Introduction

Indoor pollutant sources are ubiquitous. Volatile organic compounds (VOCs) and semi-volatile organic compounds (SVOCs) are among the broad classes of compounds found in the indoor environment through emissions and leaching from building materials, furnishings and human activities such as cooking, cleaning, use of consumer products etc. VOCs are organic chemicals with saturation vapour pressures greater than 10−2 kPa at 25°C, whereas SVOCs are those with saturation vapour pressures between 10−2 and 10−8 kPa at 25°C. 1 The resulting air pollutants can be transported from sources to indoor air, surfaces, settled dust and airborne particles.

Human exposure to VOCs and SVOCs occurs by direct contacts through hand and other skin surfaces, ingestion through hand-to-mouth and diet activities, and inhalation of gases and airborne particles. SVOCs have relatively low vapour pressure and are easier to adhere to particles compared to VOCs. The interaction between SVOCs and indoor dust is complex due to the small size, the great surface area-to-volume ratio, surface settling and re-suspension of the dust particles. Chemicals in indoor dust particles is an important exposure source for humans. The exposure is revealed in the literature by correlations between the concentration of a pollutant in indoor dust and that in human body fluids and tissues. 2-5

The role of indoor dust as an exposure source has been gaining increased attention over the years. There are several literature reviews on the occurrence and levels of organic pollutants in house dust2-5 and they summarize broadly available information about the sources, concentration levels and the pollutant’s relevance to human exposure. This editorial presents a summary of studies on per- and polyfluoroalkyl substances (PFAS), polychlorinated biphenyls (PCBs), and organophosphorus flame retardants (OPFRs) in settled dust in the indoor environment. This overview is not intended as a comprehensive review of these SVOCs in indoor dust studies. Rather, it serves as a brief discussion of the available information associated with the fate and transport mechanisms of these chemicals in indoor dust and highlights the need for experimental and empirical emission and mass transfer data for their source and exposure modelling.

Indoor Dust

In the EPA Exposure Factors Handbook Chapter 5, 6 indoor settled dust is defined as

Particles in building interiors that have settled onto objects, surfaces, floors and carpeting. These particles may include soil particles that have been tracked or blown into the indoor environment from outdoors, as well as organic matters.

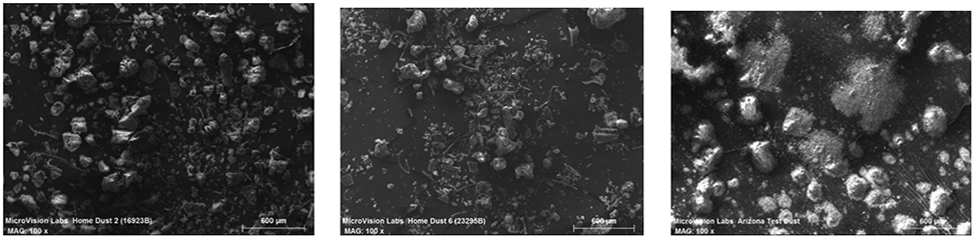

Indoor dust is different in origin, properties and composition. Size distribution and properties of indoor dust vary widely dependent upon human activities and the indoor microenvironment, such as home, workplace, schools, childcare facilities, commercial buildings, etc. In field practice, indoor dust sampling should consider the age and location of the dust. For illustrative purposes, Table 1 lists properties of samples from two types of house dust (HD) measured and compared with reference material Arizona Test Dust (ATD) and Figure 1 shows the scanning electron microscope (SEM) images of these three dust types. As we can see, the particle size, shape, density and organic carbon content in the three types of dust are significantly different.

Table 1.

Properties of the dust samples (Reproduced with permission from Liu and Folk7)

| Property | Dust Type |

||

|---|---|---|---|

| HD2 | HD6 | ATD | |

| Weight by volume, g/mL a | 0.938 ± 0.008 | 0.661 ± 0.019 | 0.723 ± 0.016 |

| Surface area, m2/g b, c | 3.599 ± 0.017 | 3.894 ± 0.017 | 10.323 ± 0.025 |

| Particle size – mean, μm b, d | 67.882 ± 0.209 | 90.510 ± 0.273 | 4.346 ± 0.008 |

| Particle size – range, μm b, e | 0.922 to 260 | 0.870 to 309 | 0.291 to 103 |

| Total carbon, % (w/w) f | 20.83 ± 0.48 f | 12.5 g | 1.03 ± 0.13 f |

| Organic carbon, % (w/w)f | 20.11 ± 0.56 f | 12.2 g | 1.03 ± 0.13 f |

Arithmetic mean ± standard deviation (SD) (n = 2); measured at room temperature by gravimetric method.

Analyzed by Micromeritics Analytical Services.

Arithmetic mean ± SD (n = 2); method: Brunauer-Emmett-Teller (BET) method with N2.

Weighted mean value ± SD (n = 2); method: light scattering (ISO 13320).

Method: light scattering (ISO 13320).

Arithmetic mean ± SD (n = 4); method: NIOSH 5040.

Estimate from the average of two separate dust samples.

Figure 1.

SEM images for different dust, left - House Dust 2, middle - House Dust 6, right – Arizona Test Dust. The scale is 600 μm. (Reproduced with permission from Liu and Folk7)

There are several scenarios of how dust settles on indoor surfaces: (1) dust without chemicals settled on a surface without a contaminated source; (2) dust without chemicals settled on a contaminated source surface; (3) dust with chemicals settled on a surface without a contaminated source; (4) dust with chemicals settled on a contaminated source surface. Indoor dust is a sink for indoor chemicals since it absorbs chemicals in the air. When the dust settles on a contaminated source surface, settled particles may interact with the surface materials through direct contact and pollutants can migrate to the dust and to the surface. Settled dust can consecutively re-suspend in the air. Indoor dust can also be generated by deterioration of indoor materials or consumer products. Thus, chemicals identified in dust particles reflect the types and levels of contamination in the indoor environment.

SVOCs in Indoor Dust

The SVOCs frequently reported in indoor dust are polychlorinated biphenyls (PCBs), polycyclic aromatic hydrocarbons, per- and polyfluoroalkyl substances (PFASs), flame retardants, phthalate, musks/fragrances and pesticides with concentrations between pg/g and a few mg/g of indoor dust. 2 Due to space restriction, this editorial only focuses on the inadvertent generated PCBs (iPCBs), PFASs and organophosphate flame retardants (OPFRs) in indoor dust that have been studied in recent years in the laboratory of United States Environmental Protection Agency’s Center for Environmental Measurement and Modeling.

Inadvertent generated PCBs

PCBs in the indoor environment have received significant attention by researchers for decades. The presence of legacy PCBs in indoor dust was determined worldwide by different sampling methods. Their concentrations range from <1 to 890 μg/g. 8 Although commercial PCB production was banned in 1979 in the USA, the presence of iPCBs has been associated with chemical production processes. For example, the most studied process leading to iPCB contamination is the production of diarylide yellow pigment and the resulting creation of PCB-11. Other iPCBs found in pigments and consumer products include PCB-28, PCB-52, PCB-77, as well as the nonachlorinated PCBs and PCB-209. 9 Inadvertent PCBs have been detected in pigmented consumer products with concentrations up to parts per million. 10 Few studies reported concentrations of iPCBs in indoor dust. Recent studies have determined the concentrations of PCB-11 in indoor dust in the range of 0.5-0.9 ng/g, while concentrations of PCB-209 were much lower.11 The role of iPCB-contaminated dust in human exposure has not yet been well characterized.

Organophosphorus flame retardants (OPFRs)

OPFRs, such as tris(2-chloroethyl) phosphate (TCEP), tris(1-chloro-2-propyl) phosphate (TCPP), and tris(1,3-dichloro-2-propyl) phosphate (TDCPP), are additives to manufactured products to reduce flammability and serve as plasticizers but can leach and accumulate in dust on surfaces. Elevated OPFR concentrations in indoor dust have been reported by many researchers globally. For instance, thirteen organophosphate esters, including TCPP, TCEP and TDCPP, were measured in most of the house dust samples from 134 urban Canadian homes by Fan et al. 12 Tajima et al. 13 measured the levels of ten OPFRs in indoor floor dust and upper surface dust from 128 Japanese dwellings of families with children in elementary school. The concentrations of TCPP, one of the main OPFRs in the dust, was reported to be < 0.56 to 621 μg/g and of TCEP to be < 0.65 to 92 μg/g. TCEP exceeded 50% detection rates in the upper surface dust with significant positive correlation (P < 0.05) between the concentrations of TCPP in floor dust and upper surface dust (n = 48). OPFRs were identified in dust from 497 homes and 151 daycare centres in Demark by Langer et al. 14. The median mass fraction of TCEP from homes was 6.9 μg/g, and that of TCEP from the daycare centres was 16 μg/g, in addition to TCPP at 5.6 μg /g, and TDCPP at 7.1 μg/ g. The maximum concentration was 1800 μg/g for TCEP and 350 μg/g for TCPP in daycare centres and 860 μg/g for TDCPP in homes. OPFRs in dust were also measured in building material markets, private cars, floor/carpet stores, offices, bedrooms and schools 15, 16 with the total concentration ranging from 5.9 to 4800 μg/g.

Per- and polyfluoroalkyl substances (PFASs)

PFASs have been detected in numerous consumer products 18-21 and are considered emerging contaminants by US EPA. 20 Widespread use of PFAS and their ubiquitous presence in the environment caused continuous exposure to most people in the USA. Research shows that cumulative exposure to certain PFAS may lead to adverse health effects 20-22 PFASs in indoor dust have been reported by a few studies internationally with a large variety in concentrations ranging from below the detection limit to hundreds of ng/g, or even μg/g. 3, 23-29 PFASs that were frequently determined at high concentrations in dust are perfluorooctanoic acid (PFOA), perfluorooctane sulfonate (PFOS) and fluorotelomer alcohols (6:2 FTOH, 8:2 FTOH). 2 The large difference between concentrations of PFASs in dust in different regions is associated with their presence in personal consumer products and the usage of household products or materials in addition to discrepancies of dust sampling methods and locations. 4, 30 Some of the PFASs in indoor dust data up to 2017 have been summarized in the review by Lucattini et al3. Notably, more research has been conducted to address the presence of indoor dust and its implications to human exposure to PFAS in recent years. 23-29

For example, Winkens, et al. 23 investigated 65 floor dust samples collected from children’s bedrooms in Finland for 62 PFAS analytes. The dust samples were dominated by polyfluoroalkyl phosphoric acid esters (PAPs) and FTOHs while five perfluoroalkyl carboxylic acids (PFCAs) and PFOS were detected in more than half of the samples in addition to PFOA median concentration of 5.26 ng/g. Eighty-one indoor air samples and 29 indoor dust samples were collected from rooms of homes and hotels, textile shops and cinemas in Tianjin, China by Yao et al 24 with FTOHs being the predominant PFASs found in hotel dust (24.8 - 678 ng/g). In 2020, evaluated PFAS in indoor dust from 184 homes in North Carolina and 49 fire stations across the US and Canada were collected and analyzed by Hall et al 25. The data shows that FTOHs and di-polyfluoroalkyl phosphoric acid esters (diPAPs) were the most prevalent PFAS in both fire station and house dust samples, with the median in the range of approximately 100 ng/g dust or greater. In addition, PFAS detected in dust samples collected from childcare centres in USA, 26, 27 from cars, homes, offices and school classrooms in Ireland, 28 and in working microenvironments (internet cafes, electronics shops, coffee shops, restaurants, etc.) in Greece29 had a total PFAS concentrations ranging from several to thousands of ng/g.

Mass Transfer Mechanisms

While SVOCs in indoor dust have been identified as a major source of indoor contamination, understanding SVOC distribution and the transport mechanisms between chemicals, dust and surrounding environments will help characterize the exposure pathways.

The mass transfer mechanisms that are responsible for SVOC transport from sources to dust include absorption, desorption, dust-air and dust-material partitioning, particle formation through abrasion, and migration via direct contact between SVOCs sources and dust. Those mass transfer processes are controlled by the physicochemical properties of SVOCs, such as vapour pressure (VP), octanol-air partitioning coefficient (KOA), dust-air equilibrium partition coefficient (Kda), dust diffusion coefficients (Dd), and dust-source material partition coefficient (Kds). Vapour pressure and KOA are properties of the chemical itself, whereas dKda, Dd and Kds also depend on properties of materials and dust. At the steady state, if Kda is known, unknown SVOC concentrations in the gas-phase can be calculated based on their measured concentrations in settled dust. These parameters can be applied to predict emissions and concentrations of SVOCs in air and dust for source and exposure models. The Kda, Kds and Dd parameters are essential for the determination of dynamic process and further the inhalation, dermal and dust ingestion exposures.

Despite the fact that numerous studies are available in the literature to measure SVOC concentrations in indoor dust and examine correlations between contaminated dust and exposure, few studies have systematically looked into the mass transfer process between SVOCs from different sources and dust. The existing data has been mainly for phthalate and brominated flame retardants with most of them being calculated by empirical equations using VP and KOA. Table 2 summarizes experimentally determined Kda (Kda’), Kds and Dd of PCB, OPFR, and PFAS available in the literature. As we can see, at present, experimentally determined values of these parameters are scarce, especially for PFAS. There is a clear need for experimental investigation.

Table 2.

Experimentally determined diffusion and partition coefficients of PCB, OPFR and PFAS from literature

| Chemicals | Kda’ (m3/g) | Kdaa (dimensionless) | Dd (m2/h) | Kds (dimensionless) | Ref |

|---|---|---|---|---|---|

| (HD/primer) | 8 | ||||

| PCB-52 | 0.04 | ||||

| PCB-66 | 0.12 | ||||

| PCB-101 | 0.11 | ||||

| PCB-105 | 0.14 | ||||

| PCB-110 | 0.11 | ||||

| PCB-118 | 0.16 | ||||

| PCB-154 | 0.08 | ||||

| PCB-187 | 0.16 | ||||

| PCB-52 | 8.8 × 106 | 4.0 × 10−14 | 31 | ||

| PCB-101 | 2.5 × 107 | 1.9 × 10−14 | |||

| PCB-110 | 3.5 × 107 | 1.9 × 10−14 | |||

| PCB-118 | 5.5 × 107 | 1.9 × 10−14 | |||

| PCB-8 | 1.6 | 6.3 × 105 | 32 | ||

| PCB-18 | 2.0 | 7.9 × 105 | |||

| PCB-28 | 6.3 | 2.5 × 106 | |||

| PCB-31 | 6.3 | 2.0 × 106 | |||

| PCB-44 | 12.3 | 5.0 × 106 | |||

| PCB-52 | 10.0 | 4.0 × 106 | |||

| PCB-66 | 39.8 | 1.6 × 107 | |||

| PCB-75 | 25.1 | 1.0 × 107 | |||

| PCB-99 | 50.1 | 2.0 × 107 | |||

| PCB-101 | 39.8 | 1.6 × 107 | |||

| TCPP | 29 (HD/foam) | 33 | |||

| TCEP | 85.5 (ATD/foam) | 6.3 × 107 (ATD/foam) | 1.3 × 10−2 (ATD/foam) | 7 | |

| 20.8 (HD/foam) | 2.0 × 107 (HD/foam) | 6.0 × 10−3 (HD/foam)b | |||

| 5.21 (HD/paint) | 4.9 × 106 (HD/paint) | 0.8 (HD/paint) | |||

| TCPP | 224.4 (ATD/foam) | 1.6 × 108 (ATD/foam) | 1.8 × 10−2 (ATD/foam) | 7 | |

| 14.8 (HD/foam) | 1.4 × 107 (HD/foam) | 6.5 × 10−3 (HD/foam)b | |||

| 3.4 (HD/paint) | 3.2 × 106 (HD/paint) | 0.55 (HD/paint) | |||

| TDCPP | 13.7 (ATD/foam) | 1.0 × 107 (ATD/foam) | 3.5 × 10−3 (ATD/foam) | 7 | |

| 273.8 (HD/foam) | 2.6× 108 (HD/foam) | 5.9 × 10−3 (HD/foam)b | |||

| 42.8 (HD/paint) | 4.0× 106 (HD/paint) | 0.39 (HD/paint) | |||

| 6:2 FTOH | 10-1000 | 23 | |||

| 8:2 FTOH 10:2 | |||||

| FTOH PFHxA | |||||

| PFOA | |||||

| PGNA | |||||

| PFOS PFDoDA | |||||

| PFDA | |||||

| EtFOSE |

Kda is dimensionless, Kda can be converted to Kda’, which is the dust-air partition coefficient in unit of m3/g, using .

Average (n = 3)

Methodology for Studying SVOC Dust Interaction

The direct measurement of emission, sorption and migration of SVOCs from consumer products and materials and settled dust is typically carried out using various environmental chambers (Table 3). The environmental conditions of those chambers, such as temperature, relative humidity, air exchange rate and air velocity, are often well controlled to avoid interferences. These chamber methods have been mainly used for measuring concentrations of SVOCs in the air and dust after the SVOC-dust interaction. Challenges for using these methods to obtain the Kda, Kds and Dd parameters include but are not limited to (1) characteristics of the dust in terms of size, shape, surface area, porosity, morphology, density, etc; (2) the ability to maintain a constant SVOC concentration in dust; and (3) the ability to reach steady-state conditions in the testing system over a long period of experimental time. As a result, our knowledge of and ability to model the fate and transport of SVOCs to house dust remains limited and there is a clear need for consistent data to reduce the variability and uncertainty in the estimation of SVOC exposures via house dust. Appropriate design and modification for experimental investigation are in great demand.

Table 3.

Methods for studying mass transfer between SVOCs and dust a

| Mechanisms | Chambers | Chemicals | Dust | Source Materials | Ref |

|---|---|---|---|---|---|

| Sorption | CLIMPAQ | DEHP | House dust | PVC flooring | 34 |

| Direct contact Sorption Abrasion | 500-L stainless steel chamber; 2.8-L glass flask | DEHP; DnBP | HD sand (SiO2); flower soil, | Plasticized PVC polymer and wall paint | 35 |

| Direct contact Abrasion Emission | 1.57-L stainless steel cylinder chamber | PBDEs | House dust | Plastic TV casing treated with the Deca-BDE formulation | 36 |

| Emission Sorption | 1.57-L stainless steel cylinder chamber; micro chamber | PBDEs; HBCDs | House dust | Fabric curtains treated with the HBCD technical formulation | 36 |

| Direct contact Sorption | 30-m3 stainless steel Large chamber | PCBs | House dust; ATD | Aluminium sheets coated with a PCB-spiked primer or caulk. | 8 |

| Direct contact Sorption Emission | 53-L stainless steel small chamber | OPFRS | 2 types House dust; ATD | Release paper coated with paint, OPFR polyisocyanurate rigid foam | 7 |

| Direct contact with temperature | Specifically designed small chamber; FLEC | DEHP; DINP | Standard dust composed of 7:3 weight ratio of standard mineral dust to standard wood powder dust; House dust | PVC flooring materials | 37 |

| Direct contact | Micro chamber | TCPP | Standard Reference Material dust | TCPP-treated polyisocyanurate insulation board | 33 |

| Direct Contact Emission | 328-cm3 round glass chamber | HBCD; BEHTBP; TBBPA; HBBZ | dust | Decorative laminate, cotton sound insulation, PVC floor, and carpet | 38 |

| Direct contact | Petri dish | HBCD | Artificial indoor dust, HD | HBCD-treated curtains | 39 |

| Direct contact | A surface electropolished stainless passive flux sampler | DEHP | House dust | PVC sheet | 40 |

| Direct contact | 10-L stainless steel canister | DnBP; BBzP, DEHP, DEHA, and DINCH. | House dust | vinyl flooring, crib mattress cover | 41 |

| Direct contact | Micro chamber; stainless-steel emission cell | TDCPP; TCPS | Standard Reference Material (SRM) 2585 dust | flame-retardant-treated polyester curtains | 42 |

| Sorption | Vacated apartment room | PCB-29, 52, 101, 138, 153, 180, 8, 18, 31, 44, 66, 74, 99, 105 | House dust | on sheets of aluminium foil (29 cm x 29 cm) lying on the floor, | 32 |

CLIMPAQ (Chamber for Laboratory Investigations of Materials, Pollution, and Air Quality); DEHP (di(2-ethylhexyl)phthalate); DnBP (di-n-butyl phthalate); PBDE (polybrominated diphenyl ether); HBCD (hexabromocyclododecane); DINP (di-isononyl phthalate); FLEC (Field and Laboratory Emission Cell); BEHTBP (bis(2-ethyl-1-hexyl) tetrabromophthalate); TBBPA (tetrabromobisphenol A); HBBZ (hexabromobenzene); BBzP (benzyl butyl phthalate); DEHA (bis(2-ethylhexyl) adipate); DINCH (1,2-cyclohexane dicarboxylic acid diisononyl ester); TCPS (tricresyl phosphate).

Concluding Remarks

Chemical exposures via contaminated dust is unquestionable. Extensive research has been focused on investigating pollutant concentrations in dust or in the environment and biomarkers. An understanding of the fate and transport and exposure pathways of SVOCs in dust is the critical link between the two research areas. More studies are needed to generate sufficient information and data regarding fate and transport and exposure of chemicals in indoor dust by developing measurement methods, obtaining key parameters that control the dynamic mass transfer process and investigating the exposure pathways. This research will support scientific and public health institutions to understand the dust mode of exposure of SVOCs and inform public health protection measures.

Footnotes

Disclaimer

The views expressed in the editorial are those of the authors and do not necessarily represent the view or policies of the U.S. Environmental Protection Agency.

References

- 1.ASTM D1356-20a. Standard terminology relating to sampling and analysis of atmospheres. ASTM International, West Conshohocken, PA, 2020. [Google Scholar]

- 2.Mercier F, Glorennec P, Thomas P, Le Bot B. Organic contamination of settled house dust, A review for exposure assessment purposes. Environ. Sci. Technol 2011; 45: 6716–6727. [DOI] [PubMed] [Google Scholar]

- 3.Lucattini L, Poma G, Covaci A, de Boer J, Lamoree MH, Leonards PEG. A review of semi-volatile organic compounds (SVOCs) in the indoor environment: occurrence in consumer products, indoor air and dust. Chemosphere 2018; 201: 466–482. [DOI] [PubMed] [Google Scholar]

- 4.Melymuk L, Demirtepe H, RozárkaJílková S. Indoor dust and associated chemical exposures. Current Opinion in Environmental Science & Health 2020; 15: 1–6. [Google Scholar]

- 5.Hou M, Shi Y, Na G, Cai Y. A review of organophosphate esters in indoor dust, air, hand wipes and silicone wristbands: Implications for human exposure. Environ. Int 2021; 146: 106261. [DOI] [PubMed] [Google Scholar]

- 6.US EPA. Update for Chapter 5 of the Exposure Factors Handbook, Soil and dust ingestion. 2017, https://ofmpub.epa.gov/eims/eimscomm.getfile?p_download_id=532518 (accessed July 5, 2021)

- 7.Liu X, Folk EE IV. Sorption and migration of organophosphate flame retardants between sources and settled dust. Chemosphere 2021; 278: 130415. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Liu X, Guo Z, Krebs KA, Greenwell DJ, Roache NF, Stinson RA, Nardin JA, Pope RH. Laboratory study of PCB transport from primary sources to settled dust. Chemosphere 2016; 149: 62–69. [DOI] [PubMed] [Google Scholar]

- 9.Vorkamp K. An overlooked environmental issue? A review of the inadvertent formation of PCB-11 and other PCB congeners and their occurrence in consumer products and in the environment. Sci. Total Environ 2016; 514: 1463–1476. [DOI] [PubMed] [Google Scholar]

- 10.Department of Ecology State of Washington, Polychlorinated biphenyls in consumer products. 2016, https://apps.ecology.wa.gov/publications/documents/1604014.pdf (accessed July 5, 2021)

- 11.Anh HQ, Watanabe I, Minh TB, Takahashi S. Unintentionally produced polychlorinated biphenyls in pigments: An updated review on their formation, emission sources, contamination status, and toxic effects. Sci. Total Environ 2021; 755: 142504. [DOI] [PubMed] [Google Scholar]

- 12.Fan X, Kubwabo C, Rasmussen PE, Wu F. Simultaneous determination of thirteen organophosphate esters in settled indoor house dust and a comparison between two sampling techniques. Sci. Total Environ 2014; 491-492: 80–86. [DOI] [PubMed] [Google Scholar]

- 13.Tajima S, Araki A, Kawai T, Tsuboi T, Ait Bamai Y, Yoshioka E, Kanazawa A, Cong S, Kishi R. Detection and intake assessment of organophosphate flame retardants in house dust in Japanese dwellings. Sci. Total Environ 2014, 478: 190–199. [DOI] [PubMed] [Google Scholar]

- 14.Langer S, Fredricsson M, Weschler CJ, Bekö G, Strandberg B, Remberger M, Toftum J, Clausen G. Organophosphate esters in dust samples collected from Danish homes and daycare centers. Chemosphere 2016; 154: 559–566. [DOI] [PubMed] [Google Scholar]

- 15.Zheng X, Qiao L, Covaci A, Sun X, Guo H, Zheng J, Luo X, Xie Q, Mai B. Brominated and phosphate flame retardants (FRs) in indoor dust from different microenvironments: implications for human exposure via dust ingestion and dermal contact. Chemosphere 2017; 184:185–191. [DOI] [PubMed] [Google Scholar]

- 16.Zhou L, Hiltscher M, Püttmann W. Occurrence and human exposure assessment of organophosphate flame retardants in indoor dust from various microenvironments of the Rhine/Main Region, Germany. Indoor Air 2017; 27 (6): 1113–1127. [DOI] [PubMed] [Google Scholar]

- 17.Guo Z, Liu X, Krebs KA, Roache FN. Perfluorocarboxylic acid content in 116 articles of commerce. U.S. Environmental Protection Agency, Washington, DC, EPA/600/R-09/033, March 2009. [Google Scholar]

- 18.Liu X, Guo Z, Krebs AK, Pope HR, Roache RF. Concentrations and trends of perfluorinated chemicals in potential indoor sources from 2007 through 2011 in the US. Chemosphere 2014; 98: 51–57. [DOI] [PubMed] [Google Scholar]

- 19.Glüge J, Scheringer M, Cousins IT, DeWitt JC, Goldenman G, Herzke D, Lohmann R, Ng CA, Trieri X, Wang Z. An overview of the uses of per- and polyfluoroalkyl substances (PFAS). Environmental Science: Processes & Impacts 2020; 22: 2345–2373. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.US EPA. EPA’s per- and polyfluoroalkyl substances (PFAS) action plan. EPA 823R18004, February 2019, www.epa.gov/pfas

- 21.Fenton SE, Ducatman A, Boobis A, DeWitt JC, Lau C, Ng C, Smith JS, Roberts SM. Per- and polyfluoroalkyl substance toxicity and human health review: current state of knowledge and strategies for informing future research. Environ. Toxicol. Chem 2021; 40: 606–630. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Ankley GT, Cureton P, Hoke RA, Houde M, Kumar A, Kurias J, Lanno R, McCarthy C, Newsted J, Salice CJ, Sample BE, Sepúlveda MS, Steevens J, Valsecchi S. Assessing the ecological risks of per- and polyfluoroalkyl substances: current state-of-the science and a proposed path forward. Environ. Toxicol. Chem 2021; 40: 564–605. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Winkens K, Giovanoulis G, Koponen J, Vestergren R, Berger U, Karvonen AM, Pekkanen J, Kiviranta H, Cousins IT. Perfluoroalkyl acids and their precursors in floor dust of children’s bedrooms - implications for indoor exposure. Environ. Int 2018; 119: 493–502. [DOI] [PubMed] [Google Scholar]

- 24.Yao Y, Zhao Y, Sun H, Chang S, Zhu L, Alder AC, Kannan K. Per- and polyfluoroalkyl substances (PFASs) in indoor air and dust from homes and various microenvironments in China: Implications for human exposure. Environ. Sci. Technol 2018; 52: 3156–3166. [DOI] [PubMed] [Google Scholar]

- 25.Hall SM, Patton S, Petreas M, Zhang S, Phillips AL, Hoffman K, Stapleton HM. Per- and polyfluoroalkyl substances in dust collected from residential homes and fire stations in North America. Environ. Sci. Technol 2020; 54:14558–14567. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Zheng G, Boor BE, Schreder E, Salamova A. Indoor exposure to per- and polyfluoroalkyl substances (PFAS) in the childcare environment. Environ. Pollut 2020; 258:113714. [DOI] [PubMed] [Google Scholar]

- 27.Wu Y, Romanak K, Bruton T, Blum A, Venier M. Per- and polyfluoroalkyl substances in paired dust and carpets from childcare centers. Chemosphere 2020; 251:126771. [DOI] [PubMed] [Google Scholar]

- 28.Harrad S, Wemken N, Drage DS, Abdallah MAE, Coggins AM. Perfluoroalkyl substances in drinking water, indoor air and dust from Ireland: Implications for human exposure. Environ. Sci. Technol 2019; 53: 13449–13457. [DOI] [PubMed] [Google Scholar]

- 29.Besis A, Botsaropoulou E, Samara C, Katsoyiannis A, Hanssen L, Huber S. Perfluoroalkyl substances (PFASs) in air conditioner filter dust of indoor microenvironments in Greece: implications for exposure. Ecotoxicol. Environ. Safety 2019; 183:109559. [DOI] [PubMed] [Google Scholar]

- 30.Xu F, Chen D, Liu X, Guan Q, Tan H, Zhou D, Shi Y, Liu J, Hu Y. Emerging and legacy per- and polyfluoroalkyl substances in house dust from South China: contamination status and human exposure assessment. Environ. Res 2021: 192: 110243. [DOI] [PubMed] [Google Scholar]

- 31.Guo Z. A framework for modelling non-steady-state concentrations of semivolatile organic compounds indoors – II. Interactions with particulate matter. Indoor Built Environ. 2014; 23: 26–43. [Google Scholar]

- 32.Andersen HV, Frederiksen M. Sorption of PCB from air to settled house dust in a contaminated indoor environment. Chemosphere 2021; 266: 129139. [DOI] [PubMed] [Google Scholar]

- 33.Liagkouridis I, Lazarov B, Giovanoulis G, Cousins IT. Mass transfer of an organophosphate flame retardant between product source and dust in direct contact. Emerging Contaminants 2017; 3: 115–120. [Google Scholar]

- 34.Clausen PA, Hansen V, Gunnarsen L, Afshari A, Wolkoff P. Emission of di-2- ethylhexyl phthalate from PVC flooring into air and uptake in dust: emission and sorption experiments in FLEC and CLIMPAQ. Environ. Sci. Technol 2004; 38: 2531–2537. [DOI] [PubMed] [Google Scholar]

- 35.Schripp T, Fauck C, Salthammer T. Chamber studies on mass-transfer of di (2- ethylhexyl) phthalate (DEHP) and di-n-butylphthalate (DnBP) from emission sources into house dust. Atmos. Environ 2010; 44: 2840–2845. [Google Scholar]

- 36.Rauert C, Harrad S. Mass transfer of PBDEs from plastic TV casing to indoor dust via three migration pathways d a test chamber investigation. Sci. Total Environ 2015; 536: 568–574. [DOI] [PubMed] [Google Scholar]

- 37.Jeon S, Kim K, Choi K. Migration of DEHP and DINP into dust from PVC flooring products at different surface temperature. Sci. Total Environ 2016; 547: 441–446. [DOI] [PubMed] [Google Scholar]

- 38.Qian Z, Xu Y, Zheng C, Zhang A, Sun J. Enhanced emissions of brominated flame retardants from indoor sources by direct contact with dust. Environ. Monit. Assess 2019; 191: 170. [DOI] [PubMed] [Google Scholar]

- 39.Kuribara I, Kajiwara N, Sakurai T, Kuramochi H, Motoki T, Suzuki G, Wada T, Sakai S, Takigami H. Time series of hexabromocyclododecane transfers from flame-retarded curtains to attached dust. Sci. Total Environ 2019; 696: 133957. [DOI] [PubMed] [Google Scholar]

- 40.Shinohara N, Uchino K. Diethylhexyl phthalate (DEHP) emission to indoor air and transfer to house dust from a PVC sheet. Sci. Total Environ 2020; 711: 134573. [DOI] [PubMed] [Google Scholar]

- 41.Bi C, Wang X, Li H, Li X, Xu Y. Direct transfer of phthalate and alternative plasticizers from indoor source products to dust: laboratory measurements and predictive modeling. Environ. Sci. Technol 2021; 55: 341–351. [DOI] [PubMed] [Google Scholar]

- 42.Tokumura M, Ogo S, Kume K, Muramatsu K, Wang Q, Miyake Y, Amagai T, Makino M. Comparison of rates of direct and indirect migration of phosphorus flame retardants from flame-retardant-treated polyester curtains to indoor dust. Ecotoxicol. Environ. Safety 2019; 169: 464–469. [DOI] [PubMed] [Google Scholar]