 nm of a spectrophotometer (T6NC, Beijing PUXI General Instruments Co., Ltd, Beijing, China), respectively. Distilled water was used as the standard. The total anthocyanin content was calculated according to equation (9). The result was expressed as mg cyanidin 3-glucoside (C3G) / g dry weight.

| (9) |

where , V is the volume of the extract, M = 449.2 g/mol, DF is the multiple of the extract diluted by the buffer solution, ε = 26,900 L/ (mol∙cm), L = 1 cm, m is the weight of the sample.

2.7.5.2. Total phenolic content (TPC)

0.5 mL of extract was transferred to 10 mL brown centrifuge tubes, and 2.5 mL of 5% (V/V) Folim-Ciocalfen reagent was added respectively. Then, after 2 min of dark reaction, 2 mL of 7.5% (W/V) Na2CO3 was added and waited for 5 min to maintain the reaction at 50 °C. Finally, the absorbance was determined at 760 nm, and 3 parallel tests were carried out for each sample. The result was expressed as mg gallic acid equivalent (GAE) / g dry weight [35].

2.7.5.3. Vitamin C

0.2 mL of sample extract was put into colorimetric tubes filled with 0.4 mL of 10% HCl, and then 9.4 mL of distilled water was added to shake evenly. The absorbance was measured at 243 nm with distilled water as a reference, and the result was expressed as mg ascorbic acid equivalent (AA)/g dry weight.

2.7.6. Analysis of antioxidant capacity of strawberry

The DPPH (2,2-diphenylpicrylhydrazyl) radical scavenging ability of strawberry was determined according to Tan et al. [5] with some modifications. 3.5 mL DPPH (0.14 mM) solution and 0.5 mL strawberry extract were mixed. After 30 min of dark reaction at room temperature, the absorbance value was determined at 517 nm, and 70% ethanol solution was used as blank.

The scavenging capacity of hydroxyl radical was measured according to the method of Zhang et al. [17]. 1 mL FeSO4 (9 mM) solution, 1 mL salicylic acid ethanol (9 mM) solution, 1 mL sample extract and 1 mL H2O2 (8.8 mM) were added into the brown centrifuge tube. After mixing well, they were placed in a water bath at 37 °C for 30 min. The absorbance value was determined at 510 nm wavelength using distilled water as blank.

2.8. Statistical analysis

All the experiments were carried in triplicate. SPSS 20.0 software (IBM, Chicago, IL, USA) was used to analyze variance and the Duncan test. The difference was statistically significant (p < 0.05). Statistical analysis was performed using Origin Pro software version 8.0 (Origin Lab Corporation, Northampton, MA, US). The correlations between the quality parameters of samples were statistically tested by Pearson’s correlation procedure and the principal component analysis.

3. Results and discussion

3.1. Effect of pretreatments on the drying process of strawberry slices

3.1.1. Drying characteristics

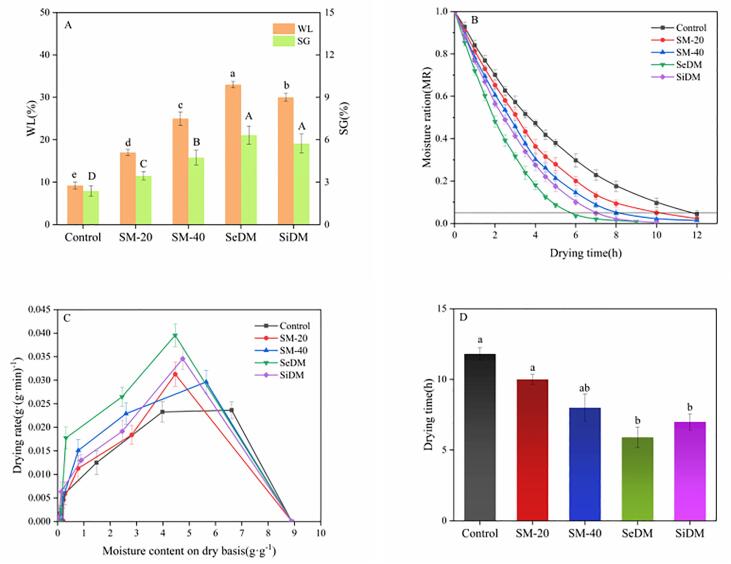

The effects of pretreatments on the water loss (WL) and solid gain (SG) of strawberry slices are shown in Fig. 2. Due to the presence of sucrose solution, there was a concentration gradient inside and outside of the strawberry cells, which promoted the mass transfer of soluble solids from liquid medium to strawberry slices and the mass transfer of water from strawberry slices to the liquid medium. This process was a dynamic equilibrium process [36]. Both osmotic dehydration and ultrasonic pretreatment will cause the WL and SG of strawberry samples. However, due to fragile peel and soft tissue characteristics, it was easy to cause the loss of pulp during the pretreatment process. Compared with control samples, the values of the WL and SG of the sample irradiated by ultrasound with different frequency modes were significantly higher (p < 0.05). This is probably because the “sponge effect” produced by ultrasonic treatment leads to the formation of micro pores in the strawberry tissue, promoting the discharge of water [24]. The results showed that ultrasonic pretreatment could promote the water removal of strawberry slices during the process of osmotic dehydration. Similar results were found in persimmon [37], plum [20] and kiwifruit [38]. Besides, the ultrasound pretreatment in different frequency modes had significant effect on the values of the WL and SG values of strawberry slices. The values of strawberry slices irradiated by dual-frequency ultrasound were significantly higher (p < 0.05) than those irradiated by single-frequency ultrasound. Similar results were also found in the degradation of waxy corn starch [24] and enzyme hydrolysis of casein [12].

Fig. 2.

Effect of different pretreatment methods on the drying characteristics of strawberry during VFD. A: Effect of different pretreatments on the water loss (WL) and solid gain (SG) of strawberry; B: Effect of pretreatments on the change of moisture ratio with time during the VFD process of strawberry; C: Effect of pretreatments on the drying rate of strawberry during the VFD; D: Effect of pretreatments on the total VFD time of strawberry.

The curves of moisture ratio (MR) and drying rate (DR) of strawberry slices under different pretreatments during VFD are also shown in Fig. 2. With the drying time increasing, the MR of strawberry slices decreased gradually. Compared with the control samples, the MR of strawberry slices pretreated by ultrasound decreased significantly faster. In the process of VFD, when the moisture ratio of strawberry slices was 0.05 g/g, the control group’s drying time was 11.8 h, and the drying time of SM-20, SM-40, SeDM and SiDM pretreated samples decreased by 15.25, 32.20, 40.68 and 50.00%, respectively. The DR increased rapidly initially and then decreased slowly when the critical moisture content was reached. This may be due to the fact that the moisture migration rate inside the material is less than the evaporation rate on the surface, so the constant speed stage is never reached [4]. After ultrasonic pretreatment, the drying efficiency of strawberry slices was significantly improved, which can be explained by the cavitation effect of ultrasound to accelerate the formation of fine pores in the material, facilitate the elimination of water, promote the sublimation of ice crystals, and thus improve the mass transfer rate [39]. The curves of MR and DR under different ultrasonic frequency modes showed apparent changes. The drying efficiency of dual-frequency ultrasound was significantly higher than that of single-frequency ultrasound, especially in the sequential mode. Among them, the MR of SeDM was the lowest and the drying rate was the highest. The reason behind this may be due to the higher working frequency of dual-frequency US, overcame single-frequency ultrasound disadvantages, such as uneven energy consumption per volume unit and directional sensitivity [40]. Moreover, the dual-frequency ultrasound can generate more cavitation bubbles and a “combined resonance” phenomenon, and produce higher sonochemical energy [41]. Amami et al. [42] also found similar results, where ultrasonic infiltration pretreatment improved the drying rate, and the drying coefficient of strawberry convection drying shortened the drying time. Therefore, ultrasonic infiltration pretreatment can be applied to raise fruits’ drying efficiency.

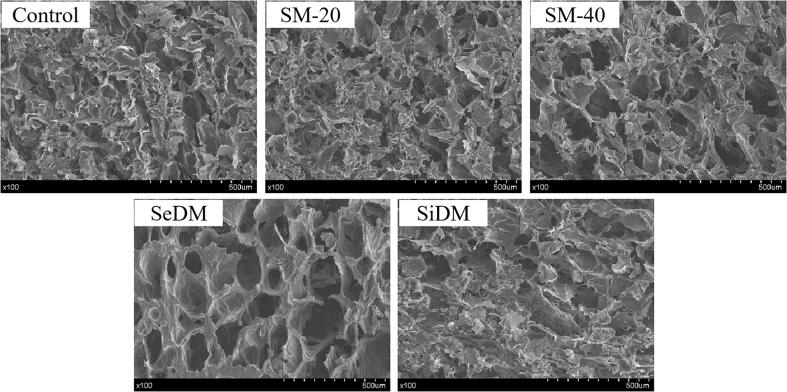

3.1.2. Microstructure

The SEM results of strawberry samples are shown in Fig. 3. In the control group, due to the infiltration of sucrose solution and water loss, the main manifestations were cell shrinkage, tight structure, cell wall distortion and cell collapse, which may also be the reason for the inadequate rehydration of the control sample [43]. After pretreated with different ultrasonic frequency modes, the porous structure was formed, and there was a phenomenon of cell rupture, and unwanted cracks were observed at the cell boundary [32]. Different frequencies of ultrasound led to different porosity and irregular arrangement or separation of cells. The SEM images of SeDM showed that the holes were the largest, which indicated that this mode had the maximum damage to the microstructure of fresh strawberry. The microstructural changes of freeze-dried strawberry slices may be connected with water migration and cell rupture, affecting the changes in water state [17].

Fig. 3.

Microstructure image of dried strawberry with different pretreatments. Magnification: 100×. Control: no-ultrasound; SM-20: single-frequency mode of 20 kHz; SM-40: single-frequency mode of 40 kHz; SeDM: sequential dual-frequency mode of 20/40 kHz; SiDM: simultaneous dual-frequency mode of 20 and 40 kHz.

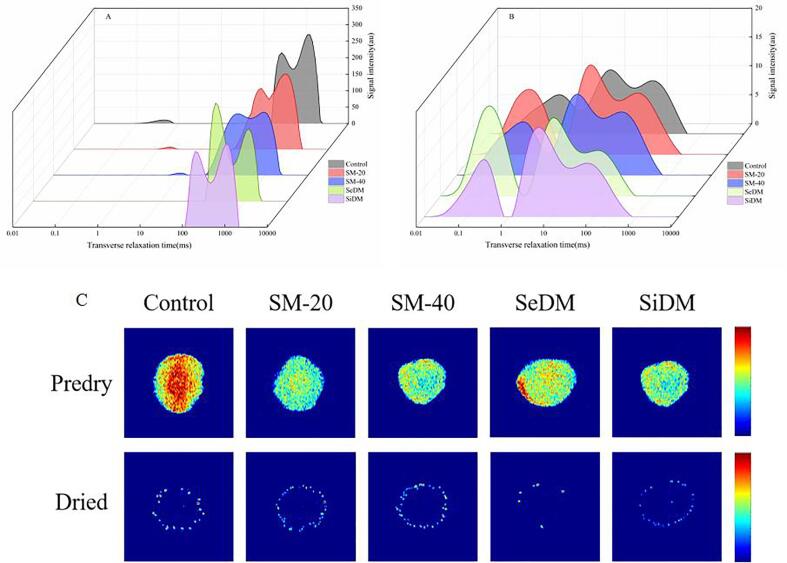

3.2. Effect of pretreatments on water state of strawberry slices

In NMR measurement, the length of transverse relaxation time (T2) can reflect the hydrogen proton's chemical environment. Therefore, it is widely used to evaluate water fluidity. As shown in Fig. 4, there are three peaks in the T2 curve of strawberry slices, which are T21 (bound water) with strong hydrogen bond and water content in the cell walls, T22 (semi-bound water) with water content in the cytoplasm and in the extracellular spaces, and T23 (free water) with fluidity and water content in the vacuole [33].

Fig. 4.

Typical distribution of T2 relaxation time and MRI images of different pretreatment methods VFD strawberry slices before and after drying. A: Distribution of T2 relaxation times of pre-dry strawberry slices; B: Distribution of T2 relaxation times of dried strawberry slices; C: MRI images of different pretreatment methods VFD strawberry slices before and after drying.

Fig. 4A shows the relaxation time distribution of strawberry slices after different pretreatments. After pretreatment, the transverse relaxation time of free water is significantly shortened (except T21). Undried strawberries were mainly free water. After pretreatments, the area of bound water (A21) was significantly reduced or even disappeared, the area of free water (A23) also kept decreasing, while the area of bound water (A22) increased. This showed that ultrasound makes the water with higher degree of freedom and unstable water move to the water with lower degree of freedom and relatively stable state, which was consistent with the change trend of the mushrooms in the initial stage of drying [44]. This is probable reason that ultrasonic pretreatment can speed up the drying rate to a certain extent. The osmotic effect of ultrasound and sucrose solution enhanced the diffusion of free water in cells, and the osmotic solution will also enter plant tissues, which was a two-way process [42].

For strawberry slices after VFD, the pretreated sample’s transverse relaxation time was significantly shorter than that of the control, and the three main peaks shifted to the left (Fig. 4B). Compared with the non-dried samples, the relative peak area had a significant change (Table 1), which indicated that most of the semi-bound water and free water in the samples were removed during freeze-drying, resulting in the change of moisture composition of the dried samples. SM-20, SM-40 and SiDM were similar to the control group and showed the largest proportion of semi-bound water, while SeDM showed the largest proportion of bound water and the smallest proportion of free water. The proportion of free water and bound water can reflect the degree of drying to a certain extent. Therefore, the less the proportion of free water, the better effect of drying.

Table 1.

The relaxation time (T21, T22 and T23) and relative peak area (A21, A22 and A23) of strawberry samples pretreated before and after drying.

| Mode | T2 (ms) |

Area of T2 (%) |

|||||

|---|---|---|---|---|---|---|---|

| T21 | T22 | T23 | A21 | A22 | A23 | ||

| Pretreatment | Control | 0.43 ± 0.05c | 265.61 ± 5.01a | 1072.27 ± 3.35b | 2.19 ± 0.10a | 39.26 ± 0.20d | 58.55 ± 0.51a |

| SM-20 | 1.75 ± 0.09b | 256.23 ± 4.20b | 925.26 ± 5.02e | 0.91 ± 0.07b | 48.78 ± 0.21b | 50.31 ± 0.32c | |

| SM-40 | 10.11 ± 0.10a | 231.01 ± 4.51c | 936.60 ± 3.71d | 0.72 ± 0.08c | 58.90 ± 0.15a | 40.38 ± 0.15e | |

| SeDM | — | 200.92 ± 4.24d | 1232.85 ± 6.02a | — | 57.79 ± 1.65a | 42.21 ± 0.25d | |

| SiDM | — | 206.02 ± 3.62d | 1065.07 ± 7.65c | — | 46.71 ± 0.22c | 53.29 ± 0.51b | |

| Vacuum freeze drying | Control | 0.43 ± 0.05a | 7.06 ± 0.13a | 75.65 ± 0.15a | 29.33 ± 0.15c | 39.62 ± 0.14b | 31.05 ± 0.50a |

| SM-20 | 0.22 ± 0.02bc | 6.14 ± 0.15c | 68.27 ± 0.21c | 32.24 ± 1.07b | 40.08 ± 0.45b | 27.68 ± 0.33c | |

| SM-40 | 0.38 ± 0.08a | 6.77 ± 0.20b | 70.83 ± 0.12b | 30.70 ± 0.25bc | 39.83 ± 0.18b | 29.47 ± 0.18b | |

| SeDM | 0.14 ± 0.04c | 4.64 ± 0.15d | 49.77 ± 0.15e | 42.33 ± 1.12a | 38.55 ± 0.31c | 19.12 ± 0.14d | |

| SiDM | 0.25 ± 0.05b | 4.82 ± 0.21d | 65.79 ± 0.12d | 24.33 ± 0.70d | 48.17 ± 0.20a | 27.50 ± 0.29c | |

Note: Values are means ± SD, n ≥ 3. Different letters in the same column mean significant difference at p < 0.05. T23 refers to the the free water’s transverse relaxation time; T21 and T22 refer to the transverse relaxation time of the bound water and the immobilized water, respectively. A21 represents the corresponding water fraction to T21, A22 represents the corresponding water fraction to T22, and A23 represents the corresponding water fraction to T23. Control: no-ultrasound; SM-20: single-frequency mode of 20 kHz; SM-40: single-frequency mode of 40 kHz; SeDM: sequential dual-frequency mode of 20/40 kHz; SiDM: simultaneous dual-frequency mode of 20 and 40 kHz.

The MRI images of strawberry samples pretreated by different modes of US and VFD are shown in Fig. 4C, which more intuitively reflects the moisture change of the strawberry slices. The signal intensity of MRI is directly proportional to the water content of the sample. The red color in the image indicates high signal intensity and high water content. We can find that a large amount of water in the control group was evenly distributed in the strawberry. After ultrasonic pretreatment, the red area was significantly smaller than that in the control group. This phenomenon was because of the destruction of cell structure caused by US, so that the water migrated from strawberry to osmotic solution at a faster rate, which is also verified by the WL in the process of mass transfer (Fig. 2A) and the reduction of the peak area of free water (Fig. 4A). After drying, there was only a weak signal around the edge of the sample. Compared with the sample without drying, the signal of the VFD sample decreased sharply. Among them, the signal of freeze-dried strawberry samples by sequential ultrasonic frequency mode treatment was the least, which hardly be detected and identified in the MRI image. This indicated that the moisture content in the SeDM dried strawberry sample is lower, and the results in the MRI image were consistent with the transverse relaxation time.

3.3. Effect of ultrasonic pretreatments on quality attributes of dried strawberry slices

3.3.1. Rehydration ratio

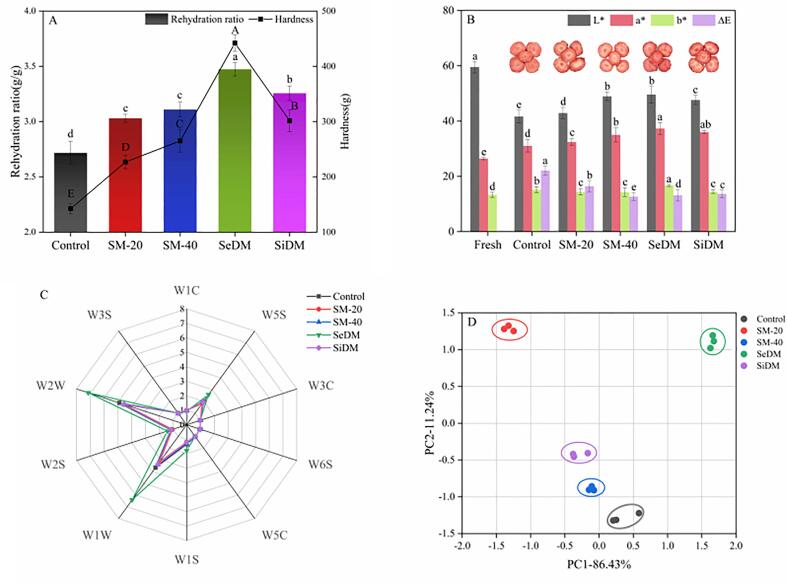

The rehydration ratio provides an idea of the the rehydration ability of dried products. In Fig. 5A, the rehydration ratio of strawberry samples pretreated with different ultrasonic treatments increased noticeably (p < 0.05). The dried strawberry samples pretreated with sequential ultrasonic treatment had the highest rehydration ratio (3.47 g/g), being 27.57% greater than that of the control group. This is due to the microchannels formed by ultrasonic waves, which facilitated the penetration of external moisture into the material [45]. Moreover, the vacuum effect in the drying process could also change the strawberries’ microstructure and promote mass transfer, thus improving the rehydration of materials [27]. Similar results were found in okra [18], carrot [46] and pumpkin [47].

Fig. 5.

Effect of pretreatments on the quality of strawberry subjected to VFD. A: Effect of pretreatments on rehydration ratio (bar graph) and hardness (line graph) of strawberry after VFD; B: Effect of pretreatments on the color of strawberry after VFD; C: Radar chart of the effect of pretreatments on flavor substances of strawberry after VFD; D: Effect of pretreatments on main components of flavor substances of strawberry after VFD.

3.3.2. Texture

Hardness is the resistance of samples to compression under a specific deformation rate, directly related to fruits and vegetables’ structure. It is an important indicator of fruits and vegetables’ texture quality [48]. As shown in Fig. 5A, the hardness values of SM-20, SM-40, SeDM and SiDM were 226.79 g, 265.16 g, 442.10 g and 301.52 g respectively, which were significantly higher than that of the control group (142.50 g). The hardness of dried strawberry slices after different ultrasonic frequency modes showed significant difference (p < 0.05). Similar results were obtained when yam was ultrasonically penetrated for 10 min at 1600 W [49], mainly because the long-term ultrasonic penetration caused the cells to collapse and shrink(Fig. 3), and the solid matter increased after penetration, so the overall hardness increased after VFD. Among them, the hardness of the sample processed in the sequential ultrasonic mode (SeDM) was the highest, and the moisture content of the sample was the lowest. Similar results were also observed by Song et al. [50], they attributed the pretreated samples’ high hardness to the product’s low moisture content.

3.3.3. Color

The color of dried products is the most intuitive indicator of product quality, and it is one of the main factors affecting consumers to buy products. As shown in Fig. 5B, after freeze-drying treatment, the L* value (light and dark value) of strawberry slices decreased significantly, whereas a* (red value) and b* (yellow value) values increased. This indicates that a certain degree of browning occurred in the process of freeze-drying, or the red pigment was condensed after a water loss, leading to surface darkening. Besides, previous studies have shown that the shrinkage and structural deformation during drying may transfer photons or absorb more brightness, thereby reducing the L* value [51]. The a* value is the most crucial reference index for strawberry slices. Compared with fresh strawberry samples, the a* value of the control group and freeze-dried strawberry slices pretreated with different ultrasonic frequency modes increased significantly, and the a* value of SeDM was the highest. This was probably due to the destruction of the cell fluid and anthocyanin of the strawberry during the pretreatment process, which were released into the interstitial spaces, producing a stronger red on the surface of the strawberry. ΔE > 3 means that there is a significant difference between dry and fresh samples. The ΔE value of the pretreated samples was less than that of the control group, which may be connected with the drying time. VFD was more conducive to maintaining the original color of dried fruits.

3.3.4. Electronic nose

The aroma is an important index to measure the dried strawberry. The electronic nose formed a radar fingerprint through the response values of 10 sensors (Fig. 5C). The response values of the five samples were similar, but the signal strength was slightly different. The sensor W2W, W1W and W5S had the greatest influence on the odor characteristics of freeze-dried strawberry slices. A similar result was also found in TianXianZui strawberry [17]. The response signals of W2W, W1W and W5S represent the aromatic compounds, organic sulfides and nitrogen oxides, respectively [30]. The higher the W2W value, the better the flavor of dried strawberry. But sulfide and nitrogen oxides have negative effects on the flavor [33]. Compared to the control group, the W2W response values of SeDM pretreatment group were higher. This indicates that the appropriate ultrasonic pretreatment played a certain role in inhibiting the loss of volatile compounds during drying. However, it is difficult to discriminate different samples only from the observed sensor response values (radar figure); thus, the internal relationships and differences of the signal information of ten sensors needs to be further explored.

The principal component analysis (PCA) diagram (Fig. 5D) determines whether the electronic nose data vary between the dried samples. The contribution rates of PC1 and PC2 were 86.43% and 11.24%, respectively. The cumulative contribution rate of the two main components was 97.67%, which indicated that the electronic nose could reflect the difference of samples. The close distance between the control group, SM-40 and SiDM indicated that their odor characteristics were similar, while SM-20 and SeDM were distributed on the upper side. There was a significant difference in the first principal component, but no significant difference in the second principal component. This trend is consistent with the radar chart, and the results showed that the odor characteristics of SeDM samples are significantly different, which may be related to the specific frequency of ultrasound reduced the damage of some chemical components.

3.4. Effect of ultrasonic pretreatments on the chemical composition of dried strawberry slices

Anthocyanins are the main colorants of strawberry fruits, responsible for their red color [17]. As shown in Table 2 that the total anthocyanin content of freeze-dried strawberry samples pretreated by ultrasound was significantly higher (p < 0.05) than that of the control, which was consistent with the changing trend of a* value (Fig. 5). These results show that ultrasound-assisted sucrose penetration was more beneficial to the retention of anthocyanin than sucrose penetration alone. Anthocyanin instability is mainly affected by light, heat, oxidation and other physical and chemical factors during processing and storage. In the process of ultrasound, the samples were far away from the light. The inhibition of the anthocyanins degradation in the strawberries was probable due to the reduction of the oxygen content and inactivation of the endogenous enzyme. Zhang et al. [17] also confirmed that ultrasonic treatment increased the anthocyanin content of dried strawberry.

Table 2.

Total anthocyanin content, total phenolic content, vitamin C and antioxidant capacity of the dried strawberry samples.

| Control | SM-20 | SM-40 | SeDM | SiDM | |

|---|---|---|---|---|---|

| TAC (mg C3G/g) | 0.88 ± 0.02d | 0.95 ± 0.03c | 1.02 ± 0.01b | 1.10 ± 0.02a | 1.04 ± 0.02ab |

| TPC (mg GAE/g) | 24.32 ± 0.12e | 25.84 ± 0.09d | 27.28 ± 0.14c | 31.83 ± 0.07a | 28.97 ± 0.11b |

| VC (mg AA/g) | 2.38 ± 0.06a | 2.22 ± 0.08b | 2.12 ± 0.05bc | 2.08 ± 0.02c | 1.77 ± 0.04d |

| DPPH (%) | 53.58 ± 0.66e | 55.45 ± 0.29d | 57.43 ± 0.52c | 63.11 ± 0.74a | 58.36 ± 0.87b |

| –OH (%) | 93.17 ± 0.14d | 99.67 ± 0.32b | 98.94 ± 0.37c | 102.32 ± 0.76a | 102.20 ± 0.21a |

Note: Values are means ± SD, n ≥ 3. Different letters in the same column mean significant difference at p < 0.05. Control: no-ultrasound; SM-20: single-frequency mode of 20 kHz; SM-40: single-frequency mode of 40 kHz; SeDM: sequential dual-frequency mode of 20/40 kHz; SiDM: simultaneous dual-frequency mode of 20 and 40 kHz.

Vitamin C is highly oxidative, and the drying process causes the loss of VC. The content of VC in freeze-dried strawberry slices subjected to different ultrasonic treatments was significantly lower than that in the control group (p < 0.05), which indicated that ultrasonic pretreatment had no positive effect on the content of VC, because VC was unstable during food processing and easily decomposed due to the influence of light, heat and other factors. Long-time ultrasound could also lead to the considerable accumulation of free radicals in strawberries, thus accelerating the oxidation of VC [52].

Table 2 also showed TPC, DPPH and –OH radical scavenging capacity after different ultrasonic treatments. Compared with the control, strawberries’ antioxidant capacity after pretreatment was significantly improved (p < 0.05). Among them, the SeDM sample had the highest total phenolic content (31.83 mg/g), followed by the SiDM sample (28.97 mg/g), and the control sample had the lowest (24.32 mg/g). It might be due to the fact that the ultrasonic treatment reduced dissolved oxygen, thereby preventing the oxidative decomposition of phenols [53]. Similar results were also found by Zhang et al. [17], which ultrasonic (US) and ultra-high pressure (UHP) pretreatment increased the total phenol and flavonoid content of vacuum-freeze dried strawberries. Some studies demonstrated that ultrasound can promote the extraction of phenolic substance, which may associated with the cavitation effect of ultrasound, leading to the release of phenolic compounds or inactivation of phenol degrading enzymes [18]. On the contrary, the total phenolic content of persimmon dried at 60 °C with hot air decreased significantly after ultrasonic assisted osmotic dehydration [19]. Therefore, ultrasonic treatment had both positive and negative effects on the retention of bioactive compounds in fruits and vegetables, depending on the characteristics of raw materials and dry methods [24]. Compared to the others, the scavenging rates of DPPH and –OH in SeDM samples were 63.11% and 102.32%, respectively, which were the highest. The DPPH content in control sample was 3.49, 7.19, 17.79 and 8.92% lower than those in SM-20, SM-40, SiDM and SeDM, respectively. The changing trend of DPPH and –OH radical scavenging ability was similar, and it was consistent with the changing trend of total phenolic content. The results were consistent with previous research outcomes [54], where the antioxidant capacity and the phenolic content exhibited a clear correlation. Studies have shown that ultrasonic treatment can increase the content of hydroxyl groups, and hydroxyl can improve the antioxidant activity [55].

4. Conclusions

The results showed that the ultrasonic pretreatment with different frequency modes significantly influenced the drying process and quality attributes of strawberry slices. All kinds of ultrasonic frequencies significantly shortened the drying time, among which the effect of sequential dual-frequency mode (SeDM) assisted sucrose infiltration was the best. It reduced drying time greatly by changing the moisture status and microstructure of strawberry slices. The rehydration capacity, hardness, and flavor of the freeze-dried strawberry slices irradiated by ultrasound were improved. Therefore, ultrasonication combined with osmotic pretreatment can increase the VFD process of strawberries and improve strawberries’ quality attributes.

CRediT authorship contribution statement

Baoguo Xu: Conceptualization, Methodology, Software, Investigation, Supervision, Writing - review & editing. Jianan Chen: Validation, Formal analysis, Visualization, Writing - original draft, Software. Essodézam Sylvain Tiliwa: Validation, Formal analysis, Visualization. Weiqiang Yan: Resources, Writing - review & editing, Data curation. S.M. Roknul Azam: Writing - review & editing. Jun Yuan: Writing - review & editing. Benxi Wei: Writing - review & editing. Cunshan Zhou: Supervision, Writing - review & editing. Haile Ma: Writing - review & editing.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was supported by the National Natural Science Foundation (Grant Nos. 31801561 and 31701554), and China Postdoctoral Science Foundation (Grant Nos. 2019T120401 and 2020T130261). The authors are grateful for the support provided by the 2020 Provincial Policy Guidance Program (Subei Science and Technology Project, SZ-HZ202002), and the Open Project Program of Jiangsu Key Laboratory of Regional Resource Exploitation and Medicinal Research, Huaiyin Institute of Technology (No. LPRK201802)

References

- 1.Karacam C.H., Sahin S., Oztop M.H. Effect of high pressure homogenization (microfluidization) on the quality of Ottoman Strawberry (F. Ananassa) juice. LWT - Food Sci. Technol. 2015;64:932–937. [Google Scholar]

- 2.Deng L.-Z., Mujumdar A.S., Yang X.-H., Wang J., Zhang Q., Zheng Z.-A., Gao Z.-J., Xiao H.-W. High humidity hot air impingement blanching (HHAIB) enhances drying rate and softens texture of apricot via cell wall pectin polysaccharides degradation and ultrastructure modification. Food Chem. 2018;261:292–300. doi: 10.1016/j.foodchem.2018.04.062. [DOI] [PubMed] [Google Scholar]

- 3.Wu X.-F., Zhang M., Ye Y., Yu D. Influence of ultrasonic pretreatments on drying kinetics and quality attributes of sweet potato slices in infrared freeze drying (IRFD) LWT - Food Sci. Technol. 2020;131 [Google Scholar]

- 4.Xu B., Zhang M., Bhandari B. Temperature and quality characteristics of infrared radiation–dried kelp at different peak wavelengths. Dry. Technol. 2014;32(4):437–446. [Google Scholar]

- 5.Tan S., Wang Z., Xiang Y., Deng T., Zhao X., Shi S., Zheng Q., Gao X., Li W. The effects of drying methods on chemical profiles and antioxidant activities of two cultivars of Psidium guajava fruits. LWT - Food Sci. Technol. 2020;118 [Google Scholar]

- 6.Zhang Y., Qiao C., Wang L., Liao D., Shi K., An J., Hu J., Wang L.S. Influence of high hydrostatic pressure pretreatment on properties of vacuum-freeze dried strawberry slices. Food Chem. 2020;331 doi: 10.1016/j.foodchem.2020.127203. [DOI] [PubMed] [Google Scholar]

- 7.Chen A., Achkar G.E.L., Liu B., Bennacer R. Experimental study on moisture kinetics and microstructure evolution in apples during high power microwave drying process. J. Food Eng. 2021;292 [Google Scholar]

- 8.Luo X., Cui J., Zhang H., Duan Y. Subcritical water extraction of polyphenolic compounds from sorghum (Sorghum bicolor L.) bran and their biological activities. Food Chem. 2018;262:14–20. doi: 10.1016/j.foodchem.2018.04.073. [DOI] [PubMed] [Google Scholar]

- 9.Xu B., Azam R.S.M., Wang B., Zhang M., Bhandari B. Effect of infused CO2 in a model solid food on the ice nucleation during ultrasound-assisted immersion freezing. Int. J. Refrig. 2019;108:53–59. [Google Scholar]

- 10.Osae R., Zhou C., Alolga R.N., Xu B., Tchabo W., Bonah E., Alenyorege E.A., Ma H. Effects of various nonthermal pretreatments on the physicochemical properties of dried ginger (Zingiber officinale Roscoe) slices from two geographical locations. J. Food Sci. 2019;84(10):2847–2858. doi: 10.1111/1750-3841.14790. [DOI] [PubMed] [Google Scholar]

- 11.Osae R., Zhou C., Tchabo W., Xu B., Bonah E., Alenyorege E.A., Ma H. Optimization of osmosonication pretreatment of ginger (Zingiber officinale Roscoe) using response surface methodology: Effect on antioxidant activity, enzyme inactivation, phenolic compounds, and physical properties. J. Food Process Eng. 2019;42 [Google Scholar]

- 12.Xu B., Chen J., Yuan J., Azam S.M.R., Zhang M. Effect of different thawing methods on the efficiency and quality attributes of frozen red radish. J. Sci. Food Agr. 2021;101(8):3237–3245. doi: 10.1002/jsfa.10953. [DOI] [PubMed] [Google Scholar]

- 13.Gao X., Liu E., Zhang J., Yang M., Chen S., Liu Z., Ma H., Hu F. Effects of sonication during moromi fermentation on antioxidant activities of compounds in raw soy sauce. LWT - Food Sci. Technol. 2019;116 [Google Scholar]

- 14.Mustapha A.T., Zhou C., Amanor-Atiemoh R., Ali T.A.A., Wahia H., Ma H., Sun Y. Efficacy of dual-frequency ultrasound and sanitizers washing treatments on quality retention of cherry tomato. Innov. Food Sci. Emerg. 2020;62 [Google Scholar]

- 15.Azam S.M.R., Ma H., Xu B., Devi S., Siddique M.A.B., Stanley S.L., Bhandari B., Zhu J. Efficacy of ultrasound treatment in the removal of pesticide residues from fresh vegetables: A review. Trends Food Sci. Technol. 2020;97:417–432. [Google Scholar]

- 16.Azam S.M.R., Ma H., Xu B., Devi S., Stanley S.L., Siddique M.A.B., Mujumdar A.S., Zhu J. Multi-frequency multi-mode ultrasound treatment for removing pesticides from lettuce (Lactuca sativa L.) and effects on product quality. LWT - Food Sci. Technol. 2021;143 [Google Scholar]

- 17.Zhang L.H., Liao L., Qiao Y., Wang C., Shi D.F., An K.J., Hu J.Z. Effects of ultrahigh pressure and ultrasound pretreatments on properties of strawberry chips prepared by vacuum-freeze drying. Food Chem. 2020;303 doi: 10.1016/j.foodchem.2019.125386. [DOI] [PubMed] [Google Scholar]

- 18.Xu Z., Feng E., Sun M., Zhou Vacuum pulsation drying of okra (Abelmoschus esculentus L. Moench): Better retention of the quality characteristics by flat sweep frequency and pulsed ultrasound pretreatment. Food Chem. 2020;326 doi: 10.1016/j.foodchem.2020.127026. [DOI] [PubMed] [Google Scholar]

- 19.Bozkir H., Rayman Ergün A., Serdar E., Metin G., Baysal T. Influence of ultrasound and osmotic dehydration pretreatments on drying and quality properties of persimmon fruit. Ultrason. Sonochem. 2019;54:135–141. doi: 10.1016/j.ultsonch.2019.02.006. [DOI] [PubMed] [Google Scholar]

- 20.Li L., Yu Y., Xu Y., Wu J., Yu Y., Peng J., An K., Zou B., Yang W. Effect of ultrasound-assisted osmotic dehydration pretreatment on the drying characteristics and quality properties of Sanhua plum (Prunus salicina L.) LWT - Food Sci. Technol. 2021;138 [Google Scholar]

- 21.Preece K.E., Hooshyar N., Krijgsman A.J., Fryer P.J., Zuidam N.J. Pilot-scale ultrasound-assisted extraction of protein from soybean processing materials shows it is not recommended for industrial usage. J. Food Eng. 2017;206:1–12. [Google Scholar]

- 22.Taiye Mustapha A., Zhou C., Wahia H., Amanor-Atiemoh R., Otu P., Qudus A., Abiola Fakayode O., Ma H. Sonozonation : Enhancing the antimicrobial efficiency of aqueous ozone washing techniques on cherry tomato. Ultrason. Sonochem. 2020;64:105059. doi: 10.1016/j.ultsonch.2020.105059. [DOI] [PubMed] [Google Scholar]

- 23.Liao J., Qu B., Liu D., Zheng N. New method to enhance the extraction yield of rutin from Sophora japonica using a novel ultrasonic extraction system by determining optimum ultrasonic frequency. Ultrason. Sonochem. 2015;27:110–116. doi: 10.1016/j.ultsonch.2015.05.005. [DOI] [PubMed] [Google Scholar]

- 24.Xu B., Ren A., Chen J., Li H., Wei B., Wang J., Azam S.M.R., Bhandari B., Zhou C., Ma H. Effect of multi-mode dual-frequency ultrasound irradiation on the degradation of waxy corn starch in a gelatinized state. Food Hydrocolloid. 2021;113 [Google Scholar]

- 25.Wen C., Zhang J., Zhang H., Duan Y., Ma H. Effects of divergent ultrasound pretreatment on the structure of watermelon seed protein and the antioxidant activity of its hydrolysates. Food Chem. 2019;299 doi: 10.1016/j.foodchem.2019.125165. [DOI] [PubMed] [Google Scholar]

- 26.Feng Y., Ping Tan C., Zhou C., Yagoub A.E.A., Xu B., Sun Y., Ma H., Xu X., Yu X. Effect of freeze-thaw cycles pretreatment on the vacuum freeze-drying process and physicochemical properties of the dried garlic slices. Food Chem. 2020;324 doi: 10.1016/j.foodchem.2020.126883. [DOI] [PubMed] [Google Scholar]

- 27.Wang X., Feng Y., Zhou C., Sun Y., Wu B., Yagoub A.E.A., Aboagarib E.A.A. Effect of vacuum and ethanol pretreatment on infrared-hot air drying of scallion (Allium fistulosum) Food Chem. 2019;295:432–440. doi: 10.1016/j.foodchem.2019.05.145. [DOI] [PubMed] [Google Scholar]

- 28.Yadav B.S., Yadav R.B., Jatain M. Optimization of osmotic dehydration conditions of peach slices in sucrose solution using response surface methodology. J. Food Sci. Tech. Mys. 2012;49(5):547–555. doi: 10.1007/s13197-011-0298-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Xie L., Zhang C., Wang J. Unified and explicit expressions of three-dimensional Green’s functions and their first derivatives for piezoelectric solids with general anisotropy. Int. J. Solids Struct. 2018;155:1–14. [Google Scholar]

- 30.Xu X., Zhang L., Feng Y., Zhou C., Yagoub A.E.A., Wahia H., Ma H., Zhang J., Sun Y. Ultrasound freeze-thawing style pretreatment to improve the efficiency of the vacuum freeze-drying of okra (Abelmoschus esculentus (L.) Moench) and the quality characteristics of the dried product. Ultrason. Sonochem. 2020;70 doi: 10.1016/j.ultsonch.2020.105300. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Xu B., Wei B., Ren X., Liu Y., Jiang H., Zhou C., Ma H., Chalamaiah M., Liang Q., Wang Z. Dielectric pretreatment of rapeseed 1: influence on the drying characteristics of the seeds and physico-chemical properties of cold-pressed oil. Food Bioprocess Technol. 2018;11:1236–1247. [Google Scholar]

- 32.Miano A.C., Rojas M.L., Augusto P.E.D. Structural changes caused by ultrasound pretreatment: Direct and indirect demonstration in potato cylinders. Ultrason. Sonochem. 2019;52:176–183. doi: 10.1016/j.ultsonch.2018.11.015. [DOI] [PubMed] [Google Scholar]

- 33.Wang L., Xu B., Wei B., Zeng R. Low frequency ultrasound pretreatment of carrot slices: Effect on the moisture migration and quality attributes by intermediate-wave infrared radiation drying. Ultrason. Sonochem. 2018;40:619–628. doi: 10.1016/j.ultsonch.2017.08.005. [DOI] [PubMed] [Google Scholar]

- 34.Coklar H., Akbulut M. Anthocyanins and phenolic compounds of Mahonia aquifolium berries and their contributions to antioxidant activity. J. Funct. Foods. 2017;35:166–174. [Google Scholar]

- 35.Li S., Yang X., Zhang Y., Ma H., Liang Q., Qu W., He R., Zhou C., Mahunu G.K. Effects of ultrasound and ultrasound assisted alkaline pretreatments on the enzymolysis and structural characteristics of rice protein. Ultrason. Sonochem. 2016;31:20–28. doi: 10.1016/j.ultsonch.2015.11.019. [DOI] [PubMed] [Google Scholar]

- 36.Rastogi N.K., Raghavarao K.S.M.S. Mass transfer during osmotic dehydration of pineapple: considering Fickian diffusion in cubical configuration. LWT - Food Sci. Technol. 2004;37(1):43–47. [Google Scholar]

- 37.Bozkir H., Ergün A.R. Effect of sonication and osmotic dehydration applications on the hot air drying kinetics and quality of persimmon. LWT - Food Sci. Technol. 2020;131 [Google Scholar]

- 38.Kroehnke J., Szadzinska J., Radziejewska-Kubzdela E., Bieganska-Marecik R., Musielak G., Mierzwa D. Osmotic dehydration and convective drying of kiwifruit (Actinidia deliciosa) - The influence of ultrasound on process kinetics and product quality. Ultrason. Sonochem. 2021;71 doi: 10.1016/j.ultsonch.2020.105377. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Jiang H., Zhang M., Mujumdar A.S., Lim R.-X. Drying uniformity analysis of pulse-spouted microwave–freeze drying of banana cubes. Dry. Technol. 2016;34(5):539–546. [Google Scholar]

- 40.Yin X., Zhang X., Wan M., Duan X., You Q., Zhang J., Li S. Intensification of biodiesel production using dual-frequency counter-current pulsed ultrasound. Ultrason. Sonochem. 2017;37:136–143. doi: 10.1016/j.ultsonch.2016.12.036. [DOI] [PubMed] [Google Scholar]

- 41.Wongwuttanasatian T., Jookjantra K. Effect of dual-frequency pulsed ultrasonic excitation and catalyst size for biodiesel production. Renew. Energy. 2020;152:1220–1226. [Google Scholar]

- 42.Amami E., Khezami W., Mezrigui S., Badwaik L.S., Bejar A.K., Perez C.T., Kechaou N. Effect of ultrasound-assisted osmotic dehydration pretreatment on the convective drying of strawberry. Ultrason. Sonochem. 2017;36:286–300. doi: 10.1016/j.ultsonch.2016.12.007. [DOI] [PubMed] [Google Scholar]

- 43.Allahdad Z., Nasiri M., Varidi M., Varidi M.J. Effect of sonication on osmotic dehydration and subsequent air-drying of pomegranate arils. J. Food Eng. 2019;244:202–211. [Google Scholar]

- 44.Lu K., Guo X., Li Y., Ming J. Characterization of moisture transformation and distribution in mushroom (Lentinus edodes) during hot-air drying. J. Food Process. Pres. 2017;41:e12812. [Google Scholar]

- 45.Alenyorege E.A., Ma H., Aheto J.H., Agyekum A.A., Zhou C. Effect of sequential multi-frequency ultrasound washing processes on quality attributes and volatile compounds profiling of fresh-cut Chinese cabbage. LWT - Food Sci. Technol. 2020;117 [Google Scholar]

- 46.Santos K.C., Guedes J.S., Rojas M.L., Carvalho G.R., Augusto P.E.D. Enhancing carrot convective drying by combining ethanol and ultrasound as pre-treatments: Effect on product structure, quality, energy consumption, drying and rehydration kinetics. Ultrason. Sonochem. 2021;70 doi: 10.1016/j.ultsonch.2020.105304. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Rojas M.L., Silveira I., Augusto P.E.D. Ultrasound and ethanol pre-treatments to improve convective drying: Drying, rehydration and carotenoid content of pumpkin. Food Bioprod. Process. 2020;119:20–30. [Google Scholar]

- 48.Zhang L., Chen F., Yang H., Sun X., Liu H., Gong X., Jiang C., Ding C. Changes in firmness, pectin content and nanostructure of two crisp peach cultivars after storage. LWT - Food Sci. Technol. 2010;43(1):26–32. [Google Scholar]

- 49.Li L., Zhang M., Wang W. Ultrasound-assisted osmotic dehydration pretreatment before pulsed fluidized bed microwave freeze-drying (PFBMFD) of Chinese yam. Food Biosci. 2020;35 [Google Scholar]

- 50.Song X., Hu H., Zhang B. Drying characteristics of Chinese Yam (Dioscorea opposita Thunb.) by far-infrared radiation and heat pump, Journal of the Saudi Society of. Agric. Sci. 2018;17:290–296. [Google Scholar]

- 51.Vieira da Silva Júnior E., Lins de Melo L., Batista de Medeiros R.A., Pimenta Barros Z.M., Azoubel P.M. Influence of ultrasound and vacuum assisted drying on papaya quality parameters. LWT - Food Sci. Technol. 2018;97:317–322. [Google Scholar]

- 52.Cheng L., Soh C., Liew S., Teh F. Effects of sonication and carbonation on guava juice quality. Food Chem. 2007;104(4):1396–1401. [Google Scholar]

- 53.Masuzawa N., Ohdaira E., Ide M. Effects of ultrasonic irradiation on phenolic compounds in wine. Jpn. J. Appl. Phys. 2014;39(5):2978–2979. [Google Scholar]

- 54.Xie P.-jun., You F., Huang L.-xin., Zhang C.-hong. Comprehensive assessment of phenolic compounds and antioxidant performance in the developmental process of jujube (Ziziphus jujuba Mill.) J. Funct. Foods. 2017;36:233–242. [Google Scholar]

- 55.Lu J., Li J., Jin R., Li S., Yi J., Huang J. Extraction and characterization of pectin from Premna microphylla Turcz leaves. Int. J. Biol. Macromol. 2019;131:323–328. doi: 10.1016/j.ijbiomac.2019.03.056. [DOI] [PubMed] [Google Scholar]