Abstract

Buckwheat contains more essential proteins, dietary fiber, vitamins, minerals, and diverse phytochemicals than wheat and rice. The aims of this study are to develop the descriptive sensory attributes and evaluate the consumer acceptability of six buckwheat jellies (memilmuk) with added mung bean starch and to analyze the relationship between their descriptive sensory attributes and consumer acceptability. Statistical analyses were performed by one-way analysis of variance (ANOVA), principal component analysis (PCA), and partial least squares regression (PLSR). A total of 18 sensory attributes of buckwheat jelly, including appearance (brown, brightness, and roughness), odor/aroma (soymilk smell, grain smell, red bean porridge smell, and buckwheat tea smell), flavor or taste (savory flavor, plain taste, buckwheat taste, sweet taste, salty taste, and umami), and texture (squashed, dry, smooth, elasticity and stickiness) were developed. Consumer acceptability tests of six buckwheat jellies were conducted by 93 consumers evaluating for color, smell, savory taste, aftertaste, harmony with the sauce, overall liking, and would recommend or try again. Buckwheat jelly with 25% of mung bean starch (BJ_916) was the most favorable jelly sample among the six samples. All attributes except color, smell, and the savory taste of samples showed a significant difference (p < 0.001). BJ_916 showed a close relationship with a grain smell, elasticity, red bean porridge smell, and sweet taste of descriptive attributes and also all attributes of consumer acceptability. The determination of sensory attributes and consumer acceptability of buckwheat jelly will help to improve sensory characteristics to fulfill consumer needs and desires. Furthermore, this current study will help facilitate the expansion of the buckwheat consumption market.

Keywords: descriptive sensory analysis, consumer acceptability, buckwheat jelly

1. Introduction

Buckwheat (Fagopyrum esculentum) is a short-season crop belonging to the Polygonaceae family [1]. Buckwheat is called a pseudo-cereal because the utilization and nutritional value of buckwheat seeds are similar to those of wheat or oat as cereal grains. Buckwheat originally came from Central Asia and is now mainly cultivated in Asia and eastern Europe [2]. Buckwheat groats are commonly used for bread, cookies, and pancakes in western Asia and eastern Europe while buckwheat noodles and pasta have been eaten in eastern Asia and Italy [3]. In Korea, buckwheat flour is consumed to make noodles, pancakes, and jelly (muk) [4]. Buckwheat includes a higher protein content (14%) than that of rice (8.2%) [5]. Furthermore, it is a good source of protein because it contains more essential proteins (cysteine and methionine) compared to rice or maize [2].

The total dietary fiber of buckwheat is also significantly higher than common grains, such as rice and maize [5]. Moreover, it is rich in dietary fiber, vitamins, minerals, and diverse phytochemicals, such as flavonoids, tocols, and rutin [6,7]. These high functional components contribute to various health benefits; it has been found to decrease blood pressure, act as an antidiabetic, have antioxidant, antimicrobial, anticancer effects, and reduce risk of cardiovascular diseases [3,8,9,10,11,12,13]. Buckwheat is also helpful for people with celiac disease because buckwheat protein is gluten free [14].

Muk is a starch jelly that is a traditional Korean food made from grains, such as buckwheat, acorn, and mung bean, and has been consistently popular due to its nutritional profiles and peculiar texture (soft and chewy). It is produced by extracting starch from grains, boiling with water until thickened, and hardening to jelly [15]. Mung bean (Vigna radiata) is a legume mainly cultivated in Asia. Mung bean contains plenty of nutrients, such as proteins, vitexin, and isoflavone. It is currently used in plant-based meat and egg alternatives as well as soups, porridge, snacks, bread, and noodles [16]. In Korea, it is a popular food ingredient used in the form of sprouts and seeds, which are made into pancakes, jelly (muk), or seasoned sprouts (namul). Specifically, mung bean starch is a very good ingredient for jelly because of its excellent gel formation ability and high elasticity [17].

Recent studies on starch gel with buckwheat or mung bean were mainly focused on the efficacy of buckwheat or mung bean, such as its quality characteristics by adding functional ingredients. The studies included the effects of chitosan on shelf life and quality on buckwheat starch jelly [18], the effects of ginkgo nut powder on the quality characteristics and antioxidant activity of mung bean starch gel [19], and the effects on the quality characteristics of mung bean starch jelly with white lotus (Nelumbo nucifera) root powder [20]. Moreover, several studies have reported the rheological and textural properties of buckwheat bread and noodles for improving quality characteristics [4,21,22]. Previous studies on buckwheat jelly have mostly focused on the quality characteristics and bioactivities rather than organoleptic properties [23,24].

This study aims to evaluate the sensory properties and consumer acceptability of the jelly to improve the taste and texture of Korean traditional buckwheat jelly (memilmuk). We hope this study will help to develop healthy and consumer-favorable products with buckwheat and to contribute to the expansion of the market for buckwheat products.

2. Materials and Methods

2.1. Preparation of Buckwheat Jelly Samples

Table 1 presents the ingredients, sample code, and cooking methods used for the samples. The buckwheat flour (Hallasan area Cheotmaeul, Hallasan Co., Seogwipo, JeJu, Korea) harvested in Jeju-do, was purchased from a local online market because Jeju-do is the region with the highest buckwheat yield in Korea [25]. Other ingredients were salt (CJ Cheiljedang Co., Seoul, Korea), soybean oil (Sajo Co., Seoul, Korea), and mung bean powder (Gomine, Foodsynergy Co., Seoul, Korea).

Table 1.

Ingredients, sample code, and cooking method of the six buckwheat jellies.

| Sample Code | Percent (%) (1) | Ingredient (g) | Cooking Method | ||||

|---|---|---|---|---|---|---|---|

| Buckwheat Flour | Mung Bean Powder | Water | Salt | Cooking Oil | |||

| BJ_265 | 100:0 | 170.0 | - | 817.0 | 3.0 | 10.0 | ① Mix the ingredients, filter twice through a sieve (Chunggye Sanggong Co., Seoul, Korea), and rest at room temperature for 15 min. ② Put the mixture in a pot, put it on induction (Shinil Industrial Co., Ltd., Seoul, Korea) and stir at 180 °C for 5 min until it thickens, then reduce the temperature to 120 °C and stir for 7 min (stirring speed: 80 times/min). ③ Add cooking oil to Step 2, stir continuously for 5 min, turn off the heat, place it flat in a square mold, and solidify. ④ After 5 h at room temperature, cut into 3 cm × 1 cm × 1 cm pieces. |

| BJ_153 | 95:5 | 161.5 | 8.5 | ||||

| BJ_870 | 90:10 | 153.0 | 17.0 | ||||

| BJ_453 | 85:15 | 144.5 | 25.5 | ||||

| BJ_335 | 80:20 | 136.0 | 34.0 | ||||

| BJ_916 | 75:25 | 127.5 | 42.5 | ||||

(1) Buckwheat flour and mung bean powder mixing ratio.

This present study evaluated and compared sensory properties between pure buckwheat flour jelly and buckwheat flour jelly with 25% mung bean flour because commercial buckwheat flour for jelly contains 25% mung bean powder [26,27]. Samples in this study were processed with buckwheat flour and mung bean flour. The samples were six buckwheat jellies (memilmuk) with mung bean powder. The samples were named as follows: BJ_265 (no mung bean powder), BJ_153 (5% mung bean powder), BJ_870 (10% of mung bean powder), BJ_453 (15% of mung bean powder), BJ_335 (20% of mung bean powder), and BJ_916 (25% of mung bean powder). The manufacturing method for the jelly was based on “Buckwheat jelly (memilmuk) recipes” from Korean Traditional local food published by Rural Development Administration in Korea [28] and developed through experimental cooking and taste evaluations. The recipe is as follows: (1) Mix all the ingredients, filter twice through a sieve, and rest at room temperature for 15 min. (2) Put the mixture in a pot, put it on induction, stir at 180 °C for 5 min until it thickens, then lower to 120 °C and stir for 7 min. (3) Add cooking oil and stir for 5 min. Turn off the heat and lay flat on a square frame to harden. (4) After 5 h at room temperature, cut into 3 cm × 1 cm × 1 cm pieces.

Samples were put in a plastic bowl (7 cm in diameter × 3 cm in height) with 20 g (3–4 pieces) of jelly each and served to participants. The samples were coded with three-digit random numbers and presented using a Latin square design to minimize the carry-over effects [29], and spring water was served to allow participants to rinse their mouths between each sample.

2.2. Panel Selection and Training

Eight panelists (six females and two males, aged 20–40) with previous experience and interest in evaluating jelly products were selected. The basic screening tests, such as a basic taste test, flavor and aroma recognition test, and an intensity ranking test, were conducted 10 times to understand the basics of sensory evaluations by panelists [30]. Samples were presented in random order and labeled with three-digit random numbers according to the William’s Latin square design method [31,32,33]. The panelists were asked to swallow the samples after evaluating for a uniform tasting result.

During the first panel training for 120 min, the panelists tasted four samples, which were selected before the bench test, and generated sensory descriptive attributes for appearance, aroma/odor, taste/flavor, and texture/mouthfeel. This was performed through open discussions with panel leaders to establish terms and definitions of the attribute.

During the second training session (120 min), the panelists developed a refined set of sensory descriptive attributes using different products. Once the lexicon of interest was selected, various products were presented to the panel for the selection of reference standards.

For the third training session (120 min), chosen sensory descriptive attributes from the first and second training sessions were evaluated and confirmed after presenting selected and rated standard intensities of each attribute. The panelists gave ratings based on a 15-point intensity rating scale (0 = none; 15 = extremely strong) for each attribute.

During the fourth session (120 min), panelists practiced using selected standard samples for the final testing procedure. Pre-evaluation tests were conducted in individual booths equipped with white light systems using written evaluation sheets. The panelists then evaluated the real samples and compared the consistency of the scores. During the fifth training session (60 min), a preliminary test was investigated using standard samples to minimize rating variations between panelists. In each sensory test, panelists were served drinking water to eliminate any aftertaste and buckwheat jelly residues between samples. The panelists randomly evaluated three replicates of six samples in each sensory test. The sensory study protocol was reviewed and approved by Konkuk University’s Institutional Review Board (IRB approval number: 7001355-202011-E-126).

2.3. Development of a Lexicon for the Six Buckwheat Jellies

The panelists developed a lexicon with 18 descriptors to describe characteristics of appearance, aroma/odor, taste/flavor, and texture/mouthfeel. Regarding appearance, three descriptors (brown, brightness, and roughness) were developed. As aroma/odor and taste/flavor descriptors, soymilk smell, grain smell, red bean porridge smell, buckwheat tea smell, savory flavor, plain taste, buckwheat taste, sweet taste, salty taste, and umami were created. Five descriptors (squashed texture, dry texture, smooth texture, elasticity, and stickiness) as texture/mouthfeel descriptors were selected by the panelists. Furthermore, a preliminary test of sensory intensity was conducted to rate the relative intensities of the descriptors. A few panelists received supplementary training tests to minimize the deviation in intensity ratings. Table 2 shows the sensory descriptors, definitions, and physical standards of the six samples in this study.

Table 2.

Sensory attributes, definitions, and physical standards of buckwheat jelly.

| Attributes (Descriptor) | Definition | Reference |

|---|---|---|

| Appearance | ||

| Brown_A | Intensity of brown color | Formula guide (Pantone, Carlstadt, NJ, USA) (1) |

| Brighness_A | Degree of brightness | Formula guide (Pantone, Carlstadt, NJ, USA) |

| Rougness_A | Degree of roughness | (Strong) Firm tobu (Pulmuone Co., Seoul, Korea) (13) (2) (Weak) Konjac jelly (Sajo Daelim Co., Seoul, Korea) (1) |

| Odor/Aroma | ||

| Soymilk_O | The smell associated with soy milk | (Strong) sugar free soymilk (Maeil Dairies Co., Seoul, Korea) 25% + water 75% (15) (Weak) sugar free soymilk (Maeil Dairies Co., Seoul, Korea) 10% + water 90% (1) |

| Grain_O | The smell associated with toasted grain | (Strong) powder made of mixed grains (Damtuh Co., Sunheon, Jeollanam-do, Korea) 10% + water 90% (15) (Weak) powder made of mixed grains (Damtuh Co., Sunheon, Jeollanam-do, Korea) 1% + water 99% (1) |

| Red Bean Porridge_O | The smell associated with red bean porridge | (Strong) red bean porridge (Bibigo Porridge, CJ Cheiljedang Co., Seoul, Korea) 100% (15) (Normal) red bean porridge (Bibigo Porridge, CJ Cheiljedang Co., Seoul Korea) 50% + water 50% (8) (Weak) red bean porridge (Bibigo Porridge, CJ Cheiljedang Co., Seoul, Korea) 5% + water 95% (1) |

| Buckwheat tea_O | The smell associated with buckwheat tea in water | (Strong) buckwheat tea (Dongsuh Foods Co., Seoul, Korea) + 80 °C water 100 cc (15) (Weak) buckwheat tea (Dongsuh Foods Co., Seoul, Korea) + 80 °C water 1000 cc (3) |

| Flavor/Taste | ||

| Savory_F | Intensity of flavor associated with boiled Nurunggi | (Strong) Nurungji Porridge (Ottogi Co., Ltd, Anyang, Gyeonggi-do, Korea) 100% (15) (Weak) Nurungji Porridge (Ottogi Co., Ltd, Anyang, Gyeonggi-do, Korea) 30% + water 70% (3) |

| Plain flavor and taste | Intensities of flavor and taste associated with plain soybean milk | (Strong) sugar free soymilk (Maeil Dairies Co., Seoul, Korea) 25% + water 75% (15) (Weak) sugar free soymilk (Maeil Dairies Co., Seoul, Korea) 5% + water 95% (1) |

| Buckwheat flavor and taste | Intensities of flavor and taste associated with buckwheat | (Strong) buckwheat tea (Dongsuh Foods Co.,Seoul, Korea) + 80 °C water 100 cc (15) (Weak) buckwheat tea (Dongsuh Foods Co.,Seoul, Korea) + 80 °C water 1000 cc (3) |

| Sweet taste | Typical taste of sucrose | (Strong) sugar 10% + water 90% (15) (Weak) sugar 1% + water 99% (1) |

| Salty taste | Typical taste of salt | (Strong) salt 0.5% + water 99.5 % (15) (Weak) salt 0.1% + water 99.9 % (1) |

| Umami | Typical taste of MSG (monosodium glutamate) |

(Strong) MSG (Miwon, Daesang Co., Seoul, Korea) 1% + water 99 % (15) (Normal) MSG (Miwon, Daesang Co., Seoul, Korea) 0.5% + water 99.5 % (8) (Weak) MSG (Miwon, Daesang Co., Seoul, Korea) 0.1% + water 99.9 % (1) |

| Texture/Mouthfeel | ||

| Squashed texture | Texture that crumbles when the sample is chewed (degree of squashed texture) | (Strong) sausage (Jinjuham Co., Seoul, Korea) (13) |

| Dry texture | Degree of dry texture associated with boiled egg yolk | (Strong) egg yolks boiled for 20 min (15) (Normal) egg yolks boiled for 10 min (10) |

| Smooth texture | Soft feel in the mouth (degree of smooth texture associated with soft tofu) | (Strong) soft tofu (Pulmuone Co., Seoul, Korea) (15) (Weak) firm tofu (Pulmuone Co., Seoul, Korea) (5) |

| Elasticity | Degree to which the sample returns to its shape when lightly pressed with the teeth in the mouth (degree of elasticity associated konjak jelly). | (Strong) konjac jelly (Sajo daelim Co., Seoul, Korea) (15) (Normal) sweet jelly of red beans (Haitai Confectionery and Foods Co., Seoul, Korea) (8) |

| Stickiness | Degree of stickiness and sticking to teeth when the sample is put in the mouth and eaten all (degree of stickiness associated with cheddar cheese) | (Strong) cheddar cheese (Maeil Dairies Co., Seoul, Korea) (15) (Weak) soft tofu (Pulmuone Co., Seoul, Korea) (3) |

(1) Indicates the brand used in this study. Other brands may be used to represent the attribute, but the reference intensities may need to be adjusted by the panel based on the intensity of that particular brand. (2) This number shows intensity of the standard reference.

2.4. Consumer Acceptance Test

The consumer panelists (n = 93, males: 20, females: 73, age: 20–60) were recruited to evaluate the consumer acceptability of the six buckwheat jelly samples. Each sample was presented to consumers using the same method as the descriptive analysis. Six randomized samples per session were presented to the consumer panelists using a randomized complete block design [31,34]. To minimize residual effects, spring water was provided between samples. Consumers were asked to rate their liking (color liking, smell liking, savory taste liking, aftertaste liking harmony with the sauce, overall liking, and likeliness to recommend and try again) using a nine-point hedonic scale (1 = dislike extremely to 9 = like extremely).

2.5. Statistical Analysis

The mean of the data was calculated using descriptive analysis. One-way analysis of variance (ANOVA) was performed to determine significant differences in sensory attributes and consumer acceptance between the six samples. A statistically significant difference was defined as p < 0.05. Duncan’s multiple range comparisons were performed by a post-hoc test if there was a significant difference at α = 0.05. Principal component analysis (PCA) was performed to obtain six samples and sensory representations of sensory attributes. Partial least squares regression (PLSR) analysis was also performed to identify associations between samples, technical attributes, and consumer acceptance. All statistical analyses were performed using SPSS (Statistical Package for Social Science) ver. 25.0 (IBM, Chicago, IL, USA) and SIMCA ver. 16.0 (Umetrics, Umea, Sweden).

3. Results and Discussion

3.1. Descriptive Sensory Analysis

Table 3 shows the intensities of the sensory attributes of six buckwheat jelly samples. Of the total of 18 sensory attributes, 8 attributes (Brown_A, Soymilk_O, Red Bean Porridge_O, Buckwheat Tea_O, dry texture, smooth texture, elasticity, and stickiness) showed a significant difference by sample (p < 0.05). The sensory attributes of Brown_A, Soymilk_O, Buckwheat tea_O, smooth texture, and stickiness were higher for jelly samples with a high buckwheat content. The samples with increased mung bean starch contents showed higher scores for red bean Porridge_O and elasticity than jelly samples with a high buckwheat content. Buckwheat proteins usually contain fewer prolamins and glutelins and more albumins and globulins than those of wheat and rye. Due to the composition of proteins, buckwheat flour has lower viscosity and elasticity compared to wheat [3,35]. However, mung bean flour has a high gel formation power, and mung bean jelly shows a smooth surface and high springiness because its texture is affected by the amount of amylose content and varieties of starch [36,37]. In the case of the dry texture attribute, the intensity score decreased in the buckwheat jelly samples with 5–20% of added mung bean starch, but it was a high score at 6.42 in the BJ_916 sample (sample with the highest mung bean starch content) with 25% mung bean starch added. Kim et al. [15] showed a similar result to this present study. They evaluated the quality characteristics of mung bean jelly (Cheongpomuk) with mung bean powder added (0, 25, 50, 75, and 100%). The results showed that the mung bean jelly with 25% mung bean powder had higher values of textural and sensory properties. The detailed confirmation of this result is necessary through assessing physicochemical properties in future studies.

Table 3.

Intensities of sensory attributes of the six buckwheat jellies.

| Sample (1) | p-Value (2) | ||||||

|---|---|---|---|---|---|---|---|

| BJ 265 | BJ 153 | BJ_870 | BJ_453 | BJ_335 | BJ_916 | ||

| Appearance | |||||||

| Brown_A | 8.00 a (3) | 7.75 ab | 7.54 ab | 7.42 ab | 7.21 b | 7.25 b | 0.017 |

| Brightness_A | 8.38 | 8.38 | 8.38 | 8.46 | 8.33 | 8.29 | 0.999 |

| Roughness_A | 5.58 | 5.71 | 5.21 | 5.42 | 5.63 | 5.67 | 0.816 |

| Odor/Aroma | |||||||

| Soymilk_O | 9.96 a | 9.19 ab | 8.90 b | 8.71 b | 8.81 b | 7.46 c | <0.001 |

| Grain_O | 4.46 | 5.10 | 5.00 | 4.81 | 5.24 | 5.79 | 0.161 |

| Red bean porridge_O | 5.21 b | 5.90 ab | 5.48 b | 5.00 b | 5.76 b | 6.83 a | 0.006 |

| Buckwheat tea_O | 12.58 a | 12.33 a | 11.95 ab | 11.38 ab | 11.48 ab | 10.96 b | 0.046 |

| Flavor/Taste | |||||||

| Savory_F | 4.42 | 4.08 | 4.08 | 3.83 | 3.79 | 3.63 | 0.626 |

| Plain flavor and taste | 6.67 | 6.29 | 5.92 | 6.00 | 6.00 | 5.5 | 0.414 |

| Buckwheat flavor and taste | 11.88 | 11.37 | 11.25 | 10.79 | 10.75 | 10.46 | 0.177 |

| Sweet taste | 2.58 | 2.54 | 2.63 | 2.21 | 2.38 | 2.92 | 0.394 |

| Salty taste | 3.63 | 3.08 | 3.08 | 3.00 | 3.04 | 3.17 | 0.365 |

| Umami | 2.29 | 2.58 | 2.46 | 2.67 | 2.33 | 2.42 | 0.995 |

| Texture/Mouthfeel | |||||||

| Squashed texture | 12.92 | 12.42 | 11.75 | 11.46 | 11.29 | 11.00 | 0.052 |

| Dry texture | 7.25 a | 6.67 ab | 6.25 bc | 5.92 bc | 5.79 c | 6.42 bc | <0.001 |

| Smooth texture | 10.71 a | 10.54 a | 9.79 ab | 9.38 ab | 9.35 ab | 8.63 b | 0.037 |

| Elasticity | 1.96 d | 2.17 cd | 2.63 bc | 2.83 ab | 2.80 ab | 3.38 a | <0.001 |

| Stickiness | 10.79 a | 10.04 ab | 9.42 ab | 9.08 bcd | 8.83 cd | 8.17 d | <0.001 |

(1) Sample information: BJ 265 (0% mung bean powder), BJ 153 (5% mung bean powder), BJ_870 (10% mung bean powder), BJ_453 (15% mung bean powder), BJ_335 (20% mung bean powder) and BJ_916 (25% mung bean powder). (2) p-value by ANOVA. (3) Data were scored on a 15 point numerical scale, where 0 = no intensity of the attribute and 15 = extreme intensity of the attribute. a–d Different superscript letters mean significantly different among groups at α = 0.05 level by Duncan’s multiple range test.

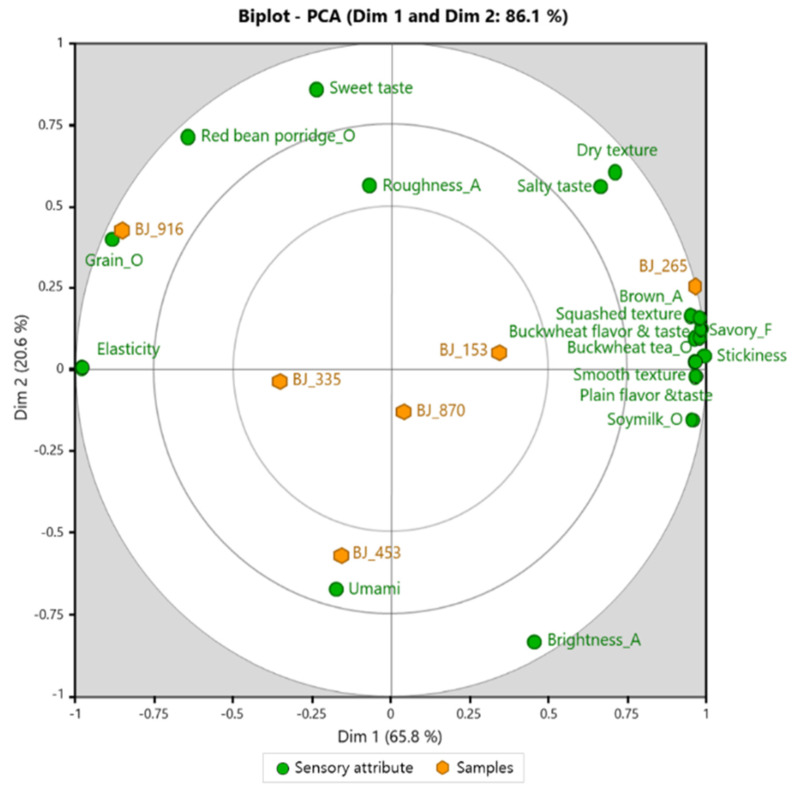

3.2. Principal Component Analysis of the Six Buckwheat Jellies

PCA was performed to provide a clear visualization of all sensory attributes in Figure 1. The PCA bi-plot accounted for 86.1% of the total variance with Dim 1 and Dim 2 explaining 65.8% and 20.6%, respectively. The sensory attributes contributing most to the right side of Dim 1 (i.e., x-axis) were Brown_A, Soymilk_O, Buckwheat tea_O, Savory_F, plain flavor and taste, buckwheat flavor and taste, squashed texture, smooth texture, and stickiness, and the BJ_265 (0% mung bean starch) sample was rated to be here. The attributes contributing to the left side of Dim 1 were elasticity and Grain_O, and the BJ_916 sample (25% mung bean starch) was rated to be here.

Figure 1.

PC loadings regarding scores of the sensory attributes and the six buckwheat jelly samples evaluated by panels.

The attributes contributing to the positive side of Dim 2 (i.e., y-axis) were Red Bean Porridge_O and sweet taste, and the BJ_916 sample (25% mung bean starch) was rated to be here. The attributes contributing to the negative side of Dim 2 were umami, and the BJ_453 (15% mung bean starch) sample was rated to be here.

Overall, the BJ_916 (25% mung bean starch) sample was located on the left side of Dim 1, while samples with low mung bean starch contents were located in the center or to the right of Dim 1 (except for BJ_453). This result shows that elasticity tends to increase according to a lowering in the content of buckwheat flour and an increase in the content of mung bean powder.

3.3. Consumer Acceptance

The results of the consumer acceptability test for buckwheat jelly samples are presented in Table 4. A total of 93 consumers scored each sample for color, smell, savory taste, aftertaste, harmony with the sauce, overall liking, likeliness to try again, and intention to recommend. All attributes except color, smell, and savory taste of samples showed a significant difference (p < 0.001), and the acceptance attributes of the sample with the highest mung bean starch content (BJ_916: 25% mung bean powder) showed the highest scores among the six samples. Kim et al. [15] also showed that the overall acceptability of jelly with 25% mung bean powder was the highest among jelly with five different levels of mung bean powder (0, 25, 50, 75, and 100%). When we eat jelly, we expect to feel a smooth surface and a soft and elastic texture mouthfeel. These textural properties are closely related to the gel formation of starch. Greater gel formation power yields higher elasticity or springiness in terms of textural property. The gel formation of starch depends on the amylose and amylopectin ratio, starch chain length, type of starch, and degree of branching [36,37,38].

Table 4.

Consumer acceptability of the six buckwheat jellies (1).

| Sample (2) | p-Value (3) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BJ_265 | BJ_153 | BJ_870 | BJ_453 | BJ_335 | BJ_916 | ||||||||

| Mean | SD | Mean | SD | Mean | SD | Mean | SD | Mean | SD | Mean | SD | ||

| Color liking | 4.60 | 1.49 | 4.81 | 1.46 | 4.62 | 1.41 | 4.89 | 1.49 | 4.95 | 1.43 | 5.04 | 1.57 | 0.381 |

| Smell liking | 4.60 | 1.83 | 4.51 | 1.62 | 4.53 | 1.51 | 4.55 | 1.49 | 4.44 | 1.79 | 4.89 | 1.74 | 0.658 |

| Savory taste liking | 4.99 | 1.84 | 4.67 | 1.62 | 4.60 | 1.50 | 4.63 | 1.46 | 4.89 | 1.80 | 5.19 | 1.71 | 0.203 |

| Aftertaste liking | 4.59 | 1.96 b | 4.70 | 1.60 b | 4.32 | 1.54 b | 4.67 | 1.66 b | 4.86 | 1.75 b | 5.44 | 1.67 a | 0.004 |

| Harmony with the sauce | 4.44 | 1.83 c | 4.89 | 1.72 bc | 4.63 | 1.73 c | 5.26 | 1.67 ab | 5.34 | 1.73 ab | 5.70 | 1.66 a | <0.001 |

| Overall liking | 4.15 | 1.82 c | 4.42 | 1.63 cd | 4.29 | 1.49 cd | 4.82 | 1.53 bc | 5.19 | 1.82 ab | 5.72 | 1.65 a | <0.001 |

| Recommend | 3.30 | 1.78 d | 3.62 | 1.82 cd | 3.58 | 1.79 cd | 4.06 | 1.85 bc | 4.37 | 2.11 ab | 4.85 | 1.85 a | <0.001 |

| Try again | 2.96 | 1.75 c | 3.10 | 1.78 c | 3.13 | 1.72 c | 3.80 | 1.85 b | 4.06 | 2.09 b | 4.68 | 1.89 a | <0.001 |

(1) Consumer acceptability test was conducted by 93 panelists using the nine-point hedonic scaling method (one point: dislike extremely, five points: moderate, nine points: like extremely). (2) Sample information: BJ 265 (0% mung bean powder), BJ 153 (5% mung bean powder), BJ_870 (10% mung bean powder), BJ_453 (15% mung bean powder), BJ_335 (20% mung bean powder) and BJ_916 (25% mung bean powder). (3) p-value by ANOVA. a–d Different superscript letters mean significantly different among groups at α = 0.05 level by Duncan’s multiple range test.

3.4. Relationships between Sensory Attributes and Consumer Acceptability

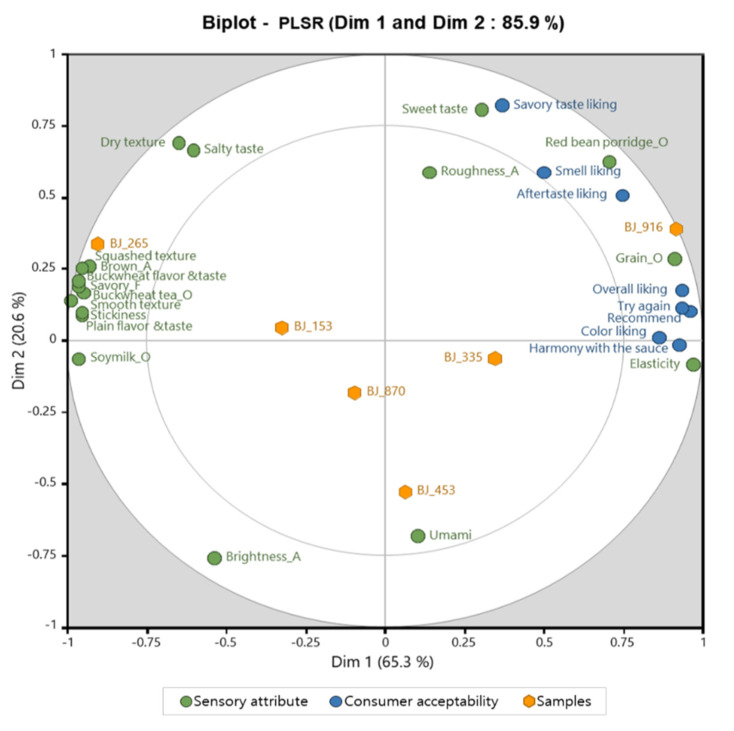

Figure 2 shows the relationships between sensory characteristics and consumer acceptability of the six buckwheat jelly samples. When PLSR analysis was conducted to determine the correlation between sensory characteristics and consumer acceptability, 85.9% of the total variance was explained by Dim 1 and Dim 2. PLSR analysis is a very suitable technique to analyze and visually summarize the correlation between two types of data [33,39,40]. BJ_916 (25% mung bean starch), which showed the highest score on consumer acceptability, was found to be near Dim 1 and had a close relationship with all attributes of consumer acceptability. For the results of descriptive sensory analysis, the BJ_916 sample (25% mung bean starch) was closely related to the attributes of Grain_O, elasticity, red bean Porridge_O, and sweet taste. Although the characteristics may have been different, a previous study analyzing the preference for rice-based snacks (Nuroongji) found that texture had the greatest effect on preference [41,42]. However, in the study analyzing the preference for commercial ready-to-eat rice, the descriptive sensory analysis factor affecting the overall liking was the odor of grains, such as the odor of starch [30]. On the other hand, in general, in studies on food preference, taste and flavor are still reported to be the most important factors [43,44]. To summarize the results of previous studies and this study, the characteristics of texture and smell seem to be very important factors in the development of jellies or snacks using grains.

Figure 2.

PLSR result indicating the association among sensory attributes, consumer acceptability and the six buckwheat jelly samples.

BJ_265, which contained 100% buckwheat flour, was closely associated with Brown_A, Soymilk_O, Buckwheat tea_O, Savory_F, plain flavor and taste, buckwheat flavor and taste, squashed texture, smooth texture, and stickiness among the 18 attributes. The BJ_453 sample (15% mung bean starch) showed a close relationship with the umami attribute.

4. Conclusions

Sensory attributes of buckwheat jelly (memilmuk) with mung bean flour added were determined using descriptive analysis. The 18 attributes were assessed; these included three appearance descriptors (brown, brightness, and roughness), four odor/aroma descriptors (soymilk smell, grain smell, red bean porridge smell, and buckwheat tea smell), six flavor or taste descriptors (savory flavor, plain taste, buckwheat taste, sweet taste, salty taste, and umami), and five texture descriptors (squashed, dry, smooth, elasticity, and stickiness). The results of the consumer acceptability test from 93 consumers showed a significant difference in harmony with the sauce, overall liking, willingness to try again, and intention to recommend attributes (p < 0.001). Among the six samples, buckwheat jelly with 25% mung bean starch (BJ_916) showed the highest score among consumers. The sample with 25% mung bean starch was closely related to a grain smell, elasticity, a red bean porridge smell, a sweet taste, and all attributes of consumer acceptability according to the results of PLSR analysis. These findings can be used to improve the organoleptic quality of buckwheat jelly and provide basic data to expand the consumer market due to its functional and sensory quality.

Author Contributions

Conceptualization, Y.K. and J.R.; methodology, J.R. and S.J.; software, Y.K.; validation, J.R. and Y.K.; formal analysis, J.R. and S.J.; investigation, J.R. and Y.K.; data curation, S.J.; writing—original draft preparation, Y.K. and S.J.; writing—review and editing, Y.K. and S.J.; visualization, Y.K.; supervision, J.R.; project administration, Y.K. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the “Cooperative Research Program for Agriculture Science and Technology Development (Project No. PJ014962032020)” under Rural Development Administration, Republic of Korea.

Institutional Review Board Statement

The study was conducted according to the guidelines of the Declaration of Helsinki, and reviewed and approved by Konkuk University Institutional Review Board (IRB Approval Number: 7001355-202011-E-126).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Footnotes

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Sanchez A., Schuster T.M., Burke J.M., Kron K.A. Taxonomy of Polygonoideae (Polygonaceae): A new tribal classification. Taxon. 2011;60:151–160. doi: 10.1002/tax.601013. [DOI] [Google Scholar]

- 2.Mota C., Santos M., Mauro R., Samman N., Matos A.S., Torres D., Castanheira I. Protein content and amino acids profile of pseudocereals. Food Chem. 2016;193:55–61. doi: 10.1016/j.foodchem.2014.11.043. [DOI] [PubMed] [Google Scholar]

- 3.Zhu F. Buckwheat proteins and peptides: Biological functions and food applications. Trends Food Sci. Technol. 2021;110:155–167. doi: 10.1016/j.tifs.2021.01.081. [DOI] [Google Scholar]

- 4.Han D.W., Chung C.H., Sung K.H. Quality characteristics of soba added with fermented buckwheat flour starter. Foodserv. Ind. J. 2020;16:207–217. [Google Scholar]

- 5.Alonso-Miravalles L., O’Mahony J.A. Composition, protein profile and rheological properties of pseudocereal-based protein-rich ingredients. Foods. 2018;7:73–90. doi: 10.3390/foods7050073. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Raguindina P.F., Itodoa O.A., Stoyanov J., Dejanovic G.M., Gamba M., Asllana E., Minder B., Bussler W., Metzger B., Muka T., et al. Systematic review of phytochemicals in oat and buckwheat. Food Chem. 2021;338:127982. doi: 10.1016/j.foodchem.2020.127982. [DOI] [PubMed] [Google Scholar]

- 7.Kalinova J., Triska J., Vrchotova N. Distribution of Vitamin E, squalene, epicatechin, and rutin in common buckwheat plants (Fagopyrum esculentum Moench) J. Agric. Food Chem. 2006;54:5330–5335. doi: 10.1021/jf060521r. [DOI] [PubMed] [Google Scholar]

- 8.Zhou X., Wen L., Li Z., Zhou Y., Chen Y., Lu Y. Advance on the benefits of bioactive peptides from buckwheat. Phytochem. Rev. 2015;14:381–388. doi: 10.1007/s11101-014-9390-0. [DOI] [Google Scholar]

- 9.Zhou X.L., Yan B.B., Xiao Y., Zhou Y.M., Liu T.Y. Tartary buckwheat protein prevented dyslipidemia in high-fat diet-fed mice associated with gut microbiota changes. Food Chem. Toxicol. 2018;119:296–301. doi: 10.1016/j.fct.2018.02.052. [DOI] [PubMed] [Google Scholar]

- 10.Borneo R., Leon A.E. Whole grain cereals: Functional components and health benefits. Food Funct. 2012;3:110–119. doi: 10.1039/C1FO10165J. [DOI] [PubMed] [Google Scholar]

- 11.Li L., Lietz G., Seal C. Buckwheat and CVD Risk Markers: A systematic review and meta-analysis. Nutrients. 2018;10:619. doi: 10.3390/nu10050619. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Saturni L., Ferretti G., Bacchetti T. The gluten-free diet:safety and nutritional quality. Nutrients. 2010;2:16–34. doi: 10.3390/nu2010016. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Kang H.W. Antioxidant and anti-inflammation effects of water extract from buckwheat. Korean J. Culin. Res. 2014;20:190–199. [Google Scholar]

- 14.Kim D.H. Ph.D. Thesis. Sejong University; Seoul, Korea: 2020. Quality Characteristics of Buckwheat Mook, Cheongpo Mook and Acorn Mook Added with Apios (Apios Americana Medikus) Powder. [Google Scholar]

- 15.Kim A.J., Han M.R., Rho J.O. Quality characteristics of Cheongpomook prepared with different levels of mungbean powder. Korean J. Hum. Ecol. 2011;20:1229–1237. doi: 10.5934/KJHE.2011.20.6.1229. [DOI] [Google Scholar]

- 16.Cho S.A., Kim S.K. Paticle size distribution, pasting pattern and texture of gel of acorn, mungbean, and buckwheat starches. Korean J. Food Sci. Technol. 2000;32:1291–1297. [Google Scholar]

- 17.Lee M.H., Lee J.S., Yang H.C. [α]-Amylase Inhibitory Activity of Flower and Leaf Extracts from Buckwheat (Fagopyrum esculentum) J. Korean Soc. Food Sci. Nutr. 2008;37:42–47. doi: 10.3746/jkfn.2008.37.1.42. [DOI] [Google Scholar]

- 18.Lee M.H., No H.K. Effect of on Chitosan shelf-life and quality of buckwheat starch jelly. J. Korean Soc. Food Sci. Nutr. 2001;30:865–869. [Google Scholar]

- 19.Joo S.Y., Choi H.Y. Antioxidant activity and quality characteristics of mung bean starch gel prepared with ginkgo nut powder. Korean J. Food Cult. 2014;29:84–90. doi: 10.7318/KJFC/2014.29.1.084. [DOI] [Google Scholar]

- 20.Park J.H., Kim E.M. Changes in the quality characteristics of mung bean starch jelly with white lotus (Nelumbo nucifera) root powder added. Korean J. Culin. Res. 2010;16:180–190. [Google Scholar]

- 21.Torbica A., Hadnadev M., Dapcevic T. Rheological, textural and sensory properties of gluten-free bread formulations based on rice and buckwheat flour. Food Hydrocoll. 2010;24:626–632. doi: 10.1016/j.foodhyd.2010.03.004. [DOI] [Google Scholar]

- 22.Lee S.Y., Shim H.H., Ham S.S., Rhee H.I., Choi Y.S., Oh S.S. The nutritional components of buckwheat flours and physicochemical properties of freeze dried buckwheat noodles. J. Korean Soc. Food Nutr. 1991;20:354–362. [Google Scholar]

- 23.Jeong Y.J., Lee M.H., Seo J.H., Lee G.D. Changes of textural and organoleptic properties as influenced by preparation conditions of buckwheat Mook. J. East Asian Soc. Diet. Life. 1998;8:155–161. [Google Scholar]

- 24.Kim H.S., Kim M.J., Lee M.S., Lee G.S., Kim A.J. Quality characteristics of nokdumook using Yangha (Zingiber mioga R.) powder. Korean J. Food Nutr. 2012;25:521–528. doi: 10.9799/ksfan.2012.25.3.521. [DOI] [Google Scholar]

- 25.Statistics Korea. [(accessed on 1 July 2020)]. Available online: https://kosis.kr/

- 26.Homepage of Bongpyeong Memil Farm. [(accessed on 22 July 2020)]. Available online: https://memil.kr/goods/catalog?page=1&searchMode=catalog&category=c00100003&per=40&sorting=ranking&filter_display=lattice.

- 27.Naver Smart Store Center. [(accessed on 22 July 2020)]. Available online: https://smartstore.naver.com/pow6024/products/5347630537?

- 28.The Homepage of Korean Traditional Local Food. [(accessed on 1 July 2020)]. Available online: http://koreanfood.rda.go.kr/kfi/tfSrch08/list.

- 29.MacFie H., Bratchell N., Greenhoff K., Vallis L.V. Designs to balance the effect of order of presentation and first-order carry-over effects in hall tests. J. Sens. Stud. 1989;4:129–148. doi: 10.1111/j.1745-459X.1989.tb00463.x. [DOI] [Google Scholar]

- 30.Lawless H.T., Heymann H. Sensory Evaluation of Food: Principles and Practices. 2nd ed. Springer; New York, NY, USA: 2010. [Google Scholar]

- 31.Kwon Y.S., Ju S. Sensory evaluation of commercial ready-to-eat rice between trained panelist and consumer. Br. Food J. 2018;120:367–377. doi: 10.1108/BFJ-11-2016-0530. [DOI] [Google Scholar]

- 32.Hwang S.H., Hong J.H. Determining the most influential sensory attributes of nuttiness in soymilk: A trial with Korean consumers using model soymilk. J. Sens. Stud. 2015;30:425–437. doi: 10.1111/joss.12176. [DOI] [Google Scholar]

- 33.Schlich P. Uses of change-over designs and repeated measurements in sensory and consumer studies. Food Qual. Prefer. 1993;4:223–235. doi: 10.1016/0950-3293(93)90166-4. [DOI] [Google Scholar]

- 34.Gwak M.J., Chung S.J., Kim Y. Sensory drivers of liking for Adlay (Coix lacryma-jobi) tea. Korean J. Food Cult. 2012;27:512–520. doi: 10.7318/KJFC/2012.27.5.512. [DOI] [Google Scholar]

- 35.Janssen F., Pauly A., Rombouts I., Jansens K.J.A., Deleu L.J., Delcour J.A. Proteins of amaranth (Amaranthus spp.), buckwheat (Fagopyrum spp.), and quinoa (Chenopodium spp.): A food science and technology perspective. Comprehensive Reviews in Food. Sci. Food Saf. 2017;16:39–58. doi: 10.1111/1541-4337.12240. [DOI] [PubMed] [Google Scholar]

- 36.Chung H.J., Liu Q., Pauls K.P., Fan M.Z., Yada R. In vitro starch digestibility, expected glycemic index and some physicochemical properties of starch and flour from common bean (Phaseolus vulgaris L.) varieties grown in Canada. Food Res. Int. 2008;41:869–875. doi: 10.1016/j.foodres.2008.03.013. [DOI] [Google Scholar]

- 37.No J.H. Master’s Thesis. Chonnam National University; Gwangju, Korea: 2013. Characterization and the Antioxidant Activities of Cheongpomuk Prepared from Whole Mung Bean Starches. [Google Scholar]

- 38.Kim H.S., Ahn S.Y. Effect Amylose and Amylopectin on the Texture of mook. Korean J. Hum. Ecol. 1997;6:157–166. [Google Scholar]

- 39.Chung S.J., Heymann H., Gruen I.U. Application of PGPA and PLSR in correlating sensory and chemical data sets. Food Qual. Prefer. 2003;14:485–495. doi: 10.1016/S0950-3293(03)00010-7. [DOI] [Google Scholar]

- 40.Chung L., Chung S.J. Understanding the factors affecting the acceptance for fermented soybean products. Food Sci. Biotechnol. 2008;17:144–150. [Google Scholar]

- 41.Suh Y.K., Park Y.H., Oh Y.J. Cooking conditions for the production of instant Nuroongi. J. Korean Soc. Food Nutr. 1996;25:58–62. [Google Scholar]

- 42.Kim M.K. Sensory Profile of Rice-Based Snack (Nuroongji) Prepared from Rice with Different Levels of Milling Degree. Foods. 2020;9:685. doi: 10.3390/foods9060685. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 43.Kim M.K., Lopetcharat K., Drake M.A. Influence of packaging information on consumer liking of chocolate milk. J. Dairy Sci. 2013;96:4843–4856. doi: 10.3168/jds.2012-6399. [DOI] [PubMed] [Google Scholar]

- 44.Kim M.K., Kwak H.S., Kim M.J., Kim S.S. Identification of sensory characteristics that drive consumer preferences of commercially mass-produced doenjang in Korea. J. Sens. Stud. 2018;33:e12323. doi: 10.1111/joss.12323. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Not applicable.