Abstract

Many mobile sound measurement applications (apps) have been developed to take advantage of the built-in or fit-in sensors of the smartphone. One of the concerns is the accuracy of these apps when compared to professional sound measurement instruments. Previously, a research team from the National Institute for Occupational Safety and Health (NIOSH) developed the NIOSH Sound Level Meter (SLM) app for iOS smart devices. The team found the average accuracy of this app to be within ±1 dBA when using calibrated external microphones with a type 1 reference device and measuring pink noise at levels from 65 to 95 dBA in 5-dBA increments. The studies were conducted in a reverberant noise chamber at the NIOSH Acoustics Laboratory in Cincinnati. However, it is still unknown how this app performs in measuring industrial/mining sound levels outside of a controlled laboratory environment. The current NIOSH study evaluates the NIOSH SLM app to measure sound levels from a jumbo drill (a large mining machine). The study was conducted in a hemi-anechoic chamber at the NIOSH Pittsburgh Mining Research Division and followed by a field evaluation in an underground metal mine. Six different iOS smart devices were used with two types of external microphones chosen from previous studies to measure sound levels during jumbo drill operations, and the results were compared with a reference device. Results show that the average sound levels measured by the NIOSH SLM app are within ±1 dBA of the reference device both in the laboratory and field. However, the type of operation being performed, the selection and use of external microphones, distance from a noise source, and environmental factors (e.g., air movement) may all influence the accuracy of the app’s performance. Although additional validation is still needed, the results from this study suggest a potential for using the NIOSH SLM app, with calibrated external microphones, to measure sound levels in mining operations.

Primary subject classification: 71, Secondary subject classification:

1. INTRODUCTION

Smartphones have been ubiquitously used in the US for basic communication and many other functions. Surveillance data have shown that smartphone ownership among US adults has increased from 35% in 2011 to 77% in 20171. The United States Census Bureau reports that every three out of four households have a handheld computer such as a smartphone or a similar device2. Among smartphone users, nearly half of them are using an iOS device3. Smartphones have computational capabilities and have become ideal instruments for revolutionizing data acquisition, processing, storage, and health monitoring and, as a result, have become of great interest to the research and scientific communities. The fact that smartphones have become so lightweight, portable, and have a variety of built-in sensors has made them suitable for field research/practice. For these reasons, sophisticated scientific applications have been developed relying heavily on these sensors, e.g., microphones, cameras, global positioning systems, proximity detectors, accelerometers, gyroscopes, and electromagnetic compasses.

Noise exposure is the one of the most common exposures in the workplace. More than 11% of the US population have hearing loss4. More than 22 million people each year are exposed to time-weighted average sound levels above 85A-weighted decibels (dBA) at work5.Noise-induced hearing loss accounted for more than 10% of all occupational illnesses according to the Bureau of Labor Statistics (BLS) in 2004 and 2005. The mining industry has been known to have the highest prevalence of hearing loss among all industries. It was estimated, from 2000 to 2008, that the average prevalence of hearing loss among miners was more than one-fourth of the population in each mining sector6. Further, the incidence rate (hearing loss rate for new cases) in mining has increased over the years, while decreasing in manufacturing, wholesale/retail trade, transportation, warehousing, and the utility industries7.

Since 2000, the Mine Safety and Health Administration (MSHA) noise rule has required all mines to implement hearing conservation programs. This rule includes a component of continuous exposure monitoring for the determination of program enrollment and compliance8. For a program to be in compliance, the sound measurement instrument should be a type 2 equivalent or higher and have minimum functions in integrating all sound levels over the appropriate range (80–130 dBA for action level; 90–140 dBA for permissible exposure level and dual-hearing protection level). The instrument should include a 90-dB criterion level with a 5-dB exchange rate on an A-weighted scale with slow response instrument settings and report a time-weighted average sound level or dose based on the criterion.

On average, a type 1 or type 2 SLM/dosimeter can cost between a few hundred and a few thousand dollars. Given the costs, smartphone-based sound measurement apps may reduce the expense associated with the requirement to monitor sound levels in mines. Therefore, there is a growing need for developing sound measurement apps for smart devices. However, validation of smartphone-based applications in a real-world mining environment remains a challenge.

Previously, NIOSH examined 192 sound measurement apps on the iOS and Android platforms and found only 4 iOS apps that met the pre-determined criteria (mean difference of ±2 dBA from a type 1 reference SLM)9.Most of the examined commercial apps are designed for casual users and lack the necessary functionality for conducting a more accurate occupational sound measurement. Recognizing this limitation and gap, the research team collaborated with an app developer to create an iOS-based SLM app, referred to here as the NIOSH SLM app. The app aims to measure and characterize occupational noise exposures at an accuracy level comparable to professional instruments. The app has been tested and validated at the NIOSH Acoustics Laboratories (in Cincinnati) for all iOS devices. It is also capable of calibrating external microphones and collecting and processing data with user-selected criteria, such as frequency-weighting filters (A, C, or Z), exchange rate (3 or 5 dB), response time (slow or fast), and threshold level (80 or 90 dB). The results can be measured in relation to total run time, equivalent continuous average sound level (Leq), maximum sound level (Lmax), peak (Lpeak), time-weighted average (TWA), corresponding dose (%), and 8-hour projected dose.

In the above NIOSH study, an average accuracy of ±2 dBA from a reference professional instrument was achieved when measuring pink noise from 65 to 95 dB in 5-dB increments in a reverberation chamber, using internal microphones manufactured by Apple. Using external calibrated microphones improved the agreement to an accuracy level of ±1 dBA10.

Several follow-up questions emerged from the above NIOSH study, including whether the app’s performance would remain acceptable when measuring more complicated sounds from industrial noise sources, and whether the performance would vary with different acoustic environments and conditions in the field. In particular, NIOSH is interested in how the app performs in field conditions in an active mining operation, as large mining machines can generate sound levels above 95 dBA. These levels, which can be generated by equipment such as dozers, front-end loaders, ash/haul trucks (on high idle), jumbo drills, and roof bolters, are beyond the range tested using pink noise in the laboratory11–13.

To address these issues, this article describes the study to evaluate the accuracy of the NIOSH SLM app using a jumbo drill as a noise source and examines app performance in both the laboratory and the field. The study reveals a number of potential influential factors on app accuracy, including the type of operation being performed, the selection and use of external microphones, distance from a noise source, and environmental conditions.

2. METHODOLOGY

2.1. Laboratory Testing

Six iPhone 6/6S devices were mounted with iPhone holders on a multi-mount horizontal bar supported with a tripod. The height of the tripod was adjusted to 1.2 meters, which is the approximate height of a person holding a sound measurement instrument. Two types of external microphones, the MicW i436 and Dayton Audio iMM6, were chosen based on previous studies14,15. Both microphones are omni-directional; however, only MicW i436 complies with the International Electrotechnical Commission’s (IEC) standard for a Class 2 SLM standard according to its manufacturer. All smart devices were tested using one type of external microphone and then the other.

A Larson Davis LxT Type/Class 1 sound level meter was used as the reference device. It was mounted on a tripod at the same height, side-by-side with the smart devices. All external microphones and the Larson Davis SLM were calibrated at a 114-dB calibration tone before and after each experiment, by a Quest model QC-20 and Larson Davis model Cal 150 acoustic calibrator, respectively. The Quest model QC-20 with a smaller ¼″ adapter was chosen to calibrate the external microphones. The Larson Davis Cal 150 was only used for calibrating the Larson Davis LxT SLM. All six smart devices and the reference device were side-by-side and manually started and stopped one-by-one to measure sound levels generated from a single-boom jumbo drill (Atlas Copco S1L). The differences in start and stop times between all devices were no more than 2–3 seconds apart, and the length of each measurement lasted the full course of each operation, i.e., drilling or moving the boom.

Drilling refers to the operation that a drill bit is drilling into a granite block (in the laboratory) or at a mining face (in the field). Boom moving refers to adjusting the boom position after drilling is complete. The jumbo drill was operated in the laboratory by a technician recently trained to operate it. On average, the duration of the boom moving operation was 26.5 ± 7.9 seconds in the laboratory test. Similarly, because jumbo drill operators are extensively familiar with the machines, it only takes them a few seconds to move a boom from one hole to the next drilling spot. In laboratory testing, it took 1–2 minutes to drill through a granite block 1.8 meters in length, and 30–45 seconds to move and adjust the boom to an adjacent spot before the next drilling. Therefore, the time lapse between start/stop of each device is much smaller than the duration of the whole sampling period. Given the non-transient and continuous nature of sound from the jumbo drill, the slight variation in starting and stopping time for each device would not significantly influence the resulting sound readings. Measurements were taken parallel to the drifter housing from 1.2 meters to 6.8 meters away, moving backward to increase the distance to 1.41 times the previous distance, intending to reduce sound pressure levels by 3 dB with each step (Fig. S1).

The testing procedure was described in detail. First, use MicW i436 external microphone on all six iPhone 6/6S devices along with the reference device to simultaneously measure drilling and boom moving sound levels at 1.2 meters away from the jumbo drill. Move backward to repeat the measurement on drilling and boom moving at 1.7 meters. Continue moving backward and conduct the measurements with each step 1.41 times the previous distance until reaching the final testing spot at 6.8 meters. Switch to Dayton Audio iMM6 external microphone and repeat the above procedures but moving forward from 6.8 meters to 1.2 meters.

2.2. Field Testing

The accuracy of NIOSH SLM app was further evaluated by measuring sound levels from single-boom jumbo drills operating in the field in an underground metal mine (Fig. S2). Avariety of smart devices (iPhone 6, 6S, 5S, iPod 4th Generation) with the NIOSH SLM app installed were tested in the field. Because of the limited space at the mining face, only one smart device was used at a time to measure sound levels side-by-side with the reference Larson Davis SLM. Both the smart device and the reference device were handheld by the researcher, with sound monitoring started and stopped simultaneously. Sound levels were collected next to the machine operator. Measurements were taken during the full course of drilling, which took about 2 minutes to complete for each hole. Similarly, the two types of external microphones, the MicW i436 and Dayton Audio iMM6, were evaluated. All devices were calibrated at 114 dB before and after each field evaluation by a Quest model QC-20 or Larson Davis model Cal 150 acoustical calibrators.

2.3. Data Analysis

For both laboratory and field testing, the differences between the NIOSH SLM app and the reference device were calculated. A Kolmogorov–Smirnov test for normality and a Levene’s test of homogeneity of variance were conducted to evaluate any violation to the assumptions of normal distribution and equal variance in t test. Two one-sided test (TOST) was conducted to test the equivalence of the NIOSH SLM app and the professional device with a practical consideration of the difference within ±1 dB (α = 0.05). Mixed effect generalized linear model was used to evaluate the contribution of the type of external microphone, the operation and the distance to the differences between NIOSH SLM app and the reference device. Partial η2, observed power and estimated marginal means were reported.

3. EVALUATION OF THE ACCURACY OF THE NIOSH SLM APP

Overall, the average difference in A-weighted equivalent sound levels (LAeq) between the NIOSH SLM app and the type 1 Larson Davis SLM measurements is 0.31dBA (95% CI 0.04–0.58) in the laboratory evaluation and − 2.06 dBA (95% CI, −3.17 to 0.94) in thefield evaluation (Table 1). Result from TOST showed that the NIOSH SLM app and the reference device are equivalent with the acceptable difference of ±1 dB (α = 0.05) in the laboratory test. However, in the field test, the NIOSH SLM app and Type 1 Larson Davis SLM were not considered to be equivalent at the acceptable difference of ±1 dB unless expanding the acceptable level to ±2.5 dB.

Table 1—

Overall differences of measurements1 between the NIOSH SLM app and type 1 SLM.

| Metric (dB) | Laboratory test | Field test | ||||

|---|---|---|---|---|---|---|

| N | Mean | SD | N | Mean | SD | |

| L Aeq | 130 | 0.3 | 1.3 | 20 | −2.1 | 2.4 |

| L max | 130 | 1.3 | 1.5 | 20 | −2.2 | 2.7 |

| L peak | 130 | −0.1 | 3.7 | 20 | 0.4 | 2.0 |

The difference: measurements from NIOSH SLM app minus Larson Davis SLM.

The accuracy of the NIOSH SLM app from the field tests is consistently lower than from the laboratory tests, regardless of the type of operation being performed and the model of external microphones used. One probable reason for the above differences is the effect of wind on external microphones. Significant air movement was noticed at the time of field data collection as a result of high ventilation volume demand at the underground mining face. Nevertheless, the above results confirmed that the NIOSH SLM app is equivalent to Type 1 Larson Davis SLM with slight variations within ±1 dB in the laboratory and ±2.5 dB in the field.

4. EVALUATION OF COMPLICATING FACTORS

The external microphones used, the Dayton Audio iMM6 and MicW i436, have shown promising performance in the previous laboratory-based study when using pink noise as a sound source. The MicW i436 supports Class 2 compliance with IEC standards, whereas the compliance of the Dayton Audio iMM6 is not reported by its manufacturer. Both external microphones are statistically different from the reference device, possibly due to the small within-device variance as discussed earlier. Nevertheless, both types achieve acceptable accuracy. The measurements using the two microphones were within ±1 dB from the reference device in the laboratory test. However, the performance of the MicW i436 was slightly better (Table 2). In the field test, the accuracy of both microphones was lower in comparison to measurements from the laboratory test. The performance of the Dayton Audio iMM6 was less accurate—more than ±2 dBA from the reference. Comparing the MicW i436 with the Dayton Audio iMM6 shows that the MicW i436 is consistently more accurate than the Dayton Audio iMM6 by 1.7 dBA (95% CI, 1.2–2.3), which applies to both the laboratory and field tests. The difference between the two is significant (p < 0.001) after adjusting for the type of operation and distance (α = 0.05). The effect size of external microphone was large with partial η2 = 0.715 (Table S1).

Table 2—

Measurement differences between the NIOSH SLM app and type 1 SLM by external microphone type.

| Microphone | Metric (dB) | Laboratory test | Field test | ||||

|---|---|---|---|---|---|---|---|

| N | Mean | SD | N | Mean | SD | ||

| i436 | L Aeq | 64 | 1.1 | 1.6 | 6 | −0.8 | 1.4 |

| L max | 64 | 1.9 | 0.9 | 6 | −1.5 | 2.4 | |

| L peak | 64 | 0.3 | 1.2 | 6 | 1.1 | 1.5 | |

| iMM6 | L Aeq | 66 | −0.5 | 0.9 | 14 | −2.6 | 2.6 |

| L max | 66 | 0.6 | 1.7 | 14 | −2.5 | 2.8 | |

| L peak | 66 | −0.5 | 5.0 | 14 | 0.0 | 2.1 | |

Several studies have evaluated the influence of the internal microphone from different iPhone models9,15. These studies have shown a greater variance using internal microphones from different iPhone models due to the user’s inability to calibrate the internal microphone, and because the accuracy of the microphone largely depends on a number of uncontrollable factors related to user history, e.g., how long the phone had been used, whether the microphone had been exposed to an extreme environment, or whether any incident occurred that could affect the phone during prior use. Based on these studies, it is not recommended to monitor ambient sound levels using an internal or non-calibrated microphone. Therefore, this study has not further evaluated the accuracy of the app using an internal microphone.

Because of the nature of jumbo drilling, a longer measurement period would be necessary to obtain an accurate estimation of the average sound levels during boom moving. For this reason, measurements from boom moving were not collected in the field, only in the laboratory. Data from the laboratory evaluation show that the average differences between the NIOSH SLM app and the reference device were within ±1dBA during drilling and boom moving (Table 3). This difference is slightly greater for boom moving than drilling, regardless of the type of external microphones (Table 4). The average difference in app accuracy between drilling and boom moving was 1.3 dBA (95% CI, 0.8–1.8; boom moving minus drilling), which is statistically significant (p < 0.001). The effect size of the type of operation was also large with partial η2 = 0.586 (Table S1).

Table 3—

Measurements differences between the NIOSH SLM app and type 1 SLM by type of operation being performed.

| Operations | Metric (dB) | Laboratory test | ||

|---|---|---|---|---|

| N | Mean | SD | ||

| Drilling | L Aeq | 71 | −0.2 | 1.0 |

| L max | 71 | 1.1 | 1.2 | |

| L peak | 71 | 0.3 | 4.7 | |

| Boom moving | L Aeq | 59 | 1.0 | 1.8 |

| L max | 59 | 1.5 | 1.7 | |

| L peak | 59 | −0.5 | 1.6 | |

Table 4—

Measurement differences between the NIOSH SLM app and type 1 SLM by type of operation being performed and external microphones.

| Microphones | Operations | Metric (dB) | Laboratory test | ||

|---|---|---|---|---|---|

| N | Mean | SD | |||

| I436 | Drilling | L Aeq | 35 | 0.3 | 0.9 |

| L max | 35 | 1.7 | 0.8 | ||

| L peak | 35 | 0.3 | 1.0 | ||

| Boom moving | L Aeq | 29 | 2.1 | 1.8 | |

| L max | 29 | 2.2 | 0.8 | ||

| L peak | 29 | 0.4 | 1.4 | ||

| iMM6 | Drilling | L Aeq | 36 | −0.7 | 0.8 |

| L max | 36 | 0.4 | 1.2 | ||

| L peak | 36 | 0.3 | 6.6 | ||

| Boom moving | L Aeq | 30 | −0.2 | 1.0 | |

| L max | 30 | 0.8 | 2.1 | ||

| L peak | 30 | −1.4 | 1.3 | ||

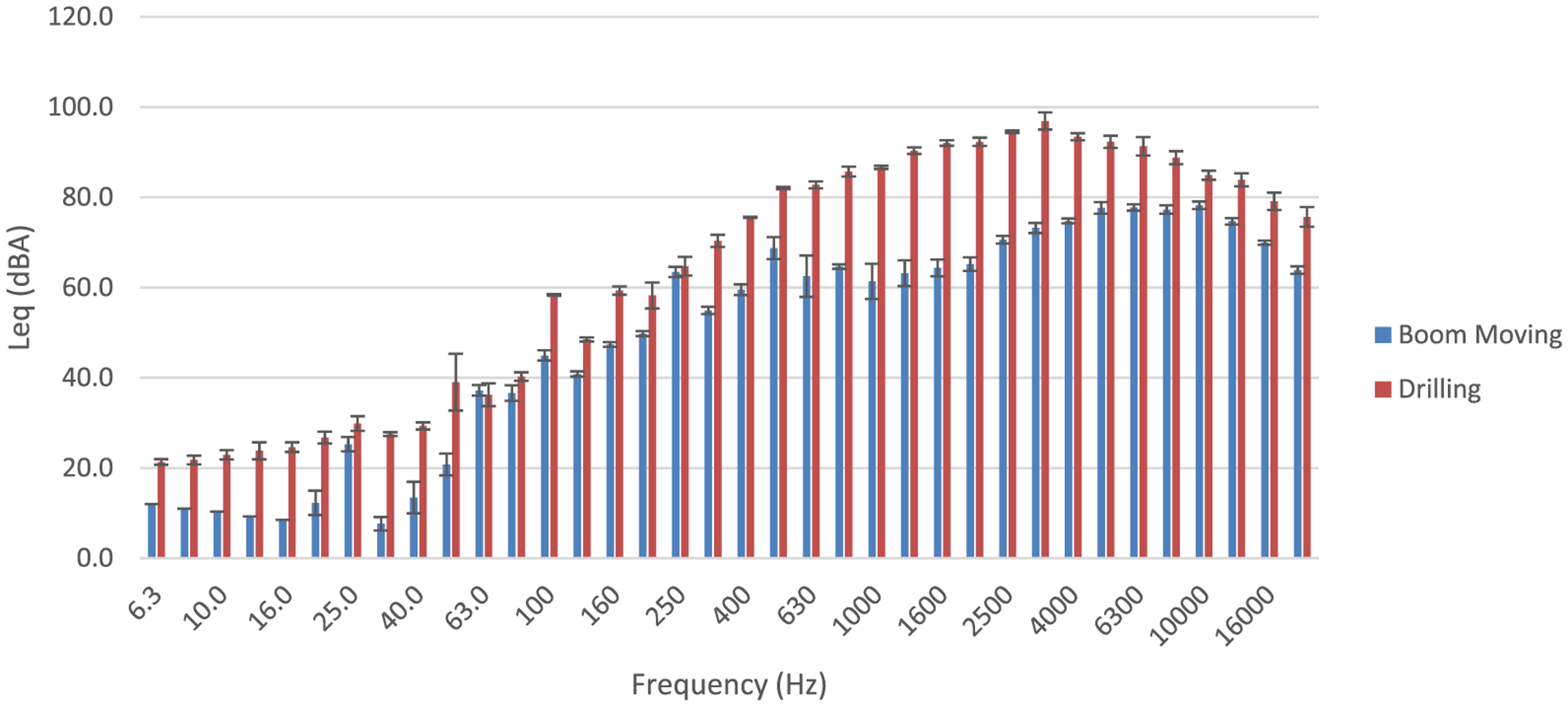

Importantly, there are several notable differences between characteristics of sound during drilling and boom moving. First, the sound levels for boom moving (90 dBA) are dramatically lower than for drilling into granite (100 dBA). Second, on the temporal domain, sound generated from drilling is continuous whereas sound from boom moving can be complex—a combination of continuous and impulsive sounds. Finally, in the frequency domain, sound levels are dominant in the range of 1000–4000 Hz for drilling sound; on the other hand, dominant sound levels are 250–500 Hz as well as 4000 Hz and above for boom moving sound (Fig. 1). These differences in sound pressure level and frequency content generated between the two types of operations could contribute to the overall changes in accuracy of the app.

Fig. 1—

One-third octave band of sound pressure level during drilling and boom moving.

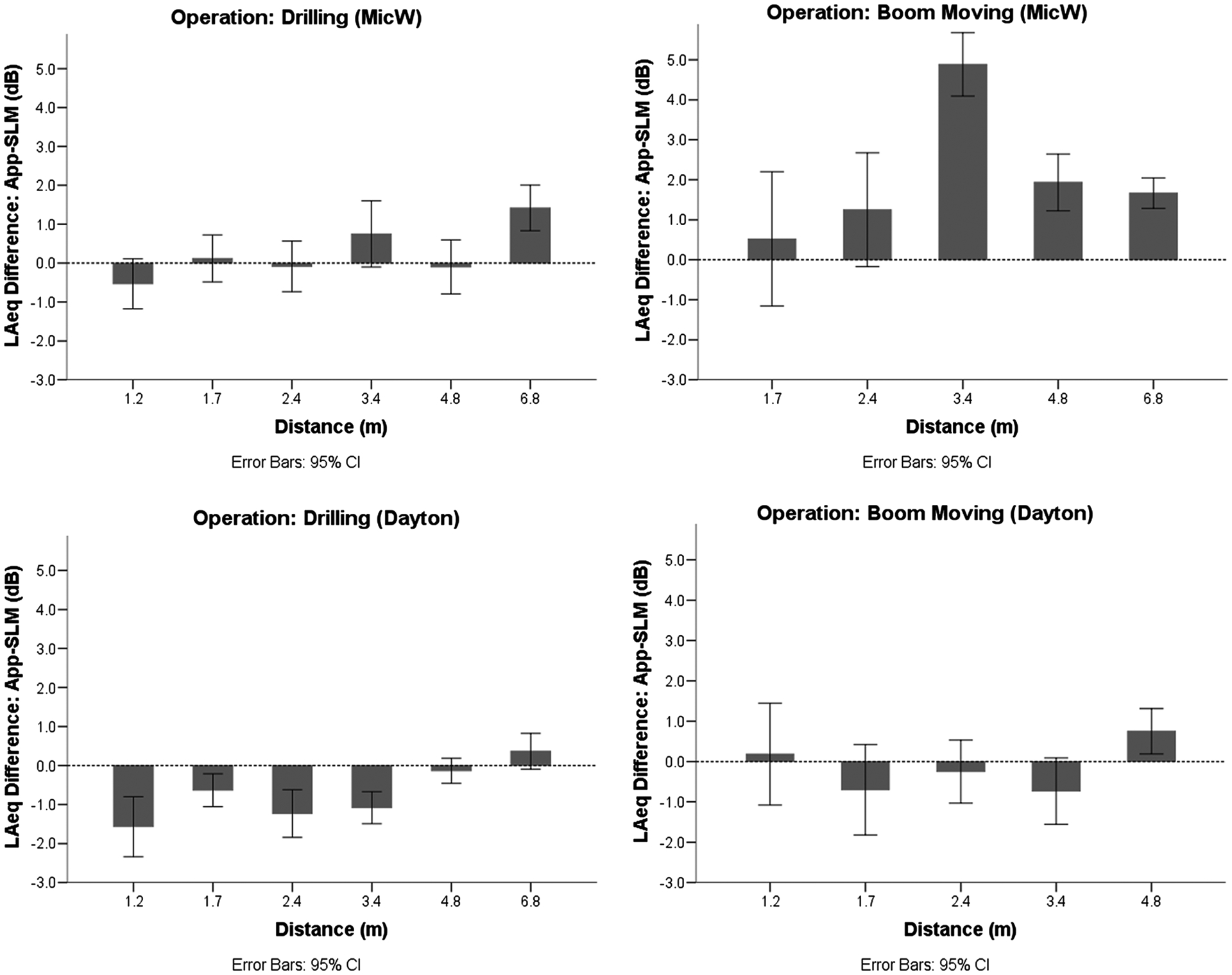

Because of limited space at the mining face, collecting sound levels from a variety of distances in the field test was not practical. Therefore, assessment of the accuracy by distance was only performed in the acoustic laboratory test. Data show that measurements from the NIOSH SLM app tended to be lower than the measurements from the reference device at a closer distance and higher at a further distance, as the average difference between the two gradually rises with the increase of the distance, regardless of the type of microphone (Fig. 2). While the frequency content is similar at different distances based on the octave band (data not shown), the data indicate that the app may underestimate exposure at an extremely high sound pressure level and overestimate at a lower sound level. This trend is less apparent during boom moving, possibly because sound pressure level during boom moving is already relatively low at closer distances (Table 5). The range of average sound levels by distance during drilling is 96–105 dBA, and the range of average sound levels by distance during boom moving is 88–94 dBA (Table 5). The mixed effect linear model shows that the distance affects the accuracy of the app with large effect size (p < 0.001, partial η2 = 0.677) (Table S1); however, the difference is no more than 1.2 dBA among any pair of comparisons (Table S2).

Fig. 2—

Change of accuracy by distance during different jumbo drill operations.

Table 5—

Sound pressure level1 at different distances during drilling and boom moving.

| Operations | Distances (meters) | N | Mean duration (s) | Mean Leq (dBA) |

|---|---|---|---|---|

| Drilling | 1.2 | 2 | 52.7 | 104.9 |

| 1.7 | 2 | 36.9 | 103.5 | |

| 2.4 | 2 | 28.7 | 103.1 | |

| 3.4 | 2 | 34.2 | 101.3 | |

| 4.8 | 2 | 42.5 | 98.4 | |

| 6.8 | 2 | 28.3 | 96.0 | |

| Boom moving | 1.2 | 1 | 28.2 | 92.5 |

| 1.7 | 2 | 23.7 | 89.2 | |

| 2.4 | 2 | 17.8 | 87.7 | |

| 3.4 | 2 | 19.1 | 94.3 | |

| 4.8 | 2 | 26.3 | 88.1 | |

| 6.8 | 1 | 27.9 | 91.2 |

Sound pressure level was measured by Larson Davis LxT SLM.

5. CONCLUSION

The NIOSH SLM app, when connected to an external microphone and calibrated pre- and post-test, shows an average of less than ±1 dBA difference from a type 1 SLM during jumbo drill operations in NIOSH’s hemi-anechoic acoustic laboratory and about ±2 dBA difference in the field at an underground mine. This finding is consistent with earlier studies by NIOSH that assessed the app by measuring pink noise (65–95 dBA) in a reverberation chamber9,14. However, many large mining machines yield sound levels above 95 dBA during operation. For example, sound levels from a jumbo drill while drilling are usually above 100 dBA. These sound levels are beyond the range of pink noise (65–95 dBA) assessed in the earlier NIOSH report.

The current study finds that the NIOSH SLM app can maintain its accuracy at high levels of sound, furthering its candidacy for potential use to monitor occupational noise exposure in the mining industry. While emitted sound levels may be similar at different mining operations, frequency content of sound generated is characteristic to each machine operation and will likely differ.

In addition, this study identifies a number of factors requiring special attention when using the app for sound measurement in the field. Consideration should be given to the selection, use, and calibration of external microphones, distance from the targeted noise source, the type of operation/nature of a sound, and noticeable environmental conditions, e.g. air movement.

A periodical test for compliance to IEC 61672 Part 3 was evaluated at the reference environmental condition (e.g., 20 °C, 50% humidity) by NIOSH16. However, it is challenging to conduct a complete evaluation for compliance to IEC 61672 Parts 1 and 2, including sensitivity tests at a variety of environmental conditions. Therefore, it is recommended to carefully interpret data collected by the app if noticeable environmental factors, e.g., air temperature, humidity, atmospheric pressure, magnetic and electrostatic fields, and vibration, are present in the ambient environment and are suspected to influence the app’s performance.

Based on the study results, the NIOSH SLM app displays great potential for monitoring occupational sound levels. Moreover, indirect potential impacts of the app on hearing loss prevention should not be overlooked. Because the majority of the working population own and carry some type of personal smart devices, the app could allow workers to monitor their own exposure with relatively reliable accuracy and standardized interpretations of the exposure results. Empowerment of individual workers to monitor their own hearing health and noise exposures could improve their overall comprehension of the potential hazard of noise and improve their satisfaction with their mandated hearing conservation program. This may also play a role in increasing the awareness of excessive exposure and the risk of hearing loss by the working population, modifying their health and safety behavior and promoting hearing loss prevention efforts at all levels in the health and safety program.

6. NEXT STEPS AND FUTURE POTENTIAL RESEARCH

Although the NIOSH Sound Level Meter app has been shown to be compliant with IEC 61672 Part 3 standard for sound level meters, it has not yet been officially validated for compliance monitoring purposes. Also, additional field tests on a variety of industrial noise sources, including but not limited to mining machines, are being conducted by NIOSH researchers to further evaluate the validation of the app for use in measuring industrial noise in a variety of occupational environments16.

Supplementary Material

ACKNOWLEDGMENT

The authors would like to thank Jeffrey Shawn Peterson, Lynn Alcorn, and Patrick Dempsey from the Pittsburgh Mining Research Division of NIOSH for the sharing of resources and their support of this study. We also thank all personnel in the Engineering and Physical Hazards Branch from the Division of Applied Research and Technology (DART), NIOSH, in Cincinnati, for their generous support with providing sampling hardware, instruments, and technical consultation. Finally, special thanks to William Murphy and Trudi McCleery from DART for their sharing of information and consultation about the app.

Footnotes

Publisher's Disclaimer: DISCLAIMER

Publisher's Disclaimer: The findings and conclusions in this report are those of the authors and do not necessarily represent the official position of the National Institute for Occupational Safety and Health, Centers for Disease Control and Prevention. Mention of company names or products does not constitute endorsement by NIOSH.

REFERENCES

- 1.Rainie L and Perrin A, “10 facts about smartphones as the iPhone turns 10”, Pew Research Center, (2017). Available at: http://www.pewresearch.org/fact-tank/2017/06/28/10-facts-about-smartphones/. Access in Dec, 2017. [Google Scholar]

- 2.U.S. Department of Commerce Economics and Statistics Administration. Ryan C and Lewis M, Computer and Internet Use in the United States: 2015, U.S. Census Bureau; (2017). [Google Scholar]

- 3.Share of smartphone users that use an Apple iPhone in the United States from 2014 to 2016, (2016), Available at: https://www.statista.com/statistics/236550/percentage-of-us-population-that-own-a-iphone-smartphone/. Access in Dec, 2017.

- 4.Tak S and Calvert MG, “Hearing difficulty attributable to employment by industry and occupation: an analysis of the National Health Interview Survey—United States, 1997 to 2003”, J. Occup. Environ. Med, 50, 46–56, (2008). [DOI] [PubMed] [Google Scholar]

- 5.National Institute for Occupational Safety and Health, Criteria for a recommended standard: occupational noise exposure, revised criteria 1998. 1–122, (1998), Publication No. 98–126.

- 6.Masterson EA et al. , “Prevalence of hearing loss in the United States by industry”, Am. J. Ind. Med, 56, 670–681, (2013). [DOI] [PubMed] [Google Scholar]

- 7.Masterson EA, Deddens JA, Themann CL, Bertke S and Calvert GM, “Trends in worker hearing loss by industry sector, 1981–2010”, Am. J. Ind. Med, 58, 392–401, (2015). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Mine Safety and Health Administration. Federal Register: Health standards for occupational noise exposure. MSHA, Department of Labor. Final rule, Fed. Regist, 64, 49548–49634, (1999). [PubMed] [Google Scholar]

- 9.Kardous CA and Shaw PB, “Evaluation of smartphone sound measurement applications”, J. Acoust. Soc. Am, 135, EL186–EL192, (2014). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Kardous CA and Celestina M, New NIOSH Sound Level Meter App. (2017). Posted on Janurary, 2017. Access in Dec, 2017. Available at: http://blogs.cdc.gov/niosh-science-blog/2017/01/17/slm-app/.

- 11.NIOSH, “Equipment noise and worker exposure in the coal mining industry”, DHHS Publ. No. 2007–105, IC 9492, 1–77, (2007). [Google Scholar]

- 12.Reeves ER, Randolph RF, Yantek DS and Peterson JS, “Noise control in underground metal mining”, NIOSH Inf. Circ, IC9518, 62, (2009). [Google Scholar]

- 13.Vipperman JS, Bauer ER and Babich DR, “Survey of noise in coal preparation plants”, J. Acoust. Soc. Am, 121, 197–205, (2007). [DOI] [PubMed] [Google Scholar]

- 14.Kardous CA and Shaw P, “Evaluation of smartphone sound measurement applications (apps) using external microphones—a follow-up study”, J. Acoust. Soc. Am, 140, EL327–EL333, (2016). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Roberts B, Kardous C and Neitzel R, “Improving the accuracy of smart devices to measure noise exposure”, J. Occup. Environ. Hyg, 13, 840–846, (2016). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Celestina M, Hrovat J and Kardous CA, “Smartphone-based sound level measurement apps: Evaluation of compliance with international sound level meter standards”, Appl. Acoust, 139, 119–128, (2018). [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.