Abstract

The killing of sheep and goats for human consumption (slaughtering) can take place in a slaughterhouse or on‐farm. The processes of slaughtering that were assessed for welfare, from the arrival of sheep and goats until their death (including slaughtering without stunning), were grouped into three main phases: pre‐stunning (including arrival, unloading from the truck, lairage, handling and moving of sheep and goats); stunning (including restraint); and bleeding. Stunning methods were grouped into two categories: mechanical and electrical. Twelve welfare consequences that sheep and goats may experience during slaughter were identified: heat stress, cold stress, fatigue, prolonged thirst, prolonged hunger, impeded movement, restriction of movements, resting problems, social stress, pain, fear and distress. These welfare consequences and their relevant animal‐based measures are described in detail in this Scientific Opinion. In total, 40 welfare hazards that could occur during slaughter were identified and characterised, most of them related to stunning and bleeding. Staff were identified as the origin of 39 hazards, which were attributed to the lack of appropriate skill sets needed to perform tasks or to fatigue. Measures to prevent and correct hazards were identified, and structural and managerial measures were identified as those with a crucial role in prevention. Outcome tables linking hazards, welfare consequences, animal‐based measures, origin of hazards and preventive and corrective measures were developed for each process. Mitigation measures to minimise welfare consequences are proposed.

Keywords: small ruminants, slaughter, hazards, animal welfare consequences, ABMs, preventive/corrective measures

Summary

The European Commission requested EFSA to provide a Scientific Opinion on the slaughter of sheep and goats.

With specific reference to arrival of the animals, unloading, lairage, handling and moving to the stunning area, restraint, stunning and bleeding, EFSA was asked to identify the animal welfare hazards and their possible origins in terms of facilities/equipment and staff (Term of Reference (ToR)‐1); define qualitative or measurable criteria to assess performance on animal welfare (animal‐based measures (ABMs)) (ToR‐2); provide preventive and corrective measures (structural or managerial) to address the hazards identified (ToR‐3); and point out specific hazards related to species or type of animal (e.g. rams, young lambs/kids) (ToR‐4). In addition, the European Commission asked EFSA to provide measures to mitigate the welfare consequences that can be caused by the identified hazards.

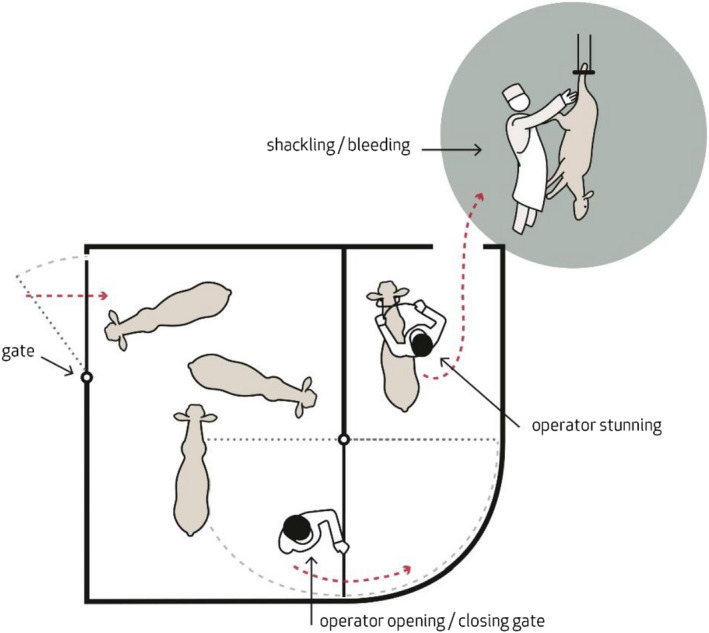

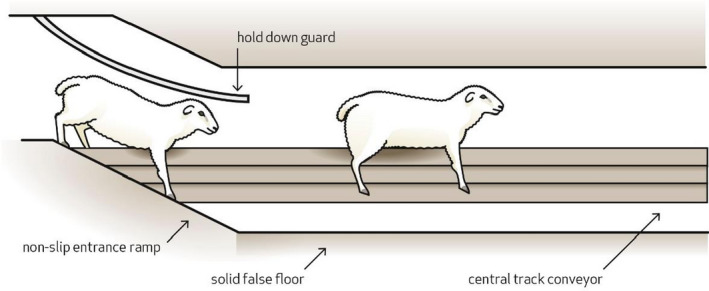

This Scientific Opinion concerns the killing of sheep and goats for human consumption that could take place in a slaughterhouse or during on‐farm slaughter. In the context of this Opinion, each related operation is a process, and several related operations (processes) are grouped in phases. The phases that have been assessed in this Opinion, from arrival until the animal is dead (including slaughtering without stunning), are: Phase 1 – pre‐stunning, Phase 2 – stunning and Phase 3 – bleeding. Phase 1 includes the following processes (in chronological order): (a) arrival, (b) unloading of the animals from the truck, (c) lairage and (d) handling and moving to the stunning area. Because restraint prior to stunning varies depending on the stunning method, restraint is assessed as a part of the relevant stunning method (Phase 2). The bleeding phase (Phase 3) includes exsanguination following stunning and slaughter without stunning.

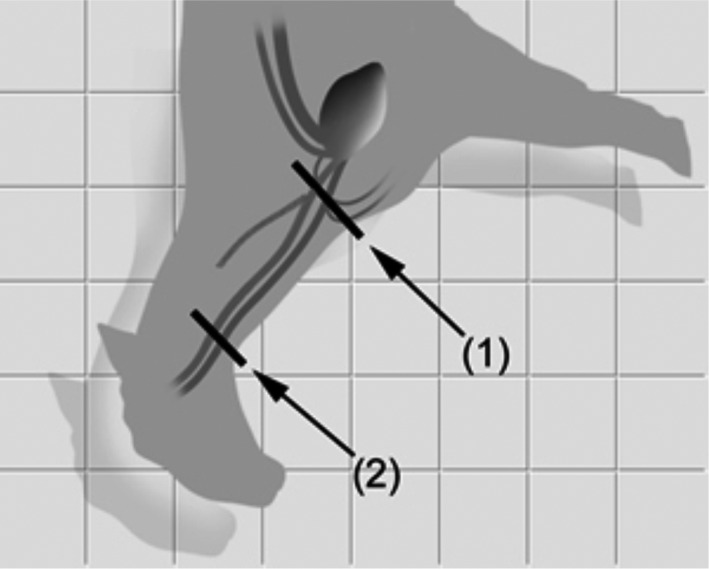

The stunning methods that have been identified as relevant for sheep and goats can be grouped in two categories: mechanical and electrical. The mechanical methods include penetrative and non‐penetrative captive bolt stunning as well as stunning using percussive blow to the head and firearms with free projectiles. Electrical methods include head‐only and head‐to‐body stunning.

In answering ToR‐1, 40 hazards related to the welfare consequences applying from arrival of sheep and goats at the slaughterhouse until they are dead were identified. The majority of hazards identified in this opinion (39 of 40) have staff as origin, and hazards can be attributed to the lack of appropriate skills to perform tasks (e.g. inappropriate handling, use of wrong parameters for electrical methods) or to fatigue.

The mandate requested to provide definitions of qualitative or measurable (quantitative) criteria to assess performance (i.e. consequences) on animal welfare (ABMs; ToR‐2) derived from these hazards; this ToR was addressed by identifying the welfare consequences occurring to sheep during slaughter and the relevant ABMs that can be used to assess qualitatively or quantitatively these welfare consequences. In total 12 welfare consequences were identified: heat stress, cold stress, fatigue, prolonged thirst, prolonged hunger, impeded movement, restriction of movements, resting problems, social stress, pain, fear and distress. Lists and definitions of ABMs to be used for assessing these welfare consequences have been provided in this Opinion.

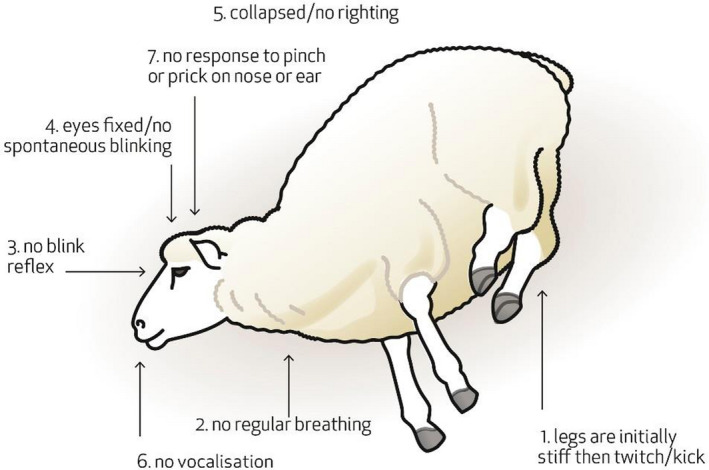

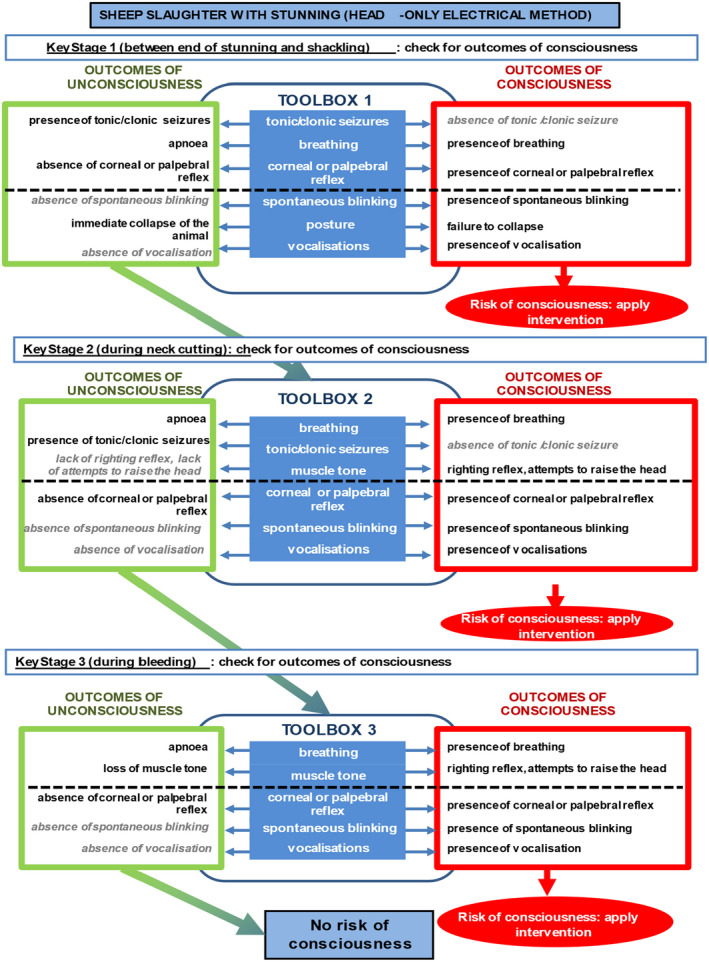

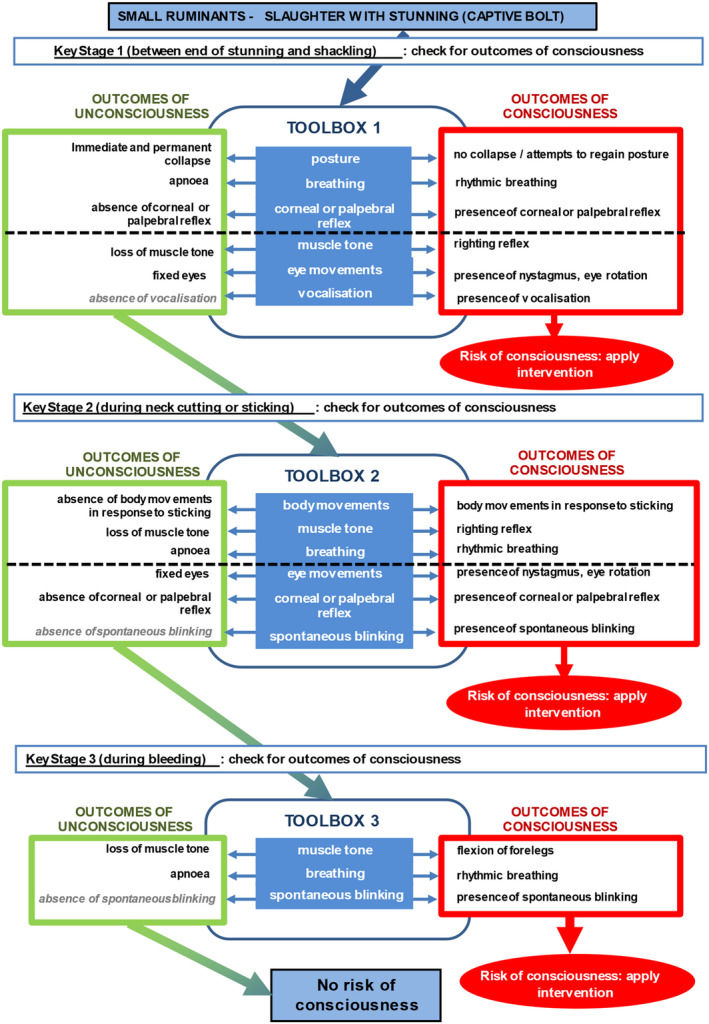

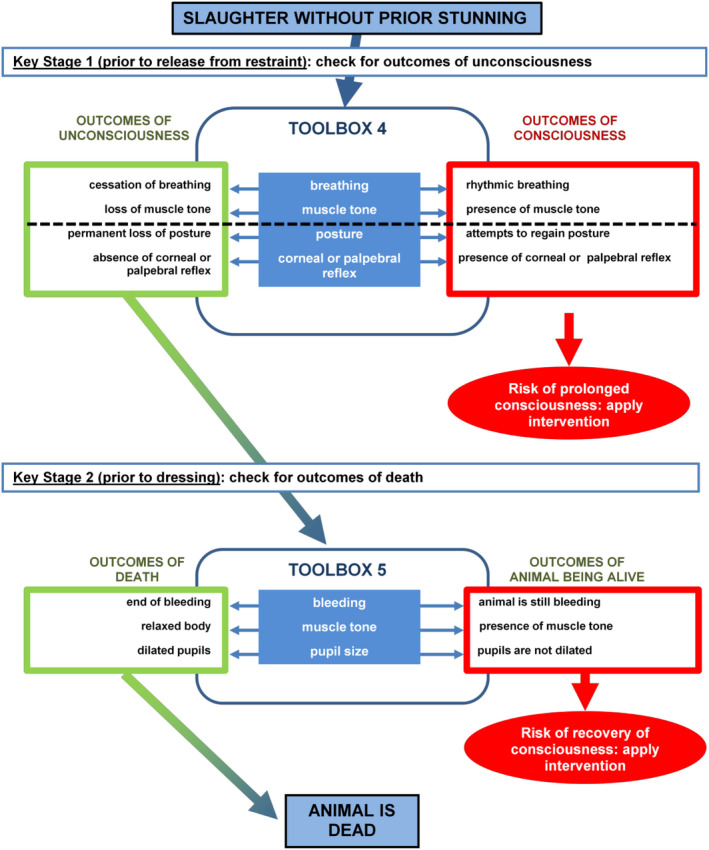

It is to be noted that ABMs during stunning are the signs of consciousness, since consciousness is the prerequisite for animals to experience pain and fear during stunning. These ABMs of consciousness are specific to the stunning methods and were proposed in a previous EFSA Opinion (EFSA AHAW Panel, 2013a). Flowcharts, including ABMs of consciousness to be used for monitoring of stunning efficacy, are reproduced in this Opinion in order to provide the European Commission with the full welfare assessment at slaughter.

In response to ToR‐3, preventive and corrective measures have been identified and described. Some are specific for a particular hazard; others can apply to multiple hazards (e.g. staff training and rotation). For most hazards, preventive measures can be put in place with management having a crucial role in prevention. However, for some hazards related to restraint and bleeding when slaughtering without stunning, no preventive measures could be identified. Corrective measures were identified for 28 hazards. When no corrective measures are available or feasible, actions to mitigate the welfare consequences caused by the identified hazards should be put in place.

To prevent sheep and goats to suffer from severe welfare consequences, a standard operating procedure (SOP) should be applied and should include identification of hazards and related welfare consequences, using relevant ABMs, as well as preventive and corrective measures.

At arrival, sheep and goats should be unloaded without delay and those showing signs of severe pain, signs of illness or those unable to move independently, should be inspected and a procedure for emergency slaughter should be applied without delay.

Keeping sheep and goats in lairage should be avoided, unless it benefits their welfare. If lairage cannot be avoided, animals should have access to water and protection from adverse weather conditions and lactating females should be milked to release the udder pressure. If milking is necessary, the milking interval should not exceed 12 h as prescribed in the EU Regulation on transport (EC Reg 1/2005). Mixing of unfamiliar goats, particularly of horned animals, should be avoided. Suckling lambs and goat kids are more susceptible when compared with adult animals to prolonged thirst and hunger. They are also more prone to cold stress and need additional protection in lairage. Therefore, suckling lambs and goat kids should be slaughtered without lairage. If slaughter is delayed, they need to be fed with suitable milk replacement at regular intervals.

During handling, sheep and goats might experience pain, fear and impeded movement. These can be assessed using ABMs: slipping, falling, escape attempts, vocalisation, injuries, reluctance to move and turning back. Sheep and goats can be handled and moved using lead animals of the same species. Dogs should not be used. When handled by operators, painful handling, such as lifting and dragging by horns or wool or one leg, hitting with a stick, etc., should be avoided. Instead, passive stimuli such as flags and paddles should be used.

Restraining, stunning and slaughter methods, which cause severe pain and fear, should not be used. To monitor stunning method efficacy, the state of consciousness of the animals should be checked immediately after stunning, just prior to neck cutting and during bleeding. Death must be confirmed before carcass processing begins.

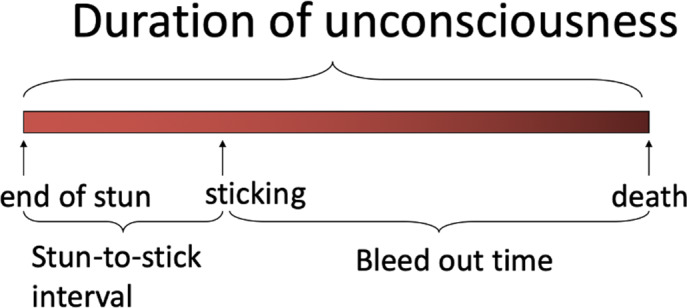

Head‐only electrical stunning results in short duration of unconsciousness and therefore the onus of preventing recovery of consciousness, leading to poor welfare outcome, relies on the prompt and accurate bleeding. 4. In the light of the available scientific evidence at present, a minimum of 1.0 A is required to guarantee effective electrical stunning of all sheep and goats, including lambs and goat kids.

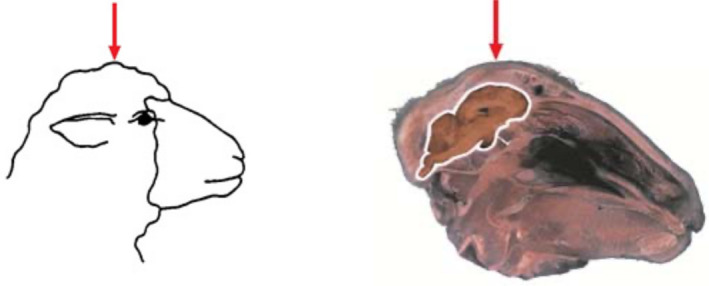

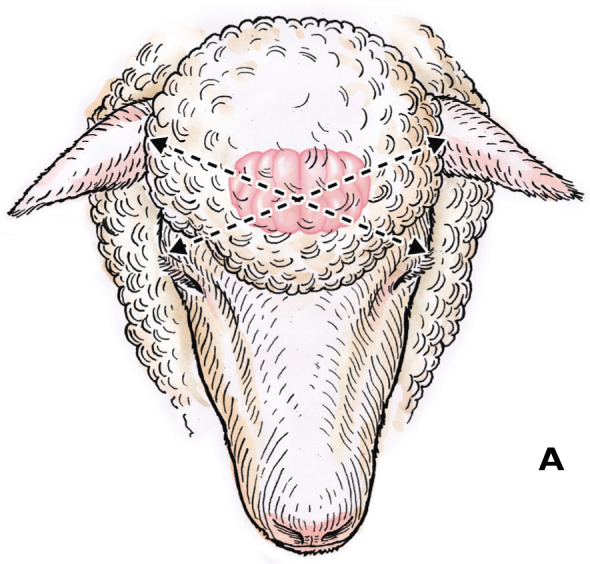

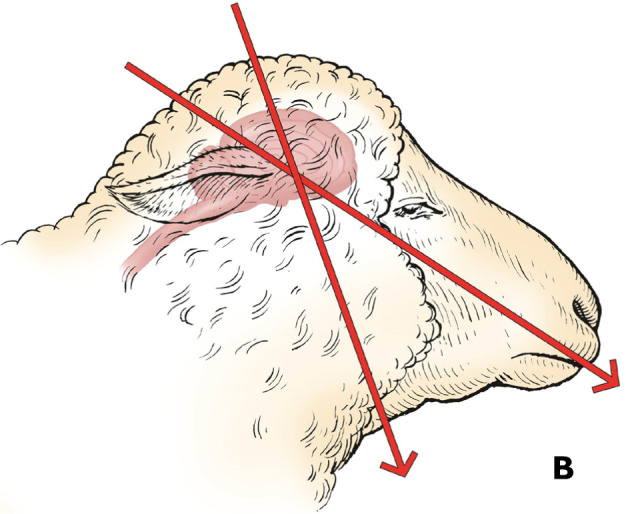

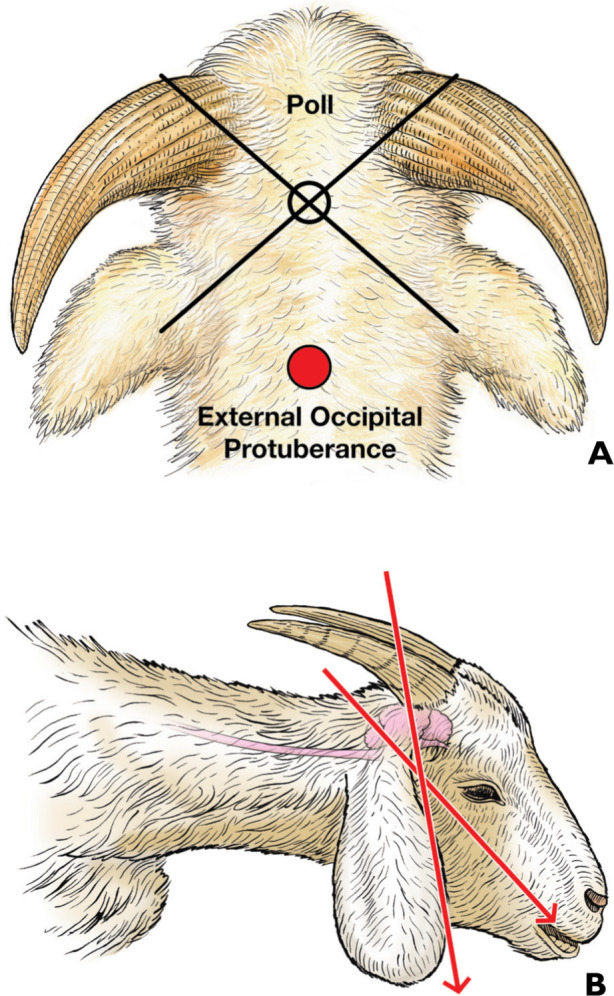

Ineffective captive bolt stunning is mostly due to wrong shooting position and direction and inappropriate stunning parameters. The use of non‐penetrative captive bolt guns for stunning sheep and goats should be restricted to animals of less than 10 kg live weight.

Exposure to CO2 at high concentrations (higher than 90% by volume) is considered a serious welfare concern by the Panel, because it is aversive and causes pain, fear and respiratory distress. Scientific evidence regarding the impact on welfare of the use of inert gases and CO2 with inert gases is lacking; therefore, more research is recommended.

The Panel considers bleeding of ineffectively stunned animals and those recovering consciousness following stunning a serious welfare concern, as it leads to severe pain, fear and distress.

Slaughter without stunning should not be practiced. The Panel considers this a serious welfare concern because it leads to severe pain, fear and distress due to restraint for the neck cutting and the cutting of soft tissues in the neck that will last until the onset of unconsciousness.

Certain animal categories like animals with heavy horns or a thick fleece or animals coming from extensive rearing systems should be handled with special care; specific measures for these situations are described in the text.

1. Introduction

1.1. Background and Terms of Reference as provided by the requestor

1.1.1. Background

The Union adopted in 2009 Council Regulation (EC) No 1099/2009 on the protection of animals at the time of killing. This piece of legislation was prepared based on two EFSA opinions respectively adopted in 2004 and 2006. The EFSA provided additional opinions related to this subject in 2012, 2013, 2014, 2015 and 2017.

In parallel, since 2005, the World Organisation for Animal Health (OIE) has developed in its Terrestrial Animal Health Code two chapters covering a similar scope:

-

–

Slaughter of animals (Chapter 7.5);

-

–

Killing of animals for disease control purposes (Chapter 7.6)

The chapter slaughter of animals covers the following species: cattle, buffalo, bison, sheep, goats, camelids, deer, horses, pigs, ratites, rabbits and poultry (domestic birds as defined by the OIE).

The OIE has created an ad hoc working group with the view to revise the two chapters.

Against this background, the Commission would like to request the EFSA to review the scientific publications provided and possibly other sources to provide a sound scientific basis for the future discussions at international level on the welfare of animals in the context of slaughter (i.e. killing animals for human consumption) or other types of killing (killing for other purposes than slaughter).

1.1.2. Terms of Reference

The Commission therefore considers it opportune to request EFSA to give an independent view on the slaughter of animals (killing for human consumption) concerning two categories of animals:

-

–

free moving animals (cattle, buffalo, bison, sheep, goats, camelids, deer, horses, pigs, ratites)

-

–

animals in crates or containers (i.e. rabbits and domestic birds).

-

–

The request covers the following processes and issues:

-

–

arrival of the animals,

-

–

unloading,

-

–

lairage,

-

–

handling and moving of the animals (free moving animals only),

-

–

restraint,

-

–

stunning,

-

–

bleeding,

-

–

slaughter of pregnant animals (free moving animals only),

-

–

emergency killing (reasons and conditions under which animals have to be killed outside the normal slaughter line),

-

–

unacceptable methods, procedures or practices on welfare grounds.

For each process or issue in each category (i.e. free moving/in crates or containers), EFSA will:

-

–

ToR‐1: Identify the animal welfare hazards and their possible origins (facilities/equipment, staff),

-

–

ToR‐2: Define qualitative or measurable criteria to assess performance on animal welfare (animal‐based measures (ABM)),

-

–

ToR‐3: Provide preventive and corrective measures to address the hazards identified (through structural or managerial measures),

-

–

ToR‐4: Point out specific hazards related to species or types of animals (young, with horns, etc.).

1.2. Interpretation of Terms of Reference

This Scientific Opinion concerns the slaughter of small ruminants.

This Opinion will use definitions concerning the killing of sheep and goats, including the related operations, provided by Council Regulation (EC) No. 1099/2009 of 24 September 20091 on the protection of animals at the time of killing, which entered into force in January 2013. The Regulation defines slaughtering as the killing of animals intended for human consumption; the related operations include handling before and during lairage, restraining, stunning and bleeding of animals. Emergency killing is intended in this Opinion as emergency slaughter (see Section 3.4).

This Opinion therefore concerns the killing of sheep and goats for human consumption that could take place in a slaughterhouse, from arrival until the animal is dead (including slaughter without stunning). In the context of this Opinion, each related operation is a process, and several related operations (processes) are grouped into phases. The phases assessed in this Opinion are: Phase 1 – pre‐stunning, Phase 2 – stunning and Phase 3 – bleeding. Phase 1 includes (in chronological order): (a) arrival, (b) unloading of animals from the truck until the lairage area, (c) lairage and (d) handling and moving to the stunning (or sticking) area. Because restraint of sheep and goats prior to stunning varies depending on the stunning method, restraint will be assessed as a part of the relevant stunning method (Phase 2). For the bleeding phase (Phase 3), a distinction has been made between (a) the bleeding of sheep and goats following stunning and (b) the bleeding during slaughter without previous stunning, including restraint.

Slaughter can also be performed on‐farm with the same phases and processes described above, except arrival, unloading and lairage. Therefore, the assessment carried out in this Opinion applies to both slaughtering in slaughterhouses or on farm.

As this Opinion will be used by the European Commission to address the OIE standards, it considers more methods for slaughter than those reported in Council Regulation (EC) No 1099/2009.

Among the methods that are used for slaughter worldwide, EFSA has applied the following criteria for the selection of methods to include in this assessment: (a) all methods known to the experts that have technical specifications, i.e. not limited to the methods described in Council Regulation (EC) No 1099/2009, and (b) methods currently used for slaughter of sheep and goats and (c) methods for which the welfare aspects (in terms of welfare hazards, welfare consequences, ABMs, preventive and corrective measures) are sufficiently described in the scientific literature.

The mandate requests EFSA to identify hazards at different stages (processes) of slaughtering and their relevant origins in terms of equipment/facilities or staff (ToR‐1). When discussing the origin of the hazards, it was considered necessary to provide further details on the actions of the staff or features of the equipment and facilities causing the hazards. Therefore, for each origin category (staff, facilities/equipment), relevant specifications have been identified by expert Opinion. Hazards originating from the farm or during transport for which welfare consequence persist on arrival are also considered in this scientific opinion.

This scientific opinion will report the hazards that can occur during slaughtering of sheep and goats in all ‘types’ of slaughterhouses (from industrial slaughterhouses with automated processes to on‐farm slaughter), but not all of the hazards apply to all slaughter situations, e.g. in small abattoirs or during on‐farm slaughter. Indeed, hazards applicable to a specific stunning method may occur in all situations where this method is applied, whereas some other hazards may not apply in certain circumstances, e.g. the ones specific to the arrival or unloading of the animals in on‐farm slaughter.

Hazards may be specified at different levels of detail and could therefore be subdivided into multiple ones depending on the chosen level of detail. For example, the hazard ‘incorrect captive bolt parameters’ for captive‐bolt stunning, could be further subdivided into ‘inappropriate bolt diameter’, ‘inappropriate exit length’ or ‘inappropriate cartridge used’. For this Opinion, it was agreed to define hazards by an agreed broad level of detail (e.g. ‘incorrect captive bolt parameters’ in the example above).

The mandate also asks to define quantitative or qualitative criteria to assess performance (i.e. consequences) on animal welfare (ABMs; ToR‐2). This ToR has been addressed by identifying the (negative) welfare consequences occurring to sheep and goats due to the identified hazards and the relevant ABMs that can be used to assess the welfare consequences qualitatively and/or quantitatively. In this scientific opinion, each welfare consequence is addressed in a separate chapter that includes information on its assessment (i.e. definition of the welfare consequence and ABMs to measure it). In some circumstances, ABMs may not exist or are not feasible in the context of slaughtering of sheep and goats; in these cases, emphasis will be given to the relevant measures to prevent the hazards or to mitigate the welfare consequences.

Animals can experience welfare consequences only when they are conscious. This applies to all sheep and goats during the pre‐stunning phase. In the stunning phase, sheep and goats may experience welfare consequences (pain and fear), if hazards occur during restraint (before stunning), if induction of unconsciousness is not immediate or if stunning is ineffective. During bleeding following stunning, sheep and goats will experience welfare consequences in case of persistence of consciousness or if they recover consciousness before death. Therefore, consciousness is not a welfare consequence per se but a prerequisite for experiencing pain and fear.

During the stunning phase, the state of consciousness is assessed to identify if animals are successfully rendered unconscious or if they are conscious (e.g. stunning was ineffective or they recovered consciousness) and therefore at risk of experiencing pain and fear. For each ABM of state of consciousness, outcomes either suggesting unconsciousness (e.g. presence of tonic seizure) or suggesting consciousness (e.g. absence of tonic seizure) have been identified.

In this Opinion, distress – which can be defined as a conscious, negatively valenced, intensified affective motivational state that occurs in response to a perception that current coping mechanisms (involving physiological stress responses) are at risk of failing to alleviate the aversiveness of the current situation in a sufficient and timely manner (Mc Millan, 2020) – has not been included as a specific welfare consequence for Phase 1 and 2 (pre‐stunning and stunning). This is due to the consideration that distress may result from e.g. pain and fear, depending on the duration and severity of the latter, which are among the welfare consequences addressed in this Opinion. Therefore, distress was not listed separately for these phases. However, animals will experience distress when ineffectively stunned or if they recover consciousness during bleeding following stunning as well as during slaughter without stunning; therefore, it has been considered as a stand‐alone welfare consequence during Phase 3 (bleeding).

In this Opinion, in the description of the processes of each phase and the relevant welfare consequences that sheep and goats can experience when exposed to hazards will be reported. In this respect, the ranking of the identified hazards in terms of severity, duration or frequency of the welfare consequences that they can cause is not considered in this mandate.

The mandate also requests to indicate preventive and corrective measures to the hazards and the welfare consequences. The preventive and corrective measures to be provided were interpreted as those measures that can be put in practice by the person responsible for the slaughtering in order to prevent or correct the identified hazards. These measures will fall into two main categories: (1) structural and (2) managerial (ToR‐3). Some corrective measures of the hazards will mitigate the welfare consequence (e.g. provision of adequate ventilation at lairage will mitigate the welfare consequence of ‘heat stress’). However, other measures, although correcting the hazard, will not mitigate the welfare consequence (e.g. stop shouting will correct the hazard of ‘unexpected loud noise’ but will not mitigate the fear of the animals already exposed to the noise). Furthermore, training the staff not to shout will prevent the hazard. When corrective measures for the hazards are not available or feasible to put in place, actions to mitigate the welfare consequences caused by the identified hazards will be discussed. In this Opinion, preventive, corrective and mitigation measures are presented differently for (i) the processes that precede stunning (arrival, unloading from the truck, lairage, handling and moving of the animals to the stunning point) and for (ii) the stunning methods. In the first case, all measures are presented in the chapter on the welfare consequence under assessment and go under the name ‘management of the welfare consequence’; in the second case, all measures are presented in a separate subchapter ‘prevention and correction of welfare consequence and their related hazards’ within the stunning method. In addition, it will be assessed whether specific categories of domestic ruminants such as suckling lambs, goat kids, horned sheep and goats might be subjected to specific hazards (ToR‐4).

The mandate also requests a list of methods, procedures or practices deemed unacceptable on welfare grounds. In order to answer to this request, the Panel is aware of two issues with this request. Firstly, it has to be noted that some methods, procedures or practices under question cannot be subjected to a risk assessment procedure because there is no published scientific evidence relating to them. Secondly, although scientific risk assessment can support discussions on what practices are acceptable or unacceptable on welfare grounds, the ultimate decisions on acceptability involve e.g. ethical and socio‐economic considerations that need to be weighed by the risk managers.

In response to this request, the Panel agrees with Chapter 7.5.10 of the terrestrial code of the World Organisation for Animal Health (OIE, 2019) as well as the methods of restraint that are prohibited and listed in EC Regulation 1099/2009. Additionally, the Panel listed practices for which welfare consequences were identified and classified as ‘severe’. To do so, expert knowledge was elicited and the available scientific evidence was assessed in order to subdivide practices into two groups, namely the group of those leading to ‘severe’ welfare consequences and the group of those not leading to ‘severe’ welfare consequences. For the practices leading to severe welfare consequences, the Panel has serious welfare concerns and therefore recommends that these practices should be avoided, redesigned or replaced by other practices, leading to better welfare outcomes. These practices are discussed in this Opinion.

2. Data and methodologies

2.1. Data

2.1.1. Data from literature

Information from the papers selected as relevant from the literature search (LS) described in Section 2.2.1 and from additional literature identified by the working group (WG) experts was used for a narrative description and assessment to address ToRs 1, 2, 3 and 4 (see relevant sections in the chapter on Assessment).

2.1.2. Data from Member States and expert opinion

The data obtained from the literature were complemented by the WG experts’ opinion in order to identify the origins of hazards, welfare consequences, ABMs and hazard preventive and corrective measures relevant to the current assessment.

2.2. Methodologies

To address the questions formulated by the European Commission in ToRs 1–4, two main approaches were used to develop this Opinion: (i) literature search and (ii) expert opinion through WG discussion. These methodologies were used to address the mandate extensively (see relevant sections in the Assessment chapter) and also in a concise way with the development of outcome tables (see Section 2.2.3).

The general principle adopted in the preparation of this Opinion was that relevant reference(s) would be cited in the text when published scientific literature is available, and expert opinion would be used when no published scientific literature was available or to complete the results retrieved.

2.2.1. Literature search

A broad literature search under the framework of ‘welfare of sheep and goats at slaughter and killing’ was carried out to identify peer‐reviewed scientific evidence providing information on the elements requested by the ToRs, i.e. description of the processes, identification of welfare hazards, origin, preventive and corrective measures, welfare consequences and related ABMs.

Restrictions were applied in relation to the date of publication, considering only those records published after a previous EFSA Scientific Opinion on the topic (EFSA, 2004). A total of 221 references were retrieved and reviewed by the WG members to select potentially relevant references. This screening produced 90 relevant references. Discrepancies were discussed between the WG members until a final subset of 46 relevant references was selected and considered in this assessment by reviewing the full papers.

Full details of the literature search protocol, strategies and results, including the number of the records that underpin each process, are provided in Appendix A to this opinion.

In addition, the experts in the WG selected relevant references starting from scientific papers, including review papers, books chapters, non‐peer review papers known by the experts themselves or retrieved through non‐systematic searches, until the information of the subject was considered sufficient to undertake the assessment by the WG. If needed, relevant publications before 2004 were considered.

2.2.2. Risk assessment methodology and structure of the opinion

The working group experts followed the risk assessment methodology from the EFSA's guidance on risk assessment in animal welfare (EFSA AHAW Panel, 2012).

Based on expert opinion through working group discussion, the WG experts first described the phases and related processes of slaughter and specifically which stunning/killing methods should be considered in the current assessment.

Using the available literature and their own knowledge, the experts then produced a list of the possible welfare consequences characterising each process related to the slaughter of sheep and goats. To address the ToRs, the experts then identified the hazards leading to those welfare consequences and their origin (ToR‐1) and the applicable preventive and corrective measures (ToR‐3). ABMs for measuring the welfare consequences were identified (ToR‐2). Measures to mitigate the welfare consequences were also considered.

Related to the structure of the Opinion, chapters are organised by phases: Phase 1 – pre‐stunning, Phase 2 – stunning and, Phase 3 – bleeding. Phase 1 is divided in processes (e.g. arrival, lairage). In Phase 2, there is only one process, stunning, under which several methods are described (e.g. captive‐bolt stunning, head‐only electrical stunning). In Phase 3, there is only one process, i.e. bleeding. For each process, there is a description of its welfare consequences, ABMs, hazards, preventive and corrective measures.

2.2.3. Development of outcome tables to answer the ToRs

The main results of the current assessment are summarised in outcome tables, which can be retrieved at the end of each specific Chapter.

The outcome tables link all the mentioned elements requested by ToRs 1, 2 and 3 of the mandate and provide an overall outcome for each process of slaughter in which all retrieved information is presented concisely (see description of the structure below, in Table 1). Conclusions and recommendations of this scientific Opinion are mainly based on the outcome tables.

Table 1.

Example of the Structure of an outcome table

| Hazard | Welfare consequence due to the hazard | Hazard origin(s) | Hazard origin specification | Preventive measure/s for the hazard (implementation of SOP) | Corrective measure/s for the hazard |

|---|---|---|---|---|---|

| (Number of section) | |||||

| ABMs: (to assess the identified welfare consequences) | |||||

The outcome tables have the following structure and terminology:

OUTCOME TABLE: Each table represents the summarised information for each small ruminant slaughter process (see Sections 3.1 to 3.3).

HAZARD: The first column in each table reports all hazards pertaining to the specific process; the number of the Chapter where each hazard is described in detail is reported in brackets. For each hazard, the individual row represents the summarised information relevant to the elements analysed for that hazard. Therefore, it links between an identified hazard, the relevant welfare consequences, origin/s of hazards and preventive and corrective measures (see example in Table 1).

WELFARE CONSEQUENCES OCCURRING TO THE SHEEP AND GOATS DUE TO THE HAZARD: This column lists the welfare consequences to sheep and goats of the mentioned hazards.

HAZARD ORIGIN: This column contains the information related to the category of hazard origin, which can be staff‐, equipment‐ or facility‐related. Most hazards can have more than one origin.

HAZARD ORIGIN SPECIFICATION: This column further specifies the origin of the hazard, namely, what actions of the staff or features of the equipment and facilities can cause the hazard. This information is needed to understand and choose among the proposed preventive and corrective measures.

PREVENTIVE MEASURE/S FOR THE HAZARD: Depending on the hazard origin/s, several measures to prevent the hazard are proposed in this column. They are also elements for implementing standard operating procedures (SOP).

CORRECTIVE MEASURE/S FOR THE HAZARDS: In this column, practical actions/measures for correction of the mentioned hazards are proposed. These actions relate to the identified origin of the hazards.

ANIMAL‐BASED MEASURES: The bottom row lists the feasible measures to be measured on sheep and goats to assess the welfare identified consequences of a hazard.

2.2.4. Uncertainty analysis

The outcome tables include qualitative information on the hazards and related elements identified through the methodologies explained in Section 2.2.

When considering the outcome tables, uncertainty exists at two levels: (i) related to the completeness of the information presented in the table, namely to the number of rows within a table (i.e. hazard identification) and (ii) related to the information presented within a row of the table (i.e. completeness of hazard origins, preventive and corrective measures on the one side and welfare consequences and ABMs on the other side). Normally, an uncertainty analysis would include a full evaluation according to EFSA guidance (EFSA, 2019). However, owing to the limited time available to develop this scientific opinion, an uncertainty analysis was only performed for the first point listed above, i.e. for the hazard identification.

Therefore, the uncertainties during hazard identification could result in two types of error:

Misclassification (false‐positive hazards): Some welfare‐related hazards may be wrongly included in the list of hazards of an outcome table without being relevant.

Incompleteness (false‐negative hazards): Some welfare‐related hazards may be missed in the identification process and so would be considered non‐existent or not relevant.

Incompleteness (false negatives) can lead to underestimation of the hazards with the potential to cause (negative) welfare consequences.

The uncertainty analysis was limited to the quantification of the probability of occurrence of false‐positive or false‐negative hazards.

For evaluation of the risk of occurrence of false‐positive hazards in the assessment, the experts elicited for each hazard the probability that it may exist during the slaughter process and should therefore be included in the outcome table (i.e. the probability of being a true positive). For evaluation of the risk of occurrence of false‐negative hazards in the assessment, the experts elicited the probability that at least one welfare‐related hazard was missed in the outcome table. False‐negative hazards relates to the global situation, i.e. including all possible variations to the slaughter practices that are employed in the world and that might be unknown to the experts of the WG. The Panel agreed that it was relevant to distinguish the probability of occurrence of false‐negative hazards under these two scenarios.

For the elicitation, the experts used the approximate probability scale (see Table 2) proposed in the EFSA uncertainty guidance (EFSA, 2019). Experts first provided individual judgements that were then discussed, and a consensus judgement was obtained.

Table 2.

| Probability term | Subjective probability range | Additional options | |

|---|---|---|---|

| Almost certain | 99–100% | More likely than not: > 50% | Unable to give any probability: range is 0–100% Report as ‘inconclusive’, ‘cannot conclude’ or ‘unknown’ |

| Extremely likely | 95–99% | ||

| Very likely | 90–95% | ||

| Likely | 66–90% | ||

| About as likely as not | 33–66% | ||

| Unlikely | 10–33% | ||

| Very unlikely | 5–10% | ||

| Extremely unlikely | 1–5% | ||

| Almost impossible | 0–1% | ||

3. Assessment

3.1. Phase 1: pre‐stunning

3.1.1. Introduction to pre‐stunning

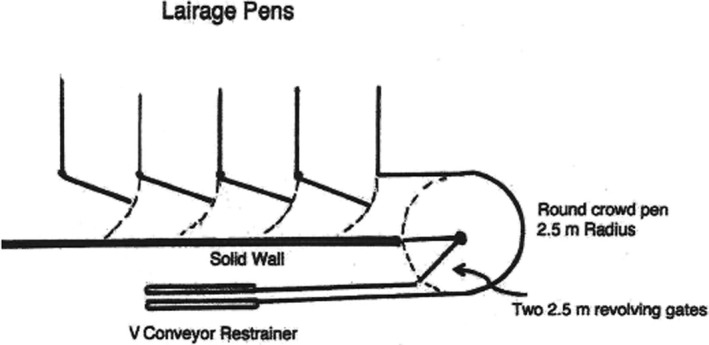

The pre‐stunning phase includes four processes: arrival, unloading from the truck, lairage and handling and moving of animals from lairage to the stunning/bleeding area. These processes are described in Sections 3.1.2, 3.1.5. The outcome tables related to each process are reported at the end of each Chapter.

It is worth mentioning that, within the EU, unloading is considered to be part of the journey and is completed only when the last animal on the truck is unloaded.

The number of animals slaughtered varies greatly between slaughterhouses around the world, e.g. nearly 25,000 sheep were slaughtered per day during July 2021 in New Zealand.2 This demands a great deal of planning and scheduling of the arrival of transport trucks and steady movement of animals from lairage/holding pens to the killing area.

The condition and management of animals before and during transport can have a cumulative effect on animal welfare at arrival. For example, rounding up and driving of sheep from the fields in large extensive production systems and long‐distance transport through difficult geographical routes would have cumulative effect on welfare. In small sheep production conditions on the other hand, there can be a lack of appropriate installations for loading/unloading and deficiencies in the vehicle structure or equipment leading to poor welfare outcomes (Gallo et al., 2018).

Another potential source of poor animal welfare seems to be the marketing source, as welfare of sheep sold through livestock markets is considered to be poorer than for animals sold directly to abattoirs. The main welfare concerns for market‐sold sheep include fatigue, fear, distress, prolonged hunger due to fasting, dehydration and pain due to injuries (Murray et al., 2000).

Although sheep and goats are often considered together as sheep and goats, there are distinct differences between the two species of animals in terms of their behaviour and temperament (AWC, 2020). Goats are more curious, bold and agile than most breeds of sheep. They are able to climb and balance and this, combined with their inquisitiveness, means they are able to escape pens that are designed to contain sheep. Goats are also usually taller than sheep and have longer legs, which has implications for whether the same handling and restraining systems may be used for both species. Goats are also less fearful of new experiences (neophobic) than sheep and will explore unfamiliar surroundings and investigate objects with their prehensile upper lip and tongue. In groups, goats display less consistent herding behaviour than sheep, and they are more independent and in general less fearful of humans (AWC, 2020). Sheep usually flee from approaching handler whereas goats may be familiar, or even aggressive towards the handler, in certain conditions.

3.1.2. Arrival

Arrival of animals at a slaughterhouse is the first process of the pre‐stunning phase and it takes place from the moment the truck arrives at the slaughterhouse until the animals are unloaded from the truck.

In general, the welfare state of animals at the time of arrival at the slaughterhouse will be the cumulative effects of several steps associated with handling, penning, loading and transport to the slaughterhouse (Terlouw et al., 2008; Ekiz et al., 2012; Fernandez et al., 2018).

Transport involves mixing with other animals, novel experiences (new environment and people) and prolonged standing, often after periods of water and feed withdrawal (Collins et al., 2018). Therefore, depending on the conditions, transport constitutes a moderate to severe stress in animals, and the physiological stresses induced can be relatively long‐lasting (Knowles et al., 1995). Some authors (Broom et al., 1996; Knowles, 1998) reported that loading the sheep on to the truck and the initial part of the journey are the most stressful steps of transport. Rearing conditions and production systems also have an effect on stress responses to handling on the farm. Animals reared under very extensive conditions are likely to be less habituated to human contact (EFSA AHAW Panel, 2014) and this may result in a bigger stress response during loading, that may persist at the time of arrival (Hall et al., 1998a).

A study carried out by Eriksen et al. (2013) in Norway indicated that lambs slaughtered at the conventional slaughterhouse had higher serum cortisol levels than lambs slaughtered on‐farm with a mobile abattoir (with no transportation). Lambs at the conventional slaughterhouse displayed a higher frequency of vocalisations and showed more aggressive behaviour than lambs at the mobile slaughterhouse. The authors suggested that such behaviours may be induced by crowding and mixing of animal groups leading to social instability and formation of new hierarchy, and/or be due to other stressors, such as feed deprivation, novel environments or handling. These results clearly suggest that transport of animals to the slaughterhouse is stressful to them.

Behavioural evidence of stress in goats such as jumping and bleating is apparent, particularly at the start of the journey (within 10 min). Goats are also prone to trapping their feet, legs or horns, e.g. in gaps in the sides of vehicles, which can result in injuries. This could also occur in sheep. Aggression may be an issue during transport in goats and is exacerbated by close confinement; it is characterised by horn hooking and head butting. The risk of injury increases when horned goats are placed in crowded conditions. Goats prefer to stand parallel to the direction of travel, although body positions frequently change (Das et al., 2001). In situations of high stocking density, goats that fall may cause others to lose their footing and downed goats are trampled on.

The incidence of dead on arrival (DOA) can be used as the ultimate welfare outcome to assess the cumulative effects of on‐farm handling and transport. Knowles et al. (1994a) reported a mortality of 0.007% in lambs transported directly from farm to slaughter (62 miles) in the south of England and 0.031% in those going through the auction market (199 miles). In Chile, mortalities of 0.1–0.13% have been reported at arrival of commercial loads of lambs at the slaughterhouses. These higher mortalities are associated with stressful procedures of rounding up in the fields, walking long distances to reach loading pens on the farm, longer distances (and time) travelled by the lambs, the low space allowances, bad roads, use of inadequate vehicles and untrained handlers (Gallo et al., 2018).

The prevalence of DOA in sheep and lambs can be high in hot weather conditions, especially if the trucks are overloaded. For example, the inspection records of Official Control Point in Southern Italy involving 60,454 sheep/goats travelling in long journeys in 225 trucks were analysed by Padalino et al. (2018). The data showed that the maximum mortality and morbidity rates for transport of lambs were 0.084% (average = 0.025%) and 0.019% (average = 0.010%), respectively, and reduced space allowance was associated with the poor welfare outcomes.

The welfare consequences that small ruminant might experience at arrival are thermal stress, restriction of movement, prolonged hunger, prolonged thirst and fatigue.

3.1.2.1. Welfare consequence ‘Thermal stress’: assessment, hazard identification and management

i) Mechanisms of thermal stress

According to the EU factsheet on Transport Guide Extreme Temperatures,3 heat stress can be caused during transport of sheep by hot weather conditions (high humidity), poor ventilation and overstocking.

Homoeothermic animals such as sheep and goats maintain internal body temperatures with minimal metabolic regulation within a range of ambient temperatures called the thermal neutral zone (TNZ). Within the TNZ, the basal rate of metabolic heat production is equal to the rate of heat loss to the environment. Homoeotherms adjust to the temperatures within the TNZ through different behavioural and adaptive responses requiring little energy expenditure (Moberg, 2000). Environmental temperatures can thus cause fluctuations in a homoeotherm's metabolic rate. This response is due to the energy required to maintain relatively constant body temperature above ambient temperature by controlling heat loss and heat gain. The degree of this response may vary not only according to the species and breed but also on the levels of insulative and metabolic adaptation.

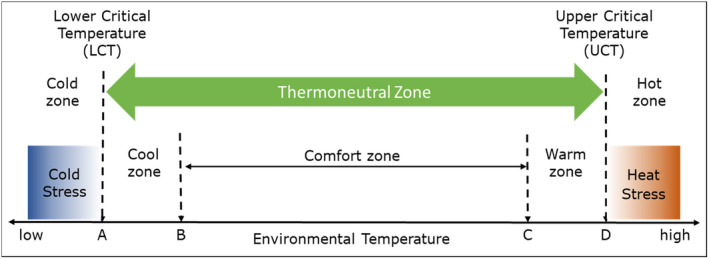

According to Figure 1, the range of ambient temperature can be split in different zones regarding thermal comfort of the animals. To prevent thermal stress, the ambient temperature should remain in the TNZ, which is the range of ambient temperature within which metabolic rate is at a minimum, and within which temperature regulation is achieved by non‐evaporative physical processes alone. Animals in the thermal comfort zone will have not experience cold or heat and their health and welfare regarding temperature are optimal. As temperature rises, they will start feeling warm (point C in Figure 1) and then reach the upper critical temperature (UCT; point D in Figure 1). UCT is the ambient temperature above which thermoregulatory evaporative heat loss processes of an animal are activated. Below the lower critical temperature (LCT; point A in Figure 1), the animals rely on thermogenesis to maintain the core body temperature. UCT and LCT are then considered to indicate the limits for the occurrence of heat (above UCT) and cold (below LCT) stress.

Figure 1.

- When the environmental temperature exceeds the threshold to the warm zone (point C in Figure 1), the animal will start activating strain responses (e.g. peripheral vasodilatation) but homoeothermy is still maintained, before UCT.

When environmental temperature starts decreasing, animals will start activating strain responses and start to feel cold (from B to A in Figure 1). When the temperature reaches the LCT, they get outside the TNZ and the cold adaptation process is intensified to increase its metabolic rate to meet the demands for heat production. First, shivering will start to increase heat production (shivering thermogenesis) and is intensified as the animal goes deeper into the cold zone, with an increase of energy consumption. If the environmental temperature continues to decrease far below the LCT, and animals cannot maintain their homoeostasis, then hypothermia occurs. When the capacity for heat production is overloaded, homoeothermy is not maintained anymore, body temperature decreases and hypothermia starts, leading to death from cold in extreme cases (Gregory, 1998).

Evaporative heat loss for cooling starts when temperatures are above the TNZ, the UCT is reached. When the environmental temperature exceeds the UCT, the rate of heat gain and heat production become higher than the rate of heat dissipation (heat loss through evaporative cooling), resulting in hyperthermia.

When animals are exposed to their UCT and are not able to cope with or respond to these temperatures, heat stress begins and as a result, the temperature of the animal may start rising, evaporative cooling mechanisms are intensified exponentially, the need for water consumption increases and, in addition to sweating, panting may occur. Animals can show postural changes where it changes its body shape or moves and exposes different areas to the sun/shade, and through radiation, convection and conduction heat exchange occurs. Vasomotor responses allow control of the flow of blood between the periphery and the core to control heat loss from the surface of the body.

When the temperature continues to rise in the hot zone, coping mechanisms to maintain homoeothermy are unsuccessful, body temperature continues to rise and fitness can be impaired (hot zone in Figure 1). When the environmental strain is very high, increase of body temperature brings acute heat stress with heavy panting and sweating and in extreme cases heat stroke and death.

During transport, before arriving at slaughter, animals may face very adverse climatic conditions. When arriving at slaughter, waiting times in a stationary vehicle may expose animals to thermal stress (heat or cold stress) depending on the external climatic conditions as well as on the variation in the internal truck environment and on the welfare state of the animals. The main determinants of the internal thermal microenvironment in the vehicle are ventilation type, internal air flow as well as the total heat and moisture produced by the animals (Norton et al., 2013; Faucitano and Pedernera, 2016). The longer the animals remain on the stationary truck before unloading, the more they can be submitted to thermal stress (Cockram, 2014). In the slaughterhouse situation, exceeding UCT or falling below LCT is considered as thermal stress. LCT and UCT in sheep and goats depend on a variety of factors including breed, age, physiological stage, among others, and are influenced by other environmental conditions such as relative humidity and wind velocity.

The susceptibility to heat stress (OSU, 20194) may vary in sheep and goats due to several factors, in particular (i) presence of fleece, horn and age of the animal and (ii) skin colour.

Hair sheep (e.g. breed such as Morada Nova) cope with heat stress better than wool sheep, because in terms of heat loss, both non‐evaporative and evaporative means are better (Correa et al., 2013). Fat‐tailed sheep are also more heat tolerant. The European sheep breeds are usually the least heat adaptive because they tend to have shorter bodies and legs, short, thick ears, tight skin and dense fleeces. Horned animals dissipate heat better than polled (or disbudded) animals. It has been shown in cattle that in temperate breeds, the surface area of the vascularised inner core is reduced while the thickness of the outer keratin sheath is increased, which limits heat loss from the horns, as in colder climates loss of heat would be a risk to welfare (Picard et al., 1994).

The TNZ for sheep is reported to be between 12°C and 27°C (Marai et al., 2007; Sejian et al., 2017), although in hair breeds, the upper limit is considered to be 30°C (Neves et al., 2009). In the European context, according to the EU factsheet on Transport Guide Extreme Temperatures,5 the TNZ for sheep varies with fleece and age:

In lambs: the TNZ ranges from 14°C to 21°C;

In fully fleeced sheep: the TNZ ranges from 0°C to 25°C (humidity > 80%) or 28°C (humidity < 80%);

In shorn sheep: the TNZ ranges from 10°C to 29°C (humidity > 80%)/or 32°C (humidity < 80%).

In sheep hyperthermia, as defined by a rectal temperature of more than 40.5°C, has been reported in conditions of high humidity and air temperature of 33°C and 40°C, in sheep with fleece and shorn, respectively (Faucitano and Pedernera, 2016).

Wool can act as an insulator that prevents air flow over the skin and maintains heat in the body. Consequently, non‐evaporative body heat dissipation mechanisms and sweating are ineffective in regulating body temperature in wool breeds (McManus et al., 2009; Titto et al., 2016). In addition, the number of sweat glands and the area they occupy are greater in hair breeds than in wool breeds, meaning sweating is a more effective body heat dissipation mechanism in hair breeds (McManus et al., 2011). Skin thickness is another phenotypic factor that causes inter‐breed differences in thermoregulatory capacity; hair sheep have thinner skin than wool sheep, which favours dissipation (radiation and sweating) of core body heat through the skin (Titto et al., 2016).

Goats tend to tolerate heat better than sheep. Goats with loose skin and floppy ears may be more heat tolerant than other goats. Angora goats have a decreased ability to respond to heat stress as compared to sheep and other breeds of goats. It has been reported that long haired goats tolerate radiant heat better than short haired goats and that white or light brown goats do better than dark brown or black goats. Short haired black goats had lowest tolerance of radiant heat (Shinde and Sejian, 2013). Hair being relatively thin and short, it facilitates air flow across the skin allowing transfer of heat accumulated on the body surface to the environment by radiation or convection (Correa et al., 2013), or, more efficiently, by evaporation of sweat (McManus et al., 2011).

In goats, the TNZ is 12–24°C (Nikitchenko et al., 1988) and goat kids, especially suckling ones, are more likely to suffer thermal stress than adults, which may also apply to lambs. In addition, wet/dry weather conditions and wind speed are expected to affect thermal comfort. Holmes and Moore (1981) estimated the LCT for sheep and goats to be dependent on coat depth and wind speed. The LCT for goats with coat depth of 57 mm was estimated to be 9°C at wind speed of 1 km/h and 12°C at 7 km/h. The LCT for sheep with 30 and 60 mm coat depths was estimated to be 9°C at wind speed of 1 km/h; 16°C at 7 km/h; –4°C at 1 km/h and 8°C at 7 km/h. Based on these estimates, it was suggested that the goats with a coat of 57 mm deep are less resistant to cold conditions than sheep with a fleece of similar depth.

ii) Skin colour

Skin colour is known to affect the ability of shorn sheep to transfer excess body heat to the environment or vice versa (McManus et al., 2011; Titto et al., 2016). Light‐coloured hair and skin in hair sheep allow them to have a lower heart rate, rectal temperature and respiratory rate compared to dark‐coloured hair sheep (Fadare et al., 2012). This occurs because light colours reflect solar radiation, while dark colours absorb it; therefore, the darker the hair and skin colour the greater the body heat accumulation in dark‐haired animals (McManus et al., 2009, 2011; Fadare et al., 2012). Similarly, it has been reported that black goats had significantly higher respiratory rate than white goats, so as to eliminate extra heat accumulated due to their body colour. Acharya et al. (1995) reported that long haired goats tolerate radiant heat better than short haired goats and that white or light brown goats do better than dark brown or black goats.

Definition of ‘Heat stress’:

Heat stress will set in once an animal is exposed to ambient temperatures above UCT and cannot maintain its body temperature.

ABMs for ‘Heat stress’:

Clinical signs of heat stress in sheep and goats include continual panting, rapid breathing and an elevated rectal temperature (over 40.6°C) (Battini et al., 2014, 2016). This can lead to weakness and inability to stand that are characteristic of a heat stroke, which potentially leads to death. Observation of panting is considered to be the only feasible ABM for heat stress at arrival.

In general, increased respiration is an attempt to increase heat loss by evaporative cooling by the animal. The respiration rate can be recorded by counting flank movements per minute. Basal resting respiratory rate for sheep is between 20 and 38 breaths/min.

However, the resting respiratory rate of sheep may increase considerably if the animals are excited. The Australian Veterinary Association (AVA, 2018) submission on heat stress (during transport) in sheep categorised type of respiration as normal: 15–35 breaths/min, mild (increased respiration rate): 70–100, moderate (panting): 100–160 and severe (open mouth breathing with tongue out): 160–220.

The basal respiration rate in goats is 15–30 breaths/min. Goats will start panting, and the severity of heat stress according to panting rate is reported to be low: 40–60 breaths/min, medium: 60–80, high: 80–120 and severe: > 200 (Sarangi, 2018).

Panting score has been used as the easiest method of evaluating the impact of heat stress. This is because it only requires direct observation of the animal. Panting is known as sheep's response to increased environmental heat and by substantial increasing of respiratory rate. There are two phases of panting in sheep (Hales and Webster, 1967); rapid shallow panting and the slower deeper panting. An increase in both first and second phase panting is highly correlated with heat stress due to increasing ambient temperature and humidity (Bligh, 1959; Ames et al., 1971). Increasing respiratory rates with open mouth breathing are the first sign of panting (Hales and Webster, 1967); however, respiratory rate varies between individuals (Bligh, 1959).

In both sheep and goats, panting scores had shown significant positive correlation with Temperature Humidity Index (THI) and a significant negative correlation with wind velocity. The panting scores used for assessing heat stress in sheep and goats (Reddy et al., 2019 following Brown‐Brandl et al. (2006) are: 0 = normal respiration, 60 or fewer breaths/min; 1 = slightly elevated respiration, 60–90 breaths/min; 2 = moderate panting and/or the presence of drool or a small amount of saliva, 90–120 breaths/min; 3 = heavy open‐mouthed panting, saliva usually present, 120–150 breaths/min; and 4 = severe open‐mouthed panting accompanied by protruding tongue and excessive salivation.

Battini et al. (2016) have used the following ABMs and scores to assess heat stress in dairy goats: 0 = normal respiration: the mouth is closed, the flank moves regularly (slightly visible) and the legs are frequently held near the body during lying; 1 = elevated respiration: from slightly to moderate panting with closed mouth, small amount of drool or saliva may be present, the posture is functional to heat dissipation, e.g. the neck is frequently extended, the legs may be held far from the body; 2 = panting: from heavy to severe open mouth panting, the mouth is open accompanied by protruding tongue and excessive salivation, the neck is frequently extended, the legs may be held far from the body.

Reddy et al. (2019) used the panting scores proposed by Brown‐Brandl et al. (2006) for assessing heat stress in dairy heifers and reported that the panting scores recorded in India were significantly increased in both sheep and goat during the summer season, with highest values recorded during the end of May. It was also observed that during the peak summer season panting scores in sheep were significantly higher.

Panting is therefore proposed as an ABM for assessing heat stress (Table 3) and, considering the results described above, the Panel suggests panting can be defined as more than 60 breaths per minute. The number and proportion of animals showing panting should be assessed.

Table 3.

ABM for the assessment of ‘Heat stress’ at arrival

Hazards leading to ‘Heat stress’:

Too high effective temperature.

Insufficient space allowance in the vehicle or truck.

Too long water deprivation.

Too high effective temperature

The effective temperature perceived by an animal is a combination of the ambient temperature, humidity and also radiation and air velocity. In hot and humid environmental conditions, poor ventilation will exacerbate the perceived temperature.

Complementary to the ABM described above, a Temperature‐Humidity‐Index (THI) can be used as an environmental measure to detect conditions that can lead to heat stress. For the calculation of THI, several different formulas have been proposed in literature which are accompanied by different thresholds for heat stress (Bohmanova, 2006). For example, the THI can be derived from a combination of wet and dry bulb air temperatures (WBT + DBT) (Silanikove, 2000) and be expressed as follows:

Formula A: THI = 0.72 (WBT + DBT) + 40.6.

Using this formula, temperature–humidity index values of 70 or less are considered comfortable, 75–78 stressful and values greater than 78 cause distress and animals are unable to maintain thermoregulatory mechanisms or normal body temperature (Silanikove, 2000).

Alternatively to Formula A, temperature and humidity are easier to retrieve with simple devices that can be installed in the arrival area than through measuring dry bulb and wet bulb temperature. Therefore, THI values can be calculated specifically for sheep using the following equation by Marai et al. (2007):

Formula B: THI = T – (0.31–0.31 × RH) × (T‐14.4).

where T is the dry‐bulb temperature in °C and RH is relative humidity in %. Marai et al. (2007) defined four heat‐stress categories: THI < 22.2 = absence of heat stress, 22.2 ≤ THI < 23.3 = moderate heat stress, 23.3 ≤ THI < 25.6 = severe heat stress and THI ≥ 25.6 = extremely severe heat stress.

According to López et al. (2015), some breeds of woolly sheep can begin to experience heat stress (calculated with formula A reported above) at THI > 72, although investigation into heat‐tolerant breeds (hair sheep) indicates it to begin at 82 units, with three heat stress levels: moderate (82–< 84), severe (≥ 84–< 86) and very severe (≥ 86). However, other authors indicate that hair sheep begin to show signs of heat stress at THI values between 78 and 79 units (Neves et al., 2009). Since hair sheep tolerate higher temperatures than wool sheep, it is probable that heat stress in any sheep breed begins at 78–79 units and not at 82 units. Hair sheep's greater tolerance to heat stress conditions is the result of genetic and phenotypic adaptations, as well as the activation of physiological, metabolic and endocrinological mechanisms. These aid in maintaining an adequate body water balance and normothermic conditions (38.3–39.9°C) at a low energy cost (Macías‐Cruz et al., 2013, 2016). Several of the mechanisms activated by hair sheep in response to heat stress conditions are also activated by wool sheep, but the latter still exhibit greater increases in body temperature as ambient temperature rises (Romero et al., 2013). Therefore, the THI value, used to define thermal neutral zone, should be adapted according to the breed of the animals and the climatic conditions animals are subjected to.

Insufficient space allowance in the vehicle or truck

The space allowance is the space provided per animal; it is expressed in m2 per animal of a certain weight. Apart from the size/weight of the animal, the minimum space requirement also depends on various other factors that include:

Ambient conditions (environmental temperature, adequate ventilation, relative humidity),

Ability of the animals to thermoregulate effectively (when THI is high – i.e. 84 or more – animals require more space for thermoregulation),

Need for animals to lie down, to be watered or to be fed.

Since the space available per animal will not change until unloading, the risk of heat stress will increase when the truck is stationary and without any mechanical ventilation.

Factors affecting space allowance include body weight, presence of wool and thickness of fleece, presence of horns, temperature and behaviour of animals during transport (SCAHAW, 2002).

According to Petherick and Phillips (2009), allometric equations of the form area = kW2/3, where k = a constant and W = liveweight, can be used to estimate the space an animal occupies as a consequence of its mass. However, this relationship between space and liveweight is nonlinear.

Sheep attempt to maintain their balance independently and do not lean against each other during road transportation, and a lack of space makes it difficult for them to do this (SCAHAW, 2002). It has been suggested that high stocking densities can become hazardous because, in addition to causing thermal stress, they prevent sheep from making adjustments to their posture and position to maintain their balance in a moving vehicle (Knowles, 1998; Knowles et al., 1998). It has been reported that all the sheep lie down after about 4 h of transport given a space allowance equivalent to a k‐value of 0.026 (Knowles et al., 1995; Cockram et al., 1996), which is very similar to a k‐value of 0.027 for a lying sheep suggested by Baxter (1992). It has been reported that sheep lie down in increasing numbers in the first 5–10 h and tend to get up if the vehicle stops during long distance road transport in Europe (Knowles, 1998), indicating some degree of synchronous behaviour in this species.

However, sheep prefer to stand during rough journeys and poor road conditions (Ruiz de la Torre et al., 2001). The space allowance also affected suckling lambs’ behaviour as the number of lambs lying down was highest when they had a space allowance of 0.25 m2/lamb in comparison with 0.12 or 0.20 m2/lamb (de la Fuente et al., 2012).

The SCAHAW (2002) reported that a space allowance of 0.31 m2/head is required for a shorn sheep weighing 40 kg to lie down, which is equivalent to a k‐value of 0.026. For journeys of less than 4 h duration, it recommended an area determined from the equation (formula 1):

Formula 1: A = 0.021W2/3

where A is area in m2, W is liveweight in kg.

Petherick and Phillips (2009) recommended that, if it is desirable for all animals within a pen or vehicle to be able to lie down simultaneously, then the amount of space needed per animal can be simply determined using the equation (formula 2):

Formula 2: A = 0.027W2/3.

The latter equation (formula 2) is the most commonly used and recommended in this Opinion.

Data concerning the relationship between space allowance and heat stress for goats are scarce; however, data provided for sheep and lambs may be considered appropriate for goats as well.

Too long water deprivation

In general, a steady core body temperature of 39°C is maintained in sheep and goat. A common thermoregulatory mechanism that affects body fluid homoeostasis is evaporative cooling, by sweating and/or panting, to dissipate heat from the body when core temperature is elevated. However, these responses result in a reduction of total body water, thereby reducing blood volume and increasing the osmotic pressure of body fluids. While both panting and sweating are highly effective means of preventing core body temperature from increasing, unless the resultant body fluid losses are replaced by intake of water, hypertonicity, hypovolaemia and circulatory collapse can ensue (McKinley et al., 2017). Thus, exposure to heat stress will increase the amount of water required to maintain homoeostasis but also exacerbate the welfare consequence of prolonged thirst.

In seminomadic farming practices around the world, dry and lactating ewes may be exposed to different degrees of water deprivation, leading to stress due to dehydration. For example, Barbour et al. (2005) reported that significant immunosuppression occurred in lactating water deprived (no water provided) Awassi ewes in the period 9–18 days post initiation of thirst.

If no water is available in the vehicle, animals that are transported to slaughter experience prolonged thirst from the time they are deprived of water on farm until they have access to water in the lairage pens (if available).

Prevention and correction of ‘Heat stress’ and its related hazards:

At the slaughterhouse, all efforts should be in place to prevent animals from entering or staying in the hot zone, in which welfare is compromised or animals may die.

The physical environment experienced on the vehicle, in particular the thermal environment, is a major risk factor. Therefore, it is vital to ensure that ventilation regimes are effective in maintaining internal conditions that are as close to the thermal comfort of the animals.

Adequate and appropriate ventilation systems are essential because during journeys of any duration, weather conditions may change imposing varying thermal stress on the animals. Seasonal differences in weather conditions are also a risk in terms of thermal stress. Long journeys involving movement across climatic zones increases the risk of thermal stress (Consortium of the Animal Transport Guides Project, 2018).

Ventilation systems can be either free or forced systems. Free ventilation systems (natural or passive ventilation) are common in vehicles used for short (less than 8 h) journeys, whereas forced systems are a requirement for long journey vehicles. Frequent stops due to traffic or border controls in hot climates can lead to heating up the vehicle interiors resulting in heat stress. Similarly, metabolic heat production in animals within a stationary vehicle while waiting to be unloaded at the slaughterhouse can exceed external temperature contributing to heat stress (Cockram, 2014). To ensure adequate airflow in a stationary vehicle, the minimum space above the top of the head should be at least 15 and 30 cm in forced or passive ventilation system, respectively (SCAHAW, 2002). In hot weather and without shade in the arrival area, it is important to keep the vehicle moving or park at right angle to wind direction to ensure adequate airflow through the animals (Knowles, 1998) or kept the forced ventilation on.

In addition, ventilation is important in limiting the concentrations of ammonia from faeces and urine inside the vehicle (Fisher et al., 2002), and a concentration of above 45 ppm is reported to be aversive to sheep (Phillips et al., 2012). The space allowance provided in the vehicle should be adequate for the animals to thermoregulate, lie down and access water (when provided).

In case signs of heat stress like panting are observed at arrival or when sheep arrive with fleece on a warm day, animals should be unloaded with priority and cooled down.

Access of the vehicle to shade is another important aspect of managing heat stress. Good ventilation and air movement at arrival would help prevent or mitigate heat stress. According to the EU factsheet on Transport Guide Extreme Temperatures3, the deck height should be sufficient to ensure correct ventilation inside the truck.

Definition of ‘Cold stress’:

When the temperature is below the LCT (Figure 1), animals are considered ‘cold stressed’ in the context of this Opinion, since they show difficulty achieving a balance between body heat production and body heat loss.

ABMs for ‘Cold stress’:

Sheep and goats subjected to cold stress show shivering. If the cold persists, body temperature will drop and sheep become lethargic, recumbent (down on their chest or on their sides), the mucous membranes (pink lining of the mouth) will turn pale to white, and the legs feel cold.

Sheep and goats are considered to be hypothermic when body temperature drops under 37.5°C.

Clinical signs of hypothermia are (Erikson, 2018): initially sheep and goats will try to maintain their body temperature by shallow breathing in order to reduce the rate of respiration, shivering, seeking shelter and huddling together. The author has used the following ABMs and scale to assess cold stress: 0 = no sign: the hair coat is flat on the back, no sign of cold stress is visible, the posture is relaxed; 1 = hair horripilation: the hair coat is bristling on the back, the posture is not a distinguished trait; and 2 = shivering: the small ruminant is shivering, the posture may help to reduce heat loss, e.g. the back is arched, the head is held downwards, the whole body is stiff.

When sheep and goats are subjected to cold stress at arrival, they may show shivering behaviour on the vehicle. Observing all animals properly can be challenging. In case it is possible, the number and proportion of animals that are shivering according to the definition from Battini et al. (2014, 2016) showed in Table 4 can be taken as a specific ABM.

Table 4.

ABM for the assessment of ‘Cold stress’ at arrival

Hazards leading to ‘Cold stress’:

Too low effective temperature

Battini et al. (2014) reviewed literature concerning ABMs used for assessing via Welfare Quality protocol, including cold stress, in dairy goats on farms. Subsequently, Battini et al. (2016) evaluated the on‐farm welfare assessment of thermal stress in dairy goats using THI ranges calculated according to Marai et al. (2001), THI = T – (0.31 – 0.31 × RH) × (T‐14.4), where T is the dry‐bulb temperature in °C and RH is relative humidity in %) as follows: cold = THI < 50; neutral = THI 50–65; and hot = THI > 65.

According to the EU factsheet on Transport Guide Extreme Temperatures3, cold stress can be caused during transport of sheep by cold weather conditions, water ingress by rain or snow and overventilation. This is also valid for goats.

In sheep, heat stress is more common than cold stress. However, sheep that are transported in open top deck in high altitudes and during inclement weather conditions may be prone to cold stress. Lambs and recently shorn sheep (up to 10 days after shearing) are susceptible to wind chill and need to be transported in vehicles with enclosed fronts or provided with protection during weather that could cause heat or cold stress.

Rain and windy weather combined with temperatures below normal will lead to cold stress in young animals, especially newly shorn sheep without shelter, and death may occur in case of extreme hypothermia. The impact of the cold weather will depend on its duration, rainfall, wind speed and temperature; the ‘wind chill’ factor can double heat loss. Rainfall causes heat loss in two ways. First, any water evaporated from the skin will cool the body in the same way as sweat evaporation. Second, rain falling on the sheep, lodging briefly in the fleece and finally dripping off will remove warmth from the skin. The loss of a sheep's insulating fleece combined with the evaporative and thermal conductivity of rain falling onto skin, and finally the chilling influence of wind, all result in rapid hypothermia.

In addition, young animals are more susceptible to hypothermia as they have less fat reserve to mobilise. Losses can be substantial in newborn lambs following cold weather if precautions are not taken. Newly shorn sheep are also prone to hypothermia. The shorter the period after shearing in which exposure to cold stress occurs, the greater the risk of hypothermia. Recently, shorn sheep may only have about three millimetres of insulating wool remaining, which can cause up to a threefold increase in heat loss, compared to un‐horned animals.

The same mechanisms of heat loss apply to goat, even though no publications is available.

Prevention and correction of ‘Cold stress’ and its related hazards:

According to the EU factsheet on Transport Guide Extreme Temperatures, in preparation for transport, it is important to consider that cold stress during transport of sheep can be prevented by: reduce space allowance if animals have more than the minimum allowed space (but without reducing it below the minimum), provide additional bedding or insulation and remove wet bedding after each trip (i.e. provide clean dry bedding for each journey), provide feed shortly before loading (to increase the metabolic heat production), adjust flaps or windows and use protective sheeting to protect all animals from rain/snow and wind chill. Make sure air circulation is not impeded, use side covers to block air movement through trailers. Be careful to maintain adequate ventilation, keep animals as dry as possible, avoid loading wet animals and, particularly for lambs, pre‐warm vehicles by using heaters prior to loading. When driving, reduce ventilation from vent flaps. When stopping, reduce the opening of the vent flaps on the windy side and open on the other side, park in an area that provides protection from the wind, add extra weather boards to keep wind or freezing rain out. Make sure ventilation is kept adequate. Some of these measures can also be applied to cold stress in lairages and holding pens.

All mentioned measures also apply to goat transport.

Lambs and recently shorn sheep (up to 10 days after shearing) are susceptible to wind chill and should be transported in vehicles with enclosed fronts or provided with protection during weather that could cause heat or cold stress. Newly shorn sheep should not be transported if staple growth is less than 7 mm or if they have been shorn less than 24 h before start of journey (EU factsheet on Transport Guide Extreme Temperatures).

3.1.2.2. Welfare consequence ‘Prolonged hunger’: assessment, hazard identification and management

Small ruminant can be subjected to prolonged hunger since they are deprived from food for the time feed is removed on farm until their arrival on the slaughterhouse. Usually, feed is not provided to sheep and goats during transport.

Definition of ‘Prolonged hunger’:

Deprivation of food leading to a craving or urgent need for food or a specific nutrient, accompanied by an uneasy sensation, and eventually leading to a weakened condition (Merriam‐Webster dictionary), as metabolic requirements are not met.

ABMs for ‘Prolonged hunger’:

There is no specific ABM to assess prolonged hunger of sheep and goats at arrival.

Hazards leading to ‘Prolonged hunger’:

Too long food deprivation

Pre‐slaughter fasting of animals occurs routinely for various durations and it helps to empty the guts. There has to be a balance between meeting the needs of the slaughterhouse and maintaining good animal welfare practice. Lambs lose up to 0.4% of their live weight per hour during the first 24 h of fasting, partly due to emptying of gut contents. Carcass weight loss starts between 12 and 24 h of fasting, and over the first 48 h, it averages about 0.9% carcass weight per hour (Gregory, 1998).

Sheep are frequently subjected to feed deprivation for about 12 h before, and then during, transport and feed may be provided later in lairage. Extensively reared sheep in some countries may have to travel for thousands of km lasting several days before reaching slaughterhouses (Hogan et al., 2007; Gallo et al., 2018). An average live weight loss in sheep of 5.5 kg over 12 h compared with control group was reported by Cockram et al. (1999). In New Zealand, the period of pre‐transport fasting can range from 3 to 12 h (Fisher et al., 2012).

Prolonged hunger results in inadequate biological functioning and it is an unpleasant emotional state (Kyriazakis and Savory, 1997). Since sheep will invest significant work to obtain food suggests that hunger generates a negative affective state that the animal seeks to alleviate (Verbeek et al., 2011). There is also supporting evidence from cognitive bias studies that the consumption of a food reward generates a positive affective state (Verbeek et al., 2014a), whilst physiological changes associated with hunger generate a negative state (Verbeek et al., 2014b). The effects of inadequate feed supply may also exacerbate the adverse effects of exposure to cold (Verbeek et al., 2012).

Kannan et al. (2000) reported that a 2‐h transportation, combined with 18 h of feed deprivation, resulted in elevated cortisol levels and approximately 10% liveweight shrinkage in Spanish does. Alcalde et al. (2017) investigated the effects of 2 or 6 h of road transport on Spanish Blanca Celtibérica breed suckling goat kids, 30–36 days old weighing on average 10 kg, from ‘high’ and ‘low’ welfare farming systems. Blood samples were collected both on‐farm and in the slaughterhouse. The results indicated that, regardless of its duration, transport caused significant effects on blood glucose, cortisol or creatine kinase, suggesting stress.

Animals subjected to prolonged hunger may be seen eating bedding materials, if provided on the vehicle or in lairage. However, bedding may not be provided and therefore eating bedding materials cannot be suggested as an ABM.