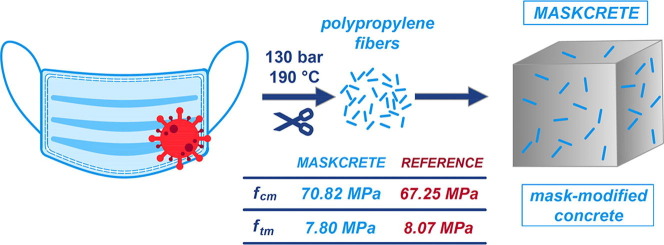

Graphical abstract

Keywords: Pandemic wastes, Modified concrete, Polypropylene fibers, Protection masks, COVID-19, Maskcrete

Abstract

After the coronavirus outbreak, a tremendous amount of personal protective equipment has been produced and used by the health service and every human. Proper medical waste management becomes an important problem, which must be solved with a minimal environmental impact. The presented manuscript introduces the recycling process, during which personal protection masks are transformed into polypropylene fibers being an addition to a concrete mixture. The designed recycling procedure provides the entire disinfection of probably contaminated medical wastes, is straightforward, and potentially enables one to modify the properties of the final product. The applied dosage referred to 1 mask per 1 L of concrete. The final product of face masks processing was studied using Fourier-transform infrared spectroscopy, thermogravimetric analysis, surface free energy, contact angle measurements, and melt flow index. The analysis indicated that polypropylene is its main component. Two concrete mixtures were composed, i.e., with the addition of processed masks and the reference one. The following properties were determined to compare the modified concrete with the reference one: compressive and tensile strength, frost resistance, water transport properties, resistance to high temperature. The obtained results indicated that the addition of processed masks slightly increased the compressive strength (by about 5%) and decreased the tensile strength (by about 3%). Simultaneously, it was reported that the addition did not affect material properties related to concrete durability as frost resistance, water permeability, and fire performance. The results evinced, that the addition of processed facemasks into concrete did not deteriorate its properties. Therefore, it is a possible way of the protective masks processing and reusing with the high recycling capacity. Further study should be conducted to optimize the dosing and to modify the properties of PP strings to improve hardened concrete properties.

1. Introduction

The demand for natural resources is now the biggest in human history and grows every year. The construction industry belongs to the economy branches which consume mostly natural resources and significantly impact the environment. Therefore, the use of recycling wastes becomes one of the crucial activities in the sustainable development towards the circular economy. The European Commission stated the several milestones [1], [2], which must be reached by the member-states before 2030: e.g., recycling 65% of municipal wastes, 75% of packing wastes, etc. The production of plastic in 2019 was estimated at around 370 million tons [3]. About 27% of this enormous mass was discarded as a landfill, the rest was recycled for production and energy recovery. Having in mind the resources reduction and plastic waste production, some attempts were made to utilize the plastic as an addition [4] or a substitution of aggregate in concrete [5]. The influence of partial replacement of an aggregate with polypropylene, polyvinyl chloride, and high-density polyethylene on concrete properties was examined by Belmokaddem et. al. [6]. They observed that independently of the applied type of wastes, the compressive strength of a hardened material was decreased. The most pronounced reduction, up to 88%, was found for high-density polyethylene. The effect of the addition of plastic wastes processed from PET bottles in two-way reinforced slabs was examined by Hama [7]. The main conclusion driven for structural concrete says that the replacement of an aggregate with plastic should not exceed 30% of its volume. The reduction of mechanical properties is caused by the hydrophobicity of most types of plastic wastes, which leads to a poor bond between the addition and the cement matrix and enhances porosity within the contact zone between materials [4]. Moreover, it was observed that plastic wastes entrap air, which increases the overall porosity in concrete [8], [9]. On the other hand, recycled plastic wastes can also improve selected properties of cement-based material, e.g. reduce its plastic shrinkage [10] or enhance the performance in fire [11], [12]. The latter case is possible due to the decomposition of polypropylene, which is a common compound of plastic wastes, beginning around 200 °C. It helps to relax the internal vapor pressure and delays the explosive spalling, which gives some additional time for evacuation. In the literature there are described various types of wastes, which can be successfully used as a component of concrete, i.e. mining wastes [13], [14], concrete and masonry recycled aggregate [15], [16], [17], rubber tires [18], [19] and many others. The application of fibers made of electronic wastes [20] or recycled glass fiber reinforced polymer (GFRP) [21] can provide an improvement of the flexural strength of the concrete.

For around two years mankind has had to face the global COVID-19 pandemic disease [22]. The SARS-CoV-2 virus was firstly reported in Wuhan in December 2019, then it has spread to almost all countries in the world [23]. The rapid increase in the infected patients and the highly transmissible nature of the virus led to a tremendous boost in the consumption of personal protective equipment (PPE). It has contributed to a major increase in the production of healthcare solid wastes [23], [24]. According to the report “Face Mask Market - Global Outlook & Forecast 2021–2026” published in October 2021 [25], the face mask market is expected to reach USD 8.04 billion in 2023; hence, the handling capacity for the healthcare wastes must be increased urgently. According to the report published in 2021 by European Environment Agency [26], the global usage of disposable face masks was already in millions of tones before the outbreak of the pandemic. Many scientists try to determine the face mask consumption in selected regions, which drastically increased since 2020. For instance, Boroujeni et al. [27] estimated that 5 351 520 disposable masks are used in Victoria, Australia per day. Considering the whole area of Peru, Torres and De-la-Torre assessed that the daily usage equals 14 983 383 masks [28]. In the denser inhabited areas, such as India or China, hundreds of millions of waste masks are produced everyday [29]. The presented data evinces that the extremely high usage of disposable masks provides steady access to personal protection equipment wastes. According to the results published in the report “Face Mask Market - Global Outlook & Forecast 2021–2026” [25], the face mask market is expected to reach 8.04 billion USD in 2023 and 8.88 billion USD by 2026. Hence, the situation seems not to change in near future, which creates tremendous opportunities regarding the production of concrete with the addition of processed masks.

As stated in [30] the COVID-19 pandemic solid wastes might be divided into the following categories: chemical wastes, infectious wastes, pathological wastes, radioactive wastes, sharp wastes, and pharmaceutical wastes. In the manuscript, the attention is focused on the second group, i.e., PPE such as boots, masks, gloves, face shields, whose usage dramatically increased during the pandemic. Such wastes can contain infective pathogens, which is why the recycling process should include a stage providing effective disinfection. Storing such wastes for nine days and using disinfectants [31], [32] can be used to inactivate the virus, which reduces the risk of further infection.

In the presented manuscript one introduced and discussed the technology which allows to disinfect and recycle the possibly infected masks used for personal protection during the COVID-19 pandemic and apply them as an addition to the ordinary concrete mixture. Such an opportunity was firstly noticed by the authors of the review article [33]. So far, according to the best of authors’, the application of the protection masks in this context was experimentally investigated and described solely by Douglas [34] and Kilmartin-Lynch, Saberian et al. [35], [36]. In both cases face masks were cut up and, in the shape of shreds, added to concrete with four different dosages. In [35], [36] hardened concretes were investigated with regard to basic mechanical properties (compressive strength, tensile strength, and Young’s modulus). It was observed that if the dosage does not exceed 0.20% of concrete volume the addition has a positive influence on the examined parameters. Contrary to the abovementioned articles, in the presented manuscript one proposed a more advanced recycling process, in which medical wastes were processed at elevated temperature and pressure into the shape of fibers and subsequently added into a concrete mixture. The applied dosage was 1 mask per 1 L of concrete, which equals the addition of 2 kg of processed material per 1 cubic meter of a mixture. The treatment of the masks with elevated temperature and pressure leads to the formation of homogenous polypropylene (PP). The recycling procedure provided complete disinfection of used masks and potentially enabled one to modify selected properties of a final product. The final polypropylene fibers were investigated using a vast range of experimental methods, i.e.: Fourier-transform infrared spectroscopy, thermogravimetric analysis, surface free energy, and contact angle measurements and rheology. The performed measurements delivered information considering the composition of the product material, the melting temperature, and the properties of the surface, which influence the polypropylene-cement paste interaction during hardening. The experimental analysis of the newly developed concrete was focused not only on basic mechanical properties of the material (compressive strength, tensile strength) but also on its transport properties (capillary adsorption, water permeability) and its stability in an aggressive environment (frost resistance and spalling test). It was revealed that the addition of PPE masks has various influences on different properties, e.g., it increased the compressive strength and simultaneously slightly deteriorated tensile strength or capillary absorption.

The conventional PP fibers, which do not come from the recycling of PPE masks, are commonly applied as an addition to concrete to i.e., limit the plastic shrinkage of a fresh material or improve its performance during fire [37], [38]. The proposed procedure of medical wastes recycling, despite its simplicity, enables one to modify specific properties of the final product. Hence, the masks processed into the shape of fibers can be potentially added to concrete not only to manage the pandemic wastes but also to improve the performance of the final material. The presented results constitute the first stage of an extensive analysis concerning the application of processed medical waste as a dispersed concrete reinforcement.

2. Materials and methods

The main material under investigation is concrete composed with the addition of polypropylene fibers recycled from PPE masks. In the first part of the section, the masks recycling process and the properties of the obtained material are provided. In the remaining part of the section, the composition and the description of the experimental research for the concrete are presented.

2.1. PPE masks-recycled polypropylene

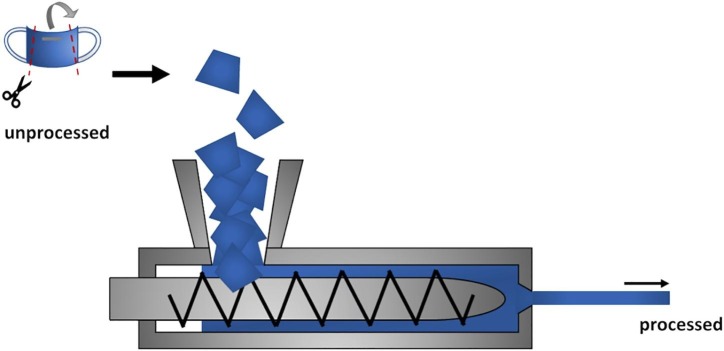

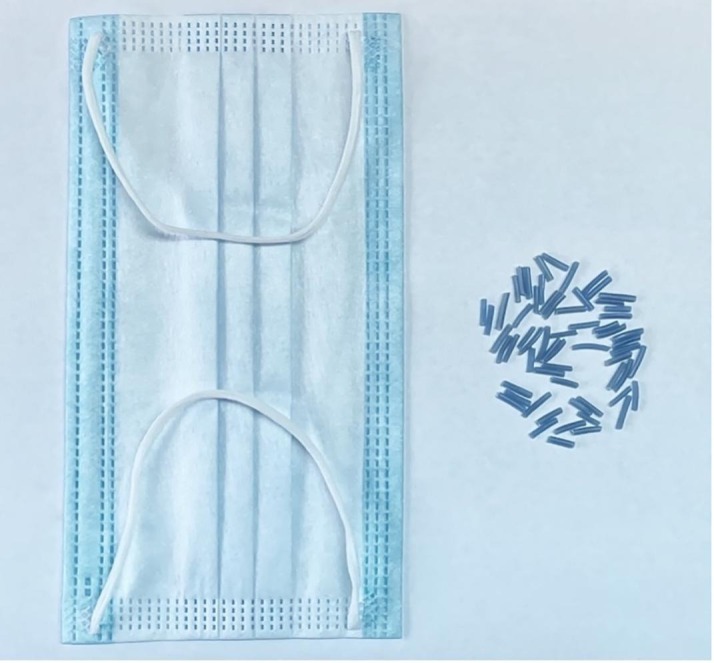

Before the proper processing, all the metal parts and ear straps of the masks were detached manually. Then, the product was cut into smaller-sized strips to provide easier dosing. At the first stage of processing a Ø25 single-screw extruder was used. The material was processed at 200 °C with a screw speed of 50 rpm. The diameter of the applied mouthpiece was 2 cm. The extrudate was rolled manually. The scheme of the extrusion process is presented in Fig. 1 . Subsequently, form plate-like samples of the recycled material were formed. To that end, the portion of approximately 14 g of the extrudate was placed between the plates of a steel mould heated to 190 °C. Surfaces of the mould were previously covered with Teflon foil to ensure the minimal adhesion of the pressed sample. The layers of material were stacked inside a steel mould, which was subsequently placed between two plates of an electrically heated hydraulic press. The sample was formed at 190 °C under a pressure of approximately 130 bar for 10 min. The material was deaerated 5 times (when the set pressure was reached). In the next step, the plate-like samples were cut into smaller pieces and extruded (opening of Ø20) at 200 °C with a screw speed of 50 rpm. Subsequently, the processed stripe was cut into 5-mm fibers. Samples of unprocessed and processed material, see Fig. 2 ., were examined with varied methods regarding their chemical structure, thermal resistance, surface properties, and rheology characterization. The strings added to concrete were about 0.5 cm long, their diameter equal to 0.5 mm.

Fig. 1.

Scheme of the extrusion process.

Fig. 2.

Unprocessed mask and fibers obtained during the recycling process.

At the first stage of recycling the elevated temperature of 200 °C was applied, which led to the inactivation of the virus [31]. Additionally, for safety, it would be reasonable to assume that there is a possibility that some virus particles are still active after the mentioned processing stage. Hence, each person belonging to the staff responsible for the recycling of the disposable masks needs to wear full protective equipment consisting of hazardous materials suit, boots, and gloves during the entire process.

In order to obtain the properties of recycled PPE masks the following tests were carried out:

-

•

Fourier-transform infrared spectroscopy (FT-IR),

-

•

thermogravimetric analysis (TGA),

-

•

surface free energy and contact angle measurements,

-

•

rheology and melt flow index.

Fourier-transform infrared spectroscopy has been employed in order to determine chemical moieties present in the analysed material. Both, unprocessed PPE masks and the final product were investigated. The FT-IR absorbance spectra were determined within the 4000–400 cm−1 range (64 scans, resolution of 4 cm−1, absorption mode). The experiment has been performed using the Thermo Scientific Nicolet 6700 FT-IR spectrometer (Thermo Fischer Scientific Instruments, Waltham, MA, USA) equipped with a diamond Smart Orbit ATR sampling accessory.

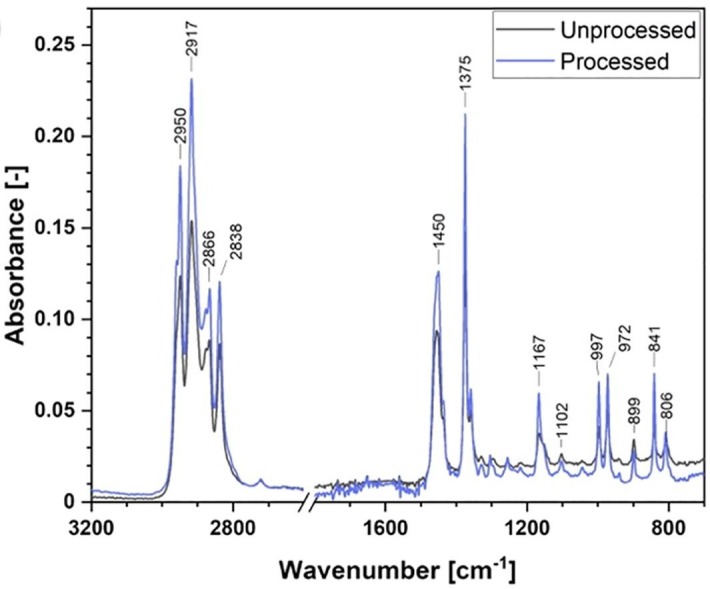

According to the obtained results, see Fig. 3 , some chemical groups typical for polypropylene (PP) could be observed. Absorption bands at 2950 cm−1, 2917 cm−1, 2866 cm−1, and 2837 cm−1 are assigned to, respectively, CH3 nonsymmetric, CH2 nonsymmetric, CH symmetric, and C–H symmetric stretching vibrations [39]. Next, the peaks at 1458 cm−1 and 1370 cm−1 are attributed to CH3 nonsymmetric and symmetric changing angle vibrations [40], whereas the peak visible at 841 cm−1 is characteristic to isomeric propylene [41]. Further assignment of the absorption bands visible in the samples’ spectra is presented in Table 1 .

Fig. 3.

Fourier-transform infrared spectra for unprocessed/processed material.

Table 1.

Tabularized values of shifts between the selected peaks visible in FT-IR spectra of samples with the assignment to some chemical moieties.

| Sample | Wavenumber assigned to the certain peak [cm−1] | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2950 | 2917 | 2866 | 2838 | 1450 | 1375 | 1167 | 1102 | 997 | 972 | 841 | 806 | |

| Assignment | CH3 nonsymmetric stretching | CH2 nonsymmetric stretching | CH symmetric stretching | CH symmetric stretching | CH3 nonsymmetric changing angle vibrations | CH3 symmetry changing angle vibrations | CH3 rocking vibration | C–C stretching (isotactic) | CH3 rocking vibration | CH3 rocking vibration | C-CH3 stretching | C–C chain vibrations |

| Ref. | [39], [42] | [39], [42] | [39], [42] | [39], [42] | [39], [42] | [38], [39] | [43] | [40] | [43] | [43] | [42] | [43] |

During the processing of the disposable masks, the polymer matrix could have degraded. Therefore, FT-IR spectra were carefully analysed regarding the signs of possible oxidation and scission of polymer chains.

According to literature Ambrogi et al. [44] referred that during the PP degradation some major peaks attributable to carbonyl groups appear in the region between 1780 and 1725 cm−1. Similarly, Yu et al. [38] found that weathering of PP-based materials leads to the formation of a broad absorption band between 1800 and 1670 cm−1 which corresponds to lactones, esters, and ketones. Accordingly, Lu et al. [45] also confirmed that photo- and thermo-oxidative aging of polypropylene leads to the creation of carbonyl groups. Yet, no significant variations in the region 1800–1600 cm−1 could be observed, Fig. 3. Therefore, it might be concluded that the processing of disposable masks did not contribute to material oxidation.

The thermal degradation process of the analysed materials was investigated in the range from 25 to 900 °C. The selected program was divided into two steps: 1. pyrolysis in argon atmosphere (temperature range: 25–600 °C, heating rate: 0.5 °C/min; argon flow of 60 cm3/min), 2. combustion in synthetic air (temperature range: 600–900 °C, heating rate: 20 °C/min; airflow of 60 cm3/min). In the experiment, the Mettler Toledo TGA/DSC 1 STARe System equipped with a Gas Controller GC10 (Greifensee, Switzerland) was employed.

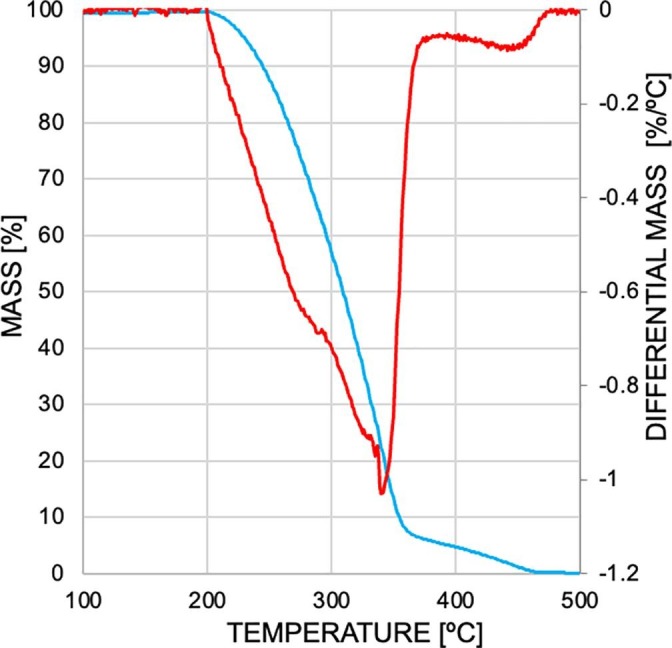

The results of the thermal analysis are presented in Fig. 4 . The beginning of the material decomposition is usually associated with the onset temperature of the process [46]. In the obtained material the onset temperature equalled around 200 °C. In Fig. 4 one can identify one dominated peak, which shows the homogeneity of the material. The slight deviations from a rectilinear relation observed around 280 °C could be connected with a degradation of the sample during the extrusion process and possible polymer chain scission [47].

Fig. 4.

Thermal degradation detected for processed material. The red line refers to differential mass and the blue line to cumulative mass.

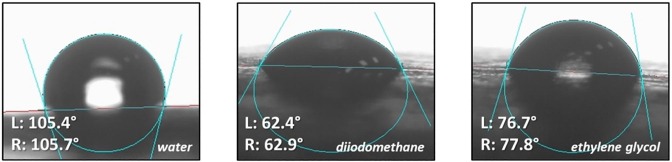

Surface free energy has been determined based on contact angle measurements performed for three liquids: distilled water, ethylene glycol, 1,4-diiodomethane for plate-like sample. The test was conducted on plate-like samples obtained before the final extrusion. Droplets of 1 μl volume were placed on the sample surface and the contact angle was measured. To that end, OCA 15EC goniometer by DataPhysics Instruments GmbH® (Filderstadt, Germany) equipped with a single direct dosing system (0.01–1 ml B. Braun® syringe; Hassen, Germany) was employed. The results are presented in Fig. 5 . Surface free energy and its components have been calculated in accordance with the Owens–Wendt–Rabel–Kaelble (OWRK) method [48]:

Fig. 5.

Exemplary contact angles for droplets of water, diiodomethane, and ethylene glycol for the processed material.

where:

– total surface free energy [mJ/m2],

– polar part of surface free energy [mJ/m2],

– dispersive part of surface free energy [mJ/m2],

– total liquid surface tension [mN/m],

– respectively: polar and dispersive part of liquid surface tension [mN/m],

– respectively: polar and dispersive part of solid surface tension [mN/m],

– contact angle [◦].

Based on the obtained results, see Fig. 5 and Table 2 , the processed PP is highly hydrophobic as water droplet exhibits a contact angle > 90°. Moreover, the polar component of surface free energy is close to 0 mJ/m2 which means the PP sample was not significantly oxidized during the processing. These observations correspond with the data presented in the literature [41], [49], [50]. Chylińska et. al [41] reported that for pristine isotactic PP (Moplen HP 456 J, Basell Orlen Polyolefines, Plock, Poland) total surface free energy (E) equals 28.10 mJ/m2 and its polar component (Ep) is about 2.76 mJ/m2. On the other hand, Kwon et al. [49] referred that Ep of PP might achieve the value of approximately 0 mJ/m2.

Table 2.

Properties of the processed material: total surface free energy (E) with its dispersive (Ed) and polar (Ep) components, average values of measured contact angles for distilled water, diiodomethane, and ethylene glycol, as well as mass (MFI) and volume (MVR) flow indexes.

| E [mJ/m2] | Ed [mJ/m2] | Ep [mJ/m2] | Distilled water [°] | Diiodomethane [°] | Ethylene glycol [°] | MFI [g/10 min] | MVR [cm3/10 min] |

|---|---|---|---|---|---|---|---|

| 30 ± 1 | 30 ± 1 | 0.01 ± 0.03 | 107 ± 1 | 62 ± 1 | 78 ± 1 | 26.5 ± 0.8 | 22.4 ± 0.7 |

The Melt Flow Index was determined for granulated extrudate in accordance with the ASTM D 1238 E standard using the Melt Flow Index Tester capillary plastometer (MeltFloW @on plus model; KARG Industrietecnik). After heating the cylinder to the temperature of 190 °C, the appropriate amount of the tested material in the form of granules was placed inside the capillary and pressed with a piston under a load of 2.16 kg (preheating before the measurement last 240 s). To assess the flowability of the material, two parameters were determined, namely, mass (MFR) and volumetric (MVR) flow rate. MFR is a mass of thermoplastic material flowing through a circular nozzle under standardized conditions and is expressed in g/10 min, whereas the MVR index refers to the volume of the sample (in cm3/10 min). The rheological parameters are presented in Table 2. Melt flow index (MFI) of the recycled material is quite high and its value equals (26.5 ± 0.8) g/10 min. Comparing to the literature, the melt flow experiment for PP is often performed at 230 °C with a loading of 2.16 kg [51]. Then, its value varies from 2.4 to 50 g/10 min depending on the PP type, e.g., Malen F-401 (Orlen Plock, Poland) – MFI = 2.4–3.2 g/10 min, Malen S-702 (Orlen Plock, Poland) – MFI = 11–16 g/10 min, PP HY-202 (Solvay) – MFI = 50 g/10 min. Gathering the information presented above, the material being a subject of this research easily flows while heated and it could be processed with simple methods at lower temperatures than required for pristine PP.

Table 4.

Concrete composition.

| Mix ingredients | CR[kg/m3] | CF[kg/m3] |

|---|---|---|

| Cement CEM I 42.5R | 425 | 425 |

| Water | 157 | 157 |

| Coarse aggregate, 8–16 mm | 524 | 524 |

| Medium aggregate, 2–8 mm | 648 | 648 |

| Sand, 0–2 mm | 576 | 576 |

| Superplasticizer | 2,97 | 2,97 |

| Processed masks | – | 2 |

| w/c | 0.37 | 0.37 |

| Workability, slump test [57], [mm] | 155 | 159 |

2.2. Concrete

The investigated concrete was composed of ordinary Portland cement CEM I 42.5R provided by CEMEX S.A.B. de C.V. For the chemical composition of the applied binder see Table 3 . The applied water-to-cement ratio was equal to 0.37 and the addition of superplasticizer (Chryso PREMIA 253) was 0.7% of cement mass. It is well reported, that the contact zone between conventional PP fibers and cement matrix is characterized by the increased porosity [52], [53]. This stems from the fact that polypropylene strings’ surface is hydrophobic. This could lead to the creation of air voids in the vicinity of fibers. Nevertheless, this effect is usually limited by the application of a larger amount of cement paste or more fluid consistency regulated by an additional portion of superplasticizer [54], [55], [56]. For the concrete composition see Table 4 . In the further analysis, the reference concrete was denoted as CR, whereas the one composed with fibers addition – as CF.

Table 3.

Chemical composition of OPC CEM I 42,5R.

| Chemical composition (%mass) | |

|---|---|

| Ignition loss | 2.8 |

| Insoluble residue | 0.46 |

| SO3 | 2.76 |

| chloride content (Cl−) | 0.066 |

| Na2O | 0.18 |

| MgO | 1.45 |

| CaO | 63.89 |

| SiO2 | 19.96 |

| Al2O3 | 5.21 |

| Fe2O3 | 2.68 |

| CaO free | 1.87 |

To examine the influence of PPE-mask recycled polypropylene strings on the properties of concrete the following experimental test were carried out:

-

•

nominal compressive strength,

-

•

compressive strength after 100 freezing-thawing cycles,

-

•

capillary rise,

-

•

water permeability,

-

•

spalling.

The proposed experimental program was intended to cover the mechanical properties as well as the durability of the concrete, which is related to water transport properties. In order to assure the homogeneity of the samples of each concrete (CF and CR) 60 L of fresh concrete containing fibers were prepared in one mixture. This was used to form the following elements:

-

•

24 cubic samples (100 × 100 × 100 mm3) – 6 for nominal compressive strength test, 6 for tensile strength test, 12 for compressive strength regarding freezing-thawing cycles,

-

•

3 cubic samples (150 × 150 × 150 mm3) – for water permeability test,

-

•

12 small cylindrical samples (80 mm in diameter, 100 mm in height).

The same set of samples was prepared from reference concrete CR with no fibers addition. All samples were stored in water for 28 days before any experiment began.

The compressive strength was determined according to the standard EN 12390–3 [58]. The test was conducted on six 28-day old cubic samples (100 × 100 × 100 mm3) of both CF and CR concrete. Samples were loaded with the rate of 0.6 kN/s until destruction.

2.3. Frost resistance

In order to assess the influence of cyclic freezing on material durability, the compressive strength was also determined for samples subjected to 100 freezing-thawing cycles. To that end, after 28 days of maturing, six fully saturated cubic samples (100 × 100 × 100 mm3) of each type were placed in a climatic chamber. The freezing scan was carried out at −20 °C for 4 h, while the thawing was performed in water at + 20 °C and was continued for at least 4 h [59]. As soon as all the freezing-thawing cycles are finished, all the samples are removed from water and the compressive strength test was conducted. To provide an appropriate comparison six cubic samples stored in water were also examined as reference material.

2.4. Tensile strength

In the presented research the parameter was investigated according to the EN 12390–6 [60] on six cubic samples for each type of material (100 × 100 × 100 mm3). An analyzed sample was placed inside the hydraulic press between two fate distance pieces. Subsequently, the specimen was loaded with a pace of 0.6 MPa/s until the damage. The tensile strength was determined based on the destructive force. In some cases, the application of fibers can affect the tensile strength of concrete or reduce the shrinkage during hydration due to the presence of a contact zone between reinforcement and paste [61].

2.5. Water permeability and capillary rise

To verify the influence of PP strings on water transport properties of concrete the water permeability and the capillary rise tests were performed on both CF and CR samples. The former experiment was conducted according to the standard procedure described in EN 12390–8 [62]. After 28 days of maturing three cubic specimens (150 × 150 × 150 mm3) of each type were stored in air for 30 days. Subsequently, samples were subjected through their lateral surfaces to the waterfront under the pressure of 5 bars for 72 h. After this time cubes were split in a half and the depth of the waterfront was measured.

The capillary rise test was conducted by means of the conventional method presented in DIN 52,617 [63]. The air-dried samples were placed in water so that their surface reached up to 0.5 cm of cubic height. The amount of absorbed water was controlled through the mass change in time intervals for 375 h.

2.6. Spalling test

In order to investigate the influence of PP fibers on the fire performance of concrete, the spalling test was conducted on both types of material (CF and CR). Various methodologies for spalling analysis are described in the literature [37], [54], [64]. In the presented manuscript one adopted the procedure described in [54], where the test was conducted on cylindrical samples of dimensions 50/100 mm. To provide a representative volume of material and to eliminate the possible influence of cylinder curvature on the obtained results, one decided to increase the diameter of cylinders to 80 mm. Samples in the shape of small cylinders (approx. 80/100 mm) were placed in a muffle oven and calcined according to the standard heating curve described in ISO 834 [65] up to the temperature of 1000 °C. The exposure to the elevated temperature lasted 3 h. Subsequently, the samples remained in the furnace and cooled down for 24 h. Finally, the mass loss of each sample was determined.

3. Results

In the first stage of this section, the attention is focused on the mechanical properties of the analysed materials, i.e. compressive and tensile strength. Subsequently, one described the investigation of transport properties of hardened concrete, which enables one to conclude about the stability of the final material. In the presented research the attention was focused on water transport properties.

3.1. Compressive strength after 28 days

Compressive strength for concrete CR and CF equals 67.25 MPa and 70.82 MPa respectively, see Table 5 . It indicates that the addition of fibers from the recycling of PPE masks does not deteriorate, but even slightly increased (by about 5%) the compressive strength, which is the most crucial parameter of concrete. Additionally, the variation of compressive strength values determined for CF is lower when compared to CR. The effect of compressive strength increase due to the addition of PP fibers was previously observed in the literature, e.g. [53]. The authors explained that it resulted from the interaction between fibers and the advancing cracks. On the other hand, the authors of [66], who applied the same dosage of conventional PP fibers as in the present manuscript, did not observe any significant change in compressive strength. Probably the final effect of PP fibers on the compressive strength of hardened concrete depends on the shape and dimensions of applied fibers. Nevertheless, the observed results along with those reported in the literature for concrete containing PP fibers differ so slightly from the reference material, that one should assume that the addition does not affect the compressive strength of the final material in a significant way.

Table 5.

Compressive strength of investigated materials.

| CR | CF | |||

|---|---|---|---|---|

| Sample No. | Crushing force[kN] | Compressive strength [MPa] | Crushing force[kN] | Compressive strength [MPa] |

| 1 | 651.28 | 65.13 | 687.53 | 68.75 |

| 2 | 672.48 | 67.25 | 702.35 | 70.24 |

| 3 | 651.06 | 65.11 | 727.43 | 72.74 |

| 4 | 661.53 | 66.15 | 695.48 | 69.55 |

| 5 | 700.58 | 70.06 | 713.68 | 71.37 |

| 6 | 697.88 | 69.79 | 722.59 | 72.26 |

| Mean value | 672.47 | 67.25 | 708.18 | 70.82 |

| Standard deviation | 22.19 | 2.22 | 15.69 | 1.57 |

3.2. Frost resistance

The determination of compressive strength on samples subjected to 100 freezing-thawing cycles enables one to conclude about the material stability under frost action. The obtained results are shown in Table 6 . The strengths obtained for both materials were similar and equal 72.48 MPa and 75.90 MPa for CR and CF concretes respectively. Comparing those values to the compressive strength of the reference samples stored in water (71.39 MPa for CR and 72.84 MPa for CF), one can observe a slight increase for both materials. However, the concrete reinforced with PP fibers evinced slightly better performance, which was consistent with results previously reported in the literature. The authors of [67] observed an increase in compressive strength for concrete with the addition of 0.45 g of PP fibers per m3 after 50 freezing-thawing cycles comparing to reference material. This observation probably resulted from a random distribution of fibers, which leaded to restraining the expansion of the material caused by the increase in volume of water during the freezing [67]. Standard deviations for both types of concrete raised nearly two times. Such an increase of results variation is natural for samples subjected to accelerated corrosion tests. Generally, one can assume that there is not any material deterioration observed after 100 freezing-thawing cycles, which is specific for concretes with a low w/c ratio. This indicated that the application of fibers from PPE-mask recycling did not affect the stability of the material subjected to frost action.

Table 6.

Compressive strength of samples subjected to 100 freezing-thawing cycles and for reference material.

| CR | CF | |||

|---|---|---|---|---|

| Sample No. | subjected to frost action |

reference |

subjected to frost action |

reference |

| Compressive strength [MPa] | ||||

| 1 | 74.53 | 69.15 | 77.71 | 72.71 |

| 2 | 73.88 | 72.43 | 75.31 | 69.93 |

| 3 | 73.72 | 73.17 | 80.44 | 72.39 |

| 4 | 64.07 | 70.27 | 75.05 | 72.82 |

| 5 | 72.92 | 69.99 | 71.73 | 71.97 |

| 6 | 75.77 | 73.3 | 75.16 | 73.24 |

| Mean value | 72.48 | 71.39 | 75.90 | 72.18 |

| Standard deviation | 4.23 | 1.80 | 2.93 | 1.18 |

3.3. Tensile strength

The tensile strength of the analysed materials was determined according to the standard procedure described in [68]. The obtained results are presented in Table 7 . The values determined for both types of concrete are similar. The tensile strength equals 8.07 MPa and 7.80 MPa for CR and CF respectively. The slight decrease in the case of concrete composed with fibers probably seems to be contrary to results obtained for conventional polypropylene dispersed reinforcement [37], [53], [61], where usually an increase in the parameter was reported. One considers that in the case of conventional PP fibers, the positive influence results from the bridging effect across the arising split, which strongly depends on the effective dispersion of PP reinforcement. The inconsistency between obtained results and those reported in the literature may stem from the fact that the applied fibers were of larger diameters comparing to those applied so far. Additionally, the hydrophobic character of fibers, see section 3.1., might cause slight deterioration of adhesive connection between two materials. Nevertheless, the tensile strength decrease equals only 3.35%, hence one can assume that the application of fibers does not affect the parameter in a significant way.

Table 7.

Tensile strength of investigated materials.

| CR | CF | |

|---|---|---|

| Sample No. | Tensile strength[MPa] | Tensile strength[MPa] |

| 1 | 7.66 | 8.19 |

| 2 | 7.64 | 7.6 |

| 3 | 8.19 | 7.37 |

| 4 | 8.79 | 7.51 |

| 5 | 8.07 | 8.32 |

| 6 | 8.07 | 7.8 |

| Mean value | 8.07 | 7.80 |

| Standard deviation | 0.42 | 0.38 |

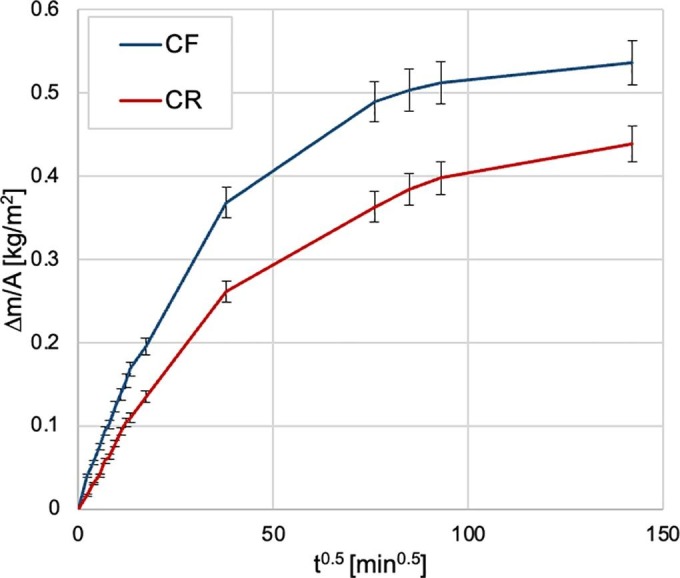

The capillary suction of the hardened concrete was investigated using the conventional gravimetric method [68]. The obtained results, which constitute the average of three samples for each type of material are presented in Fig. 6 . The mass increase of particular samples was monitored for 375 h. The relations determined for both types of concrete (CR and CF) are similar. In the first stage of the experiment (approx. 40 h), one can observe fast water absorption. Subsequently, the capillary suction slows down, and samples’ masses reach a relatively stable level. The final water uptake equals 0.43 kg/m2 and 0.53 kg/m2 for CR and CF concrete. Hence, the application of fibers led to approx. 20% increase in absorbed water mass. A similar effect was observed by the authors of [69], [70]. The acceleration of water uptake was the consequence of the increased porosity in the connection zone between fibers and cement paste, which resulted from the hydrophobic nature of PP fibers surface [52], [61], [71]. According to Yuan and Jia [69] the higher content of PP fibers, the higher water uptake due to an increase in inhomogeneity of material internal structure.

Fig. 6.

Results of capillary rise test for CR and CF concrete.

3.4. Water permeability

Contrary to the capillary rise, in the case of the water permeability test, the liquid affects a sample under external pressure. Four cubic samples of each concrete type were subjected through their lateral sides to the waterfront under the pressure of 0.5 MPa. After 72 h specimens were split in a half and the depth of the waterfront was measured. According to the standard EN 12390–8:2019 [62], the distance should be measured in the point, where the water penetration is the deepest. It is usually located in the middle of the sample’s surface exposed to elevated water pressure. The results are contained in Table 8 . In Fig. 7 there is presented the picture of exemplary samples of each considered material. The average value of waterfront depth equals 12.00 mm and 12.25 mm for CR and CF concrete respectively. The results differ by about 2%, hence one can assume, that the presence of PP fibers did not affect the water permeability of hardened concrete.

Table 8.

The results of the water permeability test for CR and CF concrete.

| CR | CF | |

|---|---|---|

| Sample No. | Depth of waterfront penetration[mm] | Depth of waterfront penetration[mm] |

| 1 | 13 | 12 |

| 2 | 10 | 15 |

| 3 | 11 | 9 |

| 4 | 14 | 13 |

| Mean value | 12.00 | 12.25 |

Fig. 7.

Exemplary samples after the water permeability test.

3.5. Spalling

Explosive spalling results from the abrupt increase in water vapor pressure within the pore system of the material exposed to fire. The addition of conventional PP fibers is one of the most effective measures to prevent spalling degradation [37], [72]. Disintegration of polypropylene begins at 200 °C, see Fig. 4. Due to its thermal decay in areas previously occupied by PP fibers, new pores are created. Such an additional space provides relaxation of the increasing vapor pressure, which limits spalling of concrete [37]. To verify the influence of the applied fibers on the explosive spalling, the small cylinders (approx. 80/100 mm) composed of CR and CF concretes were subjected to the standard heating curve according to ISO 834 [36]. After calcination, the exfoliated material was measured and referred to the initial mass of a sample. The results are presented in Table 9 . The average value of the peeled material equals 0.24% and 0.21% with regard to the initial sample mass for CR and CF concrete respectively. In Fig. 8 one presents the exemplary samples composed of both types of materials. After calcination, all of the investigated samples were covered with a visible system of connected cracks. Nevertheless, the structure of each sample remained dense, and only a minimal amount of material exfoliated independently of the concrete type (fibers modified or reference). The authors of [54] reported significant deterioration of reference material and a great improvement of fire performance in the case of concrete containing PP fibers. This could result from a smaller sample size (50/100 mm). Han et al. [37] conducted an extensive study concerning spalling phenomenon in samples containing various dosages of polypropylene fibers and remaining under lateral confinement. In every analyzed case, the deterioration of reference material was significantly larger comparing to reinforced material. However, the authors applied cement of lower compressive strength than that, which was used in the presented research. Based on the obtained results one can assume, that there was no significant difference in the behavior of reference samples and those composed with the addition of the recycled fiber. Both materials did not evince any significant degradation after exposition to fire conditions. Nevertheless, the influence of PP fibers from disposable masks on the fire performance of concrete needs to be further analyzed, which will require the optimization of the experiment parameters.

Table 9.

The results of the spalling test for CR and CF concrete.

| Sample No. | initial mass,[g] | exfoliated material, [g] | exfoliatedmaterial, [%] | exfoliated materal - mean value, [%] | |

|---|---|---|---|---|---|

| CR | 1 | 367.68 | 0.97 | 0.26 | 0.24 |

| 2 | 371.98 | 1.17 | 0.31 | ||

| 3 | 358.15 | 0.46 | 0.13 | ||

| 4 | 348.91 | 0.88 | 0.25 | ||

| CF | 1 | 356.65 | 0.59 | 0.17 | 0.21 |

| 2 | 372.98 | 0.99 | 0.27 | ||

| 3 | 385.14 | 1.13 | 0.29 | ||

| 4 | 353.78 | 0.46 | 0.13 |

Fig. 8.

Exemplary samples after water the spalling test.

4. Conclusions

The coronavirus disease is one of the most difficult challenges mankind has had to face recently. The pandemic caused an unexpected boost for the usage of personal protective equipment, from which the mask is the most popular. It led to a massive increase in the production of medical wastes. Proper recycling would limit the impact on the environment and further infections. The proposed recycling procedure is safe, straightforward and transforms waste face masks into polypropylene strings, which can serve as an addition to concrete. The proposed dosage equals a portion of fibers from 1 mask per 1 L of a concrete mixture (2 g of PP/1 L of concrete mixture). The carried-out extended experimental analysis aiming at comparing the properties of concrete containing PP fibers to the reference material enabled one to draw the following conclusions:

-

1.

The application parameters of the recycling process (190 °C, 130 bar) provided complete inactivation of virus and transformed used face masks into homogeneous polypropylene strings.

-

2.

The addition of polypropylene fibers to concrete improved its 28-day compressive strength approx. 5%. Meanwhile, there was observed a slight reduction of the tensile strength (by about 3%). It remains contrary to observations reported for commercial PP fibers, which usually lead to an increase in tensile strength [53]. However, the diameter of conventional fibers cross-section is several orders of magnitude smaller than the mask-processed strings. This indicates that the dimensions of recycled PP fibers may be further optimized. Nevertheless, the differences between the mechanical parameters of modified and reference concrete remained very small. Hence, one can assume that the application of the proposed PP fibers did not deteriorate the investigated parameters.

-

3.

Concerning capillary rise, the concrete containing PP fibers absorbed water slightly faster than the reference one, which probably resulted from increased porosity within the contact zone between strings and cement matrix. Such an effect is also widely reported for conventionally applied PP fibers [69], [70]. On the other hand, the modification did not deteriorate the water-resistance under external hydraulic pressure.

-

4.

The analysis of frost resistance of concrete indicated that after 100 freezing-thawing cycles, the compressive strength of concrete modified with PP fibers was slightly higher than that of the reference one. Hence, it might be concluded that the introduced processed masks did not influence the frost resistance, at least in the absence of deicing salts.

-

5.

The results of the spalling test indicated that there was no significant difference in the mass loss after exposure to fire of reference concrete and those containing the recycled fibers. Nevertheless, the recycled addition requires further analysis to verify a positive influence on the fire performance of concrete.

-

6.

The applied technology allows to improve the recycling capacity of the medical wastes – 1 m3 of concrete would consume 1000 masks. It was proved that the application of polypropylene strings obtained from the protective masks did not deteriorate the properties of concrete, contrarily, some were improved. Nevertheless, many problems remain unsolved, i.e., what is the optimal dosage of the masks, how durable the modified concrete is in the other aggressive environment (sulfate, chloride), etc. Further, it was shown that the tensile strength of the modified concrete is reduced when compared with the reference one. One is prompted to examine how these obstacles can be overcome, by adding the fly ash, or further processing of the polypropylene strings?

CRediT authorship contribution statement

Marcin Koniorczyk: Conceptualization, Visualization, Methodology, Supervision, Writing – original draft. Dalia Bednarska: Methodology, Investigation, Visualization, Writing – original draft. Anna Masek: Methodology, Visualization, Writing – original draft. Stefan Cichosz: Investigation, Visualization.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- 1.Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, “Youth Opportunities Initiative,“ 2011.

- 2.Pacheco-Torgal F. “1. Introduction to advances in construction and demolition waste,” in Advances in Construction and Demolition Waste Recycling. Woodhead Publishing; 2020. pp. 1–10. [Google Scholar]

- 3.https://plasticseurope.org/knowledge-hub/plastics-the-facts-2020/. (access date: 11.01.2022).

- 4.Sharma R., Bansal P.P. Use of different forms of waste plastic in concrete–a review. J. Cleaner Prod. 2016;112:473–482. [Google Scholar]

- 5.Steyn Z., Babafemi A., Fataar H., Combrinck R. Concrete containing waste recycled glass, plastic and rubber as sand replacement. Constr. Build. Mater. 2021;269 [Google Scholar]

- 6.Belmokaddem M., Mahi A., Senhadji Y., Pekmezci B.Y. Mechanical and physical properties and morphology of concrete containing plastic waste as aggregate. Constr. Build. Mater. 2020;257 [Google Scholar]

- 7.Hama S.M. Evalutions of strengths, impact and energy capacity of two-way concrete slabs incorprating waste plastic. Journal of King Saud University-Engineering Sciences. 2021;33(5):337–345. [Google Scholar]

- 8.Krishnan P., Zhang M.-H., Cheng Y., Riang D.T., Liya E.Y. Photocatalytic degradation of SO2 using TiO2-containing silicate as a building coating material. Constr. Build. Mater. 2013;43:197–202. [Google Scholar]

- 9.Záleská M., Pavlikova M., Pokorný J., Jankovský O., Pavlík Z., Černý R. Structural, mechanical and hygrothermal properties of lightweight concrete based on the application of waste plastics. Constr. Build. Mater. 2018;180:1–11. [Google Scholar]

- 10.Al-Tulaian B., Al-Shannag M., Al-Hozaimy A. Recycled plastic waste fibers for reinforcing Portland cement mortar. Constr. Build. Mater. 2016;127:102–110. [Google Scholar]

- 11.Rohden A.B., Camilo J.R., Amaral R.C., Garcez E.O., Garcez M.R. Effects of Plastic Waste on the Heat-Induced Spalling Performance and Mechanical Properties of High Strength Concrete. Materials. 2020;13(15):3262. doi: 10.3390/ma13153262. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Camilo J.R., Rohden A.B., Garcez M.R. Concrete with rejected recyclable plastic waste at high temperatures. Mag. Concr. Res. 2021;73(19):973–987. [Google Scholar]

- 13.Zhao S., Fan J., Sun W. Utilization of iron ore tailings as fine aggregate in ultra-high performance concrete. Constr. Build. Mater. 2014;50:540–548. [Google Scholar]

- 14.El Machi A., Mabroum S., Taha Y., Tagnit-Hamou A., Benzaazoua M., Hakkou R. Use of flint from phosphate mine waste rocks as an alternative aggregates for concrete. Constr. Build. Mater. 2021;271 [Google Scholar]

- 15.Silva R., De Brito J., Dhir R. Use of recycled aggregates arising from construction and demolition waste in new construction applications. J. Cleaner Prod. 2019;236 doi: 10.1016/j.wasman.2015.12.021. [DOI] [PubMed] [Google Scholar]

- 16.Debieb F., Kenai S. The use of coarse and fine crushed bricks as aggregate in concrete. Constr. Build. Mater. 2008;22(5):886–893. [Google Scholar]

- 17.González J.S., Gayarre F.L., Pérez C.-L.-C., Ros P.S., López M.A.S. Influence of recycled brick aggregates on properties of structural concrete for manufacturing precast prestressed beams. Constr. Build. Mater. 2017;149:507–514. [Google Scholar]

- 18.Bravo M., de Brito J. Concrete made with used tyre aggregate: durability-related performance. J. Cleaner Prod. 2012;25:42–50. [Google Scholar]

- 19.Valadares F., Bravo M., de Brito J. Concrete with used tire rubber aggregates: Mechanical performance. ACI Materials Journal-American Concrete Institute. 2012;109(3):283. [Google Scholar]

- 20.Suchorab Z., Franus M., Barnat-Hunek D. Properties of Fibrous Concrete Made with Plastic Optical Fibers from E-Waste. Materials. 2020;13(10):2414. doi: 10.3390/ma13102414. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Fu B., Liu K., Chen J., Teng J. Concrete reinforced with macro fibres recycled from waste GFRP. Constr. Build. Mater. 2021;310 [Google Scholar]

- 22.Zhou Y., et al. The prevalence of psychiatric symptoms of pregnant and non-pregnant women during the COVID-19 epidemic. Transl. Psychiatry. 2020;10(1):1–7. doi: 10.1038/s41398-020-01006-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.World Health Organization. Water, hygiene, and waste management for the COVID-19 virus: In terim guidance, https://www.who.int/publications-de-tail/water-sanitation-hygiene-and-waste-management-for-covid-19. (access date: 21.10.2021).

- 24.Haji J.Y., Subramaniam A., Kumar P., Ramanathan K., Rajamani A. State of personal protective equipment practice in indian intensive care units amidst COVID-19 pandemic: a nationwide survey. Indian Journal of Critical Care Medicine: Peer-reviewed, Official Publication of Indian Society of Critical Care Medicine. 2020;24(9):809. doi: 10.5005/jp-journals-10071-23550. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.https://www.reportlinker.com/p05934703/Face-Mask-Market-Global-Outlook-and-Forecast.html?utm_source=GNW. (access date: 19.01.2022).

- 26.K. Graulich et al., “Impact of COVID-19 on single-use plastics and the environment in Europe,” European Environment Agency: Boeretang, Belgium, vol. 22, 2021.

- 27.Boroujeni M., Saberian M., Li J. Environmental impacts of COVID-19 on Victoria, Australia, witnessed two waves of Coronavirus. Environ. Sci. Pollut. Res. 2021;28(11):14182–14191. doi: 10.1007/s11356-021-12556-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.F. G. Torres and G. E. De-la-Torre, “Face mask waste generation and management during the COVID-19 pandemic: An overview and the Peruvian case,” Science of the Total Environment, p. 147628, 2021.

- 29.Sangkham S. Face mask and medical waste disposal during the novel COVID-19 pandemic in Asia. Case Studies in Chemical and Environmental Engineering. 2020;2 doi: 10.1016/j.cscee.2020.100052. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Das A.K., Islam N., Billah M., Sarker A. Science of the Total Environment. 2021. COVID-19 pandemic and healthcare solid waste management strategy–A mini-review; p. 146220. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Ilyas S., Srivastava R.R., Kim H. Disinfection technology and strategies for COVID-19 hospital and bio-medical waste management. Sci. Total Environ. 2020;749 doi: 10.1016/j.scitotenv.2020.141652. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.ISWA Lebanon | A non-governmental organization, https://www.iswa.org/fileadmin/user_upload/_temp_/MoE_Lebanon_COVID19_MSW_Management_General_Guidelines_April_23_2020.pdf:https://www.iswa.org/iswa/covid-19/. (access date: 17.10.2021).

- 33.Selvaranjan K., Navaratnam S., Rajeev P., Ravintherakumaran N. “Environmental challenges induced by extensive use of face masks during COVID-19: a review and potential solutions,” Environmental. Challenges. 2021 doi: 10.1016/j.envc.2021.100039. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Douglas L. “Possible Use for Recycled Disposable Face Masks in. Concrete,“. 2021 [Google Scholar]

- 35.Saberian M., Li J., Kilmartin-Lynch S., Boroujeni M. Repurposing of COVID-19 single-use face masks for pavements base/subbase. Sci. Total Environ. 2021;769 doi: 10.1016/j.scitotenv.2021.145527. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Kilmartin-Lynch S., Saberian M., Li J., Roychand R., Zhang G. Preliminary evaluation of the feasibility of using polypropylene fibres from COVID-19 single-use face masks to improve the mechanical properties of concrete. J. Cleaner Prod. 2021;296 doi: 10.1016/j.jclepro.2021.126460. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Han C.-G., Hwang Y.-S., Yang S.-H., Gowripalan N. Performance of spalling resistance of high performance concrete with polypropylene fiber contents and lateral confinement. Cem. Concr. Res. 2005;35(9):1747–1753. [Google Scholar]

- 38.Yu L., Yan X., Fortin G. Effects of weathering aging on mechanical and thermal properties of injection molded glass fiber reinforced polypropylene composites. J. Polym. Res. 2018;25(11):1–10. [Google Scholar]

- 39.Fávaro S., Rubira A., Muniz E., Radovanovic E. Surface modification of HDPE, PP, and PET films with KMnO4/HCl solutions. Polym. Degrad. Stab. 2007;92(7):1219–1226. [Google Scholar]

- 40.Sclavons M., et al. Quantification of the maleic anhydride grafted onto polypropylene by chemical and viscosimetric titrations, and FTIR spectroscopy. Polymer. 2000;41(6):1989–1999. [Google Scholar]

- 41.Chylińska M., Kaczmarek H., Moszyński D., Królikowski B., Kowalonek J. Surface studies of UV irradiated polypropylene films modified with mineral fillers designed as piezoelectric materials. Polymers. 2020;12(3):562. doi: 10.3390/polym12030562. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Gopanna A., Mandapati R.N., Thomas S.P., Rajan K., Chavali M. Fourier transform infrared spectroscopy (FTIR), Raman spectroscopy and wide-angle X-ray scattering (WAXS) of polypropylene (PP)/cyclic olefin copolymer (COC) blends for qualitative and quantitative analysis. Polym. Bull. 2019;76(8):4259–4274. [Google Scholar]

- 43.Khafagy R.M., Badr Y. In situ FTIR spectroscopic study of the recently detected low-temperature-induced structural changes in isotactic polypropylene. J. Polym. Sci., Part B: Polym. Phys. 2005;43(20):2829–2842. [Google Scholar]

- 44.Ambrogi V., et al. Natural antioxidants for polypropylene stabilization. Polym. Degrad. Stab. 2011;96(12):2152–2158. [Google Scholar]

- 45.Lu M., et al. Photo-and thermo-oxidative aging of polypropylene filled with surface modified fumed nanosilica. Compos. Commun. 2017;3:51–58. [Google Scholar]

- 46.Vyazovkin S., Sbirrazzuoli N. Isoconversional kinetic analysis of thermally stimulated processes in polymers. Macromol. Rapid Commun. 2006;27(18):1515–1532. [Google Scholar]

- 47.Luzuriaga S., Kovářová J., Fortelný I. Degradation of pre-aged polymers exposed to simulated recycling: properties and thermal stability. Polym. Degrad. Stab. 2006;91(6):1226–1232. [Google Scholar]

- 48.Encinas N., Pantoja M., Abenojar J., Martínez M. Control of wettability of polymers by surface roughness modification. J. Adhes. Sci. Technol. 2010;24(11–12):1869–1883. [Google Scholar]

- 49.Kwon O.-J., Tang S., Myung S.-W., Lu N., Choi H.-S. Surface characteristics of polypropylene film treated by an atmospheric pressure plasma. Surf. Coat. Technol. 2005;192(1):1–10. [Google Scholar]

- 50.Chibowski E., Terpilowski K. Surface free energy of polypropylene and polycarbonate solidifying at different solid surfaces. Appl. Surf. Sci. 2009;256(5):1573–1581. [Google Scholar]

- 51.da Costa H.M., Ramos V.D., Rocha M.C. Rheological properties of polypropylene during multiple extrusion. Polym. Test. 2005;24(1):86–93. [Google Scholar]

- 52.Hannawi K., Bian H., Prince-Agbodjan W., Raghavan B. Effect of different types of fibers on the microstructure and the mechanical behavior of ultra-high performance fiber-reinforced concretes. Compos. B Eng. 2016;86:214–220. [Google Scholar]

- 53.Song P.S., Hwang S., Sheu B.C. Strength properties of nylon- and polypropylene-fiber-reinforced concretes. Cem. Concr. Res. 2005;35(8):1546–1550. [Google Scholar]

- 54.Zhang D., Dasari A., Tan K.H. On the mechanism of prevention of explosive spalling in ultra-high performance concrete with polymer fibers. Cem. Concr. Res. 2018;113:169–177. [Google Scholar]

- 55.Neville A. Polish Cement Association; Krakow: 2000. Concrete properties. [Google Scholar]

- 56.S. Mindess, F. Young, and D. Darwin, “Concrete 2nd Editio,” Technical Documents, 2003.

- 57.ASTM C143/C143M-12 Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International, 2012.

- 58.EN 12390-3:2019 Testing hardened concrete - Part 3: Compressive strength of test specimens, Comité européen de normalisation, 2019.

- 59.PN-88/B-06250, Beton zwykły., Polish Standard Comitee, 1988, in polish.

- 60.EN 12390-6:2009 Testing hardened concrete - Part 6: Tensile splitting strength of test specimens, Comité européen de normalisation, 2009.

- 61.Peng G.-F., Niu X.-J., Shang Y.-J., Zhang D.-P., Chen X.-W., Ding H. Combined curing as a novel approach to improve resistance of ultra-high performance concrete to explosive spalling under high temperature and its mechanical properties. Cem. Concr. Res. 2018;109:147–158. [Google Scholar]

- 62.EN 12390-8:2019 Testing hardened concrete - Part 8: Depth of penetration of water under pressure, Comité européen de normalisation, 2019.

- 63.DIN 52617 Determination of the water absorption coefficient of construction materials, Deutsches Institut für Normung, 1987.

- 64.Choe G., Kim G., Yoon M., Hwang E., Nam J., Guncunski N. Effect of moisture migration and water vapor pressure build-up with the heating rate on concrete spalling type. Cem. Concr. Res. 2019;116:1–10. [Google Scholar]

- 65.ISO 834-2:2019 Fire-resistance tests — Elements of building construction — Part 2: Requirements and recommendations for measuring furnace exposure on test samples, International organization for standardization, 2019.

- 66.Behnood A., Ghandehari M. Comparison of compressive and splitting tensile strength of high-strength concrete with and without polypropylene fibers heated to high temperatures. Fire Saf. J. 2009;44(8):1015–1022. [Google Scholar]

- 67.Karahan O., Atiş C.D. The durability properties of polypropylene fiber reinforced fly ash concrete. Mater. Des. 2011;32(2):1044–1049. [Google Scholar]

- 68.Karagiannis N., Karoglou M., Bakolas A., Moropoulou A. Effect of temperature on water capillary rise coefficient of building materials. Build. Environ. 2016;106:402–408. [Google Scholar]

- 69.Yuan Z., Jia Y. Mechanical properties and microstructure of glass fiber and polypropylene fiber reinforced concrete: an experimental study. Constr. Build. Mater. 2021;266 [Google Scholar]

- 70.Fallah S., Nematzadeh M. Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Constr. Build. Mater. 2017;132:170–187. [Google Scholar]

- 71.J. jun Li, J. gang Niu, C. jun Wan, B. Jin, and Y. liu Yin, “Investigation on mechanical properties and microstructure of high performance polypropylene fiber reinforced lightweight aggregate concrete,” Construction and Building Materials, vol. 118, pp. 27-35, 2016.

- 72.Zeiml M., Leithner D., Lackner R., Mang H.A. How do polypropylene fibers improve the spalling behavior of in-situ concrete? Cem. Concr. Res. 2006;36(5):929–942. [Google Scholar]