Abstract

The integration of photovoltaic into a greenhouse has been implemented to maximize the energy output and crop production yield from the same land space. The effect of greenhouse external shading of opaque crystalline silicon photovoltaic (PV) panels at 13–26% of the roof area on the microclimate and growth of Chili pepper Capsicum annuum cv. (omega) was investigated. The PV panels were divided into two arrays (each of 4 PVs) and fixed separately on two external pillars of 4 m height in the Southeast and Northwest directions, respectively. Each array of 4 PVs could be tracked from the East-West direction to North-South. There were two greenhouses, one was used as control without shading and the other had the external shading. The results revealed that the external shading of PV slightly decreased air temperatures (1–2 °C) and light intensities (25–40%) but had no effect on the dew point temperatures and relative humidity as compared to the control (unshaded greenhouse). Furthermore, the yield and growth of Chili pepper in the shaded greenhouse was insignificantly higher than that in the unshaded greenhouse. Moreover, the simulation results revealed that the estimated electric energy of photovoltaic panels was 3705 kWh/year at a tilt angle of 25° facing South.

Keywords: Photovoltaic, Greenhouse, Solar energy, Shading, Microclimate, Chili pepper

Photovoltaic, Greenhouse, Solar energy; Shading, Microclimate, Chili pepper.

1. Introduction

Solar energy is a main source of renewable energy, which is sustainable and available in the daytime worldwide. However, controlling the greenhouses environment requires energy in order to provide the optimal growth conditions for plants (Gorjian et al., 2021). Cooling and heating systems are the main energy consumers in greenhouse operations (Hassanien et al., 2018a). Thus, the integration of photovoltaic panels into greenhouses for energy and plant production has been recently practiced worldwide particularly in rural and deserts of tropical regions (Hassanien and Li, 2017; Hassanien et al., 2018b; Li et al., 2020). Ravishankar et al. (2020) reported that net zero energy greenhouses could be achieved, as well as an annual surplus of energy, in warm and moderate climates by integrating semi-transparent organic solar cells on greenhouse roof.

Several authors reported that the external integration of photovoltaic panels on the greenhouse could decrease the internal light intensity and air temperatures (Friman-Peretz et al., 2020; Gorjian et al., 2021; Marrou et al., 2013). The low light intensity of shading has been reported to decrease plant height and number of nodes, and increase the leaf area of sweet paper meanwhile, reduced sun-scald damage of fruits and increased the yield of high-quality fruits at the shading of 12–26% (Rylski and Spigelman, 1986). In comparison between glass and glass-PV greenhouses shaded by 20% of the roof area, pepper (Capsicum annuum cv. California Wonder) yield was slightly increased in PV greenhouse whereas no differences were found with respect to weight, dimensions, and thickness of the pepper fruits. However. photometric and spectroscopic studies of the pepper fruits’ extracts showed decreases in the glass-PV greenhouse (Kavga et al., 2019). The shading net (35% light reduction) was a beneficial tool in the Mediterranean area during the spring-summer season which allowed the adjustment of the light and temperature conditions in greenhouse for pepper resulting in enhancing the yield and antioxidant content (Caruso et al., 2020).

High temperatures may affect flowering, fruit set and fruit yields and may result in blossom-end rot and sunscald. Thus, the impact of shading on fruit quality and mineral nutrient composition was investigated (Dıáz-Pérez, 2019). The results revealed that fruit concentrations of N, P, K were increased under shading nets while Al, B, Mn, Mo, Na and Ni concentrations were decreased under high level of shading and no significant differences were found for the concentrations of Ca, Mg, S, Cu, Fe, and Zn However, modifying light quality and microclimate through photo selective colored shade nettings were reported to be a cost-effective approach for enhancing sweet pepper postharvest storage quality (Lima et al., 2017).

A mathematical growth model used to estimate the number of days required to produce ready transplants of pepper showed variations between transplant quality parameters and yearly production period for pepper transplants under 50% shading capacity (Sarıbaş et al., 2018). It was found that the highest fruit number and total fruit yield of pepper crop was observed under 15% shading by insect proof screen (about 7 kg m−2) which was about 80% higher than unshaded. Meanwhile, the marketable fruit yield under shading was more than 90% of the total yield compared to 60% for the unshaded (Rigakis et al., 2014). Nevertheless, shading and insect-proof screens had a reduction of 15–39% in solar radiation, of 50–87% in air velocity, of 2.3–2.5 °C in air temperature, and of 17.4–50% in evapotranspiration, but the relative humidity increased by 2–21% (Mahmood et al., 2018).

The greenhouses shading system in Mediterranean countries can be achieved using traditional techniques such as shading nets, screens (permanent or displaceable), and whitewashing. A new shading method involves the integration of photovoltaics (opaque, semitransparent, transparent), on the roof of the greenhouse for shading and energy production which is called PV greenhouses (Aroca-Delgado et al., 2018). Cossu et al. (2020) mentioned that covering the greenhouse structures by 25% with a PV panel were compatible with the cultivation of tomato, cucumber, and sweet pepper with a limited yield reduction of less than 25%. Recently, a number of studies have been conducted on the integration of organic photovoltaics and greenhouses (Friman-Peretz et al., 2020; La Notte et al., 2020; Magadley et al., 2020; Zisis et al., 2019). These studies reported that the organic photovoltaics OPV modules can generate electric energy and act as shading elements without any damage to the plants. However, the price of OPV is too expensive and the OPV modules degrade rapidly when placed on a greenhouse roof decreasing and their life span. It was reported that using the semi-transparent organic photovoltaics OPV as a greenhouse shade delayed fruit development and ripening of tomato at the beginning and then after the fourth harvest there were no significant differences between the shaded (OPV-shaded) and the un-shaded in the average weekly yield, fruit number, and fruit mass (Waller et al., 2021).

However, The integration of PV and greenhouse still very limited in Egypt due to the high initial costs of PV and the weather conditions. The aim of this study was to investigate a special integration of PV in controlled greenhouse without harming the growth of pepper plants in order to produce energy enhance yield and reduce production cost.

2. Material and methods

2.1. The experimental site

The experiment was conducted in greenhouses in the Agricultural Engineering Department, Faculty of Agriculture, Cairo University, Giza, Egypt at Latitude of 30.01° N, Longitude of 31.21° E, and Altitude of 30 m. The experimental area has an arid climate with cool winters and hot dry summers.

2.2. The greenhouses

This study aimed at investigating the effect of PV shading on the greenhouse microclimate parameters and yield of chili pepper. Two small-scale identical Quonset-style experimental greenhouses with the same orientation (North- South) were made from galvanized steel structure. The structure covering material was a plastic polyethylene film with a thickness of 160 μm and 75% of light transmission. The dimensions of each greenhouse were 10 m length, 5 m width, 3.5 m height; each one occupies a surface area of 50 m2. A sufficient distance of 3 m was kept between them to avoid mutual shading overlap. The greenhouse floor was covered with a 5 cm thick layer of medium gravels.

The greenhouses were equipped with controlled heating and ventilation systems. A fan and a cellulose cooling pad of 4.5 m2 surface area and 0.15 m thickness and mounted on the north side-wall. On the south side-wall, one identical exhaust fan was mounted at 0.75 m above the ground. The diameter of fan was 1.4 m, the air flow rate was 600 m3 min−1 and the power consumption of 1.1 kW. The cooling system was controlled by a temperature sensor connected to a control unit, where the cooling system can be set up to run either automatically or manually. During the experiment, the cooling system was set to operate if the internal air temperature (Tin) reached a set point temperature of 28 °C.

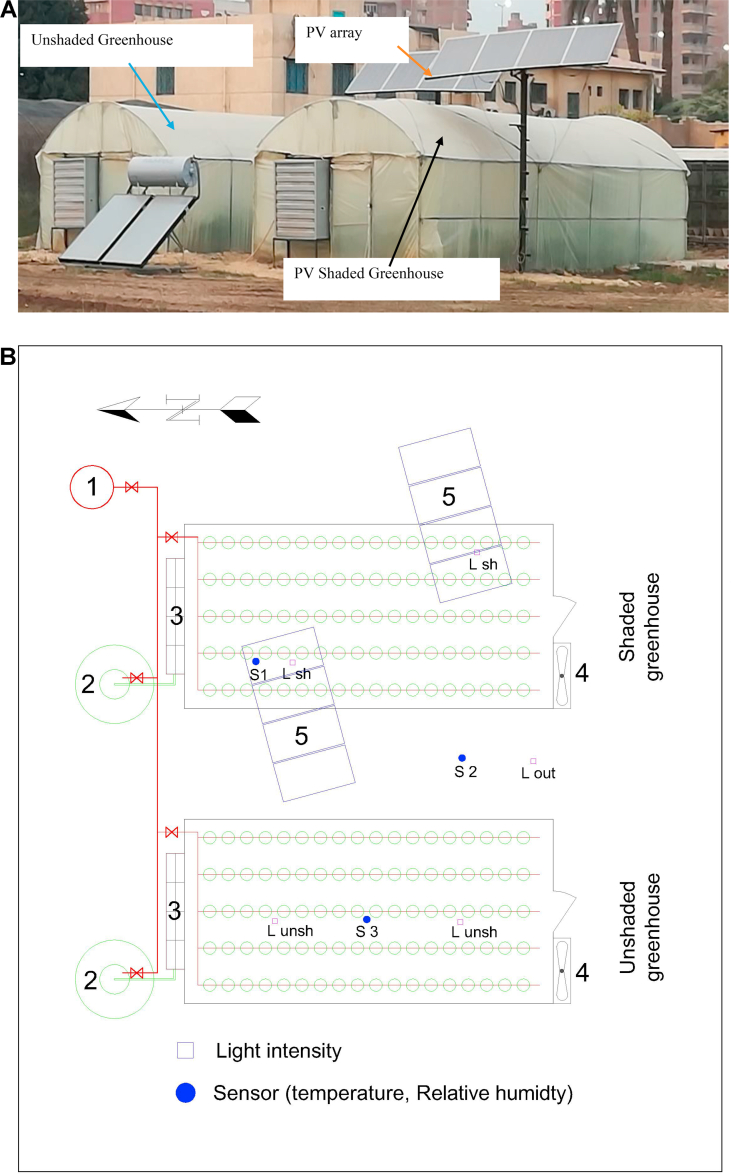

2.3. Greenhouse PV panels installation

Two PV array with a total area of 8–16 m2 were mounted on the roof of a greenhouse as a shading material, covering 13%–26% of the roof area. The PV arrays were installed opposite to each other along the greenhouse orientation axis, as shown in Figure 1. The PV specifications were Pmax = 275 W, Imp = 8.82 A, Vmp = 31.2 V, weight = 18.3 kg and dimensions = 1650 mm × 992 mm × 35 mm as shown in Table 1.

Figure 1.

A. Photo of a photovoltaic integrated with greenhouses and shading movements. B. Schematic diagram of sensors and light intensity distribution inside greenhouses. (L unsh, sh: Light intensity, S 1,2,3: sensors of relative humidity and air temperatures 2: Water tank for wetting the Pad, 3: Pad, 4: Exhaust fan, 5: PV panels).

Table 1.

Specifications of the solar panels.

| Item | Value |

|---|---|

| Name and type | STP275-20/WF |

| Rated Maximum Power (Pmax) | 275 W ± 5 % |

| Output Tolerance | 0/+5 W |

| Current at Pmax (Imp) | 8.76 A |

| Voltage at Pmax (Vmp) | 31.4 V |

| Short-Circuit Current (Isc) | 9.27 A ± 5 % |

| Open-Circuit Voltage (Voc) | 38.1 V ± 5 % |

| Nominal Module Operating Temp (TNMOT) | 42 °C ± 2 °C |

| Cell Technology | mulyi-Si |

| Application | Class A |

| Maximum System Voltage | 1000 V |

| Maximum Series Fuse Rating | 20 A |

| Weight | 18.3 kg |

| Dimension | 1650 mm × 992 mm × 35 mm |

The invented shading system consists of five functional subsystems: frame, array dual axis trackers, electric motor, panels holder and PV modules. Each array consists of 4 photovoltaic panels which were located at a distance of 0.5 m above the highest point of the greenhouse roof.

2.4. Microclimate monitoring and data acquisition system

The interior microclimatic parameters were measured in both greenhouses which included the air temperature, dew point temperature, and relative humidity. Data were collected daily at 30 min interval, using the Lufft OPUS20E data logger with three sensors (G. Lufft Mess-und Regeltechnik GmbH Company, Germany). It consisted of 10 channels with a measurement rate of 10s-24 h, data storage of 16 Mb, air temperature measurement range of -20 °C to 50 °C, at an accuracy of ±0.3 °C for the range of 0–40 °C, and a relative humidity measurement range of 0–100% at accuracy of ±2 %. Sensors for air temperatures, relative humidity, and dew point temperatures were distributed inside greenhouses at 1.5 m above the ground and one sensor was placed outside the greenhouse for measuring the ambient temperature and humidity.

The light intensity was measured by a digital portable lux meter (Model: LX1330B, China) with a measuring range of 0.1–200,000 Lux, at an accuracy of ±3% ± 10 digits for the range of 0–20,000 lux and at an accuracy of ±5% ± 10 digits for the range over 20,000 Lux. The light intensity measured directly above the level of plants.

2.5. Experiment setup, irrigation and fertilization

This experiment was implemented under the same conditions of soil, irrigation, fertilization, and management. Soil (peat moss and vermiculite) media were added to planting pots V: V (1: 1) at a pot size of 35 cm. 90 pots were placed in five rows in greenhouse with 18 plants in each row. Planting distances were 50 cm between plants in row and 100 cm between rows for each greenhouse. A drip irrigation system was applied with Jr dripline emitter discharge was 2 L h−1 90 seedlings of chili pepper (Omega) transplants were cultivated on August 20th, 2020.

2.6. Growth and yield measurements

The measurements parameters for chili pepper plants were plant height, chlorophyll contents, number of flowers including fruits, and yield after shading treatments for 35 days and repeated every week for 4 months. Also, Vitamin C levels were determined in the fruits according to the procedure reported by Horwitz (2005). The relative chlorophyll concentration (the vegetation) of the leaves was measured by a portable chlorophyll meter (model: TYS-B, China) The measurement area was 2 mm × 2 mm, the measuring interval was < 3s, the measuring range was 0.0–99.9 SPAD at -10–99.9 °C, the accuracy was ±3.0 SPAD at ±0.5 °C, the repeat was ±0.3SPAD at ±0.2 °C, the operating temperature was -10 - 50 °C). The leaf area of plant was measured by a portable leaf area meter (model: YMJ-B TPB, China). The precision was +2%, the length was ≤1000 mm, the width was ≤160 mm, the thickness was ≤8 mm, the stored datum was 200 Groups with a 6 V battery.

In order to predict the shelf-life for chili pepper (omega), two samples from shaded and unshaded greenhouses were randomly taken and stored in a flexible polyethylene film at an air temperature of 4 °C and a relative humidity of 8%. The data were recorded on 0, 3, 6, 12, 27, 39 and 45 days. Physiological weight loss (PWL) was determined following the method described by Waskar et al. (1999).

2.7. Statistical analysis

Data and results obtained from each treatment in both greenhouses were analyzed using the independent two-sample Student t-test with a p-value of 0.05. Data were presented as the mean ± standard deviation.

3. Results and discussion

3.1. Environmental parameters

There was a little fluctuation of environmental parameters inside the greenhouses, as the sensors were fixed and the sun moves on the horizon throughout the day. Subsequently, the angle of incidence on the sensor and the shading area could be changed.

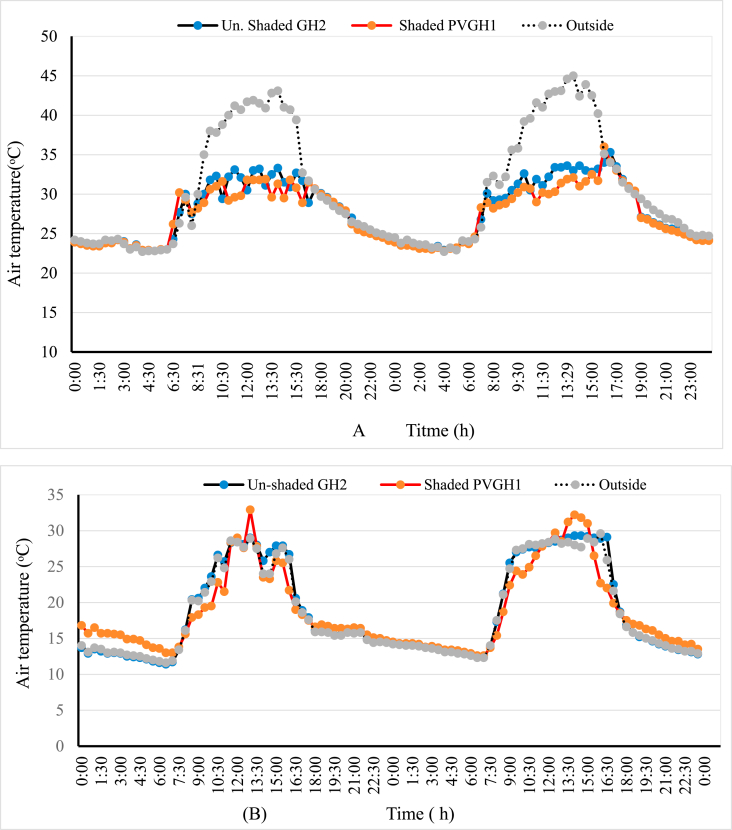

3.1.1. Air and dew point temperatures

Figure 2 shows the air temperatures inside and outside the greenhouses during the months of September and February. The results showed that the air temperature inside both greenhouses was lower than the outside temperature in September because the Fan and Pad cooling system were operated during this period as the internal sensor was adjusted to keep the temperature lower than 31 °C. The cooling system decreased temperatures by an average of 8 °C and when it worked along with the PV shading it decreased the temperature by 10 °C.

Figure 2.

(A) Air temperature on 24th September 2020, (B). Air temperature on 4th February, 2021.

However, the internal air temperature in the un-shaded greenhouse (USGH) was higher than that of the shaded greenhouse by Photovoltaic panels (PVGH). This variation is reasonable because the PV panels filtered a large portion of the solar radiation received and thus allowing less energy to pass inside the greenhouse. On the other hand, the differences between the daytime air temperatures in greenhouses and the ambient temperatures in February were smaller because the cooling system was turned off in winter.

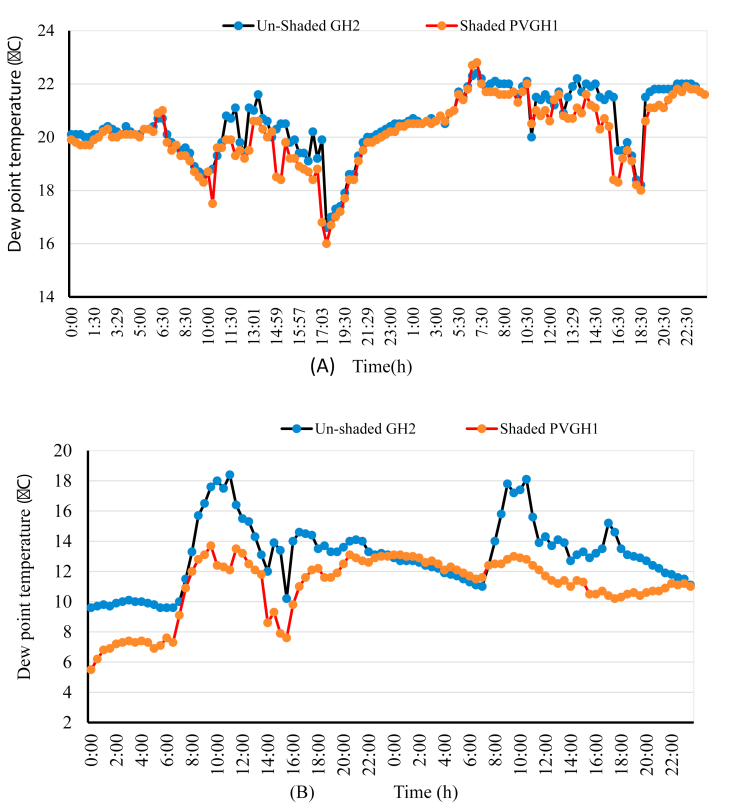

The results also showed that the dew point temperatures (Tdp) inside both greenhouses measured in September was higher than that measured in February. The lowest dew point temperature Tdp was 16 °C in September and 5 °C in February. The average Tdp inside the unshaded greenhouse was higher than that of the shaded greenhouse by 2–10 °C as shown in Figure 3(A),(B). It was also observed that the maximum Tdp in the unshaded greenhouse was 18.4 °C and the minimum was 9.5 °C while the maximum Tdp in the shaded greenhouse was 13.7 °C and the minimum was 5.5 °C in February due to the cold weather and the absent of the evaporative cooling.

Figure 3.

Dew point temperature (A) 24th September 2020, (B) 4th February, 2021.

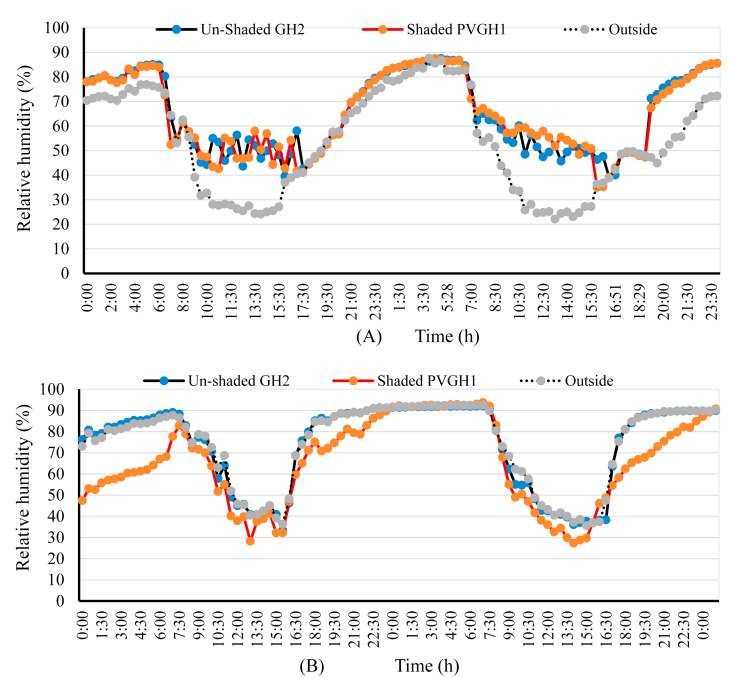

3.1.2. Relative humidity

Figure 4 shows that the average relative humidity in the PV shaded greenhouse was higher than that of the unshaded. The relative humidity varied from 20 to 35% throughout the day and from 70 to 85% at night in the PVGH during September while it ranged from 30 to 91% during February. It was observed that the minimum relative humidity outside the greenhouses was 21% at noon in September while the minimum relative humidity inside the shaded and unshaded greenhouses was 35.5% and 34.5 %, respectively as shown in Figure 4(A). However, there were no big differences in the average relative humidity at noon during February inside and outside the greenhouses as shown in Figure 4(B). The evaporative cooling increased the moisture ratio inside the greenhouse in September.

Figure 4.

Relative humidity (%) (A) 24th September 2020, (B) 4th February, 2021.

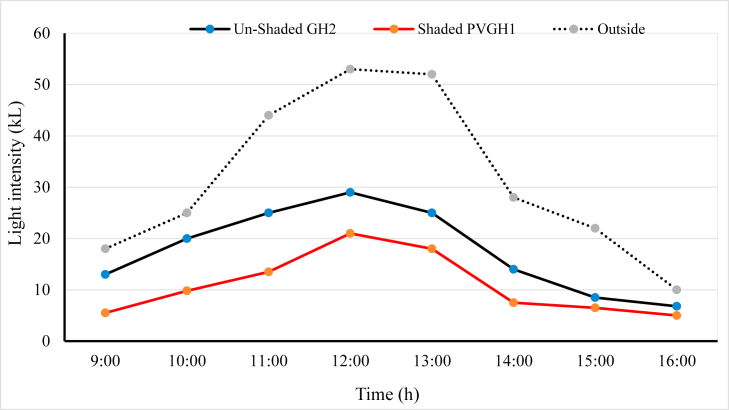

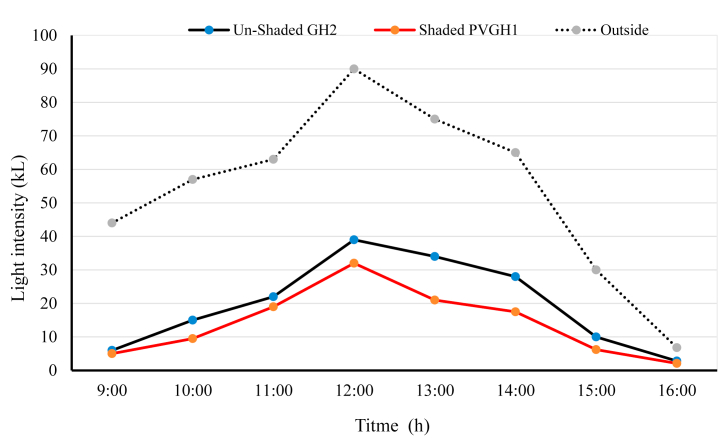

3.1.3. Light intensity

The results revealed that the light intensity measured in kilo lux (kL) in the shaded and unshaded greenhouses was lower than that measured outside the greenhouses. The light intensity measured at 1.5 m from the ground in the PV shaded greenhouse ranged from 5 to 21 kL (175 W m−2) in late December and from 2 kL to 33 kL (275 W m−2) in November which was only 25–50% of the outside light intensity. However, the light intensity measured at 1.5 m from the ground in the unshaded greenhouse ranged from 7 kL to 30 kL (250 W m−2) in late December ad from 3 kL to 39 kL (325 W m−2) in November which was only 30–80% of the outside light intensity. Meanwhile, the light intensity at the same level outside the greenhouses ranged from 10 to 54 KL (450 W m−2) in late December and from 7 to 90 kL (750 W m−2) in mid-November as shown in Figure 5 and Figure 6.

Figure 5.

Light intensity at 1.5 m from the ground on 28th December, 2020.

Figure 6.

Light intensity at 1.5 m from the ground on 16th November, 2020.

The light intensity in horticulture can be consider as a measure of the photosynthetic photon flux density (PPFD) and most of fruiting vegetables require it at the range of 200–600 μmol m−2 s−1 (Sui et al., 2012) and the low light intensity could prevent some photosynthesis in the plant (Dai et al., 2009; Zhao et al., 2012). A value of 200 W m−2 equals to 1000 μmol m−2 s−1 (Hassanien and Li, 2017). and 120 lx equals 1 W m−2 (Peter et al., 2020). Therefore, results indicated that the internal light under shaded greenhouse was appropriate for the growth of chili pepper.

3.2. Plant growth parameters and fruit quality

The morphological parameters for chili pepper measured in this study were length of plant, chlorophyll contents, flowers, concentration of Vitamin C in fruits and the fruit shelf life. All data were measured every week for 4 months (from September to December, 2020).

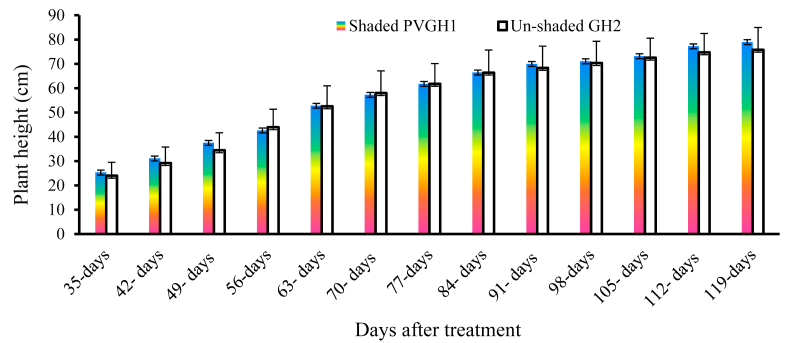

3.2.1. Plant height

The results illustrated that the partial shading of PV panels on the greenhouse had no significant effect of the pepper height as shown in Figure 7. However, plants in PVGH were slightly higher than that of the USGH because pepper required a moderate light intensity. However, the high level of shading could enlarge the plant stem and make it weak.

Figure 7.

The plant height after shading treatments, Vertical bars represent mean ± standard deviation at P < 0.05, (n = 20).

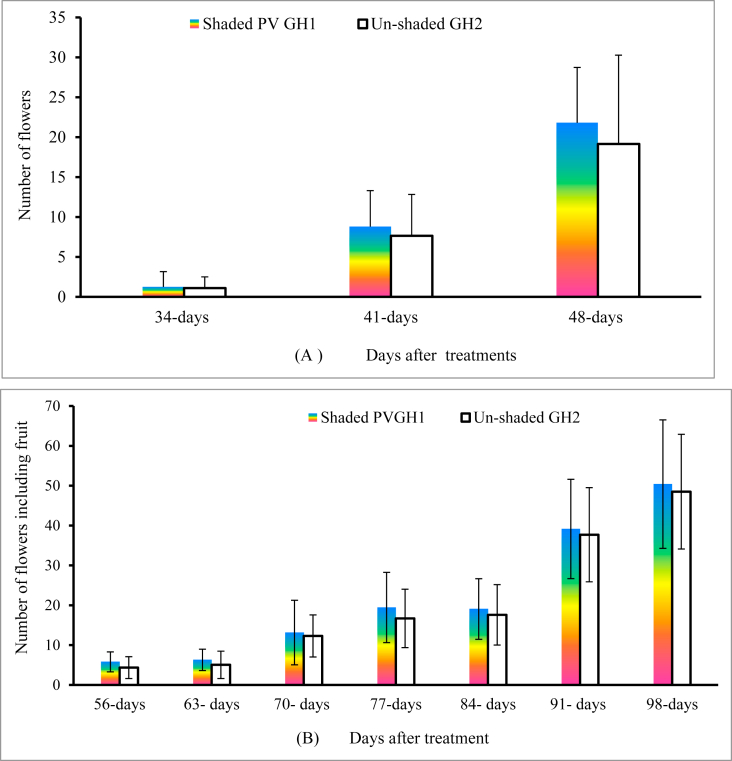

3.2.2. Number of flowers

It was observed that the number of flowers including fruit in the shaded greenhouse by PV panels (PVGH) was significantly higher than those in the unshaded greenhouse (USGH) in the first stage, particularly after 40–50 days of shading treatments in late September and early October as shown in Figure 8A. Due to the pepper prefer the moderate light and temperature for flowering. Subsequently, the variation was not significant because of the cold weather of early November and December as shown in Figure 8B. This indicated that the partial shading of PV could enhance the flowering stages and resulting in early marketing of yield.

Figure 8.

Number of flowers including fruit after shading treatments, Vertical bars represent mean ± standard deviation at P < 0.05, (n = 20).

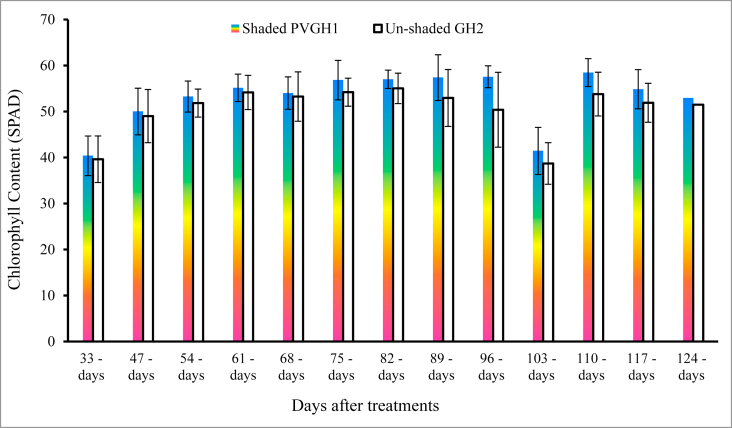

3.2.3. Effect of shading on the relative chlorophyll content

Figure 9 shows that the chlorophyll contents of shaded plants were insignificant higher than that of the unshaded plant ranging from 0.74 to 7 SPAD. In addition, the chlorophyll contents for plants in both greenhouses ranged from 40 to 57 SPAD. There were some fluctuations in the chlorophyll content due to the addition fertilizer to plants. Leaf chlorophyll content is a good indicator of chloroplast development, photosynthetic capacity, and leaf nitrogen content. Therefore, moderate shade levels of PV panels did not decrease the leaf chlorophyll content but slightly increased it. The results showed that, the growth of plant was improved which are in line with the previously published results (Agyemang Duah et al., 2021).

Figure 9.

Chlorophyll Content SPAD after shading treatments, Vertical bars represent mean ± standard deviation at P < 0.05, (n = 20).

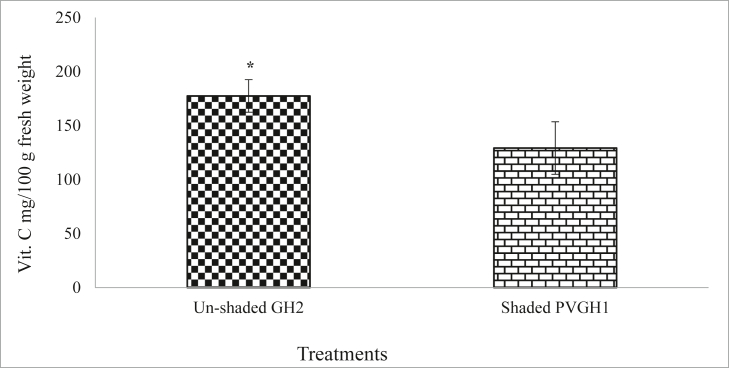

3.2.4. Effect of shading on the ascorbic acid (Vitamin C) of pepper fruit

The results revealed that Vitamin C (L-ascorbic acid) concentration in fruits of the unshaded plants was significantly higher than that of the PV shaded plants in the greenhouse. The vitamin C contents decreased as the shading ratio increased as shown in Figure 10. These results are in agreement with the previous studies (Dıáz-Pérez, 2019).

Figure 10.

Ascorbic acid concentration in pepper fruit under shaded and un-shaded greenhouses. (∗): represents a significant difference, Vertical bars represent mean ± standard deviation at P < 0.05, (n = 6).

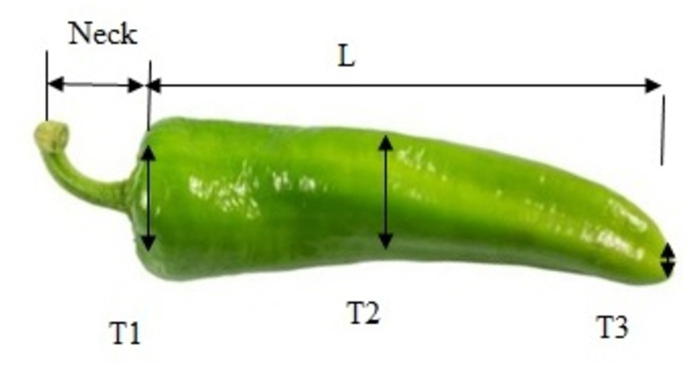

3.2.5. Yield and physical properties of chili fruit

The total yield of pepper grown in the PVGH was 142.81 kg while that of pepper grown in the USGH was 125.28 kg. The average yield per plant was 1.59 kg for the PVGH and 1.39 kg for the USGH. The yield in the PVGH was higher in the first three harvest periods which mean that the shading could enhance the flowering stage for early marketing. Therefore, the partial shading by PV insignificantly increased the total yield and improve the quality of the pepper production, Moreover, the physical properties and quality of the fruit for PVGH and USGH were better than those in the outside of greenhouses as shown in Table2. These results are in agreement with previous studies (Caruso et al., 2020) (see Figure 11).

Table 2.

The physical properties of chili pepper fruit.

| Greenhouse | Weight (gm) | Length L (cm) | Diameter T1 (mm) | Diameter T2 (mm) | Diameter T3 (mm) | Neck (cm) | Volume (cm3) | Density (g/cm3) |

|---|---|---|---|---|---|---|---|---|

| PVGH1 | 6.90 ± 2.4 | 12.32 ± 1.4 | 12.24 ± 2.1 | 10.38 ± 1.5 | 2.55 ± 0.7 | 3.95 ± 0.6 | 10.34 ± 3.5 | 0.67 ± 0.05 |

| USGH2 | 6.77 ± 1.9 | 12.08 ± 1.8 | 11.78 ± 2.0 | 10.03 ± 1.0 | 2.57 ± 1.2 | 4.05 ± 0.4 | 10.15 ± 2.5 | 0.67 ± 0.06 |

| Outside | 5.77 ± 1.7 | 11.22 ± 0.8 | 11.53 ± 1.6 | 9.75 ± 1.4 | 2.47 ± 0.6 | 4.03 ± 0.5 | 8.28 ± 2.2 | 0.70 ± 0.08 |

± represent standard deviation.

Figure 11.

Photo of chili pepper fruit with physical properties parameters.

It was observed that the weight loss percentage of pepper in the shaded greenhouse was little lower than that in the unshaded which resulted in a long shelf life for the shaded pepper as shown in Table 3. Thus, the quality of shaded fruit will be more favorite to the consumer.

Table 3.

Differential weight loss percentage of pepper under shaded and unshaded greenhouse.

| Storage period (days) | Shaded PVGH1 | Un-shaded USGH2 |

|---|---|---|

| 3 | 0.27 | 0.35 |

| 6 | 2.37 | 2.72 |

| 12 | 6.47 | 6.21 |

| 27 | 13.96 | 12.19 |

| 39 | 15.90 | 18.18 |

| 45 | 17.71 | 20.02 |

3.3. The generated electric power of PV panels

The generated electric power could be changed according to the tilt angle and the orientation of PV panels. The current experiment was implemented with manual tracking towards the South and East directions to generate more electric energy. The simulation results using the PVSYST V6.70 program revealed that the optimal tilt angle for the PV panels is 25° facing the South. Thus, the PV panels were fixed at this angle facing south and the estimated electric energy were 3705 kWh/year and 3698 kWh/year at a tilt angle of 25° and 30°, respectively. The generated electric energy were 3270 kWh/year and 3205 kWh/year at a tilt angle of 25° facing East and West directions, respectively. Therefore, the generated electric energy could cover most of the annual electric energy consumption for the cooling system. The electric energy consumption for the cooling system is about 9–10 kWh/day when it works continuously for 6–7 h per day.

4. Conclusion

The effects of PV shading on the growth of chili pepper (Capsicum annuum cv. Omega) and microclimate in greenhouses were investigated. The results revealed that the integration of PV panels into the greenhouse had no significant effect on the growth parameters (plant height, chlorophyll content, and number of flowers including fruits) of pepper. However, the concentration of C vitamin in fruit significantly decreased under PV shading. The internal air temperatures in the USGH were insignificantly higher than that in the PVGH. The relative humility in the PVGH were higher than that of the USGH. The light intensity in the PVGH were lower than that of the USGH at 1.5 m from the ground by 25–40%. The yield of chili pepper in the PVGH greenhouse was insignificant higher than that of the USGH by 14%. The results indicated that the partial shading of PV panel could speed up the flowering stage which results in early harvest for pepper and early marketing at higher price and it could also extend shelf life of fruits. The estimated electric energy was 3705 kWh/year when the PV panels were facing South at a tilt angle of 25° which could partially replace the electric energy consumption for heating and cooling demand. Further studies should be conducted under the Egyptian conditions to determine the most suitable vegetables for production in greenhouses with integrated PV panels on the roof.

Declarations

Author contribution statement

Reda Hassanien Emam Hassanien: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

M. M. Ibrahim: Conceived and designed the experiments; Performed the experiments; Wrote the paper.

A.E. Ghaly: Analyzed and interpreted the data; Wrote the paper.

E. N. Abdelrahman: Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Funding statement

This work was supported by Science, Technology & Innovation Funding Authority (STDF) of Egypt under grant number (33456).

Data availability statement

Data included in article/supplementary material/referenced in article.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- Agyemang Duah S., Nagy Z., e Souza C.S., Pék Z., Neményi A., Helyes L. Effect of net shading technology on the yield quality and quantity of chilli pepper under greenhouse cultivation. Acta Agraria Debreceniensis. 2021:5–9. [Google Scholar]

- Aroca-Delgado R., Pérez-Alonso J., Callejón-Ferre Á J., Velázquez-Martí B. Compatibility between crops and solar panels: an overview from shading systems. Sustainability. 2018;10 [Google Scholar]

- Caruso G., Cozzolino E., Cuciniello A., Maiello R., Cenvinzo V., Giordano M., de Pascale S., Rouphael Y. Yield and quality of greenhouse organic pepper as affected by shading net in Mediterranean area. Acta Hortic. 2020:335–339. [Google Scholar]

- Cossu M., Yano A., Solinas S., Deligios P.A., Tiloca M.T., Cossu A., Ledda L. Agricultural sustainability estimation of the European photovoltaic greenhouses. Eur. J. Agron. 2020;118 [Google Scholar]

- Dai Y., Shen Z., Liu Y., Wang L., Hannaway D., Lu H. Effects of shade treatments on the photosynthetic capacity, chlorophyll fluorescence, and chlorophyll content of tetrastigma hemsleyanum diels et gilg. Environ. Exp. Bot. 2009;65:177–182. [Google Scholar]

- Dıáz-Pérez J.C. Light level under shading nets affects bell pepper (Capsicum annuum L.) fruit mineral nutrients. Acta Hortic. 2019:159–161. [Google Scholar]

- Friman-Peretz M., Ozer S., Geoola F., Magadley E., Yehia I., Levi A., Brikman R., Gantz S., Levy A., Kacira M., Teitel M. Microclimate and crop performance in a tunnel greenhouse shaded by organic photovoltaic modules – comparison with conventional shaded and unshaded tunnels. Biosyst. Eng. 2020;197:12–31. [Google Scholar]

- Gorjian S., Calise F., Kant K., Ahamed M.S., Copertaro B., Najafi G., Zhang X., Aghaei M., Shamshiri R.R. A review on opportunities for implementation of solar energy technologies in agricultural greenhouses. J. Clean. Prod. 2021;285:124807. [Google Scholar]

- Hassanien R.H.E., Li M. Influences of greenhouse-integrated semi-transparent photovoltaics on microclimate and lettuce growth. Int. J. Agric. Biol. Eng. 2017;10:11–22. [Google Scholar]

- Hassanien R.H.E., Li M., Tang Y. The evacuated tube solar collector assisted heat pump for heating greenhouses. Energy Build. 2018;169:305–318. [Google Scholar]

- Hassanien R.H.E., Li M., Yin F. The integration of semi-transparent photovoltaics on greenhouse roof for energy and plant production. Renew. Energy. 2018;121:377–388. [Google Scholar]

- Horwitz W.L.G.W. AOAC International; Gaithersburg, Md: 2005. Official Methods of Analysis of. [Google Scholar]

- Kavga A., Strati I.F., Sinanoglou V.J., Fotakis C., Sotiroudis G., Christodoulou P., Zoumpoulakis P. Evaluating the experimental cultivation of peppers in low-energy-demand greenhouses. An interdisciplinary study. J. Sci. Food Agric. 2019;99:781–789. doi: 10.1002/jsfa.9246. [DOI] [PubMed] [Google Scholar]

- La Notte L., Giordano L., Calabrò E., Bedini R., Colla G., Puglisi G., Reale A. Hybrid and organic photovoltaics for greenhouse applications. Appl. Energy. 2020;278:115582. [Google Scholar]

- Li Z., Yano A., Yoshioka H. Feasibility study of a blind-type photovoltaic roof-shade system designed for simultaneous production of crops and electricity in a greenhouse. Appl. Energy. 2020;279:115853. [Google Scholar]

- Lima V.A., Pacheco F.V., Avelar R.P., Alvarenga I.C.A., Pinto J.E.B.P., de Alvarenga A.A. Growth, photosynthetic pigments and production of essential oil of long-pepper under different light conditions. An. Acad. Bras. Cienc. 2017;89:1167–1174. doi: 10.1590/0001-3765201720150770. [DOI] [PubMed] [Google Scholar]

- Magadley E., Teitel M., Peretz M.F., Kacira M., Yehia I. Outdoor behaviour of organic photovoltaics on a greenhouse roof. Sustain. Energy Technol. Assessments. 2020;37:100641. [Google Scholar]

- Mahmood A., Hu Y., Tanny J., Asante E.A. Effects of shading and insect-proof screens on crop microclimate and production: a review of recent advances. Sci. Hortic. 2018;241:241–251. [Google Scholar]

- Marrou H., Guilioni L., Dufour L., Dupraz C., Wery J. Microclimate under agrivoltaic systems: is crop growth rate affected in the partial shade of solar panels? Agric. For. Meteorol. 2013;177:117–132. [Google Scholar]

- Peter R.M., Danvers E. Johnston, Moreno Wilfrido. A conversion guide: solar irradiance and lux illuminance. J. Meas. Eng. 2020;8:153–165. [Google Scholar]

- Ravishankar E., Booth R.E., Saravitz C., Sederoff H., Ade H.W., O’Connor B.T. Achieving net zero energy greenhouses by integrating semitransparent organic solar cells. Joule. 2020;4:490–506. [Google Scholar]

- Rigakis N., Katsoulas N., Belitsiotis P., Kittas C., Bartzanas T. Pepper crop production under shading and insect proof screenhouses. Acta Hortic. 2014:599–604. [Google Scholar]

- Rylski I., Spigelman M. Effect of shading on plant development, yield and fruit quality of sweet pepper grown under conditions of high temperature and radlation. Sci. Hortic. 1986;29:31–35. [Google Scholar]

- Sarıbaş H.Ş., Saka A.K., Özer H. Mathematical growth model for organically grown pepper transplants. Biol. Agric. Hortic. 2018;34:10–17. [Google Scholar]

- Sui X.-l., Mao S.-l., Wang L.-h., Zhang B.-x., Zhang Z.-x. Effect of low light on the characteristics of photosynthesis and chlorophyll a fluorescence during leaf development of sweet pepper. J. Integr. Agric. 2012;11:1633–1643. [Google Scholar]

- Waller R., Kacira M., Magadley E., Teitel M., Yehia I. Semi-transparent organic photovoltaics applied as greenhouse shade for spring and summer tomato production in arid climate. Agronomy. 2021;11:1152. [Google Scholar]

- Waskar D.P., Khedlar R.M., Garande V.K. Effects of postharvest treatment on the shelf life and quality of pomegranate in evaporative cooling chamber and ambient conditions. J. Food Sci. Technol. 1999;2:114–117. [Google Scholar]

- Zhao D., Hao Z., Tao J. Effects of shade on plant growth and flower quality in the herbaceous peony (Paeonia lactiflora Pall.) Plant Physiol. Biochem. (Paris) 2012;61:187–196. doi: 10.1016/j.plaphy.2012.10.005. [DOI] [PubMed] [Google Scholar]

- Zisis C., Pechlivani E.M., Tsimikli S., Mekeridis E., Laskarakis A., Logothetidis S. Organic photovoltaics on greenhouse rooftops: effects on plant growth. Mater. Today Proc. 2019;19:65–72. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data included in article/supplementary material/referenced in article.