Abstract

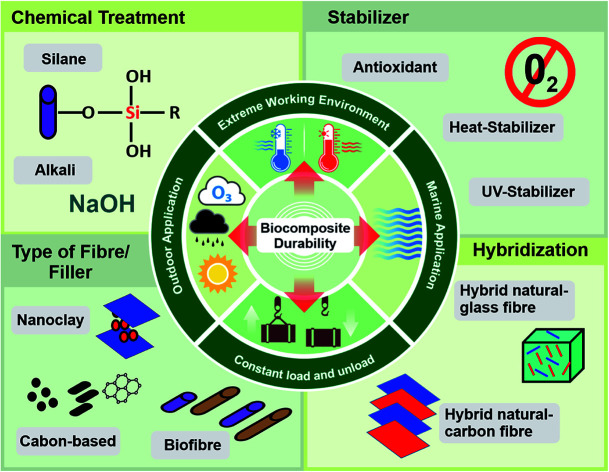

Global concerns over environmental issues have led to a tremendous growth in sustainable materials emerging from biobased plastics and their composites (biocomposites). This class of materials can be an alternative to traditional composite materials to reduce the carbon footprint and strain on the environment. Many studies and reviews have been focused on enhancing the mechanical performance of biocomposites with the aim for them to compete with traditional composites and expand their applications. However, the current scientific knowledge relating to the long-term durability performance of biocomposites is very limited in open access literature. Studies of the effects of different aging mechanisms when subjected to different service conditions and environments on the biocomposites' behaviours are needed. This review provides a focused discussion on the overview of the long-term durability performance and degradation behaviour under various aging environments (thermo-oxidative aging, accelerated weathering (ultraviolet aging), hydrolytic degradation, fatigue and creep, etc.) of the commercially important biobased-composites for the first time. Future perspectives and methods to improve the durability performance of biocomposites are also discussed in this review.

This review provides a comprehensive discussion on the long-term durability performance and degradation behaviour of the increasingly popular sustainable biobased composites under various aging environments.

1. Introduction

Traditional petroleum-based polymer composites have extensive use in a large number of diverse applications, ranging from small household devices to structural aircraft parts due to their high strength-to-weight ratios as compared to conventional materials. The intensive reliance of plastics has led to an increasing amount of plastic waste in the environment. As a result of the social and environmental awareness, there have been changes to industrial materials in recent years where manufacturers have started adopting “cradle-to-beyond the grave” approaches in their product design. With the depletion of petroleum resources and growing global environmental concerns over climate change and environmental pollution, the development of sustainable biobased materials have been growing at a fast pace. Countries including China, France, United Kingdom, Germany, the United States, Japan, and Canada have developed strategies to adapt the circular economy model through sustainable and efficient resource management to help reduce the environmental strain from waste.1–4 These countries reinforce these strategies by emphasizing rules and regulations placed on industry manufacturers to develop more sustainable and environmentally friendly products from biobased and biodegradable materials.5,6

The research and development of new biobased and biodegradable polymers from renewable resources as alternatives to conventional plastics has become an enticing area for both academic and industrial research due to the global concerns over plastic waste and pollution issues. These pro-environmental materials could be a promising solution for the global plastic waste problem. As a result, global production of polymers (biodegradable or non-biodegradable) sourced from sustainable natural resources have increased over 400% from 2016 to 2019.7 Renewable polymers can be categorized into three groups: (a) natural polymers (e.g. thermoplastic starch (TPS), cellulose and protein, etc.), (b) synthetic polymers from natural biomass feedstocks (e.g. poly(lactic acid) (PLA) etc.), and (c) synthetic polymers from microbial fermentation (e.g. poly(hydroxy alkanoate) (PHA) such as poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV)). Sustainable biodegradable polymers derived from sustainable feedstocks such as PLA, polysaccharides, poly(butylene succinate) (PBS), and PHAs are some of the successful and innovative polymers that have been developed to address these environmental issues. Biodegradable synthetic polymers sourced from petroleum feedstock, such as poly(butylene adipate-co-terephthalate) (PBAT) and poly(caprolactone) (PCL) for example, have also gained popularity in recent years even though they are not renewable. Many biobased polymers are under development with the aims to replace 100% petro-based plastics currently in use in the market. The production of large-scale partially biobased polyesters, such as bio-poly(ethylene terephthalate) (bio-PET), bio-poly(trimethylene terephthalate) (bio-PTT), and bio-poly(butylene terephthalate) (bio-PBT), have been implemented by a number of plastic production companies since 2010.8 However, the practical use of bioplastics in applications is still very limited due to high costs, limitations with small scale production, and sometimes lower mechanical performance when compared to petro-based plastics. With the help of natural low-cost reinforcement, these issues can be resolved. The use of naturally derived materials could reduce the additional carbon dioxide (CO2) produced during synthesis to the atmosphere. Furthermore, incorporation of these inexpensive natural resources as the reinforcement of biopolymers can offset the high cost of the biopolymers.

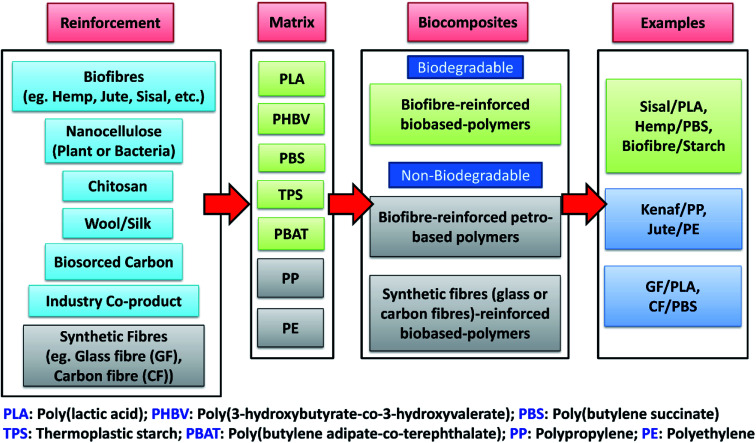

Similar to petro-based polymers, the properties of biobased polymers can be tailored and enhanced by compounding with various fillers or reinforcement to make composites. Biobased composites (biocomposites) can be developed by reinforcing different plastics (both biobased and petro-based) with a variety of inexpensive natural-derived biobased fillers (biofillers) such as flour, plant fibre, biomass, biosourced carbon, etc. However, the sustainable reinforcement for biocomposites is not only limited to plant-based fibres. Agricultural wastes from agro-based industries, consumer food waste, industrial co-product (such as distillers dried grains with solubles (DDGS) and downstream corn oil from bioethanol industry) as well as recycled materials are also defined as sustainable fillers that can be used to develop more sustainable composites with a reduced carbon footprint on the environment.9 Thermoplastic or thermosetting-based polymers can be used with different biobased fibres (biofibre), biofillers or reinforcements to form biocomposites. Biocomposites refers to composite materials that contain one or more naturally derived content, which can be part of the reinforcement phase or matrix phase or both in a composite system. They can be divided into three main groups:10 (a) biofibre-reinforced petro-based polymers (non-degradable), (b) biofibre-reinforced biobased-polymers (biodegradable), and (c) synthetic fibre (glass or carbon fibre)-reinforced biobased-polymers (non-biodegradable) (as shown in Fig. 1). The major development of biocomposites started in the late 1980s.11 The non-degradable nature of many synthetic fibre-reinforced composites have become the main motivation for scientists to develop and discover new biodegradable fibre-based biocomposites to reduce global waste. The use of biofibre in automotive applications includes products such as seat cushions, door panels, dashboards and other interior and exterior body parts.12,13 The innovation and shift of traditional composites to biocomposites for automotive industry has continued to rise due to government regulations. For example, the European Union enforced an automotive directive guideline 2000/53/EG where more than 80% of the total weight of a vehicle had to be reused and recycled in the end-of-life vehicles (ELV).14 The reused and recyclable content was increased to 95% later in 2015.15 This legislation promotes the use of recycled and biodegradable materials to achieve more sustainable automotive developments.

Fig. 1. Types of biocomposites and examples.

Biofibre can be extracted from plants, like jute, hemp, kenaf, sisal, oil palm, cotton, and bamboo, or from animals, like silk and wool. These can be compounded with various low processing temperature petro-based polymers, such as polyethylene (PE), epoxies, polyester and polypropylene (PP), or with biodegradable polymers, like PLA, PBS, etc. to form biocomposites. These renewable fibres have gained popularity in recent years to aid in developing green biocomposites for use in automotive products. Additionally, they help to reduce the weight and cost of automotive parts as the density and cost of biofibre are comparatively lower than synthetic fibres like glass and carbon fibres (density: flax fibre 1.5 g cm−3vs. E-glass fibres 2.5 g cm−3; cost: sisal fibre 0.65 USD per kg vs. E-glass fibre 2.00 USD per kg 13,15,16). Furthermore, the low density of biofibre allows for the possibility of using higher fibre content in composite products, which can reduce the non-renewable petro-based polymer content in products. This weight reduction can help in reducing the fuel consumption of cars and lead to lower carbon emissions.

With regards to life cycle assessment (LCA) and energy consumption; it was reported that the LCA of biobased composites (from biobased epoxy resin and natural fibres) was more advantageous than traditional petro-based composite (from epoxy and glass fibres) in terms of energy use and environmental impacts.17 Similarly, Miller18 reported that biofibre/PHBV-based biocomposites exhibited lower environmental impacts than conventional composite materials in terms of greenhouse gas emissions and embodied energy. These are some of the main reasons that make biofibre-based biocomposites an attractive alternative material to replace synthetic fibre-based composites for many automotive manufacturers. Other advantages over synthetic counterparts are acoustic insulation properties,16,19 less energy requirements,20 non-abrasiveness, biodegradability, etc. These biocomposite benefits and increased demand on industry has led to the explosive research and development in this field.

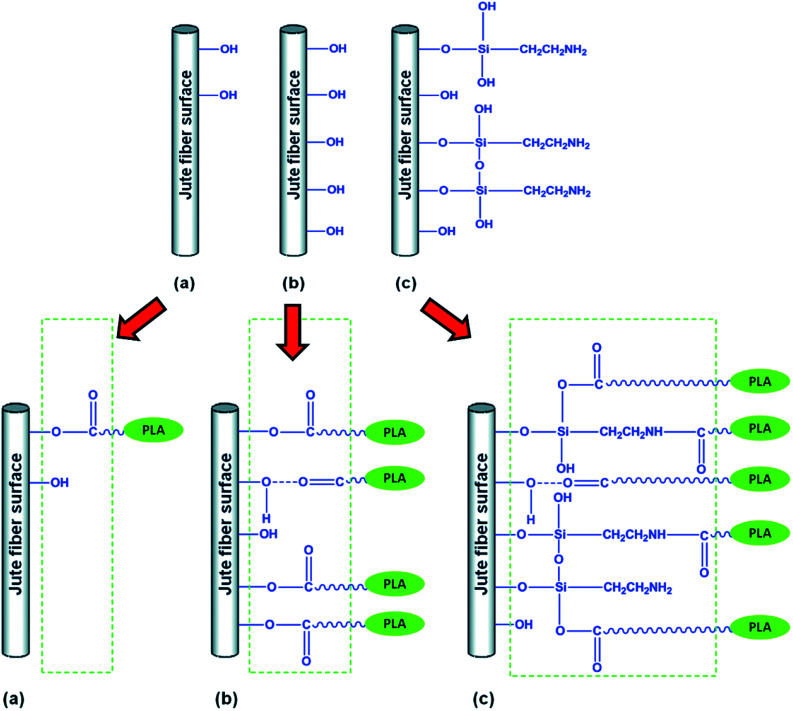

Over the last two decades, many review articles related to biofibre-reinforced biocomposites have been published.13,16,21–26 Different topics on these biocomposites have been thoroughly discussed including: reviews on their tensile properties,27 potential to replace synthetic fibres,28,29 biofibre in PP development,30 kenaf fibre biocomposites,31 flax fibre biocomposites,32 biofibres in conductive polymer composites,33 degradability of biofibre biocomposites,34 coupling agents used,35 compatibility and surface modifications,36–40 biofibre composites selection,41 hybrid biocomposites,42 nano-filler/biofibre hybrid composites,43 flammability,44 automotive applications,45 hybridization with glass fibre,46 and tribological performance.47–51 Although the performance and behaviour of biocomposites have been studied extensively, and many patented products have been fabricated, the use of biocomposites for advanced applications still needs to be explored. This is due to their insufficient mechanical strength and lack of long-term performance studies reported on this new class of sustainable materials. For instance, many works on biofibre/PLA biocomposites have been reported,52–55 however the long-term durability behaviour of these biocomposites are still not understand in depth which restricts them from advanced composite applications.

Biofibres have minimal resistance to environmental degradation. This makes them a good candidate to resolve waste pollution, as they could be degradable under appropriate composting or natural conditions. However, the long-term durability performance of plant-based composites still remains a concern, as material degradation during their service lifetime is undesirable. Both polymer matrix (biobased) and biofibre in the biocomposite can be degraded when constant exposure to harsh environments. The plants cell structures which are susceptible to different environmental attacks are listed in Table 1. Lignin is more prone to UV degradation while hemicellulose is more prone to biological and moisture degradation.56 On the other hand, different polymers exhibited different degradation behaviour and molecular breakdown upon oxidation.

The main responsibility of different lignocellulosics structure on the mechanical strength and environmental degradation. Reproduced with permission from ref. 56 (License Number: 4784941441658)a.

| Lignocellulosics structures | Strength | Thermal degradation | Moisture absorption | Ultraviolet degradation | Biological degradation |

|---|---|---|---|---|---|

| Crystalline cellulose | 1 | 4 | 4 | 3 | |

| Non-crystalline cellulose | 2 | 2 | 3 | 2 | |

| Hemicellulose and lignin compound | 3 | ||||

| Lignin | 4 | 3 | 3 | 1 | 4 |

| Cellulose | 2 | ||||

| Hemicellulose | 1 | 1 | 2 | 1 |

The number (1, 2, 3 and 4) indicates the effects responsible to the properties. 1 = strongest effect and 4 = least effect.

Durability behaviour and performance of the developed biobased materials are often overlooked when it comes to material characterization and testing. “Material durability” refers to the ability of a given material to withstand a wide variety of physical processes and chemical degradation reactions from the exterior environment. This includes moisture, oxygen and bacteria attacks, mechanical loading, wear and tear, as well as working in extreme temperature conditions. After prolonged exposure to these environments, the performance of polymer composites could be affected due to the breakdown of the macromolecule's structure from the absorption of water and other polar solutions as well as oxidation process. Accelerated aging can be defined as the process required to accelerate the aging mechanism relative to a baseline aging condition. This results in the material reaching the same aged end-state as a real-time aged material but with a shorter time.57 The mechanical properties, dimensional stability, and heat distortion temperature of the composite materials must meet a specific requirement level after performing long-term durability tests in order to assure them to be used in critical automotive parts.58

Aging studies is an important area to research in order to assess a biocomposite's outdoor durability. Taylor et al.59 investigated the long-term aging behaviour of biocomposites from flax fibres and epoxidized soybean oil-based thermosetting resins. The study found that the developed biocomposites exhibited good resistance to accelerated weather conditions. The retention in some of the mechanical properties was superior to the commercial flax/epoxy composites after aging. Mechanical properties like tensile strength, tensile modulus, and hardness could be increased at the early stage of heat aging (annealing effect). Alternatively, the toughness like elongation at break and impact strength is usually reduced after aging. This was due to the decreased chain mobility and increased crosslinking density over time after the test. The enhancement in Young's modulus of coir/PE biocomposites was found to be higher than neat PE after aging.60 Besides the crosslinking effect and chain alignment in the matrix, the stiffness improvement of the biocomposite can be attributed to the short molecules of cellulose fibres which results in an increased crystallinity of the biocomposites. In terms of heat aging behaviour, it was found that the degradation rate of LDPE was increased after blended with palm fibres (0–30 wt%) when subjected to thermo-oxidative aging test.61 The lignin structure in the palm fibre/LDPE biocomposites undergoes an oxidation process, which is evident by the reduction of C C aromatic absorption peak in the infrared spectra.61 In addition, the increase intensity of vinyl and carbonyl groups can confirm and determine the degree of composite's degradation. More details on different aging studies are discussed in later sections.

Most of the studies focused on the performance and characterization of the fabricated biocomposites, with only limited publications and reviews available on the long-term performance of biobased composite materials. The lack of research available on biocomposites durability and the emphasis on the need for this type of research was highlighted in a number of biocomposites articles.32,34 Therefore, the potential of biobased composite materials in advanced applications for use in extreme conditions should be thoroughly reviewed and understood in order to expand their applications further.

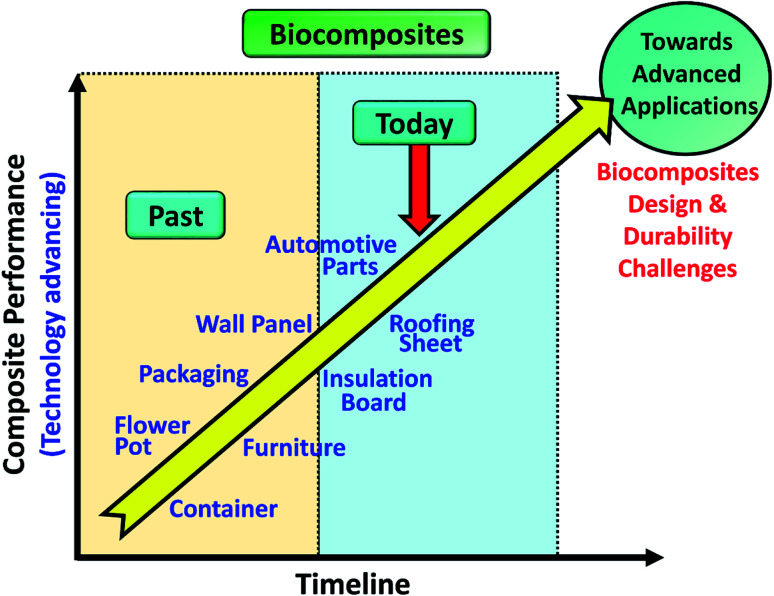

Biocomposites have been applied in many consumer applications such as furniture, wall panel, auto parts, etc. as from past to present (Fig. 2). It is important to understand the mechanism of aging on the newly developed biocomposites in order to improve their durability, performance, and service lifetime when moving towards an advanced applications direction e.g. aircraft parts and structure. In this review, studies on long-term durability behaviour and performance of sustainable biocomposites were reviewed and summarized. The effect of different aging tests such as thermo-oxidative aging, accelerated weathering, natural weathering, water absorption, fatigue, and creep, etc. on the biocomposites behaviour are discussed elaborately. The studies of biofibre modification and other sustainable fillers that are effective in retarding the rate of aging of the biocomposites were also highlighted and discussed. For the first time, the performance of biocomposites and conventional composites were reviewed and compared. This comprehensive review aims to provide useful, new information for students and researchers to advanced further in this area towards designing and development of durable biocomposites for advanced application.

Fig. 2. Biocomposites performance and their applications as of today.

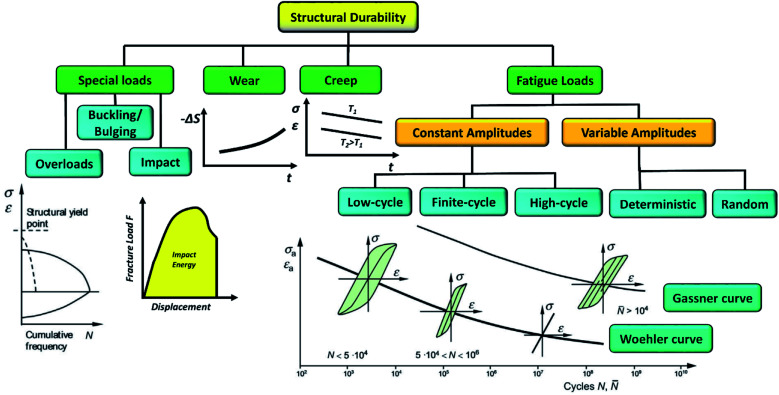

2. Method in measuring the durability performance

All materials are susceptible to aging when exposed to different environments, either in use or while in storage. The change in the material's structure can be either physical (colour or dimensional changes) or chemical (chain scission) after oxidation which is generally known as an aging process. In ambient environments, the rate of oxidative degradation is relatively slow. The oxidation process occurs rapidly at a high temperature. Outdoor environments result in faster aging processes of parts due to the harsh conditions as compared to indoor environments. There are a number of different types of aging processes important to the polymer industry; all of which are critical to evaluate when assessing a polymer's aging performance for its' final product design. The type of aging definition for polymer materials are listed in Table 2. Accelerated aging studies are imitations of specific environmental conditions which can predict the performance and investigate the degradation mechanisms of the test materials. Therefore, aging studies are very important in order to understand the material aging behaviour for the appropriate application.

Type of aging definition of polymer materials.62.

| Type of aging | Definition |

|---|---|

| Natural aging | Aging of polymers through the natural environment |

| Climate aging | Aging of polymers due to climatic conditions of a given earth band |

| Thermo-oxidative aging | Aging of polymers at elevated heat in oxygen rich environment |

| Biological aging | Aging of polymers through the action of living organisms (bacteria or fungus) |

| Mechanical aging | Aging of polymers from constant dynamic and static loads (fatigue) |

| Ozone aging | Aging of polymers by ozone |

| Photo-oxidative aging | Aging of polymers through the effect of visible and ultraviolet light spectrum in oxygen rich environment |

| Chemical aging | Aging of polymers by chemically aggressive solution or substances |

| Artificial aging | Aging of polymers in artificially created conditions |

| Thermal aging | Aging of polymers through heat |

| Light aging | Aging of polymers through the visible and ultraviolet light spectrum |

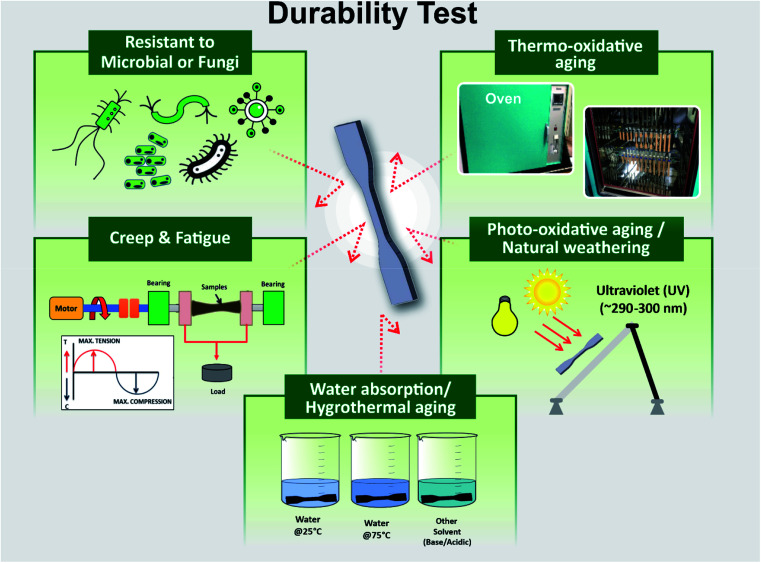

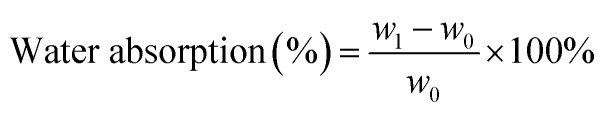

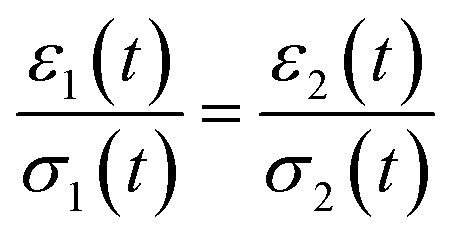

Aging tests are used to evaluate the durability performance of a material. These tests include: conditions in a climate chamber, exposure of natural weathering and UV irradiation, photo-oxidation, thermal-oxidation, water absorption, humidity, microbial, chemical degradation or a combination of these methods. Thermal cycling test (thermal fatigue) studies are also another important durability test conducted with a variation of heating–cooling cycles in a control chamber.63 After being subjected to environment degradation, the samples experience deterioration in terms of molecular weight and mechanical properties, embrittlement and cracks, color fading and spots, deformation and etc. The main symptom of aging and degradation on a polymer can be characterized by the decrease in its molecular weight as a result of bond rupture (chain scissoring).64 Durability is the extent of resistance that the properties of the developed biocomposites have to maintain in these environmental conditions. Fig. 3 presents a diagram of variety of common durability testing techniques. The aging behaviour and mechanism of the virgin polymer are usually less complex than the composite materials. This is due to the presence of different components in the composite such as fillers, fibres, additives, plasticizer, antioxidant etc., where the oxygen from the environment could transfer from one component to another component through the polymer matrix.

Fig. 3. The main durability testing for polymer composite materials.

2.1. Main characteristic of aged biocomposites

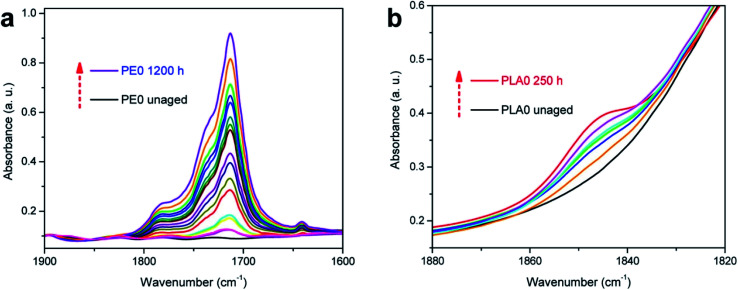

Beside the direct measurement of molecular weight changes by gel permeation chromatography, spectroscopy such as Fourier Transform Infrared spectroscopy (FTIR) and ultraviolet (UV)-visible analysis are the two most popular methods to investigate the degree of degradation of a polymer material after aging, where the possible changes in terms of chemical structures can be identified.65 Chemical compounds like ketones, carboxylic acid, anhydrides and sulfoxides are the common compound form after aging.66 The severity of degradation can generally be quantified by the carbonyl region (peak/area under the curve) or sulfoxide functionalities before and after being subjected to a prolonged period of UV irradiation or thermo-oxidative degradation (sometimes referred to as carbonyl index).66–68 The formation and the evolution of the carbonyl band intensity at ∼1890–1700 cm−1 can usually be observed due to the polymer chain scission reaction where the polymer structural linkages rupture when exposed to elevated temperatures or photo-oxidation.68–70 The products of photodegradation such as alcohols and hydroperoxides could be visible on the band of ∼3400 cm−1. On the other hand, the absorption peaks of lignin, cellulose, and other biobased substances could be degraded significantly after aging.71 The oxidation products of the aged samples and their exact quantification can also be measured analytically by treating the samples with chemical reagents i.e. sulfur tetrafluoride and nitric oxide.72,73 For example, the concentration of carboxylic acids (ketone and ester species) can be determined by sulfur tetrafluoride treatment, whereas concentrations of hydroperoxide, alcohol, and their structures (primary, secondary, and tertiary state) are estimated by nitric oxide treatment.

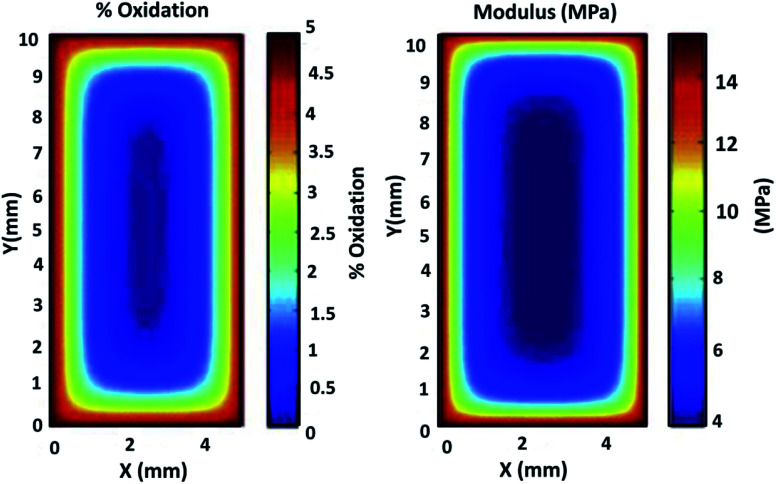

Degradation of polymers usually start from the exposure surface to the inner core. During thermo-oxidative aging, the diffusion of oxygen from the environment into the test sample can be modeled through a classic diffusion kinetic model such as Fick's second law.74 The aging reaction can become more intense with higher temperatures and prolonged duration. Physical changes such as color and alterations in mechanical performance is a more direct and clearly observed effect on material aging. The embrittlement effect after aging due to chains scissoring and chains crosslinking can commonly be seen in the rise of the mechanical modulus from tensile test measurement. Fig. 4 shows the diffusion of the oxidation content and its correlation with the mechanical modulus of a neoprene elastomer sample after it undergoes thermo-oxidative aging. Higher aging test intensity and longer duration increase the distance of oxygen diffusion into the sample from the exposed exterior surface.

Fig. 4. Correlation between oxidation diffusion and the mechanical modulus of neoprene elastomer specimen under highly accelerated thermal aging conditions of 15 days at 125 °C. This figure has been reproduced with permission from ref. 81, Elsevier, Copyright 2013 (License Number: 4707291374971).

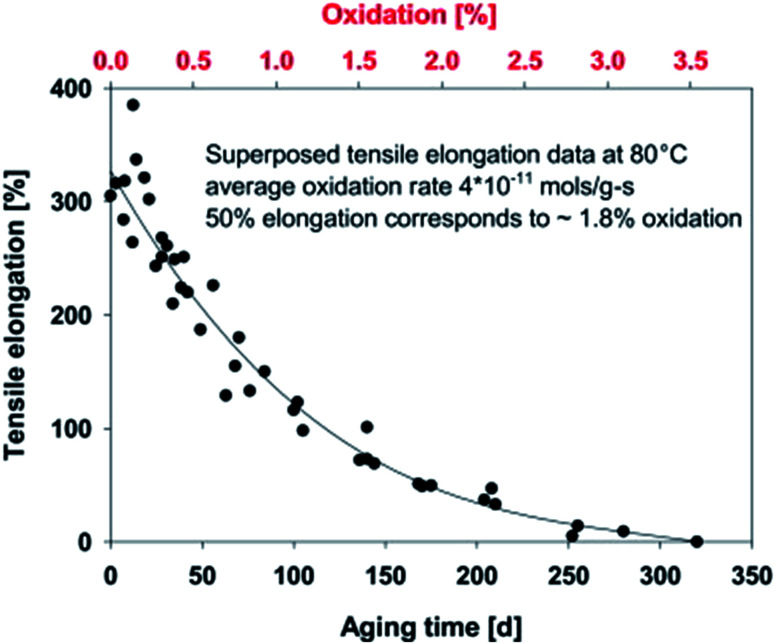

Measuring the elongation at break could estimate the loss of the molecular weight and degradation resistance of the aged sample qualitatively.75Fig. 5 displays the elongation at break of an elastomer as a function of aging time and percentage oxidation content. The elongation at the break of the sample decreases as the aging time and oxidation content increases due to the breakdown of molecular chains. Tensile toughness is very sensitive to molecular chain reduction, structural change of the chains, and morphological properties.76 Furthermore, the matrix surface cracking after thermo-oxidative aging usually results in low impact strength of the aged samples. The degree of deterioration of the interface components of the biocomposites can be investigated through interfacial shear strength and tensile strength. The intensity of the interfacial bonding of the polymer chains after oxidative crosslinking determines the tensile strength after aging.

Fig. 5. Effect of aging time and oxidation content on the elongation at break of a hydroxy-terminated polybutadiene-based elastomer aged at 80 °C. This figure has been reproduced with permission from ref. 81, Elsevier, Copyright 2013 (License Number: 4707291374971).

The change in morphology of the binary and ternary blends from PCL, PLA, and thermoplastic starch (TPS) after physical aging using atomic force microscopy (AFM) was reported by Mittal et al.77 Significant changes in the blends morphology was observed in the aged samples for 90 days due to the chains relaxation. The polymer domain reduction and interfacial separation of the blends were observed as a function of time.

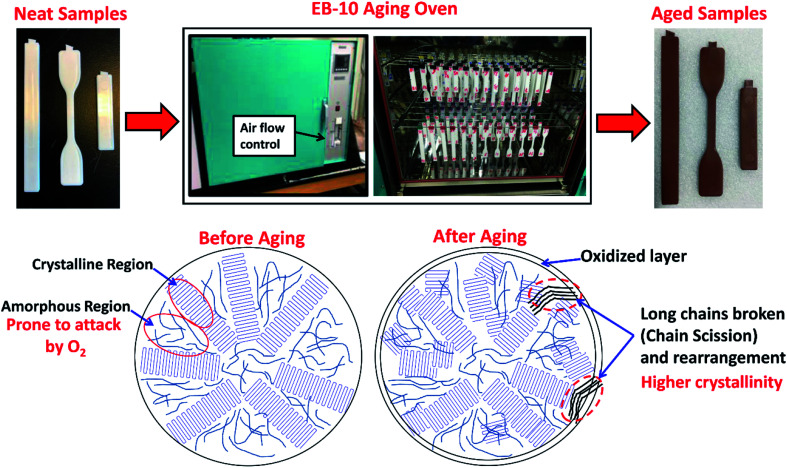

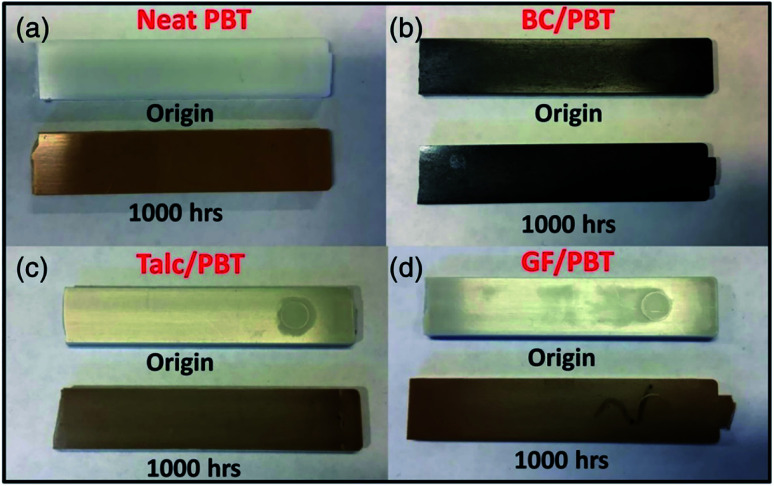

The physical changes on the appearance and schematic diagram of the intrinsic aging process before and after undergoing thermo-oxidative aging test is shown in Fig. 6. The color of the samples changed significantly after they were aged for 1000 hours in a high temperature aging oven under constant airflow. From a number of works reported on aged polyamide (PA) 6, the chromophore structure could be α-keto carboxyl,78 conjugated enones,79 pyrrole groups80 and amino compounds of NH2CH2CH2CH2CH2COCOOH and NH2CH2CH2CH2CH2COCOOCH3 that are causes for discolors and the yellowish of the aged samples.

Fig. 6. Physical and intrinsic structure changes of a semicrystalline polymer in high temperature aging oven.

2.2. Aging on thermal properties

The alteration in molecular chains arrangement, filler–matrix interfacial adhesion, and interaction during aging caused changed in the overall biocomposite's thermal properties. This included the change of degree of crystallinity, activation energy, and enthalpic relaxation.82 The aging behaviour of amorphous and crystalline structures in polymer composites demonstrated a different thermal behaviour profile when subjected to aging. The effect of aging on the crystallinity of the samples can be increased or decreased depending on the aging intensity. A very similar concept to the annealing process, the degree of crystallinity rises when a polymer undergoes different thermal-oxidative aging processes, except during aging experiments held at longer durations in a higher temperature oven, which leads to the deterioration of the polymer chains. There are two factors that could cause an increase in the degree of crystallinity of the polymers. The first can be due to the relief of thermal stress (caused during the fabrication process) of the samples83 where the spherulites could grow larger in size. The aging process in a high temperature oven or chamber allows the molecular chains to be rearranged and re-organized. Another process can be due to the re-aligning of broken chains (due to chain scissoring) into a more orderly structure in amorphous regions of the semicrystalline portion (as shown in Fig. 6 above). Due to the weaker bonds and cleaved free areas found in the amorphous region of the polymer chains, the aging process occurs more readily throughout the non-spherulite zones.84 The degree of crystallinity of neat PLA was found to increase up to ∼50% after undergoing accelerated weathering.85

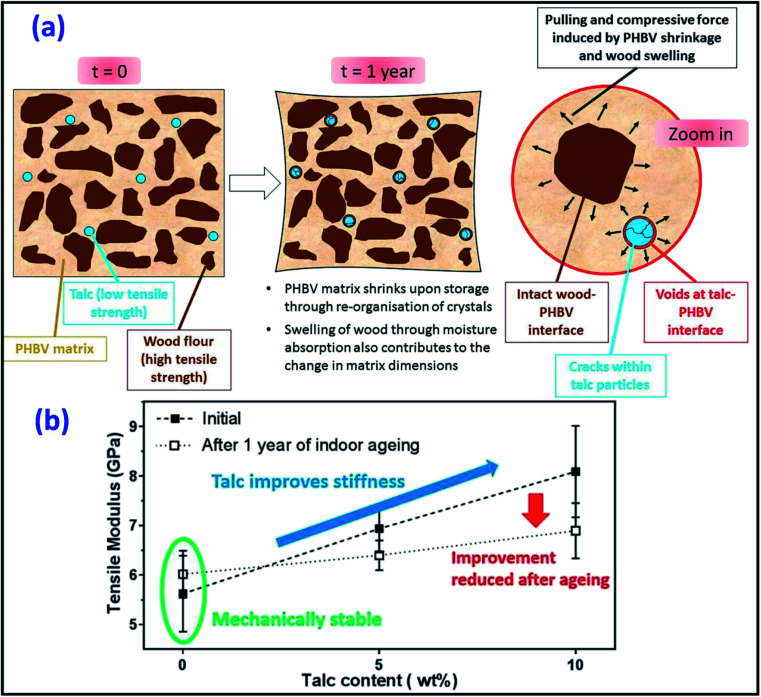

Physical aging even at room temperature for a long duration could affect the glass transition temperature (Tg)86 and other thermal properties of a polymer.87 The change in Tg of an aged polymer can be detected by dynamic mechanical analysis (DMA). The crystallinity of PLA could be increased when it is heated above 37 °C for a prolonged period. The Tg of the aged biocomposites could shift to a higher temperature due to the crosslinking process and chain mobility restriction in the early stage of aging. On the other hand, a decrease in Tg could be observed in the aged sample when chain scission was dominant. The long-term indoor stability of biocomposites from pine wood flour and PHBV were investigated by Chan et al.88 It was reported that the incorporation of a nucleating agent i.e. talc and boron nitride increased the rate of crystallization of the PHBV-based biocomposites. The biocomposites interfaces were weakened after aging for one year in ambient conditions due to shrinkage, moisture uptake, wood swelling which leads to secondary crystallization and stress localization of talc in the biocomposites. The detailed aging process is presented in Fig. 7a. The stiffness enhancement with the presence of talc in the wood/PHBV biocomposites was offset after one year of indoor aging (Fig. 7b).

Fig. 7. (a) Schematic diagram of aging mechanism of wood/flour PHBV biocomposite with the presence of talc and (b) its tensile modulus variation after one year of indoor aging. This figure has been reproduced with permission from ref. 88, Elsevier, Copyright 2018 (License Number: 4785480371285).

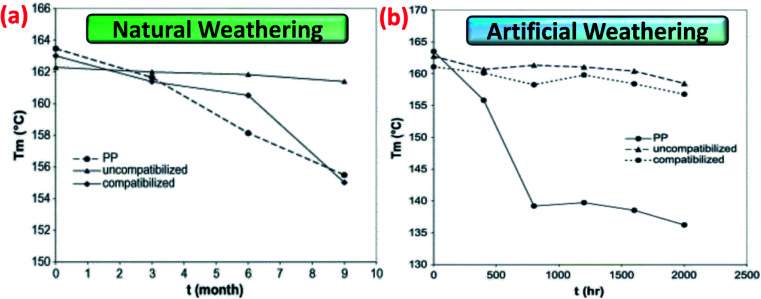

Due to molecular chain scission (macromolecule breakdown), formations of additional unstable and impure components like carbonyls and hydroperoxides in the biocomposites after aging, shifting of the melting temperature (Tm) to a lower temperature of the biocomposites was noted.89 Abu-Sharkh and Hamid90 reported an interesting result on the thermal behaviour on the date palm fibre/PP biocomposites after natural weathering aging. They observed the Tm of both neat PP and compatibilized PP-based biocomposites were significantly reduced over 9 months of natural weathering. However, the Tm of uncompatibilized date palm fibre/PP biocomposite was stable throughout the aging test (Fig. 8a). This can be attributed to the less stability of the maleated PP. In the case of artificial weathering, the Tm of neat PP was less stable than both uncompatibilized and compatibilized date palm fibre/PP biocomposite (Fig. 8b). In addition, broadening of the Tm could be visible due to the degradation of crystallite structures of the polymer after severe aging.91

Fig. 8. Melting temperatures, Tm, measured by DSC of PP-based biocomposites after undergoes (a) natural weathering and (b) artificially weathering as a function of weathering time. This figure has been reproduced with permission from ref. 90, Elsevier, Copyright 2004 (License Number: 4758351272633).

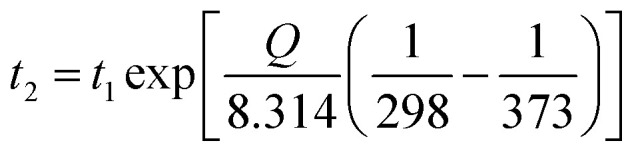

Lévêque et al.92 developed a multiscale approach to analyze and model the thermal aging behaviour of carbon fibre/epoxy composite structures. The developed models were based on the volume and surface effects; results demonstrated that the computational data closely resembles the experimental thermal aging data. However, there are still many environmental variations and other intrinsic factors unaccounted for that are affecting the final properties of the composites during an aging test. The Arrhenius equation (eqn (1)) can be used to roughly estimate the temperature–time relation of an accelerating thermal aging duration and condition of a materials.93

|

1 |

where t2 is the equivalent time at room temperature, t1 is the accelerating aging duration and Q is the activation energy of the test materials. The degradation behaviour of PLA after six months at room temperature was found to be equivalent to 3 weeks at 100 °C based on the Arrhenius equation.94 Lehrle et al.95 reported the use of pyrolysis-gas chromatography as a new approach to study and model the thermal degradation mechanism of different polymers.

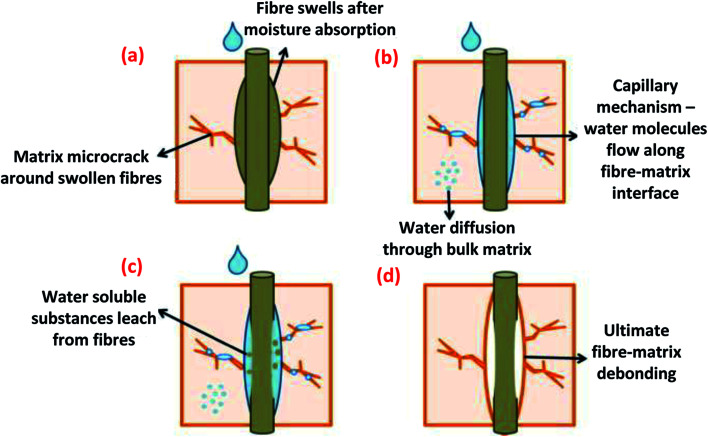

2.3. Effect of different processing method

There is a tendency that air and other volatile substances may be trapped inside the biocomposite during processing and curing40 which may affect the properties in long-term use. Due to the presence of micro-voids, biocomposites are more vulnerable to moisture diffusion and high variation in mechanical properties as compared to neat polymers. Different process engineering and parameters could yield different intrinsic structural and homogeneity of components within a biocomposite. The mechanical properties of composites can be substantially different even if the same raw materials and formulation were used, but with different processing techniques. This phenomenon has also been reported in durability studies. The green biocomposites of PLA reinforced with apple fibres and sugar beet pulp processed with extrusion followed by injection molding has been found to affect their aging behaviours.82 Clemons and Ibach96 compared the moisture absorption behaviour of wood/HDPE biocomposites processed with different processing techniques. They found that the biocomposites produced from extrusion absorbed the most moisture, followed by compression moulded sample, and the injection molded samples showed the least moisture absorption after two weeks of the water soaking test. They correlated this to the lower void content and better packing density of the biocomposites produced from the injection molding process. This was further supported by the work from Stark et al.,97 where different manufacturing methods could give different surface characteristics, which can affect their durability performance. Wood-based biocomposites were prepared with three different processing techniques i.e. injection molded, extruded and planed. Injection-molded samples showed more polymer rich surfaces than the extruded and planed samples, while planed samples displayed the highest wood phase presence and exposure on the surface. The higher packing density from the high pressure injection molded samples exhibited better interfacial adhesion and hence more stable when exposed to weathering test.97

Sustainable bioplastics and biocomposites have gained considerable interest in recent years due to their environmental friendliness as compared to conventional polymer composites. However, their performance under different extreme environment conditions is still an open question. In order to investigate and enhance their durability performance, considerable work on various types of biocomposites have been conducted and will be reviewed in the subsequent section. Depending on the application of the materials, the accelerated aging test may not accurately predict the value or represent the actual aging condition of the materials (e.g. in aerospace composite materials).81,98 This can be due to the variation of weather between seasons as well as different geographical regions between countries.59

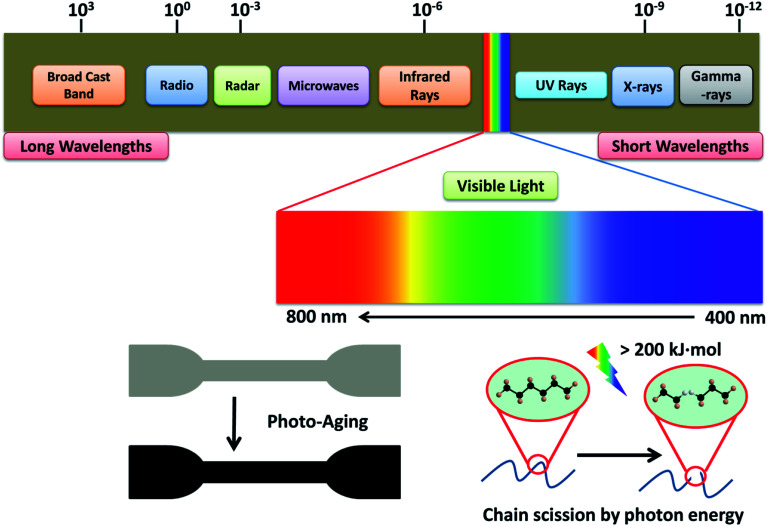

3. Photo-oxidative and weathering

Light can induce the degradation of polymers. Photo-oxidative degradation is a decomposition process where the material's chemical structure is broken down after prolong light exposure. UV stabilizers are typically added in polymers that are sensitive to UV light. Upon UV exposure, the wavelength energy of irradiation waves is the main factor causing the molecular chain breakage in the composite materials (Fig. 9). Typical polymer chains can be excited and detached at the energy around 290–420 kJ mol−1 and the energy of the UV radiation is in the range of 290–410 kJ mol−1.99 This UV energy is enough to initiate the degradation (free radical produce) and is expected to accelerate in the presence of an oxygen rich environment. The quantum energy from the wavelength of UV radiation can cause microcracks on the surface of degraded polymers.100,101 The energy of the irradiation wavelength at 295 nm is enough to break the C–N, C–C, C–O, Si–O, N–H and O–O polymer bonds.102 For PLA, UV energy of 400 nm or less could break the covalent bonds of C–O and C–C,103 and produce polymer radicals from chain scission. These polymer radicals may link to the main chain of a neighboring molecule to give a branched molecule.100 The aged samples usually experience considerable color fading and excessive embrittlement as a result of crosslinking, which leads to microcracking on the surface. At the same time, the mechanical properties are also drastically affected after prolonged UV exposure.

Fig. 9. Photo-oxidative degradation mechanism of polymer biocomposites.

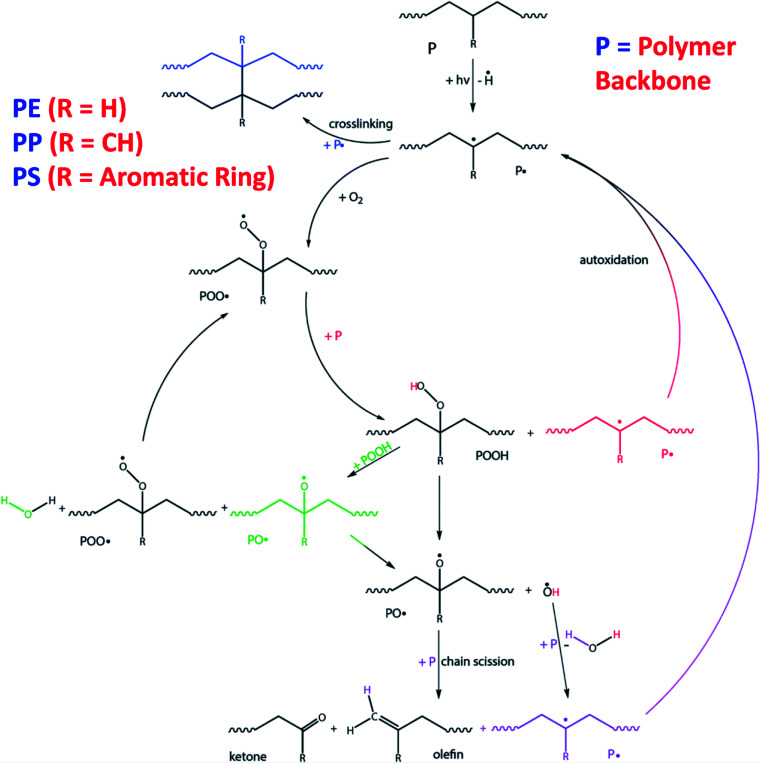

Different polymers exhibited different photo oxidative degradation. Fig. 10 shows the degradation pathway for common packaging polymers i.e. PE, PP and PS.104 The degradation involves three stages: initiation, propagation, and termination. UV light initiated the breakdown of the polymer chains, while free radicals are formed when the C–H bonds were broken by the light action.105 The process continues through reaction with oxygen in the environment to form peroxy radical and hydroperoxides.106 Termination stage take place when inert products are formed through the combination of two radicals. However, these inert products (ketones, aldehydes, etc.) are more susceptible to UV-initiated degradation, as they contain unsaturated double bonds.104 Therefore, the molecular weight of the polymers reduces as the degradation continues through these breakdown reactions.

Fig. 10. Degradation pathway upon UV-initiated degradation for common packaging polymers (PE, PP and PS) starting on their backbone structure. This figure has been reproduced with permission from ref. 104, RSC, Copyright 2015.

Dintcheva and La Mantia107 investigated the durability of commercial starch-based biodegradable polymers for potential use in agriculture film applications. They found that both maize starch polymers and synthetic biodegradable polyesters degraded drastically after undergoing the photo-oxidation process. A significant reduction in elongation at break shows poor resistance of the polymers to the UV irradiation. However, the durability performance of the biodegradable polymers can be improved after incorporation of small amounts of commercial UV stabilizers. In addition, they reported that the benzophenone compound seems to work slightly better than the benzotriazoles, the triazine, and the sterically hindered amine among the UV stabilizers investigated.

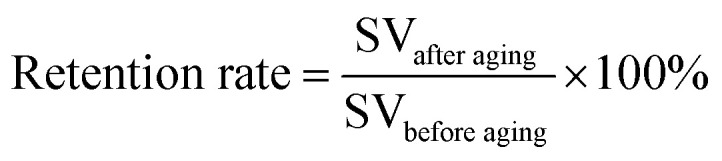

Aging can also be associated to the decline of the mechanical performance of materials. Depending on the aging intensity, the mechanical properties of the polymer composites decrease over time except for the modulus. The mechanical property's retention after photo-aging can be calculated with a simple formula as in eqn (2), where the SV stands for strength value (before and after aging) which can be impact strength, flexural strength, and tensile strength. For the biocomposite to be use in real applications, its percentage retention rate should not be less than 50% after weathering exposure.

|

2 |

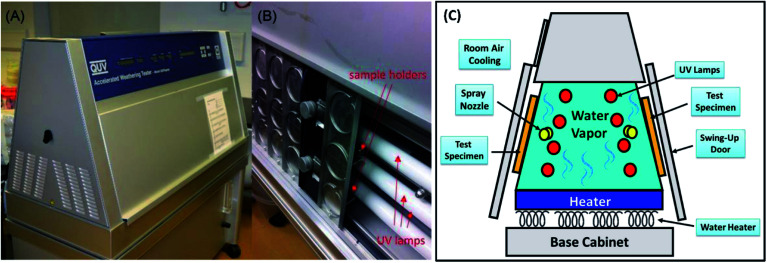

Conducting a full experimental setup for biocomposites under natural weathering exposure conditions require a lot of time and man power. Accelerated weathering tests are usually preferable over natural weathering aging, as they can be carried out with either a QUV (UV lamp) or Q-Sun (Xenon lamp) accelerated weathering chamber. Fig. 11(A–C) shows a typical QUV/spray accelerated weathering tester and its schematic diagram respectively.

Fig. 11. (A and B) The QUV/spray accelerated weathering tester. Figures adapted with permission from ref. 108, the Royal Microscopical Society, Copyright 2016 (License Number: 4761390867194) and (C) its schematic drawing diagram.

Buffum et al.94 investigated the mechanical properties of seven different service-ware made from biodegradable waste fibre and plastics i.e. bagasse, a bagasse bamboo blend, PLA, wheat straw, fibre pulp, potato starch, and a bamboo bulrush wheat straw blend after they were subjected to UV exposure and humidity. They found that most of the mechanical strength of the biopolymers decreased significantly, with PLA experiencing at least 50% reduction in tensile strength and tensile modulus. The UV exposure at the 315 nm band could accelerate the hydrolysis degradation of the ester linkage in the PLA.109 The effect of humidity was not as severe as that of UV radiation. A higher rate of degradation was reported when PLA films were subjected to elevated temperatures and relative humidity simultaneously.109 The reduction in mechanical properties can be attributed to the hydrolysis of ester linkages of PLA, which decreased with the increase of temperature and relative humidity.94,109 The study concluded that although the investigated bioplastics service-ware products possessed similar properties to polystyrene (PS) in the as-received condition, the biodegradable bioplastics were more sensitive to UV exposure and humidity as compared to traditional plastics, like PS. The mechanical strength of the PLA product can be expected to decrease significantly after 6 months under ambient conditions.94

Fibrous biocomposites such as bagasse and fibre pulp-reinforced biopolymers exhibited significant resistance to the loss of properties over time as compared to its pristine form.94 Gorrasi et al.110 studied the effect of photodegradation on thermal, mechanical, and electrical behaviour of their tailor-made hybrid clay-carbon nanotube-reinforced PLA bionanocomposites. They observed a drastic decrease in Young's modulus of neat PLA after UV exposure over time due to the chain scission of the macromolecular structures. The Young's modulus of PLA shows less reduction with introduction of clay-carbon nanotube nano-fillers in the PLA films. The formation of anhydride groups (carbonyl products) was the main photodegradation mechanism of PLA upon UV exposure.69,70 Composite materials filled with various inorganic fillers produce different chemical radicals or products during photo-oxidative aging. A higher rate of oxidation was observed when PLA was filled with different minerals like montmorillonite (Cloisite), Sepiolite, and Fumed silica.70 The metal ions and metal impurities present in mineral fillers accelerated the photo-oxidation of the polymer through the hydroperoxide decomposition process.

In another UV-aging resistant study of biocomposites reported by Gardette et al.,69 the PLA was reinforced with calcium sulphate anhydrate CaSO4 β-anhydrite II (dehydrated gypsum from a by-product of lactic acid) to produce biocomposites; the influence of filler content and particle size on aging behaviour was also investigated. The PLA biocomposites showed formation of similar photoproducts as observed in the neat PLA. The rate of degradation of PLA was found to increase with the increasing filler loading, as well as with the smaller CaSO4 filler particles size in PLA.

Pucciariello et al.111 found that the blends of LDPE and PS with addition of straw lignin displayed less UV degradation. They proposed that the presence of phenolic groups in lignin could act as an antioxidant and radical scavenger which results in delaying the UV-degradation process.111 However, the hydrophilic nature of lignocellulosic biofibre in biocomposites could promote hydrolytic degradation; which would then produce a loss in mechanical performance.112

Similar to PLA, PBAT is also prone to UV-aging. Zhu et al.113 prepared biocomposite films of PBAT-reinforced with nanosilica-supported ultraviolet absorber. Their results showed that the PBAT biocomposite film prepared through chemical grafting technique exhibited superior UV aging resistance as compared to the biocomposite prepared by physical mixing.

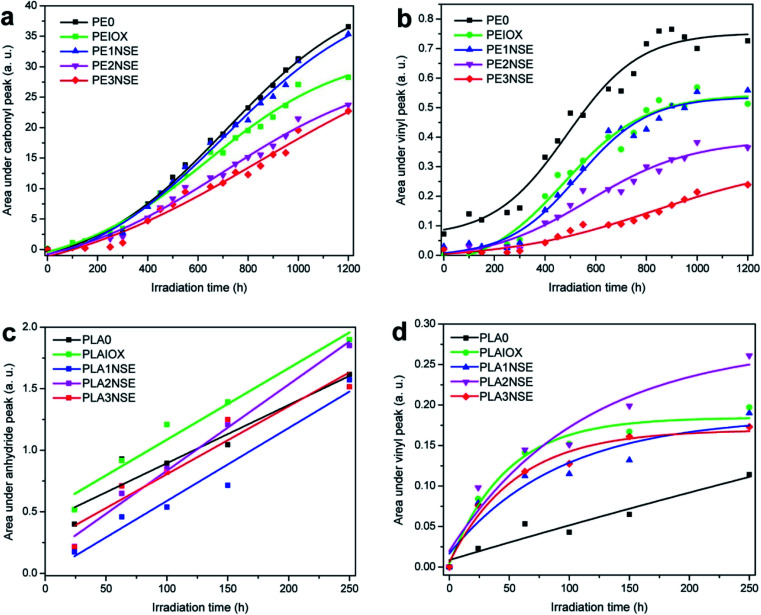

The internal structure of biofibre can also be significantly affected with prolonged exposure to UV. The lignin and hemicelluloses structures were changing as a result of macromolecular scissoring.114,115 The formation of different chemical compounds from the biofibres could act as chromophores (degradation radiation initiators) which could accelerate the degradation rate of the polymer matrix.89 Mixture products such as ketones, acids, lactones, and esters were found after aging at different carbonyl peaks such as 1712, 1750, and 1775 cm−1.116 The absorption bands of carbonyl, vinyl or anhydride increased with increasing UV exposure time, which reflects the progression of photo-oxidation (Fig. 12). It was observed that the photodegradation of palm fibre/PP was less than pineapple leaf fibre/PP biocomposites (due to a lower absorption band in carbonyl region).116 These results demonstrate that the use of different biofibres could affect the photo-aging performance of the biocomposites. The difference in the degradation rate and mechanism could be due to the lignin content and organic composition of the different biofibres. Due to the rationale that degradation happens for both fibres and matrix, increasing the fibre content should affect the photo-oxidation rate as well. Fig. 13 shows the increase in the area under the IR absorbance peak at carbonyl, vinyl, and anhydride regions as a function of UV aging time for linear low-density polyethylene (LLDPE) and PLA-based biocomposites doped with nutshell powder extract (NSE). The authors found that areas under both carbonyl and vinyl IR peaks of UV aged LLDPE were reduced after incorporation of NSE up to 3% (Fig. 13a and b).117 On the other hand, the areas of anhydride and vinyl IR peaks of UV aged PLA were unstable and increased when doped with NSE (Fig. 13c and d). This demonstrates that NSE is more effective in retarding the photo-oxidation degradation process in LLDPE as compared to PLA.

Fig. 12. Changes in the IR spectra (carbonyl region). (a) Neat LDPE film and (b) neat PLA film after UV aging. This figure has been adapted with permission from ref. 117, ACS, Copyright 2017. ACS Sustain. Chem. Eng., 2017, 5(6) 4607–4618.

Fig. 13. Effect of various NSE contents on the area changes on IR peak absorbance in (a) PE carbonyl groups, (b) PE vinyl groups, (c) PLA anhydride groups and (d) PLA vinyl groups after exposure to UV for 250 h. This figure has been adapted with permission from ref. 117, ACS, Copyright 2017. ACS Sustain. Chem. Eng., 2017, 5(6), 4607–4618.

The UV degradation of biofibre-based biocomposites can be reduced by hybridization with other synthetic fibres. Abdullah et al.118 reported that the hybridization of kenaf fibre with PET fibre-reinforced polyoxymethylene (POM) hybrid composite had better retention in mechanical properties than that of the neat kenaf fibre/POM composites. The tensile strength of the composite dropped by 50% while that of the hybrid composite with hybridization of fillers dropped by only 2% after being subjected to moisture, water spray, and UV exposure in an accelerated weathering chamber for 672 hours. Its suggested hybrid biocomposites of kenaf/PET fibres may be more suitable for outdoor applications or for automotive parts as compared to only kenaf fibre-based biocomposites.

A material's performance after subjected to outdoor natural weathering is another important aspect to evaluate the durability of the developed biocomposites for outdoor application. Natural weathering tests are very similar to UV tests where the oxidative photodegradation response of the materials can be studied and assessed by manipulating several factors such as the intensities of the exposure length, humidity, and moisture etc. However, natural weathering is more susceptible to the variation of environmental factors such as sunlight, rain, moisture, wind, fungal, and microbes attack as compared to tailor made accelerated weather equipment or UV aging oven. Enhancement of the long-term weathering performance of the biocomposites remains a challenge. With proper conditioning, it was reported that both artificial climate chambers and natural weathering yields considerable aging effects to the wood-based biocomposites.119Table 3 presents the comparison and equivalent aging duration of accelerated UV-aging test in Weather-Ometer for different climate conditions of natural weathering. These conditions could simulate approximately one year of natural weathering exposure in 2–3 months with 300–400 nm wavelength of UV light radiation.

Comparison of accelerated aging test in Weather-Ometer (xenon arc chamber) and natural weathering. Adapted and reproduced with permission from ref. 120 (License Number: 4784951380217).

| Location | Climate type | Average solar radiant exposure in one year | Equivalent duration for the Weather-Ometer exposurec | ||

|---|---|---|---|---|---|

| Totala | UVb | In days | In months | ||

| Florida, USA | Sub-tropical | 6588 MJ m−2 | 280 MJ m−2 | 95 | 3.2 |

| Bandol, France | Mediterranean | 5500 MJ m−2 | 382 MJ m−2 | 69 | 2.3 |

| Arizona, USA | Desert | 8004 MJ m−2 | 334 MJ m−2 | 79 | 2.6 |

Solar radiation measured between 300 nm and 3000 nm.

Solar radiation measured between 300 nm and 400 nm.

Regarding UV radiations only, according to 168 cycles of 120 min (EN ISO 4892-2).

Consequently, aging behaviour can vary considerably when tested in an accelerated simulated weather chamber and natural weathering exposure in different climate countries' environment. The sunlight intensity and rain fall varies geographically. Even though the weathering test can be studied in an accelerated weathering chamber with appropriate UV light and moisture condition setup, the simulated weathering chamber cannot directly simulate the real environmental condition. Part of this is because the solar radiation cannot be mimicked completely with the use of an artificial UV lamp.121 Recent studies and set-up conditions of weathering tests of biocomposites are presented in Table 4. Although there are many accelerated weathering studies reported according to the standard procedure, only a handful of studies have related their research to the actual aging progression and effective service life of the biocomposites. Full setup of experiments still need to be done in the real working conditions. However, the general behaviour on the durability performance comparison between composites can be determined.

Recent studies on accelerated weathering aging test setup and test conditions of different biocomposites and main findinga.

| Composites | Weathering condition & standard | Irradiation intensity & wavelength | Chamber environment | Test duration | Results | Ref. |

|---|---|---|---|---|---|---|

| WPCBP/WF/PP | UV-340A accelerated weatherometer, ISO 4892-1 | 0.83 | 50 °C | 15 days | WPCBP and WF enhance the retention rate of mechanical prop. of PP after UV exposure | 122 |

| Higher amount of WPCBP increases the carbonyl index due to the presence of transition metals in WPCBP which accelerate the photo-aging | ||||||

| Linseed cake/PLA | UV light, ISO 4892-3 | 0.76 W m−2, 340 nm | 60 °C | 250 and 500 h | Incorporation of biofiller accelerates the degradation | 123 |

| Hydrolytic degradation on amorphous phase (initial UV aging – 250 h) | ||||||

| Hydrolytic degradation on crystalline phase (later UV aging – 500 h) | ||||||

| SiCO/PLA | Xenon lamp, ASTM G155-13 cycle 1 | 0.35 W m−2 (340 nm) | 63 °C, 30% humidity, light and water spray for 18 min | 260 and 520 h | Tensile properties, thermal stability and rheology decreased after aging, while, % crystallinity increased | 124 |

| PF/PP, PALF/PP | Mercury pressure lamps | 400 watts (300 nm) | 60 °C | 30, 40, 50 h | PF/PP shows better properties retention than PALF/PP after photo-aging due to higher lignin content of PF | 116 |

| Wood fibre/PP (bleached and unbleached) with MAPP | Fluorescent bulb UVA, ASTM G154-00a | 0.68 W m−2 (340 nm) | 50 °C, 2 h condensation per cycle | 150, 400, 600, 800 and 1000 h | Both bleached and unbleached wood fibre composites shows reduction in mechanical prop. After accelerated weathering | 56 |

| Reduction in mechanical prop. was due to degradation of lignin, chain scission of PP and deterioration of fibre–matrix interface | ||||||

| Wood flour/PP with MAPP | Weather-Ohmeter (xenon arc | 3500 W lamp, 60 W m−2, 300–400 nm | 60 °C | 14 days | Recycled of the UV-aged WF/PP were able to recover the initial properties of the WF/PP biocomposites | 120 |

| WF/PP, lignin/PP, cellulose/PP | QUV accelerated weathering, ASTM G154 | 0.89 W m−2, at 340 nm | 60 °C, 4 h condensation per cycle | 960 h | Composite containing lignin was more sensitive to photodegradation (from color change results) | 125 |

| Lignin/PP showed better retention in flexural strength and modulus, better hydrophobicity and less cracks, on UV-aged surface than PP biocomposites | ||||||

| Starch/WF/PLA with 15% of glycerol | Fluorescent lamps, ASTM G154-06 | 0.89 W m−2, at 340 nm | 4 h condensation per cycle | 300, 600 and 1200 h | Carboxylic acid was formed on the surface after UV-aging | 126 |

| Glycerol exhibited stabilize effect on the UV durability of the biocomposites | ||||||

| Lignin/PLA | Mercury lamp | 39 mW cm−2, 200–700 nm | 30 °C, 60% humidity | 600 h | Free surface energy increased after weathering | 115 |

| Lignin/PLA show less reduction in tensile and impact strength than other samples after UV-aging | ||||||

| Mt/PLA (1 mass%) | Fluorescent lamps, SAE J2020, ASTM G154-05 and ISO 4892-3 | 0.49 W m−2, 310 nm | 70 °C, 4 h dark condensation per cycle | 50, 100, 150 and 200 h | PLA nanocomposite with 1 mass% Mt clay showed extremely beneficial effect on the durability performance after accelerated weathering (good mechanical prop. retention) | 127 |

| HNT/PLA | Fluorescent lamps, cycle-C of the ISO 4892-3 | 0.49 W m−2, 310 nm | 70 °C, 4 h dark condensation per cycle | 300 h | Intensities of the distinctive IR bands of PLA were decreased after weathering degradation due to photolysis, hydrolysis and chain scission | 128 |

| Reinforcing effect of HNT in PLA could compensate the loss in mechanical prop. After aging | ||||||

| TiO2/EVA/PLA | Accelerated weathering, ISO 4892/3 | NS | 60 °C, 8 h irradiation, 4 h humidity condensation per cycle | 8–56 cycles | Different TiO2 crystal form could affect the degree of photodegradation | 129 |

| Rutile TiO2 do not enhance the degradation, but anatase and mixed crystals TiO2 nanoparticles promoted the degradation of the nanocomposites | ||||||

| WF/PP with pigments | Accelerated weathering, ASTM G 154 | 0.89 W m−2, at 340 nm | 60 °C, 8 h irradiation, 4 h condensation per cycle | 240, 480, 720 and 960 h | Incorporation of pigments was proven to be more effective staining method for improving color stability during weathering as compared to the use of dye WF | 130 |

| WF/HDPE | Accelerated weathering, ASTM G154-12a | 0.89 W m−2, at 340 nm | 60 °C, 8 h irradiation, 4 h condensation per cycle | 500, 1000, 1500, and 2000 h | Weathering degradation of the biocomposites is affected by the type of WF | 131 |

| A. Mangium/HDPE shows better surface color and properties stability after aging than E. urophylla and P. caribaea/HDPE | ||||||

| ZnO/WF/HDPE | UVB lamps, ASTM D4329 | 313 nm | 60 °C, 8 h irradiation, 4 h condensation per cycle | 500, 1000 and 1500 h | Surface cracks, contact angle changes and mechanical prop. loss were reduced with increasing ZnO content | 132 |

| Incorporation of ZnO changed the photodegradation mechanism of the biocomposites | ||||||

| Teakwood sawdust/PBS | ASTM-G154 cycle A | NS | 60 °C, 8 h irradiation, 4 h condensation per cycle | 5 cycles, 60 h | Tensile modulus increased while flexural properties decreased | 112 |

| Loss in mechanical prop. was due to the hydrolytic degradation which induced by the hydrophilicity of lignocellulosic biofibre | ||||||

| Biofibres (Oak, cotton burr and guayule bagasse)/HDPE | Accelerated weathering, Fluorescent UV lamps, ASTM G 154 | 0.85 W m−2, 340 nm | 45 °C, UV irradiated for 4 h (60 °C), condensation for 4 h (50 °C) | 2200 h | Coupling agents helped to retain the mechanical prop. Of biocomposites after UV exposure | 133 |

| Biofibres accelerates the UV degradation rate of HDPE | ||||||

| Flax fibre/epoxidized sucrose soyate | 40 watt UVA-340 fluorescent lamps | 0.5 W m−2 | 40 °C, 4 h UV and water condensation | 1000 h each side | The properties of biocomposites reduced after weathering | 134 |

| Fibre treatments aid in improving resistance to property degradation after weathering | ||||||

| FDE/PLA, SD/PLA | UVA-340 fluorescent lamps | 60 °C, 8 h UVA radiation, 4 h condensation | 0, 250, 500, 750 and 1000 h | Larger extend of mechanical prop. deterioration was observed for FDE/PLA as compared to SD/PLA biocomposites after UV-aging | 135 |

Abbreviation: WPCBPs: waste-printed circuit boards; WF: wood flour; SiCO: capsicum oleoresin encapsulated porous silica; PF: palm fibre; PALF: pineapple leaf fibres; MAPP: maleated polypropylene; Mt: montmorillonite; HNT: halloysite nanotubes; EVA: ethylene vinyl acetate copolymer; NS: not stated; PBS: poly(butylene succinate); FDE: farm dairy effluent; SD: wood sander dust.

Free radicals formation process on the chain structures of the polymer composites as a result of photodegradation can further propagates as the weathering test continue. Moreover, the chain scission along with deterioration of the fibre–matrix interfacial bonding after degradation causes a severe reduction in mechanical performance. As a result, the molecular weight, Tg, surface properties, mechanical strength, flexibility and intermolecular forces of the biocomposite deteriorated after aging. Yew et al.136 conducted a weathering experiment for 8 weeks at 70% relative humidity on the PLA biocomposites consisting of rice starch (RS) and epoxidized natural rubber (ENR). Severe degradation was observed for the PLA biocomposites, where the tensile properties were deteriorated after weathering. The property retention of the RS/PLA biocomposites was higher when compared to the PLA-reinforced mixture of RS with glycerol and RS-glycerol water mixture. The addition of ENR increased the degradability rate of the biocomposites due to the oxidation process of unsaturated sites of ENR. The effect of natural weathering after 130 days on the Cloisite 30B nanoclay/PLA bionanocomposites was investigated by Zaidi et al.137 It was reported that the incorporation of nanoclay in PLA not only accelerated the natural weathering degradation, but also caused a reduction in thermal stability of the biocomposites. This can be due to the complex reactions and absorption of nanoclay additives, which includes catalytic effects of impurities as well as the degradation of the ammonium cations of montmorillonite (MMT). The authors also concluded that the presence of nanoclay did not alter the photo-oxidative degradation mechanism of PLA, it only accelerated degradation rates. The formation of photo products i.e. vinyl unsaturation, anhydrides, carbonyls, and hydroperoxide groups were observed due to the complex chain scission reactions during degradation.137

The mechanical properties of the jute fibre-reinforced phenolic biocomposites decreased significantly after exposure to natural weathering for two years.138 The deterioration could be more intense if the moisture content of the tested environment was high, while the colour fading of the samples continued with increased exposure time. The stress induced on the biocomposites interface from variation in the thermal expansion and shrinkage upon exposure resulted in resin cracking and fibre pop-out. The authors also observed the growth of black spots, which were confirmed as hyphae fungus due to the high moisture content of the outdoor environment.138 Significant changes in surface roughness, physical (colour), thermal, and mechanical properties of the biocomposites after the accelerated weathering test in Weatherometer was reported by Mehta et al.125 A surface coating is recommended for the biofibre-based biocomposites if it is designed for outdoor applications where it may subjected to a huge variation in moisture and heat. Polyurethane coating138 and chemical surface modification125,139 have been proved to be effective methods in slowing down the weathering degradation of the biocomposites.

Spiridon et al.114 observed changes in severity of biocomposites after accelerated weathering degradation on PLA by addition of modified fibres. They found that the enzymatically modified fibres (organosolv lignofibres) resulted in better preservation of the surface chemical, mechanical, and thermal properties as compared to unmodified fibres after weathering. Abu-Sharkh and Hamid90 investigated the aging of date palm leave fibres in PP biocomposites under natural and artificial weathering conditions with UV stabilizers. They found that the biocomposites with the help of UV stabilizers (i.e. Irgastab and Tinuvin-783) were more aging resistant than neat PP. In addition, the use of maleic anhydride (MA)-grafted PP in the composite system could reduce the overall aging resistance of the composite due to the lower stability of maleated PP.90 Islam et al.140 found alkali treated long hemp fibre/PLA biocomposites are more resistance to accelerated aging by UV irradiation and water spray than untreated biocomposites.

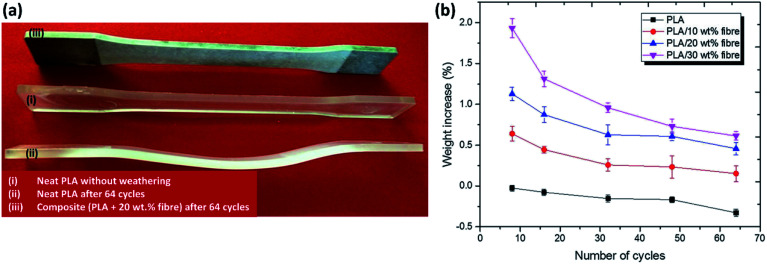

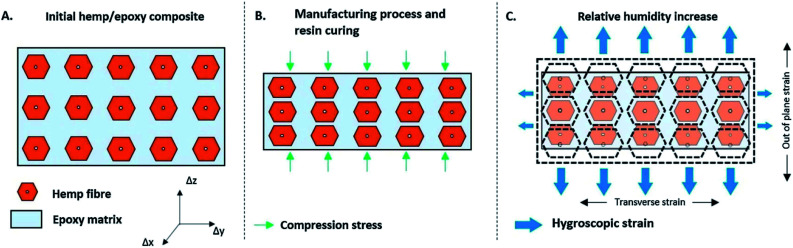

The durability performance of PLA/hemp fibre biocomposites after accelerated weathering, water spray, and condensation cycles have been investigated by Sawpan et al.85 It was found that the overall mechanical properties were decreased when increasing the test cycles. However, the impact strength of the PLA/long hemp fibre biocomposites were found to increase after accelerated weathering due to the plasticising effect as a result of porous structure formation after fibres debonding and leaching.140 The PLA was found to deform severely after accelerated weathering aging.85 The reinforcement of hemp fibres aided in retaining the stability of PLA due to presence of stiffer cellulose fibre in the matrix (Fig. 14a). In addition, the weight of the PLA and its biocomposites were found to decrease up to ∼0.30% after 64 cycles of accelerated weather aging85 (Fig. 14b). This can be attributed to the degradation of materials (blistering and erosion) when exposed to a severe weathering environment. The weight reduction on PLA biocomposites after aging due to materials degradation was also reported elsewhere.141,142 On the contradiction, some works reported an increase in material weight after aging due to absorption of the moisture by biofibres when exposed in wet environment.140 The weathering effect on the degree of degradation of biofibres can be reduced by the incorporation of synthetic fibres to form a hybrid biocomposite. Mohammed et al.143 reported superior thermal stability of kenaf fibre/GF polyester as compared to only kenaf fibre/polyester biocomposites when exposed to natural weathering for 3 months. The Tg of the composites were found to decrease with an increasing weathering period due to the molecular weight reduction in the polyester. The improvement in thermal stability of the hybrid biofibre/GF composites were attributed to the presence of the inert inorganic silica content, which can resist thermal expansion or contraction. The deterioration degree is less in hybrid biofibre/synthetic-based biocomposites as compared to the biofibre-based biocomposites.144

Fig. 14. Effect of accelerated weathering aging cycles (UV light, water spray and condensation according to ASTM G154) on PLA and its biocomposites on (a) dimension changes and (b) weight changes. This figure has been reproduced with permission from ref. 85, SpringerLink, Copyright 2019 (License Number: 4710330395191).

4. Bionanocomposites for durable applications

Due to the high surface energy and very high aspect ratio in the nano-range size (1–100 nm) for nanomaterials, the incorporation of nano-fillers or fibres into polymers can significantly increase their performance in many aspects such as dimensional stability, rheological, mechanical, electrical, thermal, and barrier properties. The thermal stability of the biopolymers have been shown to improve by using different nano-fillers such as clay145,146 and carbon nanotubes. Dispersion of nano-fillers in biocomposites are one of the popular research areas used to improve the overall composite performance. However, the incorporation of nanoclay in polymers have shown negative effects in terms of durability when compared to neat polymer, especially in the UV-light degradation process.72,76,147–154 Clay, such as MMT was ineffective in retarding the degradation of polymer. The acceleration of degradation of the organoclay-polymer composites can be due to the reaction of the degradation of alkylamonium151 and the reactions between the antioxidant and the MMT's ions forming iron or other metal species (catalytic effect).76,150 The introduction of clay in starch has shown significant improvement in thermal stability and water absorption resistance.155,156 It was confirmed that the clay/PLA nanocomposites demonstrated superior thermal stability under oxidative environments as compared to clay/PLA microcomposites.145,157 This was due to the higher degree of phase separation microstructure in the case of microcomposites. On the contrary, the addition of clay in PLA showed a decreasing trend in its thermal stability.158 The addition of both micro- and nano-MMT in polymers could accelerate the rate of photo-oxidative degradation in comparison to neat polymers.154 This can be attributed to the influence of MMT and the reactions of its ammonium ion.

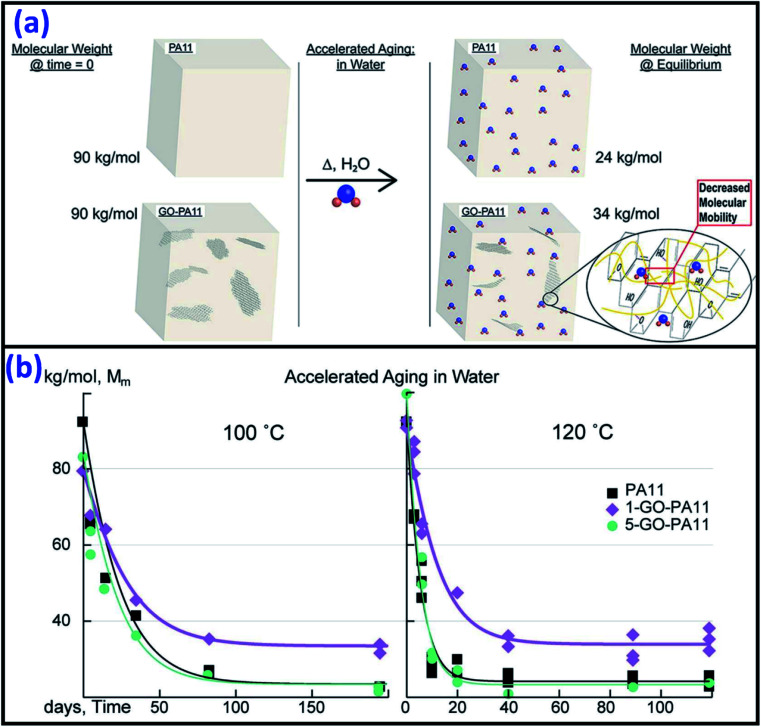

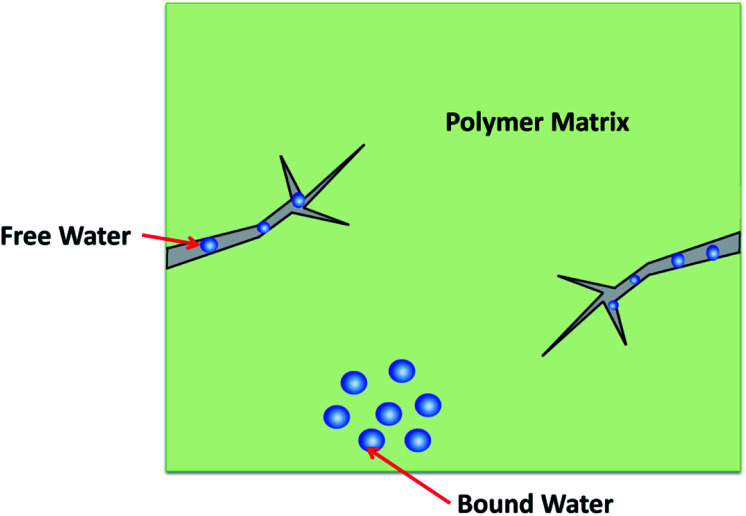

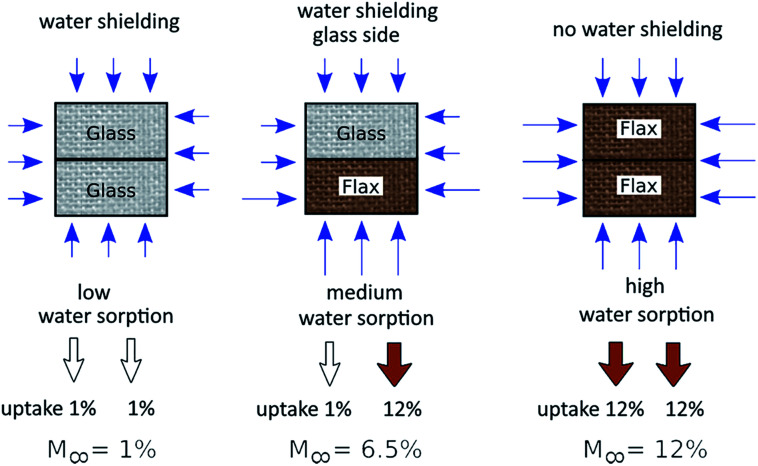

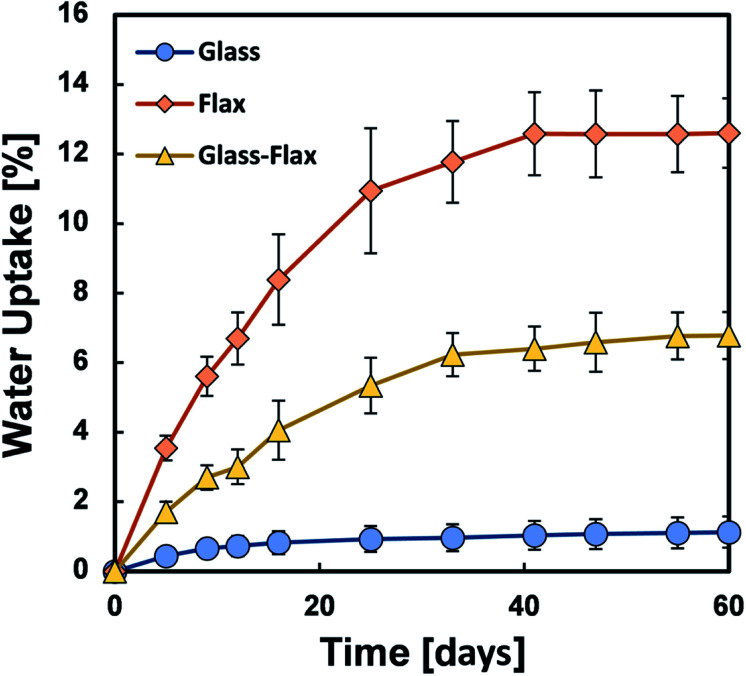

Good resistance to high temperature hydrolytic degradation was reported after incorporating appropriate amounts (1%) of graphene oxide (GO) in PA11 through a polymerization method.159 The highly asymmetric planar of GO nano-sheets could inhibit the water molecule diffusion into the nanocomposites (Fig. 15a). However, there was no significant reduction in the rate of hydrolytic degradation when further increase the GO content to 5% (due to agglomeration) (Fig. 15b).

Fig. 15. (a) The hydrolytic degradation resistance mechanism of GO nano-sheets in PA11 and (b) molecular weight reduction of the PA11 and its GO/PA11 nanocomposites after accelerated aging in water at 100 °C and 120 °C. This figure has been reproduced with permission from ref. 159, Elsevier, Copyright 2017 (License Number: 4758410550345).

Another fast emerging field of bionanocomposites is based on the use of nanocellulose. Nanocellulose can be extracted from plants (i.e. nanofibrillated and cellulose nanocrystal) and bacteria mediums (i.e. bacteria nanocellulose). The use of a small amount of nanocellulose in polymers can boost the performance of biocomposites significantly, provided that sufficient dispersion was achieved during processing. A number of works have been conducted by several authors on the reinforcing effects of nanocellulose in polymer biocomposites, such as a summary and thorough review discussed and reported by Lee et al.160 Similarily, studies on durability performance and aging behaviour of these biocomposites are limited. Cellulose nanowhiskers/PLA bionanocomposites films have shown to improve thermal stability and reduce the rate of hydrolytic degradation of PLA.161 The improvement was mainly due to the higher crystallinity of the nanocellulose which limits the water diffusion through the creation of tortuous path. On the other hand, the reverse effect was reported in the cotton-based nanowhiskers/PLA bionanocomposites.162

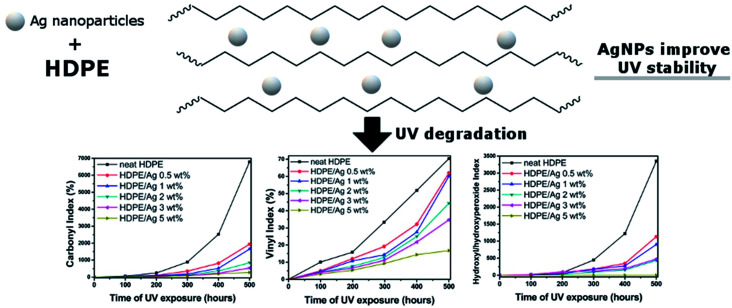

The use of other nano-fillers i.e. zinc oxide (ZnO) and titanium dioxide (TiO2) were also found to have a positive effect on enhancing the durability performance of biocomposites.132,163 The addition of ZnO in PP/wood biocomposites decreases the mechanical strength loss and surface degradation after weathering.132 The authors attributed this to its capability to absorb UV radiation. The addition of different additives and flame retardants (i.e. aluminium trihydrate, melamine, zinc borate, TiO2 and graphite) into PP-wood biocomposites was investigated by Turku and Kärki.164 They observed that TiO2 can prevent surface discoloration due to its UV-light absorption ability. However, TiO2 can facilitate chemioxidation of the biocomposite.164 Small amounts of silver (Ag) nanoparticles were able to improve the UV stability of HDPE.165 The HDPE degraded significantly when exposed to UV irradiation after 500 hours as shown in the drastic increase in the carbonyl index, vinyl index and hydroxyl/hydroxyperoxide index (Fig. 16). These indexes were reduced significantly when increasing the content of Ag nanoparticles. Metallic nanoparticles are effective inhibitors to the photo-oxidation process of the polymers.

Fig. 16. UV stability of HDPE improved with silver nanoparticles as indicated in the reduction in the carbonyl index, vinyl index and hydroxyl/hydroxyperoxide index of HDPE after UV aging. This figure has been reproduced with permission from ref. 165, Elsevier, Copyright 2018 (License Number: 4758991253218).

5. Thermal stability and thermo-oxidative aging

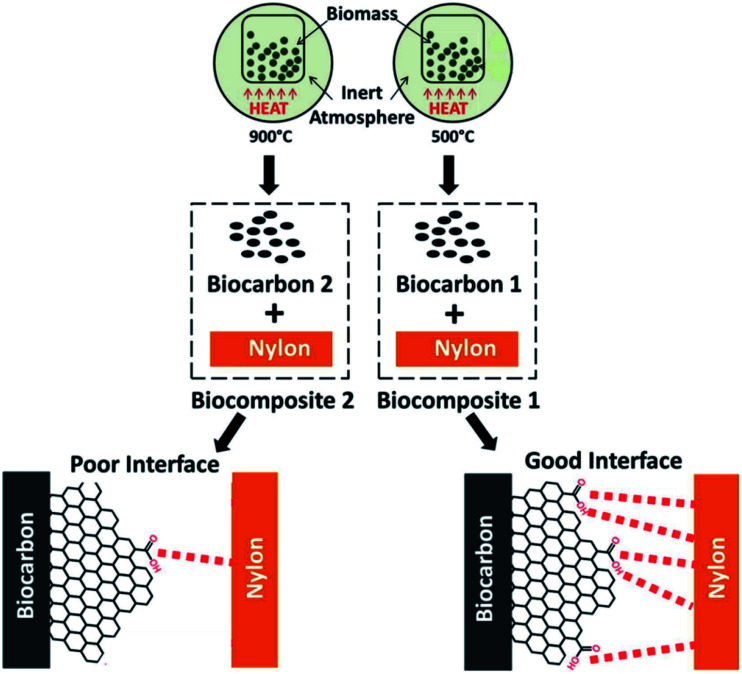

One of the disadvantages of biofibre-based biocomposites is their narrow processing window when compared to conventional composites. Lignin, a main component in biofibre starts to degrade at temperatures around 190–200 °C.27,166 The mechanical properties of the fabricated articles decline as fibre degradation occurs when processed at high temperatures due to the degradation of lignocellulosic materials, which results in losing their intrinsic structures. Therefore, the matrix choice for the biofibre-based biocomposites is usually limited to commodity plastics and thermosets. Engineering plastics like nylon, PET, and PBT matrix are relatively rare in biocomposite fabrication due to the degradation of biomaterials. The decomposition temperature and thermal stability of biofibre-based biocomposites can be improved with proper processing, and modification to improve the biofibre–polymer interaction. The thermal stability of biofibre/polystyrene (PS) biocomposites were found to be higher after surface modification and treatment as compared to a neat PS and untreated biofibre system due to the better fibre–matrix adhesion.167,168 In regards to the degradation of biofibre with high temperature processing polymers, some considerations of works have been reported. With proper processing temperature, melt controlling on the heating zone of the extruders, and the use of a second feeder close to the extruder die, it is possible to process engineering plastics with natural fibre.169 The attempt to reduce the processing temperature of engineering plastics by incorporating halide salt with biofibre is another important approach to develop biofibre/engineering plastic biocomposites.170 The addition of lithium chloride (LiCl) halide salt has showed promising effects in reducing the melting temperature of PA171 due to the formation of ionic interactions between the salt and PA molecules.172 Other coupling agents and plasticizers have also been reported as effective additives to modify the engineering plastic melting temperatures; thus making it feasible to produce biofibre/PA-based biocomposites.173,174

Biofibre-based biocomposites displayed a clear advantage when thermal and noise insulation types of application are required (critical in automotive parts). This is due to the tubular and hollow structure of the biofibre which provide effective insulation against heat and noise.175 Some works have been found that lignin can act as stabilizer and antioxidant to prevent the aging of polymer due to its antioxidant activity.111,176,177 The thermal stability of lignin/PHB biocomposites were observed to increase with the increasing content of the lignin amount.177

The thermal performance and thermal aging behaviour of biocomposites made from natural flour and PLA have been reported by Kim et al.178 They found that incorporation of flour decreases the degradation temperature of PLA. However, destarched cassava flour showed higher thermal stability than pineapple flour-based biocomposites due to its higher lignin content. The degradation temperature can be further increased with the help of compatibilizers due to the enhancement of the crystallinity; this results in higher mechanical performance of the biocomposites.178 On the thermal aging test, the tensile strength of flour-PLA biocomposites with and without compatibilizer were deteriorated due to the presence of gaps between components and shorter PLA molecules as compared to neat PLA.178

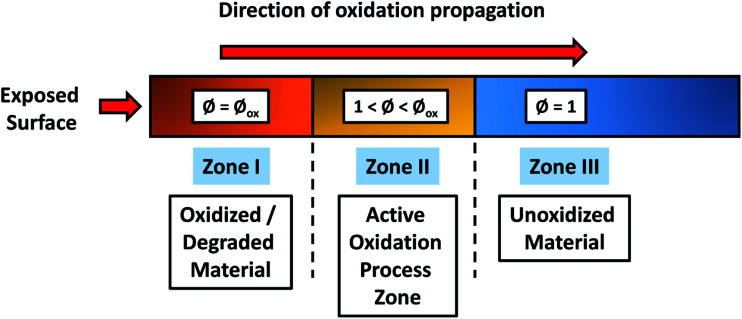

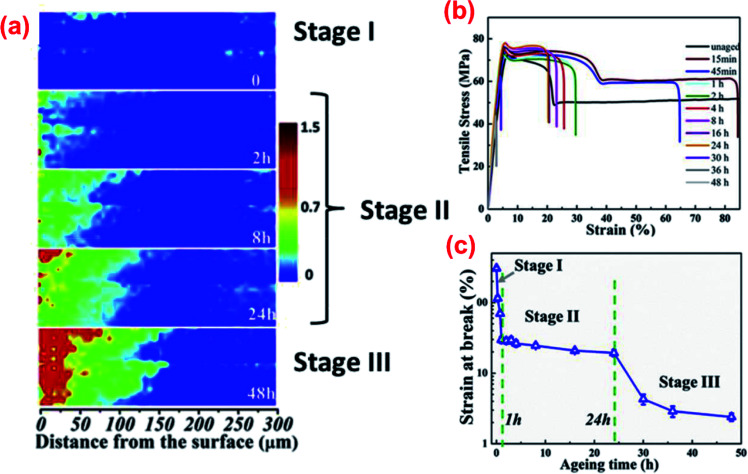

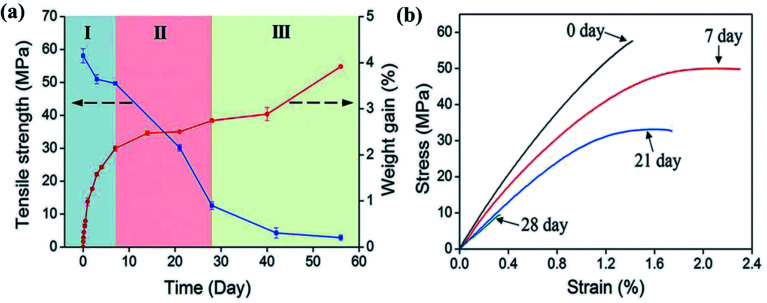

A thermo-oxidative aging experiment is an accelerated aging test conducted to investigate the aging performance of a composite material in the air rich environment at an elevated temperature. The heat accelerates the oxidation process where the oxygen slowly diffuses into the samples over time and slowly degrades the polymer chains. Basically, the degradation intensity and oxygen diffusion into the test samples can be divided into three regions as presented in Fig. 17. Region I is the outer most surface region with direct contact to the environment and is usually an oxidized polymer. The diffusion intensity is reduced in Region II resulting in a mix of oxidized and unoxidized polymer. The last phase refers to Region III which is located in the inner part of the samples where most of the polymer remain unoxidized. These degradation regions can also refer to two-phases regions or unreacted-core models.179,180 This build-up of an oxidized layer can be detected by infrared microscopy as seen in Fig. 18a. Wei et al.181 studied the fracture behaviour of PA after thermo-oxidative aging at 180 °C for 48 hours. Three stages of aging (Stage I: early stage, Stage II: moderate stage and Stage III: severe stage) were observed; tensile properties such as elongation at break were greatly affected (Fig. 18b and c). The crack initiation and propagation of PA during elongation strain is influenced by the thickness of the oxidized layer. At Stage II and Stage III region, the elongation at break reduced significantly due to the larger diffusion and extension of oxygen into the sample.

Fig. 17. Schematic of the three-zones during thermo-oxidative degradation. The active zone separating the oxidized and unoxidized regions. This figure has been redrawn and reproduced with permission from ref. 182, Elsevier, Copyright 2008 (License Number: 4707300513800).

Fig. 18. (a) Infrared images of carbonyl index in the cross-sectional region from the expose surface, (b) stress–strain curves of PA6 and (c) elongation at break value after 48 hours of thermo-oxidative aging at 180 °C. This figure has been reproduced with permission from ref. 181, Elsevier, Copyright 2018 (License Number: 4758370882321).

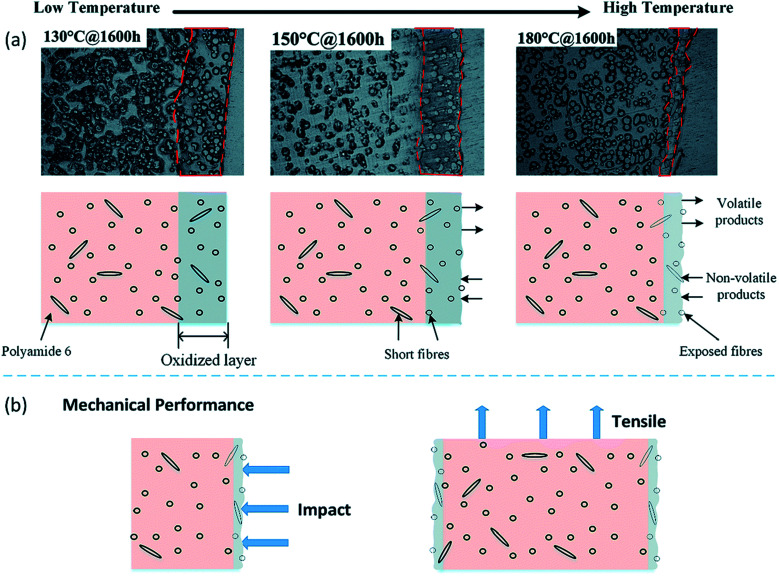

The build-up of an oxidized layer during thermo-oxidative aging could act as a barrier to prevent further oxidation propagating towards the inner core of the composite.183 At the same time, volatilization process of low-molecular weight molecules takes place. As the aging severity and duration increase, the oxidized layer thickness reduces due to the reactive zone saturation (Fig. 19). However, the inner core of the composite is still well protected throughout the aging process.

Fig. 19. Schematic diagram representation of oxidized layer buildup during thermo-oxidative aging of short fibre/PA6 composites from low temperature to high temperature. This figure has been adapted with permission from ref. 183, RSC, Copyright 2017.

The accelerated thermo-oxidation test is usually carried out at different oven temperatures and durations depending on the tested polymers and the test standards followed. However, test conditions must be appropriately selected where changes in properties (physical, chemical and mechanical) of the tested samples occur without severely distorting the samples. Acceleration factor can be used to estimate the acceleration test conditions to the actual service life. For example, the thermo-oxidative aging test of high impact polystyrene at 80 °C for 1400 hours corresponds to about ten years of service duration.184 For every increase of 10 °C in the aging test, the aging rate of the samples roughly doubles. Table 5 summarizes the test condition of thermo-oxidative aging studies conducted by different researchers on different thermoplastic composites. Note that there are not many research studies conducted on the long-term thermo-oxidative aging for biocomposites. Therefore, the research and strategy to improve the durability of biocomposites is of the utmost importance as this class of materials are gaining in popularity over the conventional composites – most likely due to global sustainability and pollution awareness.

Summary of thermo-oxidative aging test conditions and performance comparison for different thermoplastic compositesa.

| Composites | Oven temperature (°C) | Test durations | Heat stabilizers/antioxidant/additives used | Results | Ref. |

|---|---|---|---|---|---|

| LGF/PA6 | 160 | 10, 20, 30, 40 and 50 days | Copper salt, phosphorus acid | The presence of stabilizers showed better retention in terms of dynamic and static mechanical properties | 78 |

| GF/PA6, talc/PA6, BioC/PA6 | 140 | 1000 h (ISO 188:2011 standard) | — | GF/PA6 composite retained better mechanical prop. than talc/PA6 and BioC/PA6 composites | 187 |

| GF/PA6, CF/PA6 | 90, 130, 150 and 180 | 200, 400, 800 and 1600 h | — | CF showed better stabilizing effect than GF in long-term TOA test | 183 |

| Sago starch/LDPE | 70 | 1, 2, 3 and 4 weeks | SBR, ENR-50, MnS as pro-oxidant | Pro-oxidant i.e. unsaturated elastomer and metal salts enhanced the degradation rate of the biocomposites | 188 |

| GF/PBT, talc/PBT, BioC/PBT | 155 | 1000 h (ASTM D3045-92 standard) | — | GF/PBT showed the most stable in retaining its mechanical properties after TOA as compared to talc/PBT and BC/PBT | 185 |

| LGF/PA10T | 160 and 200 | 10, 20, 30, 40 and 50 days | — | Decline in mechanical performance due to interface debonding of the composite | 189 |

| iPP, HMS-PP | 90 | 6, 12 and 20 days (ASTM D 3045-2003 standard) | Irradiation with gamma rays | Irradiated samples indicates less TOA degradation as compared to neat iPP | 190 |

| PVC/NBR thermoplastic elastomers | 100 | 3, 7, 14 and 21 days (BS 7646 standard) | — | Crosslink density increases with aging time | 191 |