Abstract

The greater awareness of non-renewable natural resources preservation needs has led to the development of more ecological high-performance polymeric materials with new functionalities. In this regard, biobased composites are considered interesting options, especially those obtained from agro-industrial wastes and by-products. These are low-cost raw materials derived from renewable sources, which are mostly biodegradable and would otherwise typically be discarded. In this review, recent and innovative academic studies on composites obtained from biopolymers, natural fillers and active agents, as well as green-synthesized nanoparticles are presented. An in-depth discussion of biobased composites structures, properties, manufacture, and life-cycle assessment (LCA) is provided along with a wide up-to-date overview of the most recent works in the field with appropriate references. Potential uses of biobased composites from agri-food residues such as active and intelligent food packaging, agricultural inputs, tissue engineering, among others are described, considering that the specific characteristics of these materials should match the proposed application.

Keywords: Sustainability, Biomass, Composite materials, By-products, Agri-food waste, Biodegradable

Introduction

Climate change due to greenhouse gases emissions (GGEs) is only one of the several problems derived from an unsustainable linear economy: such as hiking raw materials prices, increasing products demand, resources depletion, irreversible environmental damage, and waste accumulation. Thus, a new regenerative economic view based on a balance between economy, environment, and society aims at a circular production/consumption system seeking to maximize resources use and avoid or, at least, minimize environmental impact [1]. A circular approach implies the substitution of fossil fuels as an energy source and petroleum-based products, such as plastics, for sustainable energy systems (i.e., solar, eolic, biofuels, etc.) and renewable feedstock (mainly biobased products); the development of easily recyclable or biodegradable products; optimization of waste management systems; and the design of products from residues.

Most petroleum-based plastics are highly resistant to degradation in nature, being able to persist for hundreds of years in the environment [2]. Even though they are potentially recyclable, only about 20% of all the plastic produced globally is properly recycled or reused [3]. Even with efficient waste management and recollection systems, the recovered polymers are often shipped to countries with low environmental regulations and control [4]. These, along with the continuous increase in total plastic production and consumption have led to severe plastic pollution, especially in the marine environment. Plastic littering in the oceans represent a hazard to marine fauna, directly damaging their habitat, constituting dangerous traps, and tampering with their food chain. Microplastic, plastic broken into small pieces by erosion, is ingested by marine mammals, reptiles, birds, and fish which can be mortal and affects seafood safety, hence human health [5]. Besides, plastic accumulated in coastal regions degrade their natural attraction having a further impact on tourism and local economies based on this activity. Therefore, biobased and biodegradable plastics have gained interest as potential substitutes for conventional polymers with a growing market and a global production accounting for about one percent of the over 368 tons of plastic that are nowadays annually produced [6]. Given their biodegradability, these biobased materials offer new end-of-life routes such as organic recycling through aerobic or anaerobic degradation, agricultural mulching, solubilization, or biodegradation in the environment, resulting in fewer wastes accumulation and soil contamination [1].

Given this context, a transition towards sustainable biobased productions is sought. Generally, biomass is recognized as a sustainable alternative to fossil fuels due to its abundant availability, carbon neutrality, and low sulfur content. However, if not based on a sustainable approach biofuels production entails extensive land use, soil acidification, and eutrophication among other environmental impacts related to intensive agro-industry such as competition amid food and energy crop growing and limited net GGE reductions [7]. In this regard, biodegradable and biobased plastics face similar challenges as alternatives to conventional plastics. Therefore, more sustainable biofuels and biobased products, such as food and pharmaceutical ingredients; fine, specialty, and commodity chemicals; polymers; and fibers have been developed from non-food crops, agricultural wastes, and forest residues to be coproduced in biorefineries [8]. Particularly, the use of agri-food waste has enormous potential in sustainable bioeconomy or green economies considering the food manufacturing industry [9]. In traditional agricultural settings, production residues are usually burnt or landfilled, which results in a noticeable CO2 generation [10]. Other typical agri-food waste management implies its use as animal feed or fertilizer supply, composting, and anaerobic digestion, yet recovery and valorization capacity of these residues remain quite limited [11]. Considering that five percent of global GGEs originate from organic waste decay and that agri-food residues contain macromolecules, such as carbohydrates, proteins, and lipids, as well as active compounds and pigments, strategies to obtain higher value-added materials from agri-food wastes and by-products are both urgent and conceivable [9, 12]. Numerous researches have been done and reviewed in this regard, from agro-industrial waste and by-products as feedstock for biofuels and bioplastic synthesis [8, 13–15], direct biopolymers, and active compounds extraction from agri-food residues [9, 16, 17], are reinforcing materials for composite materials [10, 18–24]. Therefore, the present review focuses on revising and comparing the existing studies on fully biobased composite and nanocomposite materials, considering different processing technologies, and analyzing the potential uses of the developed materials. Current limitations on fully biobased products design and market as well as LCAs availability are discussed, aiming to give a relatively broad outlook on the state of the art and future perspectives on the field of sustainable biocomposite materials.

Potential agro-industrial wastes and by-products for biobased composites

Bioplastics

Plastic material is defined as bioplastic if it is either biobased, biodegradable, or features both properties. The term biobased implies that its components are mainly derived from biomass, while biodegradation is a chemical process by which a material is converted into water, carbon dioxide, and compost by the action of naturally available microorganisms under normal environmental conditions. For a polymer to be categorized as biodegradable bioplastic should as well meet the following criteria [25]:

Chemical characteristics: at least 50% of its final composition should be necessarily organic matter.

Biodegradation: it should degrade by a minimum of 90% of its weight/volume within 6 months under-stimulated composting conditions.

Ecotoxicity: non-degradable residuals after biodegradation for 6 months should not be a potential threat to plant’s growth.

Disintegration: components’ microscopic fragments should be undetectable (< 2 mm) at least within 2 months under controlled composting conditions.

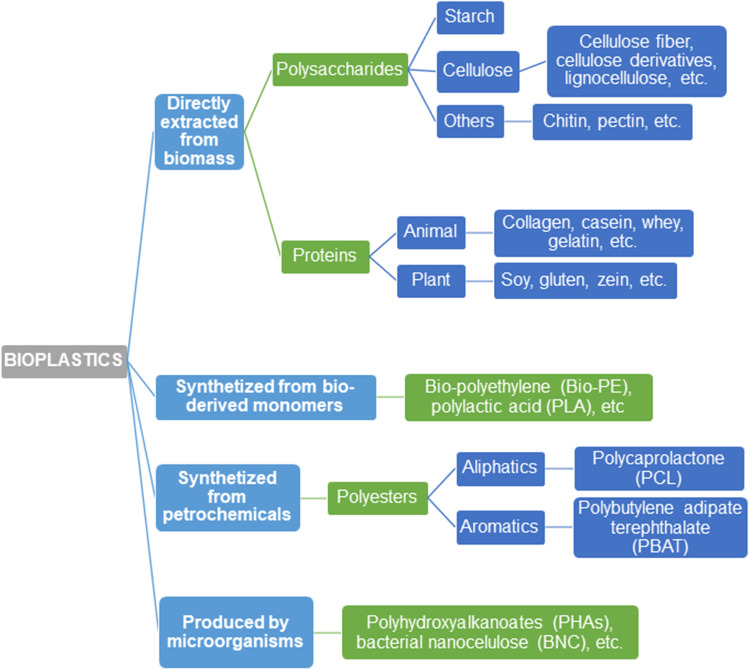

Bioplastics (both biodegradable and nonbiodegradable) can then be classified into 4 main groups: directly extracted from biomass, synthesized from a biobased monomer, synthesized from petrochemicals, and produced by microorganisms (Figure 1). They comprise a whole family of materials with different properties and applications and are nowadays ecological alternatives for many conventional plastics. The latest market data compiled by European Bioplastics in cooperation with the nova-Institute reported that the global bioplastics production capacities are set to increase from 2.11 million tons to approximately 2.87 million tons between 2020 and 2025, of which biodegradable and biobased bioplastics accounts for over 50% of the market [6]. In agreement with Siakeng et al. [26]: the biodegradable character creates a positive impact in society and also attracts researchers and industries. Therefore, this work focuses on those bioplastics that are essentially biodegradable and extracted directly from biomass or obtained by microbial fermentation of biomass.

Fig. 1.

Bioplastics classification according to production process and origin with some examples

Biopolymers from biomass

Polysaccharides are the most abundant macromolecules in nature, being many of them suitable raw materials for bioplastics. They are nontoxic and widely available since they can be obtained from many different sources such as plants, microorganisms, algae, and animals. Due to their physicochemical properties, many of them are susceptible to physical and chemical modifications leading to enhanced properties with various applications as biomaterials [27].

In particular, cellulose is a widely available polysaccharide derived from renewable resources [28]. It is generally synthesized by plants, but it is also produced by some bacteria. Plant-derived cellulose is usually found mixed with hemicellulose, lignin, pectin, and other substances, while bacterial cellulose is quite pure and has much higher water content and tensile strength owing to its longer polymer chains. The most used cellulose derivatives are methylcellulose (MC), hydroxypropyl methylcellulose (HPMC), and carboxymethyl cellulose (CMC) [29]. Above all, CMC has been reported to have excellent film-forming properties by thermal gelatinization with water-soluble polymers [30]. Moreover, nanocellulose or nanocrystalline cellulose is a versatile material with great mechanical and chemical resistance that is becoming increasingly valued for several applications, from packaging to electronics, yet limited by availability and cost [31–33].

Most plants produce starch as energy storage; thus, this polysaccharide can be extracted from rice, cassava, corn, wheat, and potatoes, among others. Starch is a carbohydrate that contains a great amount of glucose units combined through glycosidic links, however functional and structural dissimilarities are present among different botanical species [34]. Starch differ in type and content of two constitutive D-glucose macromolecules: amylose, linear, and helicoidal polymer; and amylopectin, with a branched structure [35]. The amylose content may vary from 20 to 25% in cereal starches, 15 to 30% in roots and tuber starches, and up to 40% in fruit starches, while the amylopectin content varies from 75 to 80% by weight. Even though starch has proven thermoplastic properties, its efficiency as a raw material for bioplastics depends upon its specific structure and composition [36]. Thermoplastic starch is obtained by the starch granule disruption in the presence of plasticizers. Extrusion processing employing low moisture content, high temperature, and pressure melts the starch granules into a single continuous phase component that can later be mixed with other components to form a film [25].

Pectin is an important natural polymer with diverse industrial applications. It is present in various fruits and vegetables such as berries, apples, and oranges and is extracted mainly from the processing residues of these agricultural products [37, 38]. Pectin has attracted great interest because of its distinctive characteristics: it has the ability to freeze in the presence of acids and sugars, presents high viscosity and aqueous-absorbent gel properties, and it is easily soluble in water but is insoluble in ethanol [39]. Therefore, it shows great potential for the development of biobased membranes, films, and edible coatings in the food packaging field [40, 41]. Pectin films are effective in the protection of low moisture food [42], while pectin coating are used to preserve fresh fruits and vegetables [38]. Moreover, cross-linking of pectin films with polyvalent cations, such as calcium, enhance their mechanical properties [43].

Likewise, being the second-most abundant biopolymer in the world (after cellulose), chitin is a promising raw material for bioplastics. It is the main structural component of the fungi cell wall and can be also found in shells of ocean-dwelling crustaceans such as crab and shrimp. Chitosan is obtained from the chemical modification of chitin, extracted from fungi and shells, after numerous chemical treatments. Soluble in weak acid solutions, chitosan can be dried to a solid plastic film and strengthened by soaking in alkaline solutions with promising uses for packaging and medical applications [44–49]. In addition, near 150,000 tons of chitin-rich waste is annually produced by the seafood industry worldwide [50]. These residues have a high environmental impact, little commercial uses, and high waste-disposal cost, thus extracting a high-added-value bioplastic from this waste creates an excellent cost-effective and more sustainable opportunity for the seafood industry.

Regarding marine origin biopolymers, carrageenan and alginate are worth mentioning as anionic polysaccharides found in the outer cell wall of red and brown algae. Alginates have been used for encapsulation of chemical and biological compounds with a wide range of applications in agriculture, food technologies, pharmaceutical cosmetics, chemical engineering, environmental engineering, paper and textile industry, and many others due to their nontoxicity, biocompatibility, and the ability to cross-link with cations [51–55].

Furthermore, many proteins from vegetable and animal sources can be used as the raw material for developing bioplastics materials. Wheat gluten, for instance, a by-product from the bio-ethanol industry, is relatively inexpensive, abundant, and basically used as animal feed but is thermoplastic in nature and presents interesting film formation capacity, gas barrier, mechanical and biodegradation properties that have risen the interest in its use in the packaging industry [56]. Wheat gluten-based biocomposites and nanocomposites with improved barrier and mechanical properties particularly suitable for packaging have been reported [57, 58].

Polymers from microorganisms

Microorganisms are a source of biopolymers using agricultural wastes as growth media. Although currently more expensive, bacteria have the potential of yielding bioplastics having properties comparable to those of conventional polymers that can be further modified by changing the growing medium and conditions of the bacteria. Bioplastics from the microbial production process have been optimized with a wide range of end products showing diverse properties [25]. Numerous of these microbiologically synthesize biopolymers have gained acceptability in food and other industrial applications among which polyhydroxyalkanoates (PHAs) have attracted particular interest. PHAs are polyesters of hydroxy acids naturally synthesized by bacteria as carbon reserves. These biopolymers are accumulated as cytoplasmic inclusions in certain bacteria during unbalanced growth conditions, usually characterized by an excess in feed supply and the lack of one or more essential nutrients [59]. PHAs are synthesized by different groups of bacteria from cheap renewable resources, yet in order to effectively exploit the commercial production of these biopolymers, it is important to select a bacterial strain having the highest PHAs yields growing on inexpensive carbon sources with efficient fermentation and requiring simple recovery processes.

More than 150 different PHA monomers have been identified, which renders them the largest group of natural polyesters [60]. For instance, poly(3‐hydroxybutyrate) (PHB), poly(3‐hydroxyvalerate) (PHV), and their copolymer poly(3‐hydroxybutyrate‐co‐3‐hydroxyvalerate) (PHBV) are typical examples of short‐chain‐length PHAs. Particularly, PHB is the most popular and promising PHA as an alternative biomaterial, since it has similar properties to conventional polyesters such as PE and polypropylene (PP) [61]. Its application includes packaging materials, bags, containers, sutures, targeted tissue repair, and regeneration devices, cardiovascular stents, polymer-based depots for controlled drug release or implants, and disposable items like single-use cups and diapers [62]. Despite its biobased nature, biodegradability, and versatility, the high production cost of PHB is the main obstacle for its commercialization, being this at least three times higher than the conventional plastics such as PP and PE and similar to biopolymers like PLA [14]. Such high costs are mainly attributed to expensive substrates and processing [63]. Therefore, the use of cheaper feedstocks is a key factor towards reducing PHB production costs. Food wastes [64], wastes from beer breweries [65], cheese whey [66], olive mill wastewater [67], and hydrolyzed corn starch [68] are some resources that have been investigated for sustainable PHB production.

In the last decades, bacterial nanocellulose (BNC) has gained increasing interest because of its remarkable physical and chemical properties, including green technology processing, low production costs, elevated mechanical properties, hydrophilicity, and excellent biocompatibility and biodegradability [69]. Certain gram-negative non-pathogenic bacteria genera were reported to produce nanocellulose extracellularly [70]. It should be noted that despite sharing a common backbone there are marked differences between plant and bacterial cellulose. Plant fibers are composed of lignin, hemicelluloses, pectin, and only 40–70% of cellulose [71]. In contrast, bacterial cellulose is made up of pure cellulose nanofibers, displaying high purity and strength, without requiring subsequent refining treatments. BNC ultrafine structure presents higher crystallinity and polymerization degree, greater liquid absorption capacity, larger specific surface area, and better mechanical properties making it a superior choice to plant-sourced cellulose in many applications, especially in packaging [72] and biotechnological industry [73].

Polymers synthesized for monomers derived from biomass

Among bioplastics biobased nonbiodegradable polymers as bio-PP or bio-PE account for 41.8% of the current global bioplastics production [6]. Meanwhile, along with starch-based bioplastics, PLA is one of the most largely produced biodegradable biobased polymers (18.7% of the total annual bioplastic production in 2020). This versatile compostable biopolymer is synthesized from lactic acid, a naturally occurring organic acid easily produced by chemical synthesis or fermentation. Similar to other bioplastics, one of the main obstacles in PLA commercial use is their cost, thus the use of blends with cheaper biodegradable biobased polymers (i.e., starch) and its biocomposites with low-cost natural fillers has been studied and reported [74, 75]. PLA-based packaging can now be purchased almost everywhere, from food containers, disposable cutlery to suture thread and 3D printing filaments. Consequently, research on enhanced PLA biocomposite for such applications is still under study [74, 76–81]. Due to its biocompatibility, biodegradability, nontoxicity, and high strength, it has been studied for innovative biomedical and pharmaceutical applications, as drug delivery systems, wound dressing, and scaffolds for cellular growth [82, 83].

Reinforcing materials

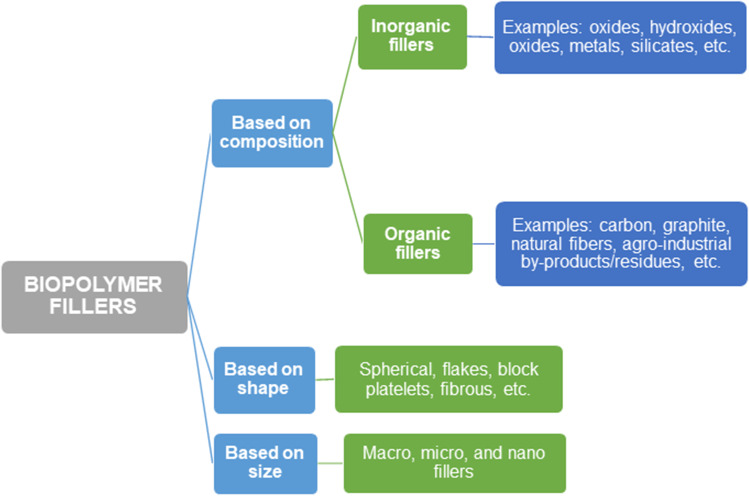

In spite of their renewable and biodegradable character, the mechanical resistance, permeability and thermal stability of biopolymers tend to be relatively low for some applications [84–86]. Consequently, the best approach to improve their properties and commercial importance is to incorporate reinforcing agents [86–90]. The resulting materials known as environment-friendly polymer composites, biopolymer composites, or biocomposites, have a wide range of next-generation applications in medicine, electronics, construction, packaging, and automotive sectors [91]. Composites can be defined as materials that are formed by two or more constituents which have separate phases and compositions conforming to micro- or nano-structures. The composite properties are strongly dependent on the matrix (continuous phase) and filler (discontinuous phase) interfacial adhesion, as well as the reinforcement composition, size, shape, and content [90]. The smaller the filler particle size, the greater the efficiency for the formation of composites [89]. Biopolymer composites are synthesized using numerous methods, being in-situ reaction, solution casting method, and melt mixing technique the most employed. Diverse types of fillers can be used that, as suggested by Kumar et al. [92], can be divided following several criteria as shown in Figure 2.

Fig. 2.

Biopolymer fillers sorting according to three different criteria with some examples

In this work, the first classification according to fillers’ origin and composition was considered. Distinctively, organic fillers derive from living organisms and are usually carbon-based compounds, while inorganic fillers are salt, metal, and elemental compound obtained from inert things. A further description of nanosized fillers (<100 nm) obtained by sustainable technology was included due to their key importance in high-performance eco-friendly biocomposite applications.

Organic fillers

Most of the organic fillers used in green composites (both biobased and non-biobased) are derived from renewable sources and are generally cellulose-rich materials. Natural cellulosic fibers, such as hemp, sisal, jute, kenaf, flax, and bamboo, among other plant tissue fibers, have been extensively used as filler of polymer composite materials as substitutes for glass-fiber mainly due to their lower density and cost, their renewable character and because they are less abrasive to processing equipment [85, 93]. Green composite materials have been extensively studied and applied in the transport and construction industries, from windows frames and insulation panels to railroad sleepers and automotive parts, and various other low-cost and mild-mechanical-demanding applications such as gardening items, agriculture mulch, and packaging [22, 94–99]. Therefore, interest in renewable and biodegradable fillers has grown as new sustainable materials are sought, specifically since these organic fillers can be obtained from agro-industrial or wood byproducts and residues [23, 88, 98, 100–102]. In this regard, fillers with diverse mechanical and surface properties, chemical composition, size, and form have been studied. Besides, conventional fibers from plant leaves and stems that are cultivated for their fibers, other such as wheat husk [103], rice straw [104], sugarcane bagasse [105], malt bagasse [106], banana leaves, and peel fibers [17, 77, 107] are by-products of agri-food production that, among others, have been studied as biocomposite fillers [18, 108–110]. Furthermore, starch from roots and tubers bagasse and peel have also been reported [19, 98, 101, 111–113], as well as algae, microalgae, and their byproducts [83, 114–117]. Recently, grasses such as Sabai grass (Eulaliopsis binata), an undervalued abundant grass in Asia [118], Cogon grass (Imperata cylindrica), one of the ten most aggressive weeds in the world [119], and Napier (Pennisetum purpureum schum) grass [120] have been considered as composite fillers with promising results. Novel green biocomposites have been lately developed from coffee silverskin and starch-rich potato washing slurries [121] or tea leaves from tea brewing wastes [122]. Oil industry by-products, as for instance sesame, rapeseed, peanut, and sunflower oil cakes have also been investigated as fillers for biocomposite films and foams [21, 123–127].

Increasing fiber contents tend to promote stiffer materials with higher impact strength yet diminishing their flexibility. Nevertheless, properties are dependent on filler source and content, surface treatments, particle size distribution, and processing conditions [88, 100, 101, 128–130]. In general, plant tissue fibers are composed of cellulose, hemicellulose, and lignin and their reinforcing efficiency depend on the cellulose nature and crystallinity and its alignment in the cell walls: high cellulose content and low microfibril angle (MFA, defined as the angle microfibrils make with respect to the fiber axis) are desirable [131, 132]. Yet, natural fibers have low thermal stability (approximately up to 200 °C) which limits the processing conditions and the recyclability of biocomposites [85]. Nonetheless, as reported by Ramamoorthy et al. [133] and Chaitanya et al. [74], fiber thermal stability can be enhanced in composite materials as the polymer matrix protects the fiber from degrading. Chemical, physical, and biological pretreatments of the fibers have been firstly proposed to improve filler-polymer interaction in hydrophobic polymer matrices, though such treatments also result in cleaner surfaces, higher moisture content, and thermal stability [134–140]. Notwithstanding, various factors should be assessed in choosing fillers treatments as for enhancing biocomposites properties without compromising their sustainable character: energy and resources consumption and processing cost (especially in the case of complex techniques that result impractical for industrial applications), effluents characteristics and volume generated, reagents toxicity in long term exposures (for work safety) and life cycle environmental impact of the process. Still, one of the major problems in the use of plant-based fillers is their properties fluctuation with botanical source, cultivation region (with different climate conditions and soil composition), and harvest season, which can be somewhat tackled by mixing batches of sources or types of fibers [131].

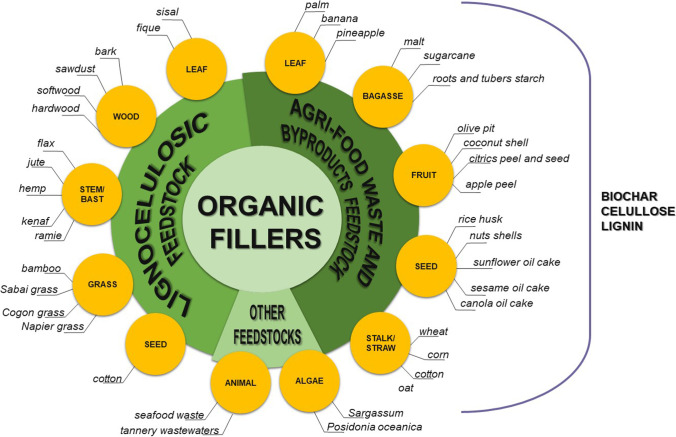

Other organic fillers are extracted from wastes. Figure 3 illustrates the main sources of organic fillers with some examples for each. Cellulose micro and nanofibers have been isolated by a series of alkali, acid, and mechanical treatments that breakdown the original plant tissue from various sources: soybean hulls [141], sugarcane and cassava bagasse [142–145], and corncob and pinewood [146], among others [120, 147, 148]. Similarly, lignin can be extracted for lignocellulose byproducts and waste [149]. Keratin and chitin, which are extracted from animal feed waste such as chicken wings or shrimp shells are also employed as composites fillers [22, 150–153]. Furthermore, biochar or activated carbon can be obtained from various biomass sources through pyrolytic processes [154, 155]. Both present high adsorption capacity, resulting in special interest in water and air decontamination.

Fig. 3.

Organic fillers main sources and some examples for each

Inorganic fillers

Mineral or metallic fillers are considered inorganic fillers: clay and nanoclay, silver nanoparticles (AgNPs), and calcium carbonate (CaCO3) are among the most common inorganic reinforcement agents of biocomposites.

Due to its great natural abundance, clay is the most frequently used inorganic filler in the composite field. These are phyllosilicate minerals usually obtained from the chemical weathering of other silicate minerals on earth [156, 157]. Clay has a good intercalation property and can swell with the absorption of water [158]. Clay can be classified into a variety of groups including kaolinite, montmorillonite, illite, chlorite, and fibrous silicate [90]. Bentonites consist mainly of montmorillonite and can be used as adsorbents, ion exchangers, wine clarification agents, and catalysts. Besides due to their eco-friendly character, availability, and reusability have also been studied as reinforcing agents of polymeric matrices [159, 160]. For their applications, the pillaring process is commonly used to modify the structural, thermal, and surface properties of bentonites. In this regard, Ninago et al. [161] proposed an environmentally friendly method to obtain Al-pillared clays by using microwave irradiation.

Among minerals, calcium carbonate (CaCO3) is a widely inorganic material used as a viscosity modifier in many industries, which is normally obtained from carbonatite-lava, stalactites, stalagmites, skeletons, or shells of some animals. It is an inorganic filler with various potential applications owing to its low-cost, abundance, and safe character [162]. Meanwhile, talc also qualifies as a good reinforcement agent because of its platy nature, presenting micron-sized length and width and nanometric thicknesses, as well as a high aspect ratio (particle diameter/thickness 20:1)[163].

Moreover, granite sand (GS) is an industrial waste derived from the granite polishing industry that can cause health problems and air pollution due to its powder form. Therefore, it is highly desirable to find uses in an effective manner to minimize these damages, reducing as well the need for new dump lands for these wastes [164]. Granite sand is a mixture of different minerals composed of muscovite, orthoclase, quartz, and biotite, among others. Particularly, muscovite is a laminar silicate of the micas-clays family and its structure facilitates the intercalation of organic-inorganic species between mineral slabs, which makes muscovite an excellent filler for polymeric materials [165]. Passaretti et al. [166] employed GS particles as fillers of thermoplastic corn starch films, demonstrating the potentiality of this mineral for this application.

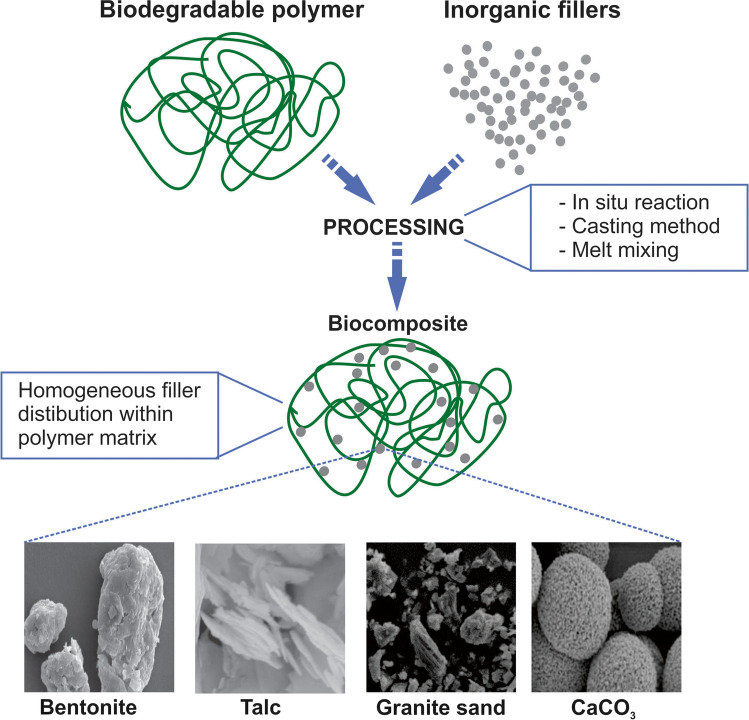

Figure 4 shows a schematic representation of the processing of biocomposite materials with inorganic fillers as well as some examples of SEM micrographs of different inorganic fillers.

Fig. 4.

Schematic representation of the processing of biocomposite materials with inorganic fillers as well as some examples of SEM micrographs of different inorganic fillers

Nanoparticles: green synthesis

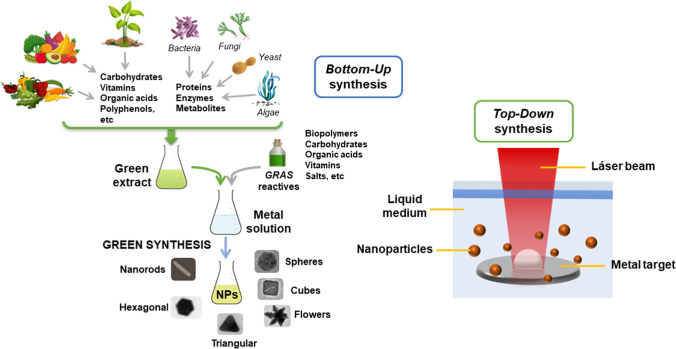

Nano-sized particles are characterized by their high surface-to-volume ratio, which confers exceptional features on them. They are synthesized through physical, chemical, or biological methods, that are classified into top-down and bottom-up synthesis regarding whether the reagents are inorganic or are generated from the break-down of a macroscopic material by some external agent (Figure 5). Several physical and chemical methods like hydrothermal, sol-gel synthesis, laser ablation, or lithography, among others, require special equipment and skilled labor [167–169]. In addition, some of these techniques involve the use of toxic reagents that pose health and environmental hazards [168, 170]. For instance, silver nanoparticles (AgNPs) can be obtained by the reduction of a silver salt using strong reducers such as sodium borohydride, which is an extremely irritant and corrosive agent with high flammability risk [171]. Nowadays, green chemistry aims at the total or partial elimination of chemical waste and the implementation of nontoxic reagents, environmentally acceptable solvents and renewable materials, obtaining products with high thermal stability, low volatility, and cost-effective production [172–176]. Not only do these eco-friendly techniques reduce the use of hazardous substances, but also employ natural renewable compounds like polysaccharides, proteins, or those derived from vegetable extracts (mainly leaves, roots, and flowers) and microorganisms like bacteria, fungi, and algae, as reducing or capping agents [177–180]. Therefore, the three main concepts of nanoparticles green synthesis are the choice of the solvent (preferably water); the use of an ecological reducing agent, GRAS (substances generally recognized as safe), or natural reagents; and a nontoxic material for nanoparticles stabilization (i.e., biopolymers). Products of natural origin contain in their structure phenolic compounds, reducing sugar and nitrogen compounds that can reduce metal cations to generate nanoparticles and, in certain cases, can also act as stabilizers (Figure 5). In turn, the implementation of these compounds is also advantageous from the economic point of view since they do not require high temperatures conditions and reduce energy consumption. Table 1 summarizes common metal and metal oxide nanoparticles obtained by green synthesis techniques.

Fig. 5.

Nanoparticles top-down and bottom-up synthesis

Table 1.

Examples of nanoparticles obtained by green synthesis techniques

| Nanoparticles | Green synthesis technique | Shape | Size (nm) | Reported applications | References |

|---|---|---|---|---|---|

| Ag | Maltose as reducing agent and soluble starch as stabilizer | Spherical with high monodispersity | 5 | - | [174] |

| Ag | Microwave-assisted using orange peel extract | Nanospheres | 7.36 ± 8.06 | - | [181] |

| Ag | In vivo synthesis of nanomaterials in plants: Brassica juncea, Festuca rubra, and Medicago sativa | Variable | Variable | - | [182] |

| Ag | Using marine algae Caulerpa racemosa | Spherical with few triangular nanoparticles | 10 nm mean | - | [183] |

| Ag | Maltose as reductor and cornstarch as stabilizing agent | Spherical | 5–20 | Included in nanocomposite films for dairy product shelf-life extension | [184] |

| Ag | Maltose as reductor and different concentrations of cornstarch as stabilizing agent | Spherical | 13.4–19.9 | Included in starch films for food packaging area | [185] |

| Ag | Lemon juice as reducing and stabilizing agent | Spherical | 5.5–13.5 | Included in starch-nanocomposite films for packaging area | [186] |

| Au | Using citrus fruits aqueous extract: Citrus limon, Citrus reticulata, and Citrus sinensis | Various shapes | 15–80 | - | [187] |

| Au | Using brown algae Cystoseira baccata | Spherical | 8.4 ± 2.2 | Anticancer activity | [188] |

| Au | Using Lawsoniainermis leaf extract | Spherical | ∼20 | Catalytic activity in the degradation of anthropogenic aromatic pollutants and dyes, like bromophenol blue and methyl red | [189] |

| Au | Using an endophytic strain Fusarium solani ATLOY – 8 has been isolated from the plant Chonemorpha fragrans | Needle and flower-like structures with spindle shape | 40–45 | The NPs have shown effective anticancer activities | [190] |

| CoO | Complexation and surface passivation with starch | Square | 15–30 | - | [191] |

| Co3O4 | Using leaves extract of plant Calotropis gigantea | Spherical | 50–60 | Thermal decomposition of ammonium perchlorate and dye-sensitized solar cells | [192] |

| CoO | Using P. granatum extracts | Spherical | 40–80 | Photo-catalytic applications | [193] |

| Co3O4 | Walnut green skin extract as reducing and stabilizing agent | Spherical | 60–80 | - | [194] |

| CoO/Co3O4 | Rosemary extract | Sheet | ∼100 | - | [195] |

| Cu/Cu2O | Synthesized by pulsed laser ablation of copper in water | Spherical and are self-assembled forming a cactus-like | 2–7 | - | [196] |

| Cu | Using carboxymethyl cellulose as capping agent | Spherical | 5.5 ± 0.5 | Inclusion on modified electrode and used as electrochemical nitrite sensor | [197] |

| CuO | Citric acid mediated synthesis using cinnamon bark extracts | Spherical | 50–300 | Catalytic degradation of dyes and antimicrobial activity | [198] |

| Cu | Microwave-mediated green synthesis using Citrus sinensis aqueous fruit extract | Round shape | 6.93–20.70 | - | [199] |

| Fe | Using Eucalyptus Tereticornis leaves extract | Cubic | 40–60 | Can be applied as an adsorption − flocculation agent in water purification and contaminated groundwater remediation | [200] |

| Fe3O4 | Using Aloe vera extract | Cubic Spinel Structure | 6–30 | - | [201] |

| Fe2O3/Fe3O4 | By laser ablation method at different values of energy | Spherical and agglomerates | 14.9–18.7 | - | [202] |

| MgO | Using bacteria | Cubic | 30 | Anticancer study | [203] |

| MgO | Using Costus pictus D. Don plant leaf extract as a reducing agent | Hexagonal | ∼50 | Antimicrobial and anticancer activity | [204] |

| MnO2 | Using fresh lemon juice and peel extract | Agglomerates of fine particles with juice and nanorods with peel extract | < 10 nm and nanorods of 8.8 nm | Possible application as positive electrode for lithium-ion batteries | [205] |

| TiO2 | Using leaf aqueous extract of Solanum trilobatum | Uneven spherical and oval | 70 | Larvicidal and pediculicidal activities | [206] |

| TiO2 | Bengal gram beans (Cicer arietinum L.) | Spherical | ∼14 | As anode in lithium-ion battery | [207] |

| TiO2 | Using leaf extract of Jatropha curcasL | Spherical | 13 | Photocatalytic degradation of tannery wastewater | [208] |

| TiO2 | Using lemon peel extract | Spherical | 80–140 | - | [209] |

| ZnO | Zn(NO3)2 as precursor and Cayratia pedata leaves extract as reducing agent | Agglomerated form confirmed by FESEM analysis | 52.24 | - | [168] |

| ZnO | Combination of sol–gel with hydrothermal growth, using tetramethylammonium hydroxide as a structure-directing agent | Nanorods | Width 15 nm, and length 236 nm | Incorporated in composite materials | [210] |

| ZnO | Laser ablation using a starch solution as controller and stabilizer agent | Spherical | 6–28 | - | [211] |

The electrical conductivity, high stability, and especially the antimicrobial activity of AgNPs have prompted numerous investigations [212, 213]. They can be synthesized by chemical reduction [212, 214, 215], laser ablation [211, 216, 217], electrical and photochemical reduction[218]. Chemical reduction of a silver salt, mostly with organic reagents, is the most widely used and profitable method for large-scale synthesis [219]. Besides, nanoparticles morphology and size can be controlled by chemical synthesis depending on the capping agent and stabilizer. Several authors have reported that spherical and small AgNPs obtained by a completely green chemical process show good antimicrobial properties even when they were used in low concentrations [212, 214, 215, 220]. Ortega et al. [221] have successfully coupled the AgNPs synthesis with cornstarch-based filmogenic suspensions to develop nanocomposite films. Thus, a simple and nontoxic method was proposed to obtain silver nanoparticles where maltose is used a reducing agent, corn starch as a stabilizer, and ultrapure water as a solvent. Proposing the use of corn starch as stabilizers allows the synthesis of AgNPs to be coupled to the filmogenic suspension and thus obtain nanocomposite films in just a few steps, optimizing both processing time and energy, and reagents consumption. Processes coupling requires a prior fine-tuning of the reagent concentrations and reaction times to obtain the AgNPs in the filmogenic suspension [185, 186]. The AgNPs formation is evidenced by the characteristic surface plasmon resonance (SPR) between 420 and 445 nm [222]. Several authors have synthesized AgNPs with lemon juice, which was spherical with diameters around 20 nm as observed by high-resolution transmission electron microscopy (HR-TEM), exhibiting negative charge considering their Z potential measurements [185, 213, 218, 223].

Likewise, ZnO nanoparticles have arisen great interest in sensing applications, since they exhibit high electron mobility, large exciton binding energy, wide bandgap, and high optical transmittance [168]. They can be synthesized with different morphologies, such as spheres, discs, ribbons, flowers, or bars [224]. ZnO nanorods stand out as reinforcement of active packaging materials due to their excellent mechanical performance and their marked antimicrobial activity [225]. They can be prepared by different methods, being the chemical reactions in solution preferred in terms of costs, simplicity, efficiency, and energy consumption [226]. Hydrothermal growth in aqueous solution is a widely used methodology in the literature for obtaining ZnO nanorods. This method uses an aqueous solution of Zn(NO3)2 containing hexamethylenetetramine (HMTA) which hydrolyzes and produces a basic environment necessary for the formation of Zn(OH)2 and stabilizes Zn+2. In general, seeds of ZnO are incorporated for the hydrothermal growth of ZnO nanorods to improve the morphology and orientation of the bars [227]. The ZnO seeds are synthesized through a simple and low-cost sol-gel process in a nonaqueous solution of zinc acetate as a precursor. The precursor hydrolyzes by heating and forms acetate and Zn ion that binds to the hydroxyl groups (-OH) present in the solution resulting in ZnO formation [228]. At this point, the concentration of hydroxyl groups in the solution determines the size of the nanoparticles obtained and, in general, is adjusted by incorporating NaOH or KOH [229]. Similarly, the chemical reduction of Zn solution using natural compounds derived from different plant extracts has been reported [168].

Several other nanoparticles with exciting and innovative applications like sensors, biomedical, energy storage, and packaging applications have been studied and synthesized by green technologies as shown in Table 1.

The mechanisms involved in the synthesis of nanoparticles have been extensively reviewed by Polte et al. [230]. Ortega et al. [186] synthesized silver nanoparticles using the active compounds of lemon juice (AgNPL) and proposed a four-step growth mechanism for this process. First, the chemical reduction of the Ag salt occurs by the reducers present in lemon juice (mainly ascorbic acid and citric acid, in addition to other components such as reducing sugars, polyphenols, and flavonoids). Polydisperse particles smaller than 1 nm are then formed by coalescence. The third step, which can last between 5 and 60 min depending on the synthesis temperature, corresponds to a metastable state where the particles reach a mean radius of 1 nm. Finally, the coalescence of the formed particles occurs until colloidal stability is sufficient to prevent aggregation. Ortega et al. [186] reported that the optimized conditions for the synthesis of AgNPL were 30 min at 90 °C, leading to a 5.5 nm nanoparticle with associated stability (ζ = −29.5 mV) that was maintained for up to 90 days. Yet studies on the stability of nanoparticles during storage are scarce and are strongly recommended for future research in the field [171, 231].

Films and foams from biobased composites

Biocomposite films

Biocomposite films are based on different biopolymer matrices and fillers and can be obtained by diverse processing methods. As an example of the enormous amount of biocomposite films that have been studied to date some of the most relevant developments in the last 10 years from different biopolymers will be mentioned.

Cellulose is the most abundant biopolymer, and it is widely employed for sustainable biocomposite materials because of its renewable character, biodegradability, and other specific properties. It can be converted to different structures with a variety of physical properties, depending on the origin of the cellulose and the method of production [120]. Cellulose microfibers (CMFs) can be obtained by refining dilute cellulose suspensions under high-pressure. Nanofibrillated cellulose (NFC), on the other hand, result from cellulose fibers disintegration using high pressure homogenizers combined with chemical or enzymatic treatments [232]. In addition, if the amorphous parts of the cellulose are removed, leaving single and well-defined crystals in a stable colloidal suspension, microcrystalline cellulose (MCC) can be obtained [233]. Thus, depending on cellulose structure and the desired properties of the final materials, this polysaccharide can be used as a biopolymeric matrix or biocomposite filler. In this respect, Kumar et al. [120] extracted cellulose fibrils (CFs) from Napier (Pennisetum purpureum schum) grass and used it as a filler of cellulose matrices. These cellulose-based composites obtained by casting, presented good thermal stability and higher tensile resistance than conventional HDPE and PP, deeming them appropriate for biodegradable packaging, wrapping, and mulching applications. Likewise, Spence et al. [234] worked on microfibrillated cellulose (MFCs) composite films containing kaolin clay and calcium carbonate obtained by casting. Even though the authors demonstrated that the addition of mineral fillers reduced films density and water vapor transmission rate (WVTR) and presented proper mechanical properties for packaging applications, their water barrier properties are low in comparison to petroleum-based plastics. Moreover, Trovatti et al. [235] studied the use of NFC as filler of bionanocomposite films with improved thermal and mechanical properties prepared by casting of water-based suspensions of pullulan: an extracellular homopolysaccharide made up of 1,6-linked maltotriose residues, produced by certain strains of the polymorphic fungus Aureobasidium pullulans. Thus, the authors assured that these novel bionanocomposites could be labeled as sustainable materials since they were prepared entirely from renewable resources and through a green approach. In another interesting work reported by Oun and Rhim [236], crystalline cellulose nanofibrils (CNF) were isolated from cotton linter pulp using an acid hydrolysis method and later used as filler of sodium carboxymethyl cellulose (CMC) composite the film’s obtained by casting. It was demonstrated that CNF is highly compatible with the CMC and the presence of this filler affected films mechanical and water vapor barrier properties. The CMC/CNF composite films have a high potential to be used as edible coating or packaging films for the shelf-life extension of fresh and minimally processed fruits and vegetables. CNFs have been also used as fillers of starch-based biocomposite films [145, 237, 238]. The addition of CNFs obtained from different biomass sources resulted in increased tensile strength and elastic modulus and led to the reduction of elongation at break, water vapor permeability, and, in some cases, oxygen transmission rate. Furthermore, Farooq et al. [239] utilized a variety of softwood Kraft lignin morphologies to obtain strong and ductile CNF nanocomposite films with potential food packaging, water purification, and biomedical applications. In this work, two techniques were employed to obtain biocomposites: casting and thermocompression. The incorporation of lignin rendered tougher film structure, materials waterproof while exhibiting complementary UV shielding and radical scavenging capability.

Starch-based materials offer a very attractive low-cost base for new biodegradable polymers due to their abundance, annual renewability, and ability to be processed with conventional plastic processing equipment [22, 35, 36]. The improvement of mechanical properties of starch-based materials is an ongoing challenge due to their poor mechanical performance, particularly tensile strength [240]. Among the various alternatives to improve these mechanical properties, blends, and composites have been proposed [22, 241–246]. Correspondingly, Ali et al. [241] developed fully biodegradable starch-based films by casting method based on modified (hydroxypropyl) cornstarch and two kinds of commercially available polysaccharide-based macro-crystals (cellulose and starch crystals). They demonstrated that the mechanical properties were modified by crystals addition, increasing the tensile strength and elastic modulus, and decreasing elongation at break. Besides, the biocomposites showed improved protection against UV radiation. Wang et al. [243] studied collagen composites with three different maize starches: waxy maize starch, normal starch, and high amylose starch, showing higher tensile strength and lower solubility in water than collagen film, and increased thermal stability and crystallinity. Noteworthily, Stasi et al. [246] suggested a novel and cost-effective reutilization of carbon waste ashes as a reinforcing agent of biocomposite films based on thermoplastic starch for agricultural applications. Carbon-based ashes produced by pyrolysis of lignocellulosic wastes were added to glycerol and maize native starch in different quantities, which were melt-processed and molded. The authors reported that ash content decreased both moisture sorption and degradation of starch biocomposites. Moreover, Yin et al. [247] proposed to improve the functional properties of starch-based films incorporating chitin obtained from shrimp shell powder into corn starch matrix. Before blending, maleic anhydride was introduced as a cross-linker and composite films were obtained by casting-evaporation. The obtained starch-based nano-biocomposite films presented superior mechanical properties, higher surface hydrophobicity, and enhanced barrier properties, in addition to antibacterial properties against Escherichia coli and Staphylococcus aureus.

Soy protein isolate (SPI) is another biobased polymer with good film-forming ability that can be produced by casting, extrusion, or injection molding [248–251]. Since SPI films have low strength and absorb a high amount of moisture which limits their applications, reinforcing filler has been proposed [252–255]. Accordingly, Martelli-Tosi et al. [254] investigated the potential use of soybean straw as reinforcing filler in SPI films. Both raw soybean straw and samples treated with alkali (NaOH 5 and 17.5%) and bleached with hydrogen peroxide (H2O2) or sodium hypochlorite (NaOCl) was studied. Films added with treated soybean straw presented higher mechanical resistance, lower elongation at break, and lower solubility in water; while the addition of non-treated soybean straw had no significant effect on SPI film properties. Alternatively, Zhao et al. [255] developed a series of epichlorohydrin-crosslinked hydroxypropyl chitosan/SPI films with different soy protein contents. The authors demonstrated that these materials were tunable in terms of their surface structure and mechanical properties by changing the SPI content. Biocomposites exhibited good cytocompatibility and hemocompatibility, improved wound contraction rates, and showed great promotion of granulation tissue regeneration and collagen deposition, which are excellent results for skin tissue engineering.

Among the biodegradable polymers, PHB is the principal and the most widely used type of the PHA, with high potentiality for replacing fossil-based synthetic packaging [256]. Even though this biopolymer displays thermophysical and mechanical characteristics similar to polystyrene and isotactic polypropylene, it presents a narrow processing window which limits its applicability [257]. Therefore, the development of PHB composites has been proposed as a solution. PHB biocomposites employing a wide range of fillers, such as cellulose nanocrystals [258], graphene [259], agave fiber [260], chitosan, and catechin [110] have been developed over the last few years. An interesting work carried out by Araque et al. [261] focused on the development of PHB and hollow glass microspheres and composite films. These materials were obtained through melt intercalation, an innovative technique with low environmental impact because it does not require solvents use. Besides, Seggiani et al. [116] studied PHAs based biocomposites with fibers from Posidonia oceanica (PO) to assess their processability by extrusion, mechanical properties, and potential biodegradability in a natural marine environment. These composites provide an interesting valorization route for PO fibrous wastes largely accumulated on coastal beaches and can be suitable to manufacture items usable in marine environments, such as in natural engineering interventions for restoration or protection of coastal habitats.

The processing methods strongly affect the properties of the biocomposite materials [262], thus a description of the most widely used methods to obtain biopolymeric films are given, mentioning the advantages and disadvantages of each of them:

Solution casting: this is the simplest and most frequently used method at a laboratory scale for biocomposite films. The casting technique consists in spreading a film-forming solution or suspension on small plexiglass or plates, in which the film thickness is controlled by the mass of suspension poured onto the plate [263]. The drying process of these films usually takes place at room temperature or in an oven with air circulation [45, 120, 264]. Polymers that are soluble in water are mostly treated with this technique and, as stressed by Bondeson and Oksman [265], the differences in hydrophobicity or the hydrophilicity of the filler and that of the matrix require the use of a suitable solvent. Besides, the solvent concentration can be decided according to the required characteristics and viscosity of the solution. The biopolymers composites obtained through this technique usually show good properties, though constituents distribution throughout the film is strongly dependent on the biopolymer and filler ratio in the solution [266]. Finally, even though this method has been extensively used for research on films based on starch and protein, the difficulty in scaling up production volumes and the long drying times, make this technique impracticable on an industrial scale [267].

Tape-casting: films and coatings can also be prepared by the tape-casting technique at a larger scale than those usually reported by literature using the classical casting technique. In the tape-casting process, a suspension is placed in a reservoir with a blade, which height can be adjusted with micrometric screws [268]. The suspension is later dried on the same support, resulting in a film that can be removed from the surface. Depending on the film’s characteristics, it can be rolled, cut, drilled, stamped, or laminated. The spreading of the film-forming solution (or suspension) can be done on larger supports or on a continuous carrier tape. The formed film is dried on the support, by heat conduction, circulation of hot air (heat convection), and infrared heating, resulting in a reduction of its thickness.

Extrusion: melt compounding or extrusion, is a conventional method widely used in the polymer industry and compound composites where the material is shaped through a die. Using extrusion to produce biopolymer-based composites could reduce manufacturing costs and render them more cost-competitive [265]. Extruders can be categorized on the number of screws in single, twin, and multiple screw extruders, further on the rotation mode of the screws can be classified in a single direction or in the opposite direction (corotating or counterrotating) or a mixture of both for a multiple screw extruder [262]. It is important to highlight that biopolymers processing by extrusion requires the use of additives, such as plasticizers and antioxidants to thermo-plasticize the polymer mix and avoid its degradation. However, it is well-known that extrusion processing these kinds of materials is not simple; hence optimization of the operating conditions (screw speed, configuration, and processing temperature) for each composite is necessary.

Blowing: blowing is a process that involves using air or nitrogen to inflate a tube of the melt as it comes out from the die. The blown film usually grows in a vertically upward direction. The die most often has a circular (annular) geometry, which is the simplest and most convenient solution even though the resulting film is less homogeneous. The thin bubble is then drawn by a series of nip rollers, flattened, and wound up in a reel. Both drawing and blowing orient the polymer molecular chains in a preferred manner. Depending on whether drawing or blowing prevailed the final film will be stronger in the longitudinal or transverse direction, respectively [269].

The inherent properties of biocomposite films are relevant for their applications. As it was stressed by Haniffa et al. [270], mechanical and thermal properties are regarded as the most relevant properties of biocomposite films. However, the physical and chemical characteristics of the main components can significantly alter these properties. The thermal, mechanical, barrier, and other relevant properties of diverse biocomposite films are included in Table 2. As it can be observed, the properties of these materials depend on many factors, being the most relevant: the type of polymer matrix, the filler type and concentration, and the selected processing method and conditions. Consequently, when comparing properties and characteristics of different films based on the same biopolymer and filler, it is necessary to consider the filler concentration and size, as well as processing technique and conditions.

Table 2.

Thermal, mechanical, barrier, and other interesting properties of biocomposite films

| Biopolymer | Filler and concentration | Processing technology | Thermal properties (°C) | Mechanical properties | Water vapor barrier | Other interesting properties | References |

|---|---|---|---|---|---|---|---|

| Cellulose | Napier grass cellulose fibrils (NGCFs) (0, 5, and 25%wt) | Casting solution | TDa = 358 − 363 |

σme = 49.7–107.9 MPa εBf = 7.8–12.7% |

- |

Good interaction filler-matrix Random orientation of NGCFs |

[120] |

| Microfibrillated cellulose | Kaolin clay and calcium carbonate (0, 2.5, 5, 7.5, and 10%wt) | Casting solution | - | - | 1.04–2.49 10−2 gm/(m2 day) | Low density | [271] |

| Nanocellulose | Barium titanate nanoparticles (0, 30, 40, 50, and 60%wt) | Casting solution | TDa ⋍ 300 | - | - |

Dielectric/electrical property Piezoelectric performance |

[272] |

| Thermoplastic starch | Carbon ashes (0, 7, 14, and 21%wt) | Melt mixing and compression molding |

Tmb = 167.51–191.95 Tgc = 97.70–146.37 |

Ed = 27.87–32.19 MPa σme = 2.27–2.65 MPa εBf = 33–66% |

- |

Degree of crystallinity = 12.7–22.2% Ashes decreased 70% the starch deterioration |

[246] |

| Thermoplastic starch | Talc nanoparticles (0–5%wt) | Melt mixing and thermocompression |

TDa = 255–275 Tm = 144.3–156.4 Tg1c = -51.8–(− 45.4) Tg2c = 45.9–46.9 |

Ed = 22.7–38.2 MPa σme = 1.19–2.34 MPa εBf = 59.0–62.2% |

0.6–1.3 10−10 g/(m s Pa) |

Degree of crystallinity = 5.4–5.6% Oxygen permeation = 388.7–527.8 cm3 mil/(m2 day) Thermosealing capacity |

[244, 273, 274] |

| Thermoplastic starch | Bentonite particles (0–5%wt) | Melt mixing and thermocompression |

Tmb = 98.5–96.9 Tgc = − 66.3–(− 65.0) |

Ed = 50.9–180.9 MPa σme = 1.96–3.89 MPa εBf = 38.4–96.2% |

- |

Degree of crystallinity = 5.6–9.6% Eventual particles intercalation |

[161, 275] |

| Thermoplastic starch | Granite sand particles (0, 1, and 5%wt) | Melt mixing and thermocompression |

TDa = 317–321 Tmb = 147.4–161.2 |

Ed = 80–405 MPa σme = 1.8–5.6 MPa εBf = 14.7–25.9% |

- |

Translucent UV absorption capacity |

[276] |

| Thermoplastic starch | Agave fibers and henquen fibers (0, 10, 20 and 30%wt) | Extrusion and injection molding | - |

Ed = 128–454 MPa σme = 11–23 MPa εBf = 10–463% |

- | Fire retardant properties | [277] |

| Thermoplastic starch | Cassava and ahipa peel and bagasse (0.5 and 1.5%wt) | Melt mixing and thermocompression |

TDa ⋍ 316 Tmb = 156.5–229.0 Tg1c = − 43.3–(− 35.8) Tg2c = 43.0–81.8 |

Ed = 78.2–217.9 MPa σme = 2.6–5.5 MPa εBf = 33.7–76.5% |

1.24–1.56 10−10 g/(m s Pa) | Light and UV blocking capacity | [98] |

| Potato starch | Coffee silverskin (0–10%wt) | Casting | - |

Ed = 450–1800 MPa σme = 5–32 MPa εBf = 2–22% |

WVTR 49.4–57.9 g/(m2 day) |

Increases the films surface hydrophobicity and roughness Antioxidant and UV-protection capacities |

[121] |

| Soy protein isolate |

Soybean straw treated and nontreated (0 and 5%wt) |

Casting | - |

Ed = 298–5527 MPa σme = 4.6–9.0 MPa εBf = 15–35% |

9.8–12.8 10−10 g/(m s Pa) |

Moisture = 12.8–15.9% Solubility in water = 36–66% |

[254] |

| Soy protein isolate | Waste from red algae Gelidium sesquipedale (Rodophyta) (0–9%wt) | Extrusion and compression molding | TDa > 300 |

Ed = 75.0–100.2 MPa σme = 4.3–5.9 MPa εBf = 2.1–65.1% |

2.29–8.57 10−12 g cm/(cm2 s Pa) |

Rough surface with low gloss Greenish and yellowish color of algae waste and soy protein |

[250] |

| Polyhydroxyalkanoates (PHAs) | Fibers of Posidonia oceanica (0–30%wt) | Extrusion and compression molding | TDa = 295–305 |

Ed = 1.24–3232 MPa σme = 21.88–24.80 MPa εBf = 2.37–6.6.47% |

- |

Total degradation time < 6 months (in marine sediment) |

[116] |

| Polyhydroxybutyrate (PHB) and polyhydroxyvalerate (PHB-HV) |

Agave fibers (10, 20, and 30%wt) |

Melt mixing and thermocompression |

Tm1b = 135.7–151.7 Tm2b = 148.7–161.8 Tgc = 10.8–17 |

Ed = 413–770 MPa σme = 13.7–15.7 MPa |

- |

Good fiber dispersion and compatibility with both matrices Impact strength = 24.5–34.4 J/m |

[260] |

| Poly(β-hydroxybutyrate) /poly(ε-caprolactone) |

Cellulosic particles (1%wt) |

Melt mixing and injection molding |

Tg1c = -53.0 to − 51.5 Tg2c = 17.5–19.7 |

Ed = 1007.7–1575.0 MPa σme = 24.6–34.9 MPa |

- | Incompatibility cellulosic particles-PHB/PCL | [258] |

| Poly (lactic acid) (PLA) |

Banaba fiber (10, 20, and 30%wt) |

Injection molding, extrusion + injection molding or extrusion + thermocompression |

TDa = 335–337 Tgc = 68–69 |

Ed = 1400–1650 MPa σme = 15–55 MPa |

- | After 20%wt, the tensile strength decreased significantly and the flexural strength of the biocomposite was found to be maximum | [76] |

| Poly (lactic acid) (PLA) |

Seaweed residue after alginate extraction (20, 30, and 40%wt) |

Melt mixing and injection molding |

TDa = 292–310 Tm1b = 127–149 Tm2b = 142–157 Tgc = 57–61 |

Ed = 3200–3500 MPa σme = 24.1–47.4 MPa εBf = 0.8–2.0% |

- | Composite show lower glow wire flammability index (GWFI) and no dripping of material upon burning, thus showing potential to be used in applications where high temperature occasionally occur | [52] |

aDegradation temperature (TD); bmelting temperature (Tm); cglass transition temperature (Tg); delastic modulus (E); emaximum tensile strength (σm); felongation at break (εB)

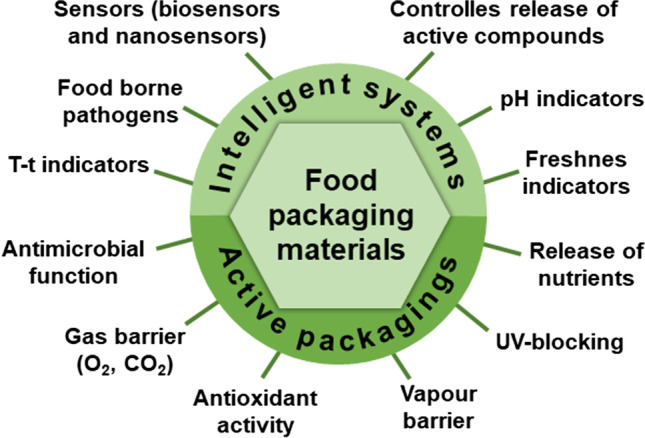

Active biobased composite and nanocomposites

Active containers, usually used in food packaging, are those containing some substance capable of preserving the organoleptic or sensory characteristics of a product to ensure its quality. Of special interest are those active packages that contain natural antioxidants and antimicrobials that not only extend the shelf-life of packaged products by preventing rancidity reactions but also prevent the growth of foodborne pathogens [278]. Biodegradable and biobased polymers are preferred in the development of active materials for single used food packaging due to their low environmental impact [221, 275, 279, 280]. Among the available natural polymers and compounds, some can be obtained from agri-food industrial waste and their use would add value to these residues and keep them in circulation, one of the premises of circular economy. A clear example is the use of chitosan, a biodegradable polymer derived from chitin with antimicrobial activity that is obtained from the fishing industry waste such as crustacean exoskeletons [281]. Likewise, by-products and wastes from fruit and vegetables processing are an important source of compounds with high nutritional and functional value such as vitamins, minerals, antioxidants, and antimicrobial compounds, though are often discarded or derived for animal feed [282]. Essential oils (EOs) that can be obtained from these sources have been widely studied as additives for the development of active food packaging, mainly due to their antioxidant and antimicrobial capacity and their GRAS (Generally Recognized As Safe) character [283, 284]. Therefore, the use of active compounds derived from agricultural by-products not only contributes to the recovery of these compounds with specific activities but also generates added value for them. EOs are mainly phenolic compounds derived from plant secondary metabolites with antimicrobial capacity and several therapeutic and health-promoting attributes. Several authors have reported that the addition of EOs can significantly affect the microstructure, mechanical and barrier properties of the material depending on how they are incorporated into the polymeric matrix [284–287]. The most commonly reported EOs incorporated in biodegradable matrices are rosemary, tea tree, cinnamon, oregano, clove, and thyme [86, 288–292]. For instance, Bof et al. [16] have developed and characterized active biodegradable films based on corn starch and chitosan (CS:CH) with the addition of lemon essential oil (LEO) and grapefruit seed extracts (GSE). The inclusion of these active compounds, which are by-products of residues derived from citrus processing, did not affect the mechanical properties of the material and provided antimicrobial capacity by contact. Similarly, Kanmani and Rhim [293] developed antimicrobial active films with GSE on carrageenan matrix, with additional UV barrier capacity, particularly important for UV-sensitive food packaging. Further interesting biocomposites materials with EOs were reviewed in Table 3.

Table 3.

Active biocomposite and nanocomposite films relevant properties

| Biopolymer | Active compound | Processing technology | Mechanical properties | Water vapor permeability | Solubility (%) | Antimicrobial activity | Antioxidant capacity | References |

|---|---|---|---|---|---|---|---|---|

| Cassava starch | ZnO nanorods (1%wt) | Casting solution |

σma = 2.8–3.2 MPa εBb = 50–58% |

4.7–5.3 10−10 g/m s Pa | 8–16 | Inhibition of E. coli growth | - | [210] |

| Cornstarch | Green synthesized AgNPs in situ (0–143 ppm) | Casting solution |

Ec = 36.9–166.8 MPa σma = 161.6–368.1 MPa εBb = 38.1–39.7% |

1.6–2.2 10−10 g/m s Pa | 29 − 34.4 (25 °C) and 34.8–52.4 | Concentration up to 28.6 ppm inhibition by contact and higher than 71.5 ppm halo of E. coli, Salmonella spp, Penicillium spp, and S. aureus | - | [184] |

| Cornstarch | AgNPs synthesized with lemon juice (0–143 ppm) | Casting solution |

σma = 2.1–4 MPa εBb = 41–55% |

0.63–1.62 10−10 g/m s Pa | 34.6 − 46 | Concentration up to 28.6 ppm inhibition by contact and higher than 71.5 ppm halo of E. coli, Salmonella spp, Pseudomona spp, and S. aureus | - | [186] |

| Thermoplastic maize starch | Chitin nanoparticles (0–9%wt) | Casting solution |

σma = 3.89–9.32 MPa εBb = 30–87% |

7–12 10−11 g/mhPa | - | Against S. aureus and E. coli | - | [247] |

| Cassava starch TPS | Rosemary extracts (2.5–10%wt of starch) | Extrusion + thermocompression |

Ec = 9.3–23.3 MPa σma = 1.75–2.28 MPa εBb = 50–70% |

2.62–4.94 10−10 g/m s Pa | 20–25 | - | 29.5–140.9 (µmolTE/g DPPH method) in hydrophilic, lipophilic, and acid simulants | [294] |

| Rice starch and fish protein | Oregano EO (4–8%wt) | Casting solution |

σma = 3.9–6.8 MPa εBb = 83.5–108.8% |

0.18–0.21 g mm m−2 kPa−1 h−1 | 8–22.6 | - | 4.2% DPPH inhibition and 63.1% peroxidase inhibition | [290] |

| Jackfruit starch and PVA | Jamun extract and/or nutmeg oil (10%wt) and ZnO nanoparticles | Casting solution |

σma = 14.11–27.22 MPa εBb = 2.8–26.6% |

- | 5–28 | Inhibition of S. typhimurium growth | - | [295] |

| Chitosan | Rosemary EO (0.5–1.5%v) + montmorillonite nanoclay (1–5%wt) | Casting solution |

σma = 63.7–83.0 MPa εBb = 3.0–4.3% |

0.31–0.47 10−10 g/m s Pa | 9.5–15.0 | With 1.5% Rosemery EO inhibition of S. agalactiae, E. coli, and L. monocytogenes | 1.4–2.2 mg gallic acid/g sample | [288] |

| Chitosan | Protocatechuic acid (0.5–2%w/v) | Casting method |

σma = 40.8–26.7 MPa εBb = 62.8–7.9% |

12.69–9.90 10−11 g/m s Pa | 19.2–31.4 | - | Antioxidant activity in aqueous and fatty food simulants | [296] |

| Chitosan | AgNPs with Tea polyphenol (0.1%) | Casting method |

σma = 32.8–53.7 MPa εBb = 25.9–12.6% |

39.0–16.7 10−9 g m−1 min−1 Pa−1 | - | Films showed antibacterial activity to both E. coli and S. aureus | Films with TP-AgNPs has improved antioxidant capacity | [48] |

| Chitosan | Oregano and or cinnamon leaf EOs (0.25%wt) | Casting method |

Ec = 1078–1471 MPa σma = 40–43 MPa εBb = 5.9–6.2% |

5.9–6.9 g mm m−2 kPa−1 h−1 | - | Reduce the growth of total aerobic and coliform microorganisms on sliced pork meat | - | [297] |

| Chitosan and rice starch | AgNPs (0 − 38 ppm) | Casting solution |

σma = 66.8–74.5 MPa εBb = 4.6–7.6% |

WVTR 47.60–59.21 g m−2 day−1 |

- | Inhibition of E. coli, S. aureus, and B. cereus | - | [298] |

| Chitosan and cornstarch |

Lemon EO (1–3%wt) |

Casting solution |

Ec = 84–30 MPa σma = 6.7–11.8 MPa εBb = 62–66% |

7.5–7.4 g mm m−2 kPa–1 h−1 | 20–23.7 | Inhibition by contact of Listeria innocua, E. coli, Alternaria alternata, Rhizopus stolonifer, Penicillium expansum | No antioxidant activity was detected (TEAC method) | [16] |

| Chitosan and cornstarch |

Grapefruit seed extract (1–3%wt) |

Casting solution |

Ec = 120–63 MPa σma = 14.4–14.6 MPa εBb = 58.3–67% |

7.5–7.8 g mm m−2 kPa−1 h−1 | 24.7 − 26.1 | Inhibition by contact of Listeria innocua, E. coli, Rhizopus stolonifer, and Penicillium expansum | No antioxidant activity was detected (TEAC method) | [299] |

| Chitosan-cassava TPS | Oregano and or cinnamon leaf EOs (0.25%wt) | Casting + melt blending + thermocompression molding (bilayer films) |

Ec = 910–918 MPa σma = 17–18 MPa εBb = 1.9–2% |

7.87–8.03 g mm m−2 kPa−1 h−1 | - | Reduce the growth of total aerobic and coliform microorganisms on sliced pork meat | - | [297] |

| Curdlan + PVA |

Thyme EO (1–2%) |

Casting method |

σma = 10.4–11.5 MPa εBb = 190–225.9% |

1.2–1.6 10−10 g m−1 min−1 Pa−1 | - | Inhibition of E. coli | - | [292] |

| Whey protein | Oregano or garlic EO (2%wt) | Casting solution |

σma = 0.3–1.4 MPa εBb = 5–15% |

- | - | Against S. Enteriditis, E. coli O157:H7, L. monocytogenes, S. aureus, and Penicillium spp. | [299] | |

| Gelatin |

Red propolis ethanolic extract + clove or basil EO (0.15–0.8%wt) |

Spreading technique |

Ec = 3.4–7.6 MPa σma = 19.3–42.7 MPa εBb = 47.2–75.4% |

0.27–0.40 g mm m−2 kPa−1 h−1 | 84.6 − 92.4 | Against S. aureus, L. monocytogenes, S. enteriditis, and E. coli | 4.6–41.8% (ABTS method); 5.5–76.6% (DPPH method) | [300] |

| Gelatin-chitosan | 3-phenylacetic acid (1–4%) | Electrospinning | - | 5.74–11.22 10−15 kg/m s Pa | 15.3–28.9 | Against S. aureus and S. enterica | - | [301] |

| Gelatin-PLA |

Encapsulated eugenol (0–4 mg/g) |

Electrospray-electrospinning |

Ec = 19.3–21.6 MPa σma = 55.9–64.4 MPa εBb = 6.01–6.75% |

- | - | Against S. aureus and E. coli |

12.15–33 mg DPPH/gDB(*) 17.8–43.8% radical scavenging |

[302] |

| PLA | Copper salt ion-exchange zeolite nanoparticles (1–3%wt) + nanocellulose (1.5–2%wt) | Dual electrospinning |

Ec = 602–807.9 MPa σma = 2.3–3.3 MPa εBb = 4.1–13.1% |

5.73–5.87 10−15 g/m s Pa | - | Against S. aureus and S. typhi | - | [303] |

aMaximum tensile strength (σm); belongation at break (εB); celastic modulus (E); (*)dry basis

On the other hand, several investigations in recent years have focused on studying the effects of the incorporation of metal or metal oxides nanoparticles in biodegradable matrices [304, 305]. Starch-based and nanoclay biocomposites have been the most studied [212, 220, 306–308], although other biopolymer matrices have been used, such as chitosan [309], agar [310, 311], proteins [312, 313], or their combination [298, 314]. Usually, this strategy manages to improve the mechanical properties and susceptibility to the water of the system and, if the nanoparticles have antimicrobial activity the composite material also acquires this property. For instance, Abreu et al. [220] incorporated silver nanoparticles into wheat starch films obtained by solvent evaporation (casting). The materials obtained presented lower hydrophilicity and bacteriostatic activity against Staphylococcus aureus and Escherichia coli. Likewise, Ortega et al. [221] showed that the incorporation of AgNPs in cornstarch-based films decreased the solubility of the material and improved the mechanical properties by increasing Young’s modulus and tensile stress values without decreasing deformation at the break. Similar effects have been reported by Malathi and Singh [315] by TiO2 nanoparticles addition into rice starch films. In this case, the authors showed that the nanocomposite material presented a better water vapor barrier, enhanced mechanical properties, and bacteriostatic activity against Escherichia coli. The incorporation of ZnO nanoparticles has also proven to be an interesting strategy for improving the properties and adding bactericidal activity to starch films. In this regard, Mirjalili et al. [316] showed that starch-based films containing ZnO nanoparticles have better mechanical properties and antimicrobial activity against Escherichia coli and Staphylococcus aureus. Likewise, Nafchi et al. [225] reported that the incorporation of ZnO nanobars reduces hydrophilicity, improves mechanical properties, and provides antimicrobial activity against Escherichia coli to sago starch films. Yet, Guz et al. [210] demonstrated that the properties of starch films containing ZnO nanobars depend strongly on their size.

Nanoparticles and EOs biocomposites have also been studied with other innovative applications, such as wound dressing [45, 317]. Table 3 summarizes different types of nanoparticles included in nanocomposite formulations, being AgNPs the most commonly used for food packaging applications since they effectively reinforce biopolymer matrices and provide antimicrobial capacity over a broad spectrum of bacteria, virus, and fungi [185, 186, 221, 318]. Although numerous nanocomposites or active systems have been studied, the available literature refers mainly to materials manufactured with the solvent evaporation methodology, which is difficult to scale up. The development of biodegradable nanocomposite materials through scalable technologies is essential for the industrial implementation of such systems. Even though extrusion is a continuous and scalable processing technology, the study of the effect of extrusion on nanoparticles or bioactive molecules is still required. In this regard, it is necessary to analyze the mixing and distribution of the components within the matrix, the resulting interactions, and their effect on the material properties, as well as the possible degradation of the additives during the manufacturing process. Recent studies have successfully extruded biocomposites of thermoplastic starch with nanoparticles and EOs [294, 319].

Particularly, since many biopolymers are hydrophilic, the naturally hydrophobic EOs must be compatibilized with the polymeric matrix generally by the addition of surfactant agents. The most widely used technique for this purpose includes the formation of an emulsion or a nanoemulsion to ensure the homogeneous distribution of the active compound in the matrix. Moreover, given the volatile nature of EOs, the processing conditions must be optimized to minimize activity loss. Consequently, when extrusion processing is desired EOs need to be protected from the drastic treatment conditions for which purpose encapsulation is a useful tool [320]. Alternatively, Li et al. [302] have efficiently encapsulated eugenol (83.4 to 92.7 g/100g) in PLA and gelatin nanofibers obtained by electrospinning. Electrospinning has also been used by Scaffaro et al. [321] to modulate EO migration from solvent casting films in a multilayer composite material. Active laminates were formulated with a PLA film containing carvacrol (14%wt) obtained by solvent casting and one or two fibrous layers of PLA applied by electrospinning. These fibrous layers modulated the carvacrol release kinetics, which proved to progressively reduce the burst delivery at an early stage of immersion, therefore increasing the delivery device lifespan from 288 to 795 h.

Inactive and nanocomposite materials, the study of the microstructure helps to understand the interrelation of the structure with the properties that determine the performance of the material, in addition to being able to infer the effectiveness of the filler inclusion within the matrix. In general, when homogeneous surfaces without pores or cracks as well as compact cross-sections are visualized by SEM the included active compounds or nanoparticles are compatible with the polymeric matrix, which also leads to its reinforcement. These observations agree with the reported mechanical behavior of the nanoreinforced materials listed in Table 3. Correspondingly, Bof et al. [16] stressed that the presence of discontinuities in the matrix of cornstarch/chitosan composite films with lemon EO (visualized as oil microdroplets by SEM) was indicative of the lack of miscibility of the active compound with the polymer and lead to poor gas barrier properties. A similar trend was found by other authors working on biodegradable films containing different EOs such as orange peel, tea-tree, and ginger oil, among others [286, 287, 322]. Consequently, the compatibility of the active agent with the matrix determines how efficiently the former is incorporated into the polymer network and therefore the film microstructure characteristics. In this regard, ATR-FTIR spectroscopy is a useful technique that has been widely employed to study the interaction among the composite constituents. In the same work, Bof et al. [16] found by FTIR analyses that hydrogen bonding occurs in the corn starch and chitosan blend films containing grapefruit seed extract as filler, leading to a more compact and denser film structure. Similarly, Sharifi and Pirsa [320] working on black mulberry fruit pulp pectin films studied the effect of both chlorophyll encapsulated with carboxymethylcellulose and silica nanoparticles addition. SEM analysis indicated that both active components act as fillers of the pectin structure. Moreover, their high compatibility was demonstrated through FTIR studies since spectra confirmed electrostatic interactions between pectin chains with encapsulated chlorophylls and silica nanoparticles. Besides, thermogravimetric analysis (TGA) results revealed that the simultaneous addition of these active compounds increases the thermal stability of the film [16, 46, 247].