Abstract

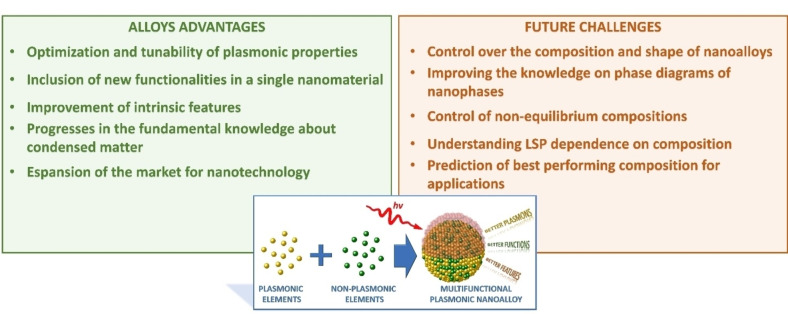

Despite the traditional plasmonic materials are counted on one hand, there are a lot of possible combinations leading to alloys with other elements of the periodic table, in particular those renowned for magnetic or catalytic properties. It is not a surprise, therefore, that nanoalloys are considered for their ability to open new perspectives in the panorama of plasmonics, representing a leading research sector nowadays. This is demonstrated by a long list of studies describing multiple applications of nanoalloys in photonics, photocatalysis, sensing and magneto‐optics, where plasmons are combined with other physical and chemical phenomena. In some remarkable cases, the amplification of the conventional properties and even new effects emerged. However, this field is still in its infancy and several challenges must be overcome, starting with the synthesis (control of composition, crystalline order, size, processability, achievement of metastable phases and disordered compounds) as well as the modelling of the structure and properties (accuracy of results, reliability of structural predictions, description of disordered phases, evolution over time) of nanoalloys. To foster the research on plasmonic nanoalloys, here we provide an overview of the most recent results and developments in the field, organized according to synthetic strategies, modelling approaches, dominant properties and reported applications. Considering the several plasmonic nanoalloys under development as well as the large number of those still awaiting synthesis, modelling, properties assessment and technological exploitation, we expect a great impact on the forthcoming solutions for sustainability, ultrasensitive and accurate detection, information processing and many other fields.

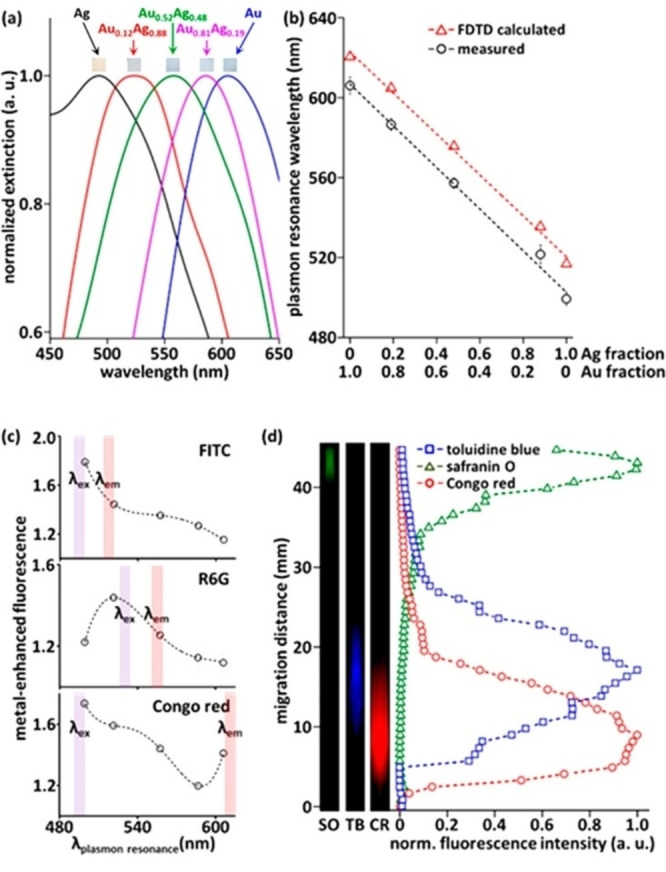

Keywords: alloy nanoparticles, bimetallic nanoparticles, plasmon resonance, density functional calculations, photocatalysis

Developing plasmonic nanoalloys: In this review, we give a general overview of the most recent advances in synthesis, modelling, properties assessment, and technological application of plasmonic nanoalloys.

1. Introduction

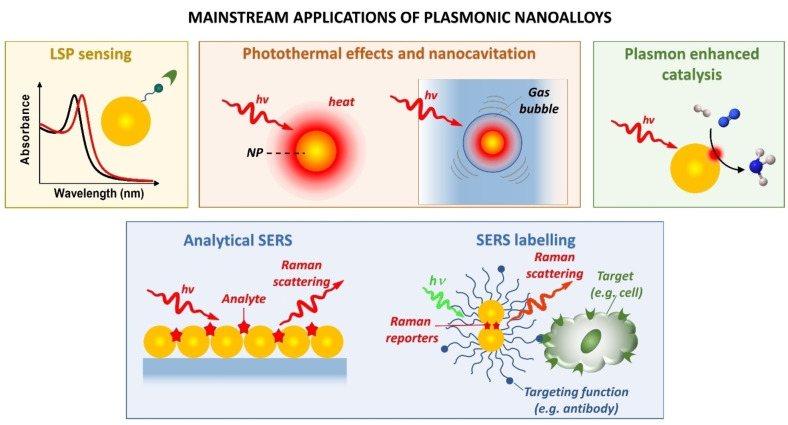

Plasmons are collective oscillations of free electrons, which can be promoted by electromagnetic light in nanoscale metals, where they have not‐propagating nature and are usually defined as localized surface plasmons (LSPs).[ 1 , 2 ] Over the last decades, plasmon excitations were exploited for an impressive range of technological applications and research studies, principally in sensing, [3] biotechnology, [4] light‐enhanced catalysis, [5] thermoplasmonic effects, [6] fundamental studies connected to local electric field enhancement of optical processes [2] and modelling of the interaction with nearby molecules down to the atomic level. [7]

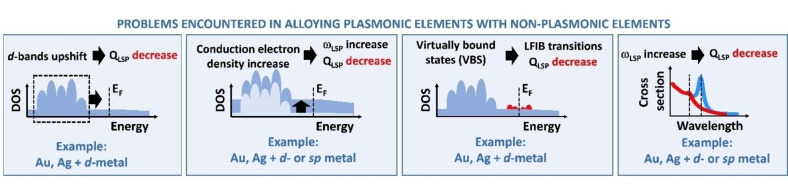

Although all materials with conduction electrons can potentially originate plasmons, only a few of them are chemically stable as nanostructures and provide plasmon resonances with appreciable intensity at optical frequencies.[ 8 , 9 , 10 ] Most metals undergo oxidation or degradation in ordinary conditions, such as Na, K or Al. Almost all the other elements have a poor plasmonic response, quantifiable by the plasmonic quality factor at optical frequencies.[ 8 , 9 , 11 ] This has restricted most of the studies about plasmonics to the nanostructures made of gold and silver, missing all the range of chemical, physical and other properties (low cost, earth abundance, sustainability, magnetism, chemical selectivity…) available from the periodic table. This problem is frequently raised due to the necessity of cheaper and alternative nanomaterials with, for instance, plasmonic and catalytic or plasmonic and magnetic properties. The simultaneous presence of these features in a single nanoparticle (NP) makes these nanosystems highly promising for several frontier research endeavours.

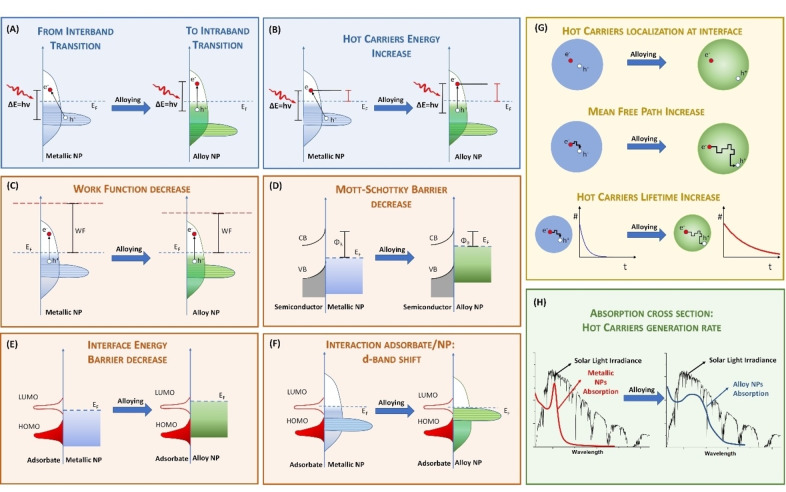

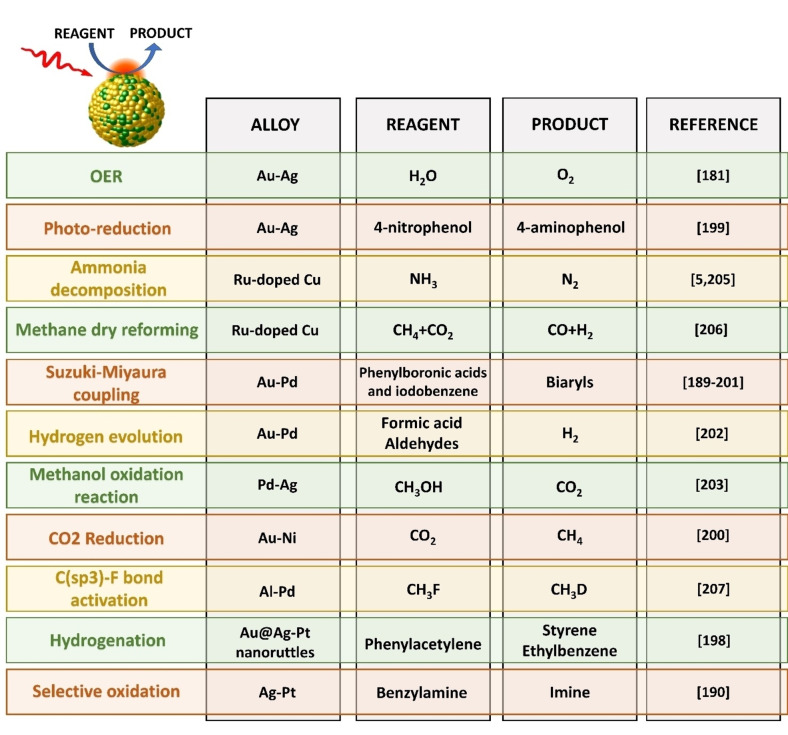

Alloying is a strategy to re‐introduce the range of properties of the periodic table into nanostructures with an appreciable plasmonic response (Figure 1).[ 12 , 13 ] It is well known that alloying two or more metals leads to new materials with properties that are not simply the average of their monometallic counterparts. In effect, this approach can open the way to multifunctional plasmonic objects of great appeal for several applications and can offer the opportunity of moulding the electronic structure of the metal to improve and maximize the efficacy for a specific plasmonic effect. In special cases, alloying can be associated with novel and still unexplored physical or chemical phenomena mutually influenced by the collective excitation of conduction electrons with light. Alloying allows the change of some undesired features connected to a plasmonic material such as cost, chemical instability, and sustainability of the final device. This scenario should not be limited to “volume” properties of a nanomaterial but also concerns the surface properties and, in particular, the surface chemistry of nanoalloys, which is markedly modified compared to single element nanoparticles (NPs).

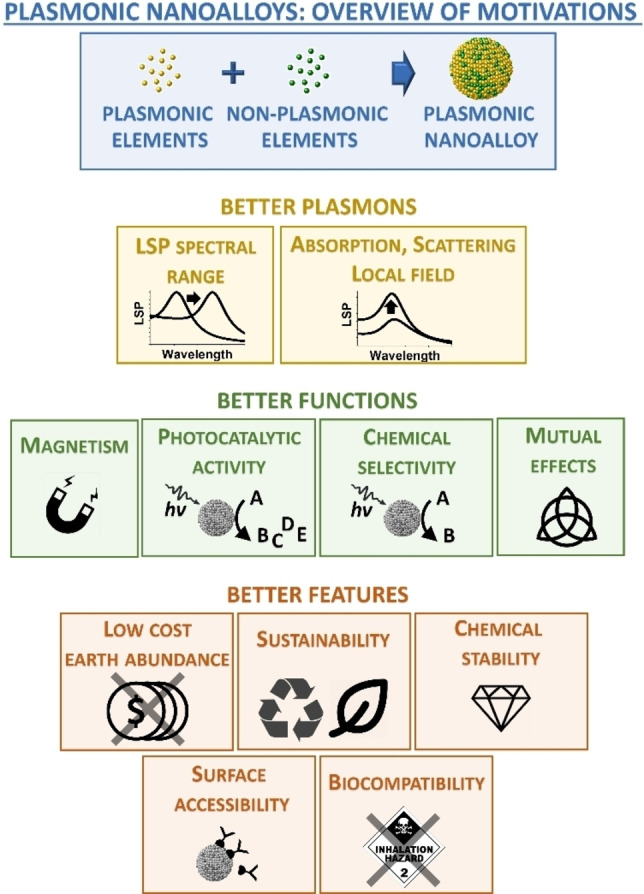

Figure 1.

Overview of the main motivations for the realization of plasmonic nanoalloys: achieving better plasmonic properties, better non‐plasmonic or hybrid plasmonic functions and better overall features compared to single element NPs.

To have an idea of the possibilities opened by alloying a plasmonic metal with one or more plasmonic or non‐plasmonic elements, one should think also about the range of atomic ratios in which each alloy can be achieved. Moreover, one also needs to consider the size, shape and environment (substrate, surface coating, etc.) as additional parameters.

On the other hand, several challenges can be identified in the field of plasmonic nanoalloys, especially concerning the synthesis with advanced control of composition, crystalline order, size, product implementation in the desired matrix. The achievement of metastable phases and disordered compounds is another crucial point because most of the possible element combinations are not thermodynamically favoured.

For these reasons, the modelling of the electronic, structural and optical properties is necessary to the development of new plasmonic nanoalloys in a more efficient and fast way than allowed by random experiments or the intuition of materials scientists. Indeed, also the modelling of nanoalloys structure and properties still suffers from a gap concerning the accuracy of results, the reliability of structural predictions, the development of suitable models for describing disordered phases on the nanoscale and their evolution over time, especially in operating conditions such as during a catalytic reaction or under photothermal heating.

Whilst there have been a few previous reviews on specific aspects of the topic,[ 2 , 8 , 13 , 14 , 15 ] here we provide a general overview of the latest achievements in the field of plasmonic nanoalloys, organized according to synthetic progresses, modelling strategies, prominent plasmon‐related properties and recently reported applications, with a special focus on plasmon‐enhanced catalysis, sensing and biotechnology.

The general aim of this review is that of fostering the research on plasmonic nanoalloys, either those already under development or the large number of those still waiting for synthesis, modelling, properties assessment and technological exploitation, which we expect will greatly impact the fields of sustainability, ultrasensitive and accurate detection, information processing and many others in the next future.

2. Synthesis of Plasmonic Nanoalloys

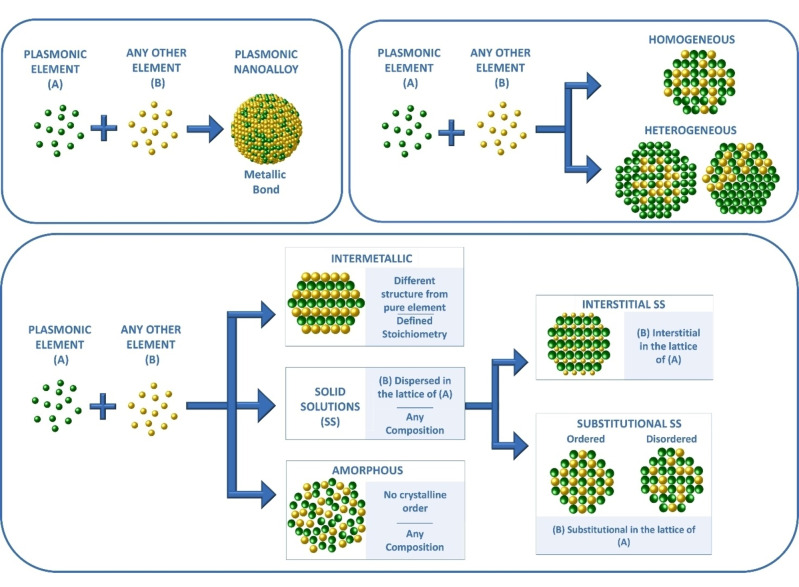

A (metallic) nanoalloy is a nanostructure composed of a mixture of elements of which at least one is a metal, all held together by metallic bonding (Figure 2). [16] Homogeneous (i. e. single phase) alloys can be classified according to the atomic arrangement of their constituents as solid solutions (SS) or amorphous. [17] A SS has a well‐defined crystal structure in which the lattice of a host element contains the guest elements as substitutional or interstitial dopants. Substitutional SSs can be disordered (the guests occupy random positions in the unit cell) or ordered (the guests are at fixed positions in the unit cell). SSs are distinguished from alloys with a well‐defined stoichiometry and a crystalline structure differing from that of single constituents, which are called intermetallics. On the opposite side, amorphous alloys do not have crystalline order (i. e. glassy metals). [18] When multiple homogeneous alloy phases coexist in heterostructures with various arrangements (Janus, dumbbells, core‐shells, matrix with embedded domains, etc.), the alloy is defined as heterogeneous. Heterogeneous alloys are frequent and, indeed, the homogeneity of products represents one major challenge in the synthesis of several nanoalloys.

Figure 2.

Classification of plasmonic alloys: the metallic bond between atomic constituents is a prerequisite. Their structure can be homogeneous or heterogeneous. The homogeneous domains can be amorphous, intermetallic or solid solutions (interstitial or substitutional).

It is worth stressing that, according to the definition of alloy provided above, the plasmonic materials based on multinary semiconductor nanocrystals are beyond the scope of this review, because of the non‐metallic nature of the chemical bond and, consequently, a density of conduction electrons which is orders of magnitude lower than in metals. Indeed, this also implies a much lower plasmonic response such as an extinction cross‐section for unit volume several orders of magnitude lower in plasmonic semiconductors than in metallic NPs, with a consequent lower capability of generating local electromagnetic field enhancement and light‐harvesting effects. Besides, non‐metallic plasmonic nanostructures were already reviewed recently.[ 19 , 20 ]

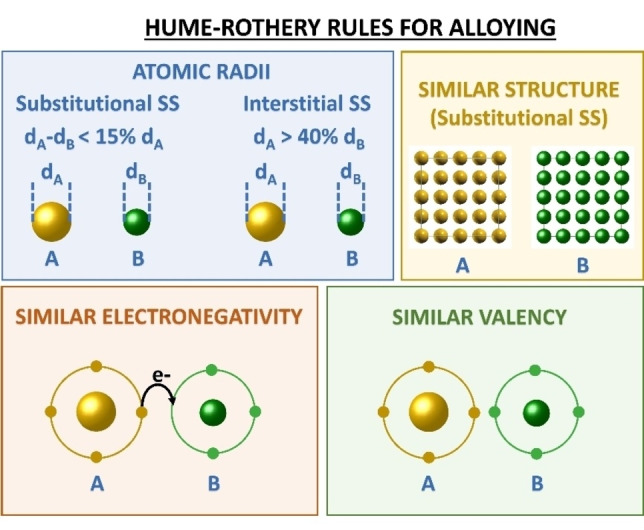

The Hume‐Rothery rules identify some key parameters for the formation of alloys, [17] such as the difference of atomic radii (<15 % for substitutional SSs and >40 % for interstitial ones), electronegativity and valency (as close as possible) and, for substitutional SSs, the crystal structure of the pure constituents, which should be similar (Figure 3). Nonetheless, metastable alloys are possible and frequent whenever the synthetic procedure allows freezing the system in a nanophase which is a relative thermodynamic minimum. Besides, the Hume‐Rothery rules do not consider the technical problems connected to the synthesis or the stability at ambient conditions when some of the alloy elements undergo oxidation very easily. This is the main issue for most of the elements in the periodic table, which are base metals with low oxidation potentials (i. e., easy loss of electrons).

Figure 3.

Hume‐Rothery rules prescribe that alloying depends on atomic radii, crystalline structure, electronegativity and valency of the pure elements.

In plasmonic nanostructures, the control of size, shape and surface accessibility is also crucial, because these features are relevant for most of the relevant properties in a nanoalloy (optical, photocatalytic, magnetic, hot‐carriers generation, etc.).

In the last decades, the advances in the synthetic routes for nanomaterials allowed tackling the challenge of obtaining new plasmonic alloys. Wet‐chemistry approaches traditionally guarantee the highest control on products in terms of composition and morphology but are limited to those metal precursors soluble in liquids and to phases at the thermodynamic equilibria. Indeed, one of the frontier topics in nanoscience is the synthesis of metastable phase alloys, requiring more drastic synthetic conditions running out‐of‐equilibrium, which may also prevent the problems of precursor solubility and different reactivity of the elements in the alloy.[ 21 , 22 ] This explains the prevalence of physical or hybrid physical‐chemical approaches to the top‐down and bottom‐up synthesis of plasmonic nanoalloys reported in the recent literature (Figure 4). In general, for nanoalloys the synthetic approaches can be differentiated also on several other parameters such as the reaction environment (gaseous, liquid or solid), the precursor type (bulk metal or chemical compounds such as metal salts and coordination compounds), the dispersion of final nanoalloys (powder, colloid, substrate, embedded in a solid matrix).

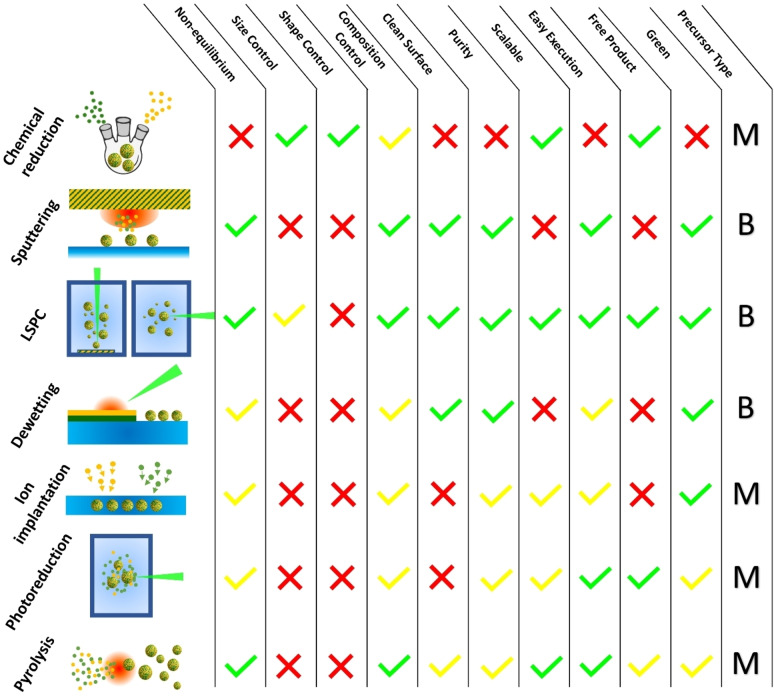

Figure 4.

Overview of the most frequently reported synthetic approaches for plasmonic nanoalloys and list of their advantages and limitations. “B”: bulk, “M”: molecular. For details see text.

2.1. Laser Synthesis and Processing of Colloids

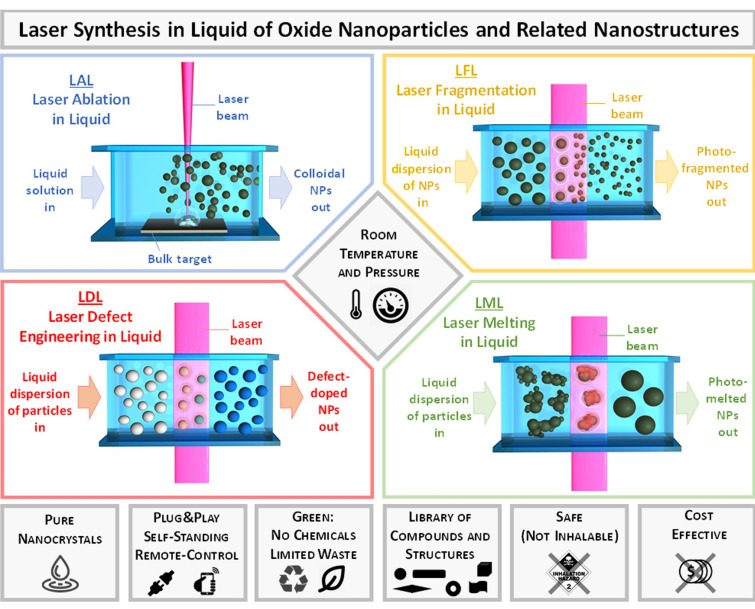

Laser‐assisted synthesis of nanomaterials in liquid phase includes a family of four different approaches described in the literature as laser ablation in liquid (LAL), laser fragmentation in liquid (LFL), laser melting in liquid (LML) and laser‐defect engineering in liquid (LDL), which are sketched in Figure 5.[ 23 , 24 , 25 , 26 ] These approaches are of general applicability for any phase or structure, not only alloys, such as pure metals, semiconductors, oxides, metal‐oxides core‐shells and doped oxides, all harvested as colloids, hence the definition of laser synthesis and processing of colloids (LSPC).[ 23 , 27 ]

Figure 5.

Sketch of the different methodologies in the family of LSPC and overview of their main advantages. Adapted with permission from Ref. [23] under a Creative Commons (CC‐BY 4.0) license. Copyright (2020) The Authors. Published by Wiley‐VCH Verlag GmbH & Co. KGaA.

LAL consists in the use of focused laser pulses for the ablation of a solid target immersed in a liquid solution and is a “green” technique. Currently, the variety of nanomaterials produced by this technique is high, thanks to the progress made to optimize the process. Among the advantages of LAL there are the low‐cost of the synthesis, the ease to obtain different types of NPs with the same set‐up, the speed and the simplicity of the method.[ 23 , 24 , 25 ] Besides, it is possible to control the synthesis remotely, even with a PC or a smartphone. [28]

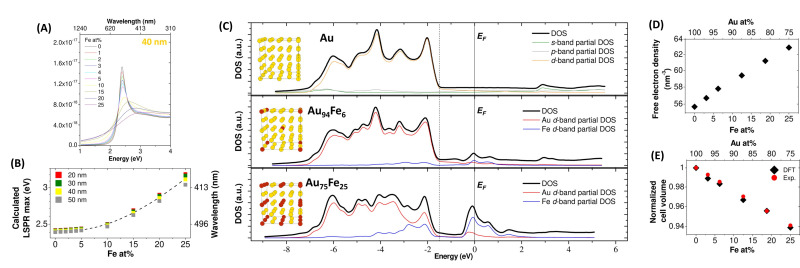

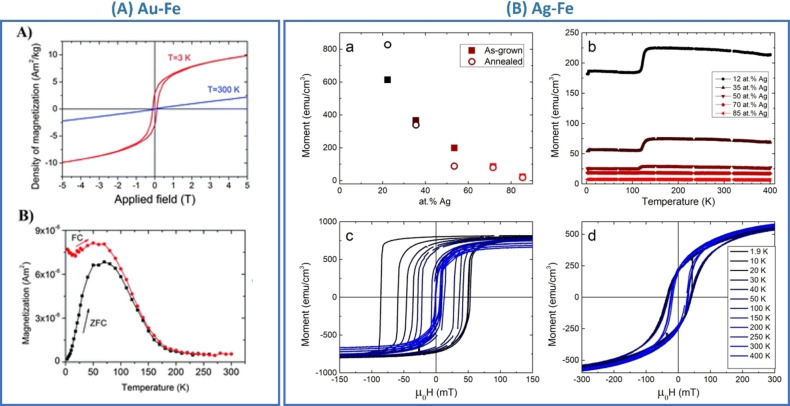

LAL proved to be useful to obtain equilibrium alloys as well as metastable phases, that have been frequently exploited for plasmonics. For instance, Au−Fe NPs were obtained by LAL and studied for the coexistence of magnetic and plasmonic properties, but also in electrocatalysis.[ 29 , 30 , 31 , 32 ] Alloying can be an advantage for the productivity of colloids by LAL. For instance, the production rate of NPs increased from 4 g/h with a pure Au target to 8 g/h with an Au/Pt 90/10 alloy target with an ultrashort‐pulsed laser and fast lateral target scanning. [33] It was also demonstrated with single‐pulse ns LAL experiments with Au/Fe multilayers that element mixing into homogeneous Au−Fe nanoalloys is possible during the synthesis.[ 34 , 35 ] On the other hand, in bulk targets the ablated volume is much larger than in the thin film experiments described in Ref. [34,35]. Recently, Waag et al. performed ps and ns laser ablation experiments on mixed metal powder targets to assess that, in bulk powder targets, the mixing of different metals prevalently takes place in the heat‐affected but initially not ablated parts of the target, instead of during material ejection. [36] Longer laser pulses (ns) have more extended thermal effects on the target than ps and fs pulses, favouring the formation of homogeneous nanoalloys starting from heterogeneous targets.

Recently Guadagnini et al. synthesized the Au−Co metastable random substitutional SSs in a single step using a nanosecond laser, resulting in Au84Co16 composition that is above the thermodynamic limit. [31] The obtained particles showed useful properties as substrates for surface‐enhanced Raman scattering (SERS). With the same method, Ag−Co NPs with an Ag83Co17 at % composition were also synthesized as a heterogeneous alloy made of an Ag matrix embedding metastable disordered Ag−Co domains. [37]

A similar approach was exploited by Johny et al. to obtain either Au−Co SS or core@shell (CS) Co@Au NPs. [38] Their work shows how the Co content in the ablation targets affects the final structure and composition of the NPs. LAL synthesis has been exploited also for the formation of Au−Fe CS NPs.[ 34 , 39 , 40 ] Even in this case, a systematic study of the synthetic conditions pointed out how the liquid environment, the target composition and its structure affect the final products. By varying the laser pulse duration from ps to ns and using pre‐alloyed targets instead of multilayers of the pure metals, CS can be obtained instead of SS NPs in acetone, which is a less oxidising environment than water.[ 34 , 39 , 40 ] These studies evidenced also that smaller NPs are SS, differing from the larger ones that are CS NPs. The reason is due to the dependence of the surface free energy on size, which is lower in SS with a size smaller than ca. 10 nm and in CS with a size larger than ca. 10 nm.

Johny et al. recently studied how micro‐inhomogeneities evolve in Au−Fe NPs obtained by LAL. [41] Structure evolution was studied by applying sufficient temperature to Au80Fe20 NPs to reach the thermodynamic equilibrium to facilitate the atomic mobility, while the evolution of crystallite sizes and lattice parameters were monitored in situ by x‐ray diffraction (XRD) and scanning transmission electron microscopy (STEM). At temperatures lower than 700 °C, the experiments evidenced the presence of two face‐centred cubic (fcc) phases with lower and larger lattice constant and, respectively, with larger and smaller size, suggesting the presence of a complex heterogeneous SS inside the NPs. By increasing the temperature above 700 °C, a single fcc phase and a larger crystallite size appeared with the decrease of microstrain, which is the lattice deformation resulting from local stress heterogeneity and dislocation density. The same analyses on Au50Fe50 NPs indicated three different fcc phases with the composition of Au74Fe26, Au82Fe18, and Au96Fe04 in addition to a Fe body‐centred cubic (bcc) phase. Also in this case, a single fcc phase appeared only above 700 °C, when the initial heterogeneous alloy relaxed to a more stable conformation driven by the thermodynamic driving force and temperature enhanced atomic diffusion.

Frequently, LAL is coupled with LFL for obtaining alloy NPs from the mixing of single element educt NPs. For instance, Fazio et al. produced Au−Ag NPs by synthesizing the Au and Ag colloidal NPs by LAL and, later, irradiating their mixture with different Au : Ag ratios to obtain Au77Ag23, Au53Ag47 and Au34Ag66 nanoalloys. [42] An aqueous dispersion of Ag NPs and Fe powder was irradiated with focused 1064 nm, ns laser pulses to obtain spherical Ag−Fe NPs. [43]

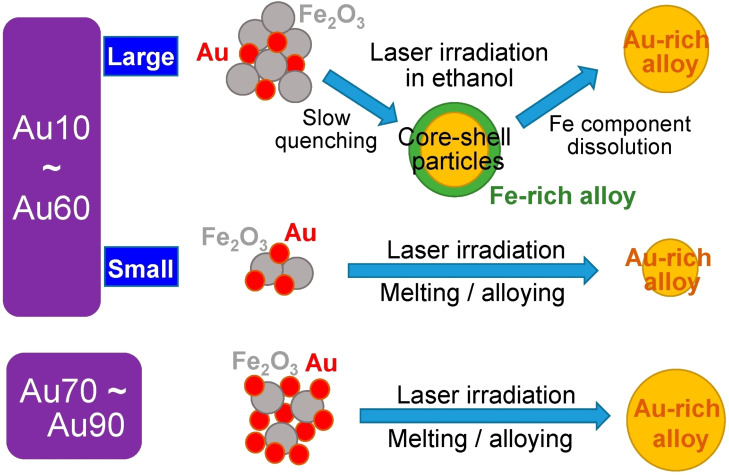

LML was exploited by Swiatkowska et al. to obtain Au−Ni metastable nanoalloys with the 56 wt% of nickel. In the LML procedure, Au−Ni NPs have been obtained by irradiating a mixture of Au and NiO NPs dispersed in a liquid, despite the Au−Ni system is difficult to obtain due to the almost complete immiscibility of the two metals. [44] In the same way, also Au−Fe submicrometric particles and other alloys were obtained. [45] The Au−Fe NPs were synthesized starting from a mixture of Au and Fe2O3 NPs (Figure 6). Interestingly, by changing the ratio between educt Au and Fe2O3 NPs, the structure of products changed. Starting with 10–60 % of Au, the largest NPs prevalently had a phase‐separated CS morphology. In the 70–90 % of Au range, all the analysed particles were compositionally homogeneous. The composition of the alloys was obtained by XRD using Vegard's law and showed a discontinuity of gold content between 20 and 70 wt% of Au in the educt, which is explained by the immiscibility gap of the Au−Fe system. For instance, in the NPs obtained from the educt with 30 wt% of Au, the gold content in the final NPs resulted in ∼75 wt%. Essentially, the NPs resulted to be gold‐rich, and a higher irradiation time corresponded to a larger content of gold.

Figure 6.

Sketch of Au−Fe NPs formation mechanism by LML for different initial gold content in the Au‐Fe2O3 educt nanoaggregates. For highest Au content, only alloy NPs are obtained. For low Au content, core‐shell morphologies are observed with a Fe‐rich shell. Reprinted with permission from Ref. [45] under a Creative Commons (CC‐BY 4.0) license. Copyright (2019) the Authors.

2.2. Laser‐Induced Dewetting and Inter‐Melting

As an alternative to LSPC, laser irradiation can be performed in a gas environment for the preparation of ultrapure alloy nanocrystals supported on substrates or collected as powders. The advantage of an inert gaseous environment is, however, balanced by the complex, expensive and not scalable set‐up (typically vacuum chambers) and by the collection of products as agglomerated powders or intrinsically embedded on a surface.

Dewetting requires the melting of thin metallic films to form nanodroplets on an inert substrate, which then will solidify in NPs. In specific cases, dewetting also allows the tuning of nanocrystal morphology and size.[ 46 , 47 , 48 , 49 ] Because of the high melting temperature of most metals, a laser source can be used, known as pulsed laser‐induced dewetting (PLiD). The driving force for the NPs formation is the minimization of the total free energy at the interface with gas and substrate.

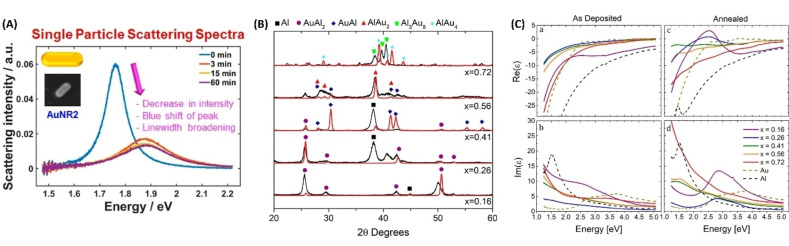

Laser dewetting and laser welding have been recently exploited to generate Au−Ag,[ 50 , 51 ] Au−Fe, [45] Ag‐Ni [52] Ag−Co/Fe [53] and Au‐Ni [44] nanoalloys. Au−Ag nanoalloys with different compositions were obtained by laser dewetting of Au/Ag thin films with various relative thicknesses of the two layers. [50] TEM elemental analysis confirmed that the NPs are Ag−Au alloys, with two elements well mixed over the whole volume of the particle. The fact that bimetallic alloys were produced with a single 6 ns laser pulse suggested that Ag and Au atoms are intermixed in the liquid phase on a nanosecond time scale.

Production of Ag−Ni magnetic‐plasmonic NPs by laser dewetting was studied starting from Ag and Ni thin films. [52] The system is interesting because the two metals have limited miscibility in the liquid and solid phases, lower than Au−Ni. Immiscibility across a large temperature and compositional range is expected to facilitate the emergence of complex particle morphologies during the liquid phase dewetting process. In fact, by acting on the initial film geometry, substrate, and laser heating conditions, various particle architectures were achieved, including Janus, core‐shell and homogeneous SS NPs. Ag and Ni were co‐sputtered at a 1 : 1 ratio and the thin films were exposed to 20 ns laser pulses to induce liquid‐state dewetting, observing a correlation of the final NPs size distribution to the as‐deposited film thickness. Starting from an initial thickness of 20, 10, 5, 3, and 2 nm, predominantly Janus NPs with an average size of, respectively, 300, 180, 45, 20 and 8 nm were obtained. Again by laser‐dewetting, Sachan and co. obtained ferromagnetic plasmonic NPs made of Ag and Co or Co−Fe (8 % of Fe) heterostructures. [53]

In a similar approach, a laser source can be exploited to weld single element metallic NPs already present on a substrate, to form an alloy, in a process called “laser welding”. In the case of adjacent plasmonic NPs, the “hot spot” effect is possible by using a laser beam resonant and polarized according to the plasmon mode oscillating along the dimer axis. Hence, the plasmonic NPs can be preferentially heated at the interparticle gap, resulting in a higher welding efficiency compared with the uniform thermal welding. Xu et al. made a thorough study for a better understanding of the laser welding process in the case of Au−Ag NPs. [51] They applied ultrafast TEM measurement in situ during the laser welding experiment on a dimer of Au and Ag NPs, to visualize the alloy formation. This evidenced that the Ag NPs shrink while Au NPs became larger, due to the inter‐diffusion between the two NPs. From the direct visualization of the process at different pulse number and time, the formation of Au−Ag NPs was divided into different stages: (i) neck formation, (ii) Ag shell formation, (iii) Au‐rich shell formation, (iv) alloy dimer formation and (v) homogeneous alloy NP formation. The neck formation is favoured by the localized heating at the inter‐particle gap, while the neck size increases with surface diffusion due to the minimization of the surface energy in heated NPs.

2.3. Sputtering, Dewetting and Arc‐Discharge

Sputtering is one of the most popular and versatile approaches for achieving nanoalloys on a substrate by a physical top‐down route and produces highly pure nanocrystals. As shown, for instance, by Nguyen and co. with Au−Ag alloys, [54] the composition can be controlled by co‐sputtering two (or more) targets to obtain NPs with different stoichiometry. By acting on the sputtering current of each target, they obtained Au−Ag NPs with five different compositions in gold from 25 to 33, 60, 66 and 75 % as well as Au−Cu NPs with different compositions in a range from Au66Cu34 to Au29Cu71. [55]

Suzuki et al. instead, used the sputter deposition from a unique bimetallic target to obtain Au−Cu NPs. [56] The purpose was the control over the order‐disorder transition between the fcc phase and the L10 structure of the Au−Cu system, which have different mechanical, catalytic and plasmonic properties. The same synthetic approach was successfully tested on Au−Pt NPs. [57]

Pd−Au is another system frequently investigated for catalytic purposes, also by sequential sputter deposition.[ 58 , 59 ] Cai's group exploited the sputtering deposition to control the Pd−Au ratio in ternary alloys of Au, Pd and Pt to obtain electrocatalytic systems with different performances. [60]

Vahl et al. suggested a novel approach for the fabrication of alloy NPs with variable composition and better size control by introducing a custom‐made multicomponent target for magnetron sputtering in a Haberland type gas aggregation cluster source. This type of source combines magnetron sputtering with gas cluster aggregation. [61] From their results for Au−Ag NPs, they show that the composition and size depend on the pressure of the gas agglomerate source and demonstrate for gold‐rich NPs that the composition can be adjusted in‐operando.

In some cases, high temperature is exploited to promote dewetting of the sputtered thin film and the formation of NPs. Heat‐induced dewetting of a co‐sputtered Ag−Au‐Cu film was devised for the identification of crystalline and grain border defectivity when the three elements are homogeneously distributed in the NPs (Au53Ag33Cu14) or when the high Cu content promotes element segregation (Au22Ag26Cu52). [62]

Sputtering can be performed also on liquid substrates and, indeed, lots of progresses have been made to obtain high‐quality NPs with this method. The advantages are the combination of a physical top‐down technique to produce highly pure nanocrystals NCs with the chemical methods to capture, stabilize, control the size and surface functionalize NPs in the liquid medium, similar to the synthesis of a colloid. Moreover, because there is no necessity of using toxic reducing agents and organic solvents, the method can be considered as a green approach to generate NPs in liquids. [63] Nguyen et al. exploited this technique for alloy and core‐shell NPs such as Ag−Au,[ 54 , 61 ] Au−Cu,[ 55 , 56 ] Pd−Au/Pt, [60] Pt−Au, [57] Pd−Au.[ 58 , 59 ]

Another method compatible with the production of nanoalloys as a colloid or a powder is the arc discharge. In this technique, the metal composing the electrode is etched by the plasma formed in the surrounding environment (gaseous or liquid) upon application of high electric potential and consequent electric discharge.[ 64 , 65 ] The NPs will have the composition of the electrode and is thus variable in a wide range, as demonstrated recently in a vacuum chamber for the synthesis of Au−Ag nanoalloys. [65]

2.4. Wet Chemistry and Other Methods from Chemical Precursors in Liquid or Gas Environment

Most synthetic methods for plasmonic nanoalloys start from chemical precursors of the metal elements which are converted into alloys in a liquid or gaseous environment. The transformation into the solid‐state is triggered by other chemical compounds, such as a reducing agent, or by a physical process such as heat or laser irradiation.

The most widely used method to produce metal (alloy) NPs consists of the chemical reduction of metal salts in liquid environment. When metal elements are prone to oxidation, organic liquids under an inert atmosphere are required. These wet‐chemistry methods have unmatched control on size, stoichiometry and shape of nanocrystals, but run under thermodynamic equilibrium, meaning that the largest part of plasmonic nanoalloys is inaccessible. Besides, surface stabilizers are required, which in most cases remain on the surface of nanocrystals affecting their properties, primarily the (photo)catalytic ones. There are several examples of alloy NPs obtained by this approach. For instance, with the co‐reduction method, Cu/Au/Pt trimetallic NPs (TMNPs) were synthesized from HAuCl4, CuSO4 and K2PtCl4 with the addition of NaBH4 at room temperature. [66] The Cu/Au/Pt TMNPs had an irregular shape and an average size of ∼10 nm, although the three elements were uniformly distributed. Co‐reduction is well suited for the deposition of alloy nanocrystals on substrates such as fibers, as demonstrated with Cu−Ag NPs obtained by immersion of electrospun hydrogels in a solution containing both CuSO4 and AgNO3 and addition of NaBH4. [67]

Often, the seeded growth technique is exploited, in which the alloy is formed on pre‐existing metal seeds which facilitate the control over shape and size. Au−Pd nanostructures have been synthesized starting from Au nanorods (NRs) made by the seed‐mediated method and, subsequently, the Pd was added in different concentrations to change the resulting NRs morphology. [68] Almost the same approach has been exploited by Rioux and Meunier to produce Au@Au−Ag NPs. [69]

With the seed‐mediated process, Ma et al. succeeded in obtaining NPs with an external crystalline Au layer which stabilized the internal Au−Cu alloy and Cu core against oxidation in water. [70] Cu NPs were first prepared as seeds by the thermal decomposition of copper acetylacetonate in oleylamine and then mixed with the Au3+ precursor, to replace the Cu atoms on the surface with Au through a galvanic replacement process. This led to a thin shell composed of an intermediate Au−Cu layer and an outer Au layer around the Cu core.

The inverse process, starting from Au seeds and proceeding with the co‐reduction of Au and Cu precursors, was exploited for the synthesis of Au−Cu alloy nanotetrapods unstable towards corrosion in an aqueous environment. [71] The 3 nm Au seeds were added into an aqueous solution containing HAuCl4 and CuCl2 with glucose and hexadecylamine as, respectively, reducing and stabilizing agents, with subsequent heating to 100 °C under a nitrogen atmosphere.

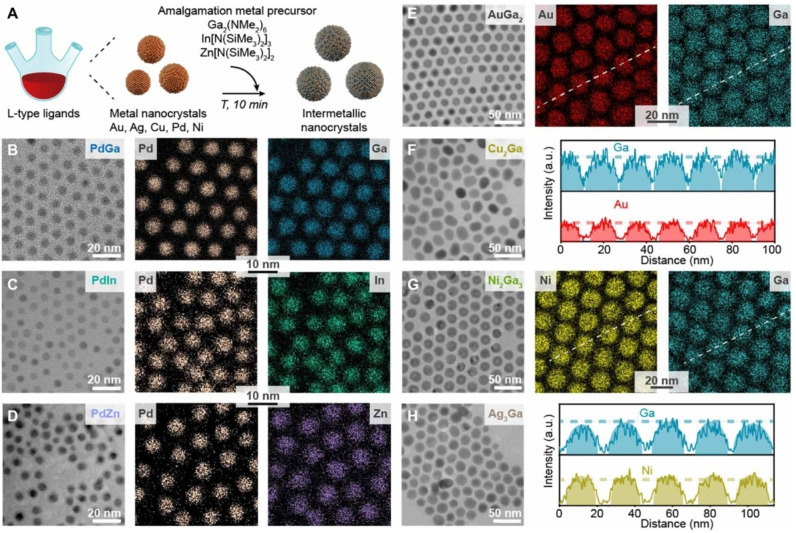

Recently, Clarysse et al. developed the amalgamation seeded growth synthesis to achieve intermetallic NPs. [72] They coupled the seed‐assisted synthesis with a controlled amalgamation of low melting point metals to produce nanocrystal with controlled size and composition. Amalgamation is referred to the process in which a low melting‐point metal inter‐dissolves inside the lattice of a solid host metal. With this method, Ga was amalgamated with Au, Ag, Cu, Pd, and Ni seeds. Besides, In and Zn were used to form Pd−In and Pd−Zn NCs. A remarkable advantage of this approach is that all the obtained intermetallic nanocrystals resulted in uniform size and composition, although structural homogeneity was not optimal for all the combinations tested (Figure 7). The control in the average composition is directly related to the concentration of the metallic precursors. For instance, by varying the concentration of Ga precursors, various intermetallic NPs like AuGa2, AuGa, Au7Ga2 or Ga‐doped Au were obtained as prevalent products.

Figure 7.

(A) Illustration of the amalgamation reaction, converting monometallic seeds into intermetallic NCs. As‐synthesized PdGa, PdIn, PdZn, AuGa2, Cu2Ga, Ni2Ga3, and Ag3Ga intermetallic NPs are shown in TEM images (B to H) and STEM EDX maps (B to E and G). Line profile scans for AuGa2 and Ni2Ga3 NPs (E and G) highlight the compositional uniformity of the intermetallic NPs. Reprinted with permission from Ref. [72] under a Creative Commons (BY‐NC 4.0) license. Copyright (2021) the Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science.

An alternative wet method for the formation of plasmonic nanoalloys has been demonstrated for a liquid Ga metal alloy by ultrasonication. [73] A bulk Ga−In liquid metal has been prepared mixing pure Ga and In at 75/25 wt% and a droplet of this is then transferred in a vial, diluted in ethanol and sonicated obtaining Ga−In NPs stabilized by a Ga2O3 shell.

Another recent synthetic approach exploits the supercritical carbon dioxide as dispersing medium for the so‐called supercritical reactive metallization, or supercritical fluid reactive deposition. This is a bottom‐up method that offers scalability in environmentally friendly conditions. [74] With this technique, it is possible to obtain monometallic NPs, thin films or alloys such as Au−Ag, [75] Cu−Ag, [76] Pd−Pt, [77] Fe−Ni, [77] Au−Pt, [78] and Au‐Pd [78] NPs.

Hydrothermal routes are being studied for the realization of plasmonic nanoalloys, such as Au−Ag NPs, through the reduction of metal salts at high temperature and pressure in the presence of green reducing agents. [79]

More violent methods starting from chemical precursors can produce also non‐equilibrium and disordered alloys. For instance, Yao and co. developed a two‐step synthesis for high entropy alloy (HEA) NPs with carbothermal shock. [80] The carbothermal shock employs flash heating and cooling of metal precursors supported on oxygenated carbon fibers to produce binary (Pt−Ni, Au−Cu, and Fe−Ni), and ternary (Pt−Pd−Ni, Au−Cu‐Sn, and Fe−Co−Ni) NPs with compositional uniformity typical of a SS. Furthermore, by adding other metal salt precursors they synthesized quinary (Pt−Co−Ni−Fe−Cu and Pt−Pd−Co−Ni−Fe), senary (Pt−Co−Ni−Fe−Cu−Au), septenary (Pt−Pd−Co−Ni−Fe−Cu−Au) and octonary (Pt−Pd−Co−Ni−Fe−Cu−Au−Sn) SSs of HEA NPs. Compared to other techniques for the synthesis of HEA NPs, such as LAL, [81] carbothermal shock does not require a bulk HEA target but just a mixture of metal precursors.

Photoreduction of metal salts has been intensely investigated in recent years with a multitude of variants. The most traditional technique is the laser spray pyrolysis and its variants such as thermal spray pyrolysis and flame spray pyrolysis, which allows massive production of agglomerated NPs, also with non‐equilibrium composition, collected on a substrate or in a liquid. In the spray pyrolysis, the liquid mixture of metal precursors is reduced by irradiation with an intense laser beam, heat or by contact of the solution with a flame, eventually with the addition of reducing chemicals or hydrogen, as demonstrated with Au−Ag and Ag−Cu NPs.[ 82 , 83 ]

Photoreduction of metal salt precursors can take place in standard laboratory set‐up by irradiation with a xenon lamp, as demonstrated with Au−Pt nanoalloys supported on Bi2O3 NPs, [84] or by irradiation with pulsed lasers to collect a colloid, such as Au−Ag NPs, [85] or a film of NPs on a substrate, such as Au−Ag−Pt NPs on glass. [86] This is possible by the formation of hydrated electrons produced in the laser plasma and the simultaneous addition of scavengers of hydroxyl ions such as isopropyl alcohol.

A special method to produce nanoalloys from metal ions is ion implantation, in which the ionized atoms are accelerated by an electric field up to the kinetic energy required for the penetration in a solid matrix. In the matrix, the NPs can nucleate already during the implantation process or successively, by thermal activation which also serves for annealing and particles growth. Although the final NPs are embedded in a solid matrix, historically this method proved to be useful for the realization and the study of alloys not easily achievable by other synthetic approaches, such as the Au−Fe NPs, [87] or in matrices which are otherwise difficult to be loaded with NPs, such as Au−Ag NPs in TiN films. [88]

3. Modelling

A comprehensive understanding of the electronic and structural properties, as well as the optical behaviour of nanoalloys, is fundamental to enlarge the number of possible applications and direct the synthesis to optimized systems among all the possibilities available. [13] On the other hand, the variety and structural complexity of nanoalloys pose great challenges also for modelling, in particular when dealing with the most heterogeneous and disordered systems.

The large range of structures and properties of nanoalloys is usually managed exploiting different approaches, where the most suited one must be chosen considering the complexity of the system and the property to be computed. In fact, the choice of a suitable computational approach is a short blanket dilemma. Predictive, high‐quality approaches, able to provide accurate properties (optical, magnetic, catalytic, etc.), are limited to simple models of the real systems, thus neglecting defects, segregation, grain boundaries, etc. Only approximate methods, conversely, can be applied to accurate models of complex systems. This picture becomes even more challenging when the complexity of the nanoalloy is coupled with its structural evolution during operation, especially at the interface with the environment, where phenomena such as surface segregation of some elements, changes of the oxidation state, dealloying, corrosion, etc. are crucial to explain the behaviour of the nanoalloy during its function.

The computational methods employed in this field can be grouped into two families: quantum‐mechanics approaches, where electrons are treated explicitly, and parametric methods, where the interaction between atoms are described through a series of parameters.

Quantum methods exploited in the modelling of NPs are mostly implemented within the density functional theory (DFT). In this context, the energy of the system is computed over electron states and the electron‐electron interaction is approximated as a local functional of the electron density (and derived quantities). A key parameter of DFT is the type of functional adopted to describe the electron density.

Ab‐Initio molecular dynamics (AIMD) is rarely exploited in this context, but molecular dynamics, its parametric counterpart where interatomic interactions are modelled through classical potentials, is routinely used. Parameterized energy contributions are used also in statistical approaches such as Monte Carlo (MC), which allows the exploration of equilibrium properties, and kinetic MC (kMC), which is used to model dynamic processes. For an introduction to the methodologies mentioned above, we refer the reader to Ref. [89].

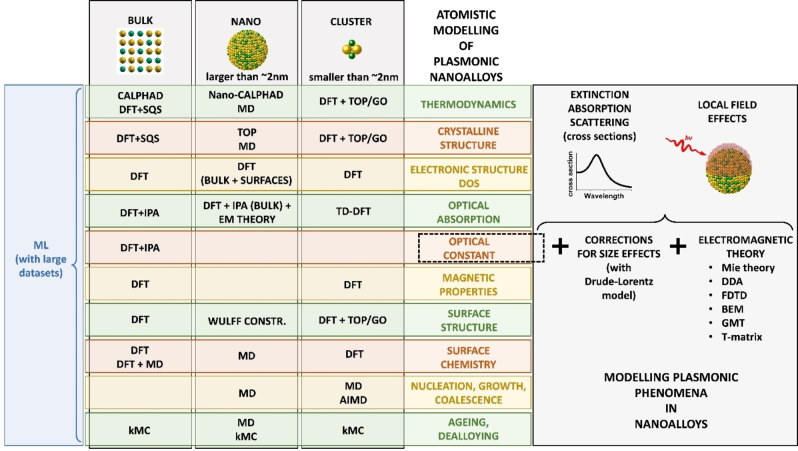

From the nanoparticle size perspective, very small systems can be modelled as clusters using DFT (Figure 8). Large nanoparticles can be treated explicitly only with MD or MC because the application of DFT to systems with many electrons is computationally unfeasible. On the other hand, DFT can be exploited also in the modelling of large NPs, provided that the property of interest can be derived from separate calculations on the bulk and the surfaces. As an example, nanocrystals equilibrium shapes can be devised using the Wulff construction, namely a method for the determination of the equilibrium shape of a crystal from surface energies (which can be conveniently obtained from DFT calculations). Of course, not all the properties are accessible by both families of methods. DFT is best suited to investigate electronic properties such as reactivity, magnetism and optical response, the latter requiring the evaluation of electronic excitations, usually performed within the independent particle approximation (IPA) or the time‐dependent DFT (TD‐DFT).

Figure 8.

Map of mainstream atomistic modelling approaches for specific aspects of plasmonic nanoalloys. Modelling of the plasmonic properties is possible starting from the optical constant. For details see text.

MD is the method of choice to inquire dynamic properties happening at the time‐scale of μs, such as coalescence and NPs formation. Phenomena happening at a longer time scale and involving activated processes, such as its structural evolution during operation, can be faced using kMC methods. MD and MC are used also to obtain equilibrium structures at finite temperatures and to predict the evolution path of alloy NPs towards their thermodynamically stable form.

In the last few years, applications of machine learning (ML) to the study of alloy NPs are also becoming popular. Within this approach, the output of a very complex function is modelled using a ML algorithm, that must be trained over a large dataset of known outputs obtained from either experiments or calculations. ML promises to be very flexible, as it can be trained to provide the desired output, which can be a fundamental property such as the interatomic interaction to be used in MD [90] or a complex observable of the systems. [91]

3.1. Modelling of Structure and Electronic Properties of Plasmonic Nanoalloys

The stability of an alloy is typically extracted from experimental phase diagrams, which are tabled for most binary and ternary systems. Even if accessible, however, phase diagrams do not usually contain information on all the metastable phases and do not take into account nanoscale effects related to the increased surface‐area‐atoms‐to‐volume‐atoms, sometimes leading to deviations from the bulk behaviour.

A thermodynamic method called CALculation of PHAse Diagrams (CALPHAD) has been developed and intensely investigated to infer the phase diagrams of multicomponent bulk systems. [92] CALPHAD is based on the bulk Gibbs energies as a function of state variables which are obtained with accurate thermodynamic models and appropriate interpolations and extrapolation of experimentally available quantities. Especially for ternary and multicomponent systems, the measured phase diagrams are needed for validation of the method. CALPHAD neglects any surface or interfaces interaction between the phases, which are relevant at the nanoscale below 100 nm and are considered in the nano‐CALPHAD (Calculation of Phase Diagrams for nano‐systems) model by including an additional surface term to the Gibbs free energy of the system. This method is formally valid above the size threshold where surface topology and quantum effects become important, that is below 3–5 nm.[ 92 , 93 ]

Concerning atomistic approaches, Gong et al. used DFT calculations of Au−Ag alloys to explain the experimental LSP energy shift with composition. [94] The valence band evidenced a clear shift of the d‐band position by varying the chemical composition of the Au−Ag alloy. By increasing the Au fraction, the d‐band moves closer to the Fermi level at the Γ‐point, with a consequent decrease of the energy difference with the first empty state in the conduction band. This finding agrees with the red‐shift of the interband transition of Ag−Au alloys when the Au content increases.

Koley and Jana performed DFT calculations to explore the phase stability of Au3Cd5 and Au3Mg5. [95] They discuss the alloys stability based on their density of states (DOS) and their crystal orbital Hamiltonian populations (COHP), a quantity providing the bonding, nonbonding and antibonding character of each band. The negative integrated COHP up to the Fermi level deliver information on the energy stabilization of the material, due to orbital interactions. The analysis of computational outcomes pointed out that the major contribution to the stabilization is given from the M−M (M=Mg and Cd) and Au−M interactions rather than the Au−Au ones. Moreover, they deduced that the structures are stabilized through the interaction between the Fermi surface and the Brillouin zone through a Hume‐Rothery mechanism. The observed behaviour is thus consistent with that of Hume‐Rothery phases (also called “electron phases”), which are alloys of noble metals with sp‐valent elements such as Al, Zn, Si, Ge and Sn and are renowned for the adoption of a different crystal structure depending on the average number of valence electrons per atom (the valence electron concentration or VEC). [96]

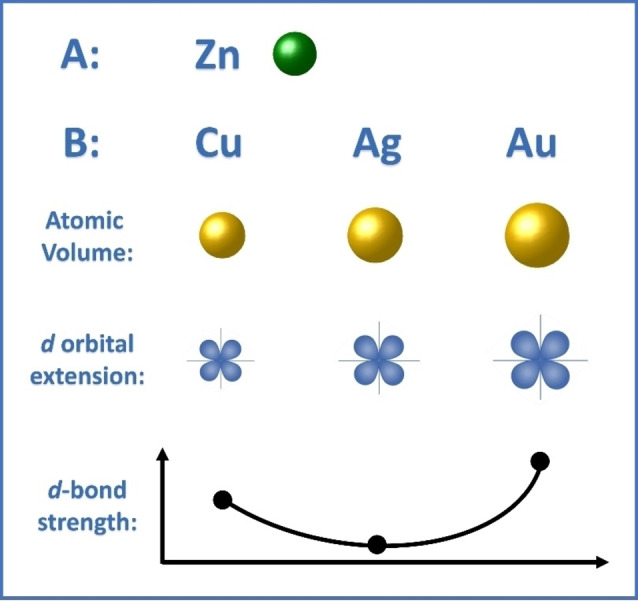

Alsalmi et al. [97] explored the phase stability in the formation of high‐temperature bcc phases of Zn alloys of the coinage metal group elements Au−Zn, Ag−Zn, and Cu−Zn. They exploited DFT calculations implemented in the VASP package. To evaluate the phase stability, the chemical and elastic formation energies have been calculated, as well the charge density distribution and the DOS. Results show that the trends are not always monotonic down the 11th group of the periodic table. The strength of the X−Zn bond decreases on passing from Cu to Ag, but then increases to its largest value for Au. The reason for this behaviour was identified in the trends of atomic‐core sizes and spatial extents of valence d‐orbitals, both increasing down the group. The effect of the first is that of increasing the repulsion between neighbouring atoms, thus pulling them apart and reducing their orbital interaction, while that of the latter is the opposite. The competing effects of these factors lead to the mentioned overall trend of the bond strength (Figure 9). Interestingly, this same mechanism could explain also the larger mixing enthalpy calculated for Ag−Fe and Ag−Co alloys compared to Au−Fe, in agreement with the experimental phase diagrams. [37]

Figure 9.

Sketch of atomic volume and d‐orbital extension for the coinage metals Cu, Ag and Au and the effect on d‐bond strength in alloys with Zn, according to Ref. [97]. The minimum is predicted for Ag−Zn alloys because of the worst compromise between atomic volume (which destabilize d‐bond formation) and d‐orbital extension (which favours d orbital hybridization).

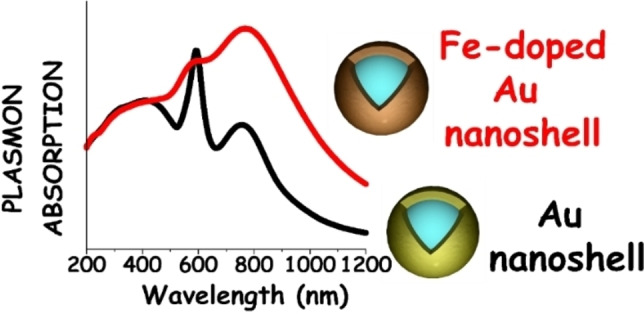

Structure optimization and the knowledge of the electronic structure helped Alexander et al. to describe the plasmonic properties of Au−Fe nanoalloys. [40] DFT calculations were performed within a plane‐wave/pseudopotential approach as implemented in the Quantum‐ESPRESSO suite. The contraction of the lattice parameter with the iron content, observed experimentally in multiple cases, [29] was well predicted from calculations and, with the shift of the Fermi level, allowed the estimation of the increase of conduction electron density in the alloy compared to pure gold. It was estimated that the Fe atoms contribute with 1.3 electrons in the fcc cell of the alloy, and this affected the LSP peak position causing a blue shift.

Au−Fe chemical stability in an aqueous environment was investigated by DFT calculations in Ref. [98]. The estimation of Gibbs free energies of the iron oxidation at the surface, as a function of the Fe concentration, confirmed that Fe readily reacts with adsorbed water molecules or dissolved atmospheric oxygen. This leads to oxidized iron species that can be easily dissolved in solution, similar to what is found in pure metallic iron. It was also showed that the energy barriers for the diffusion of Au, Fe, and O atomic species towards the alloy bulk, computed using the climbing‐image nudged elastic band (CINEB) method, are too high to allow atomic mobility at room temperature. These results explained the stability of Au−Fe alloys as a function of composition: Au‐rich nanoalloys are stable because they are passivated by an Au skin, while in alloys with a Fe concentration above a certain threshold, oxidation can proceed by pitting due to the appearance of percolation paths. In thermodynamically stable alloys, such as Au−Ag, such percolation paths are observed around 50 at % of the less noble element. [99] Conversely, in the Au−Fe system, whose mixing enthalpy is positive, the estimated threshold for the appearance of percolation paths can be much lower. Hence, a MC algorithm was exploited to simulate the distribution of Fe atoms in an Au−Fe slab where segregation was allowed, indicating that percolation appeared in 100 % of the considered structures already at Fe contents of 30–40 at %. This is due to the thermodynamic tendency to element segregation and phase separation into pure Au and Fe domains, which is inhibited at room temperature only because of the high diffusion barriers inside the metal lattice.

Atomistic models require a precise structure as input, which is usually unavailable. This problem must be faced in the modelling of bulk phases, surfaces, as well as whole nanoparticles, and affects in particular DFT but also MD methods. Different schemes were proposed to overcome this limitation. The simplest one consists in building a limited series of alloy models using chemical intuition and possibly available experimental evidence. [100] A more efficient approach, that can be exploited in DFT calculations of bulk phases, is the special quasirandom structure (SQS). This approach was introduced in the 90’s by Zunger et al. to describe the properties of wholly random crystalline systems. [101] SQSs are small models of an alloy, where elements occupy precise crystal sites, but the periodic structure mimics the long‐range correlation function of a real random alloy. SQSs were successfully employed in the calculation of structural and elastic properties, [102] as well as electronic structures. [103]

When modelling the whole NP instead of a single unit cell, optimal structures can be obtained with the topological approach (TOP) developed by Kozlov et al. in 2015. [104] The TOP allows the exploration of the chemical ordering of surface sites (facets, edges and corners) for each type of element. The method shows an accuracy comparable to DFT also for relatively large NPs. In fact, the TOP was developed to overcome the limitations of the DFT alone, which is computationally cumbersome for particles composed of hundreds of atoms and thousands of electrons. Given a certain composition and shape, the number of not‐equivalent arrangements of atoms (homotops) is of the order of 1050 for ∼200 atoms. The TOP deals with such a large number of homotops by categorizing them into classes where elements have the same local topology, and then computing the topological energy for each class. For example, the reactivity of NPs depends on their surface, therefore homotops can be grouped in terms of their exposed surface, which means the site occupancy (facets, edges and corners) of each element and the number of homoatomic or heteroatomic bonds. The topological energy could be resumed as the sum of energy contributions of the site occupancy and the interatomic bonds.

Vega et al. studied the reactivity of Pt−Au, Pt−Ag and Pt−Cu NPs using a topological approach based on preliminary DFT calculations. [105] The topological energy was estimated from DFT calculations on a limited set of homotops and MC simulations were then used to extract the most stable structures, which were finally further optimized by DFT. Their analysis revealed that gold tends to reach the surface and create a shell in small Au−Pt NPs (201 atoms) when the Au : Pt ratio is 3 : 1. When the percentage of gold is decreased to 1 : 1 and 1 : 3, an incomplete shell is formed, due to the insufficient amount of gold. Similar behaviour was found for Pt−Ag, while Pt−Cu behaves differently. Despite Cu surface energy being lower than that of Pt, in Pt−Cu 3 : 1 NPs the outer layer is composed mostly of Pt because the smaller size of Cu atoms destabilizes the surface in small NPs. The analysis was extended also to larger alloy particles of ∼4.4 nm (1463 atoms) and the effect of temperature on the chemical ordering. In Pt−Au and Pt−Ag the core‐shell geometry is preferred, with the shell composed by Au and Ag respectively. Instead, Pt−Cu NPs expose only a small amount of Cu at the surface, preferably located at edges and corners. Increasing the temperature, only a few atoms of Pt reach the surface in the case of Pt−Au and Pt−Ag. Conversely, in Pt−Cu NPs, the rearrangement is more evident: the outer layer exposes more Cu atoms scattered over Pt atoms in the facets, and the bulk is composed of randomly distributed atoms of both metals.

The TOP has been applied to several other alloys and sizes as Ag−Pt clusters with 116 and 201 atoms, [106] Pd−Au, [107] Pd−Au (201 and 405 atoms), Pd−Ag (201 and 405 atoms) and Pt−Au (201 and 405 atoms). [108]

Rapetti and Ferrando investigated the chemical ordering in Au−Ag clusters with fixed geometry using a global optimization (GO) algorithm based on DFT energies. [109] Despite the lower cohesion and surface energy of Ag, computational outcomes show that Au tends to occupy surface sites. To explain this counterintuitive behaviour, electrostatics must be considered. Au atoms acquire a negative charge, become bigger, and therefore are preferentially placed at the surface. Authors point out that charge transfers are often neglected in MD, and in some cases, this can lead to qualitative errors in MD predictions.

An example of the MD approach combined with MC simulations is found in the report of Andreazza et al. The study started from the experimental growth of Co−Ag NPs by depositing Co atoms on Ag seeds, which was followed in real‐time by grazing incidence x‐ray scattering at small and wide angles (GISAXS and GIWAXS). Then, MC was exploited to obtain equilibrium structures of the NPs, while MD was used to study the growth process. [110] Combining GISAXS, GIWAXS, MD and MC outcomes, it was shown that Co@Ag structures finally form, but the growth process is quite complex. The sequence starts with the incorporation of single Co atoms in the subsurface of the Ag seed. As the deposition proceeds, Co atoms in the subsurface act as traps for newly deposited Co units, due to the strong Co−Co interaction. Aggregates then grow and eventually merge, giving rise to a quasi‐Janus asymmetric structure. The NPs then reaches their equilibrium Ag@Co morphology when their atomic composition is 70 % Co. Proceeding further with the deposition, the structure becomes Co@Ag in the Co‐rich limit.

Nelli and Ferrando exploited MD and GO to shed light on the Au−Co, Ag−Ni, and Ag−Cu NPs evolution towards equilibrium. [111] All systems were made of metals with low bulk miscibility and high lattice mismatch. Particles of general formula X293Y293 having a truncated octahedral (TO) geometry and an Icosahedral (Ih) Ag280Cu281 structure were studied. The composition was such to allow the formation of a complete monolayer thick shell. In all cases, the global minimum was a CS particle with the noblest element as a shell, while some differences in the final shape were found. Overall, the authors confirm a complex evolution path of random alloy NPs towards their equilibrium structure, in some cases involving the formation of core@shell@shell forms, that can be possibly synthesized as metastable, kinetically trapped species.

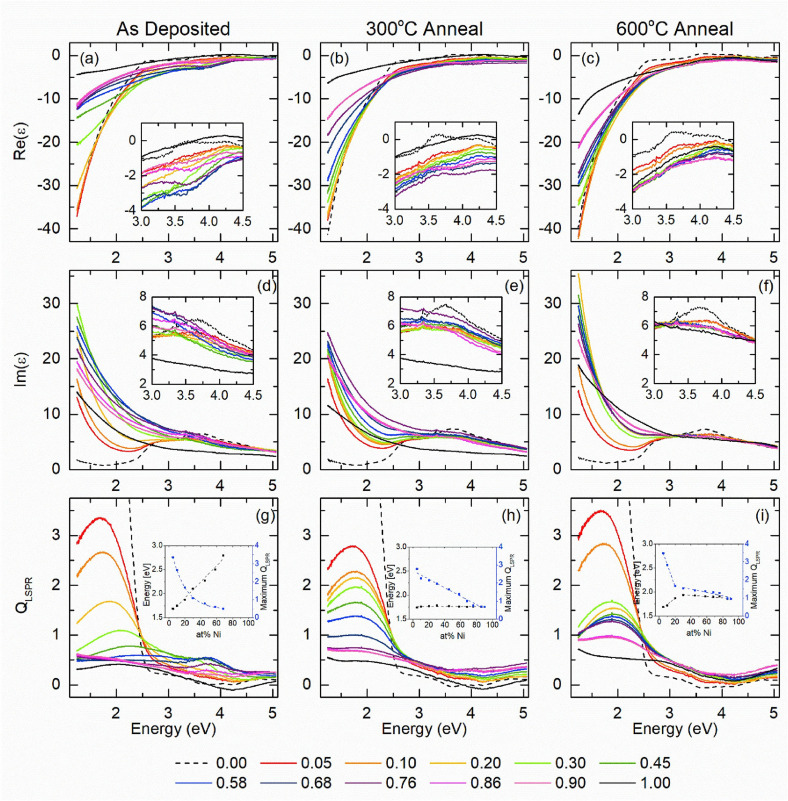

3.2. Modelling the Optical Constants of Plasmonic Nanoalloys

In the last years, many DFT calculations have been carried out to obtain the optical constants (OC) of nanoalloys. This is particularly relevant in plasmonics due to the lack of experimentally measured optical constants for a variety of alloys, especially in certain compositions that are difficult to obtain in conventional laboratory conditions. The measurement of the OCs is done by ellipsometry on thin films, which is critically influenced by surface roughness, chemical homogeneity and chemical composition. These are relevant issues in the case of metastable phases and elements prone to oxidation but also for pure element films, even in ultra‐high vacuum conditions.[ 112 , 113 ]

Recently, Bubas and Parramon proposed an approach based on the GLLB‐SC functionals to calculate the OCs of Au−Ag, Au−Cu, Ag−Cu and Pd−Au systems, which represent a satisfactory compromise between computational cost, efficiency and accuracy. [114] They used the GPAW package, based on the projector augmented wave (PAW) method, and chose the GBLL‐SC functional because of its computational efficiency and the better treatment of d‐band electrons compared to other GGA functionals. They computed the OCs of bulk alloy (Au−Ag, Au−Cu, Ag−Cu, Pd−Au) systems and monometallic equivalents within the independent‐particle approximation (IPA) and compared the results obtained with LDA, PBE (and its revisions), vdW‐DF and GLLB‐SC to the experimental reference. The GLLB‐SC functional showed overall the best performance among the others considered there, most notably it provided the best results concerning the interband transitions (IB) onset, which is particularly relevant for the LSP spectral position.

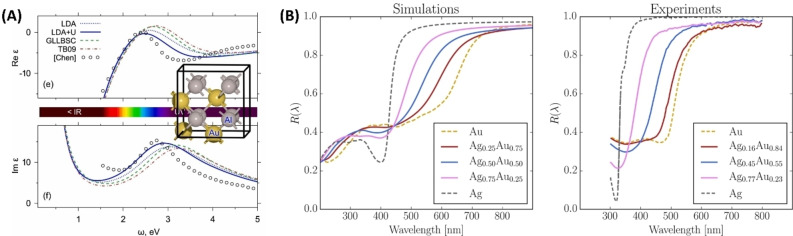

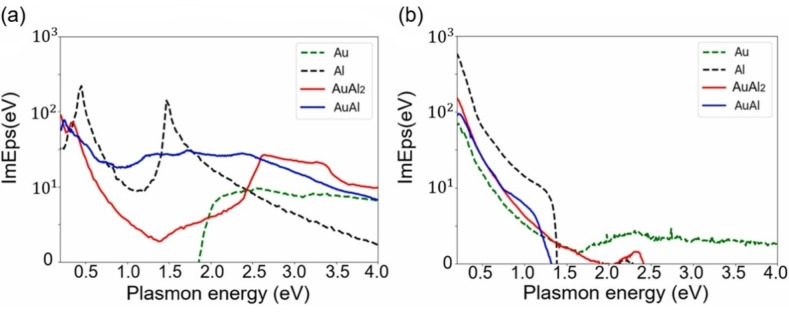

Avakyan et al. used LDA, LDA+U, GLLB‐SC and TB09 functionals to calculate the OCs of Au, Ag, Al and Mg and their alloys Au−Ag, Au‐Al2 and Mg−Au, also within the IPA as implemented in GPAW. [115] They found out that LDA+U outperforms GLLB‐SC (Figure 10A), provided that it is fed with the proper values of the U parameter. The weakness and strength of LDA+U is indeed the presence of the U parameter that, on one side requires a considerable effort to pick the correct value, but on the other side allows to fine‐tune the results to match the experiment. The TB09 functional turned out to be very precise for reproducing OCs in Ag systems, however, compared to LDA+U it failed in reproducing the crystal structure and in general the ground state properties of the system.

Figure 10.

(A) Comparison of the dielectric functions calculated for AuAl2 with different functionals and experimental data (open circles). Reprinted from Ref. [115], Copyright (2020), with permission from Elsevier. (B) Comparison between calculated (PBE functional) and experimental reflectivity spectra for various Ag−Au alloys. Reprinted with permission from Ref. [116] under a Creative Commons (CC‐BY 4.0) license. Copyright (2020), The Author(s).

Prandini et al. used the PBE functional to obtain the electronic structures for Au, Cu, Ag and the mixed alloys (Au−Ag, Au−Cu, Ag−Cu, Au−Cu−Ag). They exploited the IPA to calculate the OCs of these systems and other intermetallic compounds as AuAl2, AuIn2 and AuGa2 (Figure 10B) to simulate the colour of these metals. [116] The comparison between the calculated and experimental reflectivity of Au−Ag alloys showed that the IPA simulation reproduced well the shift of the reflectivity to a longer wavelength with the increase in the gold content. Calculations successfully reproduced the trends in reflectivity, but the reflectivity edge was found to be systematically shifted to larger wavelengths compared to experiments. This bias is due to the underlying PBE functional, indeed semi‐local functionals are well‐known to overestimate the energy of d‐bands, thus shrinking the gap between valence d‐bands and conduction sp‐bands. [117] Nevertheless, this approach is useful for a systematic study for the photorealistic simulation of metal alloy surfaces and was tested also for AgCu, AuAl2, AuGa2, and AuIn2.

Shahcheraghi et al. combined both experimental and DFT results to study the Cu−Al system (Al 15 at %). [118] They used the linearized augmented plane wave plus local orbital (LPAW+lo) method, as implemented in wien2k, alongside the PBE functional. To calculate the dielectric function, they exploit the random phase approximation (RPA) considering the polarizability of the system as a sum over independent transitions not considering the local field effects (LFE). Hence, they checked the quality of the calculated OCs against the ones measured via ellipsometry. Despite the general trend resulting similar, the calculated OC had an absorption edge shifted of 0.53 eV (180 nm) and the optical losses defined from the imaginary part of the OC were 2 units larger than in the experiment. The calculated OCs were used to simulate the reflectance measurement with results in qualitative agreement.

It is worth noting that the addition of Al to the Cu crystal leads to a random substitutional SS, while the DFT is based on models with inherent periodicity. To better mimic the alloy‘s randomness, they built different structures with various atomic arrangements by substituting the Cu atoms with Al atoms in random positions. The same strategy was used to explore the structural order‐disorder effect on the OCs of the Au−Cu system. However, the results indicated that the effect of the random site occupancy in these alloys is not crucial for the resulting OCs. [119]

Cortie et al. previously reported a seminal study about the plasmon properties of a series of Au alloys modelled with the DFT using the LAPW+lo. [120] They started from the consideration that Au is chemically inert but relatively lossy compared to other metals like Ag and Al, which however are prone to oxidation in most real operating conditions. Hence, they investigated the effect of alloying Au with other elements on the electronic structure, DOS and plasmonic quality factor. These parameters were calculated for substitutional alloys of Au with Al, Cd, Mg, Pd, Pt, Sn, Ti, Zn and Zr. As a result, only alloys with Al, Cd, Mg and Zn slightly improved the plasmonic response in a limited spectral region.

3.3. Analytical Models for the OC

An alternative to DFT for the description of OCs in plasmonic nanoalloys resort to the integration of analytical models with band structure calculations. For instance, the dielectric functions in metals can be modelled with the Drude–Lorentz (or Drude–Lorentz–Sommerfeld) formula.[ 2 , 40 , 121 , 122 ] This is an improvement of the Drude–Sommerfeld model for conduction electrons in a metal with the addition of a Lorentzian contribution to take into account the IB transitions [Eq. 1]:

| (1) |

where ϵ ∞ is the contribution from cores polarization and can be approximated as a constant, ω is the plasma frequency of the free electron gas, γ is the damping constant, j denotes the index of a Lorentz oscillator (a maximum index of j=N is assumed), aj, ω 0j and γj are the amplitude, the resonant frequency and the damping constant of the given oscillator j, and ω is the frequency of light. [123] The first two terms are the same as the Drude model describing the free electron gas in the metal, while the summation spans over the N Lorentzian contributions chosen to represent the IB transitions. This model is very useful for fitting the experimental OC of metals but cannot be used to predict it. For instance, Hashimoto et al. easily fitted the OCs of Au−Ag−Cu nanoalloys with the Drude–Lorentz model in a wide range of compositions. [124] Ma et al. implemented the Drude–Lorentz model to calculate the OCs of Au−Ag, Au−Cu, Ag−Cu, Au−Pt, and Ag−Pt alloys. [125] They assumed that the mass, the energy of bound and free electrons and in general the quantities that describe an alloy between noble metals obey the bowing rule, and thus can be described by a quadratic polynomial. The results were generally satisfactory for the alloys between noble metals at the level of a first approximation in the absence of other data.

Rioux et al. instead, modified the model by including the electronic structure of Au−Ag alloys in the IB transitions contribution, as calculated with DFT. [126] They developed a parametric analytical model that considers that the main features of the OC are in critical points (the Van Hove singularities) of the joint Density of States (jDOS). Thus, the interband contribution was modelled with the convolution of the jDOS with a single Lorentzian oscillator [Eq. 2]:

| (2) |

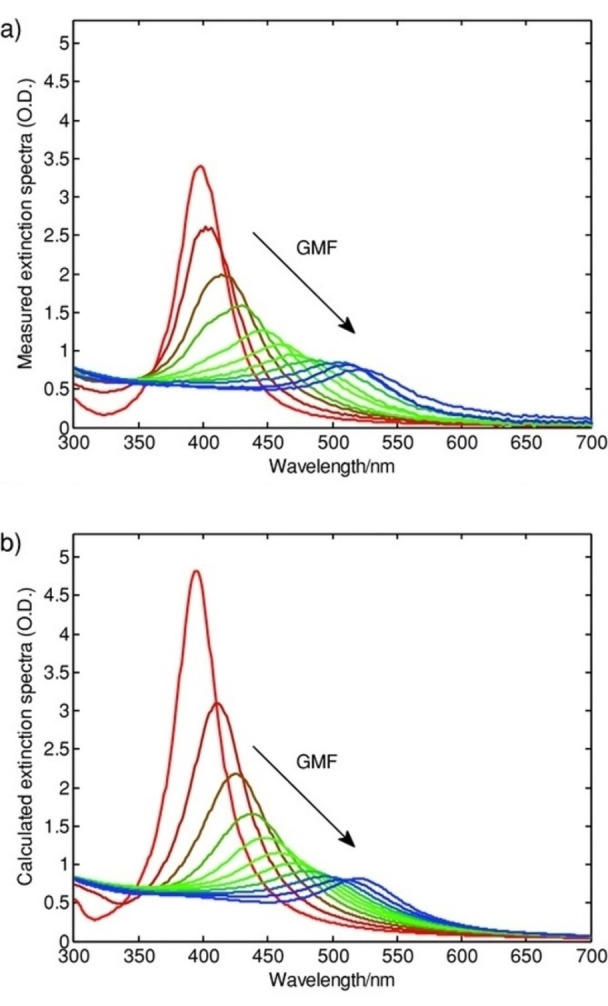

where k and l define the occupied and empty states, γ is the broadening factor, and A is an amplitude factor. This model implemented on the Au−Ag system well reproduced the dielectric functions obtained from ellipsometry measurement and the plasmonic peak position in the extinction spectra simulated with Mie theory for different compositions (Figure 11).

Figure 11.

Measured (a) and calculated (b) extinction spectra of Au−Ag alloy NPs with different gold metal fractions. The interband contribution was modelled with the convolution of the jDOS with a single Lorentzian oscillator. Reprinted with permission from Ref. [126]. Copyright (2013) WILEY‐VCH Verlag GmbH & Co. KGaA, Weinheim.

3.4. Modelling the Optical Extinction Properties of Plasmonic Nanoalloys

OCs are the required input for the calculation of the extinction (i. e. absorption plus scattering) cross‐sections of alloy NPs, as well as of the local electromagnetic field effects. There is a variety of numerical models for the calculation of optical properties at various degrees of accuracy depending on the size, shape, composition and assembly of NPs, as reviewed for instance in Ref. [2,127].

The simplest case is that of isolated spherical particles, also core‐shell, which are excellently described with the analytical Mie theory. The Mie model is based on the solution of the Maxwell equations by considering multipolar expansion of the incident, internal and scattered electromagnetic field. [128] By applying the boundary conditions, it is possible to obtain the expansion coefficients that are related to the extinction cross‐sections (absorption and scattering). With the Gans theory, the model can be extended to elliptical particles under the dipolar approximation, i. e. field homogeneity along the whole NP volume, which happens only for photon wavelength much larger than particle size.

For any shape and assembly, the most common numerical models are the discrete dipole approximation (DDA), the finite‐difference time‐domain (FDTD) and the boundary elements method (BEM).[ 2 , 127 ] All of them use the OCs directly or mediated by a Drude–Lorentz fit. In DDA the particles are modelled as a simple cubic array of polarizable volumes (dipoles) interacting with the electromagnetic wave and mutually with the surrounding dipoles. The FDTD model is based on the solution of the Maxwell's equations in the time domain within a finite space volume (the Yee cell). The space and the time discretization allow to determine the value of the electric field at that timeframe by solving the derivatives of the electric and magnetic fields. [127] The BEM model is based on the boundary conditions for the continuity of the tangential components of the electric and magnetic fields at the surface and interfaces of the system. In this way, a system of surface‐integral equations is obtained, which is solved by discretization of the integrals using a set of N representative points distributed at the boundaries of the system. In the specific case of ensembles of spherical particles, the generalized Mie theory (GMT) approach and the T‐matrix methods can provide exact electromagnetic solutions with the best computational efficiency.[ 2 , 129 ]

Literature provides several examples of the use of Maxwell‐Garnett effective medium theory (EMT) as a simple model for the description of mixed phases or when particles are distributed with high density in a small region of space. For interacting spherical particles, the interaction is considered in the model with a parameter K measuring the extent of local electromagnetic field contribution from nearby NPs. The model can be adapted also to elongated particles with the approach proposed by Garcia et al. [130] However, the accuracy of this theory is limited and not comparable to the numerical models listed above.

3.5. First‐Principles Modelling of the Optical Absorption of Small Alloy NPs

In spatially confined materials, where the surface and interface break the periodicity of the bulk phases and quantum effects make the bulk OC no more representative, first‐principles approaches like TD‐DFT can be used to obtain directly the optical absorption. This is the case of NPs composed of at most a few hundred atoms, while for thousands of atoms it is usually more accurate and computationally affordable to extract the OCs from the bulk phase and correct it with size effects as described in detail in Ref. [2,122]. The first‐principles approaches are the only one capable of predicting and understanding the appearance of plasmon resonances in ultrasmall alloy NPs. Besides, the predominance of core‐shell ordering over other chemical configurations emerges in this size range at the boundary between molecular and solid‐state behaviour, which is evidenced by the models and must be considered for the interpretation of the resulting optical properties. [131]

Recently, TD‐DFT and TD‐DFT+TB (tight binding) were used to compute the absorption spectra of Au−Ag clusters in the 10–102 atoms range.[ 132 , 133 ] They evaluated how the scalar‐relativistic (SR) and the spin‐orbit (SO) contribution affect the optical properties and the transition from molecular‐like to metal‐like (plasmonic) optical excitations. [133] This evidenced how the screening of s‐electrons by the d‐electrons as well the s‐d hybridization leads to the quenching of plasmonic excitation in Au‐rich clusters compared to Ag‐rich ones. In fact, the Ag/Au ratio correlates with a decrease of the s‐d hybridization and an increase of the s‐s transitions that enhance the intensity of collective excitations, shifting the LSP energy and intensity toward higher values with larger Ag contents. This shows that the doping of Au clusters with Ag atoms is a good method to modulate the optical response between molecular and metallic behaviours by acting on the SR and SO effects. In a subsequent study, they exploited a TD‐DFT integrated with a tight binding model as an alternative method that starts with the full DFT ground state calculation and apply approximations only for the excited state part to reduce the computational cost without significantly affecting the precision of the calculations. [132] The results for Au−Ag icosahedral and tetrahedral clusters were in good agreement with the ones obtained with the more accurate standard TD‐DFT calculations, despite the lower computational effort. [133]

Danielis et al. also used a TD‐DFT method to calculate the absorption spectra for Ag−Pd, Au−Pd, and Au−Pt clusters. They exploit the complex polarizability TD‐DFT algorithm on the ADF program to extract the spectra from the imaginary part of the polarizability. [108] The same method has been used by Olobardi et al. to study in depth the optical properties of Ag−Pt and the role of the Pt→Ag or Ag→Ag transitions in the low and high energy parts of the spectrum. [106] Medves et al. used the same complex polarizability TD‐DFT approach to simulate the photo‐absorption spectra of Au−Ag alloys, in particular Ag24Au(DMBT)18 − in which DMBT is a thiolate ligand (dimethylbenzenethiolate). [134] The good agreement of the spectra with the experimental data depended on the choice of the exchange‐correlation functional and of the geometry of the cluster.

It is worth mentioning that in TD‐DFT all excitations are treated on the same footing, and thus it is not obvious how to distinguish plasmonic peaks from pure electron‐hole excitations in the computed spectra. To overcome this limitation, plasmonicity indexes were proposed, that allow inquiring the nature of electronic excitations obtained from TD‐DFT. [135] Less obvious to read, but just as useful, Transition Contributions Maps (TCM) decompose each electronic excitation in electron‐hole transitions, giving a direct visualization of TD‐DFT outcome and facilitating the discussion on the nature of the excitation. [136]

3.6. ML Approaches to the Modelling of Plasmonic Nanoalloys

ML approaches are exploited for the identification of trends and patterns in big sets of data. Thus, the ML computational technologies are highly versatile and are being exploited to solve problems at different levels in the field of plasmonic nanoalloys.

Saidi et al. reported on the training, use and validation of a ML potential (deep neural‐network potential, DNP) for modelling Ag−Au alloys with accuracy comparable to the standard DFT method, but with lower computational cost. [90] The DNP was trained with the DFT and applied for the prediction of various alloy properties such as equilibrium crystalline structures, mechanical properties, defect energies and diffusion energy barriers for Au or Ag adatoms on the principal surfaces of the Au−Ag alloy. Besides, the DNP allowed the simulation of the nucleation and growth of a shell of Ag (or Au) on the core of Au (or Ag), as in the real case of seeded growth, confirming the preferential growth of {111} facets at the expense of the {100} ones.

Kitchin et al. trained a neural network with >5000 DFT calculations to predict the potential energy of ternary Cu−Pd−Au alloys in the whole compositional range and then used Monte Carlo simulations to obtain the segregation profile at 600 K. [137] Results showed a limited agreement with experimental data and this was explained with the inapplicability of ideal ordered crystalline models to the more complex and defective real alloys.

Mirkin et al. extended the ML approach to the synthesis of a library of multi‐element and multi‐interface nanocrystals by the scanning probe block copolymer lithography (SPBCL). [91] In SPBCL, a scanning probe is used for the deposition of microscopic volumes of liquids containing a block copolymer and metal salts, to synthesize metal NPs. This method allows the rapid screening of synthetic parameters such as metal precursor concentration. Indeed, for an eight‐dimensional chemical space (Au−Ag−Cu−Co‐Ni−Pd−Sn−Pt), the number of variables is so high that a ML approach was required to limit the number of tests and identify the conditions to harvest the desired nanomaterials. Starting from the experimental data for a smaller set of 5 metals, the ML method was trained and extended to the larger dataset in a feedback loop approach, allowing the discovery of NPs with unprecedented composition and number of interfaces.

4. Properties of Plasmonic Nanoalloys

Among the long list of properties of plasmonic nanoalloys, some general trends can be identified in the recent literature which specifically takes advantage of alloying compared to single element NPs. These trends can be tentatively grouped in the plasmonic response, the hot carriers generation and the coupling of magnetic with plasmonic features.

4.1. Plasmonic Response

Alloying usually has a deep influence on the plasmonic response of single element constituents. In terms of plasmonic efficiency versus losses, these can be quantified with the dimensionless plasmonic quality factor QP . A reliable expression of QP has been proposed as a function of the real (ϵ 1) and imaginary (ϵ 2) components of the OC at a specific frequency of light ω [Eq. 3]:[ 8 , 19 ]

which can be further approximated in the limit of low loss and the quasistatic regime for the LSP in a nanostructure as [Eq. 4]:[ 2 , 8 ]

However, the expression for QLSP is better suited to indicate the extinction cross‐section and local field enhancement features, both connected to ϵ 1. Instead, all those effects related to the efficiency of light‐to‐heat conversion (thermoplasmonics), that are connected to ϵ 2, are not directly considered by QLSP . For this reason, Baffou et al. introduced two dimensionless parameters, named Faraday and Joule numbers, to simply quantify the ability of a NP to, respectively, enhance the optical near field and produce heat just starting from the material OC, geometry and surrounding environment. [138]

Since alloying modifies the OC of a material, also the plasmonic figure of merits will be altered. For instance, gold and silver are the most prominent plasmonic materials[ 2 , 139 ] and retain their superior plasmon capabilities also in the Au−Ag alloys.

For what concerns the LSP position, taking as a reference the common case of spherical NPs in the dipolar regime, it is defined as a first approximation by the frequency of electromagnetic light at which the following relation [122] is satisfied:

Equation (5) means that the LSP spectral position and extinction cross‐section can be easily tuned by changing the real and imaginary components of the OC. For instance, in Au−Ag alloys the LSP is tuned in the 400–520 nm spectral range (for spherical NPs) simply by acting on the Au/Ag ratio and taking advantage of the full miscibility of the two elements. Indeed, the Au−Ag alloy is by far the most studied and well‐known bimetallic plasmonic system, which is often used as a benchmark for testing computational and analytical models.

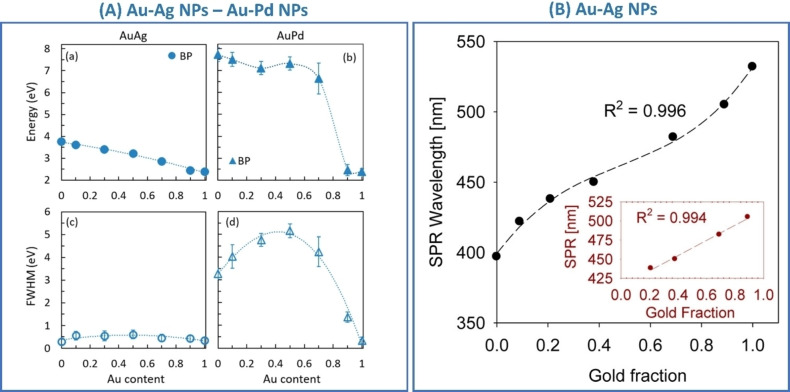

Kadkhodazadeh et al. systematically studied the plasmon resonance of single Au−Ag and Au−Pd nanodisks with different compositions using electron energy loss spectroscopy (EELS). [140] From EELS, they also obtained the complex dielectric function applying the Kramers‐Kronig analysis. The advantage of this approach was that of demonstrating at the single‐NP level the correlation of LSP energy and full width at half maximum (FWHM) with the composition. In this way, the highest FWHM in Au−Ag nanodisks was found for alloys with nearly equimolar composition, while in Au−Pd nanodisks the FWHM continuously increased with Au fraction (Figure 12A). Indeed, Au, Ag and their alloys have an identical fcc crystal structure and lattice parameter, making the precise identification of alloying very difficult in ensemble samples. Even scanning TEM elemental analysis based on energy dispersive spectroscopy (EDS) with a resolution of few nm is insensitive to surface segregation or inhomogeneities at the level of 1 nm in most cases. This helps explaining why literature reports conflicting experimental evidence about linear or non‐linear LSP position shift with composition.[ 141 , 142 , 143 , 144 ] However, the nearly linear dependence of the plasmon resonance position in spherical Au−Ag NPs is most frequently observed for Ag fraction <80 at % (Figure 12B).[ 142 , 143 ]

Figure 12.

(A) Energy and FWHM of the bulk plasmon in Au−Ag (a, c) and Au−Pd alloys (b, d) as a function of the Au content, measured by EELS in alloy nanodisks. Reprinted with permission from Ref. [140]. Copyright (2019) American Chemical Society. (B) Composition dependence of the surface plasmon resonance (SPR) wavelength for 20 nm spherical Au−Ag alloy nanoparticles with different compositions in water. The R2 value corresponds to a third‐order polynomial fit. Inset corresponds to a linear regression of the composition dependence of the SPR wavelength at intermediate gold fractions. Reprinted with permission from Ref. [142]. Copyright (2013) American Chemical Society.