Abstract

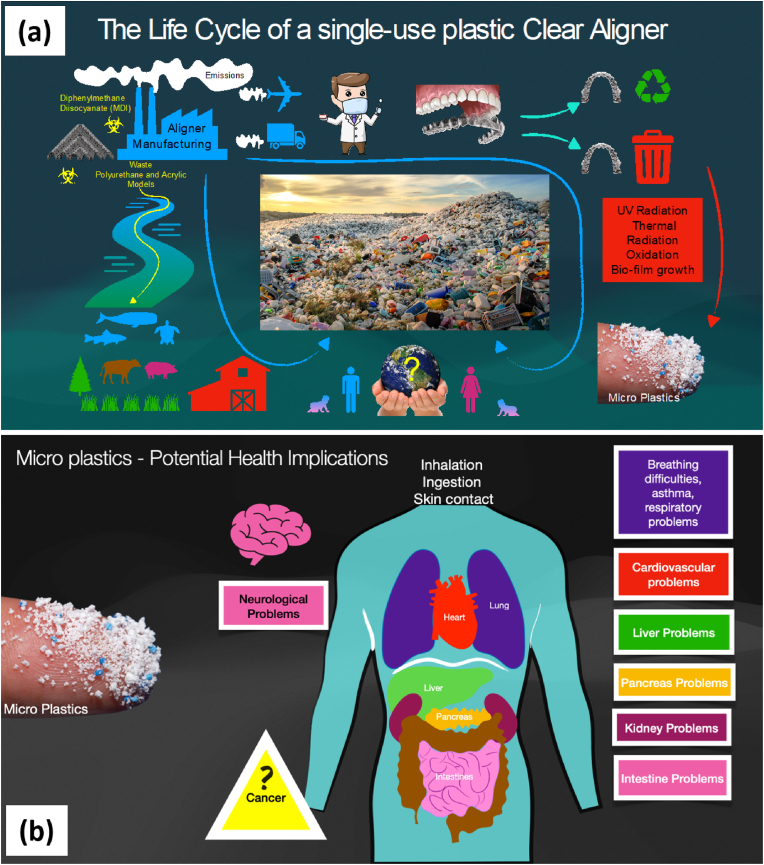

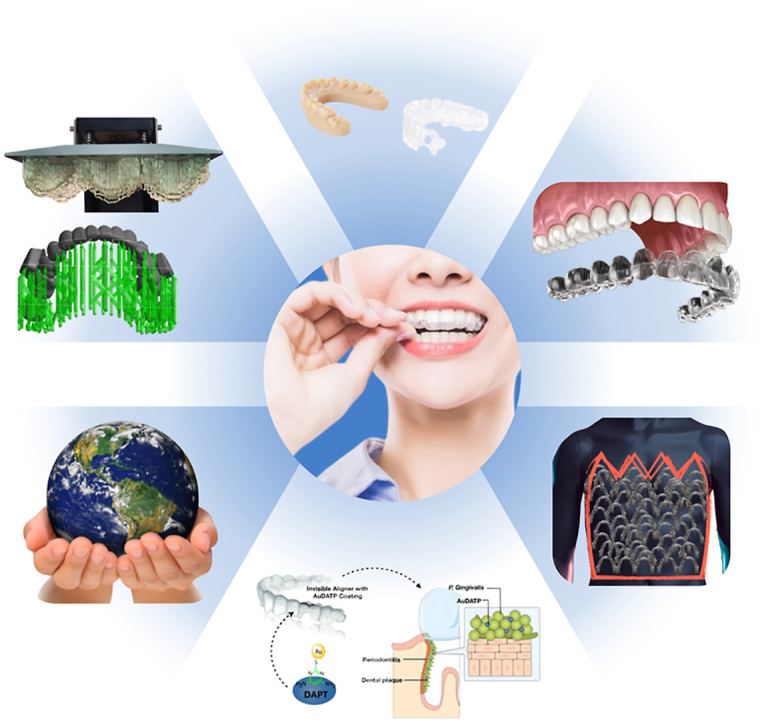

Rapid technological improvements in biomaterials, computer-aided design (CAD) and manufacturing (CAM) have endorsed clear aligner therapy (CAT) as a mainstay of orthodontic treatment, and the materials employed for aligner fabrication play an all-important role in determining the clinical performance of clear aligners. This narrative review has attempted to comprehensively encompass the entire gamut of materials currently used for the fabrication of clear aligners and elucidate their characteristics that are crucial in determining their performance in an oral environment. Historical developments and current protocols in aligner fabrication, features of contemporary bioactive materials, and emerging trends related to CAT are discussed. Advances in aligner material chemistry and engineering possess the potential to bring about radical transformations in the therapeutic applications of CAT; in the absence of which, clear aligners would continue to underperform clinically, due to their inherent biomechanical constraints. Finally, while innovations in aligner materials such as shape memory polymers, direct three-dimensional (3D) printed clear aligners and bioactive materials combined with clear aligner materials are essential to further advance the applications of CAT; increased awareness of environmental responsibilities among aligner manufacturers, aligner prescribing clinicians and aligner users is essential for better alignment of our climate change goals towards a sustainable planet.

Keywords: Clear aligners, Bioactive materials, Shape memory polymers, Direct 3D printing, Environment, Review

Graphical abstract

Highlights

-

•

Clear aligner fabrication material primary determinant of its clinical performance.

-

•

Present-day materials, characteristics, current fabrication protocols presented.

-

•

Shape memory polymers and direct 3D printed clear aligners highlighted.

-

•

Features of contemporary bioactive materials and emerging trends discussed.

-

•

Heightened environmental awareness due to increased plastic aligner use essential.

Abbreviations

- CAD/CAM

computer-aided design/manufacturing

- CAT

clear aligner therapy

- 3D

three-dimensional

- FA

fixed appliances

- PU

polyurethane

- PVS

polyvinyl siloxane

- CT

computed tomography

- FFF

fused filament fabrication

- SLS

selective laser sintering

- SLM

selective laser melting

- SLA

steriolithography apparatus

- KFDA

Korea Food and Drug Administration

- EC

European Commission

- FDA

Food and Drug Administration

- PET

polyethylene terephthalate

- PETG

polyethylene terephthalate glycol

- Tg

glass-transition temperature

- TPU

thermoplastic polyurethane

- PU

polyurethane

- PC

polycarbonate

- PP

polypropylene

- ISO

international standards organization

- HGFs

human gingival fibroblasts

- SMPs

shape memory polymers

- PRG

pre-reacted glass-ionmer

- S. mutans

streptococcus mutans

- P.gingivalis

porphyromonas gingivalis

- RCT

rondomized clinical trial

- NPs

nanoparticles

- AuDAPT

4,6-diamino-2- pyrimidinethiol-modified Au nanoparticles

- 3DPIN

3D printed in-house

- HM

Martens hardness

- EIT

indentation modulus

- ηIT

elastic index

- RIT

indentation relaxation

1. Introduction

With the rapid technological improvements in biomaterials, computer-aided design (CAD) and manufacturing (CAM), clear aligner therapy (CAT) has emerged as a promising alternative to conventional fixed appliances (FAs) in orthodontics. The demand for CAT has increased significantly over the last decade, presumably due to aggressive marketing strategies by commercial clear aligner companies that employ direct-to-consumer advertising as well as widespread utilization of various social media channels, thereby generating heightened public awareness for esthetic orthodontic treatment alternatives, especially for the adult patients [1]. The global clear aligners market size was projected to increase from USD 3.1 billion in 2021 to USD 11.6 billion in 2027 with a compound annual growth rate (CAGR) of 13% [2]. A recent survey carried out across North America also indicated that more orthodontists in the younger generations believe that clear aligners will be the main technique to treat malocclusions [3].

CAT typically comprises a series of clear plastic trays covering the dentition with a snug fit, that is to be used by the patient at all times except eating and brushing and generally changed sequentially every one to two weeks to accomplish planned orthodontic tooth movements. Although multiple commercial clear aligner systems are available today globally, the use of clear thermoformed plastic materials for clear aligner fabrication remains a common feature [4].

Although the clinical efficacy of clear aligners can be affected by a multitude of factors [[5], [6], [7], [8], [9]], the properties of materials used for their fabrication remain one of the most essential aspects in determining their mechanical and clinical features [10]. This review endeavours to comprehensively cover the advances in biomaterials used for clear aligner fabrication. Historical developments, current protocols, properties, and clinical performances of various clear aligner materials, features of contemporary bioactive materials as well as emerging trends are discussed in this narrative review of the literature.

2. Historical perspective

2.1. Origin and evolution

Harold D. Kesling in 1945, first advocated the use of rubber-based tooth positioners, fabricated from wax setups of patient's dentition, and demonstrated that these appliances not only helped in detailing orthodontically treated cases but could also sequentially reposition misaligned teeth, thereby pioneering the fundamental concepts of modern CAT with the possibility of performing significant orthodontic tooth movements with thermoplastic materials [11]. Kesling foresaw that more ambitious tooth movements could be realized with a series of aligners while recognizing the limitations of the technology available to him at that time: ‘Major tooth movements could be accomplished with a series of positioners by changing the teeth on the set-up slightly as treatment progresses. At present, this type of treatment does not seem to be practical. It remains a possibility, however, and the technique for its practical application might be developed in the future [12].

Henry Nahoum in 1964 [13], then refined Kesling's technique by developing a vacuum-based appliance that displayed firm adaptation to a patient's cast. This technique involved the fabrication of a plaster cast on which rotated anterior teeth were sectioned from the cast using a fissure bur or a goldsmith's saw and the sectioned teeth were then re-arranged with wax on the cast as per the desired outcome. A variety of thermoplastic materials, including acetates, vinyl, styrene, polyethylene, and butyrate sheets could then be vacuum formed over the designed cast to fabricate a dental contour appliance that could move teeth.

In 1971, Ponitz utilized Biocryl (polymethyl methacrylate), which was made out of cellulose acetate butyrate, polyurethane (PU), polyvinyl acetate-polyethylene polymer, polycarbonate-cycolac, and latex, to introduce an ‘Invisible retainer’. This vacuum-formed clear plastic appliance was initially fabricated for finishing and retention of orthodontic cases using base plate wax on the prepositioned cast and could obtain limited orthodontic tooth movements, chiefly by tipping crowns and could be used for subsequent retention [14].

In 1985, McNamara [15] modified Ponitz's technique and used 1 mm thick Biocryl™ polymers with a Biostar vacuum forming machine to fabricate invisible retainers for retention and final detailing. The difference between the Biostar machine and the previous vacuum former was that it used positive air pressure to adapt the thermoplastic Biocryl™ to the surface of the model rather than the vacuum pressure. However, the author admitted that the long-term durability of this clear removable retainer was not comparable to the conventional acrylic or bonded retainers.

Finally, Jack Sheridan 1993 further modified the process of fabricating clear appliances, utilizing polypropylene, a 0.030″ sheet of thermoplastic copolyester from Raintree Products, and coined the word ‘Essix appliance’ to describe an esthetic method for the alignment of anterior teeth by combining clear appliances with interproximal teeth reduction. He also recommended using a positive air pressure method for the thermoforming process like McNamara's to decrease the thickness of the sheet almost by half after fabrication [16].

However, throughout these advances, the basic principle of producing minor tooth movements with individual clear appliances did not change. Fabricating appliances by making impressions, pouring casts, sectioning individual teeth, re-arranging them into proper alignment to obtain a final cast and repeating this process at every clinical appointment was an extremely laborious and time-consuming process. The solution to which arrived in the form of a clear aligner system named Invisalign, which involved a series of removable polyurethane aligners created digitally by two Stanford graduates – Zia Chishti and Kelsey Wirth, launched in 1998 by Align Technology (Santa Clara, CA). This was the first orthodontic appliance to be fabricated using transparent and thermoplastic polymeric materials, with the aid of modern CAD/CAM technology [17]. This system involved a multiple-step process, beginning with the three-dimensional (3D) reconstruction of patients’ dentition, obtained either from an intra-oral scan or digital scanning of the study models, followed by segmentation of the individual crown with the help of a computer algorithm, and the development of treatment plans presented visually as a sequence of incremental tooth movement by a predetermined amount using the software. The next step comprised manufacturing the physical models for each stage of tooth movement using the rapid prototyping technique [18,19]. Finally, the bespoke aligners were produced using a thermoforming process and trimmed to the final configurations.

2.2. Generations of clear aligners

Clear aligners have undergone multiple transformations over the years in the quest for improved clinical efficiency to treat various malocclusions more aesthetically, comfortably, and effectively. These transformations of clear aligners in general and Invisalign in particular, are highly representative and have been summarized and reviewed as eight generations of clear aligners by Hennessy and Al-Awadhi [20], Ganta [21], Moshiri [22], and Wajekar [23] as follows.

2.2.1. First-generation aligners

The earliest forms of clear aligner systems were solely reliant on the thermoformed plastic aligner material to achieve intended results without any auxiliary elements being incorporated into the aligner system. The first case report was published in 2000 using 1st generation Invisalign to treat mild crowding and space closure cases [24]. The material used to fabricate Invisalign aligners before September 2001 was a polymer mixture and the brand name was Proceed30 (PC 30), which failed to meet all the physical, chemical, and clinical requirements for orthodontic tooth movement [25]. Clinicians encountered some difficulties and limitations with the usage of these clear aligners [26,27].

2.2.2. Second-generation aligners

With advances in aligner systems, manufacturers incorporated the use of attachments to provide better control of planned tooth movement. Clinicians could also request for composite buttons to be bonded on the teeth and utilize inter-maxillary elastics. Other features, including SmartForce™ attachments, Power Ridge™, Velocity Optimization, and interproximal reduction (IPR) became universal in the Invisalign system. A single layered polymer material Exceed30 (EX 30), an implantable medical-grade polymer made of polyurethane methylene diphenyl diisocyanate 1.6-hexanediol, tested for safety and biocompatibility by the United States Pharmacopeia, Class IV [28], was used to fabricate the aligners. The EX30 material provided 1.5 times greater elasticity and 4 times more adaptability than PC 30 and facilitated easier insertion and removal of the trays for the patient [29].

2.2.3. Third-generation aligners

In 2010, the third-generation aligners included SmartForce™ features, such as optimized attachments, designed and placed automatically by commercial software as well as indentations in the polyurethane plastic that placed increased pressure on specified points on the crown to produce a moment of a couple and root torque (Power Ridge). Further, the clinician could also prescribe non-precision attachments to be placed on the teeth wherever needed, to improve movements such as derotation and extrusion. New precision cuts were introduced to help with Class II and Class III interarch elastics [30].

2.2.4. Fourth-generation aligners

In 2011, G4 attachments were released to facilitate the clinical outcomes in open bite cases with improved optimized extrusion attachments on multiple teeth. New multi-plane movement features were available for upper laterals to enhance extrusion along with rotation and/or crown tipping. Optimized root control attachments were introduced for better mesiodistal root control of canines and central incisors [31].

Since 2013, EX 30 has been replaced by a new multi-layer aromatic thermoplastic polyurethane/co-polyester material, called SmartTrack™ (LD30). This new material provides better performance, such as a gentle and more constant force, more long-term action and improved adhesion, which eases the use for patients. Compared with EX30, LD30 has greater consistency of application of orthodontic forces, greater elasticity, chemical stability and an even more precise and comfortable aligner fit [32,33].

2.2.5. Fifth-generation aligners

In late 2013, fifth-generation enhancement improved the predictability of deep bite correction by introducing pressure areas on the lingual of the upper and lower anterior teeth, precision bite ramps on the lingual of the upper incisors, and bevelled dome-shaped retention attachments on the premolars [34]. However, a recent study by Blundell et al. found that the use of precision bite ramps does not appear to significantly improve the ability of SmartTrack™ material to predictably open the bite compared with EX30 materials [35].

2.2.6. Sixth-generation aligners

In late 2014, sixth-generation clinical innovation for orthodontic treatment of first premolar extractions was introduced using new SmartStage™ technology and SmartForce™ features to provide vertical control and root parallelism that optimize the progression of tooth movements for extraction treatment planned for maximum anchorage [36].

2.2.7. Seventh-generation aligners

Invisalign G7, a set of features designed to deliver greater control of tooth movements and improved treatment outcomes was released in 2016, particularly for teenage patients. It aimed to deliver better upper lateral incisor control, and improve root control and features to address the prevention of posterior open bites [37].

2.2.8. Eighth-generation aligners

Around late 2020, the eighth-generation enhancements were announced aiming to further improve the predictability of deep-bite correction with SmartForce™ aligner activation for anterior intrusion and improvements in the ClinCheck virtual proprietary software setup to level the Curve of Spee. G8 also minimizes unwanted crown tipping during posterior arch expansion with optimized expansion support and rotation attachments to reduce the potential for buccal crown tipping [22,38].

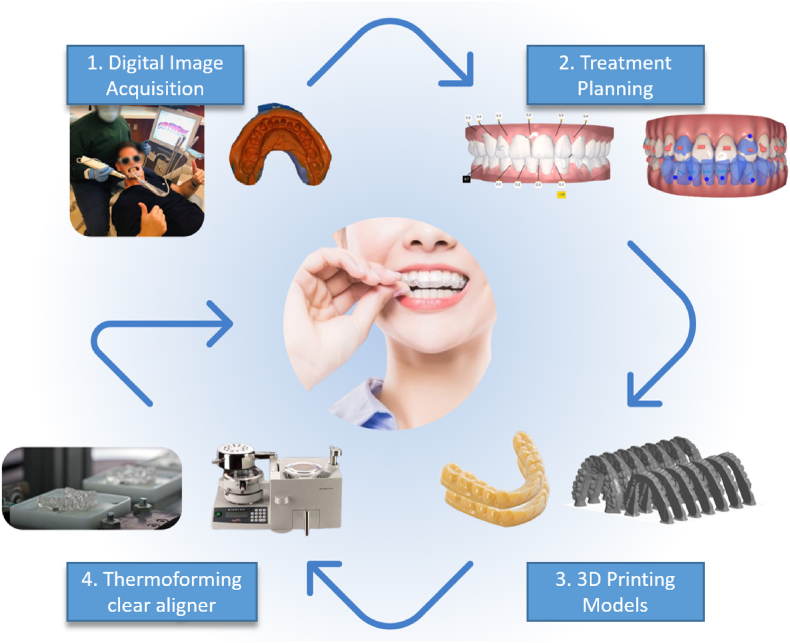

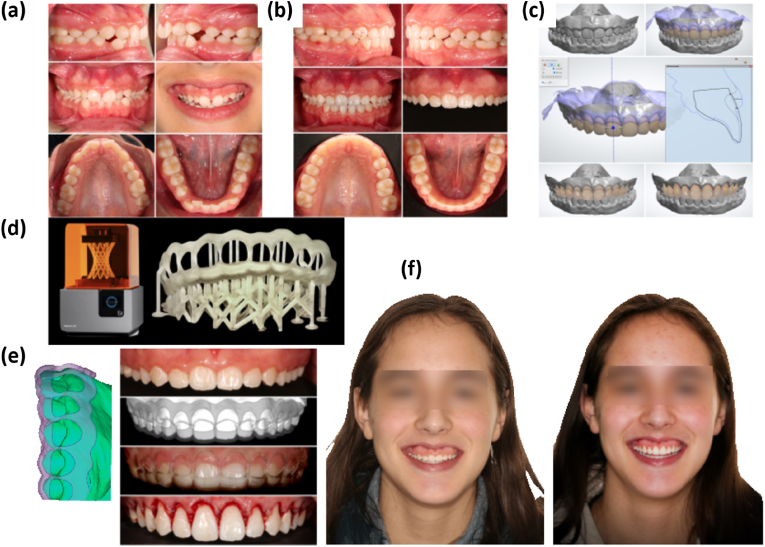

2.3. Aligner fabrication process

The pioneering methods involving the manual fabrication of clear aligners, are no longer used for commercial aligner fabrication, and the current digital fabrication method employs CAD/CAM technology and digital workflow protocol (Fig. 1). A digital image acquisition is obtained via either a direct approach (images from an intraoral scanner) or an indirect approach (high-quality polyvinyl siloxane (PVS) putty impressions that are then digitally scanned), eventually providing a digital representation of the patient's dentition that constitutes the basic framework for virtual planning of tooth movements desired with CAT [4]. Virtual treatment planning and tooth movement manipulations are then performed using CAD platforms. Computer algorithms segment the individual clinical crowns of the digitized 3D model. Additional visualization of the tooth roots is now possible by importing and overlaying computerized tomography (CT) scan data. The position of teeth is manipulated through sequential movements towards the finally desired positions, resulting in the generation of sequential virtual models with teeth in positions planned for each stage [4]. 3D model printing of each of these virtual setup models generates serial physical models via CAM technology, incorporating either subtractive (milling) or additive manufacturing (3D printing) techniques. Three-dimensional printing is currently the mainstream technology used for orthodontic model fabrication. The corresponding series of clear aligners are then thermoformed on the physical copies and finally trimmed and polished The process of 3D printing of serial digital models and the thermoforming process itself is time-consuming, labour-intensive, and costly depending on the malocclusion type, aligner changing protocol and the number of refinements. Concerns over the plastic burden on the environment have been raised and warrant research to investigate the environmental impact of clear aligner production [4].

Fig. 1.

Workflow of fabrication of clear aligners by the thermoforming process.

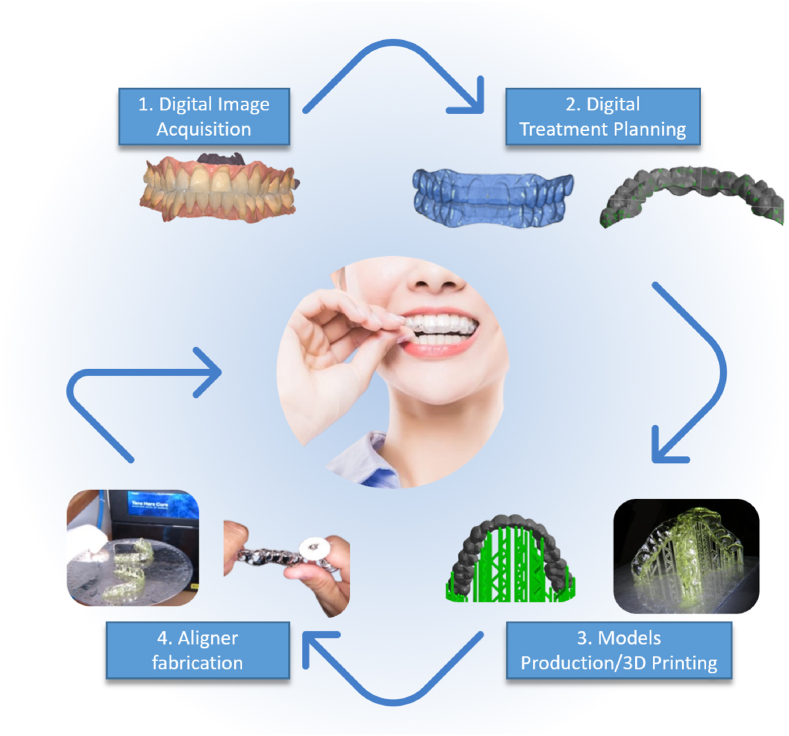

With technological advancements, the next paradigm shift would likely involve direct 3D printing of aligners from digital designs [39,40] and Nasef has been credited with the first novel attempt at 3D direct printing of retainers [41]. Current materials used for 3D printing in orthodontics include acrylonitrile-butadiene-styrene plastic, stereolithography materials (epoxy resins), polylactic acid, polyamide (nylon), glass-filled polyamide, silver, steel, titanium, photopolymers, wax, and polycarbonate. The advantages of using a clear aligner that is 3D printed are not just limited to the reduction of the cumulative errors introduced from the analog impression, intraoral scan, 3D printed physical model, and the subsequent thermoplastic process [42]. In addition to improved accuracy, 3D printing can shorten the supply chains, lower costs, and lead to a more sustainable process by generating less waste [43]. Theoretically, 3D direct printing allows the fabrication of clear aligners with customized thickness and spatial control of aligner thickness across the arch. The thickness of the aligner and the material chosen influence not only the magnitude of force delivered to teeth but also the mechanical properties of the aligners as well [40]. Although various 3D printing methods may be used for direct printing aligners, such as fused filament fabrication (FFF), selective laser sintering (SLS) or melting (SLM), stereolithography apparatus (SLA), multi-jet photocured polymer process, HP multiJet fusion technology or continuous liquid interface production technology, and powder binder printing [44]; 3D printing by photo-polymerization from clear resins seems to be a promising option, as the specific characteristics and requirements of the material properties are more appropriate [[45], [46], [47]]. Fig. 2 outlines the stepwise fabrication process of 3D direct printed clear aligners.

Fig. 2.

Stepwise fabrication process of 3D direct printed clear aligners.

3. Materials used for clear aligners

The composition of the material utilized for the fabrication of a clear aligner influences the clinical performance of the aligners [48,49] and this composition in turn is influenced by the actual manufacturing process that can basically be divided into two categories: the conventional method of vacuum thermoforming with thermoplastic material moulding on physical models and the other category of direct 3D printing without intermediary physical models [47,50]. Currently, the first fabrication process is widely adopted both commercially and clinically, including for the in-house production of aligners [51]. While, for the direct 3D printing process, with the exception of Tera Harz TC-85 (Graphy, Seoul, South Korea), which has been approved by the Korea Food and Drug Administration (KFDA), European Commission (EC) and Food and Drug Administration (FDA) as per the company website [52], there is no other 3D printable material currently available commercially that meets the standard of biocompatibility, translucency, and appropriate mechanical properties [39,40,42].

3.1. Thermoplastic polymers

Thermoplastic polymers can be classified as amorphous and semicrystalline polymers based on their inherent molecular structure. Amorphous polymers comprise irregularly arranged molecular structures characterized by a low degree of molecular packing. Semicrystalline polymers, on the other hand, comprise both areas of uniformly and tightly packed chains (crystalline domains) and irregularly arranged areas (amorphous regions). The role of crystalline domains in thermoplastic polymers can be likened to that of fillers in composite materials, which confer hardness and rigidity to the thermoplastic material. Generally, amorphous polymers are softer, transparent, exhibit low shrinkage, and possess better impact resistance. Contrastingly, semicrystalline polymers are hard, opaque, or translucent, possess good chemical resistance and exhibit a sharp melting point [50,53,54]. The polymers (either individual or blended) most commonly utilized for the manufacture of commercial clear plastic orthodontic aligners are polyester, polyurethane or co-polyester, polypropylene, polycarbonate, ethylene vinyl acetate, and polyvinyl chloride among others [4,48,54].

Clear aligner materials have evolved from single-layered or monophasic plastic to second-generation polyurethane materials, to the currently used third-generation multilayered materials that often comprise hard and soft layers. While the soft layer imparts the property of elastic deformation allowing smooth seating of the aligner, the hard layer ensures strength and durability [55].

Among polyesters, polyethylene terephthalate (PET) and polyethylene terephthalate glycol (PETG)- a non-crystallizing amorphous copolymer of PET, are extensively employed in the production of clear aligners primarily due to their excellent mechanical and optical properties [56]. Polyethylene terephthalate (PET) combines ethylene glycol with terephthalic acid and exists in both amorphous and crystalline forms, and the form type influences the material properties [57]. PET can be drawn into tapes, films, or fibres and is frequently used as a substitute for grafts and the fabrication of vascular prostheses. The amorphous structure of PET is transparent and demonstrates superior ductility, whereas the crystalline structure is opaque and white and exhibits hardness, stiffness and good strength [58]. PET can be rigid or semi-rigid depending upon the processing methods employed and displays excellent mechanical properties, toughness, and resistance against various solvents [21].

PETG is a non-crystalline co-polyester, comprised of 1,4-cyclohexane two methanol (CHDM), ethylene glycol (EG) and terephthalic acid (TPA) [59]. PETG shows excellent transparency, adequate flow property, and resistance against various solvents and can either be punched, die-cut, printed or hot stamped. PETG materials are exceptionally durable, have high impact strength, are resistant to chemical changes and are materials of choice for the fabrication of complex and intricate designs. PETG is an altered form of PET that transforms PET from a semicrystalline to an amorphous state, enabling the material to be more transparent and esthetic. The glass-transition temperature (Tg) of the material is around 80°C, allowing better handling of the material with features that resemble glass [60]. The improved transparency, mechanical, and optical properties make PETG a suitable material for the fabrication of clear aligners.

Thermoplastic polyurethane (TPU), primarily composed of di- and tri-isocyanates, and polyols [61] is another extremely versatile polymer that exhibits multiple favourable properties such as excellent mechanical and elastomeric characteristics, chemical and abrasion resistance, adhesion properties as well as simplicity of machining [48,62]. When subjected to load, TPU changes its shape but can recover its original shape when the load is removed and is able to elongate and recover due to the material's flexibility. The material also exhibits high tear resistance and a wide range of resiliency [59]. As stated previously, in 2013 Invisalign aligners transitioned from a single-layer of polyurethane, Exceed-30 (EX30) to a new polymer, SmartTrack™ (LD30)- a multilayer aromatic thermoplastic polyurethane/copolyester [5]. According to Aligntech, the new material should provide the aligners with more elasticity and produce more constant forces, thereby improving their clinical efficacy [49,54]. However, both materials show structural modifications that resulted in increased sample hardness and hyper-plasticity [25]. In terms of clinical outcomes presented by Peer Assessment Rating (PAR) score reduction, there were no significant differences between the two types of aligners [63].

3.2. Polymer blends

Thermoplastic orthodontic clear aligners should ideally exert continuous and controlled forces to produce intended tooth movements [48]. The mechanical properties of the polymers can be improved by mixing different types of polymers such as polyester, polyurethane, and polypropylene. Polymer blends of these three polymers are commonly employed in the commercial manufacturing of clear aligners [48,54]. Multiple studies on thermoplastic polymer blending have shown that polymer blends demonstrate improved mechanical and chemical properties, eventually enhancing the clinical performances of clear aligners [48,[64], [65], [66], [67], [68]].

The ratio employed for blending polymers significantly influences the features of the polymer blend. For instance, blending PETG/polycarbonate (PC)/TPU at a ratio of 70/10/20 resulted in better mechanical properties in comparison to other blending ratios, and was shown to exhibit sufficient and sustainable orthodontic forces than other commercialized products [48]. Similarly, PETG/PC2858 blended at a 70/30 ratio, expressed the best combination of tensile strength, impact strength and elongation at break [67].

3.3. 3D printed aligner materials

The potential advantages and the materials employed for 3D printed aligners were discussed previously. Direct 3D printing can avoid adverse effects of thermoforming processes, such as alteration of mechanical, dimensional and esthetic characteristics of the material [69], offering better geometric accuracy and precision, better fit, higher efficacy and mechanical resistance and reproducibility [45,70]. Materials utilized for 3D printing in orthodontics include acrylonitrile-butadiene-styrene plastic, stereolithography materials (epoxy resins), polylactic acid, polyamide (nylon), glass-filled polyamide, silver, steel, titanium, photopolymers, wax, and polycarbonates [71]. Various studies have investigated the mechanical and biological properties of resins suitable for 3D printing clear aligners [70,72]. Tera Harz TC-85 is a photopolymer material introduced by Graphy to overcome the current limitation of thermoforming sheet type aligners and the Tera Harz direct aligner can be 3D printed directly with a 3D printer. Tera Harz TC-85 is bio-compatible photopolymer material and is available in two colours as clear and white. TC-85DAC (clear) is fully transparent, whereas TC-85DAW (white) provides durability and aesthetics. In addition, Graphy Inc, claims that it can supply customized colours to meet specific needs [73].

3.4. Bioactive materials used with clear aligners

Microbial accumulation is a common problem during orthodontic treatment and studies have demonstrated elevated levels of presence of major oral pathogens, such as S. (streptococcus) mutants and P. (porphyromonas) gingivalis, during orthodontic treatment. Various attempts have been made to increase the antimicrobial properties of orthodontic appliances, and subsequent research on the application of nano-antibacterial materials in orthodontics is also increasing [74].

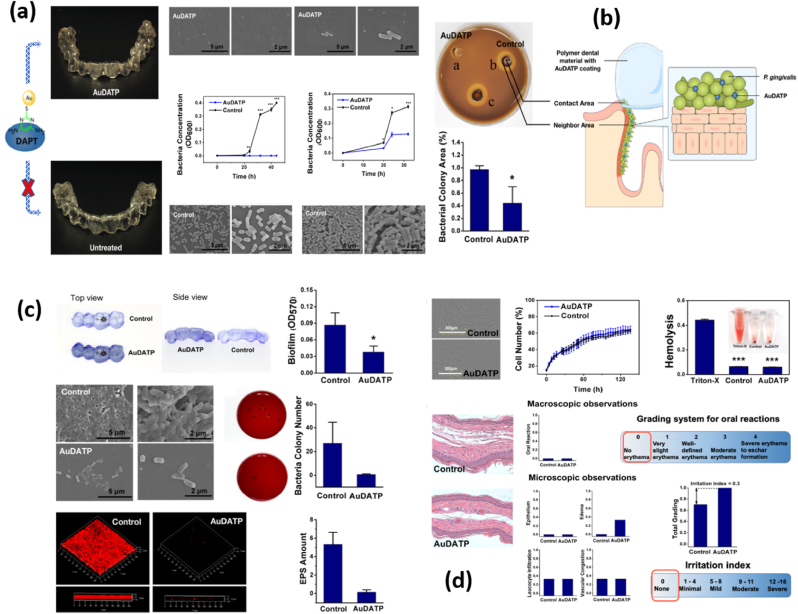

Despite the claims of proponents of clear aligner therapy, who extol aligners as a more hygienic alternative over FA due to the likelihood of facilitating better oral hygiene, the fact that patients’ teeth and gingiva are fully covered with aligners nearly the entire day, (with patients being typically instructed to use aligners 20–22 h a day except for a short removal period for food and cleaning) might increase the risk of bacterial growth and subsequent damage to the teeth and adjacent periodontal tissues. A randomized clinical trial (RCT) [75] that attempted to answer the question-of which orthodontic appliance is best for oral hygiene, clear aligners, self-ligated brackets, or conventional brackets; found no difference among the three treatment groups in terms of short-term (9 months) and long-term (18 months) oral hygiene levels. However, with proper modification, clear aligners may be used as a long-term drug delivery system for patients with P. gingivalis infection [76]. In their pilot study, Zhang et al. coated 4,6-diamino-2- pyrimidinethiol-modified gold nanoparticles (NPs) (AuDAPT) over clear aligners which presented antibacterial effects on a suspension of P. gingivalis, affecting the neighbouring area of the materials, slowing biofilm formation and showing favourable biocompatibility (Fig. 3). The antibacterial action of gold NPs has broadened a new research terrain, while other mechanical, physical, and biological properties of NP-coated aligners still warrant further investigations [77].

Fig. 3.

Gold nanoparticle-modified dental aligner can prevent porphyromonas gingivalis biofilm formation: (a) SEM images of bacterial cells accumulated on the coated AuDAPTs sample surface compared to uncoated control when immersed into bacterial suspension of different density of bacterial suspension (104 CFU/ml and 105 CFU/ml). (b) Comparison of the bacterial growth area ratio of the AuDAPT-coated samples and untreated samples. (c) CV staining images, SEM images, and confocal images of biofilms formed on AuDAPTs and control sample surface. (d) Biocompatibility of AuDAPT-coated aligners compared with control [76].

Worreth et al. have introduced a cellulose-based clear aligner material loaded with essential oils, such as cinnamaldehyde, and the tested material demonstrated antimicrobial properties against Staphylococcus epidermidis as well as S. mutans and S. mitis clinical isolates [78]. A lesser amount of biofilm was noted to be formed at the interface between the growth medium and the coating. In addition to its antimicrobial effect, cinnamaldehyde has been proven to increase the hydrophobicity of some materials, thus potentially decreasing the early adhesion of the biofilm formers and delaying the formation of a mature biofilm.

Due to the limited number of resins available for SLA, attempts to develop acrylic-based potocrosslinkable resins with different compositions and characterization in terms of mechanical, thermal and biological behaviour have been taken [79]. However, current nanomaterials have not yet achieved the perfect balance of antimicrobial effect and biocompatibility. Studies focusing on the application of nano-antibacterial materials in orthodontic aligners are few and should be given more attention [76].

Thermoplastic polymers and polymer blends continue to dominate the commercial clear aligner market and the Invisalign clear aligner system continues to be the most widely used commercial clear aligner system. However, after the expiry of its patent, several clear aligner systems have been introduced. Table 1 has attempted to organize the data from commercial aligner manufacturer websites, material safety data sheets and previously published studies to summarize the material composition, aligner thickness and commercial claims of multiple, globally popular clear aligner brands.

Table 1.

Aligner material specifications, properties and commercial claims.

| No | Clear Aligner Brand Name | Commercial Manufacturer | Aligner Material Composition | Aligner Material Thickness | Aligner Material Properties and Commercial Claims | Associated Software |

|---|---|---|---|---|---|---|

| 1. | Invisalign https://www.aligntech.com/solutions |

Align Technology Inc, San Jose, USA |

SmartTrack™ Material: LD30 A multi-layer aromatic thermoplastic polyurethane from methylene diphenyl diisocyanate and 1,6-hexanediol plus additives |

Aligner thickness stated by the manufacturer after thermoforming is 0.75 mm. |

SmartTrack™ material: applies gentle, constant force to improve control of tooth movement Comfortable and fits snugly around the teeth In comparison to EX30 used previously, LD30 exhibits a more amorphous structure and a greater elastic recovery SmartForce™: customized attachments, bite ramps and power ridges SmartStage™ technology: programs sequential tooth movement to straighten teeth more predictably |

ClinCheck Global cloud-based treatment visualization |

| 2. | Clarity https://www.3m.com/3M/en_US/orthodontics-us/featured-products/clarity-eos/clear-aligners/ |

3 M ESPE Maplewood, USA | 3 M™ Clarity™ Aligners Flex Flexible 5-layer material 3 M™ Clarity™ Aligners Force: Rigid material Proprietary 5-layer copolymer blend |

Flex: 0.625 mm Force: 0.75 mm |

Clarity Aligners Flex indicated a wire-sequencing approach Recommended for correction of rotation and proclination, when used in two-material Clarity Aligners Force indicated for a segmental mechanical approach Recommended for expansion, torque, sequential bodily movement, and segmental intrusion, when used in two-material treatment designs Outer layers resist staining and scratching, inner layers provide flexibility and resilience Overall structure provides durability even with reduced thickness |

Tx Design (TxD) Oral Care portal |

| 3. | Clear Correct https://www.straumann.com/clearcorrect/en/patients/about-the-aligners.html |

Institut Straumann AG, Basel, Switzerland |

ClearQuartz Material: Zendura Polyurethane Tri-layer proprietary material |

0.75 mm | ClearQuartz material features an elastomeric layer between two resilient, low-porosity shells The outer layers allow the aligner to be tough and stain-resistant owing to its low porosity The shells also help grip the teeth firmly The inner layer is engineered to provide consistent and continual force due to its enhanced elasticity and enhances patient comfort ClearQuartz retains 10x more of its initial force than other aligners and retains its shape throughout the wear time of the aligner |

Clear Pilot ClearComm portal |

| 4. | Spark https://ormco.com/spark/ |

Ormco Corporation, Brea, USA |

TruGEN™ and TruGEN XR Material: | 0.75 mm | More sustained force retention Better surface contact area with the tooth More efficient and effective tooth movement Clearer, more comfortable and stains less |

Approver |

| 5. | SureSmile https://www.dentsplysirona.com/en-us/categories/orthodontics/suresmile-aligner.html |

Dentsply Sirona, York, USA |

Essix Plastics: Plus, C plus Polypropylene/ethylene copolymer (>95%), stabilizers (<5%) |

Plus: 0.035 and 0.040 C plus: 0.040 inches/1 mm |

Essix Plus Plastic combines clarity with durability It is effortlessly removed from models and trims with ease Essix C plus: When making retainers and aligners for bruxers, a more flexible plastic provides additional strength to help withstand mastication pressure |

SureSmile Aligner |

| 6. | Argen Clear Aligners https://argen.com-clear-aligners |

Argen Corporation, San Diego, USA |

Argen Clear Aligners are made from premium thermoformed plastic material consisting of elastomeric layer encased in a dual shell construction |

Unspecified | Engineered for a precise fit, ongoing force retention, and exceptional durability Premium Material – a continual force for faster treatment and greater comfort for patients Improved Stain Resistance – starts clear, stays clear The consistent pressure produced by the dual-shell construction accurately moves teeth over the prescribed period of time |

Unspecified |

| 7. | Reveal https://www.henryschein.com/us-en/dental/supplies/reveal.aspx |

Henry Schein, Melville, USA |

Proprietary ClearWear™ material | Unspecified | Provides ultimate in aesthetics with precise force levels for speed of treatment Superior clarity compared to other aligners Guaranteed not to stain or cloud Zero to minimal unsightly attachments |

DDX SLX Approver portal |

| 8. | Nuvola https://www.nuvolaworld.com/nuvola-clear-aligners |

GEO Srl Rome, Italy |

Polyethylene terephthalate glycol (PET-G) | 0.75 mm | Tough and elastic Resistant to the aggressive chemical agent Proof against wear and tear Precisely designed to fit firmly Easy to wear and maintain Fidelity to their original conformation Long-lasting transparency and hygiene |

Unspecified |

| 9. | F22 https://www.f22aligner.com/en/ |

Sweden and Martina Company, Padua, Italy |

F22 Polyurethane: Evoflex: |

0.75 mm | An innovative polymer that ensures up to 17% greater transparency than other aligners on the market | Unspecified |

4. Properties of clear aligner materials

Thermoplastic materials employed for the fabrication of clear orthodontic aligners are primarily polymers that demonstrate differing characteristics and which respond varyingly to the multiple types of stress associated with the oral cavity, such as the mechanical stress associated with functional and parafunctional movements, thermal stress associated with the aligner thermoforming process and with exposure to oral temperature changes and the chemical stress created by exposure to saliva as well as and consumption of various beverages [67,80].

An ideal aligner material should exhibit high resilience, low hardness, sufficient elasticity, adequate resistance to varied stress and distortion, excellent transparency, low cytotoxicity, and high biocompatibility [67]. This paper investigated scholarly literature to comprehensively review how the properties of an ideal aligner material can influence the clinical performance of clear aligners for orthodontic treatment.

4.1. Mechanical properties, stress relaxation phenomenon and the physical performance of clear aligner materials

Thermoplastic materials in general follow Hooke's law when subjected to forces of short duration, indicating that within the elastic limit of the stress-strain curve, when the stress is proportional to strain; the material exhibits an elastic behaviour with a return to its original size and shape on the removal of applied stress [81]. The yield strength of a material can be described as the stress beyond which the strain is no longer proportional to stress and the material will no longer be elastic and instead behave as plastic. The ultimate tensile strength is indicated by the stress at which the material ruptures and the toughness of the material is defined as the energy absorbed by the material before it ruptures, which can be calculated by the area under the stress-strain curve. Thermoplastic materials with higher yield strength, higher ultimate tensile strength and higher toughness are desirable for the fabrication of clear aligners.

The modulus of elasticity or Young's modulus is a measure of the stiffness of a material and can be defined as the ratio between stress and corresponding strain. An aligner material should ideally possess adequate stiffness to exert the forces and moments needed to achieve the planned tooth movement. If the material used for aligner fabrication exhibits a very high modulus of elasticity (or high stiffness), then the resultant aligner would be very stiff leading to difficulty in aligner placement and removal for the patient. Likewise, a material with low stiffness will not be able to generate adequate forces required to move teeth [81].

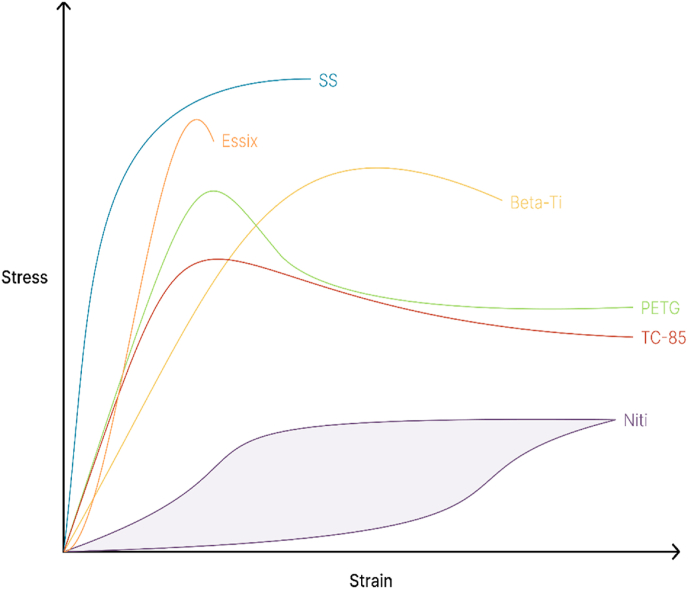

A material that can be easily deformed with minimal force can be described to possess low resiliency, which is the ability of a material to absorb energy when it is elastically “loaded” or deformed, and release that energy when “unloaded,” without causing permanent deformation of the material. The measure of resiliency is the point beyond which the material undergoes some amount of permanent deformation. Unloading can be described as the measure of the force exerted by a material to move teeth [82]. Aligners absorb less energy since they deform permanently under moderate-to-heavy loads [83] and exhibit considerably less resiliency as compared to metal archwires [84]. Clinically, dental crowding that can be resolved by a single nickel-titanium archwire, requires multiple aligners to correct the same. Metal archwires are good at storing energy (loading) and transferring (unloading) this energy to teeth over a period of time while undergoing minimal fatigue. Fig. 4 illustrates a relative comparison of the stress-strain curves of different orthodontic materials [52,81,85,86].

Fig. 4.

An illustration of the relative comparison of the stress-strain curves of different orthodontic materials does not reflect absolute values. It is based on the reference data from the literature [52,81,85,86]. SS, stainless steel. Beta-Ti, Beta titanuim. Niti, Nickel titanium. Essix, clear retainer material. PETG, polyethylene terephthalate glycol (thermoplastic aligner material). TC-85, photocurable resin (3D-printed aligner material).

When thermoplastic materials are subjected to long-term forces, they do not follow Hooke's law, and instead, exhibit ‘viscoelastic’ properties showing a time-dependent relationship between stress and strain [81]. Clear aligner materials are ‘viscoelastic’ in nature, with their properties constituting the middle ground between the properties of purely viscous and purely elastic materials. The behaviour of viscoelastic materials can vary significantly over time when subjected to a load such as the initial placement of an aligner onto the dentition and even before any of the planned tooth movement has been initiated [50]. The little energy that aligners absorb, is then mostly dissipated as heat with a relatively small amount being actually transferred to the dentition. Viscoelastic materials can absorb shock, vibrations, and force [49] and this nature allows the aligner to deform and stretch and generate forces required for the programmed tooth movement when the aligner is fitted onto the dentition.

The deflection of viscoelastic materials increases over time when subjected to constant loads, whereas constant deflection occurs if the load decreases and this phenomenon is termed stress-relaxation [49]. Stress relaxation results in a reduction of the forces exerted by the aligner when placed onto the teeth, maintaining a constant deflection rate before tooth movement begins, and this relaxation depends on the characteristics of the material of aligners and the magnitude of the applied force.

Stress relaxation, a time-dependent decrease in stress under a constant strain, is presumably the most crucial factor in determining the efficiency of clear aligners and can be observed by applying a fixed amount of deformation to material and measuring the load required to maintain it, as a function of time [87]. Stress relaxation is basically a measure of the constancy of force delivered over a period of time [87] and although maintaining a constant force is desirable in orthodontics [88], aligner materials do not seem to provide this admirably. The reduction in force noted with clear aligners is not linear with time, but quite exponential, translating to a dramatic force drop in the first few hours of aligner use, indicative of material fatigue [49]. In comparison, a nickel-titanium archwire at similar or greater stress levels remains active for weeks [89] and this force drop should be taken into consideration while planning treatment with aligners [90,91].

Lombardo and co-authors [49] examined the mechanical characteristics and investigated the stress relaxation of four different types of aligner materials, two single-layer materials based on PETG and polyurethane and two multilayer materials. All the samples were subjected to a constant load for 24 h in a humid environment and at a constant temperature after an initial resistance test. Study results showed that while monolayered materials exhibited significant resistance to absolute stress and stress relaxation speed; the multi-layered ones demonstrated a constant stress relaxation and an absolute stress resistance that was four times lower than that of the monolayered ones. Further, all four materials demonstrated significant relaxation to rapid stress in the first 8 h, which tended to plateau for some materials and decreased for others at a 24-h point. The polyurethane-based monolayer material produced higher initial stress values and a high decay rate, whereas monolayer PETG material showed the most significant stress relaxation rate during the 24 h. Multilayered materials generally displayed lower stress relaxation rates and lower initial stress values than monolayered materials.

In clinical situations, aligners are subjected to both short-term and long-term forces in the oral cavity. When an aligner is fitted onto the dentition, the aligner material is loaded with short-term forces, after the immediate fit-in. On the other hand, when the aligner is worn by the patient for a significant duration, it experiences long-term forces due to the displacement caused by the planned tooth movement and the reactionary forces generated by the musculoskeletal system [92].

With time, the force generated by the aligner material for the same deformation, decreases, due to its viscoelastic nature. This stress relaxation process is affected by the actual composition of the thermoplastic material, the temperature of the oral cavity, the magnitude of the force to which a specific part of the aligner is subjected to as well as the thickness of the material used for the fabrication of the aligner [80]. Further, the forces that aligners apply must be within the biological limitations of what human teeth can tolerate. These stress values can also help with the selection of the thickness of the aligner sheet.

Polyether compounds have been found to be tougher than polyester urethanes and have greater moisture resistance and dynamic characteristics. They also perform better at low temperatures. On the other hand, polyether materials have the lower abrasion resistance and are more likely to tear [93].

The factors highlighted above provide a fundamental understanding of the key features of clear aligners in terms of force delivery, magnitude, constancy, and decay. Aligners can be summarized to display the following characteristics: (i) apply low forces; (ii) perform better with lesser activations; (iii) exhibit low flexibility; and (iv) undergo rapid force decay [42].

4.2. Thermal properties and the influence of the thermoforming process on clear aligner behaviour

Thermoplastic materials are linear or slightly branched polymers with strong intramolecular covalent bonds and weak intermolecular Van der Waal's forces. These bonds melt and the polymers overflow at elevated temperatures and the molecular chains subsequently solidify into new shapes when cooled. Thermoplastic materials do not undergo further chemical changes at altered temperatures, hence the process of softening with heating and hardening with cooling may be repeated. In solid-state, the thermoplastic materials used for making clear aligners are semi-crystalline with amorphous strands of polymers dispersed in between. The crystalline polymers are more transparent with well-defined melting points and glass transition temperature [49]. The ability of the aligner material to adapt or conform to the models during the thermoforming process is an important requirement of an aligner material. At a defined temperature of around 110 °C, the adaptation ability of polyurethane material has been found to be superior to that of other materials [94,95].

Multiple studies have elucidated that the transparency, hardness, and thickness of aligner material, exhibit changes after being subjected to the thermoforming process during clear aligner fabrication [69, 96]. Ryu et al. [69] investigated the thickness and the transparency of aligner materials before and after the thermoforming process and demonstrated changes in four different types of clear aligner materials (two of which were copolyester-based: Essix A+ and Essix ACE, and the other two, PETG-based: Duran and ECligner). Study results revealed that thermoforming reduced the transparency of thermoplastic materials. Post-thermoforming, the transparency of the eCligner samples of 0.5 and 0.75 mm thickness respectively, was remarkably reduced compared to that of Duran and Essix A+ samples of the same thickness. The 0.75 mm thick Essix ACE sample, exhibited a significant reduction in its transparency as compared to the Ecligner material of 0.75 mm thickness. Similarly, the transparency of Duran and Essix A+ samples were found to be significantly lower after the thermoforming process. The study results also showed that the hardness of all four materials did not show a significant difference compared to their pre-thermoforming values. A significant increase in solubility in water was noted for Duran, Essix A+ and Essix ACE samples, unlike the eCligner sample, and the hardness of Essix A+ and Essix Ace samples was also noted to be lesser than that of the eCligner sample after thermoforming. Finally, Essix A+ and Essix ACE samples showed higher surface hardness post the thermoforming process.

Another study by Bucci and co-authors [96] in 2019, investigated two types of aligners, a passive and another active PETG material of 0.75 mm thickness, and found that the thermoforming process altered the thickness of clear aligners. After the thermoforming procedure, variable thicknesses were noted throughout the occlusal surface of the clear aligner ranging from a minimum value of 0.38 mm to a maximum of 0.69 mm and these values were lower than the 0.75 mm thickness of the original PETG sheets before being thermoformed. However, the authors mentioned that the variation in thickness does not seem to adversely affect the clinical performance of clear aligners.

An in vitro study by Dalaie and co-authors [97] investigated the changes in the thermomechanical properties of two PETG aligner sheets of two different thicknesses, 1 and 0.8 mm, after the thermoforming process; and concluded that the hardness of the material decreases by about 7.6% after thermoforming, for both types of material.

Thermoplastic polymers exhibit a Tg at which their rigid state transforms into a rubbery state. When the thermal properties of three commercial clear aligners (Invisalign [Align Technology, Inc., Santa Clara, CA, USA), Simpli5 [Allesee Orthodontic Appliances, Sturtevant, WI, USA], and ClearCorrect [ClearCorrect, Round Rock, TX, USA]) were compared, all three aligner systems were found to have a Tg above the accepted oral maximum temperature, with no significant differences observed before and after their clinical usage [98].

4.3. Optical properties, colour stability and clear aligner transparency

Aligner materials should exhibit good light transmittance and should ideally be able to transmit at least 80% of visible light for optimal clarity. Amorphous thermoplastic polymers exhibit high translucency and are thus preferred as clear aligner materials over crystalline polymers that are highly opaque and unaesthetic. Polyurethane, polyester, polyvinylchloride, polysulfone and polycarbonate are some of the polymers that demonstrate optical properties well suited for commercial aligner fabrication [99].

Aesthetics has played a vital role in the increased acceptance of clear orthodontic appliances and the transparency of a clear aligner is expected to remain consistent over a period of at least one to two weeks of intra-oral usage prior to an aligner change [33]. However, the transparency and colour stability of clear aligners are known to be affected by the consumption of coloured beverages, exposure to ultraviolet radiation, and use of mouthwashes [100].

Although clinicians recommend that patients remove their aligners to eat or drink (except water) to avoid pigment adsorption by the thermoplastic material, studies have demonstrated that often, many patients ignore these recommendations and consume food and/or beverages with the aligners in place, thereby undermining their transparency and consequentially their esthetics [100]. At least one study revealed that almost 50% of patients did not remove their aligners for eating and drinking [33].

Multiple studies have investigated the colour stability and transparency of clear aligners when exposed to colouring agents and saliva [33,97] evaluating various clear aligner materials such as multi-layered thermoplastic polyurethane with integrated elastomer (SmartTrack™), PETG material (Erkodur), co-polyester material (Essix ACE), two PET-based materials (Essix Plastic and Ghost aligner) and resin-based polyurethane material (Zendura). Visual inspection results on colour stability indicated that all the types of materials showed no colour change after 12 h of contact with colouring agents such as wine, coffee, black tea, cola and nicotine, except for SmartTrack™ material that displayed colour changes when subjected to coffee and red wine [33,97].

When the exposure time was increased to 7 days to different colouring agents, all the aligners showed only slight colour changes, however, immersion in coffee and black tea solution created a significant colour change for all the materials. Erkodur and SmartTrack™ samples displayed marked colour changes to coffee and black tea solution and SmartTrack™ also exhibit a substantial colour change after 7-day immersion in red wine. Immersion in a nicotine solution for 14 days, resulted in only minor colour changes for all the samples, whereas immersion in red wine for 14 days revealed enhanced colour variation, especially for Zendura and Essix P [33,97].

The colour change values of polyurethane-based Invisalign aligners have been found to be much higher than those noted for polycarboxylate and PETG-based aligners. Various studies have concluded that polyurethane is more susceptible to pigment adsorption and does not provide adequate colour stability. A clearer aligner was rated as more attractive, and a lower level of appliance display has been mentioned as necessary for societal acceptance [94,95].

4.4. Chemical resistance properties, the influence of the oral environment and clear aligner aging

Clear aligners are constantly exposed to saliva and its various enzymes apart from the temperature variations in the oral cavity and they are also sporadically exposed to beverages apart from water, all of which can adversely affect the chemical composition of their constituent thermoplastic polymers, thereby altering the aligner shape and/or its mechanical properties over time. Certain polyesters such as polycarbonates and polyamides may exhibit irreversible hydrolysis that may lead to the eventual degradation of their polymer structure, hence it is desirable that the polymers used for clear aligner fabrication are resistant to hydrolysis and water degradation [81].

An aligner is also subjected to continuous and intermittent forces associated with normal oral functions such as chewing, speaking, swallowing and parafunctional activities such as teeth clenching and grinding. An aligner material should be durable when exposed to the oral environment and possess high wear resistance to withstand masticatory and associated stresses to avoid distortion that can compromise its clinical performance [81].

Microcracks, delaminated areas, calcified biofilm deposits, and loss of aligner transparency have all been reported in Invisalign aligners that were used for 2 weeks [28,101]. An alteration in the fit of the aligner and a change in the resultant orthodontic forces exerted by the aligner can occur can as a result of intraoral hygroscopic expansion. Water absorption of thermoplastic materials has been shown to increase with time, with Invisalign aligner material showing the highest absorption values followed by PETG [102].

The temperature of the oral cavity can rise to 57 °C after the consumption of a hot beverage and it may take several minutes for it to return to its original temperature. These temperature changes have also been shown to affect the mechanical properties of thermoplastic materials [61], as evidenced by multiple in vivo and in vitro studies [61,96,97,102].

An in vitro study [102] compared eight different types of most commonly used thermoplastic materials (PETG (Duran), PC (polycarbonate, Imprelon”S″), PP (polypropylene, Hardcast), PUR (polyurethane, Invisalign), A+ (Copolyester, Essix A+), C+ (polypropylene/ethylene copolymer, Essix C+), PE (polyethylene, Copyplast), and EVA (ethylene-vinyl acetate copolymer, Bioplast)) from multiple commercial manufacturers and immersed them in a solution created to simulate the oral environment to assess the influence of oral environment on thermoplastic materials. The authors found that the elastic modulus of PETG, PC, and Essix A+ exhibited significant increases compared to the original samples on exposure to the intraoral environment, contrarily, the elastic modulus of PP, Essix C+, PE and EVA exhibited a significant reduction as compared to the original samples. No significant changes were observed in the PUR material. The same study also found an increase in the overall thickness of all thermoplastic materials due to water absorption.

The resistance of the thermoplastic material to surface cracking, when exposed to an oral environment comprising of cyclic stress is of paramount importance. Dalaie and co-authors simulated the temperature variations that occur in the oral environment through intermittent thermal cyclers for 22 h per day for 14 days and studied how the hardness, thickness and flexural modulus of two aligners (in PETG foil with thicknesses of 1 mm and 0.8 mm) vary in contact of the oral environment. Significant variations in hardness were noted only in the 0.8 mm thick PET-G sheet; not in the 1 mm ones This variation was attributed to changes in the crystalline and amorphous structures of the polymers or the release of plasticizers due to exposure to intermittent thermal cycling [97].

Another study [61] evaluated three thermoplastic materials- PETG (Duran), PP (Hardcast), and PU polymers (PU1, PU2, PU3) with different Tg and different crystalline structures and noted that the mechanical properties of each material were significantly reduced after 2500 thermal cycles. A significant decrease was observed for Hardcast material (crystal plastic) which had the highest Tg (155.5°) and PU1 (crystalline or semicrystalline plastic) with the lowest Tg (29.6 °C). Duran (73.3°), PU2 (56.5°) and PU3 (80.7°), with intermediate Tgs, exhibited more stable mechanical properties. The authors concluded that the mechanical properties of all thermoplastic materials decreased with the gradual temperature changes and that polyurethane polymers exhibited excellent shape memory throughout the range of intraoral temperature variations.

An in vivo study conducted by Bucci et al., in 2019 [96] considered the temperature variations in the oral cavity along with normal oral functions and parafunctional habits to which clear aligners are subjected. A series of passive and active aligners formed from PETG sheets were utilized in this study. Patients were instructed to wear these aligners for 22 h per day for 10 days and the study evaluated changes in aligner thickness over time. The authors found small reductions in the thickness of the aligners after 10 days but stated that these were not significant enough to affect the clinical performance of the clear aligners and opined that PETG demonstrated adequate stability in the oral environment.

4.5. Biocompatibility and cytotoxicity of clear aligners materials

As an intra-oral appliance material, thermoplastic polymers are expected not to leach out any potential toxins that may produce adverse local or systemic reactions, not be carcinogenic in nature and not produce any developmental defects [61].

The paucity of evidence-based literature due to few controlled trials with clear aligners and contradictory results mentioned in published literature continues to fuel the debate about the possibility of potentially toxic effects associated with the use of invisible aligners. Furthermore, the ever-burgeoning influx of multiple commercial aligner systems necessitates the continued need to test the cytotoxicity of orthodontic clear aligners produced by various manufacturers [50].

Allareddy and co-authors have summarized the adverse clinical events reported during the use of Invisalign aligners according to a retrospective analysis by the FDA. The most frequently reported adverse events associated with aligners, during a ten-year observation period included difficulty in breathing, sore throat, swollen throat, swollen tongue, hives, itchiness, and anaphylaxis [103].

Some in vitro studies have evaluated the potential cytotoxicity of thermoplastic materials used for the fabrication of various commercial clear aligner brands. The International Standards Organization (ISO) recommends the in vitro use of Human Gingival Fibroblasts (HGFs) cell lines to verify the biocompatibility of dental materials [104], as these cells are the primary cell lines present in the intra-oral tissues and are the most exposed to any toxic effects of the dental materials such as when the plastic aligners are in intimate contact with the periodontal tissues during patient use.

Ahrari and co-authors [105] investigated the cytotoxicity of four aligner materials- Duran (Germany), Biolon (Germany), Zendura (United States), and SmartTrack™ (United States) and found that Biolon showed the highest toxic effects on HGFs, followed by Zendura and SmartTrack™. Duran exhibited the lowest levels of toxicity. Table 2 shows that all the materials tested in the study exhibited low in vitro toxicity on the tested cells [104,[106], [107], [108]].

Table 2.

A summary of cell viability (cytotoxicity) at each time point (7 or 14 days) or solution concentrations (5%, 10%, and 20% vol/vol) of different clear aligner materials.

| Brand | Category | Composition | Cell viability (%) | Days or final solution concentration (% v/v) | Cytotoxicity |

|---|---|---|---|---|---|

| Duran [104] (Scheu-Dental GmbH, Iserlohn, Germany) |

Thermoformed | Polyethylen terephthalate glycol (PETG) |

84.6 ± 4.02 | 14 days | Slight |

| Biolon (Dreve Dentamid GmbH, Unna, Germany) |

Thermoformed | Polyethylene terephthalate glycol (PETG) |

64.6 ± 3.31 | 14 days | Slight |

| Zendura (Bay Materials LLC, Fremont, CA, USA) |

Thermoformed | Polyurethane resin (PU) |

74.4 ± 2.34 | 14 days | Slight |

| SmartTrack™ (Align Tech, San Jose, CA, USA) |

Thermoformed | Multilayer aromatic thermoplastic polyurethane/copolyester | 78.8 ± 6.35 | 14 days | Slight |

| E-Guard [106] (EnvisionTEC, Rockhill, SC, USA) |

3D printed | Photopolymer | 75.06 ± 8.98 | 7 days | Slight |

| Dental LT (Formlabsinc) |

3D printed | Photopolymer | 77.74 ± 3.22 | 7 days | Slight |

| SmartTrack™ (Align Tech, San Jose, CA, USA) |

Thermoformed | Multilayer aromatic thermoplastic polyurethane/copolyester | 94.07 ± 3.00 | 7 days | No |

| TC85A [107] (Graphy, Seoul, South Korea) |

3D printed | Photopolymerizable polyurethane | 97.6 ± 14.6 98.3 ± 15.9 92.0 ± 13.0 |

5% 4 10% 8 20% h |

No No No |

| SmartTrack™ [108] (Align Tech, San Jose, CA, USA) |

Thermoformed | Polyurethane | 82.6 ± 13.6 60.3 ± 8.8 54.5 ± 23.1 |

5% 7 10% 2 20% h |

Slight Slight Moderate |

| Eon (Eon Holding, Amman, JO) |

Thermoformed | Polyurethane resin (PU) |

85.1 ± 18.3 54.8 ± 16.8 60.4 ± 20.7 |

5% 10% 20% |

Slight Moderate Slight |

| Suresmile (Dentsply-Sirona, Charlotte, NC, USA) |

Thermoformed | Polyurethane resin (PU) |

85.4 ± 16.4 70.7 ± 15.8 56.8 ± 11.3 |

5% 10% 20% |

Slight Slight Moderate |

| Clarity (3 M, St Paul, MN, USA) |

Thermoformed | Polyurethane resin (PU) |

89.3 ± 15.0 72.9 ± 21.1 71.8 ± 15.4 |

5% 10% 20% |

Slight Slight Slight |

Cytotoxicity: No, cell viability more than 90%; Slight, cell viability 60%–90%; Moderate, cell viability 30%–59%; Severe, cell viability less than 30%.

Eliades et al. [109] evaluated the potential release of Bisphenol-A (BPA) from the thermoplastic material used for the fabrication of Invisalign aligners and demonstrated the non-existence of any estrogenic and toxic effects of aligner material on HGFs, which was in contrast to the slight toxicity levels documented by the previously mentioned study by Ahrari et al. [105].

Alexandropoulos and co-authors [110] have mentioned that the chemical composition of thermoplastic materials does not include elements necessary for the release of BPA and it is Isocyanate and not BPA, which is the component that could cause potential adverse effects. Another study found that tissue exposure to isocyanate release from Invisalign aligners can trigger deleterious oral health effects such as allergic contact reactions. On contacting oral tissues, isocyanates react by rapidly binding to cellular proteins and biomolecules, creating an immunogenic event that leads to a sensitization reaction in humans. Experiments have shown that the contact of the gingival epithelial cells with the thermoplastic material in a saline-based environment provoked an interruption of the membrane integrity, reduced cellular metabolism and reduced cell-cell contact capacity. However, these reactions did not occur in artificial saliva. Such studies provide valuable inputs in evaluating and controlling the cytotoxic effects of thermoplastic materials used for clear aligner fabrication [111]. A systematic review of the biological effects of 3D resins used in clear aligners or retainers also reveals that the evidence of the release of bisphenol A and other monomers, either in vitro or clinical studies, remains ambiguous due to few robust results in the current literature. There is an absolute need for further studies in these domains, especially given the possible implications for the fertility of young patients [112].

5. Emerging trends

5.1. Shape memory polymers

The efficacy of conventional aligner materials is restricted by the rate-limiting staging of the amount of tooth movement planned and built into an individual aligner [80,[113], [114], [115]] and material manufacturers aim to continually improve material type and resultant properties, thereby creating novel materials that can play an active role in the fabrication of orthodontic appliances [116]. Materials that can respond appropriately to various types of external stimuli such as electrical, thermal, or magnetic impulses among others, and generate a predictable and repeatable response are known as smart materials or stimuli-responsive materials [117].

Shape memory materials constitute a subset of smart materials that can display an alteration in their macroscopic shape upon the application of an appropriate stimulus; retain this temporary shape stably and recover back to their original shape on the re-application of another stimulus [118,119]. Shape memory polymers (SMPs), alternatively known as actively moving polymers, in turn, constitute a sub-category of shape memory materials [119,120]. The shape memory mechanism of SMPs relies on two crucial traits-the presence of a stable polymer network that determines the original shape of the material and a reversible polymer network that allows the material to transform to an altered or a temporary shape [121,122].

SMPs can display low density, considerable elastic deformation and high chemical stability; can be programmed to display adjustable physical properties and are relatively transparent, thus making them well suited to function as a novel clear aligner material, with the resultant aligner exhibiting a potential ability for significant self-shape recovery [116,123]. The shape memory effect in SMPs relies on the presence of a two-domain system that possesses two different glass transition temperatures; wherein one of the two domains is hard/elastic at room temperature and the other one is soft/ductile [124]. The shape memory mechanism in SMPs responsive to thermal stimuli relies on a reversible activation and deactivation of a polymer-chain motion in the switching segments respectively above and below a specified temperature termed as the transition temperature - that could either be their glass transition temperature or their melting temperature [116,122,125]. On reaching the transition temperature, the deformed shape memory material displays an elastic property to recover back to its original shape and this shape recovery in turn can generate forces that are able to produce orthodontic tooth movement [126].

SMPs could display more than one temporary shape, due to an extended shape recovery temperature range and a much higher recoverable strain level [121,127]. Shape memory polyurethane resins comprise polar and non-polar molecules that can distinguish into microdomains of hard and soft segments, the combination of which allows the material to achieve both high strength (from the hard segments) and high toughness (from the soft segments), facilitating the fabrication of durable orthodontic aligners that can move teeth over extended periods of time [128,129]. Further, the polyurethane resin is resistant to stain depositions enabling the aligner to stay clear in the intra-oral environment for a greater duration.

Elshazly and co-authors [130] conducted a preliminary, in vitro investigation of a clear aligner fabricated from thermal-responsive SMPs, to overcome the rate-limiting staging restriction of conventional aligner materials and demonstrate the possibility of using a single shape-memory aligner instead of three successive conventional aligners to achieve planned orthodontic tooth movement. This study involved the creation of a custom-made aligned typodont model with a movable upper central incisor and the generation of resin models utilizing orthodontic software and a 3D printer. Aligners were then fabricated by thermoforming ClearX sheets (0.76 mm thick, shape memory sheet material, supplied by Kline-Europe GmbH, Düsseldorf, Germany) on the resin aligned model and each aligner was tested for repositioning of the movable central incisor on the typodont model.

ClearX system sheets are fabricated from a thermo-responsive, shape memory, polyurethane-based thermoplastic material, which the manufacturers claim, possesses the ability to recover to its original thermoformed shape after a reforming step of thermal activation at a certain temperature for a pre-defined time duration. Initiation of the shape memory recovery was achieved by subjecting the aligner to an activation cycle by placing it in an activation device known as ClearX aligner booster (v. 2.1, Kline-Europe GmbH, Düsseldorf, Germany), a programmed electric device, that can be wirelessly connected and controlled by a mobile application (ClearX Mobil App. v. 1.1.4, Kline Europe GmbH, Düsseldorf, Germany), developed to create the needful medium required for the shape memory aligner to regain its original shape. The activation was achieved by immersing the aligner in hot water at 67C for 10 min within the container of the ClearX booster device. Models were scanned after each step and the corrective movement was measured through the superimposition of scans. Study results showed that the total correction efficiency of the aligner fabricated from the SMP material was approximately 93% (1.76 mm), with a corrective movement of 0.94 ± 0.04 mm after the reforming step, 0.66 ± 0.07 mm after the first activation step, and 0.15 ± 0.10 mm after the second activation step [130].

The authors [130] mentioned that although the results were promising, this study could only be considered as a proof of concept, due to the multiple limitations of an in vitro, typodont-based investigation. The study postulated that shape memory polymer materials could increasingly be used for the fabrication of orthodontic aligners and could enable the fabrication of a single shape-changing aligner that may be able to replace up to three successive conventional aligners. Consequently, the number of aligners used per orthodontic treatment could be reduced, reducing overall fabrication costs and the duration required for the correction of complex malocclusions [[131], [132], [133]] along with a reduction in the consumption of plastic. The study concluded that aligners made of SMPs could thus be a promising future choice for orthodontic clear aligner therapy.

5.2. 3D printed clear aligners

The current workflow for fabricating a series of clear aligners from a model either obtained from an impression, or a direct 3D intraoral scan, is cumbersome, labour intensive, and expensive [19,134,135]. Furthermore, studies have shown that the thermoplastic process employed for the fabrication of clear aligners can have several deleterious effects on the properties of the aligner material [44,69,96]. This has propelled the need for a more viable alternative to the conventional, thermoplastic, aligner fabrication process, which is currently being tested in the form of 3D direct printed clear aligners [44] using suitable resins.

3D printing, alternatively termed additive manufacturing, was conceptualized in the 1980s and now finds several applications in multiple disciplines of dentistry that enable dentists to custom design and print dentures, orthodontic appliances, maxillofacial prostheses and orthognathic surgical guides [49]. Fig. 5 & Fig. 6 demonstrate clinical applications of 3D printing of a surgical guide and the use of 3D printed stent in orthodontically treated multidisciplinary cases, respectively.

Fig. 5.

A multidisciplinary case treated with orthodontic appliance and 3D direct printed stent aided periodontal surgery. (a) Intra-oral photos before treatment. (b) Intra-oral photos after treatment. (c) 3D design simulates the amount of crown lengthening procedure. (d) 3D printer and 3D direct printed stent. (e) Frontal close-up view of before, during, and after the procedure. (f) Frontal smiling photos before and after orthodontic-periodontal combined treatment.

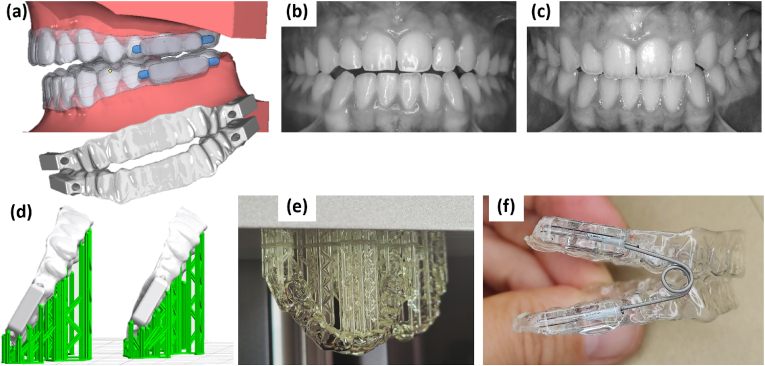

Fig. 6.

A multidisciplinary case treated with orthodontic appliance and 3D Digital Smile Design, digital wax-up and direct printed periodontal crown lengthening guide, and restorative stent for injection moulded composite restoration.

3D printing permits a layer-by-layer production of pieces, rather than relying on machining, moulding, and other subtractive methods [136]. An application of 3D printing during the production of thermoformed clear aligners is the 3D printing of the dental model on which an actual clear aligner is later thermoformed; this process led to a reduction in geometric inaccuracies and other errors associated with manual impression making [42]. Just as digital impressions and 3D printing of models proved superior to manual impressions and plaster models, clear aligners that are 3D printed directly may eliminate the cumulative errors resulting from analog impressions and the subsequent thermoplastic workflow [42]. Direct 3D printing shows promise for greater accuracy, shorter supply chains, significantly shorter lead times, and lower costs apart from being a more sustainable process that generates significantly less waste than subtractive and thermoforming processes [43]. 3D printed aligners are supposed to have better fitting accuracy compared with thermoforming clear aligners since some studies have reported significant changes in material properties due to the thermoforming process, which will decrease the force and regular thickness and affect the fitting accuracy of the aligners [45,69,134]. While a study examining the accuracy of 3D printed retainers compared with conventional vacuum-formed and commercially available vacuum-formed retainers has shown that average differences of the conventional vacuum-formed retainers ranged from 0.10 to 0.20 mm. The commercially available and 3D-printed retainers had ranges of 0.10–0.30 mm and 0.10–0.40 mm, respectively. The 3D printed retainers showed the greatest deviation although it is accepted to be clinically sufficient [137]. Despite the advances in different 3D printing technologies, there is a dearth of suitable materials for such printing for clinical use and consequently, literature on the materials and their properties is scarce as well.