Abstract

International datasets on economy-wide material flows currently fail to comprehensively cover the quantitatively most important materials and countries, to provide centennial coverage and to differentiate between processing stages. These data gaps hamper research and policy on resource use. Herein, we present and document the data processing and compilation procedures applied to develop a novel economy-wide database of primary stock-building material flows systematically covering 177 countries from 1900- 2016. The main methodological novelty is the consistent integration of material flow accounting and analysis principles and thereby addresses limitations in terms of transparency, data quality and uncertainty treatment. The database systematically discerns four processing stages from raw materials extraction, to processing of raw and semi-finished products, to manufacturing of stock-building materials. Included materials are concrete, asphalt, bricks, timber products, paper, iron & steel, aluminium, copper, lead, zinc, other metals, plastics, container and flat glass. The database is compiled using international and national data sources, using a transparent and consistent 10-step procedure, as well as a systematic uncertainty assessment. Apart from a detailed documentation of the data compilation, validations of the database using data from previous studies and additional uncertainty estimates are presented.

• Systematically compiled historical database of primary stock-building material flows for 177 countries.

• Consistent integration of economy-wide material flow accounting and detailed material flow analysis principles.

• Methodological enhancements in terms of transparency, data quality and uncertainty treatment.

Keywords: Material flow analysis, Resource use, Long-term analysis, Uncertainty assessment, Industrial ecology, Social metabolism

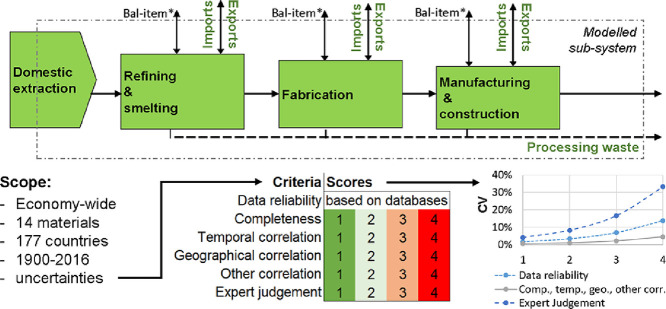

Graphical abstract

Specifications table

| Subject Area: | Environmental Science |

| More specific subject area: | Industrial Ecology |

| Method name: | Economy-wide material flow analysis for stock-building materials |

| Name and reference of original method: |

|

| Resource availability; | Supporting Information |

Method details

This article describes the methodological approaches used to compile the database presented in the article “From resource extraction to manufacturing and construction: flows of stock-building materials in 177 countries from 1900 to 2016”, which was recently published in the journal ‘Resources, Conservation and Recycling’ [142].

1. The model scheme–Quantified processes and flows

As theoretical and methodological background for the quantification of primary stock-building material flows, the herein presented database combines harmonized methods and principles from economy-wide material flow accounting [45,74] and material flow analysis [20,53].

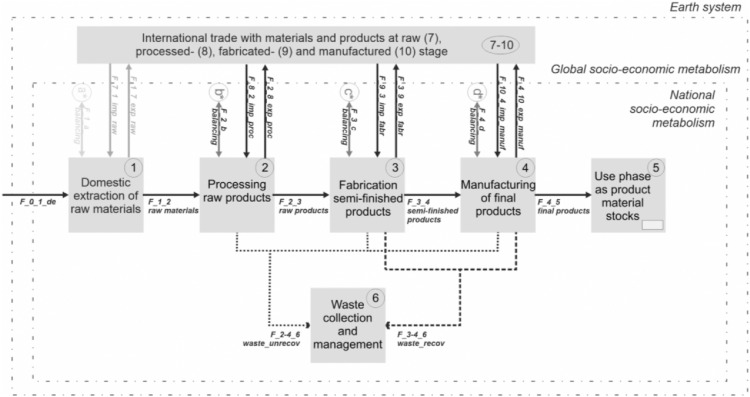

The systems definition shows the boundaries applied and processes discerned in this work (Fig. 1). Process 1 is defined as the Domestic extraction of raw materials and represents activities from mining and forestry sectors where natural resources are extracted directly from the environment (e.g. iron ore) and includes all used extraction, while excluding un-used extraction, as defined in economy-wide material flow accounting [45]. Domestic extraction follows a territorial principle, i.e., it accounts for all materials extracted within the national territory or each country, no matter where extracting companies are legally based. Process 2 is defined as the Processing of raw products, which constitutes the first step where raw materials are transformed and refined in usually highly standardized industrial processes to produce raw products (e.g. smelting ores into metals such as crude steel and separating them from gangue and extractive waste). Process 3 is defined as the Fabrication of semi-finished products, which are also typically fabricated in standardized ways, but are mostly clustered in other economic sectors and industries than raw processing (e.g. steel beams). The last process 4 is the Manufacture of final products, which usually involves more diverse and unstandardized industrial methods and yield a broad variety of final products (e.g. buildings, infrastructure, machinery, etc.). Process 5 (use phase) and 6 (waste management) are outside of the scope of this study and not further investigated.

Fig. 1.

Process and flow scheme for the systematic definition of the herein presented data (definitions are given in Table 1). Boxes indicate processes, continuous lines indicate materials going to the next processing stage and dotted lines materials going to waste (recoverable and unrecoverable). Recovered material flows from latter processing stages are not reinstated in the system.

Detailed definitions on the terms and calculations of all quantified parameters are given in Table 1. Exogenous data for process 2 (processing of raw products) was collected, as most comprehensive datasets were available at that stage (except for wood and paper, where production data on semi-finished products was collected), as well as trade data and factors for processing losses and wastes for each of these processing stages. All other model variables (endogenous data) were calculated by combining these exogenous variables as shown by the equations in Table 1. So far, imports and exports of raw materials (F_7_1, F_1_7) have not yet been quantified, but only derived global domestic extraction by applying global yield factors from previous studies, as explained in Section 9 [74]. When inconsistencies occurred due to ill-matched production and trade data, balancing flows for each processing step (a*, b*, c*, d*) were introduced, which represents the globally accumulated error of data matching. Details on data collection and processing can be found in Section 3.

Table 1.

List of processes, flows and system variables.

| Index | Definition | Compilation method |

|---|---|---|

| Processes | ||

| P1 | Extraction of raw materials | |

| P2 | Processing of raw products | |

| P3 | Fabrication of semi-finished products | |

| P4 | Manufacturing of final products | |

| P5 | Use phase of product material stocks | |

| P6 | Waste collection, management and treatment | |

| P7 | Trading of raw materials | |

| P8 | Trading of raw products | |

| P9 | Trading of semi-finished products | |

| P10 | Trading of final products | |

| Material input/output flows | ||

| F_0_1 | Domestic extraction | See Section 9 |

| F_1_2 | Raw material output | Exogenous data |

| F_2_3 | Output of raw products | F_1_2*(1-L2-W2) + F_8_2 – F_2_8 |

| F_3_4 | Output of semi-finished products | F_2_3*(1-L3-W3) + F_9_3 – F_3_9 |

| F_4_5 | Output of final products / primary gross additions to stock (GASprim) | F_3_4*(1-L4-W4) + F_10_4 – F_4_10 |

| Material trade flows | ||

| F_7_1 | Imports of raw materials | Not compiled |

| F_1_7 | Exports of raw materials | Not compiled |

| F_8_2 | Imports of raw products | Exogenous data |

| F_2_8 | Exports of raw products | Exogenous data |

| F_9_3 | Imports of semi-finished products | Exogenous data |

| F_3_9 | Exports of semi-finished products | Exogenous data |

| F_10_4 | Imports of final products | Exogenous data |

| F_4_10 | Exports of final products | Exogenous data |

| Processing wastes | ||

| F_2–4_6 | Unrecoverable wastes from extraction, processing, fabrication and manufacturing | F_1_2*L2; F_2_3*L3; F_3_4*L4 |

| F_3–4_6 | Recoverable wastes from processing, fabrication and manufacturing | F_1_2*W2; F_2_3*W3; F_3_4*W4 |

| L2–4 | Unrecoverable waste shares of total production output | Exogenous data |

| W3–4 | Recoverable waste shares of total production output | Exogenous data |

Furthermore, the present database only quantifies primary material flows that stem directly from resources extracted from the environment in the same time period and do not include flows of secondary materials; the approach to exclude secondary materials from production and trade data is explained in Section 7. From primary inputs, furthermore losses and wastes occurring during the different processing stages were deducted, to identify only materials that directly stem from the environment for stock construction. Unrecoverable processing wastes (waste_unrec) represent the unrecoverable part of processing wastes that is treated further by waste management or dissipatedly lost to the environment. Recoverable processing wastes (waste_rec) represent the recoverable part of occurring wastes and are especially for metals usually designated as new scrap. As the goal of this work is to quantify primary material flows, recovered materials are not reinstated in the system but rather collected in waste collection and management.

The herein defined processing stages vary widely across the range of materials we consider in this work. We therefore defined production processes and product groups included at each processing stage in line with the material-specific scientific literature available. Definitions (and respective examples) at each of the processing stages for each of the 14 materials considered in this work are given in Table 2.

Table 2.

Classification, definition and examples of materials and products at the four distinguished processing stages.

| Material | Processing stages |

|||

|---|---|---|---|---|

| (P1) Raw materials | (P2) Raw products | (P3) Semi-finished products | (P4) Final products | |

| Concrete | Limestone, clay, sand and gravel | Cement, sand and gravel | Concrete | buildings, infrastructure |

| Asphalt | Crude oil, sand and gravel | Bitumen, sand and gravel | Asphalt | roads, infrastructure |

| Bricks | Clays and kaolin | Bricks | Articles of bricks | buildings, infrastructure |

| Paper | Industrial roundwood overbark | Industrial roundwood underbark | Primary paper and paperboard | Articles of paper and paperboard, printed matter |

| Wood | Industrial roundwood overbark | Industrial roundwood underbark | Sawnwood, wood-based panels, other industrial roundwood | Wood and cork manufactures |

| Iron & steel | Iron-based ore | Crude steel, casting iron | Semi-finished iron and steel products (plates, sheets, rails …) | Final iron and steel products (buildings, machinery, appliances …) |

| Aluminium | Bauxite | Primary aluminium | Semi-finished aluminium products (plates, tubes, pipes …) | Final aluminium products (Machinery, appliances, packaging …) |

| Copper | Copper ore | Primary copper | Semi-finished copper products (plates, tubes, cables …) | Final copper products (Machinery, electric appliances …) |

| Lead | Lead ore | Primary lead | Semi-finished lead products | Final lead products (batteries, accus …) |

| Zinc | Zinc ore | Primary zinc | Semi-finished zinc products and alloys (anti-corrosion agent …) | Final zinc products (machinery, infrastructure …) |

| Other metals | Metal ores | Metal content (in non-steel alloys) | Semi-finished other metal alloys | Final products from other metals |

| Plastics | Crude oil, natural gas | Thermoplastics, rubber, fibers | Semi-finished plastics and rubber products | Final products of plastics and rubber (plastics content) |

| Container glass | Limestone, silica sands, soda ash | Hollow/container glass | Containers and glassware | Final products of container glass (bottles, cups …) |

| Flat glass | Limestone, silica sands, soda ash | Flat glass | Flat glass | Final products of flat glass (windows, mirrors …) |

2. Country selection, GDP and population data

In this dataset, 177 currently existing countries are discerned. Because country definitions changed over the last 120 years and data availability for some countries can be problematic, one consistent classification of countries for the entire time series was applied. Firstly, all countries which are currently not contended and have more than 300 000 inhabitants were selected, primarily because the excluded smaller countries have very poor data availability. Secondly, historically divergent country definitions were corrected, which stem from country fusions and dissolutions as well as other territorial changes to the best of our knowledge, based on a review of territorial changes throughout the 20th century. Historical country aggregates like the USSR were disaggregated into its successor states by back-casting shares of the earliest available datapoint of the historic aggregate to arrive at a contemporary country classification. The historic country aggregates that were corrected in most of the data sources were Belgium-Luxembourg, Czechoslovakia, Ethiopia incl. Eritrea, Serbia and Montenegro, Sudan, USSR and Yugoslavia. The final list of the 177 countries covered in this dataset can be found in Table 3.

Table 3.

List of countries included in the novel database and several world regional groupings. Income levels are taken from the World Bank [139] classification for 2016 (limits in Gross National Income (GNI) per capita in US$)–L= low income (<=1005), LM= lower middle income (1006–3955), UM= upper middle income (3956–12,235), H= high income (>12,235). World regions from Wiedenhofer et al. [137] –IOW – Industrial Old World, INW – Industrial New World, FSU – Former Soviet Union, Asia, other, China, India, MENA – Middle East & Northern Africa, LACA – Latin America & the Caribbean, SSA – Sub-Saharan Africa.

| Countries | UN Code ISO3166 | Geographical region | MISO Region [137] | World-Bank Income level |

|---|---|---|---|---|

| Afghanistan | 4 | Southern Asia | Asia, other | L |

| Albania | 8 | Southern Europe | IOW | UM |

| Algeria | 12 | Northern Africa | MENA | UM |

| Angola | 24 | Sub-Saharan Africa | SSA | LM |

| Argentina | 32 | Latin America and the Caribbean | LACA | UM |

| Armenia | 51 | Western Asia | FSU | LM |

| Australia | 36 | Australia and New Zealand | INW | H |

| Austria | 40 | Western Europe | IOW | H |

| Azerbaijan | 31 | Western Asia | FSU | UM |

| Bahamas | 44 | Latin America and the Caribbean | LACA | H |

| Bahrain | 48 | Western Asia | MENA | H |

| Bangladesh | 50 | Southern Asia | Asia, other | LM |

| Belarus | 112 | Eastern Europe | FSU | UM |

| Belgium | 56 | Western Europe | IOW | H |

| Belize | 84 | Latin America and the Caribbean | LACA | UM |

| Benin | 204 | Sub-Saharan Africa | SSA | L |

| Bhutan | 64 | Southern Asia | Asia, other | LM |

| Bolivia | 68 | Latin America and the Caribbean | LACA | LM |

| Bosnia and Herzegovina | 70 | Southern Europe | IOW | UM |

| Botswana | 72 | Sub-Saharan Africa | SSA | UM |

| Brazil | 76 | Latin America and the Caribbean | LACA | UM |

| Brunei | 96 | South-eastern Asia | Asia, other | H |

| Bulgaria | 100 | Eastern Europe | IOW | UM |

| Burkina Faso | 854 | Sub-Saharan Africa | SSA | L |

| Burundi | 108 | Sub-Saharan Africa | SSA | L |

| Cambodia | 116 | South-eastern Asia | Asia, other | LM |

| Cameroon | 120 | Sub-Saharan Africa | SSA | LM |

| Canada | 124 | Northern America | INW | H |

| Cape Verde | 132 | Sub-Saharan Africa | SSA | LM |

| Central African Republic | 140 | Sub-Saharan Africa | SSA | L |

| Chad | 148 | Sub-Saharan Africa | SSA | L |

| Chile | 152 | Latin America and the Caribbean | LACA | H |

| China | 156 | Eastern Asia | China | UM |

| Colombia | 170 | Latin America and the Caribbean | LACA | UM |

| Comoros | 174 | Sub-Saharan Africa | SSA | L |

| Congo | 178 | Sub-Saharan Africa | SSA | LM |

| Congo, DR | 180 | Sub-Saharan Africa | SSA | L |

| Costa Rica | 188 | Latin America and the Caribbean | LACA | UM |

| Côte d'Ivoire | 384 | Sub-Saharan Africa | SSA | LM |

| Croatia | 191 | Southern Europe | IOW | UM |

| Cuba | 192 | Latin America and the Caribbean | LACA | UM |

| Cyprus | 196 | Western Asia | IOW | H |

| Czech Republic | 203 | Eastern Europe | FSU | H |

| Denmark | 208 | Northern Europe | IOW | H |

| Djibouti | 262 | Sub-Saharan Africa | MENA | LM |

| Dominican Republic | 214 | Latin America and the Caribbean | LACA | UM |

| Ecuador | 218 | Latin America and the Caribbean | LACA | UM |

| Egypt | 818 | Northern Africa | MENA | LM |

| El Salvador | 222 | Latin America and the Caribbean | LACA | LM |

| Equatorial Guinea | 226 | Sub-Saharan Africa | SSA | UM |

| Eritrea | 232 | Sub-Saharan Africa | SSA | L |

| Estonia | 233 | Northern Europe | FSU | H |

| Ethiopia | 231 | Sub-Saharan Africa | SSA | L |

| Fiji | 242 | Melanesia | Asia, other | UM |

| Finland | 246 | Northern Europe | IOW | H |

| France | 250 | Western Europe | IOW | H |

| Gabon | 266 | Sub-Saharan Africa | SSA | UM |

| Georgia | 268 | Western Asia | FSU | LM |

| Germany | 276 | Western Europe | IOW | H |

| Ghana | 288 | Sub-Saharan Africa | SSA | LM |

| Greece | 300 | Southern Europe | IOW | H |

| Guadeloupe | 312 | Latin America and the Caribbean | LACA | H |

| Guatemala | 320 | Latin America and the Caribbean | LACA | LM |

| Guinea | 324 | Sub-Saharan Africa | SSA | L |

| Guinea Bissau | 624 | Sub-Saharan Africa | SSA | L |

| Guyana | 328 | Latin America and the Caribbean | LACA | UM |

| Haiti | 332 | Latin America and the Caribbean | LACA | L |

| Honduras | 340 | Latin America and the Caribbean | LACA | LM |

| Hong Kong SAR | 344 | Eastern Asia | Asia, other | H |

| Hungary | 348 | Eastern Europe | IOW | H |

| Iceland | 352 | Northern Europe | IOW | H |

| India | 356 | Southern Asia | India | LM |

| Indonesia | 360 | South-eastern Asia | Asia, other | LM |

| Iran | 364 | Southern Asia | MENA | UM |

| Iraq | 368 | Western Asia | MENA | UM |

| Ireland | 372 | Northern Europe | IOW | H |

| Israel | 376 | Western Asia | MENA | H |

| Italy | 380 | Southern Europe | IOW | H |

| Jamaica | 388 | Latin America and the Caribbean | LACA | UM |

| Japan | 392 | Eastern Asia | IOW | H |

| Jordan | 400 | Western Asia | MENA | LM |

| Kazakhstan | 398 | Central Asia | FSU | UM |

| Kenya | 404 | Sub-Saharan Africa | SSA | LM |

| Kuwait | 414 | Western Asia | MENA | H |

| Kyrgyzstan | 417 | Central Asia | FSU | LM |

| Laos | 418 | South-eastern Asia | Asia, other | LM |

| Latvia | 428 | Northern Europe | FSU | H |

| Lebanon | 422 | Western Asia | MENA | UM |

| Lesotho | 426 | Sub-Saharan Africa | SSA | LM |

| Liberia | 430 | Sub-Saharan Africa | SSA | L |

| Libya | 434 | Northern Africa | MENA | UM |

| Lithuania | 440 | Northern Europe | FSU | H |

| Luxembourg | 442 | Western Europe | IOW | H |

| Madagascar | 450 | Sub-Saharan Africa | SSA | L |

| Malawi | 454 | Sub-Saharan Africa | SSA | L |

| Malaysia | 458 | South-eastern Asia | Asia, other | UM |

| Maldives | 462 | Southern Asia | Asia, other | UM |

| Mali | 466 | Sub-Saharan Africa | SSA | L |

| Malta | 470 | Southern Europe | IOW | H |

| Martinique | 474 | Latin America and the Caribbean | LACA | H |

| Mauritania | 478 | Sub-Saharan Africa | SSA | LM |

| Mauritius | 480 | Sub-Saharan Africa | SSA | UM |

| Mexico | 484 | Latin America and the Caribbean | IOW | UM |

| Moldova | 498 | Eastern Europe | FSU | LM |

| Mongolia | 496 | Eastern Asia | Asia, other | LM |

| Montenegro | 499 | Southern Europe | IOW | UM |

| Morocco | 504 | Northern Africa | MENA | LM |

| Mozambique | 508 | Sub-Saharan Africa | SSA | L |

| Myanmar | 104 | South-eastern Asia | Asia, other | LM |

| Namibia | 516 | Sub-Saharan Africa | SSA | UM |

| Nepal | 524 | Southern Asia | Asia, other | L |

| Netherlands | 528 | Western Europe | IOW | H |

| New Zealand | 554 | Australia and New Zealand | INW | H |

| Nicaragua | 558 | Latin America and the Caribbean | LACA | LM |

| Niger | 562 | Sub-Saharan Africa | SSA | L |

| Nigeria | 566 | Sub-Saharan Africa | SSA | LM |

| North Korea | 408 | Eastern Asia | Asia, other | L |

| North Macedonia | 807 | Southern Europe | FSU | UM |

| Norway | 578 | Northern Europe | IOW | H |

| Oman | 512 | Western Asia | MENA | H |

| Pakistan | 586 | Southern Asia | Asia, other | LM |

| Panama | 591 | Latin America and the Caribbean | LACA | UM |

| Papua New Guinea | 598 | Melanesia | Asia, other | LM |

| Paraguay | 600 | Latin America and the Caribbean | LACA | UM |

| Peru | 604 | Latin America and the Caribbean | LACA | UM |

| Philippines | 608 | South-eastern Asia | Asia, other | LM |

| Poland | 616 | Eastern Europe | IOW | H |

| Portugal | 620 | Southern Europe | IOW | H |

| Puerto Rico | 630 | Latin America and the Caribbean | LACA | H |

| Qatar | 634 | Western Asia | MENA | H |

| Réunion | 638 | Sub-Saharan Africa | SSA | LM |

| Romania | 642 | Eastern Europe | IOW | UM |

| Russia | 643 | Eastern Europe | FSU | UM |

| Rwanda | 646 | Sub-Saharan Africa | SSA | L |

| Saudi Arabia | 682 | Western Asia | MENA | H |

| Senegal | 686 | Sub-Saharan Africa | SSA | L |

| Serbia (incl. Kosovo) | 688 | Southern Europe | IOW | UM |

| Sierra Leone | 694 | Sub-Saharan Africa | SSA | L |

| Singapore | 702 | South-eastern Asia | Asia, other | H |

| Slovakia | 703 | Eastern Europe | FSU | H |

| Slovenia | 705 | Southern Europe | FSU | H |

| Solomon Islands | 90 | Melanesia | Asia, other | LM |

| Somalia | 706 | Sub-Saharan Africa | SSA | L |

| South Africa | 710 | Sub-Saharan Africa | SSA | UM |

| South Korea | 410 | Eastern Asia | IOW | H |

| South Sudan | 728 | Sub-Saharan Africa | SSA | L |

| Spain | 724 | Southern Europe | IOW | H |

| Sri Lanka | 144 | Southern Asia | Asia, other | LM |

| Sudan | 729 | Northern Africa | SSA | LM |

| Suriname | 740 | Latin America and the Caribbean | LACA | UM |

| Swaziland | 748 | Sub-Saharan Africa | SSA | LM |

| Sweden | 752 | Northern Europe | IOW | H |

| Switzerland | 756 | Western Europe | IOW | H |

| Syria | 760 | Western Asia | MENA | LM |

| Taiwan | 158 | Eastern Asia | Asia, other | H |

| Tajikistan | 762 | Central Asia | FSU | LM |

| Tanzania | 834 | Sub-Saharan Africa | SSA | L |

| Thailand | 764 | South-eastern Asia | Asia, other | UM |

| The Gambia | 270 | Sub-Saharan Africa | SSA | L |

| Timor-Leste | 626 | South-eastern Asia | Asia, other | LM |

| Togo | 768 | Sub-Saharan Africa | SSA | L |

| Trinidad and Tobago | 780 | Latin America and the Caribbean | LACA | H |

| Tunisia | 788 | Northern Africa | MENA | LM |

| Turkey | 792 | Western Asia | IOW | UM |

| Turkmenistan | 795 | Central Asia | FSU | UM |

| Uganda | 800 | Sub-Saharan Africa | SSA | L |

| Ukraine | 804 | Eastern Europe | FSU | LM |

| United Arab Emirates | 784 | Western Asia | MENA | H |

| United Kingdom of Great Britain and Northern Ireland | 826 | Northern Europe | IOW | H |

| United States of America | 840 | Northern America | INW | H |

| Uruguay | 858 | Latin America and the Caribbean | LACA | H |

| Uzbekistan | 860 | Central Asia | FSU | LM |

| Venezuela | 862 | Latin America and the Caribbean | LACA | UM |

| Vietnam | 704 | South-eastern Asia | Asia, other | LM |

| Yemen | 887 | Western Asia | MENA | LM |

| Zambia | 894 | Sub-Saharan Africa | SSA | LM |

| Zimbabwe | 716 | Sub-Saharan Africa | SSA | L |

A comprehensive population dataset for calculating per-capita values and back-casting specific material flows was derived by combining several sources. For 1950–2018, data from the UN population division [113] was used, which is comprehensive for all countries in the dataset. For early years, 1950 UN population numbers were extrapolated with country-level trends available from the historical population datasets provided by the Maddison project [92] and the CLIO Infra project [44]. The Maddison time series are continuous for many countries back until at least 1900, while the CLIO Infra data source only provides data every ten years. Therefore, Maddison trends were used whenever possible, supplemented with data points from the CLIO Infra dataset. All residual data points were linearly interpolated. For historic country aggregates, population accounts were disaggregated along the same procedure as applied for material flow data, which is explained in Section 3/Step 3. If neither Maddison nor CLIO Infra data was available, which was the case for 10 small countries in the database, the respective world-regional trend to back-cast 1950 UN population numbers was used.

For gross domestic product (GDP), the Maddison database [92] is the most comprehensive data source providing GDP per capita in international Dollars of 1990 (i.e. in Purchasing Power Parity) for almost all countries back until 1950 and an extensive selection of countries for earlier years. GDP accounts for the rest of the countries were not estimated as they are less stable than population accounts, and therefore GDP was only calculated by multiplying per-capita values with population for a selection of countries. After 1950, no GDP data was available for 24 countries of the dataset; before 1950, no data was available for 82 countries. Therefore, investigations with GDP were only conducted after 1950 to ensure sufficient coverage.

3. Data collection, processing and estimation procedures

To develop a consistent material flow dataset for 14 materials covering the entire time period of 1900 to 2016, systematic and standardized procedures were developed along the following ten steps.

Step 1 – Identify, assess and collect relevant data sources: All relevant data available from different data sources was gathered for each material category and datasets were analyzed according to which indicators come closest to production of raw products or semi-manufactured products, or in case calculated production flows from other available indicators. In addition, relevant trade flows were identified and categorized, different data sources compared and the one with the highest country coverage chosen. Details on the data sources utilized are described in Section 4.

Step 2 - Harmonize datasets to the common classification within our database structure: The following data processing steps were applied to the reported data to ensure harmonization with our classifications and avoid loss of existing information:

-

•

Simple unit conversions (e.g. pound to kg),

-

•

Re-estimations based on factors (e.g. volume to weight using standard factors),

-

•

Sequencing of data from datasets with overlapping time periods by always using the latest available dataset,

-

•

Harmonization of country names,

-

•

Combination of different data sources to one comprehensive dataset.

Step 3 - Correct major changes of country definitions over the studied time period: To arrive at a consistent set of 177 contemporary nation states, major changes in country territory and definitions happening throughout the 20th and 21st century were corrected by applying the following two standard procedures:

-

○

Country fusion: aggregate previous countries or territories into the newly formed country

-

○

Country dissolution: disaggregate material flow data reported for the historic country aggregate by shares of the earliest available datapoints of the sum of the historic aggregate for each successor state (used for e.g. the USSR, former Yugoslavia, Czechoslovakia, Sudan …)

Step 4 – Interpolating data gaps & plausibility checks: After collecting and cleaning datasets, various gaps, outliers and data errors remain to be corrected. A conservative but systematic data cleaning approach was developed along three rationales, which are also reflected in the uncertainty scoring of the respective datapoints.

-

•

Outlier removal: Single outliers in country time series were replaced if both neighbours were larger or smaller than 2.5 times the single value for values larger than 10 kt and 10 times for lower weight values, or the absolute value was larger than trade from 1962 to 2018 divided by 3. The margins for outlier removal were chosen after an initial assessment on which margins remove very large outliers but otherwise leave original data largely as reported. In addition, several obvious outliers in production and trade data have been removed based on expert appraisal. Outliers lying in-between two datapoints were replaced by linear interpolation, outliers at the end of a time series were replaced using the appropriate method for extrapolation or back-casting explained in Step 5.

-

•

Interpolation: Frequently there are smaller gaps of a few years within otherwise reported data. These gaps were interpolated linearly. For interpolated data points, uncertainty was scored based on the distance to the nearest available datapoint (for details on uncertainty scoring see chapter 10).

-

•

Plausibility checks: Further literature screenings on plausibility of long-term time series trends was conducted. Background information was compiled that informed manual data cleaning as wells as estimation methods.

Step 5 – Back-casting and extrapolating data for non-available years: Data availability across the 14 materials differs: some datasets date back to early 20th century, while others start as late as 1970 and sometimes time series do not continue until 2016 (see Section 6 for details). The following simple principles were utilized for back-casting and extrapolating data for those countries where the data does not cover the entire time period of 1900 to 2016.

-

•

Extrapolation: For specific countries and materials (especially cement and bitumen), reported data ends either 2014 or 2015. Data was then extrapolated with the average annualized growth rates of the last available 4 years. This approach has only been applied after 2010 to avoid the economic crisis bias. In certain cases of time series ending earlier, data was extrapolated with GDP trends from the Maddison Project Database [92].

-

•Back-casting: Stock-building material use was modelled into the past using additional data sources or expert judgements, to have information for very early years. For each material, cut-off values were defined, which were considered too small to conduct back-casting procedures (described further in Section 6 for each material separately). Trade data was back-casted for all processing steps back until 1900 with a standardized approach using growth rates of global trade flows (constant US$) sourced from Federico and Tena-Junguito [43]. Production data was back-casted using one or a combination of the following approaches:

-

○If additional data was available on the extraction of the raw materials of a product (e.g. crude oil production for bitumen), time series were back-casted with these trends for certain available years and countries. Further information when and where this approach was applied can be found below for each material separately.

-

○Decide on a reasonable socio-technical “starting point” for the use of the material, then back-cast using GDP trends (if available) or linearly interpolate to the latest available datapoint. This applies to concrete, asphalt, plastics, aluminium, chromium, manganese.

- ○

- ○

-

○

Step 6 – Estimations applied for materials and countries with very fragmented data: Especially for asphalt, wood, bricks, container and flat glass, data quality was still insufficient after the previous steps. Additional materials-specific estimation procedures were applied for each material, to arrive at full temporal and country coverage. These are explained in chapter 6.

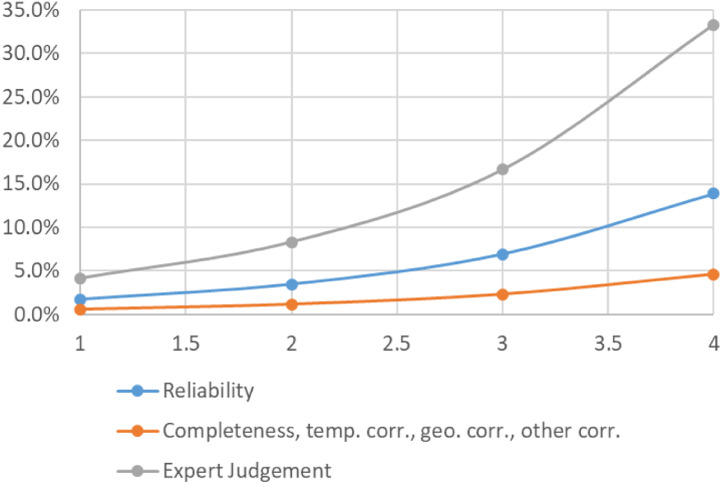

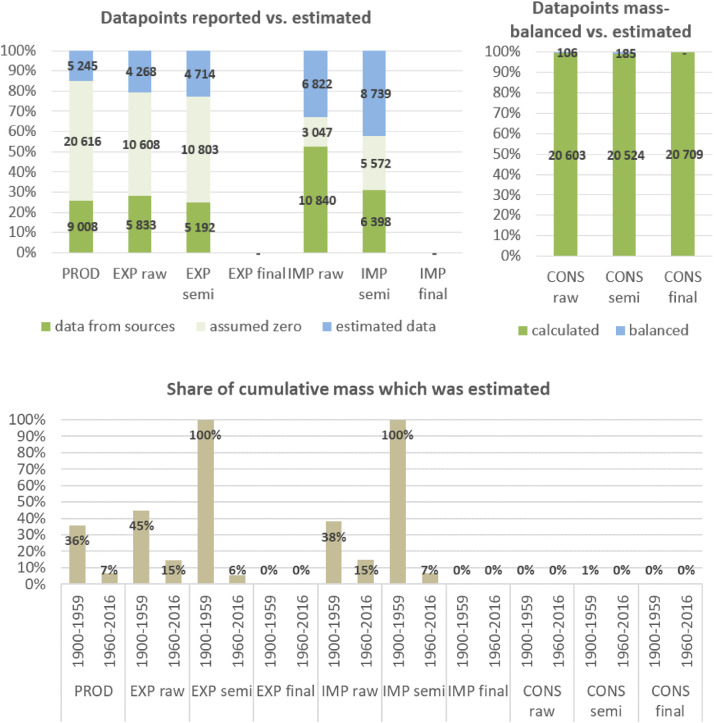

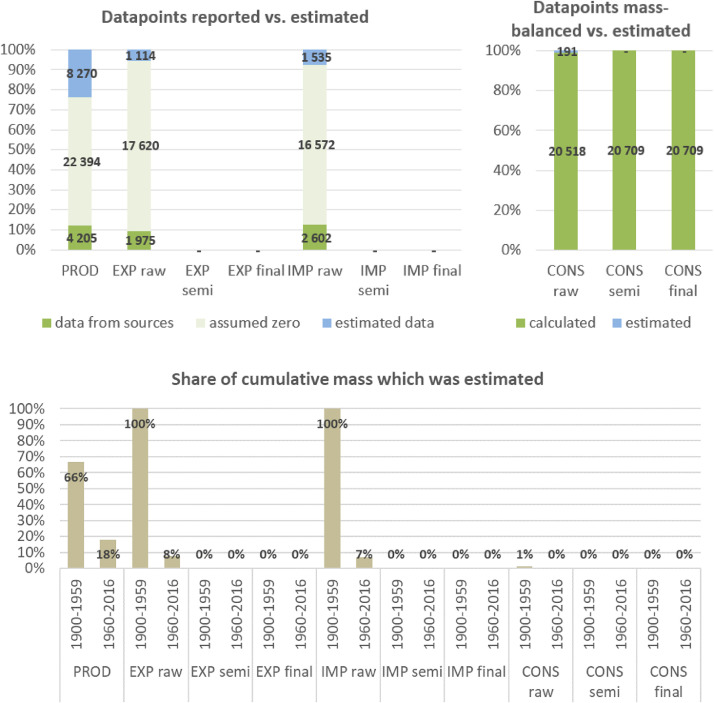

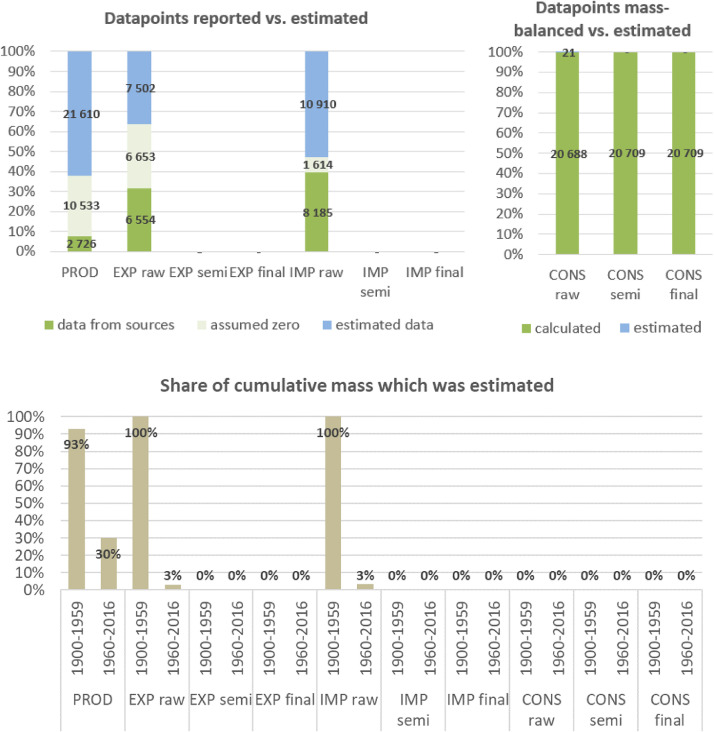

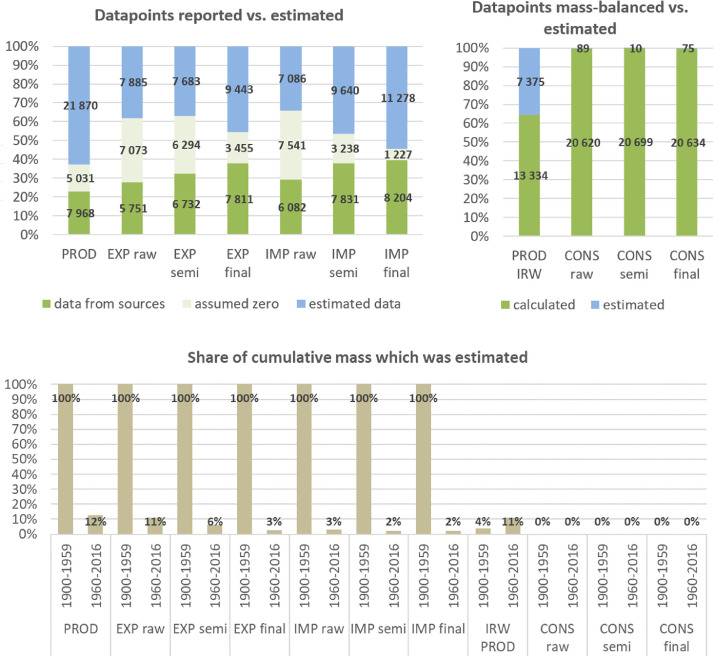

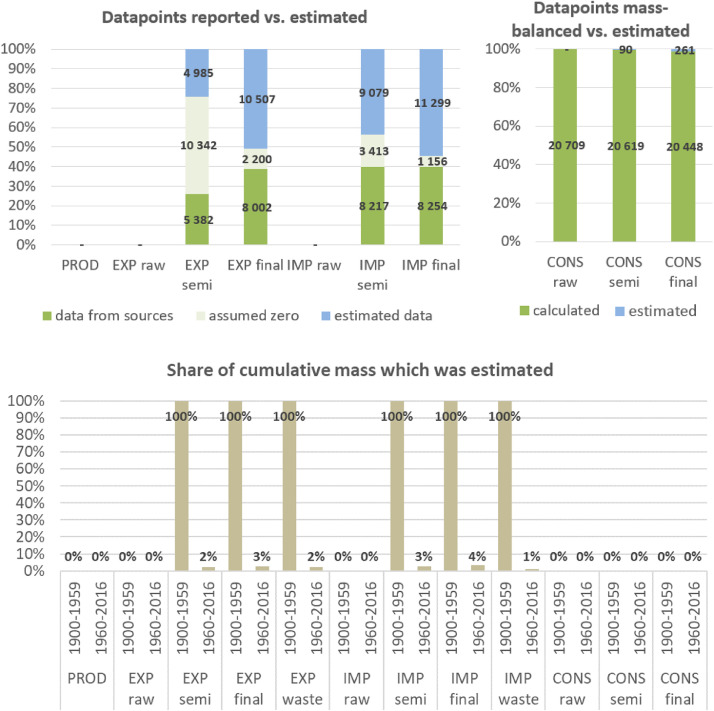

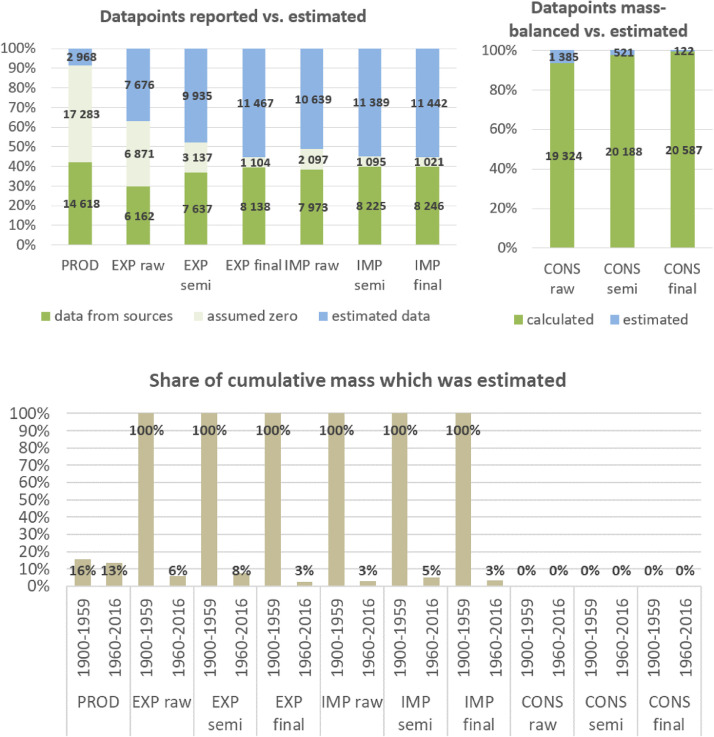

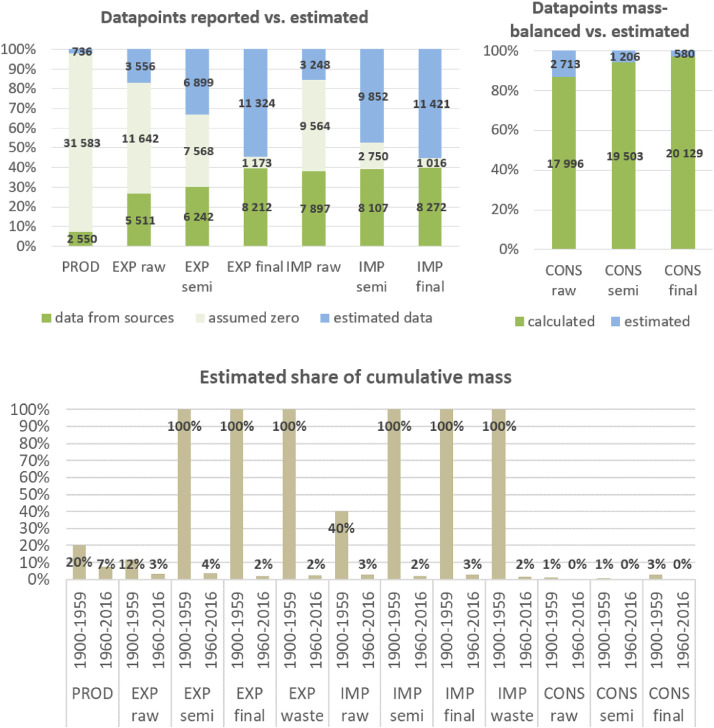

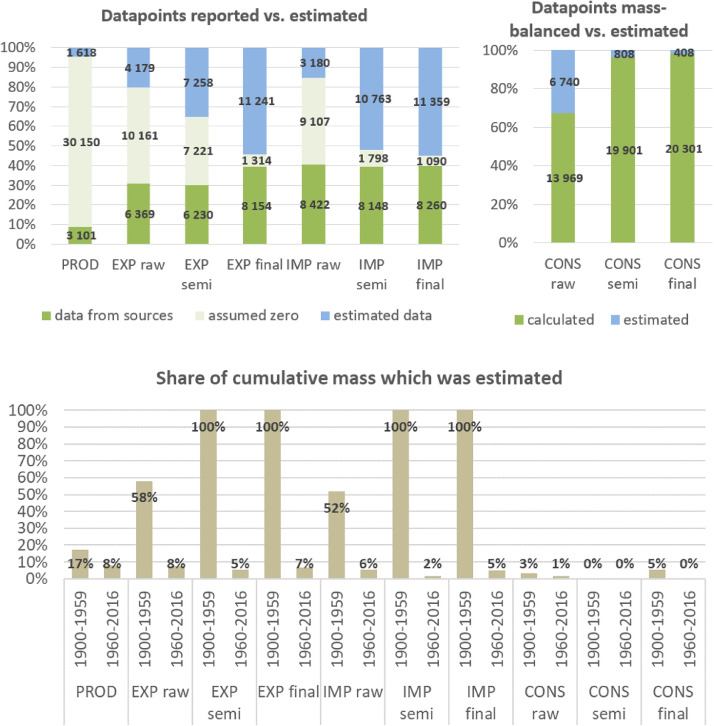

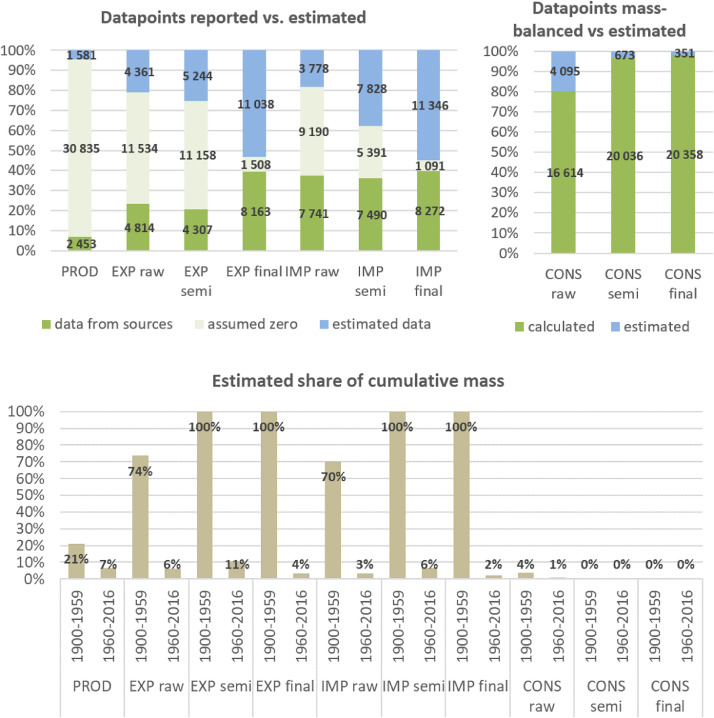

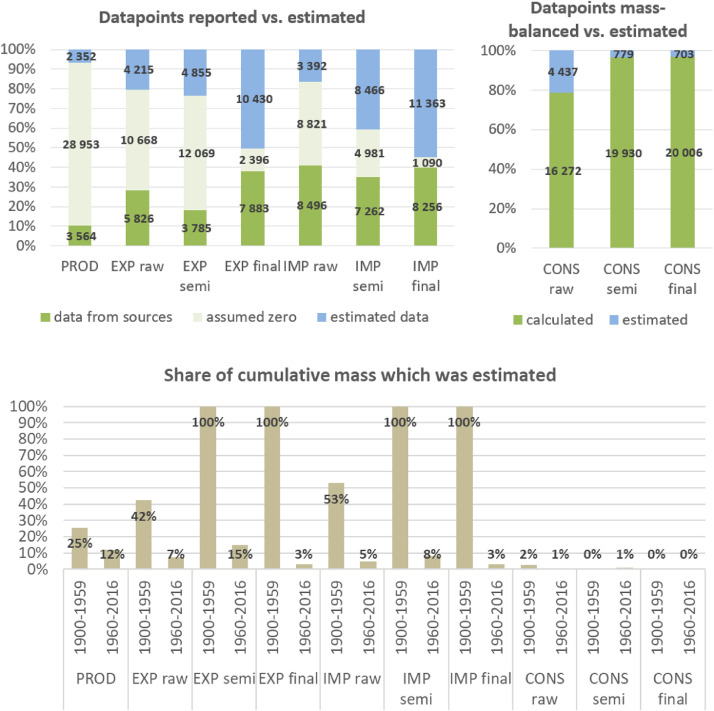

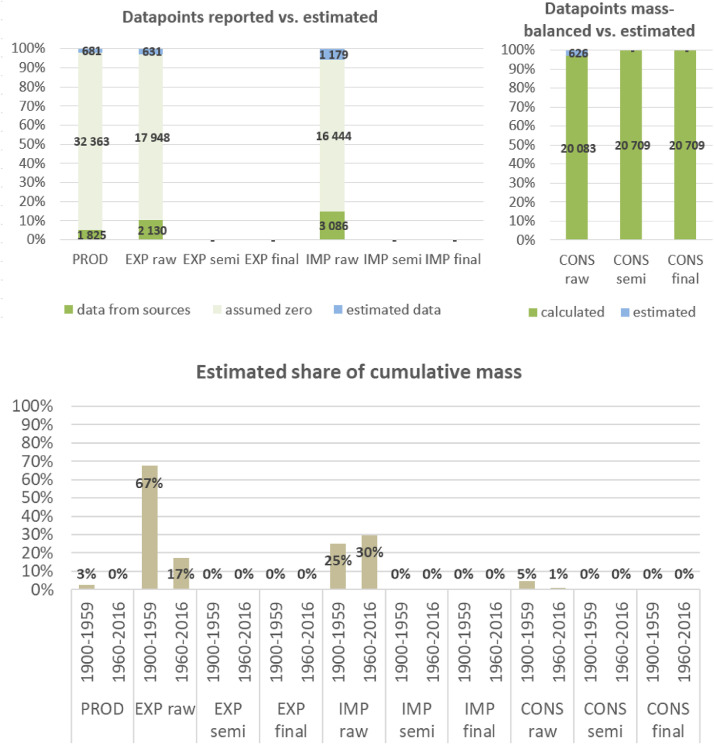

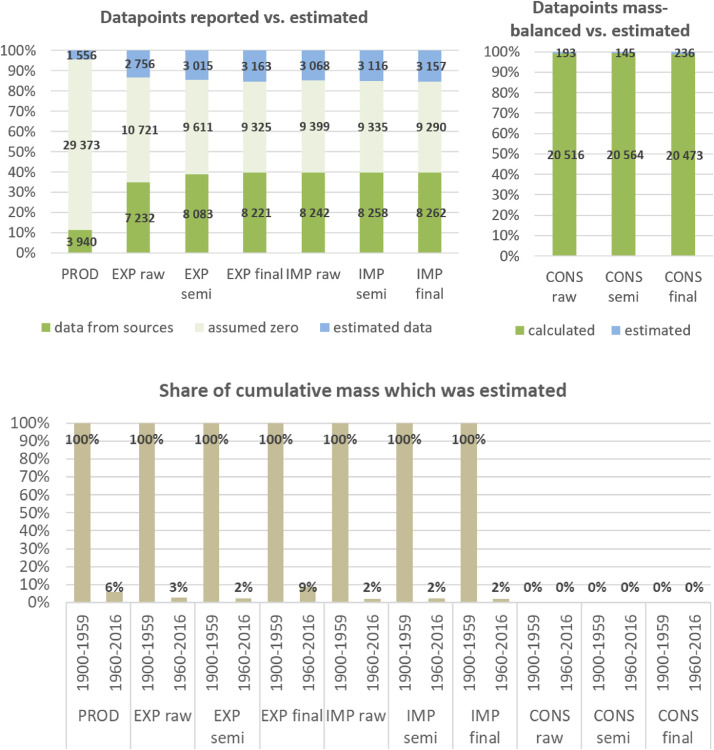

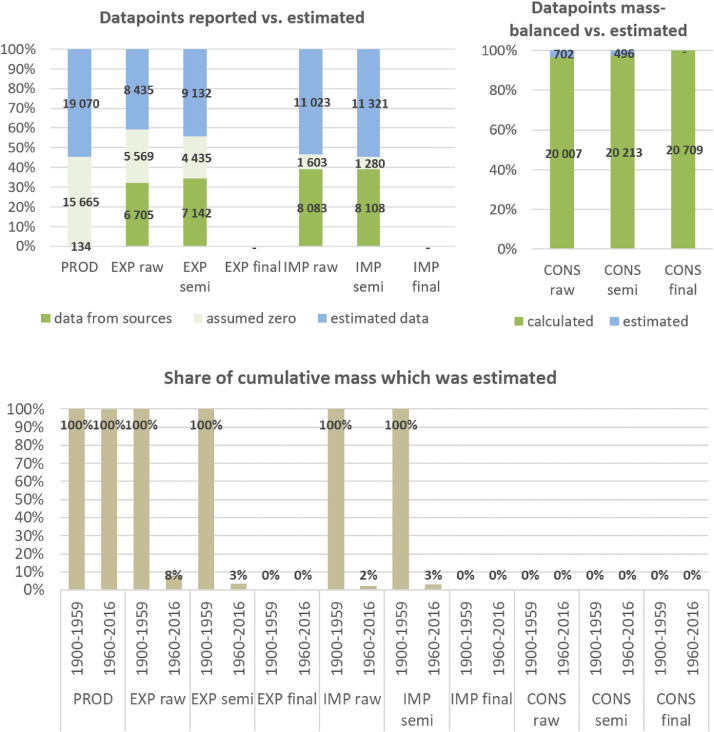

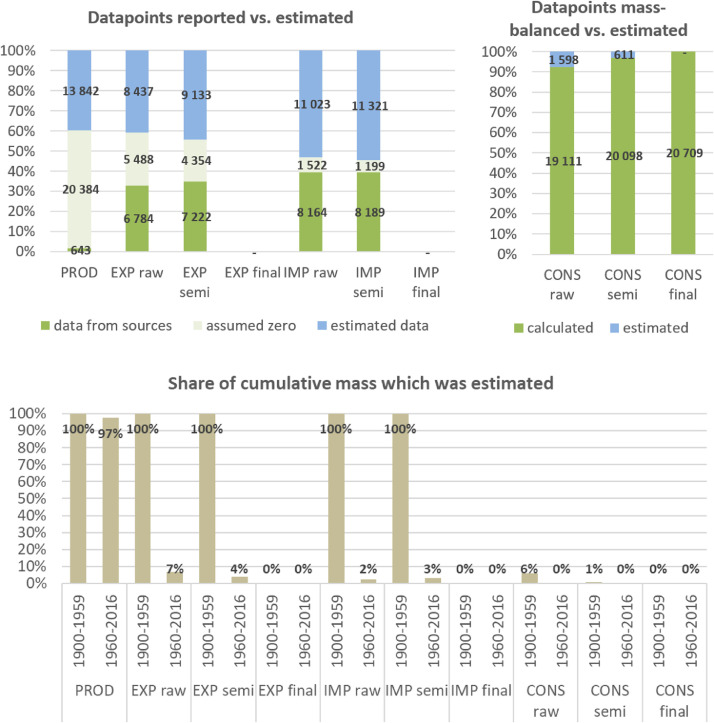

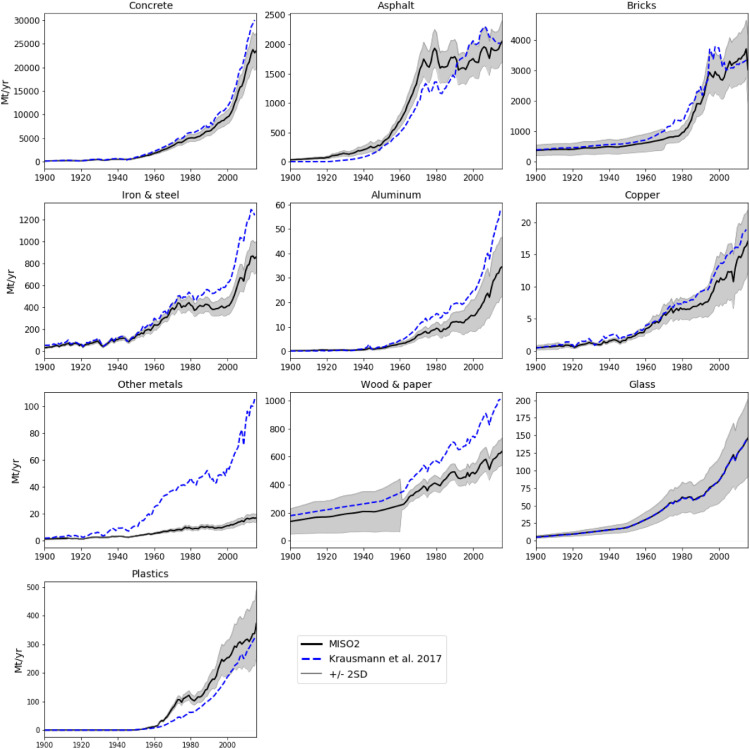

Step 7 – Developing uncertainty estimates for each datapoint: Scoring of the reliability of data sources and estimation methods based on an evaluation framework proposed by Laner et al. [75] translating to normally distributed standard deviations for each datapoint. In addition, it was surveyed how many of the datapoints have been estimated as outlined above in comparison to the datapoints coming from data sources and how much these estimates account for of the total mass. Further information on the implementation of the uncertainty assessment and detailed results for each material can be found below in chapter 10.

Step 8 – Deriving production outputs by subtracting processing waste: To consider the amounts that are unrecoverable or recoverable waste arising during processing, production estimates on each processing stage were multiplied with recoverable and unrecoverable waste rates to derive production outputs. Waste rates were compiled in a literature review and are given below in chapter 8.

Step 9 – Deriving apparent consumption estimates: For each processing stage, apparent consumption estimates were calculated by adding net-trade balances (imports minus exports) to production outputs. Uncertainty estimates of consumption estimates follow Gaussian error propagation rules.

Step 10 – Creating a balancing item to deal with inconsistencies in the database: Apparent consumption estimates can turn out negative due to missing production/import data or overestimation of exports. If consumption turned out negative, these values were linearly interpolated and differences between the new (interpolated) and the old (negative) values in a global balancing item summed up. In addition, these estimates were considered in our uncertainty assessment as further interpolations (for uncertainty scoring see Section 10) and their uncertainties were added to the uncertainties derived from Step 7. In addition, the global net-trade balance mostly does not sum up to zero due to several reasons: not all countries are covered in the database, classifications of products can vary between countries, several data adjustments were applied. As it is not possible to solve this problem on a bilateral trade level, the mismatch of trade data in the global balancing item of the consumption accounts was also accounted for, which can be understood as the “accumulated error” of production and trade data. The total global accumulated error from all mis-matching mass-balances is shown in Section 10.6.

Balanced consumption estimates (as derived from step 10) of each processing stage are then the inputs for the next processing stage and Steps 8–10 will be repeated until finally the primary gross additions to stock (GASprim) for each material could be calculated.

4. Data sources

Some of the materials are consistently covered by international databases (e.g. cement, paper, iron and steel) while other can only be found in data sources showing severe reporting gaps for countries and time periods (e.g. bricks, bitumen, glass). For each material separately, relevant international databases and country-level scientific literature was reviewed to gather as many reported datapoints as possible. Which major databases to use was decided based on their country and time coverage and the definition of the reported production flows which comes closest to production of raw products or semi-manufactured products.

If the databases also reported trade flows, these were compiled as well. Most of the trade flows were collected from the UN Comtrade database and the reported products categories were further divided into processing stages (see Sections 1 & 5). In addition to international databases, we compiled data from scientific literature to complement and validate international databases Table 4. gives an overview on which processing stages have been covered by which data sources, where flows were assumed to be zero (no data available), and where flows could either be derived from mass-balancing previous flows or from estimation procedures.

Table 4.

Data compilation methods and main data sources distinguished along processing stages. References for all data sources will be listed in Section 6 below. mass-bal.= mass-balancing of previous flows; zero= no data available, assumed zero; estimate= estimation/gap-filling.

| Material | Input flow data to processing stages |

|||||

|---|---|---|---|---|---|---|

| (2) Raw products |

(3) Semi-finished products |

(4) Final products |

||||

| Production | Trade | Production | Trade | Production | Trade | |

| Cement | Cembureau | Cembureau | mass-bal. | Comtrade | mass-bal. | zero |

| Bitumen | IEA, UNICPS | IEA | mass-bal. | zero | mass-bal. | zero |

| Bricks | UNICPS | Comtrade | mass-bal. | zero | mass-bal. | zero |

| Paper | FAO | FAO | FAO | zero | mass-bal. | Comtrade |

| Wood | FAO | FAO | FAO | zero | mass-bal. | Comtrade |

| iron & steel | WSA, [97] | Comtrade | mass-bal. | Comtrade | mass-bal. | Comtrade |

| aluminium | WBMS, BGS | Comtrade, BGS | mass-bal. | Comtrade | mass-bal. | Comtrade |

| Copper | WBMS, BGS | Comtrade, BGS | mass-bal. | Comtrade | mass-bal. | Comtrade |

| Lead | BGS | Comtrade, BGS | mass-bal. | Comtrade | mass-bal. | Comtrade |

| Zinc | BGS | Comtrade, BGS | mass-bal. | Comtrade | mass-bal. | Comtrade |

| Other metals | BGS | BGS | mass-bal. | zero | mass-bal. | zero |

| Plastics | IEA | Comtrade | UNICPS | Comtrade | mass-bal. | Comtrade |

| Container glass | UNICPS, glassgobal | Comtrade | mass-bal. | Comtrade | mass-bal. | zero |

| Flat glass | UNICPS, glassgobal | Comtrade | mass-bal. | Comtrade | mass-bal. | zero |

| Sand & gravel | estimate | zero | mass-bal. | zero | mass-bal. | zero |

5. Trade data compilation

Countries increasingly depend on trade to obtain resources, materials and products [48,108]. Therefore, the quantification of material flows which are consumed within a country requires a detailed account of materials in traded commodities. Physical trade flows for all materials were therefore assessed and compiled along the four processing stages as described in Section 2 (raw materials, raw products, semi-finished and final products). The database draws on trade information for 347 commodities, distinguishing content for 10 materials, for all countries worldwide for the period 1962–2018. Commodities were divided into the four processing stages of the system definition (see Section 1) according to their labels (see Table 5).

Table 5.

List of SITC1 and SITC3 commodities classified into the four processing stages explained in section 1.

| Processing stage | SITC1 codes (values in brackets SITC3 codes) |

|---|---|

| Raw products | 242,244,26621,26622,26632,5811,5812,58131,58191,58199,664,671,672,679,6821,6841,6851,6861 |

| Semi-finished products | 2312,243,26623,26633,5332,53332,59959,59974,59975,59991,59994,59999,6112,6123,62101,62102,62103,62104,62105,631,641,65161,5162,65163,65164,65165,65191,65194,65229,65351,65352,65361,65362,6537,65391,65395,65401,65402,65403,65404,65405,65542,65543,65545,65546,65582,65583,65591,65592,65741,65742,66182,66183,665,673,674,675,676,677,678,68221,68222,68223,68224,68225,68226,68421,68422,68425,68426,68521,68522,68524,68621,68622,68623,69311,69312,69313,6932,69331,69332,69333,69341,69342,69343,2313,26631,65171,65172,65174 |

| Final products | 53333,53334,53335,54191,5530,57111,57112,5712,5713,5714,6121,6122,6291,6293,6294,62998,62999,632,633,642,65406,6551,65541,65561,65562,65563,65571,65572,65581,6561,6562,6566,65691,65692,6575,6576,6623,6624,66362,66391,6911,6912,6913,69211,69212,69213,69221,69222,69231,69232,69411,69412,69421,69422,695,696,69711,69712,69721,69722,69723,6979,6981,6982,6983,6984,6985,69861,69862,6988,69891,69892,69894,69896,69897,7111,7112,7113,7114,7115,7116,7117,7118,7121,7122,7123,7125,7129,7141,7142,7143,7149,715,717,718,7191,7192,7193,7194,7195,7196,7197,7198,7199,722,723,724,72501,72502,72503,72504,72505,726,7291,7292,7293,7294,7295,7296,7297,7299,7311,7312,7313,7314,7315,7316,7317,7321,7322,7323,7324,7325,7326,7327,732873291,73292,73311,73312,7333,7334,7341,73491,73492,7351,7353,7358,7359,8121,8123,81241,81242,81243,8210,8310,84111,84112,84113,84114,84121,84122,84123,84125,84126,84129,84141,84142,84143,84144,84151,84152,84153,84154,84159,8416,84202,85101,85102,85103,85104,861,86241,86242,8911,8912,8914,8918,8919,892,8930,894,8945,8951,89521,89522,89523,89592,89593,89594,89711,89713,89714,8972,89924,89927,89933,89934,89935,89941,89942,89943,89951,89952,89953,89954,89956,89957,89961,89962,89993,89997,89998,89999,95101,95102,95103,95104,95105,95106 |

| Raw materials and scrap | 2511, 2820, 28402, 28404, 28406, 28407, (579, 66411) |

For process 2, curated materials-specific data sources were used such as Cembureau (cement [30]), IEA (bitumen [61]), FAO (solidwood and paper [42]) and BGS (metals [17]) (summary in Table 4). Because trade data from these databases in most cases only reports material flows for raw products and/or do not distinguish raw and semi-finished products properly (e.g. crude steel and steel pipes), we utilized data from the United Nations Commodity Trade Statistics Database (UN Comtrade) [114] to quantify physical trade for processes 3 and 4. In order to include the trade of materials contained in final products and to fill the gaps of the above mentioned data sources for other processing stages, trade in commodities was additionally obtained from the UN Comtrade database.

Trade in physical units is only reported in ca. 90% of data entries, compared to monetary trade values. To improve the country and time coverage of physical trade data from UN Comtrade, the data was corrected following procedures from [35,98], where we:

-

1.

Downloaded bilateral commodity trade data for the commodities listed in Table 5 in the SITC1 classification for all countries from the UN Comtrade application programming interface (API).

-

2.

Computed the average of double reported physical and monetary commodity trade flows (for flows reported twice, once as export of country A and once as import of country B).

-

3.

Calculated a global weighted average price for each commodity and year with available monetary and mass trade figures (weighted by mass of commodity trade).

-

4.

Manually checked the time-series of global average prices per commodity for consistency: for some years and commodities few trade entries were available which led to large deviations of average prices from other values in the time series. To increase consistency, values that deviated more than 10 times from the average of the two directly neighbouring years were substituted by the neighbours’ average.

-

5.

Used the global average price per commodity and year to fill the gaps of physical trade where monetary, but no physical commodity trade figures were given (divided monetary trade by average price). In step five a total of 4 129 628 out of 52 339 158 datapoints was added (8.6%).

-

6.

Removed outliers in bilateral trade data: Trade flows per commodity were grouped per exporter-importer-pair and sorted from 1962 to 2018. Afterwards, local extrema were identified (comparing trade mass for year t with the years t + 1 & t-1). In the case that the deviation of the extrema was larger than the boundaries given in Step 4 in Section S3, the extrema was substituted with the average of its neighbours. This procedure was repeated by comparing the average of two years to the direct neighbours of these datapoints. If the deviation was larger than the proposed boundaries, both values were substituted by interpolation. The datapoints added in Step 5, together with removing outliers in Step 6, contributed to covering an additional 2% of material mass in globally traded commodities for the whole period 1962–2018.

-

7.

Computed commodity imports and exports per country and the associated material imports and exports by multiplication with material intensity information from ([80,93,96,98]; [129].). Material intensities were applied as time-constant values, except for the materials iron & steel and aluminium, for which intensities of commodity SITC 7321 (‘Passenger motor cars, other than buses’) were considered dynamic according to information from Liu & Müller [79]; and plastics, for which material intensities in traded commodities not reflecting raw plastic materials (e.g. plastic resins) were assumed to decrease from 2000 back to 1962 according to the trend in global plastic polymer resin and fibre production from Geyer et al. [47]. Except for the commodity codes for which material content information was reported in the prior studies, only commodities for which a material content of close to 100% of the respective material could be assumed were considered (e.g. 100% wood for “wood manufactures, nes”). Material contents used are given in the Supporting data file attached to this article. After calculating material content, ca. 87% of the original commodity trade is reflected in the dataset on material trade.

-

8.

Removed outliers in imports and exports for country time-series: as still some larger outliers made it through previous steps, again values were compared to their two direct neighbours in the time series. If both neighbours were larger than, 10 times the value in question for flows lower than 1 Megaton per year (Mt/yr), or 2.5 times for values larger than 1 Mt/yr these values were substituted by the average of both neighbours. These boundaries appeared to be appropriate for removing large outliers while still preserving year-to-year variations in trade that seemed sensible to us.

-

9.

The SITC1 classification was chosen in order to span the years back to 1962. However, not all flows of interest were available via this classification type. Therefore, in addition trade in plastic and glass waste and scrap were downloaded in classification SITC3 without any further manipulation (SITC3 codes 579 & 66,411).

-

10.

After all these modifications, UN Comtrade data has been further processed as described above in Section 3, including further interpolations and manual outlier removals, for each compiled dataset on imports and exports of raw, semi-finished, final and waste products of 10 materials.

-

11.

Furthermore, for trade before 1962 (which is the earliest year for which data from UN Comtrade was available), all trade datasets were back-casted using growth rates of global trade flows (constant US$) sourced from Federico and Tena-Junguito [43] until 1900, before we assumed trade flows to be negligible (see Section 3).

-

12.

As a last step, uncertainties were assessed for all further data preparation steps as described in Section 10. Uncertainties of the modifications described in points 1–8 in this section could not be considered.

Following the principle of the conservation of mass, the global sum of imports and exports should be zero. The combination of trade data sources in our study could not always hold up to that and for some materials, the global net-trade balance is unequal to zero due to several reasons: trade customs declarations are sparsely registered in some countries, re-exports and re-imports are often not taken into account, imports for sales on unofficial markets or for military and defence purposes are not recorded in official statistics, our database does not cover all countries worldwide (but only the 177 presented in Section 2), products may be classified differently across countries and some data was estimated by several sources, including own estimations. Solving this problem on a bilateral trade level is not possible due to missing data and indications. Therefore, the net-trade balance was counterbalanced in the global balancing item of our consumption accounts (see Section 3).

6. Detailed documentation for each material

For each material, all data has been processed as described in Sections 3 and 5. Details on diverging data-processing and estimation procedures between the different materials are described in the following section. Details on uncertainty scoring of different data sources and estimation procedures presented in the following will be provided in the specially established Section 10 below.

6.1. Concrete

Concrete is the most widely used construction material and is composed of sand and gravel bonded together by fluid cement that hardens over time. Data on cement production and trade was mainly sourced from World Statistical Reviews of the European Cement Association (CEMBUREAU) for the years 1913–1995, 1996–2003, 1999–2009, 2001–2010 and 2004–2014 [26], [27], [28], [29], [30]. Data coverage in the provided datasets is very high, with data points for 165 out of the 177 countries investigated herein. Therefore, we did not additionally estimate cement production for missing countries. Statistics from CEMBUREAU refer to both cement and clinker, as countries usually do not differentiate between the two. For the two most recent years 2015 and 2016, we additionally added data from the latest CEMBUREAU Activity Report [31] for the main world cement producers and extrapolated data for all other countries using average growth rates of 2010–2014.

We classified cement production and trade flows reported by CEMBUREAU as raw products (p2 as defined in Table 2) and additionally added UN Comtrade data for trade in concrete components (p3). As we define final concrete products to be buildings and infrastructures, we assume no trade in final products. We define concrete as semi-finished product (p3) made out of the raw products cement and sand and gravel. We estimated the amount of sand and gravel necessary for concrete production by applying a ratio of cement-to-sand and gravel of 1:5, which is commonly used throughout the literature (e.g [24,74]).

Following previously established procedures for back-casting material flows using technological “starting points” and economic growth as proxies [74,135], we back-casted cement production using GDP growth rates for the years previous to 1913 if the latest reported datapoint is higher than 50 kt per year. The use of concrete in construction and therefore the use of modern Portland cement took off at around 1850 [34], which we therefore set as technological starting point and linearly reduced cement production from 1900 values to zero in 1850, assuming that all previously occurring historical uses of cement are negligible amounts for the purposes of this study.

6.2. Asphalt

Asphalt is produced from sand and gravel combined with bitumen, a refined petroleum product, and is primarily used for surfacing of roads and for roofing material. Data on bitumen production and trade was primarily sourced from the World Energy Balance database of the International Energy Agency [61] and from UNICPS [116,117]. The IEA database contains detailed harmonized information on energy and fossil fuel production and consumption for 180 countries and regions worldwide back until 1971 and for EU countries back until 1960. The 2017 dataset only contains data from 1960 to 2015, so we had to estimate 2016 values using average growth rates of 2011–2015. In addition to IEA data, we also used data on bitumen production from the United Nations Industrial Commodity Production Statistics database (UNICPS) [116,117], which does not have the same level of data quality as IEA data (confidentiality restrictions, differing product definitions, insufficient data collection) but reports data until 1950. When no IEA data was available (mostly between 1950 and 1970), we therefore used UNICPS data.

Data quality and coverage for country-level bitumen production and trade is intermediate and several corrections and estimations were necessary. IEA reported bitumen production flows for 91 countries in the country sample. Imports are insufficiently covered as they are only reported for 98 countries. Asphalt is used for road paving almost everywhere nowadays and over the last decades. We therefore additionally estimated bitumen production for 46 major countries based on per-capita values of countries in the same GDP decile in 2015, i.e., a classification of countries based on their per-capita GDP values in 2015.

Back-casting for bitumen production for the years prior to 1950 was done as follows: For 20 major countries, trends of historic oil production until 1800 can be found in Podobnik [101], which we used to back-cast bitumen production until 1900. When no such historical oil production data was available and the last reported datapoint was higher than 3 kt/year, we back-casted bitumen production using GDP growth rates until 1900. For some early industrializing countries like the USA, UK, France, Germany, USSR and Japan, Kern & Mayländer [68] report that asphalt road pavements started to be widely used around 1870. We therefore assumed a technological starting point in 1870 and linearly reduced bitumen production flows from 1900 to zero in 1870 or – if historical oil production data was available – linearly reduced the bitumen share of oil production from 5% in 1900 to 0% in 1870.

We classified bitumen production and trade flows as raw products (p2) and assume no trade in asphalt concrete products (p3) or final products like roads or roofing material (p4). Asphalt, which is made out of bitumen and sand and gravel, was classified as semi-finished product (p3). We estimated the amount of sand and gravel used for asphalt production by applying a ratio of bitumen-to-sand and gravel of 1:19, which is used throughout the literature (e.g [74,89]).

6.3. Bricks

Bricks produced from clay are used to build walls, pavements and other elements of masonry. Data on construction bricks made of clay was primarily sourced from the United Nations Industrial Commodity Production Statistics database (UNICPS) [116,117], (codes 37,350–1 A and 37,350–1 B).

Clay bricks are produced in different types and classes. To convert reported numbers from different statistics into mass of bricks, conversion factors were used. We used as volume conversion factor 0.0017m3 per unit of brick [71] and for conversion into mass an average factor of 2.84 kg per unit of brick derived from different sources (see Table 6).

Table 6.

Mass conversion factors and their sources used to derive the average applied to bricks.

Because data quality and coverage are generally very low for bricks, only data rows for countries reporting >10 datapoints were included. In addition to that, data from scientific literature and country-specific reports were used to compile time series for the UK [112], the USA [111], Japan [87], Austria [70], China [126] and India [37,42,110].

As the global dataset was not complete after inclusion of these data sources, linear interpolations were made wherever data rows showed gaps and some outliers had to be corrected. Extrapolations from values reported for past years up to 2016 were done by using the last reported value of t/cap and multiplying it with the country's population. For countries that did not report any data, estimates were derived by calculating an average of t bricks/capita from all countries that reported data grouped into high-income and low-income countries by using the classification of World Bank valid for 2016 [139]. The according value (low/high-income average) in t/cap was assigned to all countries that did not report any data and multiplied by population for every year.

Back-casting for bricks was done depending on population development, because bricks are a traditional building material assumed to be used rather independently of industrialization developments or fossil fuel use [71]. Therefore, in order to estimate bricks for early years, the first reported data point was converted into a value of t/capita and constantly back-casted until 1820 using population trends.

We classified bricks production and trade flows as raw products (p2) and assume no trade in articles of bricks (e.g. walls or ovens) (p3) or final products like buildings (p4).

6.4. Wood & paper

In this dataset, we only consider wood products and paper which accumulates as socio-economic material stocks, e.g. wood processed to sawnwood, wood-based panels and wood products as well as paper and exclude all wood use for fuel. Data has primarily been sourced from the FAO statistical database on food and agriculture [42], which comprehensively covers all major forestry production and trade flows for over 245 countries and territories worldwide back until 1961. Data coverage seems to be complete for paper and paperboard production and trade, no data can be found only for two countries in the sample and consumption estimates are consistent.

Data on wood products has been combined from reported data on sawnwood, wood-based panels and other industrial roundwood, which are usually reported in volume measures and were converted to weight using IPCC factors [63]. The category “other industrial roundwood” is typically used for the production of poles, piling, posts, fencing, pit props, tanning, etc. and is therefore included [63]. Data coverage on wood production is rather complete, covering 153 countries of the sample. To increase completeness even further, we estimated wood production for another six countries by using average shares of sawnwood and wood-based panels production of industrial roundwood production reported by FAO. We identify the residual 19 countries without solid-wood production to be small enough to be plausibly dependant on imports. Furthermore, we assume no starting point for wood and paper use in the time period covered here, as wood has been a primary resource for centuries. Prior to 1961, we therefore back-casted wood and paper production using population growth rates until 1820.

We classified paper and paperboard production and trade from FAO as semi-finished products (p3) and additionally added UN Comtrade data on trade in final products such as books or printed media (p4). We additionally excluded secondary paper production from reported total paper production and trade as explained in detail in Section 7. In line with paper production, we classified solid-wood production and trade flows reported by FAO as semi-finished products (p3) and additionally added UN Comtrade data for trade in final wood products such as furniture (p4).

Industrial roundwood (after bark removal) is usually classified as the raw product (p2) for wood and paper semi-finished products [42] and its production and trade is also comprehensively reported by the FAO in volume measures, which we as well converted to weight measures using IPCC factors [63]. In this unique case, we could therefore compile production data on two stages of the processing chain and could derive losses that occur from the processing of industrial roundwood to wood semi-finished products (stemming from water loss, energy recovery of waste products, unrecoverable sawdust, etc.) by mass-balancing of the data. We derived processing loss rates by calculating industrial roundwood (IRW) consumption (production + imports – exports) and then dividing the difference to total production of wood semis (sawnwood, wood-based panels, paper, others) by IRW consumption. For many countries and years, IRW consumption seems to be vastly underestimated as the amount of reported semis production is higher than the reported IRW consumption. In accordance with the literature [3,66,76,103], we assume accounts of wood semi-finished products to be more comprehensively reported and developed an approach to estimate IRW production where IRW data is inconsistent, as described in the following paragraph.

From a comprehensive global study on wood flows conducted by Bais et al. [3], we could derive plausible global processing losses for sawnwood, paper and other products for the years 1990, 2000 and 2010 by dividing the reported unrecovered wastes by respective IRW inputs. The resulting factors were interpolated for the years between and held constant for earlier and later years and weighted by production flows of the specific product group to derive global average processing loss factors. The resulting global average processing losses do not vary much over time, ranging from 32% in 1900 to 31% in 2016. We then used global average processing losses to extrapolate IRW consumption from data on the production of semi-finished wood products for datapoints where the calculated losses are below a third of the global average (11%). In addition, a few countries do not report production of semi-finished products but still IRW consumption. For these cases, we assumed IRW consumption to be zero to comply with the rule of prioritizing reported production of semi-finished products. The global average processing losses we derived from this approach then range from 36% in 1900 to 33% in 2016, which is in line with the literature [3,71,84]. In total, we end up with 31% of datapoints for IRW production to be estimated as explained above, but total mass of estimated datapoints only accounts for 3% of the total mass of IRW production from 1900 to 2016. Uncertainties of these estimation procedures are assessed as explained below in 10.

6.5. Iron & steel

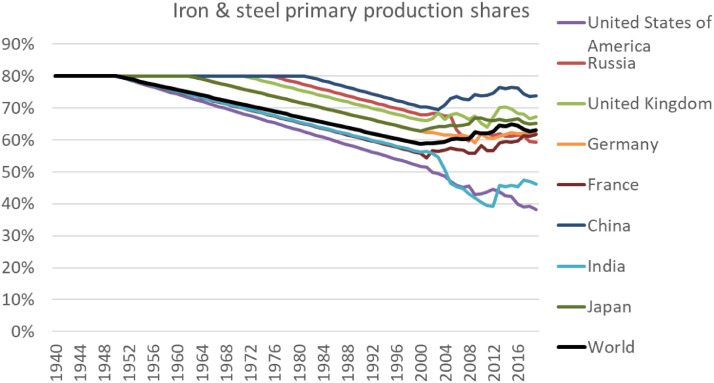

Iron and steel have been the most abundantly used metal resource throughout human history and the reporting of iron and steel flows has been well-established for a long time. Steel is an alloy with the major component being iron, with typically a few percent of carbon to improve its fracture resistance and strength compared to iron and small concentrations of other metals to attain certain properties (which are also accounted for in this category). Global steel production took off with industrial production around 1860, before iron products have either been wrought or cast [98].

There are several international data sources on iron and steel production and trade flows (e.g [17,121,140]), which have all been utilized by various studies over the last decades (e.g [46,57,97,98]; [129]). For this database, we build on the approach of Pauliuk et al. [97], who comprehensively compiled international and selected national data sources to quantify iron and steel flows for all countries worldwide from 1700 to 2008. We updated this time series until 2016 using data from the World Steel Association [140] and Comtrade [114]. The Steel Statistical Yearbooks from worldsteel entail detailed information on pig iron, directly reduced iron (DRI) and crude steel production and trade back to the year 2000 [140].

We compiled data on production of crude steel and casting iron from Pauliuk et al. [97] and worldsteel (2020). Cast iron has been calculated by using a global ratio of cast iron to pig iron and DRI consumption (after trade). Pauliuk et al. [97] estimated this share to decrease from 100% in 1860 to 7% in 2008, which we then held constant for the years until 2016. As Pauliuk et al. [97] mostly derived their data from worldsteel data for recent years and worldsteel shows a higher country coverage, we derived production of raw products from worldsteel accounts for the years 2000–2016 and used data from Pauliuk et al. [97] before 2000. Prior to 1900, Pauliuk et al. [97] only published their final GAS estimates publicly, which we therefore used as a proxy for production flows and assumed trade as well as processing losses in following processing steps to be zero. To derive iron and steel trade flows for all processing stages, we applied the approach proposed by Pauliuk et al. [97] to Comtrade data, which goes back to 1962. Earlier trade flows back to 1900 have been estimated; trade data handling is described in detail in Section 5. We additionally excluded production and trade of secondary iron and steel from the accounts as described in Section 7. The novel accounts for primary iron and steel production agree well with production accounts on pig iron reported by USGS and BGS.

We classified crude steel and casting iron as raw products (p2) and additionally added UN Comtrade data on trade in raw products (p2), semi-finished products like steel plates or rails (p3) and final products like machinery or appliances (p4).

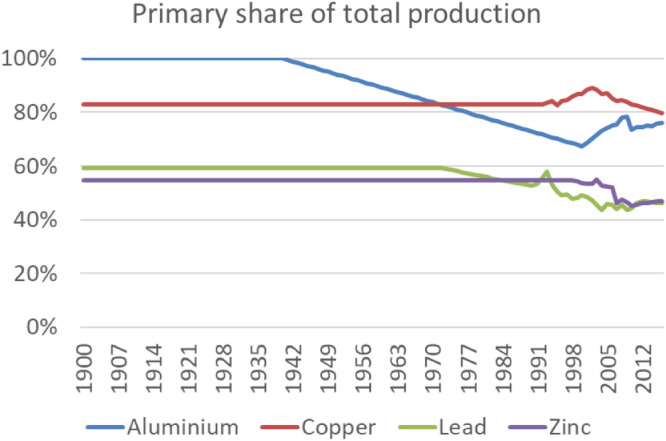

6.6. Aluminium, copper, zinc, lead, chromium, manganese, nickel and tin

Non-ferrous metals account for only a small fraction of total metal consumption of countries compared to iron and steel, although they are of huge importance to industrial production and their environmental impacts are wide-ranging [55]. In this database, we include the most widely used and technologically crucial metals aluminium, copper, lead, zinc, chromium, manganese, nickel and tin, as they cover the majority of non-ferrous metals used throughout history in terms of mass [54,107]. Their applications and properties are wide-ranging [127]. Aluminium is largely used in transport utilities, packaging, building and construction and electricity-related uses and its use increased vastly over the 20th century due to its relatively low costs, high conductivity, light weight and durability. Copper is used as a conductor of heat and electricity and for many other purposes for a long time, as it is one of the few metals that can occur in nature in a directly usable metallic form. Lead was used extensively due to its abundance, low extraction costs and beneficial properties until the discovery of its toxicity in the late 19th century led to the phase-out of its use in many applications. However, it is still used in several applications that are supposed to not affect human health. Zinc, chromium, nickel and tin are largely used in alloys, mostly to enhance the properties of steel.

Many organisations and research groups investigate extraction, production and use processes of these metals and data reporting has also already a long history. Two major primary data reporters on historical flows throughout the 20th century are the Br. Geol. Surv. [5], [6], [7], [8], [9], [10], [11], [12], [13], [14], [15], [16], [17] and the United States Geological Survey [121]. BGS reports production as well as imports and exports of a wide range of mineral commodities and represents, as far as this is possible, official national accounts. In the case of metals, production data of different steps in metal processing can be selected (mine production, smelter, refining), each expressed in terms of metal content. Data are reported for all countries in the world and can be downloaded for the years from 1970 onwards. The years prior to 1970 are available as pdfs in BGS archives, dating back till 1913. The USGS database contains – besides comparable country-level data – partly very detailed information on the structure of the mineral industry within specific countries, particularly in terms of commodity, major operating companies, major equity owners, location of main facilities, and annual capacity. This provides valuable information, especially on metal contents or primary and secondary production. The time period accessible via the online database usually dates back to 1990, earlier publications until the 1930s are only available as pdf files.

Often databases do not refer to standard statistical codes, therefore some caution is required when working with more than one database to avoid either incomprehensive or double counting. We therefore decided to gather primarily data from one of the two data sources and use the other for cross-checking. We also compared flows from the BGS and the USGS database and data was highly coinciding. As the BGS database provided easily accessible data for 20 more years, we decided to primarily use BGS data and digitalized information for early years (1913–1970) from the pdf yearbooks (1925, 1927, 1930, 1933, 1936, 1939, 1948, 1953, 1959, 1965, 1971, 1973) using optical character recognition (OCR) software. For aluminium and copper, we additionally used data from the World Bureau of Metal Statistics [131], who provide a comprehensive production dataset for major metals from 1950 onwards, providing a higher level of completeness than BGS.

For the purpose of gathering data on raw products (p2), we compiled data on production and trade of primary aluminium, refined copper, refined lead, zinc slabs, refined nickel, refined tin, chromium ore and concentrates and manganese ore. Details on the categories included in the production and trade data compiled from BGS and WBMS can be found in Table 7. Categories in trade data from 1913 to 1970 are highly diverse, which is why we only show some of the main selected categories. For chromium and manganese, BGS only reports data on ore extraction. To estimate the metal content in gross ore accounts, we combined ore grades for chromium and manganese from different sources to derive regional and temporal differences [18,73,121]. We multiplied these ore grades with production and trade of ores and concentrates, but of course not with trade in metals themselves. Comparing the novel metal accounts with estimates from Wang et al. [127] at that stage delivers high overlaps on the global level, which is why we are confident about the initial production estimates.

Table 7.

Categories included in production and trade statistics from BGS (and WBMS for aluminium and copper).

| Metal | Production (BGS & WBMS) | Trade 1970–2016 (BGS & WBMS) | Trade 1913–1970 (BGS) |

|---|---|---|---|

| Aluminium | Primary aluminium | Unwrought, unwrought alloys | Unwrought, semi-manufactures, alloys, … |

| Copper | Refined copper | Unwrought, unwrought refined, unwrought alloys | Rough and refined copper, semi-manufactures, alloys, unwrought, … |

| Lead | Refined lead | Unwrought, unwrought refined, unwrought alloys, semi-manufactures | Crude and refined unwrought, alloys, semi-manufactures, … |

| Zinc | Zinc (slab) | Unwrought, unwrought alloys, crude, refined | Refined zinc, semi-manufactures, unwrought, … |

| Chromium | Chromium ore and concentrates | Ores and concentrates, metal | Metal and alloys, chromate and bichromate, … |

| Manganese | Manganese ore | Ores and concentrates, metal | Concentrates, metal, alloys, … |

| Nickel | Nickel (smelter/refinery) | Unwrought, unwrought alloys | Unwrought, alloys, semi-manufactures, … |

| Tin | Tin (smelter) | Unwrought, unwrought refined, unwrought alloys, semi-manufactures | Unwrought, alloys, semi-manufactures, … |

Comparing BGS trade datasets with Comtrade data for the years 1962–2016 indicates a higher completeness of Comtrade data (after modification as explained in Section 5). BGS trade data is unfortunately not giving a common classification of traded products, as countries report their trade at various aggregation levels (which we depict in the uncertainty estimates). To be sure to avoid either double counting or underrating of data for at least the years after 1962, we only used trade data from Comtrade, which is following a common classification system, for the metals for which comprehensive datasets could be derived: aluminium, copper, lead and zinc. For these metals, we added BGS data for the years prior 1962 for processing stage 2, which connects well to Comtrade estimates. For chromium, manganese, nickel and tin, only BGS data was available and used for the first processing step, trade at following processing stages was assumed zero. BGS trade data for many developing countries has not been available for recent years after 2002 due to unknown reasons, which is why we extrapolated data for these years, so that global exports more or less equal global imports.

Further data processing and estimation steps have been conducted as described in Section 3. For the metals, for which only total production (primary and secondary) was reported (copper, lead, zinc, nickel) and for trade flows of all metals, we excluded secondary production as described in detail in Section 7. Back-casting of production flows prior to 1913 has been deliberated for each material separately. The first large-scale production method for aluminium was developed in 1886, after which production increased rapidly as prices fell drastically [36]. We therefore introduced a technological starting point for aluminium production at 1886 until which we linearly reduced production towards zero, in case the last datapoint was higher than 5 kt/yr. The use of copper, lead, zinc and tin intensified in line with industrialization processes [73], which is why we back-casted their production flows with GDP changes rates, in case the last datapoint in 1913 was higher than 5 kt/yr for copper and zinc and higher than 2 kt/yr for lead, nickel and tin. As chromium and manganese have almost entirely been used as components of steel alloys, we back-casted their production flows with global crude steel production change rates back to 1820. Back-casting of trade flows was done using growth rates of global trade flows (constant US$) sourced from Federico and Tena-Junguito (2016) until 1900, before we assumed trade flows to be negligible.

The novel database constitutes a comprehensive quantification of all major stock-building material flows at different production stages. Therefore, an important issue is to avoid double-counting of materials that have been combined in material compounds or alloys. These considerations largely matter for metals, which exist and are reported in various forms of alloys. While it is beyond the scope of this paper to investigate alloys of all other metals, we at least consider major iron and steel alloys, which cover the bulk use of metals in society. Some of the metals we quantified in this work are to a large extent used as components of (mostly stainless) steel: chromium at about 90%, manganese at around 85% and nickel at around 68% of their total production flows. Data on end-uses for several years and some developed countries indicating metallurgical use could be derived from USGS and WBMS yearbooks ([119,[130], [132]). As these fractions are already accounted for in the total amount of crude steel production, we subtracted them from the accounts on the production of other metals in processing stage 2 to avoid double-counting in the final consumption estimates. All other compound usages of metals (e.g. zinc galvanizing) have not been considered in this database and are continuously reported in their elementary form.

As we could not compile full trade datasets for chromium, manganese, nickel and tin and the estimates for these metals are in total not very robust, we decided not to show these results separately, but included them into the aggregate of all other metals. While this group represents an approximate account for the mass flows of all other metals, the data quality is in general too low to warrant a more detailed analysis.

6.7. Plastics

The category plastics includes a wide range of synthetic and semi-synthetic materials that usually use polymers as main ingredients. Modern plastics are produced industrially and are mostly derived from fossil fuel-based petrochemicals in processes of polymerization, copolymerization, condensation, polycondensation and polyaddition [77]. Plastics production and especially trade flows are hard to estimate, as plastics are included in a huge variety of raw, semi-finished and final products. We utilized international databases ([61,116,[117], [118]) and various additional data sources (e.g [2,39,99]) to compile country-level plastics production and trade flows. The final dataset covered seemingly complete time series for 127 countries from 1970 to 2016.

Plastics production data can be primarily found in the United Nations Industrial Commodity Production Statistics database (UNICPS) [116,117]. Data has been combined from two different UNICPS datasets from 1970 to 2003 and 1995–2016 and for the latter dataset, if no weight measure is available, conversions of values in US$ to kg using average UNICPS kg/US$ factors have been conducted. For the early dataset, no additional monetary or physical data was available for conversion. Details on which commodity categories have been compiled and which conversion factors have been applied can be found in Table 8.

Table 8.

UNICPS plastics commodities used and conversion factors applied.

| UNICPS dataset 1970–2003 |

UNICPS dataset 1995 - 2016 |

|||

|---|---|---|---|---|

| UNICPS code | UNICPS commodity category | UNICPS code | UNICPS commodity category | kg/US$ |

| 351310 | Alkyd resins | 34710–1 | Polyethylene having a specific gravity of less than 0.94, in primary forms | 0,95 |

| 351313 | Aminoplastic resins | 34710–2 | Polyethylene having a specific gravity of 0.94 or more, in primary forms | 0,87 |

| 351316 | Phenolic and cresylic plastics | 34720–1 | Polystyrene, in primary forms | 0,78 |

| 351318 | Artificial resins and plastic materials | 34720–2 | Styrene-acrylonitrile and acrylonitrile-butadiene-styrene copolymers, in primary forms | 0,52 |

| 351319 | Polyethylene | 34730–1 | Polyvinyl chloride, in primary forms | 0,99 |

| 351320 | Ethylene-vinyl acetate copolymers | 34740–1 | Polycarbonates, in primary forms | 0,47 |

| 351322 | Polypropylene | 34740–2 | Polyethylene terephthalate, in primary forms | 0,99 |

| 351323 | Acrylic polymers | 34790–1 | Polypropylene, in primary forms | 3,52 |

| 351326 | Polyacetals | 34790–2 | Acrylic polymers in primary forms | 1,00 |

| 351328 | Polyvinyl chloride | 34790–3 | Polyamides in primary forms | 0,51 |

| 34790–4 | Amino-resins, phenolic resins and polyurethanes, in primary forms | 1,42 | ||

| 34790–5 | Silicones in primary forms | 0,29 | ||

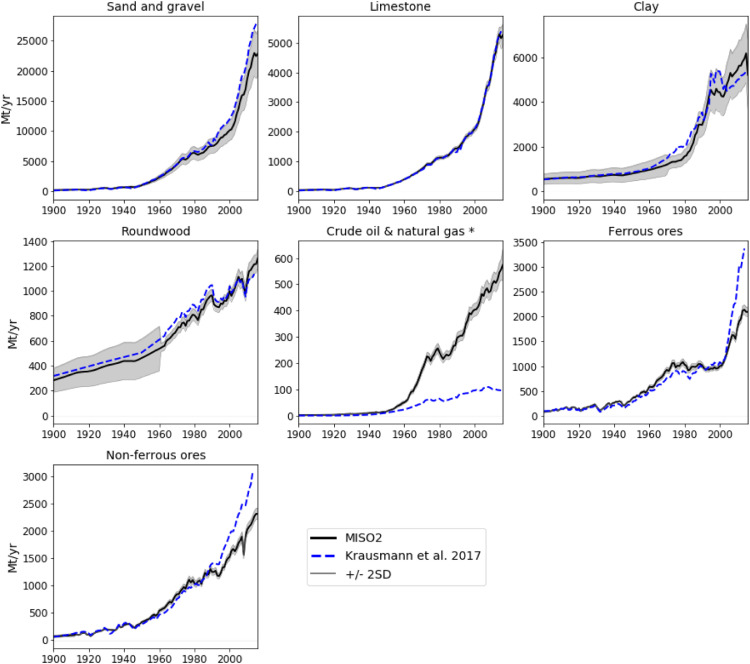

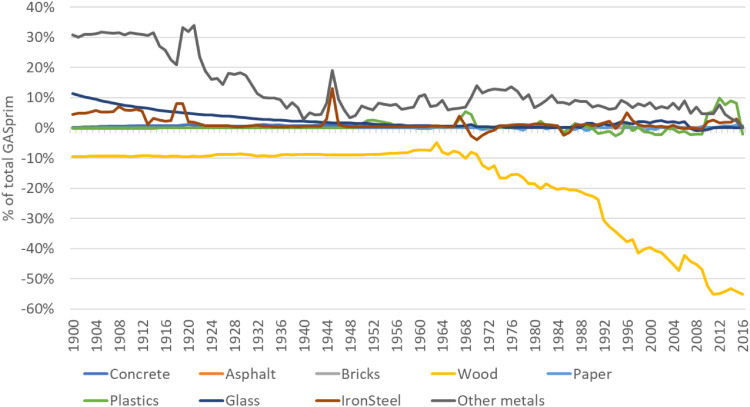

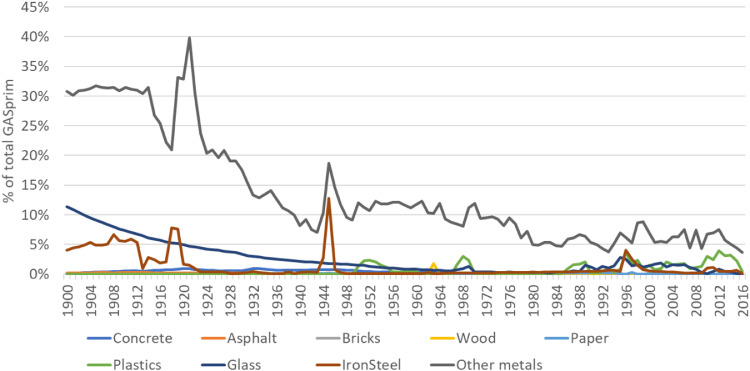

| 34800–0 | Synthetic rubber | 0,19 | ||