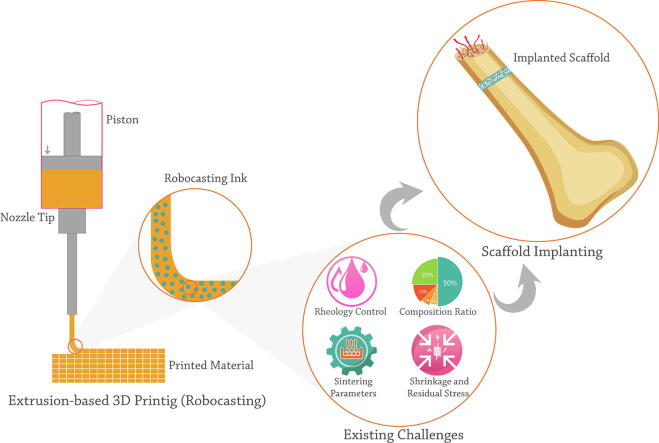

Graphical abstract

Keywords: Bone tissue engineering, Biphasic calcium phosphate, Extrusion-based 3D printing, Robocasting, Additive manufacturing

Abbreviations: AM, Additive manufacturing; ALP, Alkaline phosphatase; BJP, Binder jet printing; BCP, Biphasic Calcium Phosphate; BMSCs, Bone marrow stromal cells; BMP-2, Bone morphogenic protein 2; BTE, Bone tissue regenerating; CPO, Calcium peroxide; CaPs, Calcium phosphates; CAD, Computer-aided design; ELISA, Enzyme-linked immunosorbent assay; FEM, Finite element modeling; FDM, Fused deposition modeling; GelMA, Gelatin-methacryloyl; GNPs, Graphene Nanoplatelets; hAT-MSCs, Human adipose tissue-derived mesenchymal stem cells; hBMSCs, Human bone mesenchymal stem cells; hMSCs, Human mesenchymal stem cells; HA, Hydroxyapatite; IGF-1, Insulin-like growth factor-1; PDGF-AB, Platelet-derived growth factor-AB; PRF, Platelet-rich fibrin; PEG, Poly ethylene glycol); PMMA, Poly-methacrylate; PCL, Polycaprolactone; PLA, Polylactic acid; PLGA, Polylactic-co-glycolic acid; PVA, Polyvinyl alcohol; SLS, Selective laser sintering; SLM, Selective laser melting; SBF, Simulated Body Fluid; SLA, Stereolithography; SFE, Surface free energy; TRAP, Tartrate-resistant acid phosphatase; TIPS, Thermally-induced phase separation; 3D, Three-dimensional; TE, Tissue engineering; TGF- β1, Transforming growth factor- β1; TCP, Tri-Calcium Phosphate; TNF-α, Tumor necrosis factor; UDMA, Urethane di-methacrylate; VEGF, Vascular endothelial growth factor; β-CPP, β-Calcium Pyrophosphate; β-TCP, β-Tricalcium Phosphate

Highlights

-

•

Biphasic calcium phosphates offer a chemically similar biomaterial to the natural bone, which can significantly accelerate bone formation and reconstruction.

-

•

Robocasting is a suitable technique to produce porous scaffolds supporting cell viability, proliferation, and differentiation.

-

•

This review discusses materials and methods utilized for BCP robocasting, considering recent advancements and existing challenges in using additives for bioink preparation.

-

•

Commercialization and marketing approach, in-vitro and in-vivo evaluations, biologic responses, and post-processing steps are also investigated.

-

•

Possible strategies and opportunities for the use of BCP toward injured bone regeneration along with clinical applications are discussed.

-

•

The study proposes that BCP possesses an acceptable level of bone substituting, considering its challenges and struggles.

Abstract

Background

Tissue engineering (TE) is the main approach for stimulating the body’s mechanisms to regenerate damaged or diseased organs. Bone and cartilage tissues due to high susceptibility to trauma, tumors, and age-related disease exposures are often need for reconstruction. Investigation on the development and applications of the novel biomaterials and methods in bone tissue engineering (BTE) is of great importance to meet emerging today’s life requirements.

Aim of review

Biphasic calcium phosphates (BCPs) offer a chemically similar biomaterial to the natural bone, which can significantly promote cell proliferation and differentiation and accelerate bone formation and reconstruction. Recent advancements in the bone scaffold fabrication have led to employing additive manufacturing (AM) methods. Extrusion-based 3D printing, known also as robocasting method, is one of the extensively used AM techniques in BTE applications. This review discusses materials and methods utilized for BCP robocasting.

Key scientific concepts of review

Recent advancements and existing challenges in the use of additives for bioink preparation are critically discussed. Commercialization and marketing approach, post-processing steps, clinical applications, in-vitro and in-vivo evaluations beside the biological responses are also reviewed. Finally, possible strategies and opportunities for the use of BCP toward injured bone regeneration are discussed.

Introduction

Bone tissue engineering

Increasing the demand for life quality leads to developing the new converging technologies. Recent developments in science and technology promise a better future for humankind [1]. Tissue engineering (TE) is one salient example of these science and technology converging areas [2]. Restitution of the function and regeneration of the damaged tissues and organs could be considered the vision of TE while developing novel scaffolds that cells could survive on them is its mission [3].

Since bone is extensively faced with trauma, tumors, and age-related diseases, such as osteoporosis and osteoarthritis, there is currently a demand for an effective treatment method. Even though healthy bone tissues have the high regenerative ability, patients with primary diseases, such as those with diabetes or poor nutrition, suffer from prolonged bone regeneration procedures [4].

Significant bone defects emerging from genetic malformations, infections, surgical resection, or trauma maintain a considerable challenge for clinicians [5], [6], [7]. During the last years, clinical treatments based on replacing the lost bone tissue with autogenous bone grafts, allogeneic banked bone, xenogeneic sources, and synthetic bone substitutes have been developed [8], [9]. However, each method has its advantages and disadvantages, leading to limited structural and functional recovery [10]. To remove the limitations of usual treatment methods of bone injuries, comprehensive strategies have been developed [11], [12], [13]. One of them is fabricating engineered constructs to promote bone regeneration.

One of the most fundamental objectives of TE is to produce functional constructs for damaged tissues [14]. Multiple three-dimensional (3D) scaffolds have offered temporary skeleton for new tissue ingrowth [11]. On the other hand, several requirements should be met by a developed scaffold to cause the restoration of the native tissue structure and function [15]. Biocompatibility, biodegradability, mechanical characteristics, the amount and size of porosities, and surface charge are primary factors for modifying cell adhesion and proliferation, diffusion of nutrients and gases on the surface of developed scaffolds, and subsequently assuring the success of tissue regeneration [16], [17]. Appropriate scaffolds for bone regeneration applications possess some characteristics, including highly bioactive and degradable, along with 3D interconnected porous architecture and matched mechanical-loading ability [18].

The use of the appropriate biomaterial to provide biocompatibility and biodegradability of the scaffold would result in success in the subsequent stages of tissue growth [19]. Scaffolds should meet certain requirements in terms of each target tissue's status and cellular functions, such as having enough interconnected porosities, biological properties, and the ability to mimic the natural mechanical and physical properties of tissues [20].

Since targeted tissues need appropriate growth factors (GFs) and nutrients, constructed scaffolds should serve as a suitable cell development niche [21]. GFs regulate tissue morphogenesis, angiogenesis, and neurite outgrowth in development, while in adults, they play a decisive role in tissue healing and homeostasis [22]. GFs, like proteins and steroid hormones, play a significant role in controlling cellular function by acting as signaling molecules and binding to cell transmembrane receptors, greatly promoting cell ingrowth, proliferation, and differentiation [23], [24]; however, scaffold preparation is still a challengeable discussion in BTE [25]. This study aims to cover recent advancements and current challenges focusing on extrusion-based 3D printing (as a novel way of developing complicated bone constructs) for the engineering of BCP (as a potential material for inducing osteogenesis and promoting bone regeneration) structures. Using various additives for bioink preparation, the strategy to commercialization and marketing, post-processing operations, clinical applications, and potential future prospects are all discussed.

Materials used in BTE

Analyzing the bone structure would lead our attention to the best compatible scaffold. It has been demonstrated that almost 60–70% of the dry mass of bone is the mineral part, which is mainly dedicated to hydroxyapatite (HA, Ca10(PO4)6(OH)2) [26]. Most of the rest is collagen, along with other substances like proteins and inorganic salts. Additional elements like silicon, carbonate, and zinc in various bone mineral causes the Ca: P ratios ranging from 1.37 − 1.87; whereas, HA possesses a constant Ca: P ratio of 1.67 [26].

Many researchers have devoted studies to developing the best-matched bone tissue scaffolds [27], [28], [29], [30]. A wide range of biomaterials, such as polymers, ceramics, and hydrogels, have a great potential ability for employing in BTE [31]. Polylactic Acid (PLA) [32], [33], Polylactic-co-glycolic Acid (PLGA) [34], [35], Polycaprolactone (PCL) [36], [37], [38], HA [39], [40], [41], β-Tricalcium Phosphate (β-TCP) [42], [43], [44], Gelatin-Methacryloyl (GelMA) [45], [46], BCP [47], [48], [49], and composites [50], [51], [52], [53], [54] are the most used biomaterials in BTE due to their acceptable mechanical and cell-friendly properties. Even though many efforts have been made to modify the composition of employed bone scaffolds, reaching a well-adapted composition in BTE has been a matter of discussion, in recent years. Kindly note that calcium phosphate-based bone substitutes are well-received by researchers and clinicians [55].

Calcium phosphate-based bone substitutes

Mineral calcium phosphates (CaPs) mainly contain calcium cations unitedly with orthophosphate, metaphosphate or pyrophosphate anions, and sometimes hydrogen or hydroxide ions [56]. CaPs, in the form of neat [57] or composite [29], [58] scaffolds, are now at the center of the researchers' attention for use in BTE applications due to their biological and physical properties and similarities to the natural bone composition [3], [52], [59].

One of the attractive functional composites is the composition of HA with other Calcium Phosphate-based materials like Tricalcium Phosphate (TCP). TCP has three polymorphs: β-TCP (rhombohedral), α-TCP (monoclinic), and α'-TCP (hexagonal) [60]. The last two types are high-temperature forms; whereas, the former has a broad application in the biomedical fields. The composition of β-TCP and HA is also a kind of Calcium Phosphate ceramic called Biphasic Calcium Phosphate (BCP) with high similarity with bone mineral composition [61].

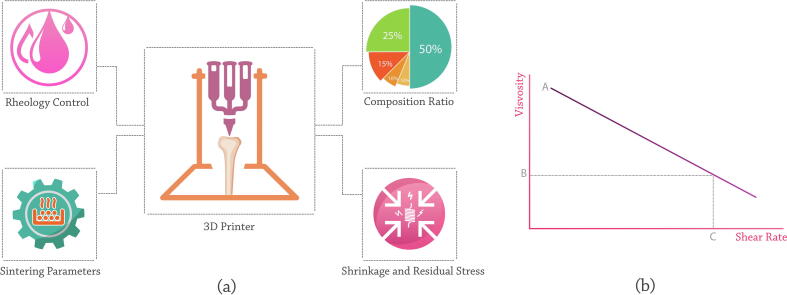

BCP scaffolds can be developed as bone substitutes in personalized shape and geometry through traditional like replica molding [62] and advanced like additive manufacturing (AM) [63] techniques. Utilizing AM methods in fabricating BCP-based bone constructs is a controversial method (Fig. 1) [64]. Variety in employed composition ratio, processing method, and environmental conditions lead to the salient differences in mechanical properties, pore size, cell responses, and consequently bone formation ability of fabricated constructs by AM technique [65].

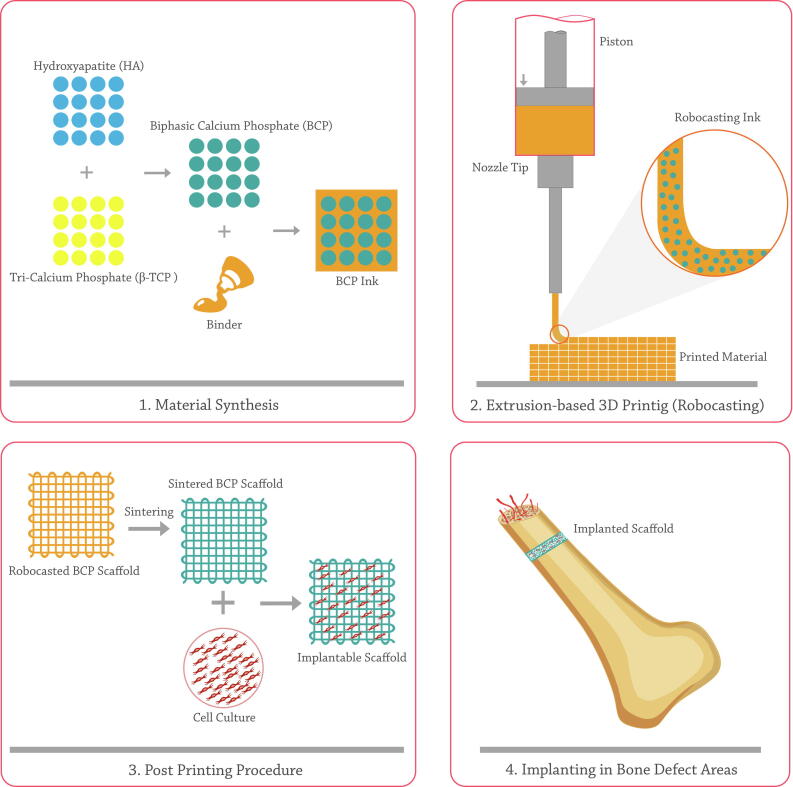

Fig. 1.

A schematic of BCP robocasting steps and its application in bone regeneration.

Commercial concept of BCP

Given the current high growth in BTE requirements, producing an ideal material that meets the majority of the criteria would have the potential for commercialization by regenerative medicine firms. Based on the literature, BCP composition positively correlates with commercialization principles, considering a variety of composition ratio, porosity, and structure, resulted in various mechanical and biological performance [66]. High similarity of the biological [61] and mechanical properties [67] of BCP constructs to the natural bone tissue evoke the undeniable fact that BCP possesses the potential of commercialization and being available in the market. On a lighter note, the bench's progression to the bedside process is expected due to the effective application of BCP and its structures in multiple bone repair and dentistry applications [68].

Market evaluation illustrates that commercialized BCP is available with the HA: β-TCP ratio of 70: 30 to 60: 40 in powder, dense, and porous bulk forms [69] (Table 1). OsteonTM II (Dentium, USA) (HA: β-TCP ratio of 30: 70 and 250 μm sized porosities), is an evident BCP product that is gracious, especially in maxillary sinus augmentation. Excellent wettability and highly resorbable properties due to higher β-TCP content are its key features. The most application of OsteonTM II is in oral issues, such as periodontal defects, cystic cavities, extraction socket grafting, ridge augmentation, and sinus lift, while it also has orthopedic surgery applications [70].

Table 1.

Most prevalent BCP products available in market.

| BCP product | HA: β-TCP composition ratio | Manufacturer & Country | Granule’s size | Ref. |

|---|---|---|---|---|

| OsteonTM II | 30:70 | Dentium, USA | 0.2–2 mm | [70] |

| MBCP® | 60:40 | Biomatlante, France | 0.5–1 mm | [71] |

| MBCP+® | 20:80 | Biomatlante, France | 0.5–1 mm | [71] |

| Ceraform | 65: 35 | Teknimed, France | 3 mm | [68] |

| Interpore200 | – | Interpore, USA | 0.425–1 mm | [72], [73] |

| Triosite® | 60:40 | Biomatlante, France | 0.5–4 mm | [74] |

| GENESIS-BCPTM | 60:40 | Dio Implant, South korea | 0.1–2 mm | [75] |

| In’Oss™ | – | Biomatlante, France | – | [76] |

MBCP® (Biomatlante, France), MBCP+® (Biomatlante, France), Triosite® (Biomatlante, France), and GENESIS-BCPTM (Dio Implant, South korea) are other commercialized BCP products available in the market [71], [77]. MBCP® has a HA: β-TCP ratio announced by the manufacturer of 60: 40; whereas, MBCP+® has a ratio of 20: 80. Granules geometry was reported as 0.5–1 mm for both mentioned ones [71]. Miramond et al. [71] reported an elevated similarity ratio between MBCP® and MBCP+® scaffolds, utilizing them in preclinical studies. They showed that the geometry and morphology of granules, as well as grain size and macro- and micro-porosities, are homogenous.

In addition, the efficiency of the Triosite® bone graft substitute was critically evaluated in a prospective randomized study involving 341 patients undergoing posterior spinal fusion with associated instrumentation [78]. Triosite® possesses a HA: β-TCP ratio of 60: 40, and pore size of 300–600 µm for macropore and approximately under 10 µm for micropore structures [74]. Moreover, GENESIS-BCPTM has a HA: β-TCP ratio of 53.4: 43.6 with 65.5% porosity, 84.9% crystallinity, and Ca: P ratio of 1.61 [75].

Besides, for fussier handling in orthopedic surgeries, the mixture of hydrogel and BCP is preferred, which forms a new product that can be an appealing issue for active firms in this field. In’Oss™ (Biomatlante, France) is an injectable bone substitute that includes HA, β-TCP, and a kind of well-handling hydrogel [71]. In’Oss™ is a moldable bone graft that can fit into various grafting sites by keeping the original graft geometry. It is easy to use with no pre-mixing or required preparation. Its sticky viscosity allows easy positioning, along with adapting quickly to the shape of the defect. Exemplary contact with the bone surface and maximizing the bone-implant interface is another advantage of In’Oss™ [76]. In’Oss™ is recommended for socket preservation after tooth extraction and furcation defects. Its application around the implant during immediate implantation is possible due to its high shape-ability which can surround complicated-shape implants [76].

Methods for the fabrication of bone tissue scaffolds

Various scaffold fabricating methods have been developed depending on the property of targeted tissue, usability, viability, type of materials, surface topography, porosity volume, mechanical properties, and production scale [79]. Here, we consider traditional methods and recent advancements in BTE scaffolds fabrication.

Methods for the fabrication of polymer-based scaffolds

Solvent casting and particulate leaching [80], gas foaming [81], emulsion freeze-drying [82], electrospinning [83], [84], thermally induced phase separation (TIPS) [85], and AM [86] methods are used to produce polymeric-based bone scaffolds. Solvent casting is a simple and most generally used technique for the fabrication of 3D polymeric scaffolds through mixing water-soluble salts like Sodium Chloride and Sodium Citrate particles into a biodegradable polymer solution and casting into a mold with a desired shape [13]. Solvent removal via evaporation or lyophilization leads to leaching out the salt particles to achieve a porous structure (Fig. 2a) [13].

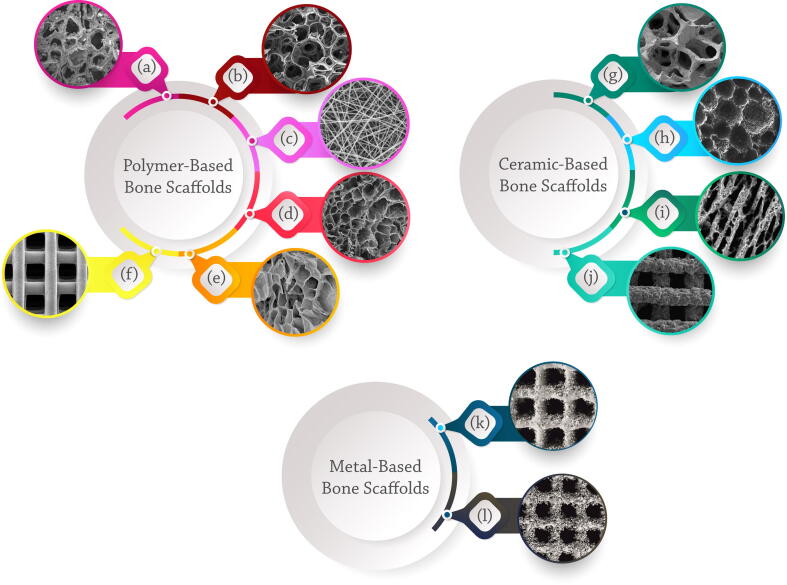

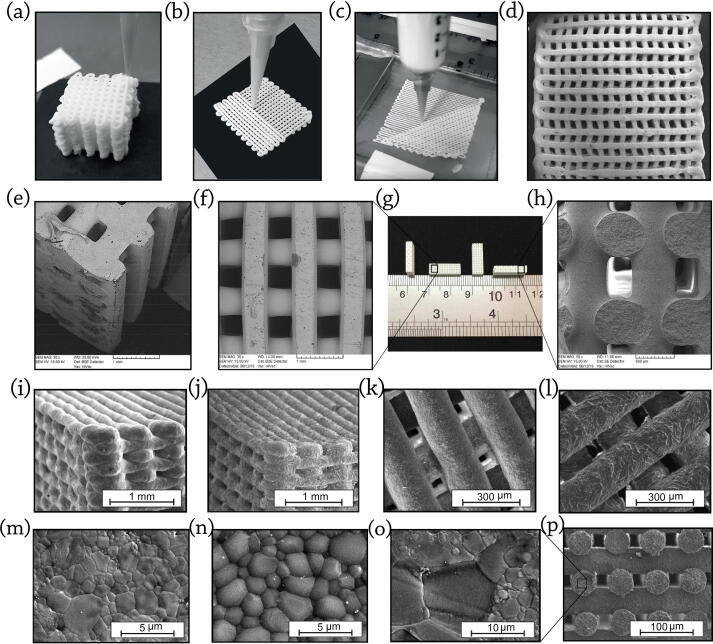

Fig. 2.

SEM images of (a-f) polymeric and (g-j) ceramic scaffolds prepared by various methods: (a) PLGA-based scaffold with 92.38% porosity prepared by solvent casting and particulate leaching method, reproduced with permission from [258] (b) Gelatin-based scaffold with 85% porosity, prepared by gas foaming method, reproduced with permission from [259] (c) Gelatin/Glycosaminoglycan-based scaffold with a composition ratio of 90/10, prepared by electrospinning method, reproduced with permission from [260] (d) Gelatin-based scaffold crosslinked via acetone–water solution (4:1 v/v) containing a water-soluble EDC, prepared by freeze-drying method, reproduced with permission from [261] (e) PCL/ PLA/ gelatin nanofibers/ Taurine scaffold with a composition ratio of 1:1:0.4:0.01, prepared by thermally induced phase separation technique, reproduced with permission from [262] (f) PCL-based scaffold with square pore geometries and regular dimensions of 500 µm × 500 µm, prepared by 3D printing technique, reproduced with permission from [263] (g) Bio-glass/ Polyurethane-based scaffold, with 93 % porosity, prepared by replica method, reproduced with permission from [264] (h) BCP-based scaffold with a HA: β-TCP ratio of 1: 1, prepared by direct foaming method, reproduced with permission from [265] (i) HA-based scaffold with 47% porosity, prepared by freeze-casting method, reproduced with permission from [104], and (j) Li2Ca4Si4O13 scaffold with a controlled pore size of 250 µm, prepared by 3D printing method, reproduced with permission from [266], (k) Ti6Al4V-based bone scaffold fabricated via SLM method, reproduced with permission from [267], (l) Titanium-based bone scaffold fabricated via SLS method, reproduced with permission from [268]. All mentioned scaffolds have been successfully used in BTE applications, while the 3D printed ones possess superior results compared to other bone scaffolds.

Gas foaming is a technique for fabricating synthetic scaffolds that avoids the use of solvents [87]. High-temperature compression molding of the polymer into a solid disc is the first step of the procedure. The solid polymer rests in a high-pressure Carbon dioxide chamber for several days after the disc is formed. Throughout this time, the gas infiltration makes a porous structure (Fig. 2b) [88]. An advantage of gas foaming is the absence of caustic solvents. Hence, the presence of residual compounds in the final scaffold is not a main concern, in this technique. The possibility of incorporation of bioactive molecules in the fabricated structure is another advantage of using gas foaming method [87].

The electrospinning technique was developed since 2012, for preparing continuous fibers with the diameter in the range of submicron to nanometer [89]. Electrospinning depends on the high electrostatic forces, leading to producing fibers using just a solvent, which can disperse nanoparticles and dissolve the polymer (Fig. 2c). This method is employed to assemble nanofibers of polymers [90], metals [91], ceramics [92], and composites [93].

Hekmati et al. [94] revealed that the distance of needle tip to collector significantly affected the diameter of nanofibers made by electrospinning method. Their results indicated that reducing the distance of needle tip to the collector led to raising the diameter of the electrospun nanofibers. Moreover, polymer concentration, solution viscosity, flow rate, electric field intensity, and air humidity are some effecting parameters on the final fibrous scaffold [89].

Freeze-drying, also called “lyophilization”, is a drying method through solidifying by freezing following solvent evaporation by sublimation upon heating [95]. Sublimation includes direct evaporation and condensation of a solid without forming an intermediary liquid phase [96]. During the process, the product loses more than 90% of its initial water. The transformation of the solid to the gas phase occurs without water and solvent passage through the liquid state [95]. Fig. 2d shows a SEM image of freeze-dried Gelatin-based scaffold crosslinked via Acetone–water solution (4:1 v/v) containing a water-soluble EDC.

A wide variety of porous constructs, especially polymeric membrane, can be fabricated via thermally-induced phase separation (TIPS) technique [85]. Fig. 2e demonstrates a PCL/ PLA/ Gelatin nanofibers/ Taurine scaffold with a composition ratio of 1:1:0.4:0.01 prepared by TIPS technique. In this way, a kind of polymer acts as a solvent and is casted in the form of film at a high-temperature. The polymer is dissolved by heating the mixture approximately near 60˚C for two hours in the solution, which consists of water and 1, 4-dioxane, while other components’ dispersion, like Hydroxyapatite and Calcium Phosphates, could be applied through ultrasonication [85]. The homogeneous solution should then be heated to 15˚C above the measured cloud point temperature that the polymer solution becomes turbid. Final porous structure will be yielded by cooling the solution down to the quenching temperature obtained by a ramp temperature profile and removing the extra solvent [85].

However, mentioned traditional scaffold fabricating methods have some limitations in developing efficient bone scaffolds. Solvent casting and particulate leaching lead to a product with limited degree of pore size. Gas foaming is a moderately expensive method, and demands a series of equipment, while it is also limited to specific polymers such as PLGA, PCL, PLA, and poly (ethylene glycol) (PEG). Meanwhile, freeze-drying technique needs high capital cost of equipment and energy cost, along with lengthy processing time. It takes typically 36–72 h per each drying cycle [97]. Due to high applied pressure during freeze drying method, there are some possible damages to products due to the changes in pH and tonicity. Moreover, achieving fibrous structures with low mechanical performance and containing residual solvent are essential disadvantages of electrospinning technique.

All limitations lighten up using AM techniques in bone scaffold preparation, due to its application in a wide range of polymers, ceramics, and metals [98], [99]. Stability, model reproducibility, and the architecture control ability of 3D scaffolds are the primary superiority of AM techniques, leading to improved biological and mechanical performances of tissue-engineered constructs [100]. Fig. 2f shows a 3D printed scaffold, which possesses a high porosity and internal interconnectivity.

Methods for the fabrication of ceramic-based scaffolds

Todays, ceramic-based bone scaffolds are prepared through conventional and advanced techniques. Conventional methods for making porous bone substitutes mainly include replica and sacrificial template, freeze-casting, and direct foaming methods [12]. A synthetic or natural template, which is impregnated with a ceramic suspension, was engaged in the replica method [101]. Missing template after drying leads to creating a replica of the primary template structure. Numerous synthetic and natural cellular structures could be hired as templates to produce macroporous ceramics through this technique. A high porosity rate scaffolds, based on ceramic/polymer blends could be prepared by the replica method. Fig. 2g shows a bio-glass/polyurethane-based scaffold with 93% porosity, possessing high interconnectivity, which is considered essential in ameliorating the cell activity and viability.

The sacrificial template method causes the obtaining of porous substitutes representing a negative replica of the original sacrificial template instead of the replica technique's positive morphology [102]. This method consolidates some pore former or sacrificial material to act as a place holder within the ceramic powder or slurry.

In the direct foaming method, gas bubbles are incorporated into a ceramic suspension. By setting and drying the slurry, the ceramic retains the resulting spherical pores [101]. Dried constructs are sintered at high temperatures to obtain high-strength ceramic scaffolds. The total porosity of the obtained foam is comparable to the amount of gas incorporated into the suspension or liquid medium during the foaming process [102]. Fig. 2h demonstrates an SEM image of a BCP-based scaffold with a HA: β-TCP ratio of 1: 1, prepared by the direct foaming method. The vacancies of gas bubbles are seen in these scaffold types, while they could prepare an appropriate area for enhancing cell attachment [103].

The freeze-casting technique is also used for the preparation of ceramic-based bone scaffolds [104]. In this technique, ceramic slurry is flowed into a mold and then frozen. Upon demolding, the frozen solvent temporarily plays as a binder and hold the ceramic particles together. Afterward, to purify the solvent under vacuum, the sample is freeze-dried. The freeze-drying method prevents drying stresses and shrinkage that may cause cracks and warping during regular drying. Sintering the freeze-drying products would lead to a porous construct with improved strength, stiffness, and desired porosity. The result is a ceramic-based bone scaffold with a complicated and usually anisotropic porous microstructure generated through the freeze-casting technique. A Hydroxyapatite-based scaffold with 47% porosity prepared by the freeze-casting method is shown in Fig. 2i.

It has been reported that AM methods are superior techniques in the field of both polymeric- and ceramic-based scaffolds fabrication [21]. The amount of interconnected porosities of ceramic-based scaffolds, which is a significant parameter in BTE, could be easily tuned through 3D printing method. Fig. 2j illustrates a ceramic-based bone scaffold with controlled pore size, square pore geometries and regular repeatable dimensions prepared by 3D printing method.

Methods for the fabrication of metal-based scaffolds

The most applicable bioinert metals used in bone implants and scaffold applications include Titanium alloys, Ti6Al4V, Cobalt-Chrome (CoCr) alloys, and 316L stainless steel [105]. Titanium and its alloys could be used as appropriate bone scaffolds since they are high-strength, bioinert, not biodegradable, and possess low density and modulus of elasticity [106]. Due to the outstanding corrosion resistance and biomechanical capabilities, Ti6Al4V is the most commonly used titanium alloy in orthopedics [107]. However, the osteointegration of Ti6Al4V is unsatisfactory because of its bioinert and high elasticity properties, which may limit early bone-implant attachment and long-term stability, resulting in aseptic loosening and providing a challenge to its widespread usage [108].

CoCr alloys have widely been employed in prosthetic arthroplasty. Their mechanical characteristics seem to make them a desirable material for total hip and knee joint arthroplasty [109]. Recent investigations, however, have highlighted some concerns about the osteogenic activity of the CoCr alloy, which may result in the loosening of arthroplasty employing this alloy [110]. Among the several types of metallic implants, the most popular bone-implant material is the surgical grade 316L stainless steel, which has strong mechanical properties, a relatively low cost, and widely availability [111]. However, the release of metal ions, such as iron, nickel, and chromium, in the biological environment is the most serious disadvantage of 316LSS biomedical applications [112].

Bone scaffolds could be fabricated from all the mentioned metallic biomaterials through selective laser melting (SLM) and selective laser sintering (SLS) techniques. SLM is an AM technique that uses a high-power-density laser to melt and fuse metallic powders. The SLM technique is based on the application of extremely thin layers of metallic powders to construct a platform, which are then totally melted by the heat energy caused by one or more laser beams (Fig. 2k) [113]. SLS is a powder-based AM process that employs laser light to melt and fuse powders, which are then stacked layer by layer to build a printed object based on 3D model data. Powder design and preparation have the substantial impact on the performance of SLS sintered components [114]. Even though the powdered material is melted in SLM, the working temperature in SLS method is below melting point. When a laser heats a powder material below its melting point, it fuses to produce a solid. The operating concept of both printing methods is almost the same (Fig. 2l).

A primary issue in utilizing metallic scaffolds is implant loosening, which is caused by the failure of an implant surface to integrate with the surrounding bone and other tissues owing to micromotions [115]. Another crucial element of the usage of metallic alloys in bone applications is osseointegration (the implant ability for integration to the bone and other tissue). To assure the implant's safety and effectiveness throughout its expected lifetime, it must be well integrated with the bone. A previous study [116] has demonstrated that increasing the roughness or performing other surface treatments may improve the bone response to implant surfaces [117]. Although the exact molecular processes are unknown, it is apparent that the surface's chemical and physical qualities influence implant–surface interactions through regulating cell activity, growth factor production, and osteogenic gene expression [118].

An available cost-effective strategy to cover the mentioned issues is coating the prepared metallic scaffold via ceramic slurries to increase the scaffold interaction and integrate with the bone and other surrounding tissues. Calcium Phosphate ceramics could be suitable for this application since they could interact appropriately with surrounding tissues. It was shown that HA has osteoconductive capabilities and that mechanical fixation of HA-coated implants was superior to uncoated implants under ideal surgical conditions [119]. Recently, researchers reported that coating the BCP on Ti6Al4V-based scaffolds significantly impacted their behavior in physiological medium, namely their dissolution-precipitation and corrosion protection capabilities [120].

Methods for the fabrication of composite scaffolds

Uncomplicated composite bone substitutes could be prepared by the described methods above, while complex structures need some accurate techniques. The composition of polymer and ceramic is desirable for BTE applications, while 3D printing is an appropriate technique to prepare these scaffolds. Fig. 3a and b show 3D printing of PCL-CaCO3 composite bone scaffolds. The amount of ceramic in polymer content could be variable (Fig. 3c-f), while their biological behavior, including bio-mineralization in phosphate buffered saline (PBS)-Lipase are different (Fig. 3g-h). It should be noted that emerging novel methods in the engineering fields such as AM and rapid prototyping widen the converging technologies avenue, especially in health-related sciences [64]. Hence, to accomplish personalized medicine and produce specialized engineered tissues, AM techniques are useful [64].

Fig. 3.

3D printing is an appropriate technique for preparing ceramic/polymer-based scaffolds. 3D printing of PCL-CaCO3 composite bone scaffolds: (a) prepared scaffolds via 3D printing. SEM images of the (b) pure PCL (c) PCL-33 wt% CaCO3 (d) PCL-50 wt% CaCO3. SEM images of the magnified cross-sections material contrast mode of (e) PCL-33 wt% CaCO3 (f) PCL-50 wt% CaCO3. (g, h) Bio-mineralization over 20 days in phosphate buffered saline (PBS)-Lipase. All images are reproduced with permission from [269].

A majority of bone tissue-specialized scaffolds are prepared via AM techniques (Fig. 4a). Stereolithography (SLA) [121], [122], SLS [123], [124], fused deposition modeling (FDM) [125], [126] and binder jet printing (BJP) [127], [128] have been used for composite bone scaffold fabricating, in recent years. SLA, which is called photo-solidification, is the procedure of model manufacturing via photochemical activity, causes forming polymers from cross-linking monomers and oligomers [129]. The main limitation of this method is developing functional photopolymerizable hydrogels for BTE.

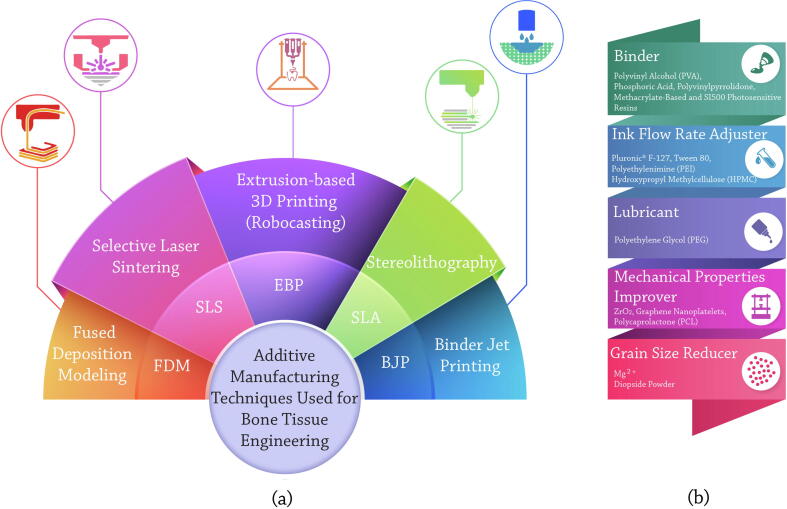

Fig. 4.

(a) Additive manufacturing techniques for preparing 3D bone tissue scaffolds, including FDM, SLS, EBP, SLA, and BJP methods (b) Ink preparation materials and efficient additives for BCP robocasting, including binder, ink flow rate adjuster, lubricant, mechanical properties improver, and grain size reducer.

In the SLS method, laser energy source is engaged to melt the polymer and ceramic powders. Like any other technique, SLS possesses some advantages and disadvantages. Manufacturing capability of great functional bone scaffolds with complicated geometry, along with an elevated level of accuracy, are its advantages. However, its accuracy is not as high as SLA. Moreover, due to the lack of support, the selective laser sintering of samples saves printing and post-processing time. Preparing powder-based models and scaffolds via SLS method is prevalent in BTE, while the non-powder forms are not appropriate candidates for this technique [123].

The extrusion process of heated feedstock plastic filaments through a nozzle tip is called fused deposition modeling (FDM), one of the most widely used AM techniques for preparing prototypes in conventional engineering plastics [130]. In FDM, the nozzle size affects resolution of fabricated constructs. Nozzle clogging is a common phenomenon in FDM technique, which may significantly affect its efficiency. Also, the main concern of FDM method is that the upper layers may deform the lower ones and destroy the fabricated structure [131]. While it is suggested to utilize FDM technique in a ventilated environment due to the heating feedstock plastic and its gases, FDM printers and used materials are very affordable, in which high-quality constructs could be manufactured via the FDM technique due to the accurate control and considerable production speed.

In the binder jet printing (BJP) method, a liquid binding material is selectively deposited via moving the inkjet print head across the powder's bed. Then a thin layer of powder is spread across the completed section. This process is repeated with each layer until the whole model is printed [132].

Since the fabricated constructs via the BJP method do not require any mechanical support, less materials are used in the BJP method, compared with FDM and SLA techniques [133]. Hence, the time needed for post-processing processes is lessened. Moreover, since all of the unused powder can be reused in future works, BJP is more economical. This fact comes more attractive, while in other techniques, such as SLS, only approximately 50% of un-used material is re-usable [134].

Unlike the FDM technique, there is no warping or shrinking due to the differential cooling in the BJP method as it does not use heat. However, poor mechanical property of final product is the limitation of the BJP technique [135]. Even with sintering, samples created via BJP are not as persuasive as samples prepared with either SLS or FDM techniques.

Mentioned AM techniques, as well as extrusion-based 3D printing [18] are recommended facilities in achieving a person’s bone defect geometry via fabricating and implanting a specified scaffold [136]. However, each one maintains its fascinating benefits, making it difficult to choose a suitable one that provides constructs with high physical and mechanical similarity to the target tissue [137]. Meanwhile, extrusion-based 3D printing method, known as robocasting, is one of the AM methods that directly prints an ink from a paste-like material. This paste-like material could be a polymer or some ceramic particles in viscose slurry. Adjusting its viscosity needs to try various conditions, altering the additive amounts [64].

Robocasting could be considered as a capable method for fabricating scaffold in TE, due to the high precision in the manufacturing process [138], lack of powder bed [139], the capability of fabrication of complicated structure [140], and lack of need to post-processing operation [139]. With the help of computer-aided design (CAD), the software can slice the model [141] and the printer machine lead to generate 3D structures layer by layer. The material flow is caused by a pneumatic system, a piston, or a screw. However, the recent models of precise printers enjoy from a ball screw mechanism that translates rotational motion to the linear one [142]. Due to the high potential of the robocasting method in the fabricating, complex bone scaffolds could be prepared by this strategy.

This paper aims to review the published reports on the robocasting of BCP and discuss the undeniable potential of BCP in regenerating bone tissue. To the best of our knowledge, there is not any review of robocasting of BCPs to date; whereas, its biological properties are well-known in this area. It is forecasted that utilizing these techniques will improve human life quality via developing all human tissue scaffolds [143].

Preparation of BCP bone scaffolds via robocasting technique

To discuss fabricating BCP bone scaffolds via the robocasting technique, it is necessary to describe green body scaffold fabricating, appropriate ink preparation, and effective additives in the BCP robocasting procedure. Some additives are essential in ink preparation, while others could enhance the desirable features. The final physical and biological performance of the fabricated scaffolds depends mainly on the prepared ink and its properties.

Green body scaffold fabricating

Green body is a term dedicated to the scaffolds that are not condensed by heating procedure after printing [144]. Green body scaffold fabricating is possible via AM techniques, especially robocasting. Even though the AM techniques, especially robocasting, are promising methods for fabrication of green body scaffolds, success in the engineering of complicated structures by AM is strongly dependent on the viscosity and formidability of employed ink [145].

In the case of ceramic-based scaffolds, the ceramic structure should be post-sintered, after fabrication by the AM method, to have adequate strength and stability. The alternative possibility is also strengthening the ceramic-based scaffolds in other ways instead of sintering [146]. Some ceramics such as tri-calcium silicate (Ca3SiO5, C3S) possess the ability to consolidate via soaking in the water; while utilizing photosensitive resins and UV sources are other methods [146], [147].

Maeng et al. [148] studied green body scaffold manufacturing procedures using frozen terpene crystals. They claimed that BCP/ frozen terpene crystals composite surrounded by BCP/ urethane di-methacrylate (UDMA) walls can extrude through a fine nozzle and then effectively photo-polymerized by UV light. In this way, green filaments with high shape maintaining ability were prepared. Removing terpene crystals via freeze-drying method leads to producing some pores in BCP filaments, which were adjustable by modifying terpene content [148].

Ink preparation

A proper ink for robocasting is composed of binders and, in some cases, lubricant to flow from the storage under applied forces [149]. Based on previous studies, a composition of PVA and phosphoric acid could be used as binders to make biocompatible artificial stents with adequate compressive strength [149], [150]. Some studies showed that using phosphoric acid as a binder has better performance on the mechanical properties of final printed BCP structure than PVA binder [149], [150]; therefore researchers utilized it more than other materials in the ink preparation process [18], [151], [152], [153]. Conversely, printed BCP structure by PVA binder have a higher absorbance rate and higher cell proliferation than the ones printed by phosphoric acids; therefore, choosing an appropriate binder composition plays a vital role in the robocasting process [150]. Furthermore, to achieve an acceptable viscosity of the ink in the robocasting, adding 0.25 wt% Tween80 to the binder solution is preferred [150].

Considering a specified amount of PEG as a lubricant for ink preparation as well as using poly-vinyl-pyrrolidone as a binder has attracted a lot of attention, in recent years [154]. Seitz et al. [154] employed 2 wt% dispersant lubricant to provide low viscosity slurry for using in robocasting and 4 wt% binder for preparing an appropriate slurry. Fig. 4b shows ink preparation-needed materials and efficient additives for BCP robocasting.

Efficient additives

All the materials that improve a specific feature of the ink and scaffold, are summarized as efficient additives. Materials that improve mechanical properties, adjust the ink viscosity and rheology, reduce the grain size, etc., are introduced as efficient additives. To manufacture the scaffolds with complicated structures, an admitted printing method, which uses sacrificial materials, is suggested [155]. Sacrificial materials act as supporting structures in the printing process, at the first, and should be removed after printing [156]. Pluronic® F-127 (BASF Corporation, USA) is a salient example of these materials commonly used in BCP robocasting for the temporary support [157]. Also, it can be used as an appropriate ink flow rate adjuster. Pluronic® F-127 content and its particle size in the ceramic powder are adjustable since they are influential on the flow of robocasting ink. It has been confirmed that the ink flow rate increases with the rise of Pluronic® F-127 content [157].

To improve the mechanical properties of BCP scaffolds, ZrO2 has been proposed as an appropriate additive [65]. Woo et al. [65] added 10 wt% ZrO2 to produce some BCP scaffolds, which led to better mechanical strength and osteogenic differentiation ability. They reported that by adding this amount of ZrO2, the highest efficacy could be obtained: the best viscosity of printing along with the ideal mechanical properties [65]. Also, they found that the differentiation of human mesenchymal stem cells (hMSCs) indicated an elevated expression of bone morphogenic protein 2 (BMP-2), cultured on zirconia involved samples, compared with the samples containing no additive.

Additionally, graphene nanoplatelets (GNPs)-reinforced BCP scaffolds were prepared by Zhao et al. [158] via the hot pressing procedure. They reported that measuring the maximum bending strength and fracture toughness in parallel to the hot pressing direction, resulted in about 55% and 76% higher amounts than monolithic BCP scaffold, respectively [158]. Also, Peroglio et al. [159] demonstrated that the infiltration of BCP scaffolds with PCL improves their mechanical properties via crack bridging by polymer fibrils.

Previous studies demonstrate that PVA [160], Phosphoric Acid [161], Polyvinylpyrrolidone [162], Sodium Alginate [163], and Methacrylate-based photosensitive resins [164] are some efficient additives that have been used as binder in BCP robocasting procedure. Moreover, Hydroxypropyl Methylcellulose (HPMC) and Polyethylenimine (PEI) [65] were used as ink flow rate adjuster and flocculant, respectively, to regulate the ink viscosity.

Adding Mg2+ to the BCP compound could significantly decrease grain size and increase density and mesoporous precipitates after sintering [165]. Ramezani et al. [166] added diopside (MgCaSi2O6) powders, which had approximately 30.0 ± 4 nm size, to the BCP scaffolds, which decreased the prepared scaffold's grain size. They reported that increasing the diopside powder content from 0 to 15 wt% resulted in a considerable drop in the scaffolds' average grain size from 6 ± 0.9 μm to 1.9 ± 0.6 μm, respectively [166]. Several studies showed that grain size significantly affected physical, mechanical, and biological characteristics [165], [167]. An undeniable fact, which should be considered, is the additive’s content and its amount. For example, the extra accumulation of Ca2+ ions in β-TCP scaffolds hurt the osteoblastic cells [168].

Robocasting of BCP

Robocasting of BCP-based scaffolds have been a matter of discussions and debates in developing 3D complicated scaffolds for BTE applications (Table 2). Franco et al. [157] worked on the fabrication of the Calcium Phosphate scaffolds using the robocasting and ceramic powders involved- Pluronic® F-127 solution inks. They developed HA, β-TCP, and BCP with the HA: β-TCP ratio of 35: 65. Pluronic® F-127 acts as a non-ionic block copolymer that does not affect the slurry’s pH value. They reported that decreasing the sintering temperature as well as increasing the amount of Pluronic® content led to an increase in the scaffold micro-porosity. They also observed that increasing the amount of micro-porosity was an essential feature of biological response but has a direct negative effect on the scaffold strength. Also, by measuring the shrinkage of the produced specimens, they found that the shrinkage rate was not the same in different directions.

Table 2.

Summary of BCP-based bone scaffold robocasting studies representing the biomaterials, compressive strength, additional elements, and porosity size.

| Biphasic materials | Compressive strength of BCP (MPa) | BCP weight ratio (HA: β-TCP) | Compressive strength of HA: β-TCP (MPa) | Additional elements on scaffolds | Cell type / source | Pore size (μm) | Ref. |

|---|---|---|---|---|---|---|---|

| HA/β-TCP | 34 | 35: 65 | 102: 77 | Pluronic® F-127 solution | – | 200 μm between lines and a layer height of 180 μm | [157] |

| HA/β-TCP | 14.2 | 80: 20 | – | – | – | 30–80 | [169] |

| HA/β-TCP | 15 | 50: 50 | -: 11 | Hydroxypropyl methylcellulose (HPMC) | – | 500 | [170] |

| HA/TCP | 1.1 | 60: 40 | 0.7: 0.8 | Polyvinylpyrrolidone, poly(ethylene glycol) (PEG) | – | 100 | [154] |

| HA/β-TCP | 22 | 60: 40 | – | calcium peroxide (CPO), polycaprolactone (PCL) | Human osteoblasts | 500 | [171] |

| HA/β-TCP | 21 | 60: 40 | – | CPO, PCL | Human osteoblasts | 500 | [172] |

| HA/β-TCP | 23 | 60: 40 | – | CPO, PCL | Human osteoblasts | 500 and 300 in vertical direction | [173] |

| HA/β-TCP | 2.6 (60/40) | 100: 0, 20: 80, 40: 60, 60: 40 | – | phosphoric acid, polyvinyl alcohol, Tween 80 | Bone marrow / New Zealand rabbits | 800 | [150] |

| Calcium pyrophosphate (CPP)/β-TCP | – | – | – | Mg2+ | MC3T3-E1 osteoblastic cells | – | [165] |

| HA/β-TCP /Calcium carbonate | 1.81 | 30: 70 | – | PLGA solution as a coating layer | osteoblastic cell line MG63 | 300 | [63] |

| HA/β-TCP | 4.32 | – | – | SI500 photocurable liquid polymer resin | NIH3T3 cells, dental pulp mesenchyme from the mandibular incisor of P3.5 mice | – | [174] |

| HA/β-TCP | 1.23 | 60: 40 | – | Methacrylate | – | – | [175] |

| HA/β-TCP/ Chitosan | --, 1.5, 2 | 23: 77, 46: 54, 87: 13 | – | Chitosan, genipin | human dermal neonatal fibroblasts | 500 | [176] |

| HA/β-TCP | 11 | – | – | ammonium polycarbonate, HPMC, and polyethylenimine | human osteosarcoma derived MG-63 cell line | 120–500 | [177] |

| HA/β-TCP/PVA | 0.4 | 60: 40 | – | polyvinyl alcohol (PVA), Platelet-rich fibrin (PRF) | bone marrow-derived mesenchymal stem cells (BMSCs) / male New Zealand White rabbits | 500–600 | [178] |

| HA/β-TCP | – | 60: 40 | – | 2 wt% dispersant (acrylic acid copolymer) | Monocytic cells from the RAW 264.7 cell line | 100 | [179] |

| HA/β-TCP | – | 35: 45 | 51: 15 | Darvan® C dispersant, HPMC, and PEI | – | 250 | [180] |

Petit et al. [169] made BCP scaffolds containing 80 wt% HA and 20 wt% β-TCP via the robocasting method. They intentionally added poly-methacrylate (PMMA) beads to the compound to create artificial defects to investigate the impact of defects on the applied external stresses in uniaxial compression experiments. By observing specimens with structural defects over compressive loading, it can be concluded that control of defect formation can remarkably prevent the initiation of cracking and propagation. Ex-situ experiment's results showed the brittle behavior of the specimens due to the presence of defects and crack initiation in the sample [169]. Using finite element modeling (FEM), samples with existing artificial defects showed similar results to the struts' real condition. The findings showed that increasing the number of loading and unloading cycles leads to increasing the Young's Modulus in scaffolds.

Richard et al. [170] compared the mechanical properties and biocompatibility of two series of 3D printed scaffolds. In their work, cylindrical-shaped β-TCP and 50 wt% HA-50 wt% β-TCP scaffolds were fabricated by robocasting method. The average compressive strength of β-TCP and BCP samples were measured to be 11 ± 5.4 and 15 ± 6.9 MPa, respectively [170], which showed no significant difference. The results showed that 50 wt% HA-50 wt% β-TCP scaffolds, fabricated by robocasting methods, have more mechanical properties similarities to the natural bone than pure β-TCP scaffolds. They noted that the pore size and empty spaces in BCP scaffolds are more similar to the ingrowing trabecular bone, due to the metabolic activities such as vascularization, oxygen delivery, growth factors, and cell nutrition [170].

Seitz et al. [154] used HA, β-TCP, and BCP (with the composition of 60 HA: 40 β-TCP) for 3D printing. Various CaPs ratios were examined, which were sintered at 1250 ˚C to reach adequate mechanical strength. All granulates were less than 100 µm in diameter, which had a significant effect on the slurry's viscosity. The results showed that the pore channel size (200–600 μm) was significantly different from the theoretical size (580–870 μm) due to the sintering and shrinkage of 3D printed constructs. They suggested that the theoretical and actual size difference could be compensated in the parameter designing in the CAD stage. The results of the compressive strength test also showed that BCP and HA specimens had the highest and the lowest amount of compressive strength, respectively. Their findings also showed that there is a relation between the mechanical strength and the internal channel network. They concluded that diverse phase compositions of Calcium Phosphate (in the forms of HA, β-TCP, or BCP) could be employed in BTE applications that can adapt to their degradation behavior and mechanical properties.

Zhou et al. [165] used BCP nano-sized particles to regenerate the damaged bone tissue. By preparing precursors in the form of amorphous nanoparticles and then sintering at 900˚C, the dense BCP ceramic powders were obtained. They found that adding Mg2 + to the BCP powders increased the formation of β-TCP instead of β-Calcium Pyrophosphate (β-CPP). Their results also showed that decreasing the particle size, enhancing the density of the sintered ceramics, and strengthening the negative electric charge on the BCP surface have important roles in mechanical strength and cell proliferation. They also illustrated that the obtained precipitates are highly porous, composed of nanoscale and equiaxed particles, and can support vascularization and the formation of bone tissue and osteoblast cells. Due to mentioned properties and a high rate of similarity with natural bone features, their developed nano-sized particles can be extensively 3D printed and used as bone grafts.

Castilho et al. [63] studied the synthesis and fabrication of HA/ β-TCP/Calcium Carbonate bone scaffolds using Phosphoric Acid as a binder on a hydraulic setting reaction of a binder/powder. They employed an extrusion-based 3D printing method to develop complexly shaped BTE scaffolds, using the starting powders for the printing process, consisted of β-TCP and Calcium Carbonate mixtures in different Ca: P ratios of 1.65, 1.71, 1.83, and 2.00. Upon printing the specimens, they were sintered at 1200˚C for 5, 10, and 15 h to induce a partial phase transition from the mixture of β-TCP and Calcium Carbonate into HA. The final HA amount in the printed specimens was depended on the molar ratio of β-TCP to Calcium Carbonate at the start point. The authors confirmed that the compressive strength of the BCP scaffold is directly related to the amount of β-TCP. However, the micro-porosity in the scaffold was entirely independent of the BCP compounds. The results also showed the highest cell proliferation and growth in BCP scaffolds compared to either HA or β-TCP scaffolds. Their findings also showed that increasing the Ca: P ratio caused increasing the toughness modulus of fabricated scaffolds. They also claimed that increasing the amount of porosities and decreasing the grain boundaries of the scaffolds led to decreasing the resistance of printed scaffolds to the crack propagation. The authors also confirmed the use of the robocasting method for fabricating BCP-based bone substitutes, based on mechanical properties, porous structure, pore size, and interconnectivity [63].

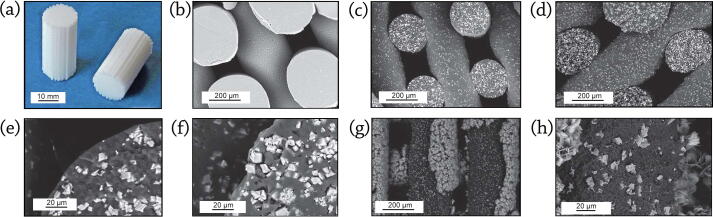

Fig. 5 shows the robocasted BCP scaffolds and their corresponding SEM images. As shown in this Figure, BCP constructs could be printed using nozzles in various diameters (Fig. 5a-c). However, using nozzles with small internal diameters lead to shrinkage of the distance of the rows and minify the porosities. The printed constructs possess ordered layers on each other that result in proper mechanical and biological performances (Fig. 5d). Fig. 5e-h show the optical view from BCP scaffolds produced by Touri et al. [172], [173] along with the corner, top and cross-section SEM views. They reported that the distance among the printed rods and the diameter of each rod was approximately 500 μm. Miranda et al. [180] showed SEM images of HA, β-TCP, and BCP scaffolds, possessing a rod diameter of 220 μm as well as a 50 μm gap between rods (Fig. 5i-l). The further details of the grains’ morphology are available in Fig. 5m-p [157].

Fig. 5.

3D printed scaffolds using different nozzles in: (a) Ø 80 μm; (b) Ø 60 μm; and (c) Ø 40 μm, show that utilizing nozzles with small internal diameters lead to shrinkage of the distance of the rows and minify the porosities, reproduced with permission from [270] (d) The printed BCP/PVA scaffold having a high porosity and connectivity rate, reproduced with permission from [178] (e) SEM view from the corner of printed BCP scaffold, reproduced with permission from [172]. SEM images of the BCP printed scaffold from (f) top view (g) Optical view, (h) cross-section view, reproduced with permission from [173]. SEM micrographs showing the morphology of: (i) printing plane view of HA scaffolds (j) printing plane view of β-TCP scaffolds (k) detail of the HA rod surface (l) detail of the β-TCP rod surface after sintering at 1300˚C for 2 h, reproduced with permission from [180]. SEM image of the: (m) HA scaffold (n) β-TCP scaffold after polishing and thermal etching (2 h at 1000˚C) along with: (o, p) their combination output (BCP), reproduced with permission from [157]. The micro and macro structure of prepared scaffolds affects the mechanical and biological features.

Wang et al. [150] printed BCP scaffolds using two ink binders, including a combination of 0.6 wt% polyvinyl alcohol (PVA) + 0.25 wt% Tween80, and a combination of 8.75 wt% phosphoric acid + 0.25 wt% Tween80. The results showed that HA: β-TCP bioceramic scaffold with a weight ratio of 60: 40 had the highest mechanical strength and adaptability to the cell culture medium among all examined samples with different weight ratio of HA: β-TCP, including 20: 80, 40: 60, and 60: 40. The authors showed that the compressive strength of all examined scaffolds increased with increasing the HA content. Moreover, they revealed that the binding mechanism in PVA and Calcium Phosphate powder is a physical bond, whereas the Phosphoric Acid and powder's binding mechanism is a dissolution-precipitation reaction [150].

Kindly note that higher printing speeds are generally preferred since they shorten the time it takes to construct a component and allow for more consistent flow. On the other hand, high printing speed impair tool path accuracy when changing direction and cause sharp edges to become rounded. Buj et al. [181] reported that the relationship between infill and speed is critical. In general, low infill with low-speed results in high roughness values; however, a distinct combination of trials with high infill and fast speed also results in high roughness [181]. Low infill paired with fast printing results in the lowest roughness values. Low infill suggests that less material must be deposited on each layer, yet fast printing speed decreases printing time, minimizing ink drying and promoting proper ceramic layer deposition.

Although decreasing the printing time, a high printing speed could alter the mechanical performance of the scaffold [182]. Upon enhancing the printing speed, the filaments could not deposit correctly on the bottom layers printed before, and the connection among the filament and its bottom layer decreased, which would be altered the mechanical performance and the porosity amount of the fabricated construct [182]. Therefore, increasing the extruding velocity is suitable only if the connection and interaction between the layers could be constant. This could be achieved by enhancing the filling rate by increasing the material depositing pressure. Once again, it is emphasized that the optimum condition of each robocasting procedure should be driven, depending on the material and machine used.

An irrefutable issue in tissue engineering is tissue hypoxia, while the vascularization network is being formed. Hypoxia can diminish tissue regeneration via limiting the nutrients delivery, such as oxygen and glucose, as well as wastes removal [183]. Although utilizing additive manufacturing techniques could manage this challenge in various tissues’ engineering, this issue still remains as a significant concern in engineered bone constructs. Therefore, researchers try to address this matter via novel ideas.

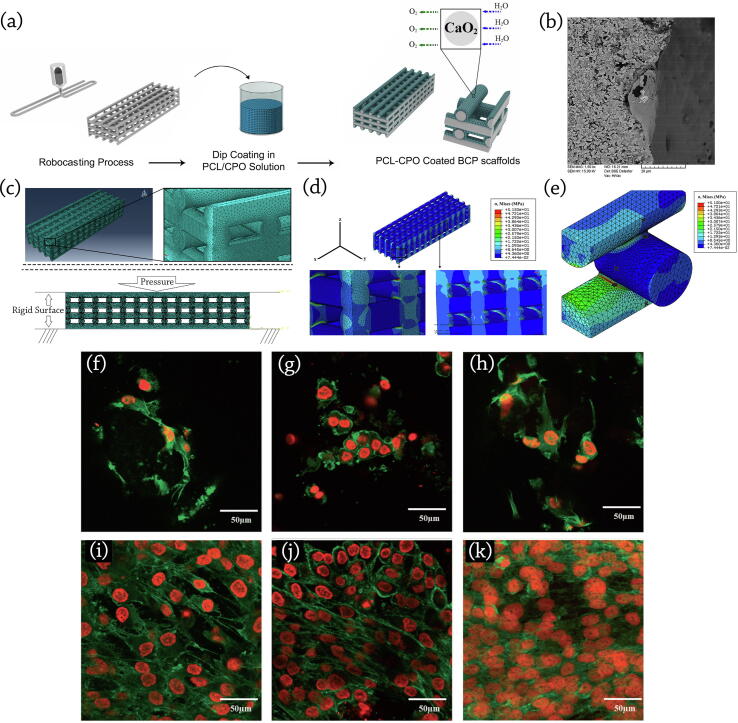

Touri et al. [171] demonstrated that bone tissue scaffolds equipped with Oxygen-generating elements/compounds could increase Oxygen concentration and cell survivability in around the 3D printed scaffolds. They developed 3D printed 60 HA: 40 β-TCP scaffolds coated by Calcium Peroxide-included Polycaprolactone (PCL) [171]. PCL was used in scaffold coatings to reduce Calcium Peroxide (CaO2, CPO)’s Oxygen release rate and prevent a burst release. Their findings showed that the samples with 3 wt% CPO in the coated layer had a high potential ability to enhance Osteoblast cell viability and improve bone tissue regeneration. Their research depicted that the use of Oxygen-generating elements, such as CPO in developing BTE scaffolds could affect cell viability, differentiation, and proliferation.

The osteoblastic function was monitored by measuring the amount of Alkaline Phosphatase (ALP) activity, which is a good criterion for measuring Osteoblasts’ differentiation and mineralization. Results showed that scaffolds containing 3 and 5 wt% CPO had better ALP activity than other samples. They also concluded that CPO-included PCL-coated scaffolds had a high potential for bone formation [172]. In the next step, developed scaffolds were implanted in a rabbit's radius bone to evaluate the bone growth and healing process in-vivo. Based on previous studies, at least Oxygen release with the pressure of 25 mm Hg is required for cell proliferation and differentiation in most tissues [172], [184]. Finally, by decreasing the number of live cells through increasing the content of CPO, the safety of developed scaffolds containing 3 wt% CPO was concluded [172], [184].

Schumacher et al. [185] studied the effect of different weight ratios of materials used in the process of BCP preparation on the mechanical properties and porosity of final scaffolds. They worked on the shape and angle of the pores in prepared scaffolds by ink-jet printing to investigate their effect on compressive strength. Fabricated BCP composites consisted of HA: β-TCP with weight ratios of 80: 20, 60: 40, 40: 60, and 20: 80, were studied in different pore patterns [185]. They concluded that the composition and micro-porosity of printed BCP scaffolds had a significant effect on the compressive strength. The maximum compressive strength was reported up to 27.6 MPa for the printed scaffold with round-shaped pores, where the composition with 60/40 ratio of HA: β-TCP, possesses 26.0 % volume porosity. As they reported, the experiments' observations show a decrease in the compressive strength of the scaffolds by increasing the porosity volume. They conducted their research on the statically & dynamically cell culture effects on three types of the printed scaffold: pure HA, BCP with the composition of 60 wt% HA: 40 wt% β-TCP, and pure β-TCP [168]. The results of ST-2 bone marrow stromal cells (BMSCs) culturing on the scaffolds showed that the cell proliferation and growth rate in the dynamic culture condition were far better than the static one; this can be due to the accumulation of waste and shortage of nutrients inside the scaffold in the static culture, while the culture medium perfusion in dynamic situation compensate it [168]. Beside the fact that almost all studies have shown that BCP is a suitable bone substitute that can accelerate the bone regeneration process [174], [186], its performance in-vitro and in-vivo should be more discussed.

In-vitro evaluation of BCP scaffolds

Detsch et al. [187] performed an in-vitro study of osteoclastic cell differentiation on 3D printed Calcium Phosphate bone scaffolds, including pure HA, pure β-TCP, and BCP, possessing a composition of 60 wt% HA: 40 wt% β-TCP. They investigated the osteoclastic cells’ activation, proliferation, and differentiation using monocytic cell line RAW 264.7, and demonstrated that Osteoclast-like cells could adsorb on the surface of scaffold containing Calcium Phosphate granules. The authors showed that 3D printed BCP scaffolds had the best performance for Osteoclast activation. As Osteoclasts express highly tartrate-resistant acid phosphatase (TRAP, especially isoform 5b) [187], the TRAP staining is used commonly to distinguish between TRAP-positive Osteoclasts and undifferentiated monocytes. Their results depicted the monocytic precursor cells’ differentiation into Osteoclast-like cells in 21 days of culture, while TRAP-positive cells were observed on all samples.

Detsch et al. [187] also evaluated lacunae formation on the scaffolds’ surface upon the cells’ removal from the scaffolds after 21 days. Lacunae's diameter and depth could be determined via a 3D model generated from three SEM stereo images using specialized software (MeX 5.0; Alicona Imaging, Austria). They reported that apparent differences in lacunae formation could be found, depending on the scaffold’s surface material. HA surface led to only acidifications and sporadic lacunae, while the β-TCP scaffold’s surface showed no osteoclastic resorption. Meanwhile, the BCP scaffold witnessed many lacunae on its granules. Moreover, the highest rate of resorption lacunae was observed on the BCP scaffold, with the HA: β-TCP composition rate of 40: 60 [187].

Yang et al. [75] evaluated the degree of in-vitro bioactivity of GENESIS-BCPTM and MBCP®, which is extended throughout for up to four weeks. They found that the former maintains bioactivity throughout, while the latter is only partially activated over four weeks. Also, they noted that GENESIS-BCPTM possess a superior bioactivity degree in comparison with MBCP® bone graft [75].

Hosseinabadi et al. [188] evaluated the yield strength and the elastic modulus of PLGA and PLGA/BCP composite scaffolds before and during in-vitro degradation. For this purpose, they used nano-granules of BCP, with various compositions, between 10 and 50 wt% as a reinforcing material. All samples were fabricated by the TIPS method, possessing more than 89% porosity. Their study showed that PLGA/BCP scaffolds have better mechanical properties and more weight loss than pure PLGA during eight weeks of in-vitro degradation. They noted that adding 30 wt% BCP cause the highest yield strength among other samples during the first six weeks of in-vitro degradation [188]. Also, they emphasized that decreasing the pH value arising from the acidic degradation products of PLGA could cause cell death. Besides, the released Alkaline ions during the degradation period, emitted from the BCP nano granules, could prevent the creation of the acidic environment. They noted that increasing BCP particles in the composite scaffolds results in increasing the hydrophilicity, which led to more weight loss. At the same time, the degradation rate of the PLGA polymer in the composite scaffolds was decreased by the presence of Alkaline ions [188].

Nie et al. [189] developed scaffolds based on a composition of BCP/PVA through the emulsion foam freeze-drying method. They indicated that the pore size, strength, and porosity of the scaffolds could be controlled by optimizing the BCP/PVA weight rate, while they fabricated composite scaffolds possessing 20, 30, 40, and 50 wt% PVA. Moreover, in-vitro degradation and cytocompatibility of scaffolds investigated a low variation of pH values (approximately 7.18–7.36) in the SBF solution. Increasing PVA concentration leads to a decrease in the degradation rate of BCP/PVA scaffolds. Their study on MTT assay indicated that the BCP/PVA porous scaffold has no negative effect on cell growth and proliferation, and the human bone mesenchymal stem cells (hBMSCs) possessed a convenient spreading morphology on the BCP/PVA scaffold surface.

In-vivo evaluation of BCP scaffolds

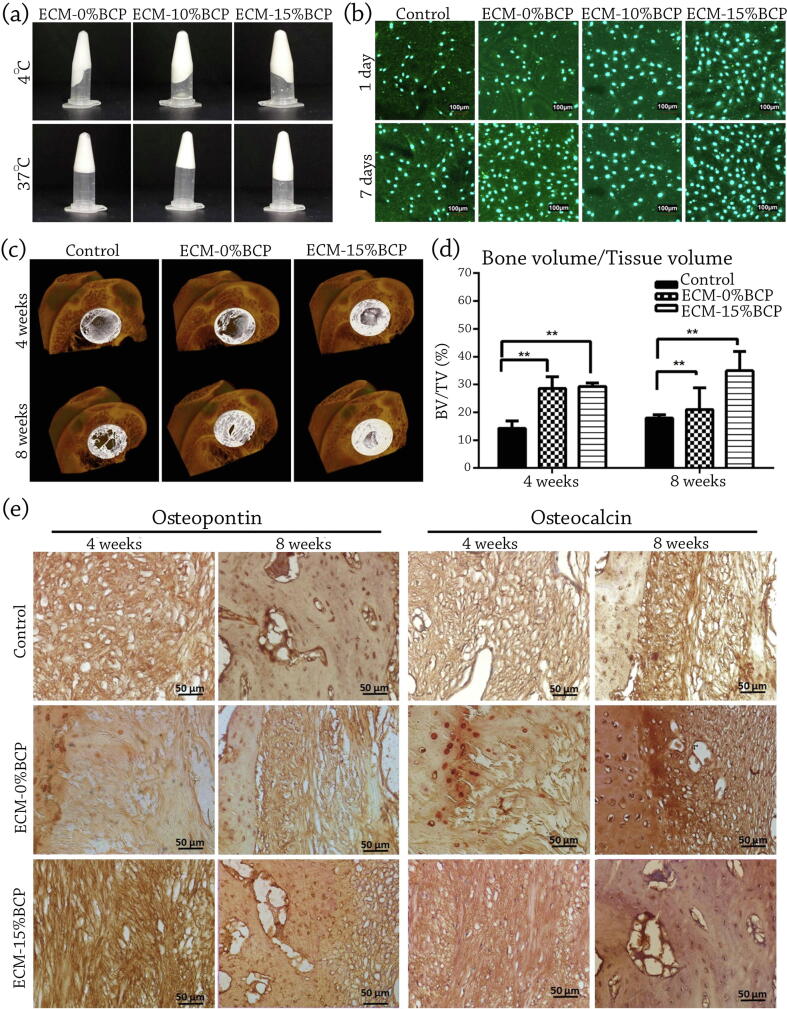

Ventura et al. [98] aimed to evaluate the bone regeneration capability of BCP powder-loaded Porcine dermis decellularized ECM composite. They fabricated two types of injectable composites, containing 10% and 15% w/v BCP in ECM hydrogel (Fig. 6a and b). Then, they implanted prepared hydrogels in the rat femoral head for an assessment of four and eight weeks. Based on their micro-CT and histological staining results, the fabricated injectable BCP–loaded decellularized ECM hydrogels illustrated an elevated bone formation compared with the unfilled defect (Fig. 6c). A notable progress has been seen in bone formation via ECM-15 wt% BCP in rabbit's femoral head defect after four and eight weeks through bone volume/tissue volume quantification (Fig. 6d). They concluded that developed injectable hydrogel possesses a high ability in non-load bearing BTE applications. The authors also reported that new bone formation in the defect filled with ECM alone and ECM-15 wt% BCP after four weeks injection was observed to be up-raised level of 2.00 and 2.055 fold compared to the unfilled control defect, respectively [98]. They also studied the bone formation in eight weeks and revealed that bone formation witnessed a 1.165 and 1.941-fold increase in ECM alone injected, and the defect with ECM-15 wt% BCP, respectively. Their claims positively correlates with Osteopontin and Osteocalcin positive staining results (Fig. 6e) [98]. Their study showed that the presence of BCP powder in Porcine dermis decellularized ECM composite could improve the osteogenic ability. As increasing the BCP amount from 0 to 15 wt% resulted in superior bone formation in eight weeks, it could be noted that used scaffold’s composition and its structure possesses a vital role on osteogenesis.

Fig. 6.

(a) The gelation and preparation of Porcine dermis decellularized ECM containing different content of BCP (b) Confocal micrographs showed that the injectable ECM hydrogel extracts do not affect the morphology and proliferation of MC3T3-E1 cells after 24 h exposure. (c) Representative sample of 3D reconstructed Micro-CT of the femoral head explant with white color as the defect site of control (d) Bone volume/tissue volume quantification showed significant increase in bone formation ability of ECM-15 %BCP implanted in rabbit's femoral head defect after four and eight weeks (**p < 0.005 denotes significant difference) (e) Representative sample of high magnification of positive stain of Osteopontin and Osteocalcin of the central defect of the representative sample of control, ECM-0% and ECM-15 wt% BCP implanted in femoral head after four and eight weeks. (Scale bar = 50 μm), (a-e) reproduced with permission from [98]. Bone formation in eight weeks witnessed a 1.165 and 1.941-fold increase in ECM alone injected, and the defect with ECM-15 wt% BCP, respectively. At the same time, Osteopontin and Osteocalcin positive staining results approve this data.

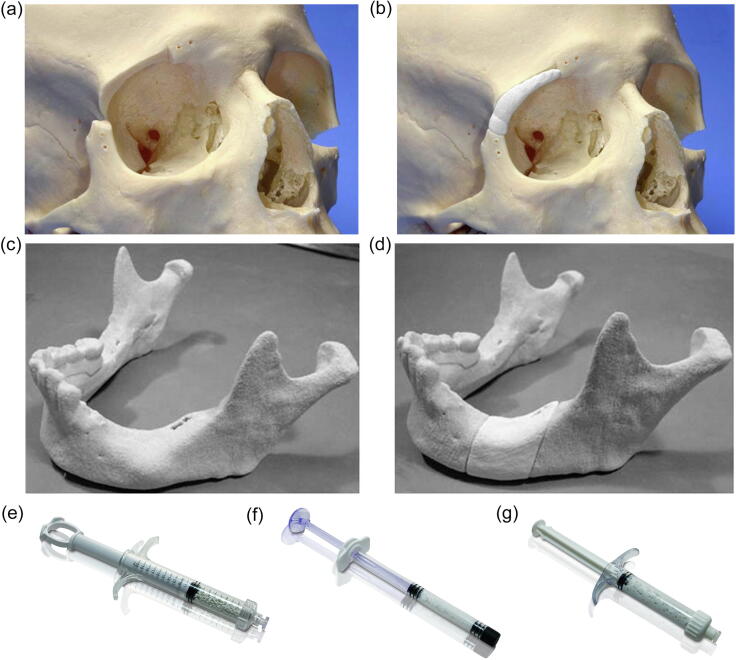

Table 3 summerizes pre-clinical and clinical studies performed on BCP scaffolds’ evaluation. As seen in this table, Yang et al. [75] investigated the GENESIS-BCPTM and MBCP® scaffold’s efficacy implanted in the bone defects of mouse and rabbit samples. They implanted scaffolds into 10 mm bone defects in mouse skull and damaged cortical sites of New Zealand white rabbits and studied the new bone formation at 6, 12, and 16 weeks post-implantation. The authors prepared Hematoxylin and Eosin (H&E) stains and micro-CT images to evaluate the amount of newly bone formation. They found that GENESIS-BCPTM scaffolds are more efficient in bone formation in mouse skull compared to the MBCP® scaffolds. In the case of rabbits, the authors concluded that both scaffolds were efficient in bone formation performance, while GENESIS-BCPTM scaffolds showed more appealing results than MBCP®. They noticed that bone scaffolds based on GENESIS-BCPTM are well-established candidates for bone regeneration.

Table 3.

Pre-clinical and clinical studies performed on BCP scaffolds’ evaluation.

| Study type | BCP scaffold type | Model/site | Post-implantation study time | Primary outputs | Ref. |

|---|---|---|---|---|---|

| Pre-clinical (In-vivo) | 10 and 15 wt% BCP powder-loaded Porcine dermis decellularized ECM composite | Rat femoral head | 4 and 8 weeks | The fabricated injectable BCP–loaded decellularized ECM hydrogels showed an elevated bone formation compared with the unfilled defect | [98] |

| GENESIS-BCPTM and MBCP® powder BCPs | 10 mm bone defects in Mouse skull and damaged cortical sites of New Zealand white Rabbits | 6, 12, and 16 weeks | They noticed that bone scaffolds based on GENESIS-BCPTM are well-established candidates for bone regeneration. | [75] | |

| MBCP®, and MBCP+® powder BCPs | Dorsum of the SWISS nude mice | – | MBCP® and MBCP+® scaffolds provided osteoinduced bone approximately 0.15% and 1.3% of biomaterial surface, respectively, without using any cells. | [71] | |

| 100% HA, 100% β-TCP, and BCP with HA: β-TCP ratio of 76: 24, 63: 37, and 56: 44, 20: 80. | Mouse ectopic model | – | HA: β-TCP composition ratio of 20: 80 showed the fastest rate of bone induction | [190] | |

| Porous BCP scaffolds fabricated via robocasting, containing 3 wt% CPO and coated by PCL | Radius bone of a rabbit | – | Results showed that prepared bone constructs were suitable for apatite precipitation and bone ingrowth. | [172] | |

| Robocasted BCP/PVA bone scaffolds containing platelet-rich fibrin (PRF), using nano-BCP powder with a composition ratio of 60% HA and 40% β-TCP | Mouse ectopic model | 4, 8, and 12 weeks | The printed BCP/PVA/PRF scaffolds released significantly higher levels of primary growth factors in the early stages than the non-printed BCP/PVA/PRF scaffolds. The presence of PRF in BCP/PVA bone scaffolds led to a better cell adhesion, proliferation, and osteogenic differentiation. BCP/PVA/PRF scaffolds showed better bone formation performance compared with BCP/PVA scaffolds. |

[178] | |

| Clinical | 3D-printed BCP construct with a 30 HA: 70 β-TCP composition ratio | Human maxillary buccal plate | 7 years | Biomaterial volume reduced by more than 23% and that newly produced bone volume constituted more than 57% of the entire mineralized tissue after 7 years of post-implantation. perfect scaffold integration, in which the soft tissue, biomaterials, bone portions were 15.2, 25.6, and 59.2, respectively. |

[191] |

| Various composition ratios of HA: β-TCP in the BCP scaffolds | Human fresh dental sockets | 3 and 6 months | The newly formed bone in the alveolar defect area filled with HA: β-TCP scaffolds with the composition of 60.28: 39.72 and 78.21: 21.79 was reported to be 69.3% ± 6.03% and 46.6% ± 7.66%, respectively. | [192] |

Miramond et al. [71] performed an in-vivo study to investigate the osteoinductivity of two available commercial BCP in the market, MBCP®, and MBCP+® through forming several pockets of implantation on the dorsum of the SWISS nude mice. MBCP® and MBCP+® scaffolds provided osteoinduced bone approximately 0.15% and 1.3% of biomaterial surface, respectively, without using any cells. They reported a high similarity of physicochemical characteristics among two mentioned scaffolds. Their study showed that MBCP+® scaffold possesses a higher ionic exchange rate with host tissues, while it has a higher in-vivo dissolution rate, too. The authors pointed out that the higher content of β-TCP could cause a difference in osteoinductivity.

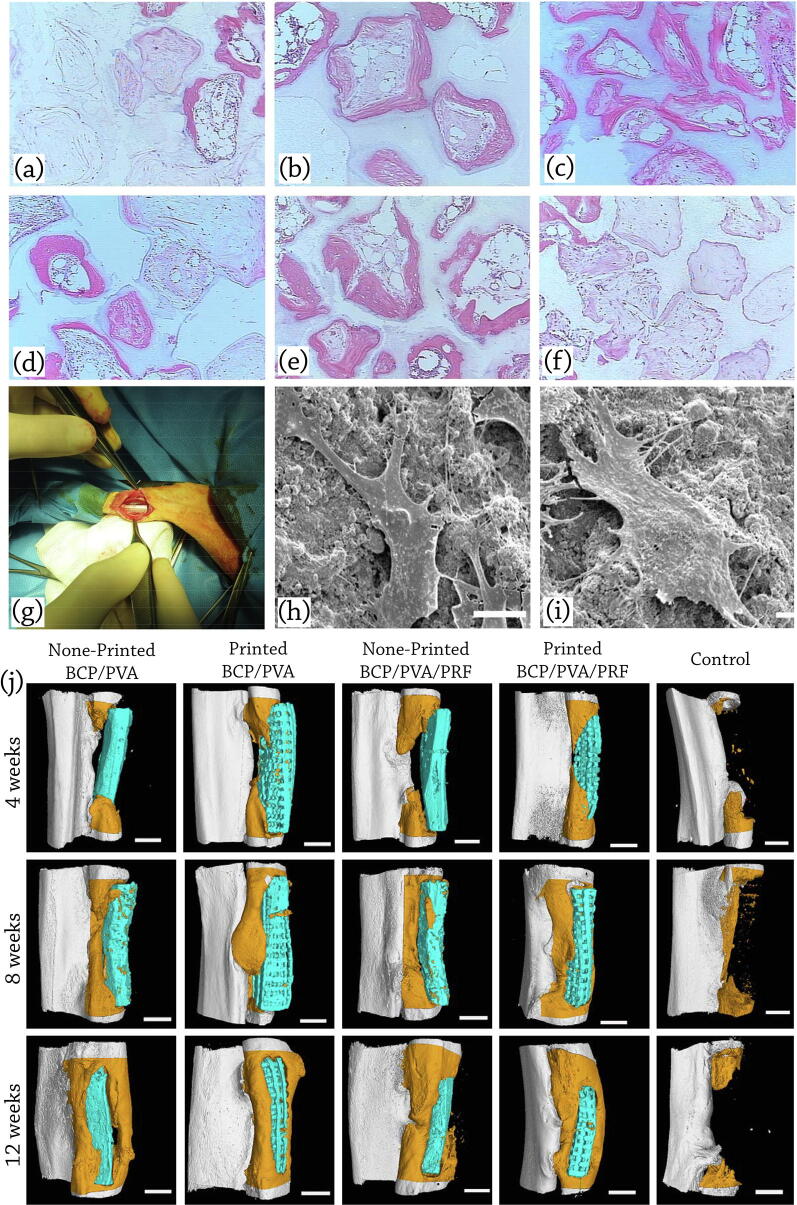

Arinzeh et al. [190] carried out an examination to evaluate the suitable ratio of HA: β-TCP, promoting bone formation. Seeding hMSCs on BCP samples with HA: β-TCP composition ratio of 20: 80 showed the fastest rate of bone induction in a mouse ectopic model among all examined samples of 100% HA, 100% β-TCP, and HA: β-TCP ratio of 76: 24, 63: 37, 56: 44, and 20: 80 (Fig. 7a-f).

Fig. 7.

In-vivo applications of BCP scaffolds: representative histological micrographs of (a) 100 HA, (b) 76 HA/24 β-TCP, (c) 63 HA/37 β-TCP, (d) 56 HA/44 β-TCP, (e) 20 HA/80 β-TCP, and (f) 100 β-TCP at 12 weeks post implantation (H&E staining). Bone is stained pink, ceramic has a shadowy white appearance, loose connective tissue is stained a light pink, cells are stained a dark pink, reproduced with permission from [190]. Seeding hMSCs on BCP samples with HA: β-TCP composition ratio of 20: 80 showed the fastest rate of bone induction in a mouse ectopic model among all examined samples. (g) Implanted scaffold in the radius defect of the rabbit; reproduced with permission from [172]. (h) SEM analysis of the adhesion status of BMSCs on the printed BCP/PVA scaffolds (i) printed BCP/PVA/PRF scaffolds, reproduced with permission from [178] (j) Micro-CT scans and 3D reconstructions to visualize healing of critical size bone defects in the rabbit radius at 4, 8, and 12 weeks after implantation of scaffolds seeded with BMSCs. Defects were implanted with non-printed BCP/PVA scaffolds, printed BCP/PVA scaffolds, non-printed BCP/PVA/PRF scaffolds, printed BCP/PVA/PRF scaffolds, and the sample with no following treatment (control). The scaffolds are shown in blue, and newly formed radius bone is shown in dark orange in the micro-CT images; scale bars: 3 mm, reproduced with permission from [178]. The incorporation of PRF, promoted the biological activity through enabling the sustained release of bioactive factors from the scaffold.

Touri et al. [172] proposed the implantation of porous BCP scaffolds fabricated via robocasting, containing 3 wt% CPO and coated by PCL in the radius bone of a rabbit model to evaluate the scaffolds’ bone regeneration efficacy (Fig. 7g). They have shown that the oxygen released from prepared scaffolds caused an elevated rate of cell density, viability, and proliferation. They also claimed that prepared bone constructs were suitable for apatite precipitation and bone ingrowth.

Song et al. [178] developed robocasted BCP/PVA bone scaffolds containing platelet-rich fibrin (PRF), to investigate the effect of PVA and PRF on the bone regeneration capability. Also, to determine the preparing method’s effect on scaffold’s performance, they fabricated non-printed BCP/PVA scaffolds with/without PRF via freeze-drying technique, while they used nano-BCP powder with a composition ratio of 60% HA and 40% β-TCP.

The authors pointed out that the incorporation of PRF, promoted the biological activity through enabling the sustained release of bioactive factors from the scaffold [178]. They measured the GFs’ concentration released from BCP/PVA/PRF scaffolds using enzyme-linked immunosorbent assay (ELISA) kits and reported that vascular endothelial growth factor (VEGF), platelet-derived growth factor-AB (PDGF-AB), transforming growth factor- β1 (TGF-β1), and insulin-like growth factor-1 (IGF-1) are the primary GFs assessed by ELISA. The printed BCP/PVA/PRF scaffolds released significantly higher levels of mentioned growth factors in the early stages and considerably lower levels at 14 and 21 days than the non-printed BCP/PVA/PRF scaffolds.

PRF is a fibrin matrix with a simplified preparation method, which does not require any Thrombin or Calcium Chloride addition [193]. In PRF, platelet cytokines and GFs are trapped, which are efficient in facilitating the hemostasis, wound healing, and the differentiation of pre-osteoblasts due to the presence of secreted GFs [194], [195]. A variety of activated platelets and leukocyte GFs are involved in the fibrin matrix of PRF, while they could release gradually by degrading the fibrin [196]. Previous studies confirmed that PRF promotes Osteoblast adhesion, along with upregulating the collagen protein expression, which are almost effective in new bone formation [197], [198], [199].