Abstract

Hydrogels are polymer networks infiltrated with water. Many biological hydrogels in animal bodies such as muscles, heart valves, cartilages, and tendons possess extreme mechanical properties including extremely tough, strong, resilient, adhesive, and fatigue-resistant. These mechanical properties are also critical for hydrogels’ diverse applications ranging from drug delivery, tissue engineering, medical implants, wound dressing, and contact lenses to sensors, actuators, electronic devices, and soft robots. Whereas numerous hydrogels have been developed over the last few decades, a set of general principles that can rationally guide the design of hydrogels using different materials and fabrication methods for various applications remain a central need in the field of soft materials. This review is aimed to synergistically report: i). general design principles for hydrogels to achieve extreme mechanical and physical properties, ii). unconventional polymer networks to implement these design principles, and iii). future directions for the orthogonal design of hydrogels to achieve multiple combined mechanical, physical, chemical, and biological properties. Since these design principles and implementation strategies are based on generic polymer networks, they are also applicable to other soft materials including elastomers and organogels. Overall, the review will not only provide a comprehensive discussion on the rational design of soft materials, but also provoke interdisciplinary discussions on a fundamental question: why does nature select soft materials with unconventional polymer networks to constitute the major parts of animal bodies?

1. Introduction

As hydrophilic polymer networks infiltrated with water1, hydrogels are the major components of animal bodies, constituting most of their cells, extracellular matrices, tissues, and organs. Not surprisingly, hydrogels have been widely used in biological and biomedical applications such as vehicles for drug delivery2–5, scaffolds for tissue engineering6–8, models for biological studies9–13, medical implants14,15, wound dressing16–18, and contact lenses15,19. More recently, intensive efforts have been devoted to exploring hydrogels’ emerging applications in devices and machines20 such as hydrogel sensors21–24, actuators25–28, electronic devices29–31, optical devices32–34, iontronic devices27,35, soft robots26,36,37, batteries38,39, super-capacitors40, adhesives41–43, and coatings44,45.

The mechanical properties of hydrogels are crucial to the survival and wellbeing of animals, and greatly affect the abovementioned applications of hydrogels. The pioneering works in the field of polymers and soft materials have laid the foundation for understanding the elasticity, swelling, poroelasticity, viscoelasticity, fracture and fatigue of hydrogels (e.g., Ref.46–59 and the references in them). However, the inverse question – how to design hydrogels that possess certain mechanical properties or certain properties in general – still poses a challenge in the field of polymers and soft materials59–62. This challenge becomes even more daunting, when one targets at hydrogels’ extreme mechanical properties, such as extremely high values of fracture toughness63, strength64,65, resilience66,67, interfacial toughness43, fatigue threshold68–70 and interfacial fatigue threshold71.

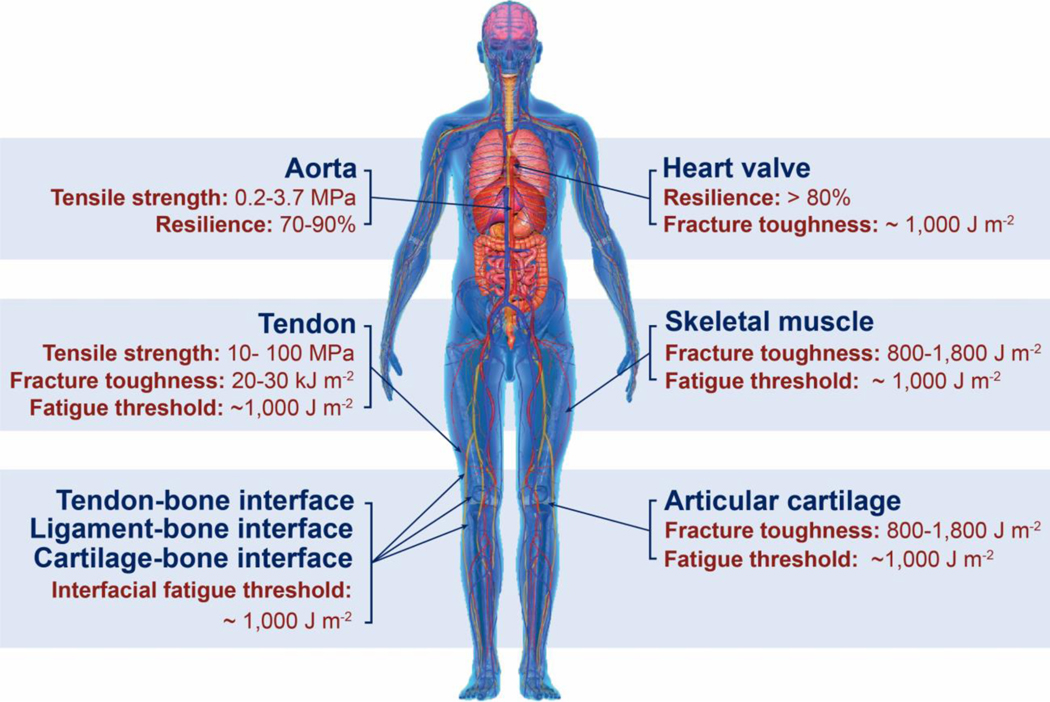

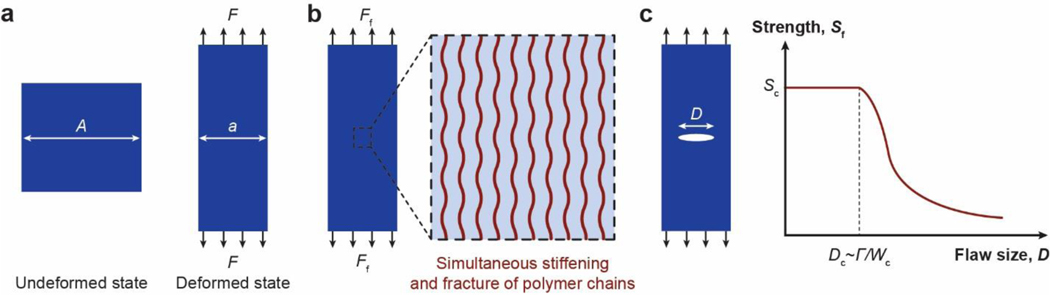

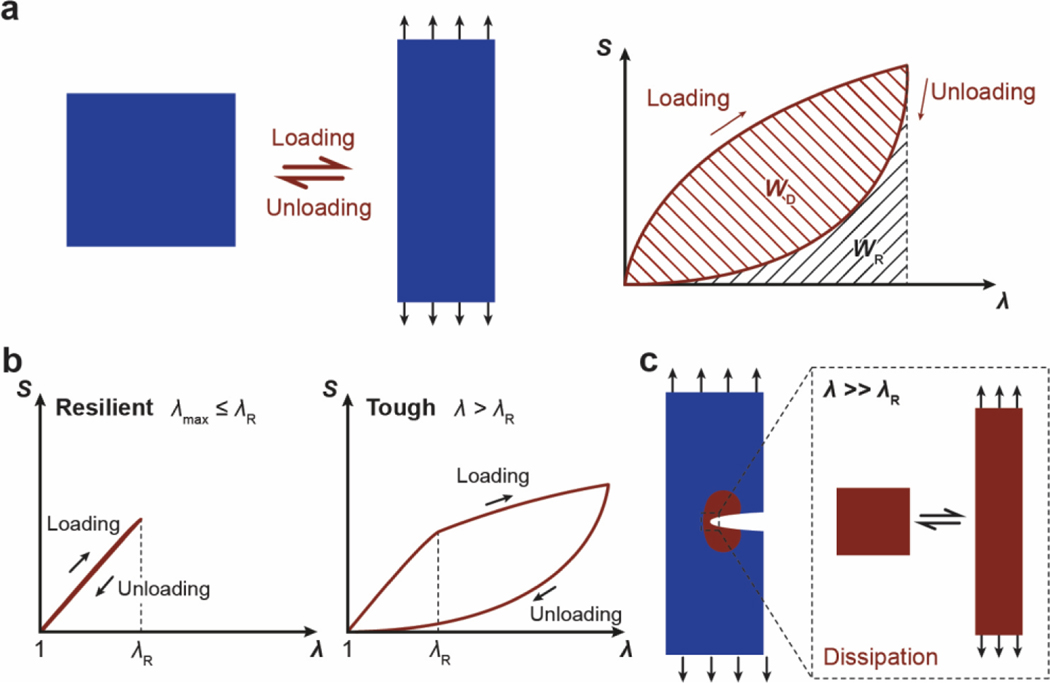

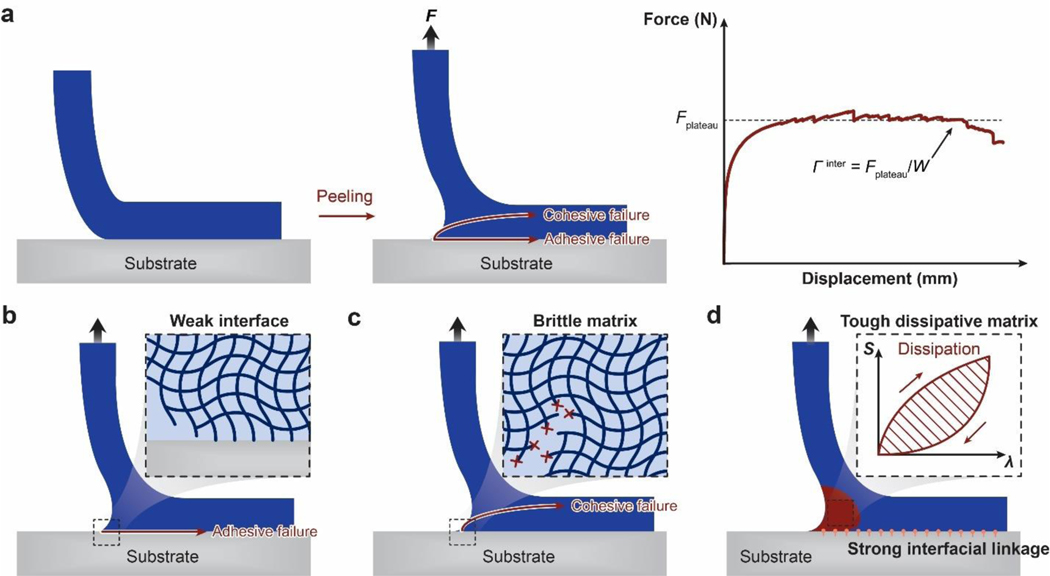

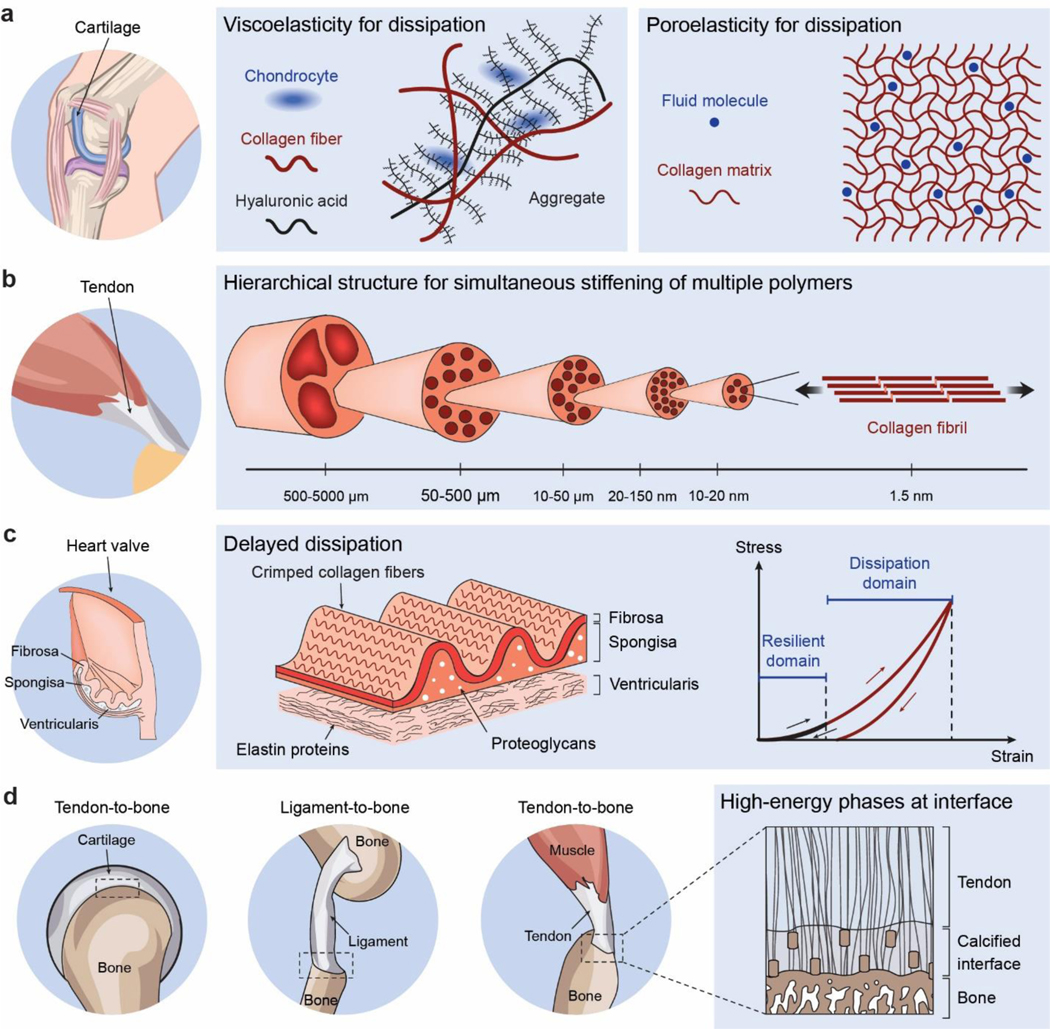

Despite the abovementioned grand challenge, the design of hydrogels with extreme mechanical properties is of both fundamental and practical importance. From the fundamental aspect, many biological hydrogels have achieved extreme mechanical properties necessary for their survival and well-being through evolution (Figure 1). For example, cartilage is a tough connective tissue that covers the surfaces of joints to provide reduced friction72. The human knee joint cartilage (i.e., articular cartilage) typically needs to sustain compressive stresses of 4–9 MPa for 1 million cycles per year, while maintaining high fracture toughness around 1,000 Jm−2 73. The high fracture toughness of articular cartilage is mainly attributed to its abundant strong collagen fibers interpenetrated with proteoglycan macromolecules, which provides both viscoelasticity and poroelasticity for mechanical dissipation74,75. The viscoelasticity of articular cartilage is mainly associated with local rearrangement of aggrecan, adhesive interactions of aggrecan, and reconfiguration of collagen75; the poroelasticity of articular cartilage is governed by the interstitial fluid movement through the porous extracellular matrix74. Tendon is a strong connective tissue that connects muscle to bone and muscle to muscle. The human patellar tendon can sustain a high tensile strength76, owing to its unique hierarchical fibrous structure that enables the simultaneous stiffening of bundles of collagen fibers before their tensile failure77,78. Heart valves generally possess both high resilience around 80% and high fracture toughness around 1,200 Jm−2 79,80, which are two seemingly contradictory properties. The elastin and crimped collagen fibers in the heart valve are elastic and non-dissipative under moderate deformation giving the heart valve the high resilience (Figure 2)81, whereas under large deformation, the stiffening and fracture of the collagen fibers dissipate substantial mechanical energy making the heart valve tough as well82. The adhesion of soft connective tissues on bones can be extremely fatigue-resistant. For example, the cartilage-bone interface in the human knee joint can sustain compressive stresses of 1 MPa along with an interfacial toughness around 800 Jm−2 over 1 million cycles of loads73,83. The fatigue-resistant adhesion of soft tissues (e.g., tendons, ligaments, and cartilages) to rigid bones is commonly achieved through nanostructured interfaces of aligned collagen nano-fibrils and ordered hydroxyapatite nanocrystals84–86. What are nature’s design principles, if any, for various biological hydrogels to achieve extreme mechanical properties? This is still a largely unanswered question, even in light of the pioneer works in the field of polymers and soft materials (e.g., Ref.46–58 and the references in them).

Figure 1. Biological hydrogels in the human body can possess extreme mechanical properties.

Aorta with tensile strength of 0.2–3.7 MPa73; heart valve with resilience above 80% and fracture toughness around 1,000 J m−2 79,80; tendon with tensile strength of 10–100 MPa96, fracture toughness of 20–30 kJ m−2 and fatigue threshold of 1,000 J m−2 97; skeletal muscle with fracture toughness around 2,490 J m−2 and fatigue threshold around 1,000 J m−2 73; articular cartilage with fracture toughness of 800–1,800 J m−2 98; and tendon/cartilage/ligament-bone interfaces with interfacial fatigue threshold around 800 J m−2 71,83.

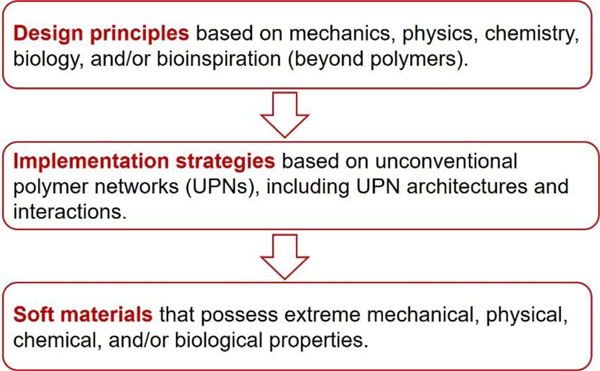

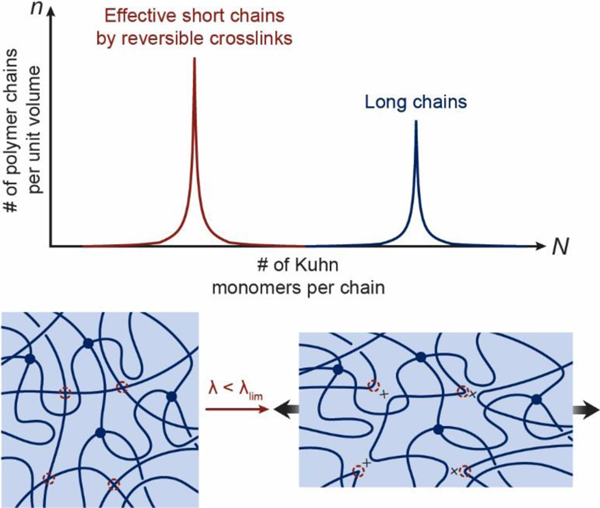

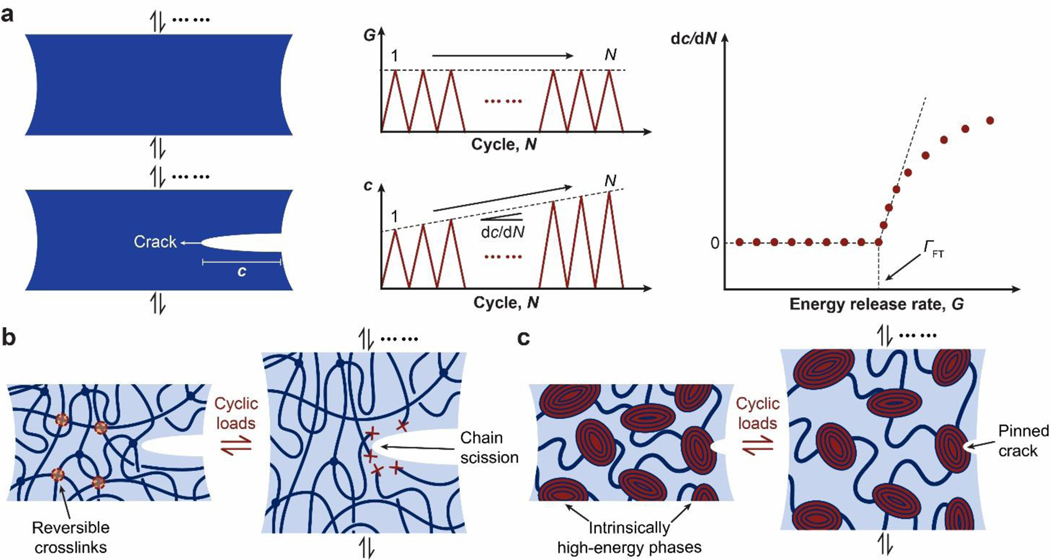

Figure 2. Design principles and implementation strategies for various biological hydrogels to achieve extreme mechanical properties:

a. high toughness of cartilage due to viscoelastic and poroelastic dissipation of the polymer networks75,99,100, b. high tensile strength of tendon due to simultaneous stiffening of multiple polymers in the fibrous hierarchical structure77,96, c. high resilience and toughness of heart valve due to delayed mechanical dissipation101,102, d. high interfacial fatigue threshold of cartilage-/ligament/tendon-bone interfaces due to intrinsically high-energy phases including nano-crystals and nano-fibers strongly bonded on the interfaces71. a is adopted from Ref99. b is adopted from Ref77. c is adopted from Ref101,102. d is adopted from Ref71.

From the practical aspect, applications of hydrogels generally require the hydrogels to possess specific properties. For example, hydrogels designed with different moduli and viscoelastic properties have been used to regulate stem cell fate and activity10,12,84,87. The applications of hydrogels as artificial cartilages and spinal discs require the hydrogels to be fatigue-resistant under cyclic mechanical loading68,69,88,89. The mesh size of hydrogels’ polymer networks is critical to their applications in controlled drug delivery33,90,91. More recent applications of hydrogels as various devices require the hydrogel to possess specific properties, for instance, stimuli-sensitivity for hydrogel sensors and actuators37,92–94, strong adhesion for hydrogel coatings43, optical transparency for hydrogel optics33, electrical conductivity for hydrogel electronics30, and water absorption/release for hydrogel water harvesters95.

Over the last few decades, intensive efforts have led to the development of a plethora of hydrogels that possess extreme mechanical properties using diverse material candidates, including various natural and synthetic polymers, macro-/micro-/nano-fillers, and macro-/micro-/nano-fibers. Whereas the properties of these hydrogels are remarkable, their design often follows the Edisonian approach – trial and error with specific material candidates. As the field rapidly evolves, emerging applications of hydrogels in biomedicine pose escalating demands on the rationally-guided design of hydrogels beyond the Edisonian approach, requiring broad choices of material candidates and fabrication methods and achievements of multiple combined extreme properties. However, a set of general principles capable of rationally guiding the design of hydrogels using different materials and fabrication methods for various applications remain a central need in the field of soft materials. In this review, we aim to provide:

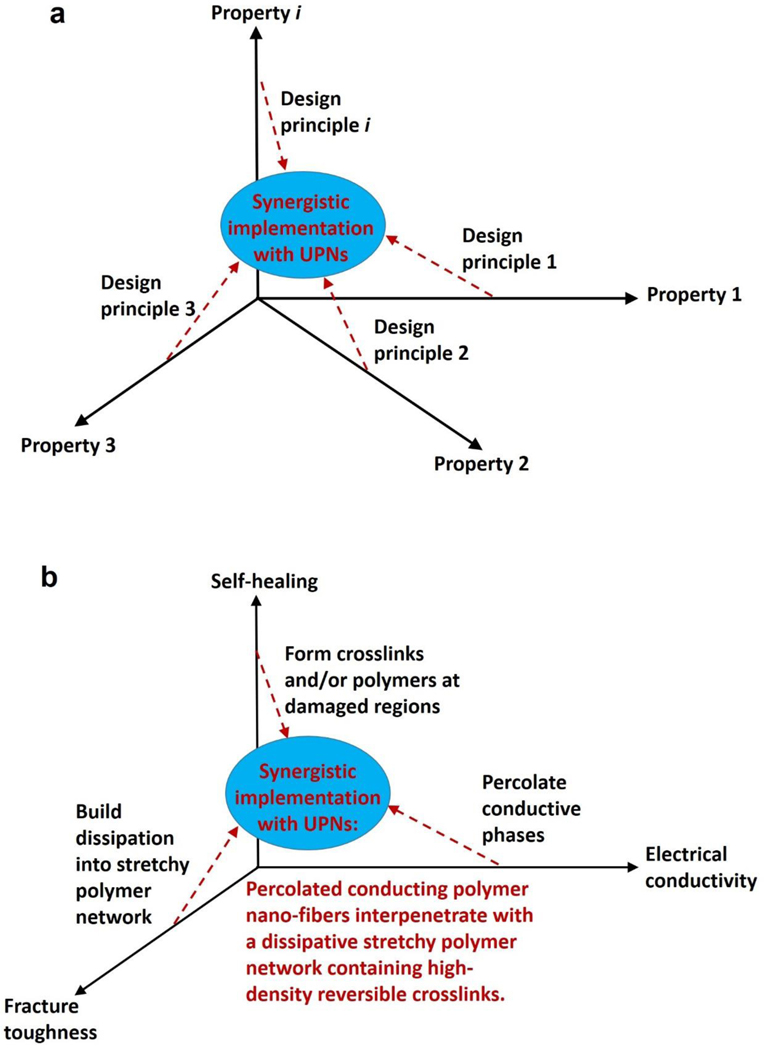

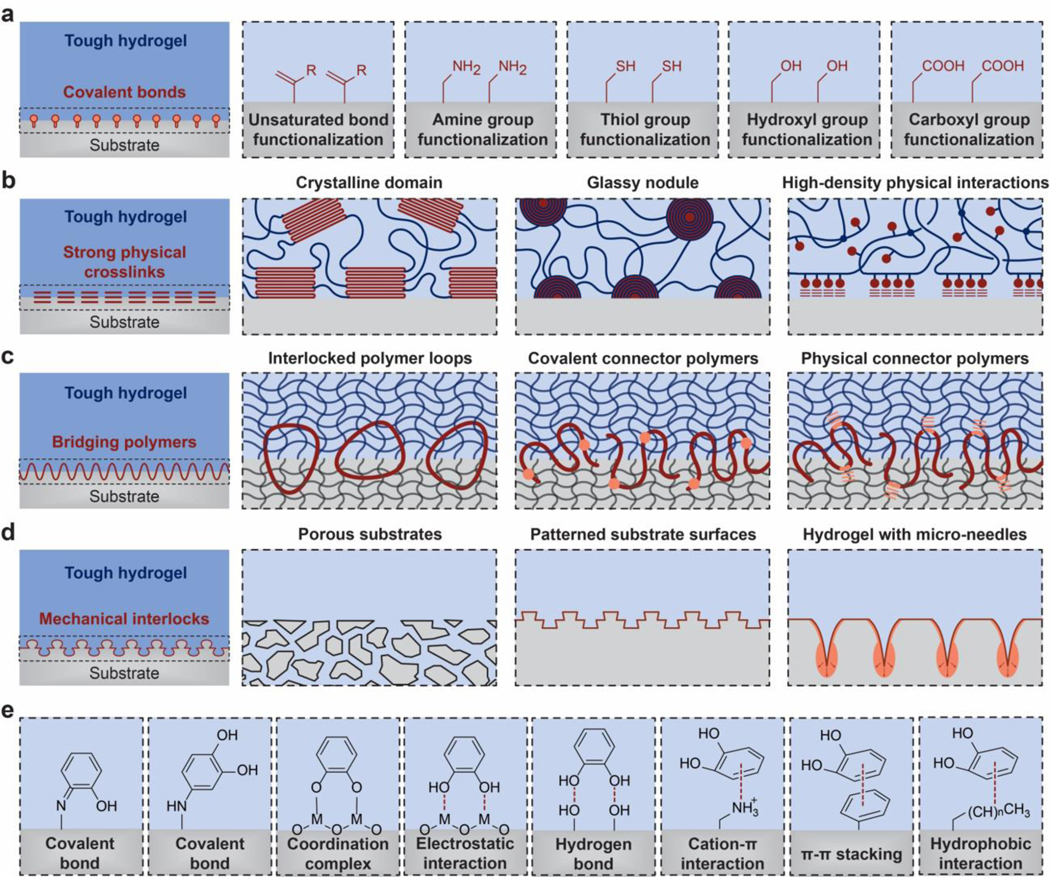

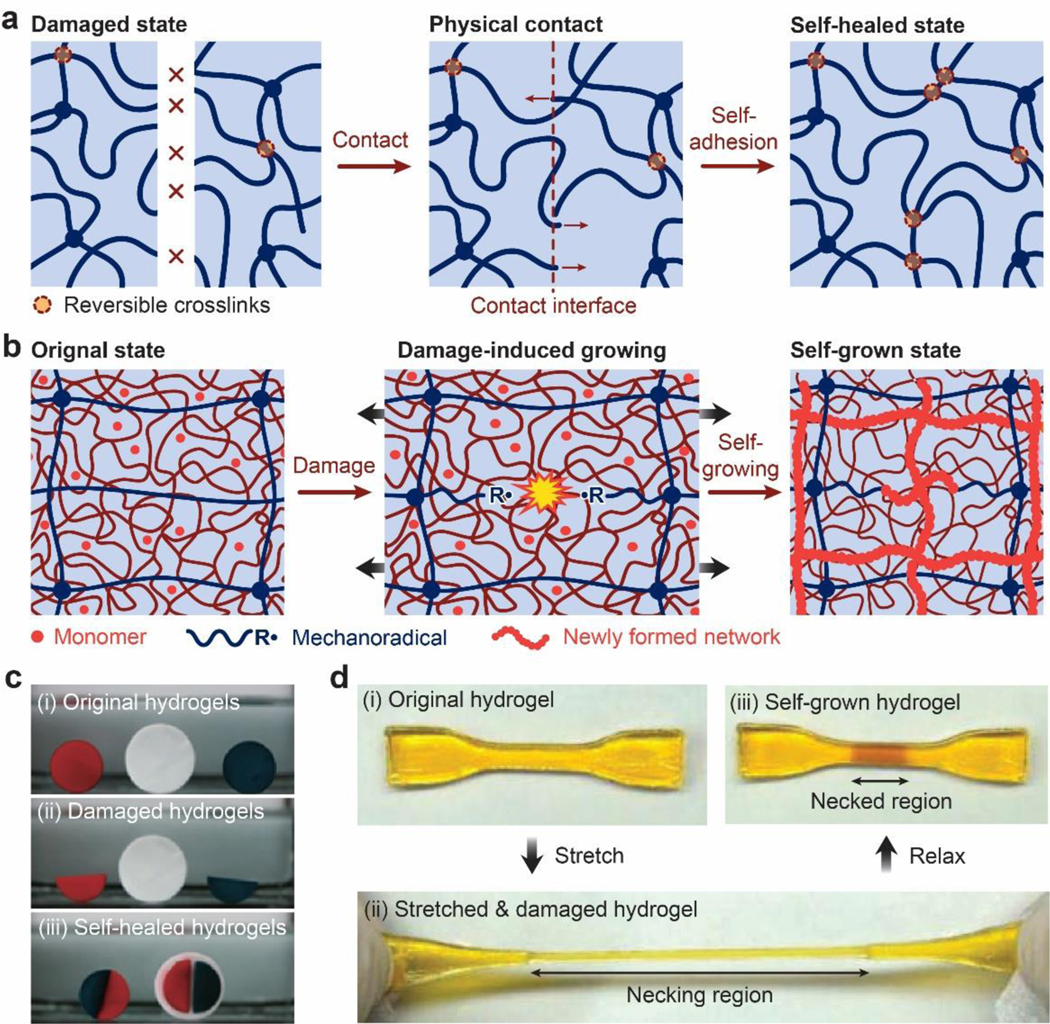

A set of general principles for the rational design of hydrogels to achieve extreme mechanical properties, including extremely high fracture toughness, tensile strength, resilience, interfacial toughness, fatigue threshold, and interfacial fatigue threshold; and extreme physical properties, including high electrical conductivity, patterned magnetization, high refractive index and transparency, tunable acoustic impedance, and self-healing. The design principles are generally based on fundamental mechanics and physics (beyond polymers) or inspired by biological hydrogels (e.g., muscles, cartilages, tendons, and heart valves) (Figure 3).

A set of unconventional polymer networks (UPNs) to implement the design principles discussed in i). using various material candidates and fabrication methods. The UPNs can be broadly categorized into: UPN architectures including ideal polymer networks, polymer networks with slidable crosslinks, interpenetrating and semi-interpenetrating polymer networks, polymer networks with high-functionality crosslinks, and nano-/micro-fibrous polymer networks; and UPN interactions including strong physical crosslinks, weak physical crosslinks, and dynamic covalent crosslinks (Figure 3).

A proposal of orthogonal design principles and synergistic implementation strategies for the design and fabrication of future hydrogels to achieve multiple combined mechanical, physical, chemical, and biological properties (Figure 3).

Figure 3.

This review summarizes the design principles and implementation strategies for soft materials including hydrogels, elastomers and organogels to achieve extreme properties.

Notably, since the aforementioned design principles and implementation strategies for hydrogels are based on generic polymer networks, they are also applicable to other soft materials comprised of polymer networks, including elastomers and organogels. In fact, many extreme mechanical and physical properties were first achieved in other soft materials than hydrogels. For example, high values of fracture toughness, tensile strength, resilience and interfacial toughness were realized in elastomers long before in hydrogels; ferromagnetic domains in soft materials were first programmed and 3D printed with elastomer inks as well.

The review is organized as the following. Section 2 will discuss common natural polymers, synthetic polymers, and permanent covalent crosslinks for hydrogels. Section 3 will introduce conventional polymer networks, and demonstrate that a number of mechanical properties of conventional polymer networks are coupled. Section 4 will define a set of unconventional polymer networks (UPNs), including both UPN architectures and UPN interactions, and then discuss that UPNs can provide decoupled mechanical properties. Thereafter, Sections 5 will systematically reveal the design principles for various extreme mechanical properties of hydrogels and implement strategies based on UPNs for each of the design principles; Sections 6 will briefly discuss the design principles and implementation strategies for hydrogels that possess a set of extreme physical properties. In Section 7, we will conclude the review by proposing orthogonal design principles and synergistic implementation strategies to design future hydrogels achieving multiple combined mechanical, physical, chemical and biological properties.

2. Polymers and crosslinks for hydrogels

A rich library of polymers and crosslinks have been used for the design and fabrication of various hydrogels. These polymers can be broadly categorized into natural polymers and synthetic polymers. In this section, we will briefly discuss the commonly-used natural polymers, synthetic polymers and permanent covalent crosslinks for hydrogels; we will discuss other types of crosslinks for hydrogels in Section 4.

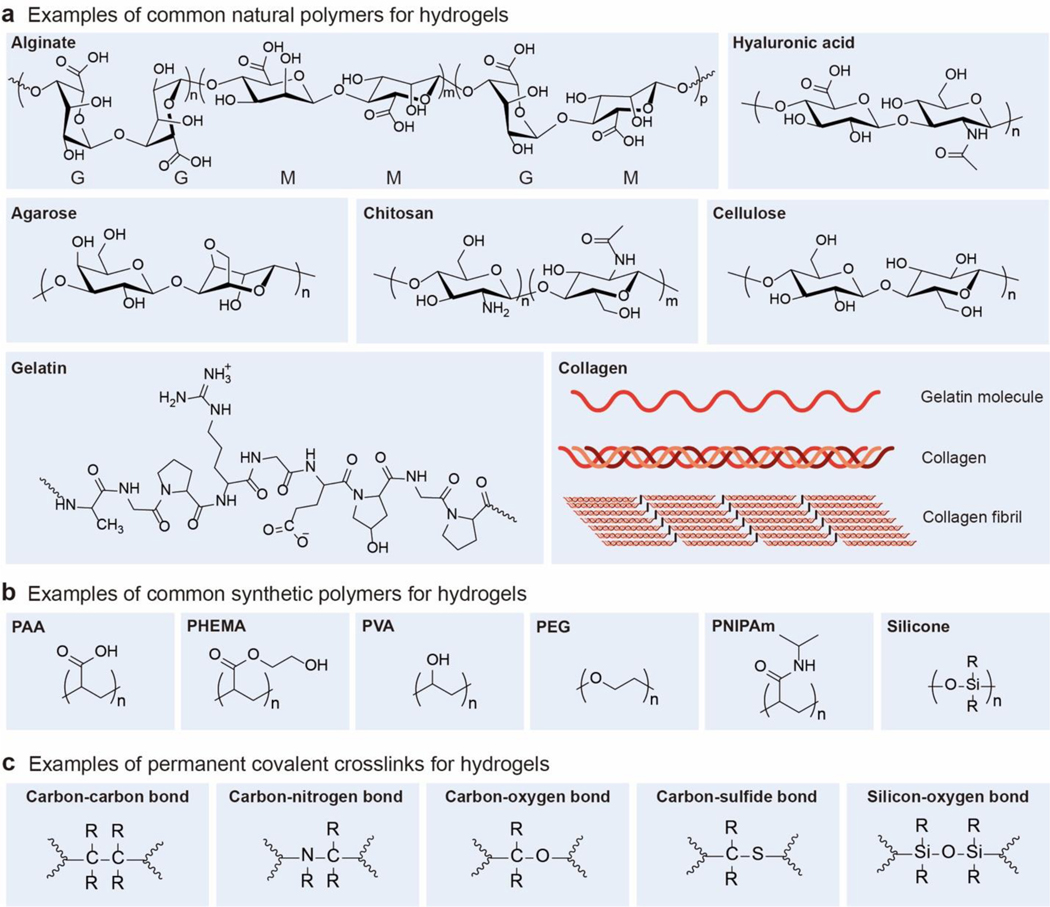

2.1. Common natural polymers for hydrogels

Naturally derived polymers have been widely used to compose the polymer networks of hydrogels (Figure 4a). Hydrogels based on natural polymers usually possess biological properties compatible with extracellular matrices due to the similarity in their compositions. In addition, the natural polymer networks can often degrade in and be absorbed by the body through metabolism and tissue remodeling processes. Furthermore, the majority of natural polymers have reactive sites amenable to crosslinking and modification, which can endow the corresponding hydrogels with tailored biological and/or mechanical properties. In this subsection, we will briefly discuss a few natural polymers commonly-used for hydrogels. For more detailed discussions, a few classical reviews are recommended4–6,61,103.

Figure 4.

Chemical structures and schematics of typical examples of a. common natural polymers, b. common synthetic polymers, and c. permanent covalent crosslinks for hydrogels. R represents an organyl substituent or hydrogen.

Alginate.

Alginate is a polysaccharide which is usually obtained from brown-algae cell walls and two kinds of bacteria, Azotobacter and Pseudomonas104. Alginate is known to be a family of linear copolymers containing blocks of (1,4)-linked β-D-mannuronic (M) and α-L-guluronic acid (G) residues. The blocks are composed of consecutive G residues (GGGGGG), consecutive M residues (MMMMMM), and alternating M and G residues (GMGMGM)105. Alginate hydrogels can be formed with various covalent and physical crosslinks. In particular, the ionic crosslinks have been widely used for alginate hydrogels, because the G blocks106 (and GM blocks107) in alginate can be readily bound with one another by divalent cations such as Ca2+, Mg2+, Ba2+, and Sr2+ 108–110. The mechanical properties of alginate hydrogels can be easily tuned to match those of various tissues by changing different parameters, such as the molecular weight, polymer concentration, chemical modification, G/M ratio, and type or density of crosslinks106,111. Alginate hydrogels have been widely used as scaffolds in tissue engineering, such as intervertebral disk regeneration112, adipose tissue regeneration113, cardiac regeneration114, and liver regeneration115, since alginate allows the formation of hydrogels under physiological conditions and thus enables easy cell and drug encapsulation.

Hyaluronic acid.

Hyaluronic acid (also known as hyaluronan or hyaluronate) is a linear polysaccharide that consists of alternating units of a repeating disaccharide, β−1,4-D-glucuronic acid and β−1,3-N-acetyl-D-glucosamine116,117. Hyaluronic acid is present in all mammals, especially in various soft connective tissues, acting as a space filler, lubricant, and osmotic buffer118. Hyaluronic acid can be covalently crosslinked into hydrogels by various hydrazide derivatives119,120. The abundant carboxyl and hydroxyl groups on the polysaccharide structure of hyaluronic acid also offer many active sites for chemical modifications121. For example, hyaluronic acid can be modified with thiol122,123, haloacetate124, dihydrazide119,125, aldehyde126,127 and tyramine128 groups, which can react with corresponding covalent crosslinkers through addition or condensation reactions129. As another example, hyaluronic acid can also be modified by methacrylic anhydride or glycidyl methacrylate to possess reactive methacrylic groups, which can be polymerized by radical polymerization130–132. Owing to the naturally-derived, nonimmunogenic, biodegradable, and nonadhesive properties133–135, hyaluronic acid hydrogels have been widely used as scaffolds in cell therapy and tissue engineering, such as cell delivery136, molecule delivery137,138, stem cell therapy139,140, cartilage engineering137,141, cardiac repair142 and valvular engineering143.

Collagen.

Collagen is one of the major proteins in animal bodies. There are approximately 29 types of collagens discovered so far144. The structures of collagens can be defined at different levels, including primary structure (amino acid triplet), secondary structure (α-helix), tertiary structure (triple helix), and quaternary structure (fibril) 145,146. The primary structure of collagen is the tripeptide sequence of –(Gly– X–Y–)n–, where Gly is glycine, X, and Y are other amino acids than Gly. The sequence of the amino acids governs the peptide folding into a secondary structure, mainly left-handed α-helix, which is stabilized by the hydrogen bonds between amino acid residues147. Three left-handed secondary α- polypeptide chains then form a tertiary structure by the aldol condensation crosslinking, aldehyde amine condensation crosslinking, and aldol histidine crosslinking148. The triple strands can further self-assemble into a collagen fiber as the quaternary structure149.

Acid-solubilized collagens can self-assemble to form physically-crosslinked hydrogels when the collagen solutions are neutralized and heated. Since the physically-crosslinked collagen hydrogels are usually mechanically weak and thermally unstable150,151, they have been strengthened and stabilized with chemical crosslinks such as glutaraldehyde, genipin, carbodiimides or diphenylphosphoryl azide152–154. Collagens can be biodegraded by collagenases and metalloproteases; the crosslinked collagens usually have slower degradation rates than the uncrosslinked collagens155. Because collagens usually have low antigenicity, low inflammatory response, good biocompatibility and natural cell-adhesive motifs156–158, collagen hydrogels have been widely used as scaffolds for drug and protein delivery159,160 and reconstructions of liver161, skin162, blood vessel163, and small intestine164, cartilage165, vocal cord166, and spinal cord167.

Gelatin.

Gelatins are naturally derived polymers obtained through breaking the triple-helix conformation of collagens into single-strand molecules. There are two types of gelatins, type A and type B, which are obtained with acid and alkaline treatments of collagens, respectively168. Gelatins can be physically crosslinked by simply reducing the temperature of aqueous solutions of gelatins below a certain temperature169,170. The physically-crosslinked gelatins are usually unstable for long-term biomedical applications under physiological conditions. To further stabilize the physically-crosslinked gelatin hydrogels, covalent crosslinkers171 such as aldehydes (e.g., formaldehyde, glutaraldehyde, and glyceraldehyde)172,173, polyepoxides174 and isocyanates175 have been widely used to react with and bridge the free amine groups (from lysine and hydroxylysine) or free carboxylic acid (from glutamic and aspartic acid) on the gelatin molecules. Besides the introduction of covalent crosslinkers, the gelatin backbones can also be modified by methacrylates to form covalently-crosslinkable gelatin methacryloyl hydrogels176. In addition, synthetic polymers can also be coupled on gelatin chains through grafting-from177, grafting-to178, and grafting-through179 methods and enhance the mechanical properties of gelatin hydrogels. Furthermore, the gelatin molecules tend to form physical interactions with various dopants, such as carbon nanotubes180, graphene oxide181, and inorganic nanoparticles or minerals182,183. The aforementioned covalent crosslinks, modifications and/or interactions can significantly improve the mechanical properties of gelatin hydrogels172,184. The easy gelation process and the excellent biocompatibility make gelatin hydrogels attractive for biomedical applications, such as drug delivery185 and tissue engineering186,187.

Fibrin.

Fibrin is a naturally-derived polymer obtained from thrombin-treated fibrinogen188. Fibrin is involved in the natural wound healing process by forming extensive fibrous networks. Fibrin can form clots or hydrogels when mixing fibrinogen and thrombin solutions at room temperature189. The resultant fibrin hydrogels usually have weak mechanical properties due to the nature of physical crosslinks. To improve the mechanical properties of fibrin hydrogels, chemical crosslinkers such as genipin can be introduced to crosslink the amine residues on fibrin proteins and form stable covalently-crosslinked networks190. In addition, fibrin hydrogels can also be combined with synthetic polymers such as polyurethane191, polycaprolactone192, b-tricalciumphosphate193 or polyethylene glycol194 to enhance the mechanical strength of the hydrogels. Fibrin hydrogels have been widely used as sealants and adhesives to control bleeding in surgery195, and as scaffolds for cardiac tissue engineering196, neurological regeneration197, ocular therapy198, cartilage and bone reparation199,200, muscle cells engineering201, and exogenous delivery in wound healing202. In particular, fibrin hydrogels can be produced autologously from a patient’s blood, thereby reducing the risk of foreign-body reactions203.

Agarose.

Agarose is a neutral polysaccharide composed of β-D-galactopyranosyl and 3,6-anhydro-α-L-galactopyranosyl, mainly extracted from red algae (Rhodophyceae)204. As a thermoresponsive polymer, agarose can be heated to dissolve in water, and then cooled down to form a hydrogel. During this gelation process, the agarose structure changes from a random-coil configuration to bundles of associated double helices with multiple-chain aggregation in the junction zone205,206. The gelling temperature and mechanical properties of agarose hydrogels can be tuned by changing the concentration, molecular weight, and structure of the agarose in the hydrogels207,208. Agarose hydrogels have been used as scaffolds for cell encapsulation209, cartilage reparation210 and nerve regeneration211, due to its low immunoreaction in human bodies212. Notably, since the native agarose does not possess cell adhesion motifs, cell adhesion peptides have been covalently conjugated to the agarose backbone to enhance the interactions between cells and agarose hydrogels213.

Chitosan.

Chitosan is a linear polysaccharide composed of β-(1–4)-linked D-glucosamine and N-acetyl-D-glucosamine units, which is mainly prepared by partial deacetylation of chitin (obtained from crab and shrimp shells) to less than 40% of N-acetyl-D glucosamine residues214,215. The physical, chemical and biological properties of chitosan materials are highly related to the molecular weight and the degree of deacetylation216,217. Chitosan can form physically-crosslinked hydrogels by hydrophobic interaction, hydrogen bonding218,219, metal coordination (with metal ions such as Pt(II), Pd(II), Mo(VI)220,221), and electrostatic interaction (with multivalent anions such as sulfates, citrates and phosphates ions222,223; with anionic polyelectrolytes214 such as polysaccharides224,225, proteins226,227 and synthetic polymers228). These physically-crosslinked chitosan hydrogels usually have weak mechanical properties and short lifetime, which is also highly influenced by pH, temperature and environments215,229. To enhance the mechanical properties of chitosan hydrogels, covalent crosslinkers have been introduced into the hydrogels. The commonly-used covalent crosslinkers include di-aldehydes230,231, formaldehyde232, di-glycidyl ether233 and genipin234,235, which can react with the residual functional groups (such as OH, COOH, and NH2) on chitosan backbones to form the amide bonds, ester bonds, and Schiff base linkages218,236,237. In addition, chitosan can also be modified with methacrylate or aryl azide groups to form photo-crosslinkable macromers238. The gelation degree and mechanical properties of these chitosan hydrogels can be controlled by UV irradiation time and intensity239–241. Furthermore, chitosan hydrogels can be modified with biofunctional ligands such as Arg-Gly-Asp (RGD) peptides to facilitate cell adhesion and proliferation242,243. Chitosan hydrogels have been widely used in biomedical applications such as drug delivery244, cell encapsulation245, neural tissue engineering246 and bone regeneration245, owing to their excellent biocompatibility and biodegradability247.

Cellulose.

Cellulose is the most abundant natural polysaccharide, and the main constituent of plants and natural fibers such as cotton and linen248–250. Some bacteria such as acetobacter xylinum are also able to produce cellulose251. Cellulose has a chemical composite of 1,4-β-glucosidic linked glucose units, which results in high crystallinity (over 40%) and difficulty in dissolving in water and other common solvents252. Solvents such as N-methylmorpholine-N-oxide253,254, ionic liquids255,256, and alkali/urea (or thiourea) aqueous257,258 systems have been developed to dissolved native cellulose. Cellulose can also be modified through partly esterification or etherification of the hydroxyl groups on the backbones248. These cellulose derivatives, including methyl cellulose259, hydroxypropyl cellulose260, hydroxypropylmethyl cellulose261,262 and carboxymethyl cellulose263 are easier to dissolve and process compared to the native cellulose.

Cellulose and its derivatives can be chemically crosslinked to form stable three-dimensional networks. Bifunctional or multifunctional molecules, such as 1,2,3,4-butanetetracarboxylic dianhydride264, succinic anhydride265, citric acid266, epichlorohydrin267, ethylene glycol diglycidyl ether268, and divinyl sulfone269 can form covalent ester or ether bonds between cellulose chains. Cellulose chains can also be covalently crosslinked by the irradiation of electron beam and gamma rays270,271, which avoids the usage of toxic crosslinkers and allows the simultaneous sterilization of the resultant hydrogels. Cellulose and its derivatives can also be blended with natural polymers, such as chitosan272, starch273, alginates274 and hyaluronic acid275, or synthetic polymers such as polyethylene glycol276, polyvinyl alcohol277 and poly(N,N-dimethylacrylamide)278 to form interpenetrating polymer networks with excellent mechanical properties. Notably, bacterial cellulose produced from certain bacterial species such as acetobacter xylinum can directly form cellulose hydrogels with high purity and tensile strength279,280. Since cellulose-based hydrogels are proven to have superior hydrophilicity, biodegradability, biocompatibility, and transparency, they have been widely used in drug delivery281, tissue engineering282, blood purification283, strain sensor284 as well as water purification285.

2.2. Common synthetic polymers for hydrogels

In addition to the natural polymers, synthetic polymers have been widely used for the design and fabrication of hydrogels (Figure 4b). The synthetic polymer networks of hydrogels are commonly formed by copolymerization of monomers for the polymer backbones and crosslinkers, or by reactions of synthetic polymers, macromers and/or crosslinkers.

Poly(acrylic acid).

Poly(acrylic acid) (PAA) is a linear polymer prepared by radical polymerization of acrylic acid monomers. The backbone of PAA contains a large number of carboxyl groups. PAA can form hydrogels through covalent and physical crosslinking. Covalently-crosslinked PAA hydrogels are usually formed by copolymerization of di-/multi-vinyl crosslinkers together with acrylic acid monomers286. In addition, the carboxyl groups of PAA can form physical interactions with various doping agents such as clay287, graphene oxide288 and cations289, which can act as physical crosslinks for PAA hydrogels; the carboxyl groups can also form hydrogen bonds between PAA chains and introduce self-healing or self-adhesive properties to PAA hydrogels290. Furthermore, the abundant carboxyl groups on PAA can associate with water molecules to facilitate the absorption of water by PAA hydrogels291. Since the carboxyl groups are sensitive to pH and ionic strength, the equilibrium swelling ratio of PAA hydrogels is affected by the pH and ionic strength of the solutions for the hydrogels292,293. PAA hydrogels can also incorporate other linear polymers, such as biological polymers, to form various adhesives and hydrogels for biomedical applications41,294.

Poly(2-hydroxyethyl methacrylate).

Poly(2-hydroxyethyl methacrylate) (PHEMA) hydrogels can be prepared by free-radical polymerization of 2-hydroxyethyl methacrylate (HEMA) monomers with covalent crosslinkers such as trimethylene glycol dimethacrylate (TEGDMA), initiators such as sodium pyrosulfite (SMBS), and catalysts such as ammonium persulfate (APS). The HEMA monomers can also be copolymerized with acrylic or acrylamide monomers to control the swelling and mechanical properties of the resultant hydrogels295. PHEMA hydrogels are optically transparent and mechanically stable in the physiological environments. Pure PHEMA hydrogels are also resistant to cell adhesion and difficult to degrade in the physiological environments; however, various biofunctional and bioactive motifs can be coupled onto the hydrogels to improve their cell interactions and degradability296,297. PHEMA hydrogels are famous for their ophthalmic applications such as contact lens298 and artificial cornea299.

Poly(vinyl alcohol).

Poly(vinyl alcohol) (PVA) is mainly obtained from the partial hydrolysis of poly(vinyl acetate)300. PVA can form stable and elastic hydrogels through either physical or covalent crosslinking301,302. The physically-crosslinked PVA hydrogels are commonly obtained by repeated freezing and thawing of PVA solutions303, which gives elastic, tough, strong and fatigue-resistant PVA hydrogels69,71,304. PVA can also be covalently crosslinked through the use of difunctional crosslinkers such as glutaraldehyde, acetaldehyde, formaldehyde, epichlorohydrin, and other monoaldehydes305,306. Electronbeam and gamma irradiation can also crosslink PVA to avoid residual covalent crosslinkers in the hydrogels307. Pure PVA hydrogels are nonadhesive to cells, but several oligopeptide sequences can be conjugated onto the backbones of PVA hydrogels to enhance their cellular interactions308. PVA hydrogels have been extensively studied and used in biomedical applications309,310, such as articular cartilage replacement and regeneration311,312.

Poly(ethylene glycol) or poly(ethylene oxide).

Poly(ethylene glycol) (PEG) is usually obtained from the anionic or cationic polymerization of ethylene oxide. When the PEG has a molecular weight more than 10 kDa, it is also named poly(ethylene oxide) (PEO) since the end groups are negligible313. There are various methods to crosslink PEG polymers into hydrogels. The ends of PEG chains can be modified by unsaturated groups, such as acrylate or methacrylate ends, and then be used as macro-crosslinkers to form hydrogels with other unsaturated monomers by the photo-/UV-induced radical polymerization314,315. PEG can also form hydrogels by electron beam irradiation via radiation-induced free radical processes316. Furthermore, the end groups of the PEG chain can be modified with various reactive pairs, such as Nhydroxysuccinimide/NH2317, maleimide/thiol318, and acetylene/azide319. Since these functional chain-end motifs usually have high reaction efficiency and fast reaction kinetics, the obtained hydrogels by the coupling reactions of these groups can give relatively well-defined network architectures67.

PEG polymers can also form physically-crosslinked networks. Similar to the chemical crosslinking method, the ends of PEG chains can be modified with various motifs for physical crosslinking. For example, nucleobase pairs of adenines and thymines320, ureido-pyrimidinone (UPy) units321, or host-guest molecules322 can be introduced onto the chain-ends of PEG molecules to prepare physically-crosslinked PEG hydrogels. These physically-crosslinked PEG hydrogels can exhibit switchable, self-healable or stimuli-responsive properties and high mechanical strength323. Besides the modification and utilization of chain-end groups, physically-crosslinked PEG hydrogel can also be prepared by using PEG block copolymers324. PEG-b-PPG (poly(propylene glycol)) is one of the most widely used PEG-derived block copolymers to prepare thermo-responsive physical hydrogels325. These physical hydrogels are formed by the hydrophobic interaction of PPG blocks. The phase transition behavior of these hydrogels can be optimized by balancing the hydrophobic PPG block and the hydrophilic PEG block. Based on the same gelation mechanism, PEG block copolymers with poly(DL-lactic acid) (PDLLA)326, poly(dl-lactic acid-coglycolic acid) (PLGA)327,328, polylactide (PLA)329, poly(caprolactone)(PCL)330 and poly(propylene sulfide)(PPS)331 can also form physically-crosslinked hydrogels with injectable or stimuli-responsive properties. PEG, as well as its derivatives, are widely used in biomedical applications due to their non-toxic and non-immunogenic properties332. While the inert biological property of PEG hydrogels can prevent undesired interactions between native PEG hydrogels and cells333,334, PEG hydrogels can also be modified with various bioactive conjugations such as growth factors 335 and cell-adhesive peptides336 through Michael-type addition337,338or click chemistry334. PEG hydrogels with these bioactive molecules can facilitate their biomedical applications339 such as drug or cell delivery340,341 and tissue engineering342.

Poly (N-isopropylacrylamide).

Acrylamide and its derivatives have been widely used to prepare hydrogels by radical copolymerization with crosslinkers. One interesting hydrogel based on acrylamide and its derivatives is the poly(N-isopropylacrylamide) (PNIPAm) hydrogel. Uncrosslinked linear PNIPAm exhibits a coil-to-globule phase transition in aqueous solutions when the temperature is raised above a critical temperature343,344. The PNIPAm can be covalently crosslinked by crosslinkers such as bis-acrylamide derivatives through the radical polymerization process. The crosslinked PNIPAm hydrogels also possess the reversible thermo-responsive behavior with a critical temperature of around 34 °C 345, above which the hydrogel structure will collapse and exude water346,347. While the thermo-responsive behavior of PNIPAm hydrogels is usually slow, many studies have improved the phase-transition speed of PNIPAm hydrogels by incorporating porous structures during the hydrogel formation348,349. The thermo-responsive PNIPAm hydrogels can be used as actuators for soft robotics350, injectable scaffolds for tissue engineering351, and on-demand detachment of cell sheets352,353.

Silicone.

Silicone hydrogels are hydrogels that contain silicone polymers as one of its polymer components354. Silicone polymers are commonly hydrophobic355. In order to form silicone hydrogels, hydrophilic monomers and/or polymers have been introduced into the silicone matrix by blending or copolymerization to improve the hydrophilicity of silicone hydrogels356,357. For example, hydrophilic polymers such as PHEMA can be blended directly into the silicone polymer matrix, forming a hydrophilic interpenetrating polymer network358. Hydrophilic monomers such as N-vinylpyrrolidone (NVP) can be copolymerized with silicon-macromers to form hydrophilic silicone hydrogels359. Hydrophilic polymer segments such as PEG360 can also be copolymerized onto silicone segments to form block-modified361,362 or graft-modified363 hydrophilic silicone hydrogels. Since these hydrophilic silicone hydrogels usually have excellent gas permeability as well good biocompatibility, they have been used in biomedical applications such as contact lenses364,365, histological engineering materials366,367, and drug-delivery carriers368,369.

2.3. Common permanent covalent crosslinks for hydrogels

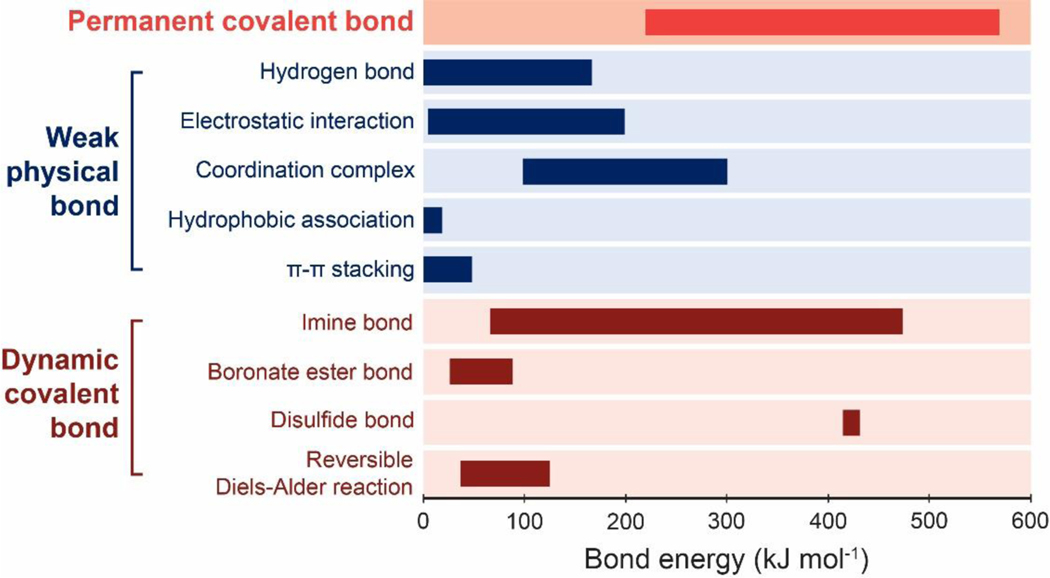

In this section, we will discuss permanent covalent crosslinks that are commonly used in hydrogels (Figure 4c); we will discuss other types of crosslinks in Section 4. The energy of permanent covalent crosslinks ranges from 220 kJ/mol to 570 kJ/mol (Figure 5)370–372.

Figure 5.

Bond energies of various types of permanent covalent crosslinks370–372, weak physical crosslinks 373–376, and dynamic covalent crosslinks372,377–381.

Carbon-carbon bonds.

The energy of the carbon-carbon bond is around 300 to 450 kJ/mol370–372. Hydrogels covalently crosslinked by carbon-carbon bonds are usually formed by radical copolymerization of monomers and di-/multi-vinyl crosslinkers. The crosslinkers can be small molecules with two double bonds such as N,N’-Methylenebisacrylamide (MBA) or macromolecules with several acrylate groups6,382. These crosslinkers are compatible with various initiation and polymerization systems4,237,383. For example, photo-radical initiators can be added into the pre-polymerization solution together with monomers and di/multi-vinyl crosslinkers302,384,385. Once the initiator is irradiated by UV light, radicals will be generated to initiate the polymerization of the double bonds on monomers as well as crosslinkers386,387. As a result, hydrogels can be formed in-situ and with patterned structures or biology functions384,388. The polymerization of vinyl monomers and crosslinkers can also be carried out with a system composed of peroxydisulfate and N,N,N′N′-tetramethylene-diamine (TEMED), where TEMED can accelerate the decomposition of peroxydisulfate to generate a large number of radicals389. This initiation and polymerization system can effectively and rapidly form various hydrogels under room temperature.

The carbon-carbon crosslinks of hydrogels can also be formed by high-energy irradiation (e.g., gamma and electron beams). Similar to UV light, high-energy radiation can be used to polymerize unsaturated compounds such as monomers and crosslinkers with vinyl groups or acrylate groups390,391. High-energy radiation can also crosslink polymers without unsaturated bonds392, because radicals can be generated from the homolytic scission of the polymer chains under high-energy radiation. The radiolysis of water molecules in the solvent can also generate hydroxyl radicals that attack polymer chains to form macroradicals393. These radicals can then undergo recombination and termination to form covalent polymer networks crosslinked by carbon-carbon bonds.

Carbon-nitrogen bonds.

The energy of the carbon-nitrogen bond is around 300 to 430 kJ/mol370,372. Hydrogels covalently crosslinked by carbon-nitrogen bonds are usually formed by highly effective chemical reactions of complementary groups. For example, the amide bonds have been widely used as the covalent crosslinks for hydrogels by the condensation reactions between amines with carboxylic acids and derivatives394. N-hydroxysuccinimide (NHS) and N,N-(3-dimethylaminopropyl)-N-ethyl carbodiimide (EDC) are widely used to facilitate the condensation reaction of amines with carboxylic acids67. The addition of NHS and EDC will also suppress possible side-reactions and give better control of the crosslink density in the hydrogels395. The carbon-nitrogen bonds can also be formed through the addition reactions of amines with electrophiles such as adipic acid dihydrazide and diisocyanates crosslinkers6,103,396. These di-functional crosslinkers have been widely used to crosslink natural macromolecules due to the high reaction efficiency. The mechanical properties of the resultant hydrogels can be controlled by tuning the concentration and ratio of the polymers and the crosslinking agents. Another category of reactions that can form carbon-nitrogen crosslinks for hydrogels is the azide-alkyne cycloaddition reaction, which is one typical click reaction to connect alkyne and azide into triazole. The click reaction has high efficiency without side reactions397. Furthermore, the azide-alkyne cycloaddition can be conducted in the absence of metal catalysis398, expanding the applicability of the azide-alkyne cycloaddition for preparing biocompatible hydrogels.

Carbon-oxygen bonds.

The energy of the carbon-oxygen bond is around 280 to 370 kJ/mol370–372. The most common carbon-oxygen bond is the ester bond formed by the reactions between hydroxyl groups and carboxylic acids or derivatives399. Such ester crosslinks can be hydrolyzed easily and make the hydrogels degradable under ambient temperature and physiological conditions. Besides the ester crosslinks, the carbon-oxygen bonds are also present in ether groups and urethane groups, which can become crosslinks due to the reaction between side groups on polymers (such as hydroxyl groups on polysaccharides or PVA) and reactive crosslinkers (such as glutaraldehyde400,401, divinyl sulfone402, dibromide403 or diisocyanate404).

Carbon-sulfide bonds.

The energy of the carbon-sulfide bond is around 220 to 310 kJ/mol372. The covalent crosslinking of hydrogels through carbon-sulfide bonds are mainly formed by the thiol-click reactions405,406. The inherent electron density of the sulfide atom makes thiols prone to react with many functional groups through a radical or catalyzed process407,408. Thiol groups can be easily converted into nucleophilic thiolates or electrophilic thiyl radicals, which then proceed with nucleophilic reactions or radical chain processes to achieve the thiol-click reactions409. Specifically, for the radical thiol-click reactions, the thiol group can be activated by heat and/or UV light to generate radicals that initiate the radical-mediated thiol-ene or thiol-yne reactions410; for the nucleophilic thiol-click reactions initiated by strong bases, the thiol groups can readily react with electron-poor ene-functional compounds through the Michael addition, with isocyanates derivatives through carbonyl addition, with halide through SN2 nucleophilic substitution, and with epoxies motifs through SN2 ring-opening reactions411–414. The thiol-click reactions commonly have high efficiency and high conversion rate without any side products, even in the presence of water, ions, and oxygen. The thiol-click reactions have been extensively used to prepare hydrogels for various biomedical applications415,416.

Silicon-oxygen bonds.

The energy of the silicon-oxygen bond is around 420 to 570 kJ/mol370–372. The silicon-oxygen bonds are mainly used in the formation of silicone-based hydrogels360,417,418, and can usually enhance the mechanical properties of the silicone-based hydrogels419. In addition, silicon-oxygen bonds have been widely used to form strong bonding between hydrogels and diverse engineering materials with modified surfaces such as salinized surfaces43.

3. Conventional polymer networks

3.1. Conventional polymer networks in the dry state

As illustrated in Figure 6, a conventional polymer network is defined as long-chain polymers crosslinked via permanent covalent bonds into a network, in which entanglements and reversible crosslinks of the polymer chains are negligible47,50,55. Conventional polymer networks have provided the basic models for the development of unentangled rubber elasticity including the affine network model and the phantom network model47,50,55. Conventional polymer networks have also been widely adopted in synthetic hydrogels, although biological hydrogels (Figures 1 and 2) usually reply on more complex polymer networks.

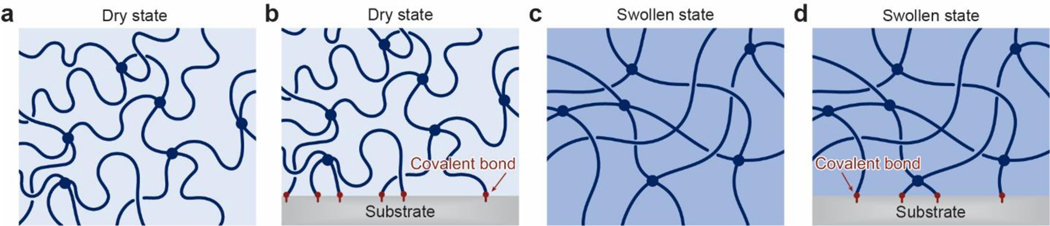

Figure 6.

Schematics of a conventional polymer network a. in the dry state and b. covalently bonded on a substrate, and c. in the swollen state and d. covalently bonded on a substrate.

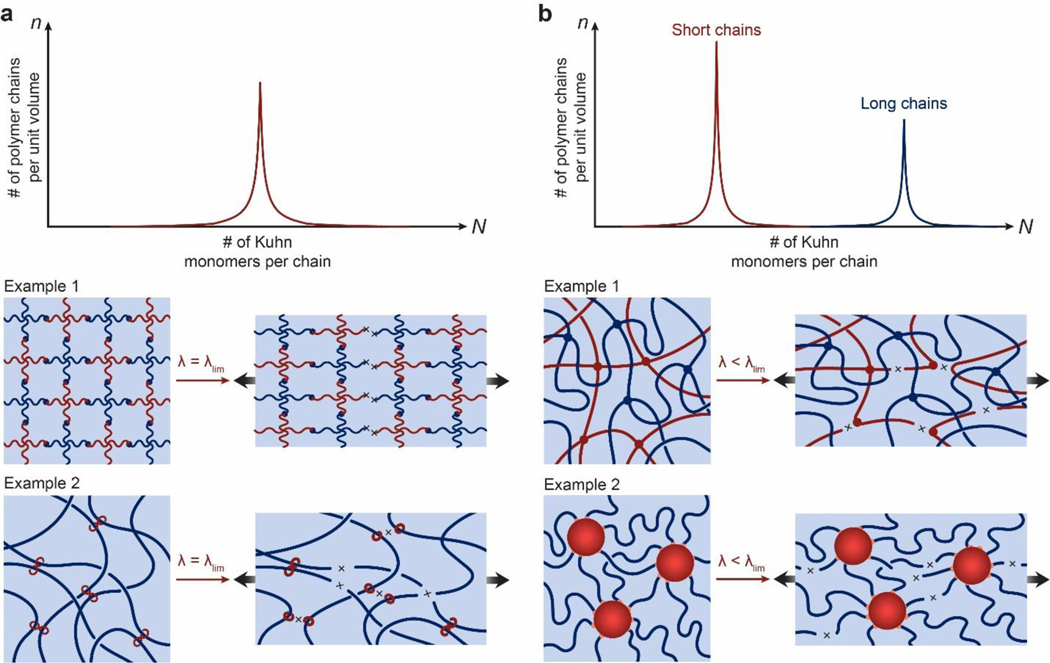

In the dry state (Figure 6a), a conventional polymer network contains n polymer chains per unit volume, where a chain is defined as the segment of polymer between two successive covalent crosslinks. Each polymer chain contains N Kuhn monomers, and the length of each Kuhn monomer is b. The end-to-end distances of a polymer chain at the relaxed and fully stretched states are and Nb, respectively. Therefore, the stretch limit of polymer chains in the dry polymer network can be calculated as47,50,55

| (1) |

The stretch limit of the bulk polymer network scales with , and the pre-factor of the scaling relation depends on the polymer network architecture54.

Assuming that the dry polymer network follows the affine network model, the shear modulus of the network under initial deformation can be expressed as47,50,55,

| (2) |

where k is the Boltzmann constant and T is the absolute temperature.

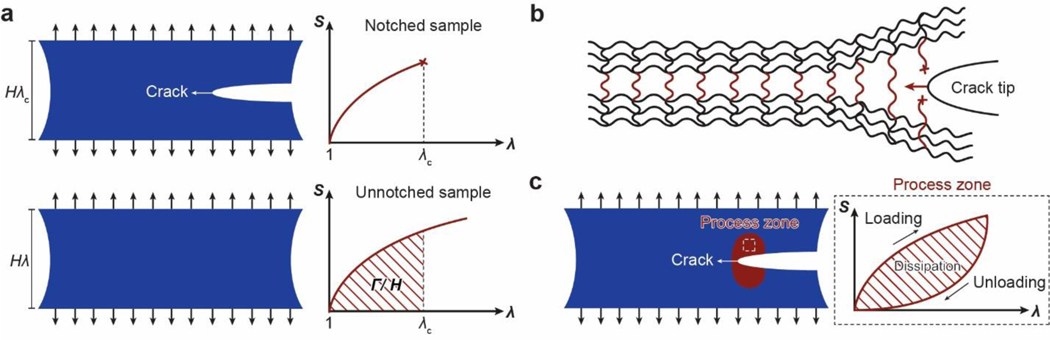

Following the Lake-Thomas model49, the fracture toughness of the dry polymer network is its intrinsic fracture energy , which is the energy required to fracture a single layer of polymer chains per unit area,

| (3) |

where is the number of polymer chains per unit area, is the energy required to fracture a polymer chain, and is the energy required to fracture a single Kuhn monomer.

Also based on the Lake-Thomas model48,49, the fatigue threshold of the dry polymer network is the intrinsic fracture energy . If the dry polymer network is covalently bonded on a substrate (Figure 6b), both the interfacial toughness and the interfacial fatigue threshold of the adhesion are on the level of as well43,71,420.

By substituting the typical ranges of b, N, n, kT and Uf into Eqs. 1–3, we can estimate that the shear modulus G can be on the order of kilopascals to megapascals, the chain stretch limit can reach up to a few tens (without chain entanglement), and the intrinsic fracture energy can reach up to a few hundreds of joule per meter squared55.

The mechanical properties of the dry polymer network are coupled with one another. It is commonly assumed that the polymer chains occupy the major volume of the polymer network in the dry state, and therefore the volume conservation of the polymer network gives

| (4) |

where v is the volume of a Kuhn monomer.

By substituting Eq. 4 into Eqs. 1–3, we can express the chain stretch limit , shear modulus G and intrinsic fracture energy of a conventional polymer network in the dry state as functions of its polymer-chain length N,

| (5) |

From Eq. 5, it is evident that enhancing the polymer-chain length N increases the chain stretch limit and intrinsic fracture energy but decreases the shear modulus G of the conventional polymer network in the dry state. These mechanical properties of the conventional polymer network in the dry state are coupled through the following relation,

| (6) |

3.2. Conventional polymer networks in the swollen state

A dry conventional polymer network with the physical parameters discussed in Section 3.1 can imbibe water and swell into a hydrogel composed of the conventional polymer network and water (Figure 6c). The swelling of the dry polymer network stretches polymer chains in the network by a ratio of λs, named the chain stretch of swelling.

Since the swelling of the dry polymer network stretches its polymer chains by a ratio of λs, the end-to-end distance of a polymer chain in the hydrogel at the relaxed and fully stretched states are and Nb, respectively. Therefore, the stretch limit of polymer chains in the hydrogel can be calculated as,

| (7) |

The stretch limit of the bulk hydrogel scales with , and the pre-factor of the scaling relation depends on the polymer network architecture54.

The swelling of the dry polymer network reduces its shear modulus by a ratio of λs47. Therefore, the shear modulus of the hydrogel under initial deformation can be expressed as,

| (8) |

Note that n in Eq. 8 is the number of polymer chains per unit volume of the dry polymer network.

The swelling of the dry polymer network reduces the number of polymer chains per unit area by a ratio of but does not significantly change the energy required for fracturing a polymer chain in the network. Therefore, the intrinsic fracture energy of the hydrogel can be calculated as,

| (9) |

The fracture toughness and fatigue threshold of a hydrogel with the conventional polymer network are the hydrogel’s intrinsic fracture energy 48,49. If the hydrogel’s polymer network is covalently bonded on a substrate (Figure 6d), both the interfacial toughness and interfacial fatigue threshold of the adhesion are on the order of the hydrogel’s intrinsic fracture energy as well43,71,420.

By comparing Eqs. 1–3 and Eqs. 7–9, we can see that swelling the dry polymer network into the hydrogel reduces the stretch limit , shear modulus G and intrinsic fracture energy of the dry network by factors of λs, λs and , respectively47,50,55. By substituting the typical ranges of λs, b, N, n, kT and Uf into Eqs. 7–9, we estimate that the shear modulus G of the hydrogel with the conventional polymer network can be on the order of pascals to megapascals, the chain stretch limit can reach up to a few times (without chain entanglement), and the intrinsic fracture energy can reach a few tens of joule per meter square.

By substituting Eq. 4 into Eqs. 7–9, we can express the chain stretch limit , shear modulus G and intrinsic fracture energy of the hydrogel with the conventional polymer network as functions of its polymer-chain length N,

| (10) |

From Eq. 10, it is evident that enhancing the polymer-chain length N increases the chain stretch limit and the intrinsic fracture energy but decreases the shear modulus G of the hydrogel with the conventional polymer network. These mechanical properties of the hydrogel are coupled through the following relation,

| (11) |

Notably, the chain stretches due to equilibrium swelling of a conventional polymer network can be calculated. Without loss of generality, let consider a dry conventional polymer network with a cubic shape. When the polymer network reaches the equilibrium state in water, one side of the cube increases its length from the dry state by a ratio of . At the equilibrium state, the Helmholtz free energy for stretching polymer chains and for mixing polymers and water per unit volume of the dry polymer network can be expressed as47,421,

| (12a) |

| (12b) |

where χ is the Flory polymer-solvent interaction parameter and vs is the volume of a solvent molecule. Subsequently, the Helmholtz free energy per unit volume of the dry polymer network can be expressed as47,421,

| (13) |

When the polymer network reaches the equilibrium state in water, minimizes the Helmholtz free energy47,421,

| (14) |

By solving Eq. 14, one can obtain of the hydrogel at the equilibrium swollen state. The chain stretch of the hydrogel at the equilibrium swollen state scales with , and the pre-factor of the scaling relation depends on the polymer network architecture54. While Eqs. 12–14 assume that the polymer network of the hydrogel is uncharged, the effect of charges on the equilibrium swelling of hydrogels can be accounted for by introducing additional terms to the Helmholtz free energy function47,422. It should be noted that hydrogels are not necessary to reach the equilibrium swollen state in many situations, for example, when the hydrogels are insulated from water or do not have sufficient time to equilibrate with water.

4. Unconventional polymer networks

Section 3 has established that hydrogels with conventional polymer networks have intrinsically coupled mechanical properties, including shear modulus, stretch limit, fracture toughness, fatigue threshold, interfacial toughness and interfacial fatigue threshold of adhesion (Eq. 11). This section will discuss unconventional polymer networks (UPNs), which constitute most biological hydrogels (Figures 1 and 2) and have been widely used in synthetic hydrogels to achieve extreme mechanical properties.

The UPNs are defined as polymer networks that are different from the conventional polymer networks in terms of the architectures of polymer networks and/or the interactions among polymer chains in the networks63,423–431. Therefore, the UPNs can be broadly classified into two categories: the UPN architectures and the UPN interactions.

4.1. Unconventional polymer network architectures

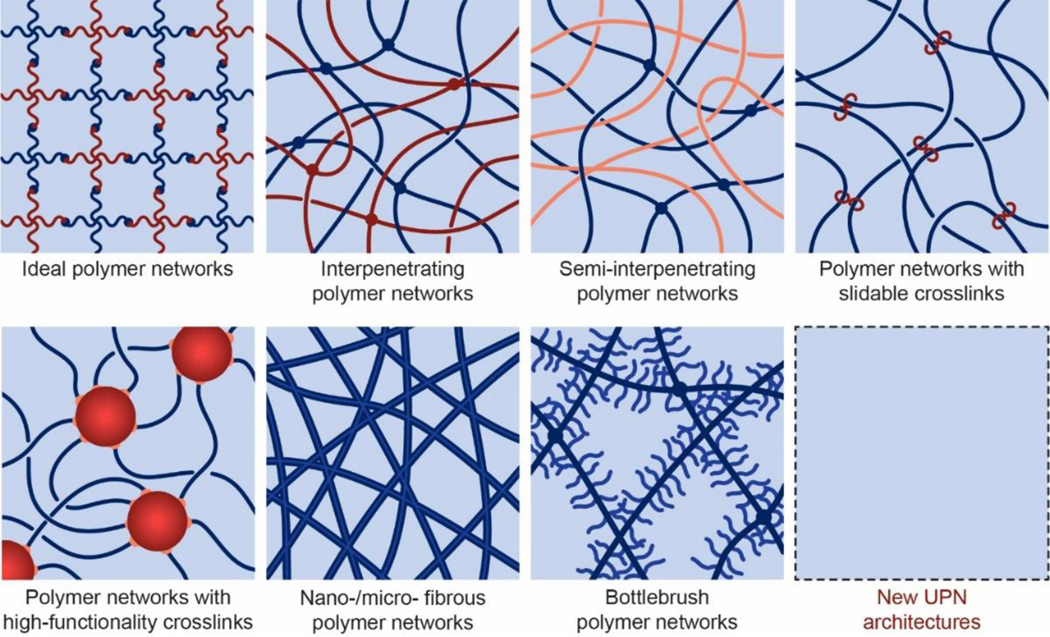

As illustrated in Figure 7, the UPN architectures are dramatically different from the architecture of the conventional polymer networks composed of randomly-crosslinked polymer chains (Figure 4). Almost all biological tissues (Figures 1 and 2) possess UPN architectures. Over the last few decades, multiple UPN architectures have been proposed and synthesized for soft materials including elastomers and hydrogels to achieve extreme properties. Based on their topologies, the typical UPN architectures can be classified into a number of categories, including ideal polymer networks, polymer networks with slidable crosslinks, interpenetrating polymer networks, semi-interpenetrating polymer networks, polymer networks with highfunctionality crosslinks, nano-/micro-fibrous polymer networks, and bottlebrush polymer networks.

Figure 7.

Schematics of unconventional polymer network architectures, including ideal polymer networks, polymer networks with slidable crosslinks, interpenetrating polymer networks, semi-interpenetrating polymer networks, polymer networks with high-functionality crosslinks, nano-/micro-fibrous polymer networks, bottlebrush polymer networks, and future new UPN architectures.

4.1.1. Ideal polymer networks.

Ideal polymer networks are polymer networks that have uniform chain length, uniform functionality, and no defect (Figure 7)317. Following the pioneer work by Sakai et al.317,432–434, the ideal polymer networks have been commonly fabricated using multi-arm macromers, where the arms of adjacent macromers are crosslinked into polymer chains. Because the lengths of the macromer arms are uniform and the reaction efficiency of the crosslinking is high, various ideal polymer networks with uniform chain length, uniform functionality, and almost no defect have been achieved67,317,435–445. The tetra-arm PEG317,446,447 is among the most frequently used macromers for the fabrication of hydrogels with ideal polymer networks. The ends of the PEG macromers are commonly modified with pairs of reaction groups such as N-hydroxysuccinimide and amine67,317,448, tetrabenzaldehyde and tetrabenzaacylhydrazide449, maleimide and thiol450, or boronic acid and diol435,439,446. Due to the almost defect-free nature, the ideal polymer networks have been made highly stretchable and resilient67. It should be noted that, although the conventional polymer networks usually have non-uniform chain lengths and topological defects, their mechanical properties are commonly calculated based on the models of ideal polymer networks as discussed in Section 3. Therefore, the ideal polymer networks by themselves still have coupled mechanical properties.

4.1.2. Polymer networks with slidable crosslinks

A slidable crosslink, commonly in the form of two covalently-crosslinked polymer rings, can interconnect two polymer chains that thread through and slide inside the rings (Figure 7)451. Polymer networks with slidable crosslinks are both mechanically stable and reconfigurable due to the permanent and slidable nature of the crosslinks, respectively. Under mechanical loads, the slidable crosslinks tend to reconfigure the polymer network in a way that the polymer chains in the network sustain the same level of forces, approximating an ideal polymer network.

The polymer networks with slidable crosslinks are mainly synthesized from cyclodextrins-based polyrotaxanes452–454. Cyclodextrins are a series of cyclic oligosaccharides with 6, 7, or 8 glucose units (named α-, β-, or γ- cyclodextrin, respectively); cyclodextrins-based polyrotaxanes are inclusion complexes composed of linear polymer chains that are threaded through the cyclodextrin molecules and then capped by bulky groups at the chain ends454–456. The formation of cyclodextrins-based polyrotaxanes mainly depends on the size matching between the interior cavities of the cyclodextrins and the cross-section of the polymer chains457. Many polymer chains have been investigated to form cyclodextrin-based polyrotaxanes including linear homopolymers, linear block copolymers as well as branched polymers457. The αcyclodextrin has the smallest cavity size and can form inclusion complexes with PEG or PCL, but not with PPO chains458,459. While the β-cyclodextrin can form complexes with PCL or PPO but not PEG458,460,461. The γ-cyclodextrin, which has the largest cavity size, can thread through a PPO chain or two chains of PEG or PCL462. The cyclodextrins can be crosslinked with each other to interconnect the threaded polymer chains and form the polymer networks with slidable crosslinks60,356. Because a polymer network with slidable crosslinks under mechanical loads approximates an ideal polymer network, the mechanical properties of the polymer network with slidable crosslinks are usually coupled with one another as discussed in Section 3451,463–465.

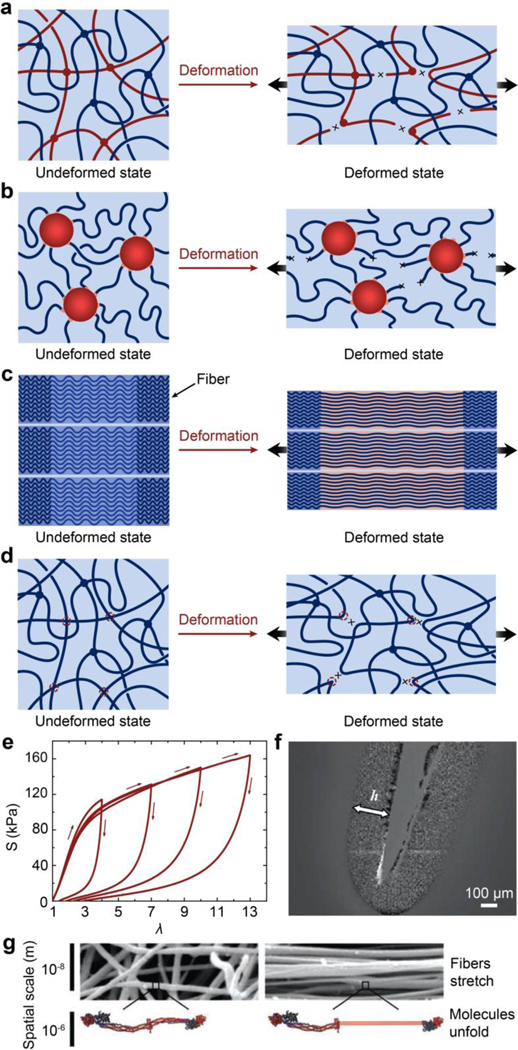

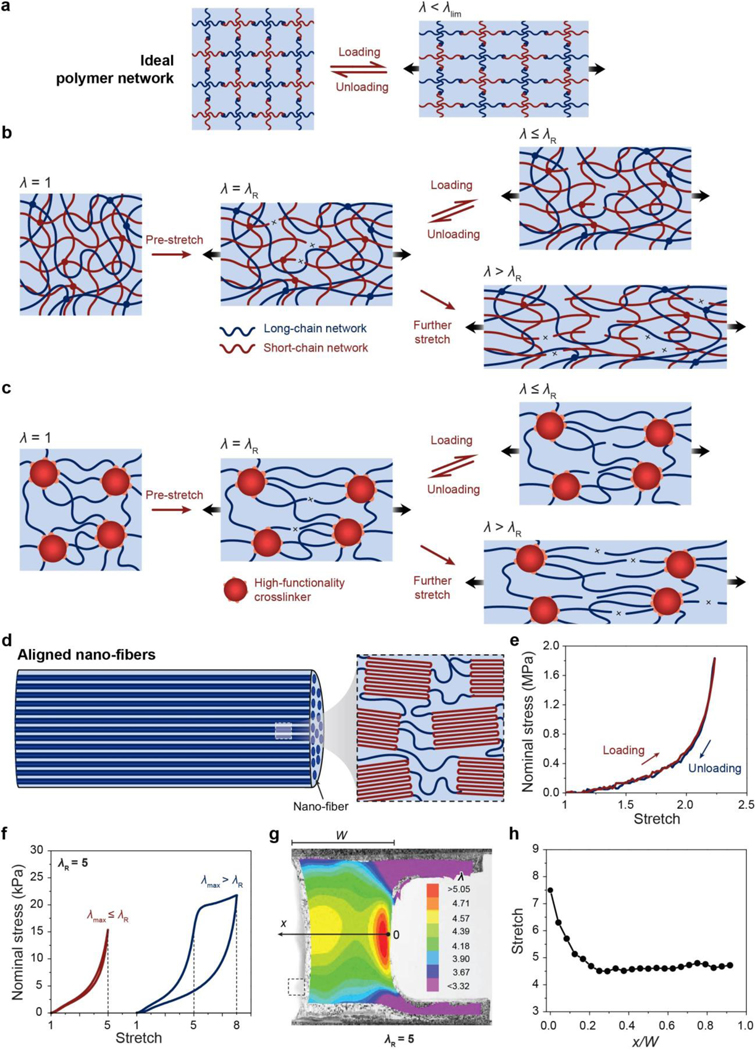

4.1.3. Interpenetrating and semi-interpenetrating polymer networks

Interpenetrating polymer networks are comprised of two or more interpenetrated polymer networks, which are individually crosslinked but not joint together (Figure 7); semi-interpenetrating polymer network are comprised of two or more interpenetrated polymer networks, in which at least one network is uncrosslinked and others are individually crosslinked but not joint together (Figure 7)356,383,466–473. The interpenetrating and semi-interpenetrating polymer networks are entangled or interlocked in a way that they cannot be pulled apart unless the networks are broken470–473. Hydrogels based on the interpenetrating and semi-interpenetrating polymer networks are commonly prepared following the sequential or simultaneous method. In the sequential method, one polymer network is first prepared and then immersed into a solution of monomers, initiators and/or crosslinkers for another polymer network. Thereafter, the interpenetrating or semi-interpenetrating polymer network is formed by polymerizing the second polymer network within the first network. As a remarkable example, Gong et al. have adopted the sequential method to fabricate the so-called double-network hydrogels with high fracture toughness63. In the simultaneous method, a mixture of the polymers, monomers, initiators and crosslinkers for all polymer networks form the interpenetrating or semi-interpenetrating polymer networks in one step or one pot474. This one-step or one-pot fabrication process is a merit for the simultaneous method compared to the sequential method. One remarkable example of the simultaneous method is the simple fabrication of the polyacrylamide-alginate hydrogel with high stretchability and fracture toughness475. A wide range of material candidates including both natural and synthetic polymers as discussed in Section 260,356,383,467–469,475–477 have been used to synthesize hydrogels with interpenetrating and semi-interpenetrating polymer networks via various crosslinking strategies237,383,469,478. As will be discussed in Section 4.4, the interpenetrating and semi-interpenetrating polymer networks can provide decoupled and extreme mechanical properties for hydrogels, such as extremely high stretchability and fracture toughness63,475,479–481.

4.1.4. Polymer networks with high-functionality crosslinks.

The functionality of a crosslink refers to the number of polymer chains interconnected at the crosslink. Common covalent crosslinks as discussed in Section 2.3 usually have relatively low functionality (e.g., less than 10), and there is usually a single polymer chain bridging between two adjacent covalent crosslinks. To dramatically enhance the functionality of a polymer network, various types of high-functionality crosslinks can be introduced into the polymer networks, including crystalline domains215,300,302,482, glassy nodules483,484, nano-/micro-particles356,383,477,482,485–487, and micro-phase separations488–490 (Figure 7). For example, poly(vinyl alcohol) can form crystalline domains to crosslink the polymer networks through the freeze-thaw method302,491; poly(methyl methacrylate) can form glassy spheres and crosslink poly(methyl methacrylate)-based block copolymers into networks492; exfoliated particles, such as nano-clays493, graphene oxide494 or stratified lamellar bilayers495, can crosslink polyacrylamide into mouldable or self-healable hydrogels; mixtures of styrene, butyl acrylate, and acrylic acid can form microspheres and crosslink the residual polymer chain into microsphere composite hydrogels496.

Multiple polymer chains (e.g., over 10) can be interconnected at each high-functionality crosslink (Figure 7). In addition, there can be multiple polymer chains bridging between two neighboring high-functionality crosslinks, where the lengths of the polymer chains can be highly non-uniform60,436. As will be discussed in Section 4.4, the polymer networks with high-functionality crosslinks can provide decoupled and extreme mechanical properties for hydrogels, such as extremely high fracture toughness, resilience, tensile strength and fatigue resistance.

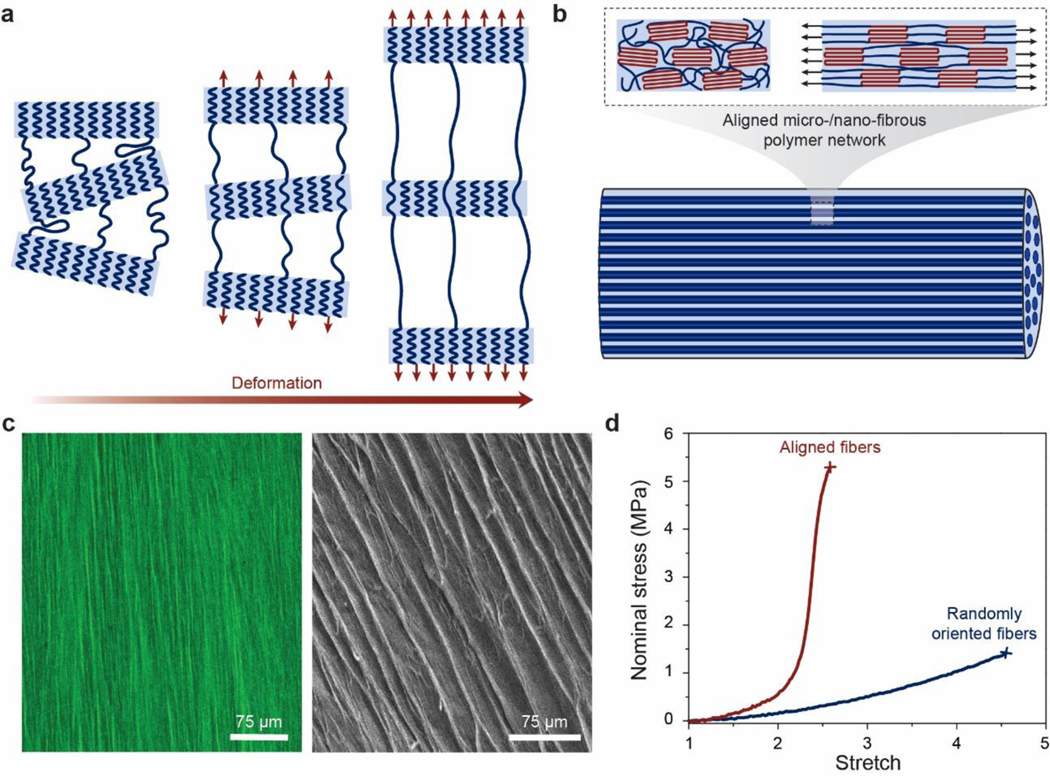

4.1.5. Nano-/micro-fibrous polymer networks

Both synthetic and natural polymers can assemble into fibers (or fibrils referring to short fibers) with diameters ranging from nanometers to micrometers via covalent or physical bonds. The nano-/micro-fibers can further entangle, aggregate, and crosslink into percolated polymer networks6,64,497–502 (Figure 7). In biological organisms, cells can secrete proteins (e.g., collagens) and polysaccharides (e.g., celluloses), which then assemble into nano-/micro-fibrous polymer networks103,250,503–506. These naturally-derived fibers and fibrous networks have been widely harnessed for the fabrication of hydrogels with nano-/micro-fibrous polymer networks382,507–510. In addition, a wide range of natural and synthetic polymers have been fabricated into nano-/micro-fibrous polymer networks with the spinning techniques511–513, among which the electrospinning is most popular due to its simplicity, low cost, and wide applicability514. In particular, the diameter, alignment and density of the fibers can be readily controlled by tuning the parameters of the electrospinning process515–519. As will be discussed in Section 4.4, the nano-/micro-fibrous polymer networks can provide decoupled and extreme mechanical properties for hydrogels, such as extremely high fracture toughness, tensile strength, resilience and fatigue resistance520,521.

4.1.6. Other UPN architectures

Many other types of UPN architectures can provide extraordinary mechanical properties as well. For example, the bottlebrush polymer networks (Figure 7) have shown extremely low shear moduli and tissue-like stress-strain relations in the solvent-free state522,523. Although these UPN architectures have not been widely used in hydrogels, they may be exploited for the design of hydrogels in future524. Furthermore, it is also expected that new UPN architectures will be invented together with the development of polymers and hydrogels.

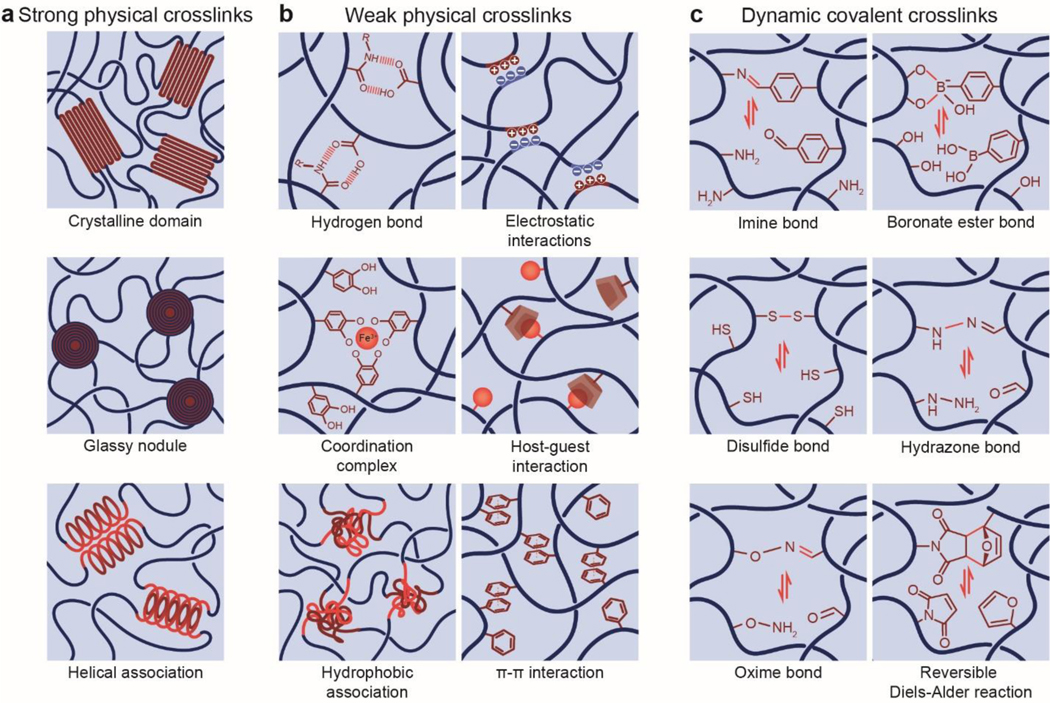

4.2. Unconventional polymer network interactions

As illustrated in Figure 8, the UPN interactions are defined as inter-polymer and intra-polymer interactions that are different from those in the conventional polymer networks (i.e., permanent covalent crosslinks, excluded volumes, and osmotic interactions) (Figure 8). The UPN interactions are vastly abundant in biological organisms525, and they have been intensively studied for the design of soft materials such as elastomers and hydrogels to achieve extreme mechanical properties among many other purposes237. Based on the nature of the UPN interactions, they can be broadly classified into three categories55: strong physical crosslinks, weak physical crosslinks, and dynamic covalent crosslinks.

Figure 8.

Schematics of unconventional polymer network interactions including a. strong physical crosslinks, b. weak physical crosslinks, and c. dynamic covalent crosslinks.

4.2.1. Strong physical crosslinks

In addition to the permanent covalent crosslinks discussed in Section 2.3, various types of strong physical bonds can act as effectively permanent crosslinks in polymer networks. Typical examples of strong physical crosslinks include crystalline domains, glassy nodules, and helical structures. The energy of strong physical crosslinks is similar to that of permanent covalent crosslinks.

Crystalline domain.

A specific subset of synthetic and natural polymers can form crystalline domains under appropriate conditions. A crystalline domain, with the size from nanometers to micrometers, can serve as a strong physical crosslink for multiple amorphous polymer chains connected to it (Figure 8). As an example in synthetic polymers, PVA can form crystalline domains by repeated freeze-thaw cycles or by annealing at temperatures above its glass transition temperature300,302,482. The formation of PVA crystalline domains is mainly due to the hydrogen-bonding interactions of the hydroxyl groups on PVA chains4. As an example in natural polymers, chitin and chitosan can form semi-crystalline polymer networks with crystalline domains crosslinking amorphous chains by treating the chitin and chitosan with strongly acidic or basic solutions to overcome the inter-chain electrostatic repulsions215,218. As another example in natural polymers, cellulose can also form highly crystalized nanofibers due to the strong interaction between glucose units526. These cellulose nanofibers can further aggregate and form a stable network by alkaline treatments497,527. It should be noted that heating the abovementioned semi-crystalline polymer networks above their melting temperatures can destroy the crystalline domains in the networks, although most crystalline domains are stable at room and body temperatures.

Because a crystalline domain usually interconnects multiple polymer chains, they often act as highfunctionality crosslinks in the polymer networks as discussed in Section 4.1. In addition, the energy required to pull a polymer chain out of a crystalline domain is much higher than that required to fracture the same polymer chain71; therefore, crystalline domains can also introduce intrinsically high-energy phases into the polymer networks. These attributes of crystalline domains have endowed the hydrogels containing crystalline domains with extreme mechanical properties, such as tough, strong and fatigue-resistant, which will be discussed in Section 5.

Glassy nodule.

Glassy nodules are formed by the reversible liquid-glass transition of amorphous polymers when the temperature is decreased below their glass-transition temperatures528. In order to harness glassy nodules as strong physical crosslinks, block copolymers that contain at least one segment with a high glass-transition temperature have been commonly used. As the temperature reduces to room or body temperature, the segments with the high glassy-transition temperature form glassy nodules that effectively crosslink the adjacent amorphous polymer chains (Figure 8)529. For example, the polystyrene segments in the polystyrene-b-poly(N-isopropylacrylamide)-b-polystyrene copolymers can form glassy nodules at room temperature to crosslink the block copolymers chains into a polymer network530. As another example, poly(methyl methacrylate) has a glass transition temperature around 115 °C531; therefore, the poly(methyl methacrylate) segments in the poly(methyl methacrylate)-b-poly(n-butyl acrylate) copolymers can form glassy spheres at room temperature to crosslink the polymer network492. Similar to crystalline domains, glassy nodules can also act as high-functionality crosslinks and intrinsically high-energy phases in polymer networks to give the corresponding hydrogels extreme mechanical properties, which will be discussed in Section 5.

Helical association.

Many natural polymers, due to their precisely-controlled structures, can assemble into nanometer-scale helical fibers (or fibrils), which then can aggregate or entangle to form a crosslinked network (Figure 8)103,507,509,510. For example, the well-known triple-helix structure of type I collagen is formed by the self-assembly of three peptide strands. These collagen triple helices can pack together to form collagen nanofibers and further self-assemble into an interconnected hydrogel network532,533. As another example, the linear agarose chains are disordered coils in aqueous solutions at high temperatures, and can form double-helix strings534 or simple helical chains535 when the temperature is decreased to room or body temperature. These stings or chains can associate to form agarose fibers through hydrogen bonding and further be entangled to form the interconnected hydrogel network536.

4.2.2. Weak physical crosslinks

Compared to the strong physical crosslinks, many other physical crosslinks in polymer networks are relatively weak, transient and reversible. Typical examples of weak physical crosslinks include hydrogen bond, electrostatic interaction, metal coordination, guest-host interaction, hydrophobic association, and π-π stacking. The energy of weak physical crosslinks is usually lower than that of strong physical crosslinks and permeant covalent crosslinks.

Hydrogen bond.

The energy of a single hydrogen bond ranges from 0.8 kJ mol−1 to 167 kJ mol−1 (Figure 5) 373,374. Many natural polymers can form hydrogels by the intermolecular hydrogen bonds. For example, gelatin can form polymer networks of helical structures crosslinked by hydrogen bonds170; certain types of polysaccharides, such as agarose, amylose, amylopectin and carrageenan, can also form helical structures in solutions and crosslinked into hydrogels by hydrogen bonds537. A number of synthetic polymers are also capable of forming physical hydrogels via hydrogen bonds. For example, PVA hydrogels can be obtained by forming hydrogen bonds between polymer chains through repeated freezing and thawing of PVA solutions303. PAA or polymethacrylic acid (PMA) can form complexes with PEG by hydrogen bonds between the oxygen groups of PEG and the carboxyl groups of PMA538 or PAA539.

Despite the abundance of hydrogen-bond groups (-OH, -NH, -C=O, -C-O) in natural and synthetic polymers, the hydrogen-bond interactions in hydrogels are usually screened due to the water molecules in hydrogels. To enable effective hydrogen-bond crosslinks, hydrophobic moieties with multiple self-complementary hydrogen-bond groups have been introduced478,540,541. For instance, functionalizing PEG, PHMEA and PNIPAM with amine triazine or diamino triazine groups enables the formation of triple hydrogen bonds per crosslink478,490,540,542. Similarly, the introduction of ureidopyrinimidone (UPy) groups onto PEG, PHMEA, PNIPAM, PAA and PDMAA chains gives quadruple hydrogen bonds per crosslink478,540,541. Complementary DNA base pairs (A-T, C-G) can also serve as hydrogen-bond motifs when attached to polymer chains543.

Electrostatic interaction.

The energy of electrostatic interactions ranges from 5 kJ mol−1 to 200 kJ mol−1 (Figure 5)375. Natural and synthetic polymers with fixed charges, named polyelectrolytes, can be physically crosslinked by electrostatic interactions105,475,544,545. As a typical example of the anionic polyelectrolytes, alginate has been physically crosslinked with a wide range of divalent cations such as Ca2+, Ba2+ and Mg2+. Although the energy of a single ionic bond in alginate is relatively low, multiple (e.g., over 20) adjacent ionic crosslinks on the alginate chains can form a densely-crosslinked region following the “eggbox” model6,103,105,546, giving relatively stable alginate hydrogels. As a typical example of the cationic polyelectrolytes, chitosan has been crosslinked by multivalent anions such as citrate and tripolyphosphate547–549. Electrostatic interactions of oppositely charged polyelectrolytes can also give physically-crosslinked hydrogels. For example, anionic poly(L-glutamic acid) and cationic poly(L-lysine) can form an injectable hydrogel by simply mixing them in phosphate buffered saline solutions544. As another example, poly(3-(methacryloylamino) propyl-trimethylammonium chloride) and poly(sodium p-styrenesulfonate) can form polyion complexes and give a series of tough and self-healing hydrogels by the stepwise polymerization of the oppositely charged monomers550. It should be noted that the formation of ionic crosslinks usually requires low ionic strength of the solvents for the hydrogels to avoid charge shielding.

Coordination complex.

A coordination complex consists of a central metal ion, especially transition metal ion, and a surrounding array of organic ligands551,552. The energy of coordination complexes ranges from 100 kJ mol−1 to 300 kJ mol−1 (Figure 5) 375. Coordination bonds provide structural support in many living tissues, such as human bone553, insect mandible554 as well as mussel byssal thread555. Hydrogels crosslinked by coordination complexes are primarily achieved by functionalizing polymer backbones with chelating ligands, which then form coordination complexes with metal ions. Bisphosphonate556–558, catechol559–561, histidine562–564, thiolate565,566, carboxylate567,568, pyridine569, bipyridine570, and iminodiacetate564,571 have been widely used as the chelating ligands; Cu2+, Zn2+, Fe3+, Co2+ and Ni2+ are the commonly-used metal ions. Bisphosphonate ligands can be modified onto hyaluronan572, gelatin573 or PEG557 to form coordination complex with Ca2+, Mg2+ or Ag+. Besides bisphosphonate, catechol ligands are also widely used to functionalize various polymers such as PEG574,575, gelatin576, hyaluronic acid577, chitosan578, polyacrylamide560, and PAA561. As a typical example, PEG-modified with 3,4dihydroxyphenyl-L-alanine (DOPA) residues can form coordination complexes with metal ions (Cu2+, Zn2+ and Fe3+ ions) when the pH is above 8478,575. In natural proteins, the histidine amino acid can give an imidazole ligand residue59, which is one of the most important chelators in the human body579. PEG-modified with histidine can form coordination complexes with metal ions (Cu2+, Co2+ and Ni2+ ions) to achieve the physically crosslinking of the PEG hydrogels478,580. The mechanical properties of the hydrogels crosslinked by coordination complexes can be tuned by varying the metal ions and/or the chelating ligands562,581.

Host-guest interactions.

Host-gust interactions refer to two or more molecules or ions that are held together in unique structural relationships by forces other than those of covalent bonds461,582,583. The two most common host moieties are cyclodextrins and curcubit[n]urils. Cyclodextrins (CDs) are cyclic oligosaccharides which compose of 6 to 8 D-glucose repeating units linked by α−1,4-glucosidic bonds584,585. Commonly-used CDs include α-, β-, and γ-CDs which are composed of 6, 7, and 8 D-glucose repeating units, respectively. These CDs have a truncated cone shape with the secondary and primary hydroxyl groups on the smaller cone rim exposed to the solvent583, which makes the CDs show a relatively hydrophobic inner cavity and a relatively hydrophilic outer surface. Therefore, these CDs can act as the host molecules for various hydrophobic guest molecules with appropriate molecular sizes through hydrophobic and van der Waals interactions383,457,461. For example, common guests for α-CD include azobenzene586 and ferrocene587; common guests for β-CD include adamantane588, benzimidazole589, 3-(Trimethylsilyl)propionic acid590, azobenzene586, ferrocene591, bipyridine592, phenolphthalein593 and cholesterol594; common guests for γ-CD include ferrocene587. Among various guest molecules, adamantane is widely regarded as having one of the greatest affinities due to its complementary size for β-CD and high hydrophobicity595. In addition, the complexation of azobenzene or ferrocene to CDs is responsive to light596 or redox conditions597,598, respectively.

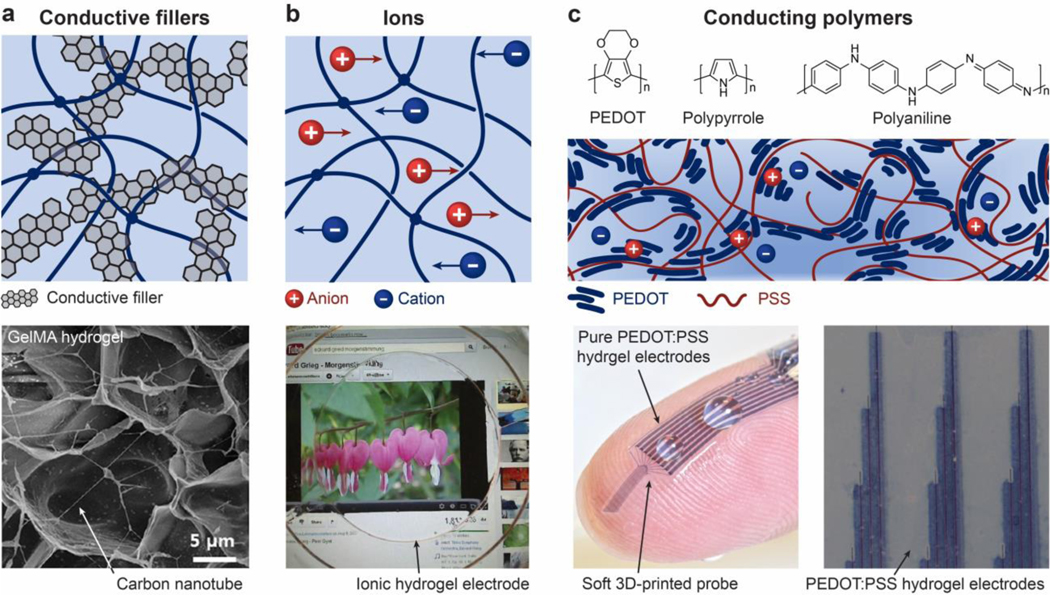

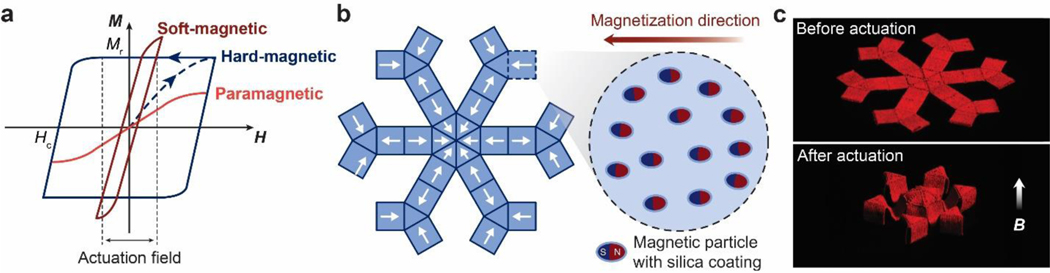

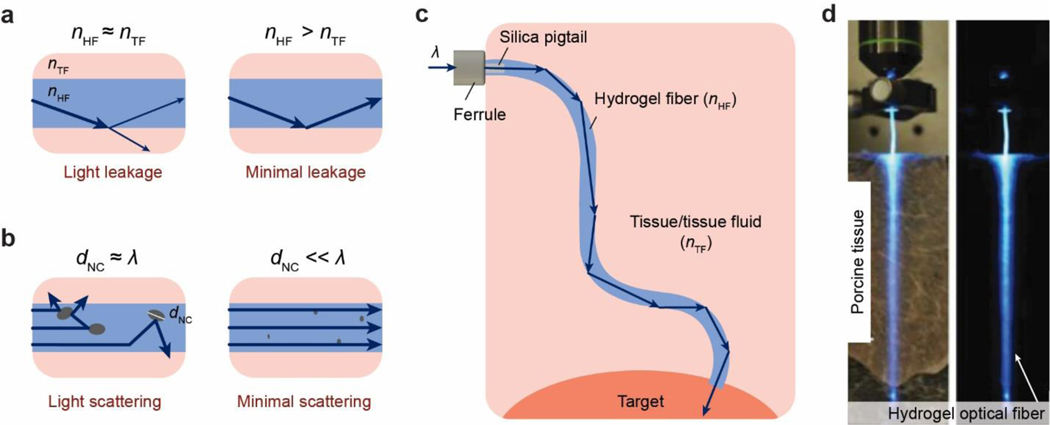

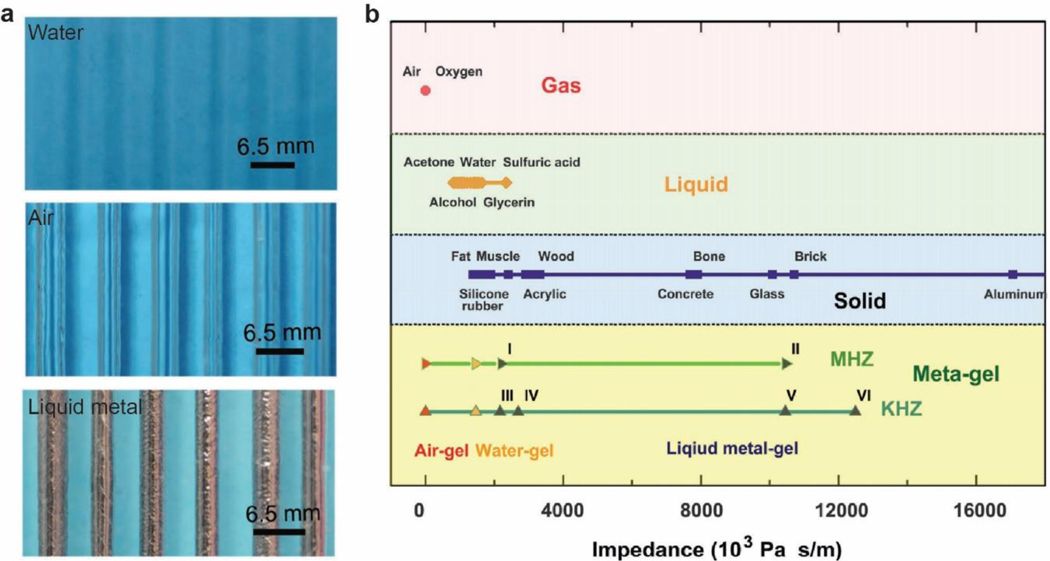

The cucurbit[n]urils (CB[n, n=5–8]) are pumpkin-shaped macrocyclic oligomers made from the condensation reactions of formaldehyde and glycoluril583,599. The CB[n]s usually have a structure of a rigid hydrophobic cavity with two identical hydrophilic polar carbonyl groups surrounding the portals. The cavity size ranges from 4.4 to 8.8 A° (for CB[n], n = 5–8) and the portal diameter ranges from 2.4 to 6.9 A°600. The binding affinities of CBs are often greater than that of other cavitands601, mainly due to the formation of the strong charge–dipole, hydrogen bonding, and hydrophobic/hydrophilic interactions by the rigid inner cavities and the negative portals of CB[n]s602. In particular, CB[7] can form strong 1:1 complexes with positively charged amphiphilic guests including adamantane, ferrocene, p-xylylene and trimethylsilyl derivatives containing one or two amino groups, as well as viologen derivatives603,604. CB[8] also displays remarkable binding affinities towards positively charged and relatively large guests such as amantadine derivatives. Furthermore, the cavity of CB[8] is large enough to accommodate two organic guests simultaneously, thus forming highly stable ternary complexes. For example, CB[8] can form stable complexes with two doubly-charged 2,6-bis(4,5-dihydro-1Himidazol-2-yl)naphthalene molecules605, or one viologen (paraquat) and one 2,6-dihydroxynaphthalene together606.