Abstract

Copper(i) catalyzed alkyne azide cycloaddition (CuAAC), the quintessential example of ‘click chemistry’, provides an adaptable and adequate platform for the synthesis of nanogels for sustained drug release at targeted sites because of their better biocompatibility. The coupling of drugs, carried out via various synthetic routes including CuAAC, into long-chain polymeric forms like nanogels has exhibited considerable assurance in therapeutic advancements and intracellular drug delivery due to the progression of water solubility, evacuation of precocious drug release, and improved upthrust of the pharmacokinetics of the nanogels, thereby rendering them as better and efficient drug carriers. The inefficiency of drug transmission to the target areas due to the resistance of complex biological barriers in vivo is a major hurdle that impedes the therapeutic translation of nanogels. This review compiles the data of nanogels synthesized specifically via CuAAC ‘click’ methodology, as scaffolds for targeted drug delivery and their assimilation into nanomedicine. In addition, it elaborates the ability of CuAAC to graft specific moieties and conjugating biomolecules like proteins and growth factors, onto orthogonally functionalized polymer chains with various chemical groups resulting in nanogels that are not only more appealing but also more effective at delivering drugs, thereby enhancing their site-specific target approach and initiating selective therapies.

Copper(i) catalyzed alkyne azide cycloaddition is the quintessential example of ‘Click Chemistry’, provides an adaptable platform for the synthesis of nanogels for sustained drug release at targeted sites owing to their better biocompatibility.

1. Introduction

In the domains of biomedicine, bio-nanotechnology, and pharmaceutics, polymer-based drug nanocarriers have always been fascinating drug therapies for targeted site-specific drug delivery.1–3 A wide range of diseases including neurological disorders, cardiovascular diseases, and malignancies can be treated and healed in a better and more efficient manner using polymeric drug delivery systems owing to the targeted and controlled release of therapeutics,4–6 thereby reducing the side effects of drugs, especially those for cancer which is a major threat to human health after cardiovascular diseases which are the leading cause of human fatality.7–10 It was reported by the International Agency for Research on Cancer (IARC), in 2018, that there were 18.1 million cancer diagnoses globally, with a projected increase to 29.5 million by 2040.10 Cancer therapy still has high side effects of anti-cancerous drugs, while damaging the fast-growing cells of the body as well as the tumor sites in adequate immune responses resulting in adverse side effects,11,12 To tackle such issues, researchers have focused on the development of nanocarriers to transport the drugs for high intracellular drug delivery.13,14

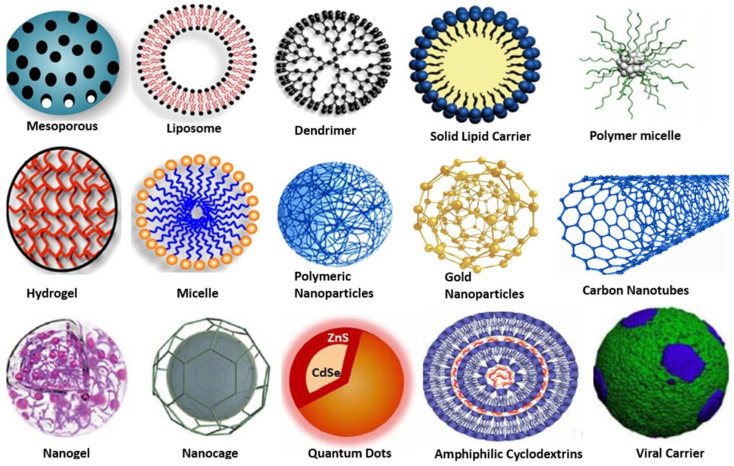

The design and expansion of nanocarriers play a key role in the development of new advanced therapeutic ways as the nanotechnology implied for their synthesis additionally empowers the drugs of concern to enhance their vital properties like solubility and increased concentration at the target site for higher potency and reduced side effects.15 These desirable traits of drugs in consideration with the stealth behavior of the nanocarriers towards the immune system are being explored for the treatment of many chronic and acute disorders, as the nanoparticles potentially improve the therapeutic index, decrease off-target toxicity, and change the pharmacokinetic profile of pharmaceuticals16 so that the desirable drug gets incorporated into the body and accumulates at the required site while exhibiting pharmacophoric properties exclusively towards the target cells, known as ‘targeted drug delivery’. A variety of nanocarriers have been reported in the literature for applications in targeted drug delivery such as mesoporous nanocarriers, dendrimers, carbon nanotubes, gold nanoparticles, quantum dots, nanogels, etc., and are represented in Fig. 1.17

Fig. 1. Structural representation of various nanocarriers, as potential agents, for targeted drug delivery. Adapted from ref. 17, used under Creative Common CC-BY license.

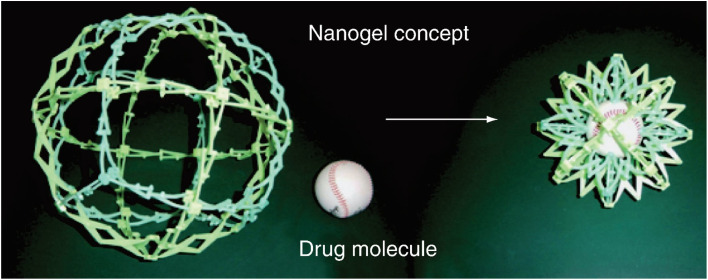

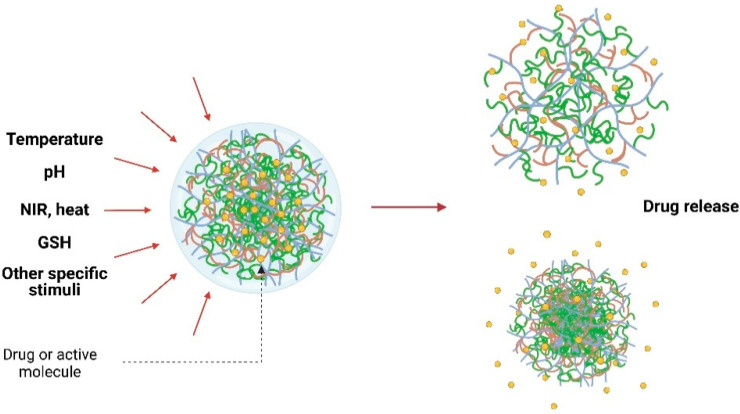

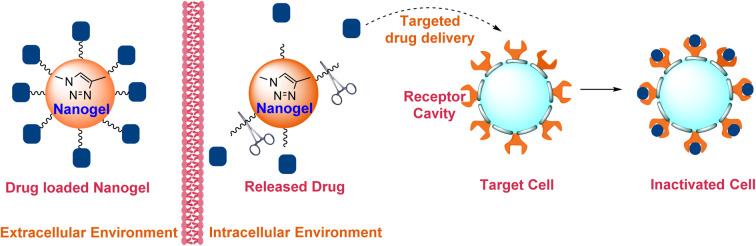

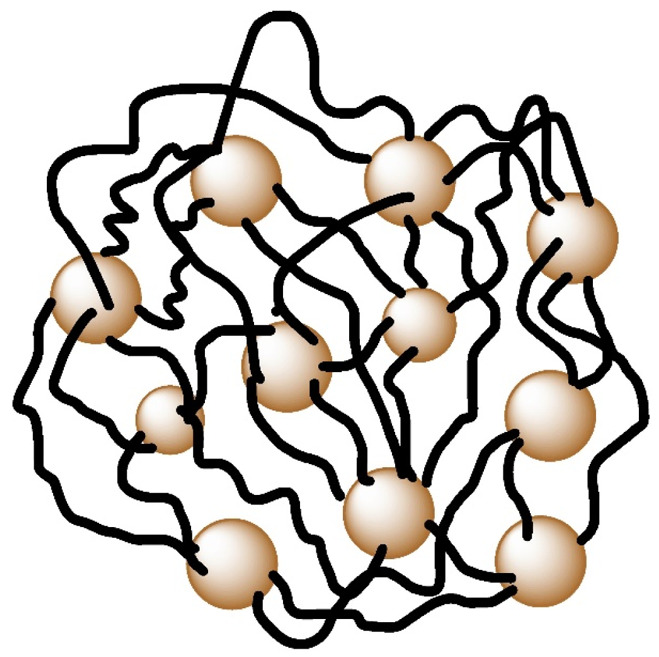

Nanogels have proved to be apt agents for targeted drug delivery due to their high biocompatibility and beneficial dimensions ranging from human organs, and cells to viruses.18,19 Nanogels essentially are submicron-sized hydrogels comprised of either physical or chemical crosslinked polymeric chains that make 3D customizable permeable organization having great limits with regards to water retention without dissolving in an aqueous solution.20–22 The vast array of nanogels and their significant potential to cross biological barriers23 due to their nanometric dimensions have highlighted them to act as carriers (Fig. 2)24 for the transport of bioactive species, resulting in the development of the best therapeutic strategy known as the ‘controlled drug delivery’ approach, whose aim is the controlled release of the administrated drug within the optimum range of concentration, thereby limiting the potential adverse effects.25,26

Fig. 2. A pictorial depiction of drug loading by the nanogels.24 Adapted from Nanomedicine, 2010, 5(2), 165–168 with permission of Future Medicine Ltd.

Due to the numerous advantages like stealth behavior, high drug loading ability, and sustained release presented by these nanogels as ‘targeted drug delivery’ agents, the researchers have upsurged their efforts to synthesize such polymeric systems via different efficient and cost-effective methodologies wherein Cu(i)-catalyzed alkyne–azide cycloaddition (CuAAC), the prototypical ‘Click Chemistry’ pathway27,28 has been extensively and successfully explored for the synthesis of tailor-made novel nanogels.29 This review enlists the diverse nanogel systems, as drug delivery agents, that have been synthesized via CuAAC. The structural characteristics, the type of reactants (monomers/polymers) used, and the functional behavior of the reported nanogels have been presented and discussed in the forthcoming sections following some general characteristic features, the classification, and the mechanism of action of these nanogels.

2. Characteristic aspects and classification of nanogels

2.1. Push for the requirement of nanogels

The conventional anti-cancerous drugs used in therapy have numerous side effects on the normal growing cells of the host body, apart from tumor sites like hair nails, skin, etc.30 To overcome these undesirable side effects, researchers have developed various polymer-based macromolecular drug delivery systems, including nanoparticulate drug delivery systems, wherein the drug is loaded on the target site by physical interaction.31,32 The conjugation of anti-cancer drugs to the polymer-based skeleton to form polymeric prodrug is an excellent strategy to improve the solubility of the specific hydrophobic drugs, thereby preventing the early and premature release of drugs with the improvement of drug pharmacokinetics.

2.2. Physicochemical and stability aspects of nanogels

2.2.1. Physicochemical properties

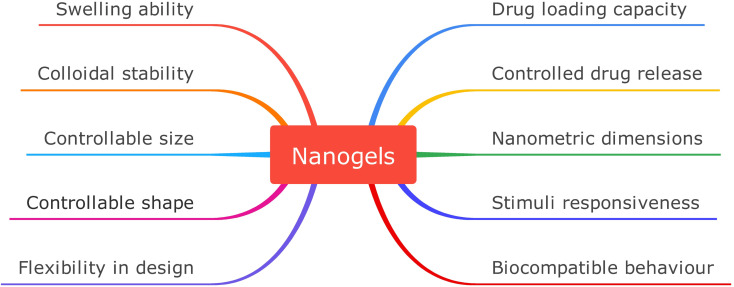

Physicochemical qualities influence the interaction of particles with various biological substances (e.g., proteins or membranes) of the tissue into which they are introduced, and hence have a significant impact on the absorption and release processes of medications. Therefore, a thorough understanding of the chemical constitution and physical properties of polymeric particles is essential for determining whether they may be successfully developed as drug-delivery vehicles and how they interact with their possible biological environment/system.33,34 The tuneable features of nanogels drug delivery systems include size, ease of production, biocompatibility, and response to different external factors like changes in temperature, pH, light, hydrophobicity, etc. Some of the relevant physicochemical features of nanogels and the effects and biological utility thereof have been compiled below and represented in Fig. 5:

Fig. 5. Representation enlisting distinguishing physicochemical properties of nanogels.

• Nanometric dimensions: this property is attributed to surface area and volume ratio, so if the structure is well-created, these smaller dimensions enable nanoparticles to pass through different biological membranes and infiltrate tissues and cellular pathways.23,35 The nanoscale size of the nanogels is crucial for their ability to permeate and remain in the tumor, and the nanometric dimensions give them a higher surface area to the volume aspect ratio, making hydrophobic medicines more soluble. Quantum mechanical properties, biological reactivity, and the nanogels' intrinsic surface qualities are all controlled by their nanometric size.36,37

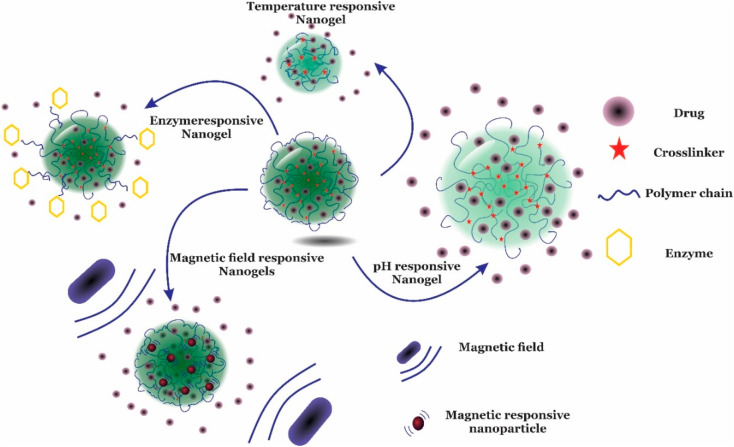

• Response to external stimuli: nanogel designing is done in such a way that they must respond to specific stimuli and must retain high drug encapsulation stability while circulating, but while reaching the targeting site, the drug should release readily in response to the appropriate stimulus. Recent advances have demonstrated that stimuli-responsive release of drugs in response to changes in pH, temperature, redox, light, enzymes, etc. (Fig. 3)38 is the most common release mechanism now in use regardless of physical embedding or covalent connection of the nanogels.39,40 As a result of these factors, the nanoparticle-composed gel undergoes several ancillary or conformational changes which also alter the hydrophilicity and hydrophobicity of the gels made of nanoparticles, thereby resulting in drug release.18,41

Fig. 3. An illustrative representation of different modes of drug release by nanogels in response to different types of stimuli. Adapted from ref. 38, used under Creative Common CC-BY license.

• Swelling behavior: nanogels possess this peculiar property due to solvent penetration which causes expansion of the polymeric framework, resulting in increased volume in the system. This property can be controlled with the help of external stimuli like pH, temperature, or particular molecules (Fig. 4)42 that can change the swelling/de-swelling qualities, which further can be regulated by different structural factors like the extent of crosslinking, the presence of different kinds of functional groups, charge concentration, etc.43,44

Fig. 4. A representation of targeted drug release from nanogel via swell–shrink action stimulated by external factors. Adapted from ref. 42, used under Creative Common CC-BY license.

• Size and shape control: the size of the nanogels can be controlled chemically by limiting the rate of phagocytosis and helping in the passive transport of loaded drugs inside the intracellular cavity. Also, nanogel shapes can be manipulated with proper design to increase their quality and performance. The best example of this is the non-spherical type of nanogels which are used for drug delivery and circulate for a longer time in the circulatory system.45,46

• Drug loading: this characteristic of nanogel depends mainly on the properties of the polymeric system used to synthesize the nanogel, and the kind of functional groups attached to the polymeric unit. Physical entrapment, as well as covalent and noncovalent interactions, and passive/diffusion-based drug loading are the different pathways for incorporating drugs into the nanogels. The drug loading efficiency is established by the hydrophobic core, which permits cargo loading via hydrophobic or electrostatic interactions. The hydrogen bonding and van der Waal forces of interaction within the gel network are initiated by these dangling functional groups of polymeric chains, thereby making it easier to transport drugs.47–49

• Drug release: drug delivery at the targeted site is the main approach to the use of nanogels. This includes diffusion release, drug degradation, or response to the external environment. Drug release can be manipulated and controlled by mechanisms like framework degradation, diffusional release, or in response to external stimuli like pH, temperature, redox potential, etc. By suitable nanogel composition, the release may be regulated and prolonged, thereby making it possible to time and place the delivery of medicine so that it meets the body's physiological needs. In addition to the physicochemical properties of the nanogels, the process of drug release is also related to how the cargo are loaded into the nanogels. Swelling nanogels to increase mesh size or degradation unlocks a door for drug diffusion, but medicines need to be dissociated to be released.47–49

• Colloidal stability: in the cellular matrix and body fluids, nanogels possess higher colloidal stability, which helps to ensure good performances in drug delivery and drug stability. The polymeric chains utilized for nanogels synthesis form crosslinked networks that enclose the loaded molecule, increasing its colloidal stability. The colloidal stability of nanogels is also reported to get improved with active free radicals. The stabilizer or dispersion, typically a block or graft copolymer, binds covalently to the surface of the expanding particles to prevent coagulation and increase the nanogel system's colloidal stability.42,50

• Biocompatible behavior: although nanocarriers can have interactions with cells and tissues, they must not have any cytotoxic, apoptotic, or necrotic effect on the individual.51 Biocompatibility of nanogels gives the sophistication when in use must perform optimal and desired functions without provoking any kind of general or systemic destructive effects.52–54 Due to their composition of biocompatible polymers, nanogels when implemented at the molecular scale, do not cause any negative biological reactions like mutagenic or immunological activation. This biocompatibility of nanogels is an extremely desirable characteristic of any nanocarrier for drug delivery purposes.46

2.2.2. Stability of nanogels

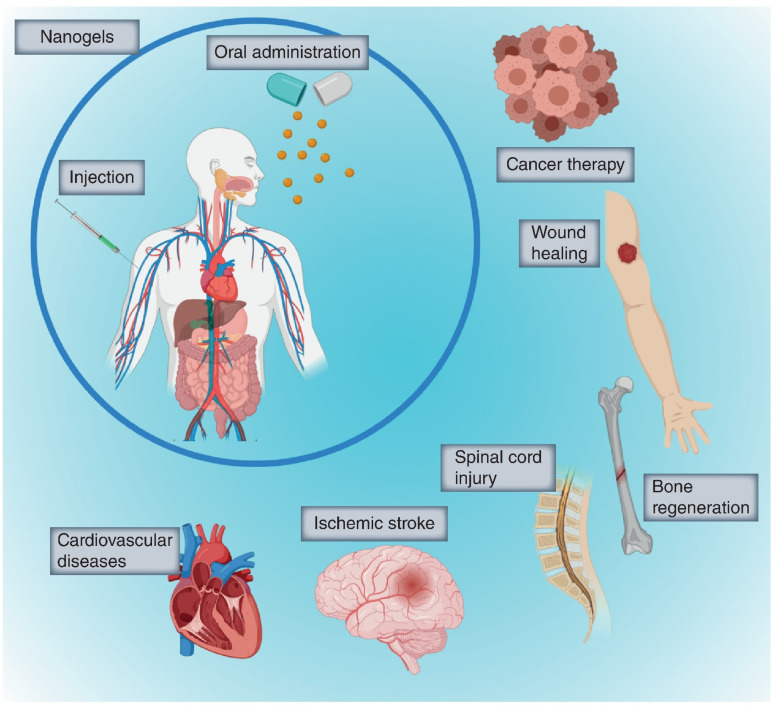

The development of nanogels is carried out with a focus to possess properties like high stability through crosslinked constructions, and deformability to improve the restricting and maintenance inside designated tissue.55–58 The immensity of this possibility has sparked a lot of financing, as well as research, focused on developing these nanoparticulate drug delivery methods. Further, the thermodynamic stability for drug loading on nanogels is achieved by the attachment of ligands, antibodies, and drugs like doxorubicin having specific molecular recognition to the surface of nanocarriers.15 As a result of the significantly high structural and thermodynamic stability, the nanogels are being utilized in the drug delivery field, preventing drug degradation and premature release while also safeguarding the molecule in vivo59 including cancer treatment, CNS problems, cardiovascular damage, wound healing, and a variety of other human body diseases (Fig. 6).

Fig. 6. Target organs for implementation of nanogels as drug carriers in vivo.59 Adapted from Nanomedicine, 2020, 15(27), 2707–2727 with permission of Future Medicine Ltd.

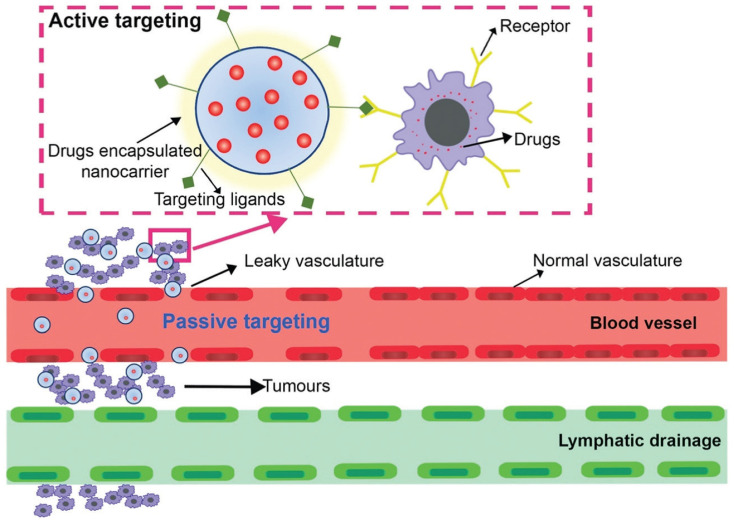

2.3. Mechanism of action, biodistribution, and toxicity

Besides the targeted drug delivery, nanogels are now a leading choice for scientists with the aim to reduce the adverse effects of drugs while keeping in view the health of the host.60 For the nanogel to reach the target site, the mode of circulation and the strategies of the drug delivery system (active and passive targeting) (Fig. 7) are the top consideration factors.37,61 While the passive targeting strategies work on the enhanced permeability, the retention effect of the cytosol in the cell is wholly chance-dependent and is based upon the circulation time in the host.62 The active mode of drug transportation involves more specific and efficient delivery of the drug to the target site63 as it is mediated by affinity ligands connected to a carrier, avoiding the accumulation of the drug in normal tissues and thus helps in enhancing the efficiency of therapeutic doses and helps in limiting the side effects on normal organs of the host.64

Fig. 7. A schematic representation of the phenomena of active and passive targeting exhibited by a nanocarrier encapsulating the drug. Reproduced from ref. 65 with permission from the Royal Society of Chemistry.

Nanogels' surface physicochemical qualities are directly linked to their biodistribution in vivo. Nanogels can have a wide range of morphologies, from core–shell to spherical, depending on the particles used and the assembly method. Chemical processes or physical crosslinking based on hydrogen bonds, ionic interactions, or other intermolecular connections can produce these varying morphologies. That being said, the biocompatibility of the surface embellishment is a crucial factor that can significantly affect biodistribution.66,67 To maintain their biodistribution, nanogels can be PEGylated, which makes them more hydrophilic, protects them from any charge their core may carry, and creates a steric hindrance for interaction with serum proteins. In addition, the biodistribution and clearance from the circulation of these ‘stealth’ nanogels are significantly affected by particle size.68,69 Researchers generally are of the opinion that smaller particles with a higher curvature can decrease opsonization responses and subsequent clearance by macrophages, resulting in longer circulation times and greater tumor accumulation.70 Apart from the biodistribution, the intrinsic toxicity of nanogels is also an important parameter for practical implementation. The polymeric ingredients used in nanogel synthesis must be either non-toxic in the first place or degrade into non-toxic byproducts during metabolism. For instance, polymeric systems based on methacrylates and acrylates can be hydrolyzed into small molecule alcohols and non-toxic poly-methacrylic acid and poly-acrylic acid, respectively. On the other hand, enormous surface/mass ratio, and interactions with cells including surface activation, uptake, intracellular breakdown or deposition, all of these factors impact possible toxicity and side effects by abnormally stimulating and/or harming the cells taking up such carriers.18,19,39,46

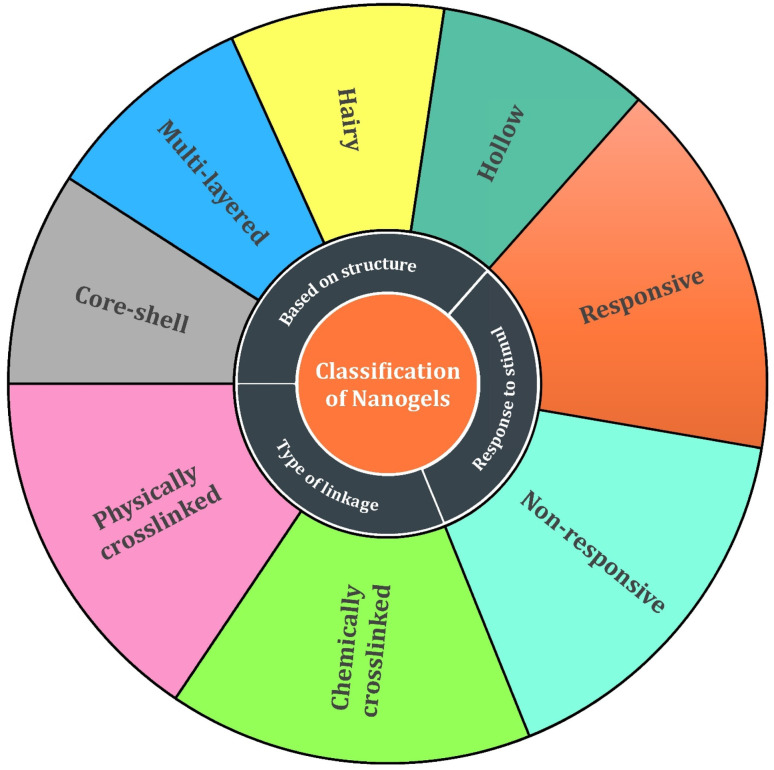

2.4. Classification of nanogels

Multiple factors influence the design and development of nanogels which include the tuning of nanogels for desired functions, point of action, polymeric constituents required for production, and the long-term releasing behavior of the loaded drugs. This classification of nanogels based on various factors is illustrated in Fig. 8.

Fig. 8. A schematic view of the classification of nanogels based on various aspects.

2.4.1. Structure of the nanogel

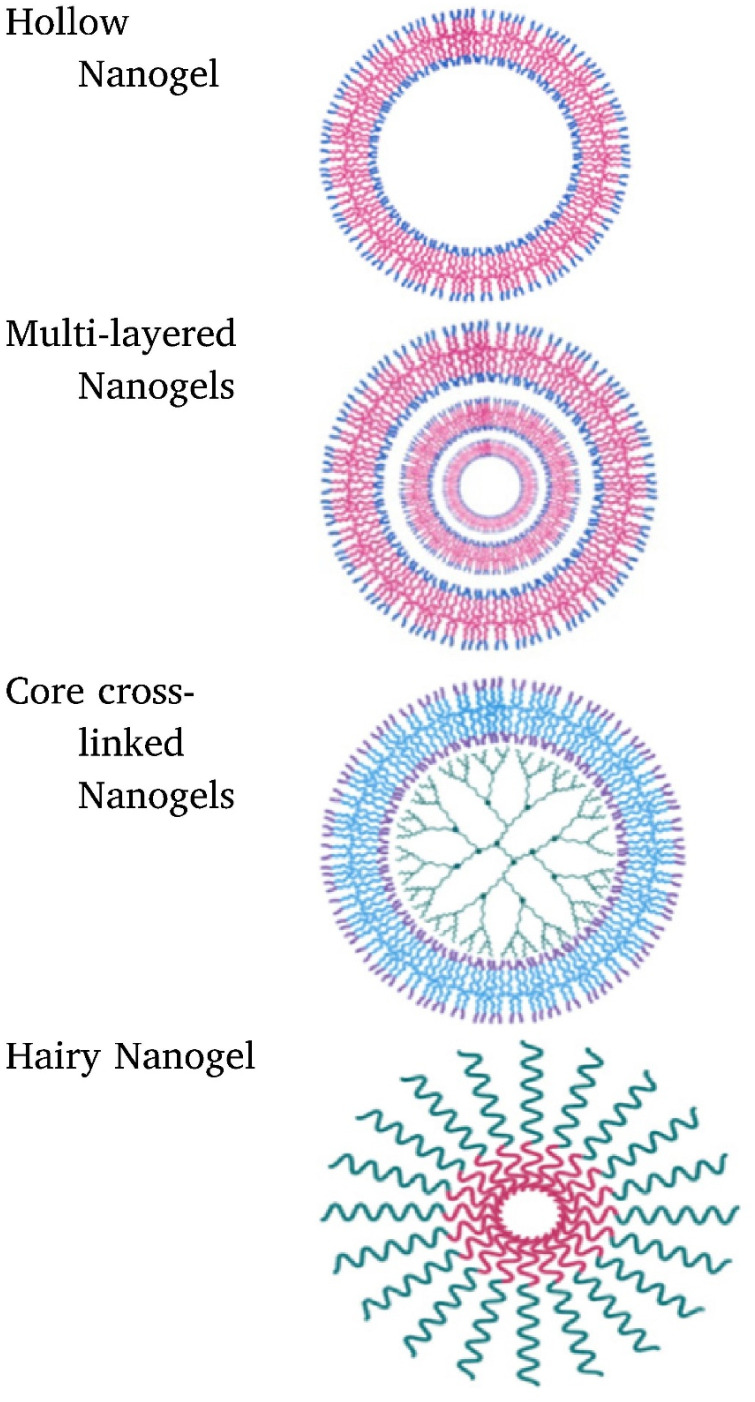

As per the structural aspects, the nanogels can be classified as hollow nanogels, which are those possessing a cavity at their centre matrix. This structure imparts a relatively greater surface area which can be advantageous for site-specific targeting whereas multi-layered nanogels are designed by interwinding different layers of polymers, which may be constituted of either single or multiple polymers. Such nanogels have exemplary benefits to deliver high toxicity bearing drugs and slow drug release can be prolonged. In addition to the above two categories, there are core–shell nanogels, that can be embedded with a core of Au–Ag nanorods, carbon dots, etc. and the fourth common category is hairy nanogels, which possess hair-like projections on their surface, as shown in Fig. 9.22,35,71

Fig. 9. Representative classification of nanogels based on their structures. Reprinted from ref. 35. Copyright 2020, with permission from Elsevier.

Nanogels can be categorized based on the linkage present in network chains of the gel structure into two categories primarily:

(a) Physically cross-linked nanogels: these types of nanogels are formed either by weaker linkages like van der Waals interactions, hydrophobic forces of attraction, or by hydrogen bonding but have a poor preference in comparison to chemically cross-linked nanogels owing to the stability factor.72,73 The nanogels can be those that are liposome modified, micellar type, and hybrid nanogels. These types of nanogels have the ability to form a complex with various substances like proteins, drugs, and DNA molecules36 and possess various desirable features such as reversibility, no chemical reactions, and/or toxic bioactive agents.35 When utilizing associating polymers, it might be challenging to create stable physically cross-linked nanogels with regulated sizes due to the relative weakness of their non-covalent contacts.74

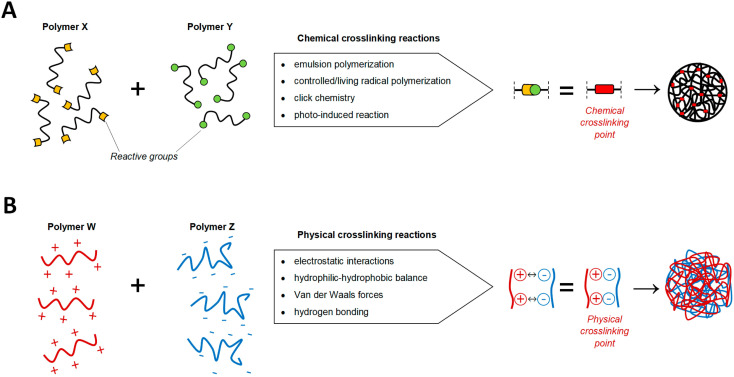

(b) Chemically cross-linked nanogels: these nanogels are characterized by permanently joined polymer chains via strong covalent linkages at different junctions.75 The permanent chemical linkages across the gel networks in chemical cross-linked nanogels and the functional groups present in the gel networks determine their characteristics.76 These nanogels are of several types based on the mode of synthesis like inverse emulsion polymerization, photo-induced crosslinking polymerization, reversible addition–fragmentation chain transfer (RAFT) polymerization, click chemistry crosslinking polymerization, etc. (Fig. 10). Out of these, click chemistry crosslinking polymerization is the optimistic mode for the synthesis and formulation of nanogels due to its promising advantages:

Fig. 10. Synthetic strategy of nanogels using chemical and physical crosslinking approaches. (A) Different chemical processes utilizing the nature of the corresponding groups can be used to generate covalent crosslinking's covalent bonds (red) between the active reacting species (yellow and green) of polymers X and Y. (B) The self-assembly of a Nano-scaffold is enabled by the physical interactions between polymers W and Z. Adapted from ref. 79, used under Creative Common CC-BY license.

• Developing robust nanocarrier products with high efficacy.

• Insertion of desirable moieties into the nanocarrier system with high precision.

• Imparting multi-functionality to the nanocarriers via different molecules/functional groups.

• Facile synthesis in aqueous conditions.

• Effortless affixation of high molecular weight-antibodies onto the nanoparticles etc.77,78

3. ‘Click chemistry’ as the synthetic route for nanogel synthesis

3.1. Current synthetic strategies for improved efficacy and payload for nanogels

As apparent from Fig. 10, the literature suggests that the synthesis of nanogels is formally achieved by crosslinking the polymeric units involved, for which there are broadly two categories, i.e. chemical crosslinking method including click chemistry, emulsion polymerization, controlled radical polymerization, and photo-induced reaction; and physical crosslinking methods.79 When compared to their covalently crosslinked counterparts, the comparatively lower mechanical strength, and more degradation-prone nature of physically crosslinked nanogels renders them more sensitive to the sol–gel transition caused by changes in environmental stimuli, thereby raising questions about their viability for use in harsh in vivo conditions like blood circulation. However, the therapeutic efficacy of a drug is significantly improved when the payload is contained within a nanogel that has been covalently crosslinked.80 As a result, more and more exploration of the chemical routes for crosslinking polymeric structures for nanogels synthesis is being currently undertaken to improve the performance and efficiency of the synthesized nanogels, some of which are discussed in Table 1.

Current methodologies implied for improved performance and efficacy of the nanogels.

| Methodology | Description |

|---|---|

| Emulsion polymerization | The thrust behind this process is to control the dimensions of the end product which is achieved by the polymerization process within a small volume. This is done by the formation of monodisperse stable organic/aqueous droplets containing the monomeric/polymeric chains as well as the catalysts and crosslinking agents.79 Since bimolecular termination is inhibited by the spatial separation of propagating chains in emulsion polymerizations, it is possible to simultaneously achieve high rates of polymerization and create polymer with a high molecular weight,81 thereby making this methodology an effective contender for nanogel synthesis |

| Controlled/living radical polymerization | Adding crosslinking agents allows for the synthesis of crosslinked particles or gels with a controlled polymer molecular weight in this methodology. Through the incorporation of quiescent forms in the dispersing species, the rate of bimolecular termination and lengthening of the life of the expanding polymer chains can be reduced.82 By adjusting the size and molar mass of the nano scaffolds, CLRP has proven to be effective in nanogel design wherein tuning the final morphology and structural composition such as porosity of the nanogels is possible due to the wide range of molar mass and branching structure of the nanogel building blocks that can be achieved by varying the concentrations of monomers and crosslinking agent83,84 |

| Photo-induced crosslinking | This technique is environmentally friendly as no crosslinking agents or catalysts are required, and no waste products are generated. For crosslinking, light irradiation is used on reactants that have a photo-activatable group. A photoinitiator kickstarts the reaction by being broken down by light to produce reactive radical species39,80 |

| Click chemistry | This methodology promises rapidity, adaptability, regiospecificity, high yields, and purity under aqueous reaction conditions. Oxygen, water, common organic solvents, synthesis conditions, biological substances, and pH all show high tolerance. The researchers address this ‘click’ methodology to have the potential to alter the status quo of polymeric nanogels synthesis and inspire novel approaches to the creation of polymeric drug therapies85,86 |

3.2. ‘Clicking’ polymeric moieties to synthesize nanogels

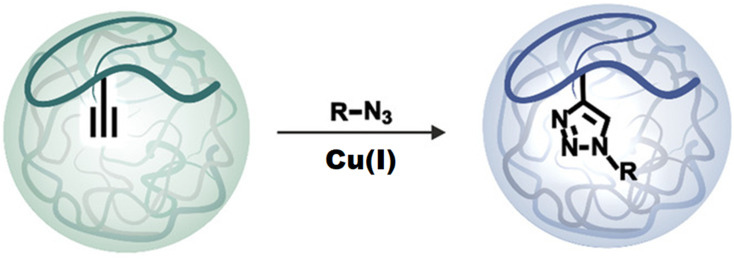

Click chemistry,87 being one of the most apparent synthetic routes88,89 has arisen as a profoundly encouraging strategy since 2001, when Dr Karl Barry Sharpless presented this methodology to the global research community for which he was recently awarded the Nobel prize in chemistry, 2022. Due to its facile synthetic route and the significant advantage of no by-product formation, it is utilized for synthesizing and fine-tuning nanogels with incredible selectivity, gentle response conditions, and thermodynamically favorable and stereospecific product formation (Fig. 11). Further, click chemistry has found its importance in material science, bio-chemistry,90 and bio-medical fields,91 with emphasis on the production and synthesis of polymeric structures,92 cancer therapeutics,93 antimicrobial agents,94,95 and chemosensors for selective identification of biomolecules in the living cells96 as well as ion recognition.97–100 Thus, click chemistry is a convenient approach for the synthesis of drug-like compounds that use a few simple and repeatable processes to speed up the drug development process.101–104 The nanogels synthesized via click chemistry are extremely compatible with encapsulated bio-actives such as live cells, proteins, and medicines,29,105 owing to click re-unique action's biorthogonality. As a result, this methodology has an enormous influence on the growing era of medicinal chemistry, with the considerable development of nanogels and innovative techniques for screening compounds.

Fig. 11. An illustration of the synthesis of nanogels following the ‘click’ reaction. Adapted from ref. 106, used under Creative Common CC BY-NC-ND license.

3.3. Types of click reactions used for nanocarriers designing

There are a bunch of strategies that can effectively synthesize nanogels that require the use of polymers. These polymers can be of natural origin that include collagen, albumin, fibrin, and some polysaccharide polymers like hyaluronic acid, chitosan, agarose, and heparin whereas the synthetic precursors include poly-lactic acid, polyglycolic derivatives, polyacrylates, and polymethacrylates.67 The characterization of these starting materials is based on the behalf of target-specific functional groups responsible for the formation of covalent linkage and help in interlinkage for the development of a three-dimensional network of nanogels. Some of the ‘click-based synthetic routes followed for the synthesis of nanogels are listed below:79,80

3.3.1. Alkyne–azide click reactions

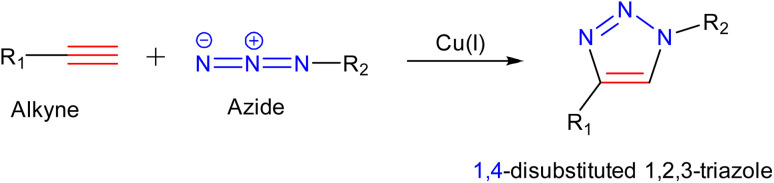

3.3.1.1. Copper(i)-catalyzed alkyne azide cycloaddition

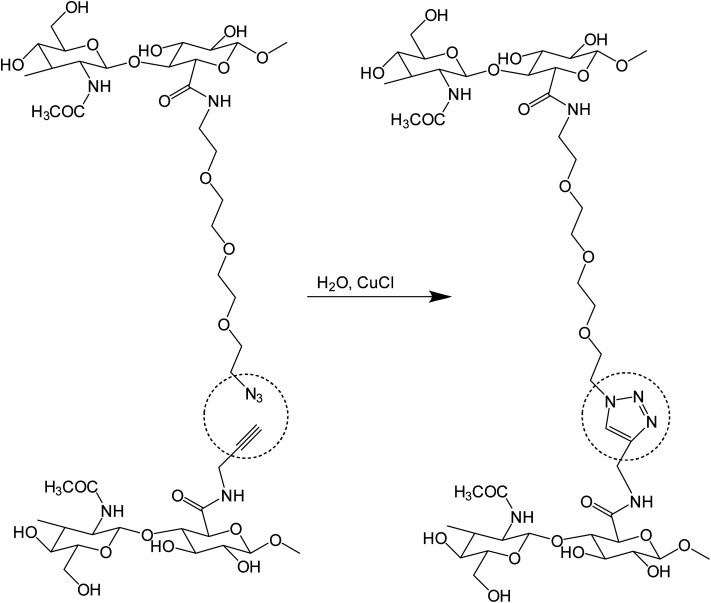

This is a quick method that ensures rapid reaction time, high yield and purity, regiospecificity, adaptability, and aqueous reaction conditions107 (Fig. 12). Both the azide and the triple bond can be grafted onto polymeric backbones with relative ease (through nucleophilic substitution, for instance) and a stable conjugate is formed.108 Since the reaction is typically unaffected by steric effects, therefore substituted primary, secondary, or tertiary aromatic azides can readily engage in this transformation with alkyne-derived components.79

Fig. 12. A schematic representation of Cu(i) catalyzed alkyne–azide cycloaddition.

Crescenzi and co-workers reported the synthesis of hyaluronic acid (HA)-sodium salt based ‘click’ hydrogels via sewing of water-soluble polysaccharide derivatives equipped with side chains bearing alkyne and azide moieties, as shown in Fig. 13. The polysaccharide-bearing nanogels were proved to act as a drug reservoir for doxorubicin after executing gelation in aqueous solutions of benzydamine and doxorubicin. These hydrogels were effective scaffolds for cells in tissue engineering as well as for the controlled drug release of therapeutically important macromolecules.109

Fig. 13. A schematic representation of the synthesis of HA-based hydrogels from alkyne and azide-bearing polysaccharides.109.

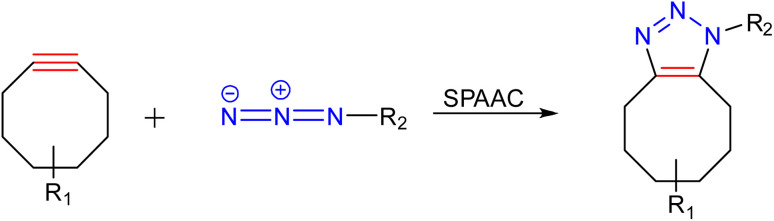

3.3.1.2. Strain-promoted alkyne azide cycloaddition (SPAAC)/copper-free reaction

The major advantage of strain promoted alkyne azide cycloaddition (SPAAC) is the absence of any metal atom/ion that can be toxic to cells and progression at ambient temperature. The highly efficient kinetics and selectivity of SPAAC render prevention of any undesirable side reactions that could occur during the conjugation process. Besides, the reaction is generally inert towards functional groups found in naturally occurring amino acids, nucleotides, and carbohydrates,110 which contributes to its attractiveness for bio-conjugation applications and selective alterations of biomolecules111 as well as nanocarrier synthesis (Fig. 14).

Fig. 14. A schematic representation of strain promoted alkyne azide cycloaddition.

Hodgson research group reported the synthesis of hydrogels wherein SPAAC between PEG chains having aza-dibenzocyclooctynes and azide functionalities were used to create a range of PEG hydrogels (Fig. 15), which possessed mechanical and rheological qualities that could be adjusted by changing the polymer molecular weight and the number of cross-linking groups per chain. The rapid gelation was recorded upon the combination of the two components in an aqueous solution, with no further stimuli or catalysts required, suggesting the system may be useful as an injectable hydrogel.112

Fig. 15. Combination of PEG chains having aza-dibenzocyclooctynes and azide functionalities via SPAAC to yield injectable hydrogel.112.

3.3.2. Thiol-click chemistry

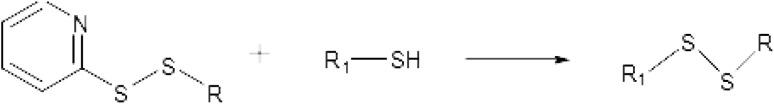

3.3.2.1. Thiol–ene reaction and thiol–disulfide exchange

The thiol–ene photopolymerization reaction equips the researchers to synthesize homogeneous polymer networks with the advantages of oxygen inhibition insensitivity, diminished stress, and simplified polymerization kinetics.113,114 The overall rate, amount, and incidence of the thiol–ene click reaction (Fig. 16) have been successfully regulated through spatial and temporal control of the photoinitiation component, resulting in polymeric materials with an outstanding range of characteristics. Thiol–disulfide exchange (Fig. 17) also has received significant attention to stabilize hydrogels/nanogels since the oxidizing chemicals are routinely used in the production of macro-, micro-, and nano-scale disulfide-stabilized hydrogels/nanogels, which may have an adverse effect on the enclosed drug. This is significant for drug delivery since the blood's general redox potential is oxidative, which favors the development of disulfides, while the intracellular compartments are often reductive, leading to the deconstruction of disulfide bonds upon cellular internalisation.115

Fig. 16. A schematic representation of the thiol–ene click reaction.

Fig. 17. A schematic representation of the thiol–disulfide exchange reaction.

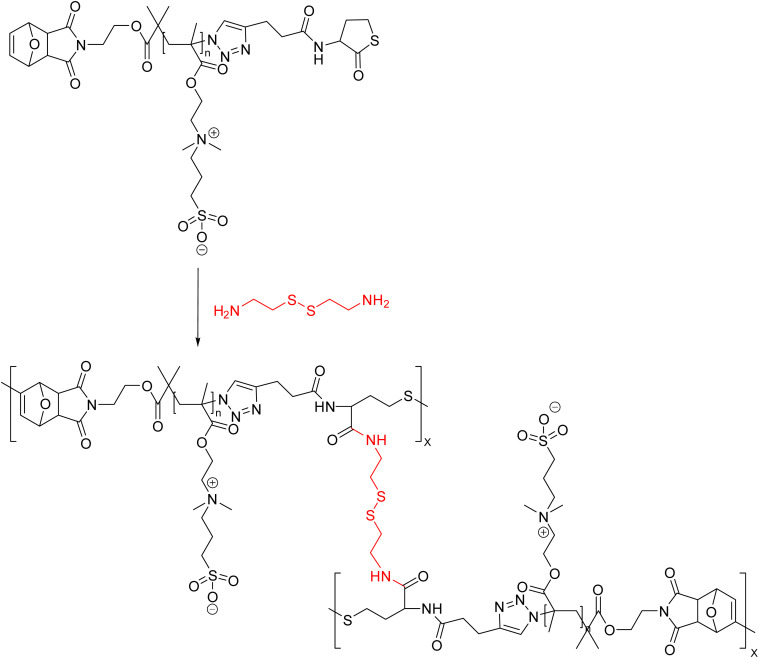

Zwitterionic nanogels are essentially polymers with stoichiometrically equal numbers of positively and negatively charged groups along the primary polymer backbone. Zwitterionic nanogels are superhydrophilic because of the presence of strong coulombic interactions along the polymer backbone; as a result, they do not behave as usual polyelectrolytes and exhibit excellent resistance to excessively saline conditions. Additionally, having neutrally charged serum or plasma on their backbones, they have been demonstrated to have great anti-fouling capabilities and also resist macrophage phagocytosis and prevent protein adsorption during drug delivery to tumor membranes, allowing for stable blood flow.116,117 Phan and co-workers presented the combination of cystamine and α,ω-functionalized poly(sulfobetaine)s (FPSBs) to synthesize the zwitterionic nanogels (Fig. 18). Aminolysis of cystamine crosslinkers resulted in the opening of thiolactone rings of PSB, and the liberated thiol-groups react with furan-maleimide double-bonds to produce nanogel networks by the thiol–ene ‘click’ reaction. Glutathione (GSH) as a reducing agent destroyed nanogels easily. Furthermore, the drug loading capacity of the nanogels was also demonstrated by loading them with doxorubicin (DOX) with drug loading capacity of 24.3%. The nanogels possessed low cytotoxicity against normal HEK293 cells but strong cytotoxicity against HeLa cancer cells.118

Fig. 18. A schematic representation of combination of cystamine and α,ω-functionalized poly(sulfobetaine)s (FPSBs) to yield redox-responsive nanogels via thiol–ene reaction.118.

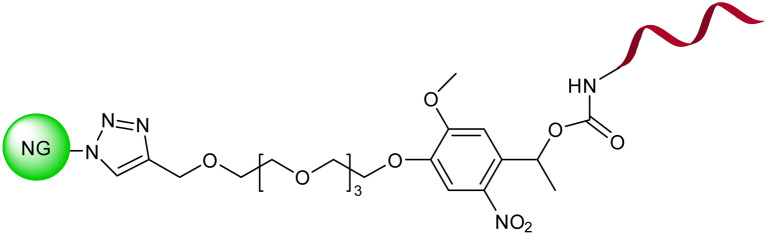

4. CuAAC in nanocarriers and nanogels designing with 1,2,3-triazole linkers

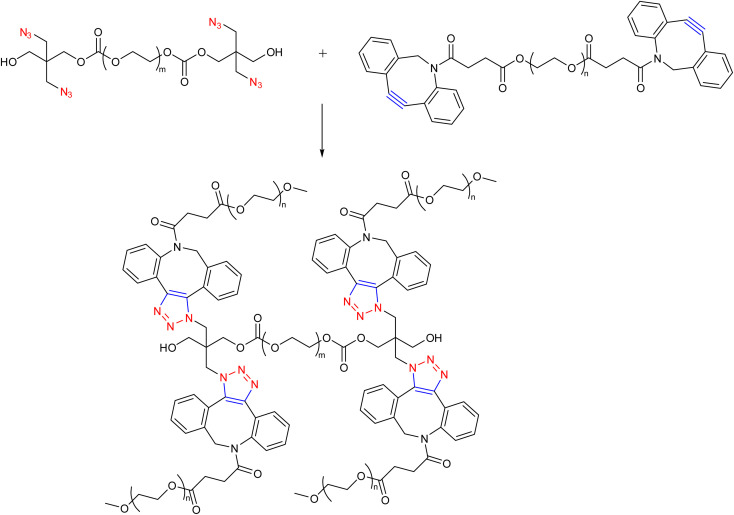

CuAAC methodology in nanocarrier designing involves optimized bioconjugation, providing faster and more efficient reactions in the production of a variety of conjugated triazole-linked neoglycoconjugates, based on copper-catalyzed coupling reactions.119–123 Utilizing the click methodology, a variety of biomolecules including polyethylene glycol (PEG), lactose, DNA, biotin, and various recombinant proteins have been immobilized in a stable manner even without the generation of any side products. CuAAC in relation to the synthesis of nanocarriers and nanogels is classified under the chemical methods, as it results in the formation of covalently crosslinked polymeric nanogels. Besides the swelling nature, which is considered a ‘superior’ property of nanogels, the top aspects taken into consideration during the synthesis of nanocarriers are-high biocompatibility, high loading with high surface area, and colloidal stability ensuring targeted and adequate drug delivery via an active and passive mode of transportation and drug release due to quantified surface properties and particle size,68,124 all of which can be achieved via CuAAC pathway.

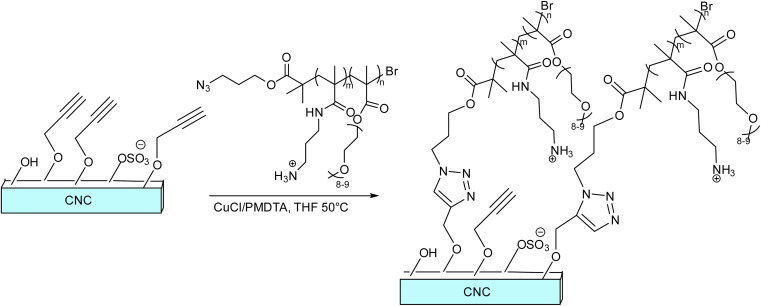

Roberts and co-workers demonstrated the stitching of PAPMA4-stat-POEGMA40-N3 copolymer to cellulose nanocrystals (CNCs) to form a type of elongated colloidal nanoparticles via Cu(i) catalyzed alkyne–azide cycloaddition to subsequently use them for drug-delivery applications, as shown in Fig. 19. The amino groups of the copolymer allow for the attachment of diagnostic or therapeutic moieties, and the copolymer itself acts as a ‘stealth’ corona to reduce protein adsorption. The synthesized CNCs were revealed to be harmless in both human ovarian cancer (HEYA8) and human breast cancer (MDA-MB-436) cell lines. Further findings also provided credence to the use of polymer-coated CNCs in medicine and suggested the need for further in vitro and in vivo research to determine the extent to which they can function as drug-delivery agents.125

Fig. 19. A schematic representation of conjugation of PAPMA4-stat-POEGMA40-N3 copolymer to cellulose nanocrystals (CNCs).125.

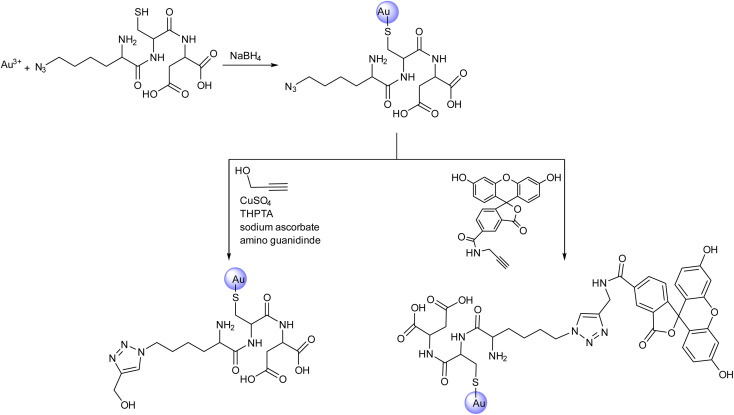

Meer et al. reported the surface modification of azide-conjugated ultra-small gold nanoparticles with alkyne containing groups (Fig. 20) via CuAAC to yield strongly fluorescing nanoparticles that were traceable inside eukaryotic cells. The nanoparticles were subjected to functionalization with azide-functionalized tripeptide lysine(N3)-cysteine-asparagine and subsequently reacted with alkyne-terminated fluorescein (FAM) to give the FAM-clicked ultrasmall gold nanoparticles. These nanoparticles were taken up very efficiently by HeLa cells after 24 hours, thereby demonstrating their penetrating ability into the nuclear membrane to a significant extent. Each nanoparticle had about 8 fluorescein molecules covalently bonded to it.126

Fig. 20. A schematic representation of azide conjugation of ultrasmall gold nanoparticles and their subsequent ‘click’ conversion by reacting with different alkyne moieties.126.

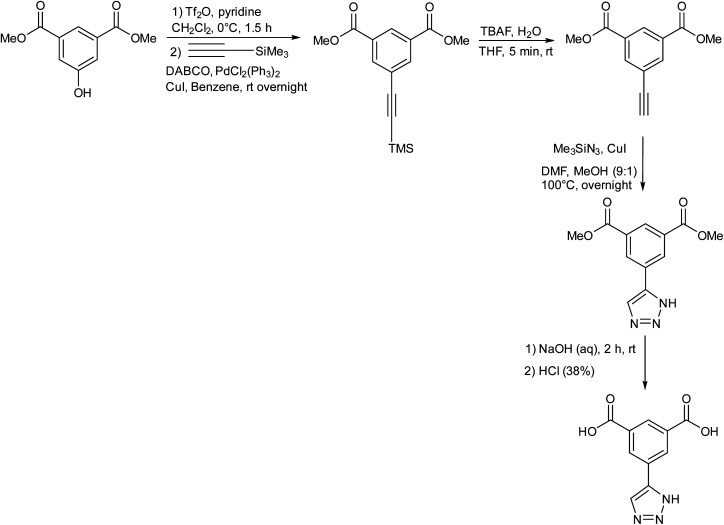

Haring research group presented the synthesis of ‘click-TIA’ as shown in Fig. 21, which when subjected to sonication in water resulted in the production of supramolecular viscoelastic hydrogels. It was demonstrated that the substitution of 1,2,4-triazole ring with 1,2,3-triazole moiety in the compound induced the synthesis of hydrogelator. The hydrogel was implied as a drug carrier for oxytetracycline by encapsulation of the drug and exhibited controlled release.57

Fig. 21. A schematic representation of the synthesis of click-TIA in multiple steps.57.

Quadir et al. presented polypeptide-based block copolymers modified with click chemistry for the synthesis of pH-sensitive nanoscale drug delivery systems. N-carboxyanhydride-based ring-opening polymerization resulted in the production of PEG-polypeptide copolymers with pendant amine chains and subsequent functionalization was carried out via azide–alkyne cycloaddition. Self-assembly into stable polymersomes and disassembly in a pH-responsive manner were seen in the produced block copolymers that contain a polypeptide block with amine-functional side groups., as shown in Fig. 22. To encapsulate hydrophilic cytotoxic drugs like doxorubicin at physiological pH, these block copolymers self-assemble into vesicular nanometer-scale structures, which then spontaneously disassemble at endosomal pH levels following cellular uptake.127

Fig. 22. A schematic representation of the synthesis of PEG-polypeptide copolymer from N-carboxyanhydride using CuAAC.127.

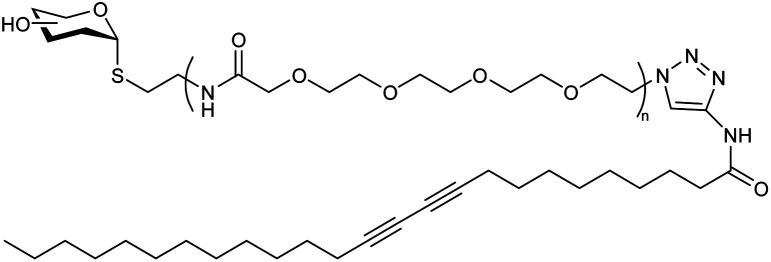

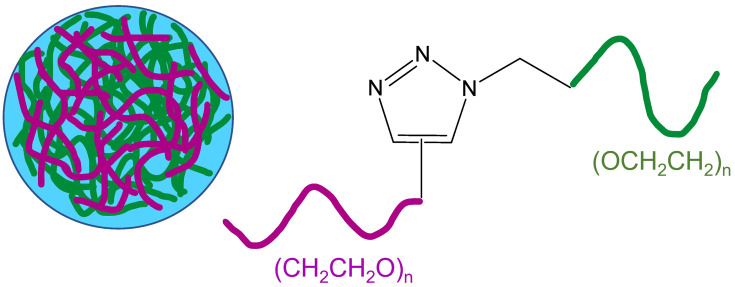

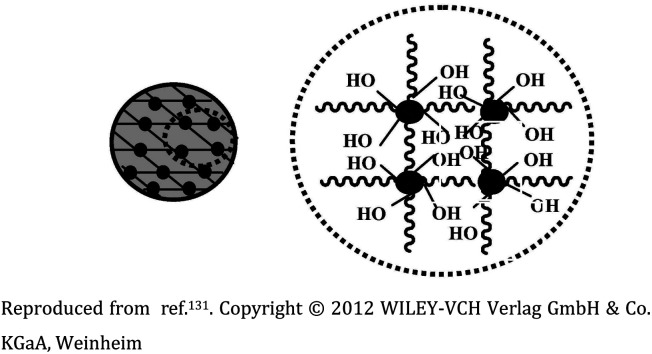

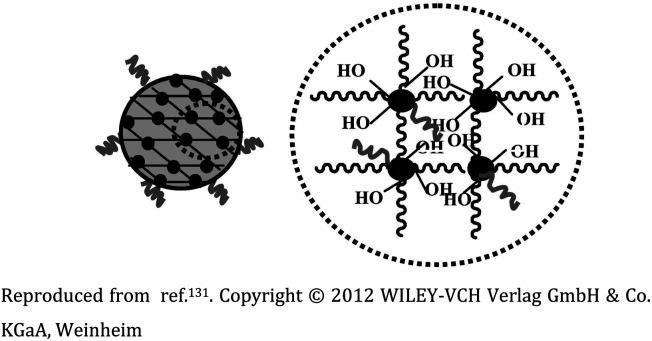

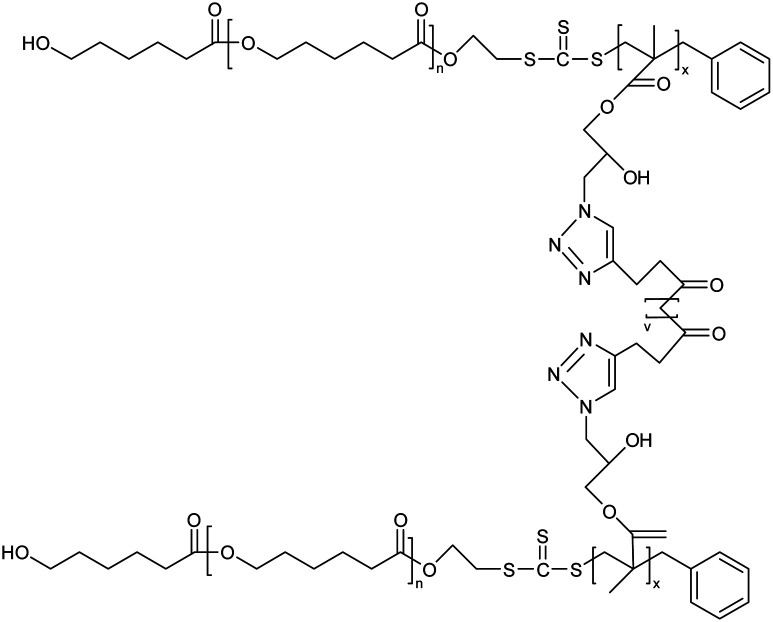

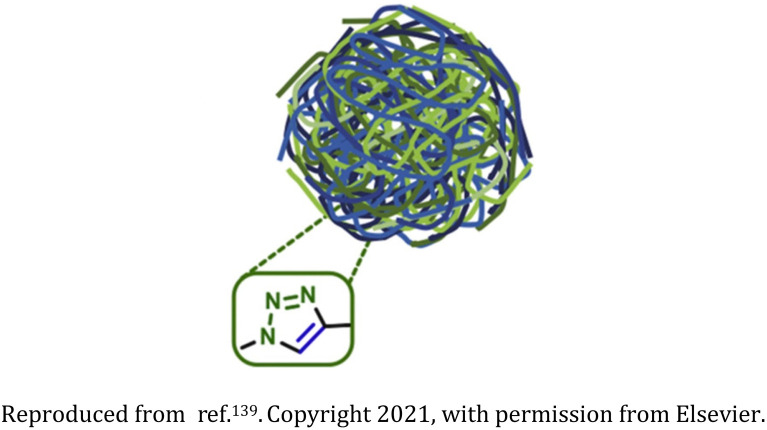

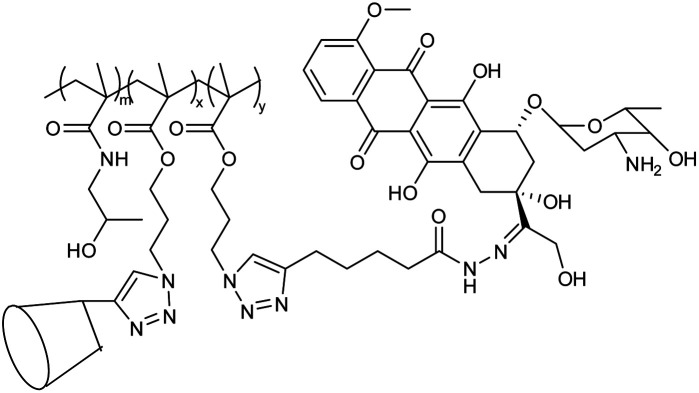

Abandansari research group reported a Boltorn®H40 and poly(vinylpyridine) based nanogel synthesized via CuAAC through mini-emulsion polymerization wherein poly(vinylpyridine) (PVP) was utilized as a pH sensitive crosslinker and H40-poly(ε-caprolactone) (H40-PCL) dendrimers were used as the core (Table 2, entry 1). The nanogel exhibited swelling on exposure to low pH environment, thereby releasing the loaded drug.128 Assali and coworkers developed poly(diacetylene) (PDA) based nanogel having diacetylenic hydrophobic part and oligoethyleneoxide based hydrophilic part connected through 1,2,3-triazole ring (Table 2, entry 2) Due to the presence of PDAs, the nanogel displayed intense blue colour, attributing to the absorption of the enyne moieties in the visible region.129

‘CuAAC’-mediated 1,2,3-triazole appended polymeric nanogel systems based on different types of polymer/polymeric systems and functionalization agents with their corresponding characteristic aspects and functions.

| Entry | Nanogel material | Basic structure | Aspect(s) of nanogel | Key function(s) | Reference |

|---|---|---|---|---|---|

| 1 | Boltorn® H40 and poly(vinylpyridine) nanogel |

|

CuAAC assisted in covalent bond formation resulting in the chemically cross-linked nanogels comprising hyperbranched dendrimer (H40-PCL) with PVP as a crosslinker through mini emulsion polymerization | pH-sensitive nanogel utilized in the release of a hydrophobic anti-cancer medication | 128 |

| 2 | Nanogel formed through diacetylenic-based glycolipids |

|

The presence of a 1,2,3-triazole ring between the hydrophobic and hydrophilic part of the diacetylene-based glycolipids resulted in their self-organization into 1D-nanotubes, and at higher concentrations, these bundled nanotubes crosslinked to form the nanogels | Nanocontainer for cytotoxic topotecan drug incorporation and its site-specific release | 129 |

| 3 | Poly(ethylene glycol) (PEG) monomers-based nanogel |

|

Alkyne and azide functionalized PEG monomers were crosslinked via CuAAC to synthesize the nanogel and the polymerization was subsequently ceased by the addition of a Cu-chelating agent | The nanogel coatings efficiently exhibit short-term protein resistance, encompassing superior surfaces which could be well utilized for in vitro diagnostics | 130 |

| 4 | Ga-porphyrin-OH nanogel based on PEG |

|

Fluorescent nanogel synthesized via reverse (mini)emulsion-CuAAC having uniform size | Applicability in near-infrared (NIR) imaging due to their fluorescence and cell affinity | 131 |

| 5 | Ga-porphyrin-FA nanogel based on PEG |

|

The diameter of nanogels ranged between 30–120 nm, with an emission maximum between 700 and 800 nm. Applicability in near-infrared (NIR) imaging due to their fluorescence and cell affinity | Folate immobilization on the surface to target tumor cells for cell imaging and drug release | 131 |

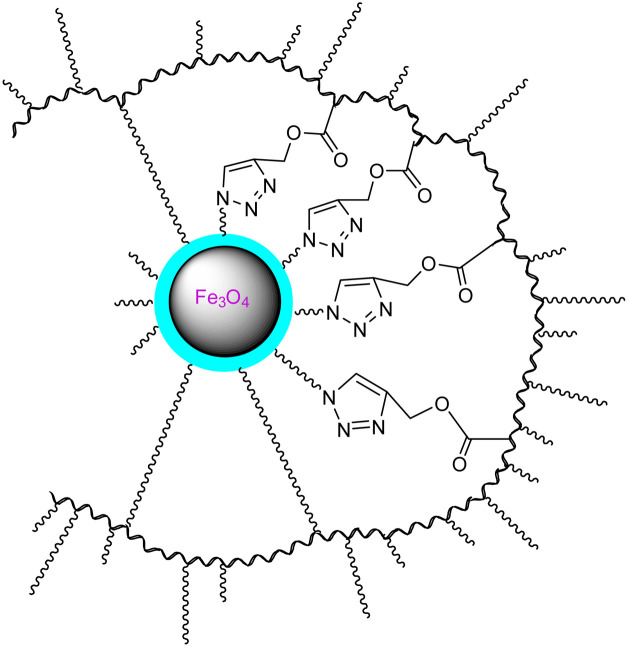

| 6 | Hydroxyethyl methacrylate (HEMA), acrylated methyl ether poly (ethylene glycol) (ACMPEG), and Fe3O4 based nanogel |

|

Click chemistry and surfactant-free emulsion photopolymerization in combination to produce amphiphilic nanogels from vinylated SPIONs/HEMA/PEG | Carrier for the anti-cancer drug quercetin | 132 |

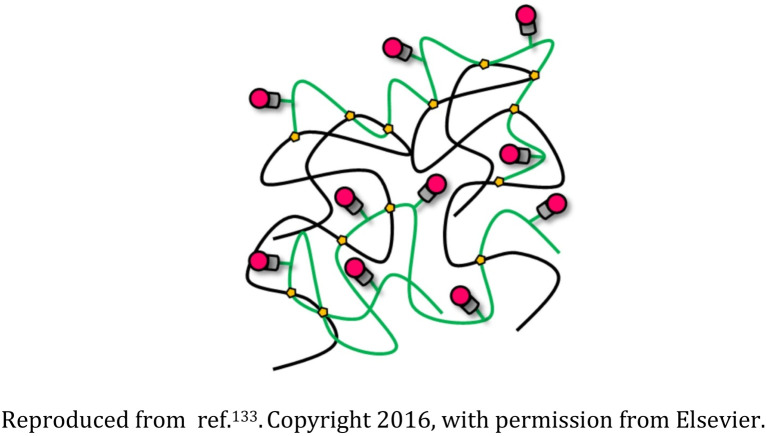

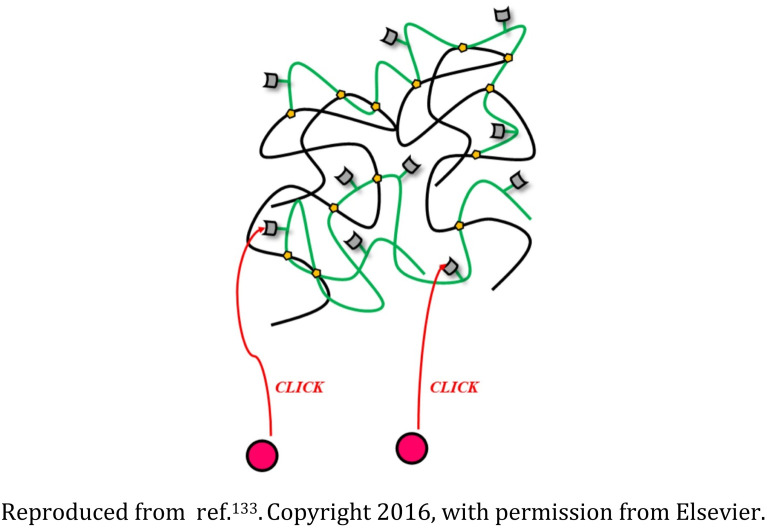

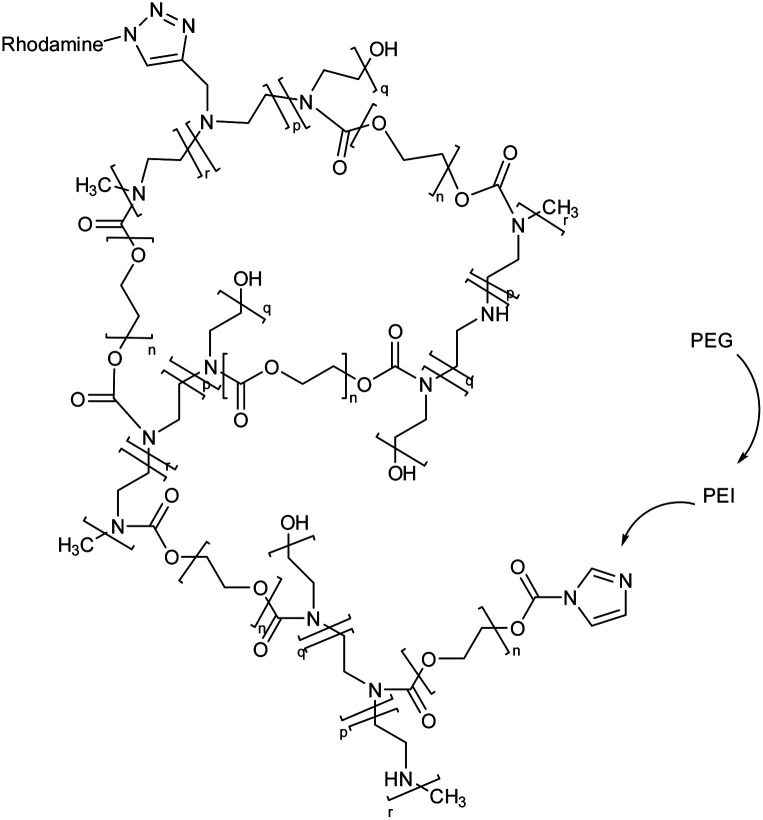

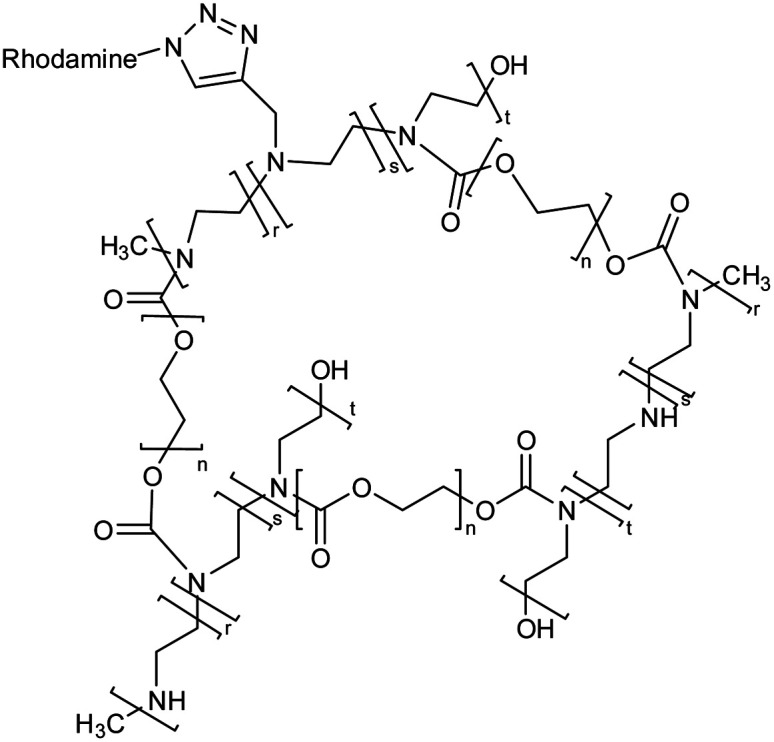

| 7 | Polyethylene glycol (PEG), polyethyleneimine (PEI), and rhodamine-based nanogel |

|

The nanostructures were biodegradable and appropriate for transporting drugs or genetic material and also could be tracked as they interacted with the cells | Drug delivery devices for sustained release of the succinimide anticonvulsant drug ethosuximide | 133 |

| 8 | Polyethylene glycol (PEG), polyethyleneimine (PEI), and rhodamine-based nanogel |

|

The nanostructures were biodegradable and appropriate for transporting drugs or genetic material and also could be tracked as they interacted with the cells | Drug delivery devices for sustained release of the succinimide anticonvulsant drug ethosuximide | 133 |

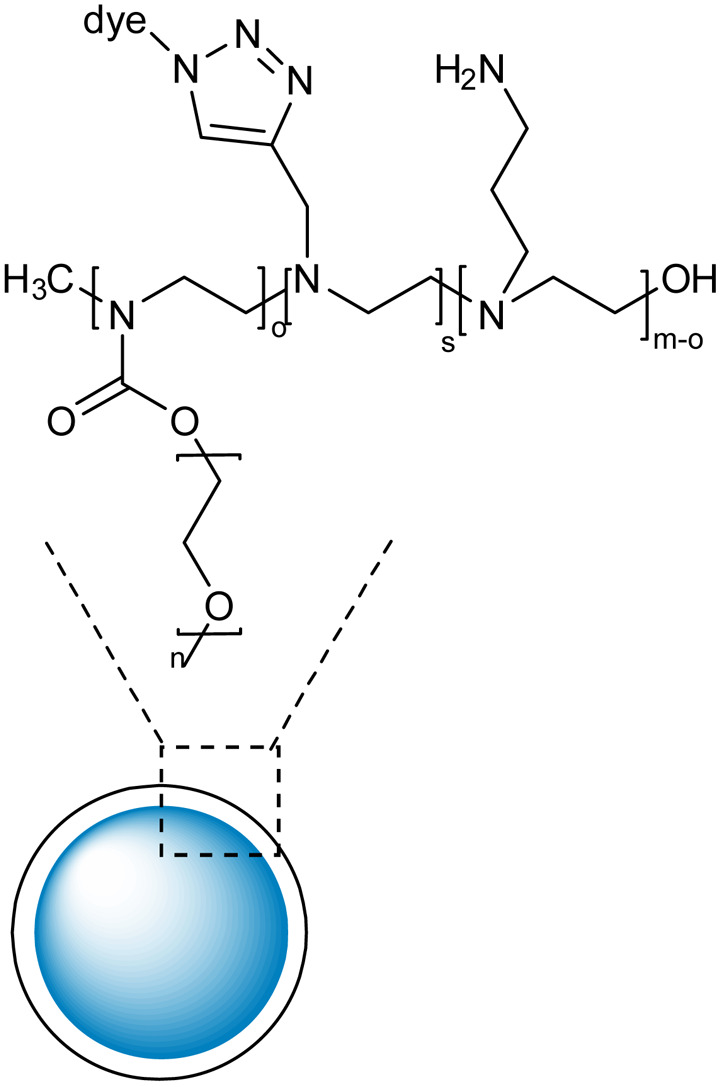

| 9 | Polyethylene glycol (PEG), and polyethyleneimine (PEI) based nanogel framed via rhodamine |

|

The potential of the nanogels to enhance or decrease microglia internalization was evaluated after they were coated with various concentrations of PEG monomethyl ether | Transportation of drugs or genes into the microglia environment, enhancing their therapeutic efficacy for reduction of microglia internalization | 134 |

| 10 | Polyethylene glycol and polyethyleneimine based nanogel |

|

The nanogel loaded with the anti-hepatic stetosis properties bearing polyphenol i.e., hydroxytyrosol (HT) on in vitro administration exhibit the reduction of intracellular triglyceride levels | Potential pharmacological treatment of non-alcoholic fatty liver disease (NAFLD) | 135 |

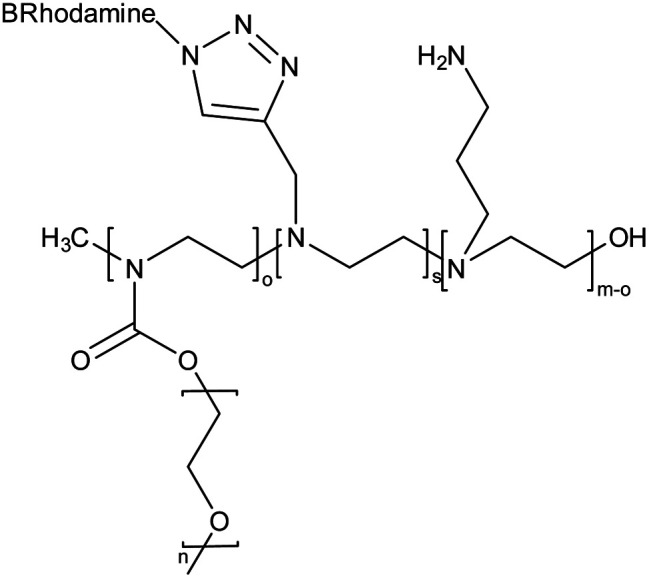

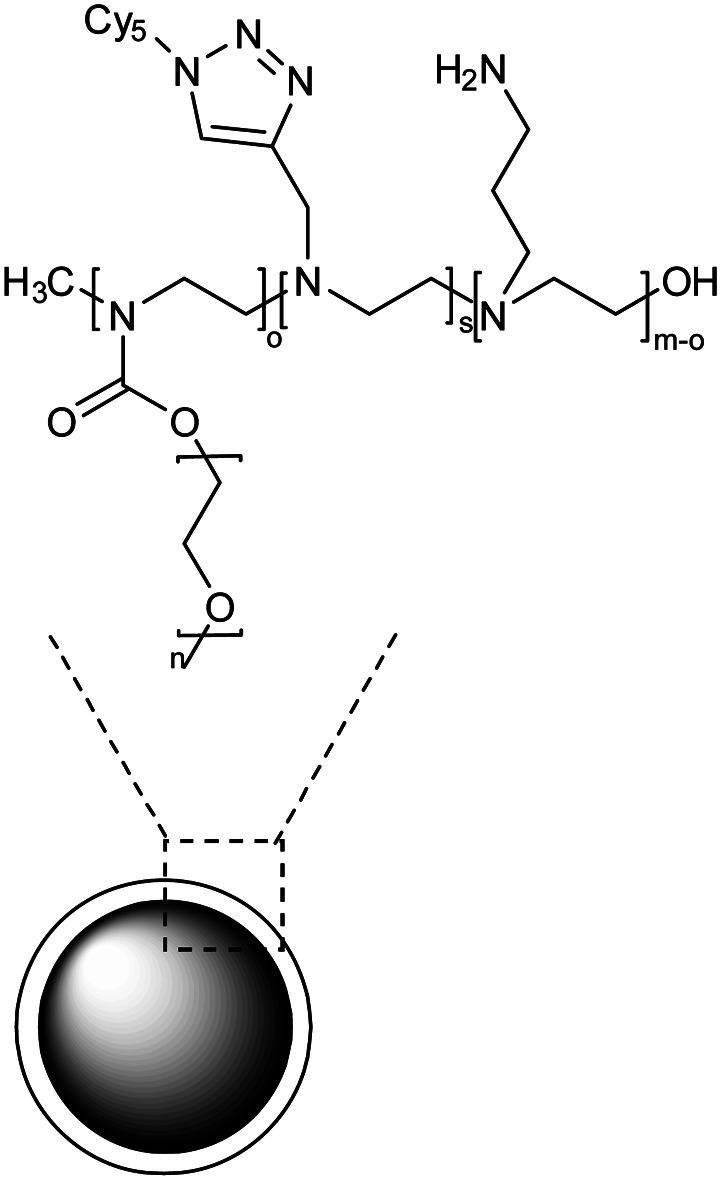

| 11 | Polyethylene glycol and polyethyleneimine-based nanogels with high colloidal stability and biocompatibility |

|

RhB and Cy5 fluorescent dyes bearing azide groups were used for the synthesis of the nanogels and utilizing the unreacted amines in the PEI chains, the primary amines linkers were grafted around the nanogel surface | Drug carrier for rolipram to reduce astrogliosis | 136 |

| 12 | Amine and pyridine-functionalized PEG-PEI based nanogel |

|

The nanogel was synthesized via emulsification-evaporation method and a microscopic molecular examination of the surface features of these systems and an evaluation of their cytocompatibility were also performed | Efficient drug delivery devices with prolonged sustained release | 137 |

| 13 | Polyethylene glycol (PEG) and polyethylene-imine (PEI) based nanogel coated with primary amines |

|

The nanogel was synthesized by emulsification-evaporation method and experimental analysis indicated that activated astrocytes were more likely to be targeted by NG in vitro than microglia or neurons | Targeted delivery of rolipram to quench the pro-inflammatory effects mediated by astrocyte activation | 138 |

| 14 | Poly(ε-caprolactone)-b-poly(glycidyl methacrylate) (PCL-b-PGMA) block copolymers based nanogel |

|

A combination of ring-opening polymerization and reversible addition–fragmentation chain transfer polymerization was implied for the synthesis of copolymers for nanogel production | Potential carrier for low molecular weight drugs | 124 |

| 15 | Poly-amino acid-based nanogel |

|

Biodegradable and biocompatible cross-linked nanogels synthesized from polyglutamic acid ∼100 nm in size | Hydrophilic drug carriers for the chemotherapeutic agent doxorubicin for triple-negative breast cancer treatment | 139 |

| 16 | Anisotropic gold nanoparticles incorporated-polymeric thermoresponsive nanogel |

|

Nanogel was thermoresponsive in nature and synthesized via click chemistry and thermo-nanoprecipitation with gold nanoparticles as the crosslinking agent | High NIR light-to-heat conversion efficiency for photothermal therapy | 140 |

| 17 | Photoresponsive oligonucleotide-based nanogel |

|

The photoirradiation of nanogel led to hyperchromic shift at 260 nm and a simultaneous redshift of the absorption in the 350–400 nm region | Control of protein release via managing the dissociation of a protein's DNA complex | 141 |

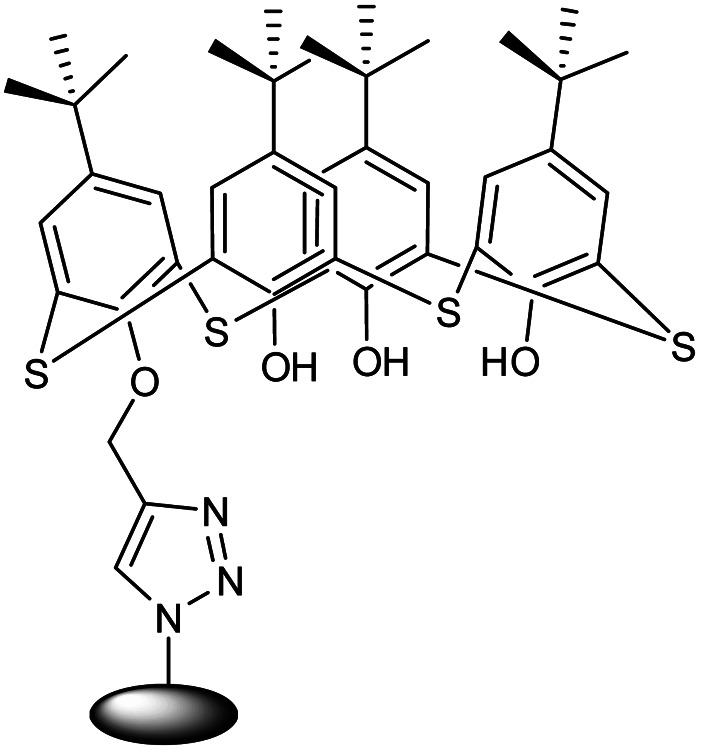

| 18 | Thiacalix[4]arene functionalized chitosan-based nanogel (CS-g-TC4A) |

|

The unique multifunctional nano adsorbent nanogel was an efficient sorption agent with controlled super-paramagnetic and sorption capabilities | The synthesized CS-g-TC4A nanogel having a triazole ring was used as an effective adsorbent for metal ions | 142 |

| 19 | Hyaluronan and riboflavin derivatives based nanohydrogel |

|

The nanohydrogels formulation could be freeze-dried when dextrose was added as a cryoprotectant since they were extremely stable in water solutions | Drug carriers for the delivery of hydrophobic drugs | 143 |

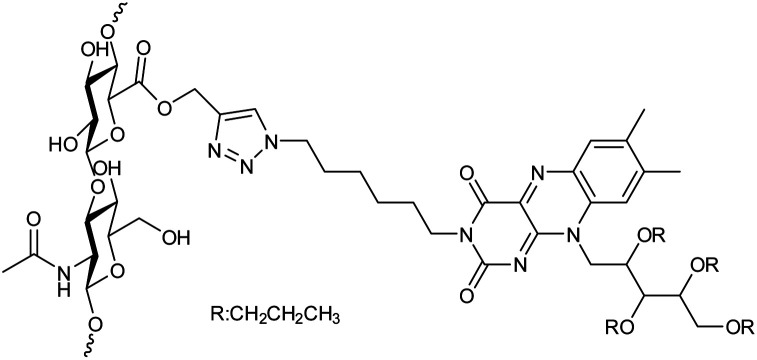

| 20 | Thermoresponsive poly(N-vinylcaprolactam) nanogels functionalized with glucose and maltose |

|

The nanogels were synthesized via semibatch precipitation polymerization which shrank upon heating and was equipped with a thermoresponsive structure and surface functionalities that allow for biorelevant interactions | Enhanced affinity for biomolecules due to the presence of carbohydrates results in greater potential for therapeutic uses as drug-delivery agents | 144 |

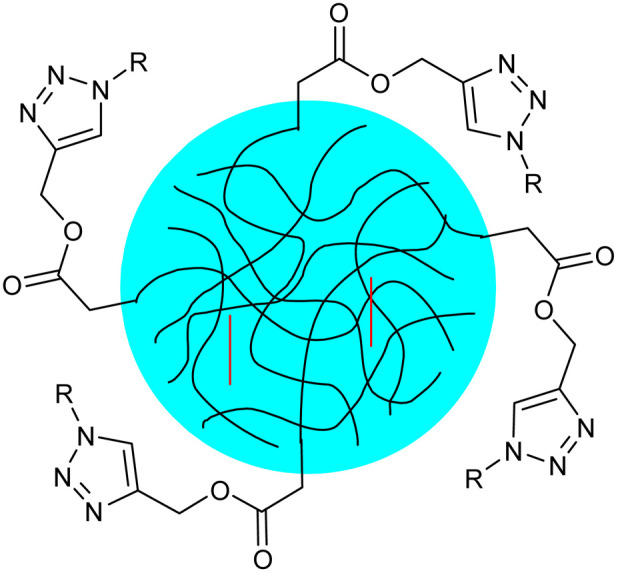

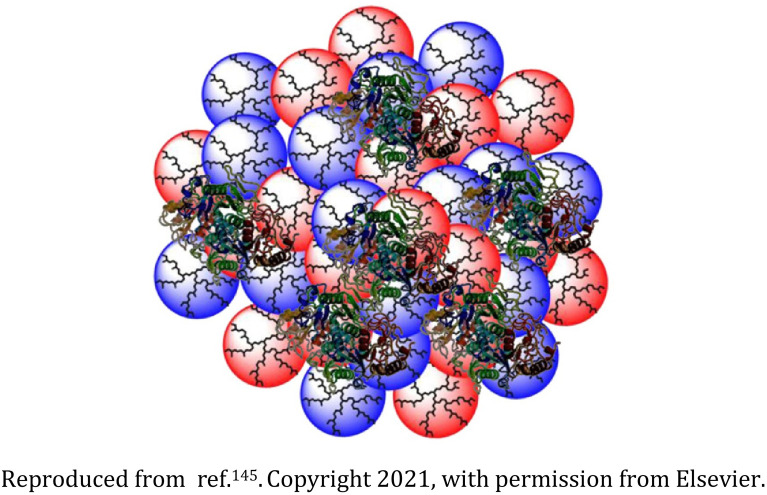

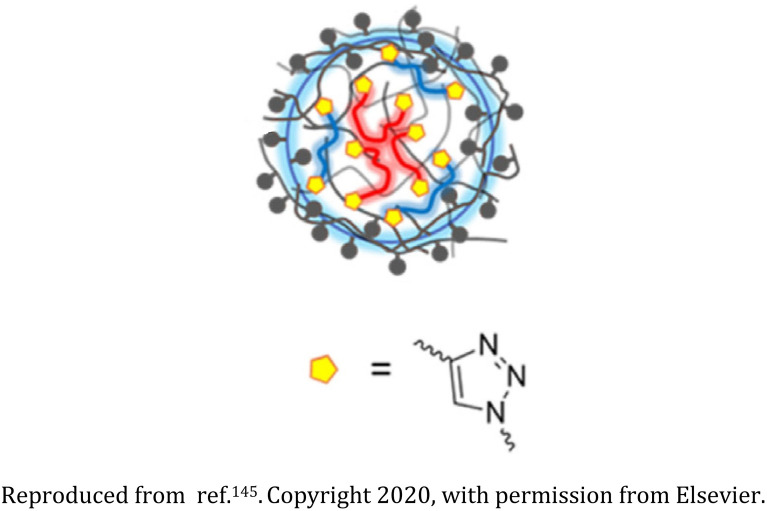

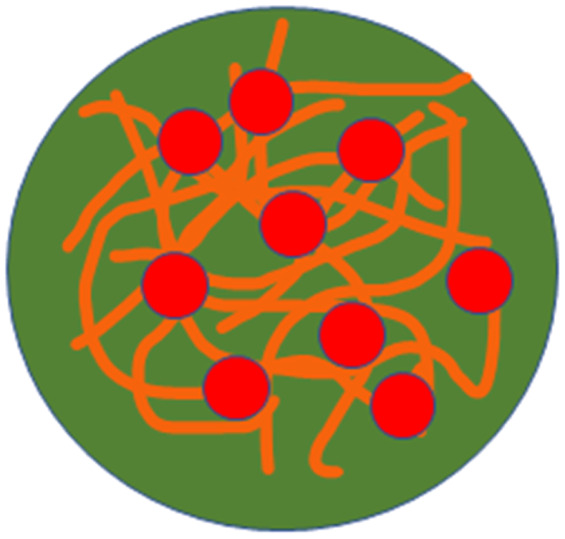

| 21 | Biodegradable dendritic polyglycerol nanogel |

|

The dendritic polyglycerol nanogels were synthesized by inverse nanoprecipitation wherein the introduction of benzacetal bonds induced the biodegradability | Effective protein encapsulation and release among other biomacromolecules | 145 |

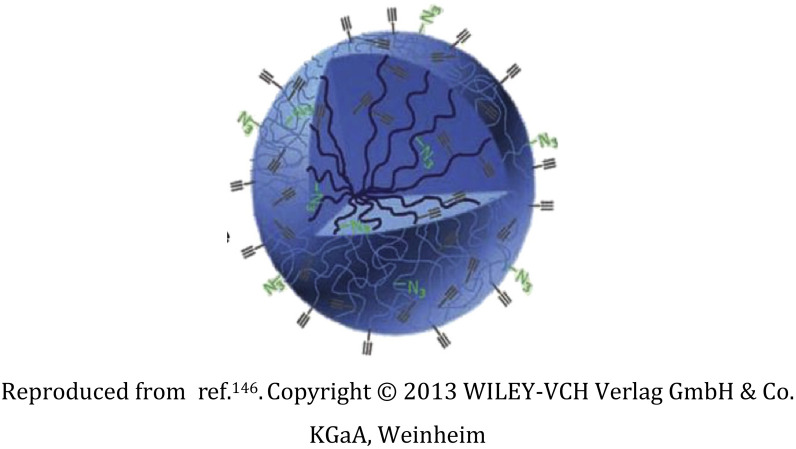

| 22 | Bisphosphonate ligand-functionalized dextran nanogel |

|

Controlled functionalization of the nanogel with bisphosphonate ligand through astoichiometric click-chemistry in-emulsion method | Hepatic avoidance, binding to the bone on the inside of marrow cavities, and anti-osteoporotic actions | 146 |

| 23 | Alkynopoly(acrylic acid), diazido-poly(ethylene glycol), and diazido-poly(butylene succinate) based nanogel |

|

Amphiphilicity of the nanogel is controlled via variations in the hydrophobic diazido-poly(butylene succinate) and the hydrophilic diazido-poly(ethylene glycol) | Interaction with multi-walled carbon nanotubes (MWCNTs), thereby acting as a potential dispersant of MWCNTs in hydrophilic media | 147 |

| 24 | Nanogel based on (adamantly (AD)-benzoic imine-conjugated poly [poly(ethylene glycol) monomethyl ether methacrylate]-co-poly(2-hydroxyethyl methacrylate) (PPEGMA-co-PHEMA-AD) as well as doxorubicin (DOX)-hydrazone and b-cyclodextrin(b-CD) |

|

The polymeric nanogels were synthesized via host–guest interactions, for dual pH-triggered multistage drug delivery, and nanogels were reorganized into smaller nanoparticles in response to tumor acidity | Deep penetration of the drug at the tumor site, the release of doxorubicin in endosomal or lysosomal acidity (pH ∼5) | 148 |

| 25 | A pH and reduction dual-sensitive prodrug nanogel |

|

The nanogel displayed excellent size stability against large-volume dilution, high salt concentration, and prolonged incubation in phosphate-buffered saline | Release doxorubicin in the intracellular acidic and reducible environment after being successfully absorbed by cancer cells | 149 |

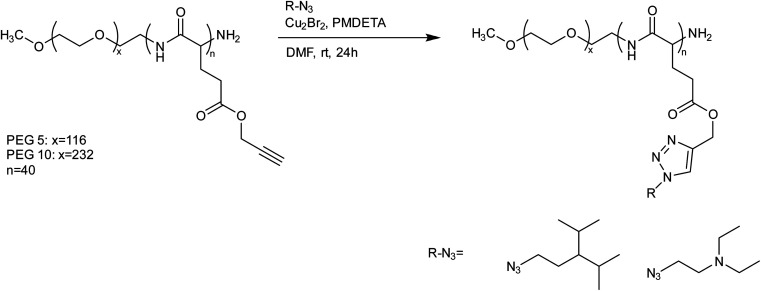

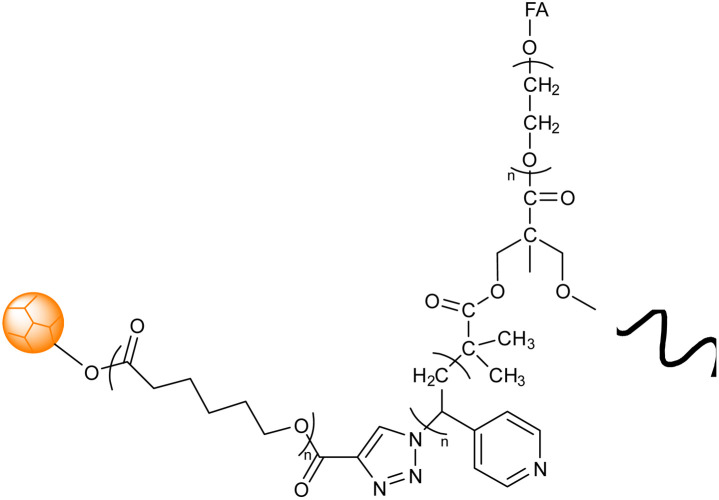

Donahoe group presented the synthesis of nanogels via CuAAC from poly(ethyleneglycol) (PEG) monomers functionalized separately with alkyne and azide moieties (Table 2, entry 3). An exceptional aspect of this procedure was the closure of nanogel synthesis by the addition of copper-chelating agent.130 Fu et al. reported PEG based fluorescent nanogels having –OH groups and Ga–porphyrin complex; and Ga–porphyrin complex with folate functional groups (Table 2, entry 4, 5). Due to their fluorescent nature, the nanogels were proposed to be applicable in near infrared (NIR) imaging.131 Khoee and Abedini reported the synthesis of Fe3O4 nanoparticles based nanogel from vinylated SPIONs/HEMA/PEG (Table 2, entry 6) which was utilized as a carrier for the anticancer drug quercetin.132 Mauri et al. reported two different synthetic routes for a fluorescent-labelled nanogel using PEG, alkyne functionalized polyethyleneimine (PEI) and rhodamine azide via CuAAC which possessed therapeutic applications (Table 2, entry 7, 8)133 and utilized PEG, alkyne functionalized polyethyleneimine (PEI) and rhodamine azide to synthesize nanogels which were coated with PEG monomethyl ether (mPEG) for the treatment of microglia (Table 2, entry 9).134 The group also developed polyethylene glycol and polyethyleneimine-based nanogel systems (Table 2, entry 10) for the treatment of hepatic steatosis in an in vitro model wherein the developed nanogel technology outperforms more traditional drug administration routes and was therefore a potential technique for the management of non-alcoholic fatty liver disease (NAFLD).135 Papa research group in 2020 synthesized nanogels from PEG and PEI polymers and fluorescent-labelled them with Cy5 and RhB dyes (Table 2, entry 11) to subsequently imply them for the treatment of activated astrocytes in spinal cord injury.136 Pinelli et al. in 2021 demonstrated different functionalization methodologies for PEG-PEI nanogels which resulted in specific body tissue targeting (Table 2, entry 12).137 Vismara et al. in 2019 developed nanogels from PEG activated with carbonyldiimidazole (CDI) and PEI (Table 2, entry 13) which were used as a vector for the anti-inflammatory drug rolipram.138

Cao et al. in 2015 synthesized nanogels from poly(ε-caprolactone)-b-poly(glycidyl methacrylate) (PCL-b-PGMA) block copolymers functionalized with azide groups and the crosslinking agent dipropargyl adipate (DPA) in a facile one-step procedure (Table 2, entry 14).124 Castano research group in 2021 synthesized biocompatible and biodegradable poly-amino acid-based nanogels from polyglutamic acid (PGA) (Table 2, entry 15). The nanogels were utilized as a drug carrier for doxorubicin (DOX) for the treatment of triple negative breast cancer (TNBC).139 Glitscher and coworkers in 2022 synthesized polymeric thermoresponsive nanogels by integrating anisotropic gold nanoparticles which acted as crosslinkers as well as light-to-heat transducers (Table 2, entry 16).140

Lai group in 2017 reported photoresponsive nanogel functionalized with DNA (Table 2, entry 17) which exhibited enhanced absorption at 260 nm and a simultaneous bathochromic shift at 350–400 nm in UV-vis region.141 Lakouraj and coworkers presented chitosan-g-thiacalix[4]arene based nanogel synthesized via CuAAC using monopropargyl thiacalix[4]arene and chitosan-azide (Table 2, entry 18).142 Manzi research group in 2017 combined amphiphilic derivatives of hyaluronic acid (HA) and riboflavin (Rfv), via CuAAC, to develop a biocompatible polysaccharide nanohydrogel (Table 2, entry 19) as a potent drug carrier for hydrophobic drugs.143

Siirilä and coworkers in 2020 developed poly(N-Vinylcaprolactam) (PNVCL) based nanogel (Table 2, entry 20) which exhibited thermoresponsive behavior and was functionalized with glucose and maltose moieties for drug delivery.144 Steinhilber group reported the synthesis of dendritic polyglycerol nanogels (Table 2, entry 21) by crosslinking of the precipitated nanoparticles by bioorthogonal CuAAC wherein benzacetal bonds were incorporated to obtain biodegradability.145 Heller et al. in 2013 presented clickable groups bearing nanogels synthesized through astoichiometric click-chemistry in-emulsion method wherein functionalization of the nanogel was done with bisphosphonate ligand which subsequently resulted in enhanced and efficient binding to the inner walls of marrow cavities (Table 2, entry 22).146 Kertsomboon research group developed amphiphilic nanogels using alkyno-poly(acrylic acid) (alkyno-PAA), diazido-poly(ethylene glycol), and diazido-poly(butylene succinate) (Table 2, entry 23) which were implemented to be dispersants of multi-walled carbon nanotubes (MWCNTs) in hydrophilic media.147 Zan research group in 2014 synthesized nanogels based on the copolymer poly[N-(2-hydroxypropyl) methacrylamide]-co-poly(3-azidopropyl methacrylate) (PHPMA-co-PAzPMA) conjugated with doxorubicin (DOX)-hydrazone and b-cyclodextrin (b-CD) (PHPMA-co-PPMA-DOX-CD) (Table 2, entry 24).148 Additional research showed that the nanoparticles could easily break through collagen hydrogels designed to simulate the thick matrix of tumor tissue. Zhang and colleagues in 2016 created a nanoscale drug formulation (CLP) by conjugating DOX with an acid-sensitive hydrazone bond and cross-linking with a reduction-responsive disulfide-containing linkage in the core (Table 2, entry 25). CLP was round and had a diameter of 60.6 ± 13.7 nm; it retained its uniform size even after being diluted many times, exposed to high salt concentrations, and incubated for extended periods of time in phosphate-buffered saline. CLP had considerable promise for optimum anti-tumor therapy due to its simple production, favorable stability, controlled release qualities, superior biodistribution, and enhanced suppression of tumor growth.149

5. Polymer functionalization: a fine-tuning process for tailor-made nanogels

The fundamental component of a functional polymer is its synthesis, which can aid in functionalization with the increase in the efficiency of drug delivery. The considerable efforts to develop novel polymerization routes owe to the exploration possibilities of material in addition to the scientific research interests.92 Post nanogel synthesis, the primary aim is the qualitative and selective modification of synthesized polymer under mild conditions with none or negligible side reactions.129,150,151 To use synthetic polymer for drug delivery, it is important to design a polymer system that must mimic the action of living tissues, so that it is suitable for drug delivery.152 The process of polymer functionalization provides a way to tackle the modification process by performing specific grafting, in the desired manner, to the functional group of long-chain polymers, condensing the macromolecules via coupling to elaborate the nanogels to get the required shape and size for preferred drug transport, and productive interaction with the biological environment.134 Therefore, cross-linking, mechanical properties, degradation, and the tuneable property must be undertaken to obtain final nanogels of desired biocompatibility.153

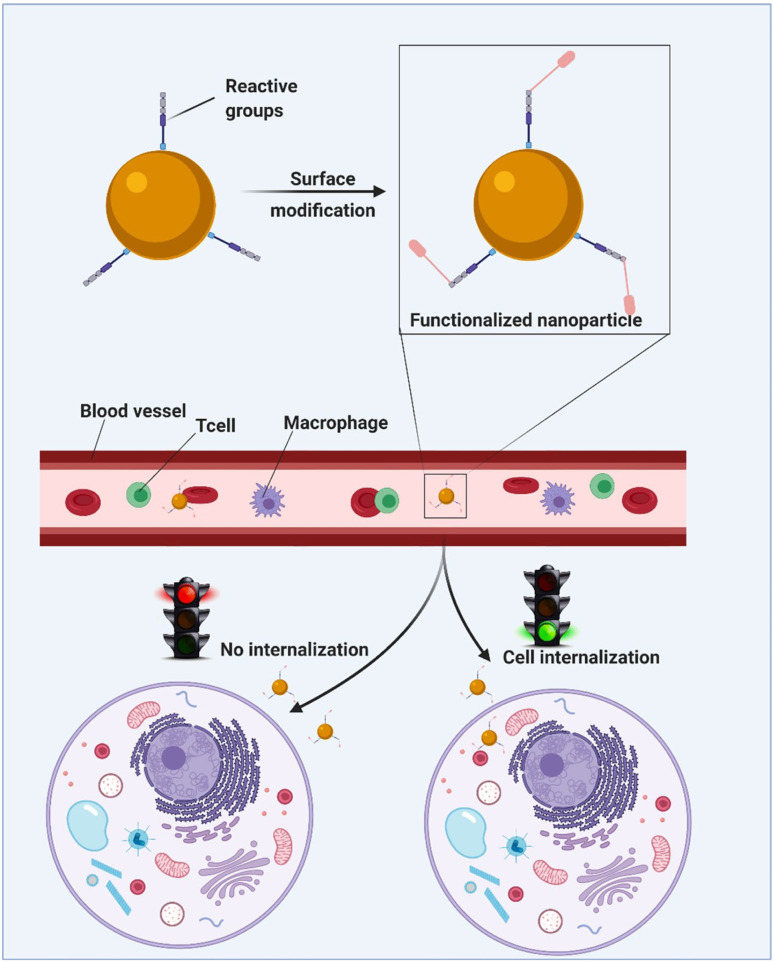

Approach through click chemistry ensures that molecules and polymers are activated by introducing a suitable click functional group and then repeating the process for stable conjugation of the polymer. This technique is normally carried through copper(i) catalyzed azide–alkyne cycloaddition but it may be alternately carried out using a copper-free strain-promoted azide–alkyne approach to avoid the CuAAC reaction cytotoxity.154,155 The main advantage of this reaction is the moderate environment in presence of simple conditions like aqueous conditions which usually give high yields. This method leads to a stereospecific way of reaction completion and provides non-toxic side products which can be eliminated without chromatographic separation techniques, as shown in Fig. 23.38,153 In addition, thiol–base reactions,156,157 ester bond activation,66 ring opening, and closing reactions,134,158 oxime linkage,136–140 and multicomponent reactions159 also lead to effective post-polymerization depending upon the substituent required.

Fig. 23. An illustrative representation of the polymer functionalization process resulting in cell internalization. Adapted from ref. 160, used under Creative Common CC-BY license.

6. Conclusion and challenges

This review describes the summarised property of CuAAC-mediated ‘click’ nanogels as robust and efficient tools for drug delivery. Nanogels can hold a wide range of moiety combinations like water and biological fluids, making them extremely adaptable carriers for targeted drug delivery, and have advantages over conventional carrier systems because of their greater drug loading, swelling, biocompatibility, and colloidal stability. Click reactions are helpful to perform the strategies for the development of tailor-made nanogels via polymer functionalization under moderate conditions which enable the researchers to graft the desired alkyne and azide functionalities on suitable polymeric systems and subsequently combine them to synthesize the nanogels with high yields, purity and short reaction time. Also, click chemistry results in the increased binding between nanogels and target cells and hence enhances targeting focusing, thereby overcoming the weak points of nonspecific drug administration.

However, certain issues regarding this methodology need to be addressed, the most prominent one being the use of Cu(i) catalyst in the synthesis, and its associated in vivo toxicity. Furthermore, polydispersity is also an issue related to the nanogels, which ought to be addressed by using suitable synthetic methodologies and optimum polymer and crosslinker concentrations. Also, the utilization of fillers like graphene, carbon nanotubes, and synthetic polymers can cause toxic by-products following the degradation of the nanogels inside the body. As a result, it becomes imperative to design more biocompatible drug delivery systems within appropriate concentrations to overcome the toxic aspects. These valuable features of nanogels and a better understanding of their behavior in vivo can guide our future efforts to improve the pharmacokinetic profile, improved drug loading capacity, and effectual delivery of nanogels to the desired target site. In light of this, we anticipate that the potential and usefulness of CuAAC ‘click’ chemistry in the production of nanogels will be substantially higher in the future.

Abbreviations

- CDI

Carbonyldiimidazole

- CuAAC

Copper(i) catalyzed alkyne azide cycloaddition

- CNCs

Cellulose nanocrystals

- CNS

Central nervous system

- DOX

Doxorubicin

- DPA

Dipropargyl adipate

- EPR

Enhanced permeability and retention

- GSH

Glutathione

- H40-PCL

H40-poly(ε-caprolactone)

- HA

Hyaluronic acid

- IARC

International agency for research on cancer

- mPEG

PEG monomethyl ether

- MCRs

Multi-component reactions

- MWCNTs

Multi-walled carbon nanotubes

- NAFLD

Non-alcoholic fatty liver disease

- NIR

Near infrared

- PAA

Poly(acrylic acid)

- PCL

Poly(ε-caprolactone)

- PCL-b-PGMA

Poly(ε-caprolactone)-b-poly(glycidyl methacrylate)

- PDA

Poly(diacetylene)

- PEG

Polyethylene glycol

- PEI

Polyethyleneimine

- PGA

Polyglutamic acid

- PNVCL

Poly(N-vinylcaprolactam)

- PVP

Poly(vinylpyridine)

- RAFT

Reversible addition–fragmentation chain transfer

- TNBC

Triple negative breast cancer

Conflicts of interest

There are no conflicts to declare.

Supplementary Material

References

- Kim J. Shim J. Kim Y. J. Char K. Do Suh K. Kim J. W. Macromol. Biosci. 2010;10:1171–1176. doi: 10.1002/mabi.201000097. [DOI] [PubMed] [Google Scholar]

- Yuan W. and Li H., in Nanostructures for Drug Delivery, ed. E. Andronescu and A. Grumezescu, Elsevier Inc., Amsterdam, 1st edn, 2017, ch. 14, vol. 1, pp. 445–460 [Google Scholar]

- Nicolas J. Mura S. Brambilla D. Mackiewicz N. Couvreur P. Chem. Soc. Rev. 2013;42:1147–1235. doi: 10.1039/C2CS35265F. [DOI] [PubMed] [Google Scholar]

- Tsimberidou A. M. Cancer Chemother. Pharmacol. 2015;76:1113–1132. doi: 10.1007/s00280-015-2861-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sharkey R. M. Goldenberg D. M. Ca-Cancer J. Clin. 2006;56:226–243. doi: 10.3322/canjclin.56.4.226. [DOI] [PubMed] [Google Scholar]

- Lee Y. T. Tan Y. J. Oon C. E. Eur. J. Pharmacol. 2018;834:188–196. doi: 10.1016/j.ejphar.2018.07.034. [DOI] [PubMed] [Google Scholar]

- Hegde P. S. Chen D. S. Immunity. 2020;52:17–35. doi: 10.1016/j.immuni.2019.12.011. [DOI] [PubMed] [Google Scholar]

- DePinho R. A. Nature. 2000;408:248–254. doi: 10.1038/35041694. [DOI] [PubMed] [Google Scholar]

- Jones P. A. Baylin S. B. Cell. 2007;128:683–692. doi: 10.1016/j.cell.2007.01.029. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ferlay J. Colombet M. Soerjomataram I. Mathers C. Parkin D. M. Piñeros M. Znaor A. Bray F. Int. J. Cancer. 2019;144:1941–1953. doi: 10.1002/ijc.31937. [DOI] [PubMed] [Google Scholar]

- Goodman M. Semin. Oncol. Nurs. 1989;5:29–52. doi: 10.1016/0749-2081(89)90080-6. [DOI] [PubMed] [Google Scholar]

- Sun C. C. Bodurka D. C. Weaver C. B. Rasu R. Wolf J. K. Bevers M. W. Smith J. A. Wharton J. T. Rubenstein E. B. Support Care Cancer. 2005;13:219–227. doi: 10.1007/s00520-004-0710-6. [DOI] [PubMed] [Google Scholar]

- Tong R. Tang L. Ma L. Tu C. Baumgartner R. Cheng J. Chem. Soc. Rev. 2014;43:6982–7012. doi: 10.1039/C4CS00133H. [DOI] [PubMed] [Google Scholar]

- Rösler A. Vandermeulen G. W. M. Klok H. A. Adv. Drug Delivery Rev. 2012;64:270–279. doi: 10.1016/j.addr.2012.09.026. [DOI] [PubMed] [Google Scholar]

- Adair J. H. Parette M. P. Altinoǧlu E. I. Kester M. ACS Nano. 2010;4:4967–4970. doi: 10.1021/nn102324e. [DOI] [PubMed] [Google Scholar]

- Cheng Z. Al Zaki A. Hui J. Z. Muzykantov V. R. Tsourkas A. Science. 2012;338:903–910. doi: 10.1126/science.1226338. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yaqoob A. A. Ahmad H. Parveen T. Ahmad A. Oves M. Ismail I. M. I. Qari H. A. Umar K. Mohamad Ibrahim M. N. Front. Chem. 2020;8:1–23. doi: 10.3389/fchem.2020.00001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Anooj E. S. Charumathy M. Sharma V. Vibala B. V. Gopukumar S. T. Jainab S. I. B. Vallinayagam S. J. Mol. Struct. 2021;1239:130446. doi: 10.1016/j.molstruc.2021.130446. [DOI] [Google Scholar]

- Chacko R. T. Ventura J. Zhuang J. Thayumanavan S. Adv. Drug Delivery Rev. 2012;64:836–851. doi: 10.1016/j.addr.2012.02.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kendre P. N. Satav T. S. Polym. Bull. 2019;76:1595–1617. doi: 10.1007/s00289-018-2430-y. [DOI] [Google Scholar]

- Yallapu M. M. Jaggi M. Chauhan S. C. Drug Discovery Today. 2011;16:457–463. doi: 10.1016/j.drudis.2011.03.004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hajebi S. Rabiee N. Bagherzadeh M. Ahmadi S. Rabiee M. Roghani-Mamaqani H. Tahriri M. Tayebi L. Hamblin M. R. Acta Biomater. 2019;92:1–18. doi: 10.1016/j.actbio.2019.05.018. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cuggino J. C. Blanco E. R. O. Gugliotta L. M. Alvarez Igarzabal C. I. Calderón M. J. Controlled Release. 2019;307:221–246. doi: 10.1016/j.jconrel.2019.06.005. [DOI] [PubMed] [Google Scholar]

- Vinogradov S. V. Nanomedicine. 2010;5:165–168. doi: 10.2217/nnm.09.103. [DOI] [PubMed] [Google Scholar]

- Zha L. Banik B. Alexis F. Soft Matter. 2011;7:5908–5916. doi: 10.1039/C0SM01307B. [DOI] [Google Scholar]

- Oh J. K. Drumright R. Siegwart D. J. Matyjaszewski K. Prog. Polym. Sci. 2008;33:448–477. doi: 10.1016/j.progpolymsci.2008.01.002. [DOI] [Google Scholar]

- Fisher O. Z. Kim T. Dietz S. R. Peppas N. A. Pharm. Res. 2009;26:51–60. doi: 10.1007/s11095-008-9704-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kabanov A. V. Vinogradov S. V. Angew. Chem., Int. Ed. 2009;48:5418–5429. doi: 10.1002/anie.200900441. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jiang Y. Chen J. Deng C. Suuronen E. J. Zhong Z. Biomaterials. 2014;35:4969–4985. doi: 10.1016/j.biomaterials.2014.03.001. [DOI] [PubMed] [Google Scholar]

- Moody C. T. Palvai S. Brudno Y. Acta Biomater. 2020;112:112–121. doi: 10.1016/j.actbio.2020.05.033. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Liyanage P. Y. Hettiarachchi S. D. Zhou Y. Ouhtit A. Seven E. S. Oztan C. Y. Celik E. Leblanc R. M. Biochim. Biophys. Acta, Rev. Cancer. 2019;1871:419–433. doi: 10.1016/j.bbcan.2019.04.006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kamphuis M. M. J. Johnston A. P. R. Such G. K. Dam H. H. Evans R. A. Scott A. M. Nice E. C. Heath J. K. Caruso F. J. Am. Chem. Soc. 2010;132:15881–15883. doi: 10.1021/ja106405c. [DOI] [PubMed] [Google Scholar]

- López-León T. Carvalho E. L. S. Seijo B. Ortega-Vinuesa J. L. Bastos-González D. J. Colloid Interface Sci. 2005;283:344–351. doi: 10.1016/j.jcis.2004.08.186. [DOI] [PubMed] [Google Scholar]

- Khan A. Othman M. B. H. Chang B. P. Akil H. M. Iran. Polym. J. 2015;24:317–328. doi: 10.1007/s13726-015-0324-5. [DOI] [Google Scholar]

- Shah S. Rangaraj N. Laxmikeshav K. Sampathi S. Int. J. Pharm. 2020;581:119268. doi: 10.1016/j.ijpharm.2020.119268. [DOI] [PubMed] [Google Scholar]

- Kumari L. and Badwaik H. R., in Polysaccharide Carriers for Drug Delivery, ed. S. Maiti and S. Jana, Elsevier Ltd, Amsterdam, 1st edn, 2019, ch. 18, vol. 1, pp. 497–557 [Google Scholar]

- Attia M. F. Anton N. Wallyn J. Omran Z. Vandamme T. F. J. Pharm. Pharmacol. 2019;71:1185–1198. doi: 10.1111/jphp.13098. [DOI] [PubMed] [Google Scholar]

- Hesaroeiye S. G. Bagtash H. R. Boddohi S. Farahani E. V. Jabbari E. Gels. 2020;6:1–32. [Google Scholar]

- Neamtu I. Rusu A. G. Diaconu A. Nita L. E. Chiriac A. P. Drug Delivery. 2017;24:539–557. doi: 10.1080/10717544.2016.1276232. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Du X. Gao Y. Kang Q. Xing J. Front. Bioeng. Biotechnol. 2021;9:1–17. doi: 10.3389/fbioe.2021.771851. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pinelli F. Saadati M. Zare E. N. Makvandi P. Masi M. Sacchetti A. Rossi F. Int. Mater. Rev. 2022:1–25. [Google Scholar]

- Kaewruethai T. Laomeephol C. Pan Y. Luckanagul J. A. Gels. 2021;7:1–18. doi: 10.3390/gels7040228. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Matusiak M. Kadlubowski S. Rosiak J. M. Radiat. Phys. Chem. 2020;169:108099. doi: 10.1016/j.radphyschem.2018.12.019. [DOI] [Google Scholar]

- Vinogradov S. V. Bronich T. K. Kabanov A. V. Adv. Drug Delivery Rev. 2002;54:135–147. doi: 10.1016/S0169-409X(01)00245-9. [DOI] [PubMed] [Google Scholar]

- Qureshi M. A. Khatoon F. J. Sci.: Adv. Mater. Devices. 2019;4:201–212. [Google Scholar]

- Eckmann D. M. Composto R. J. Tsourkas A. Muzykantov V. R. J. Mater. Chem. B. 2014;2:8085–8097. doi: 10.1039/C4TB01141D. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Xing L. Fan Y. T. Shen L. J. Yang C. X. Liu X. Y. Ma Y. N. Qi L. Y. Cho K. H. Cho C. S. Jiang H. L. Int. J. Biol. Macromol. 2019;141:85–97. doi: 10.1016/j.ijbiomac.2019.08.237. [DOI] [PubMed] [Google Scholar]

- Zhang H. Zhai Y. Wang J. Zhai G. Mater. Sci. Eng., C. 2016;60:560–568. doi: 10.1016/j.msec.2015.11.041. [DOI] [PubMed] [Google Scholar]

- Setia A. and Ahuja P., in Organic Materials as Smart Nanocarriers for Drug Delivery, ed. A. M. Grumezescu, Elsevier Inc., Amsterdam, 1st edn, 2018, ch. 8, vol. 1, pp. 293–368 [Google Scholar]

- Li C. Obireddy S. R. Lai W. F. Drug Delivery. 2021;28:1594–1602. doi: 10.1080/10717544.2021.1955042. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Medeiros S. F. Filizzola J. O. C. Oliveira P. F. M. Silva T. M. Lara B. R. Lopes M. V. Rossi-Bergmann B. Elaissari A. Santos A. M. Mater. Lett. 2016;175:296–299. doi: 10.1016/j.matlet.2016.04.004. [DOI] [Google Scholar]

- Anderson J. M. Rodriguez A. Chang D. T. Semin. Immunol. 2008;20:86–100. doi: 10.1016/j.smim.2007.11.004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kulkarni A. A. and Rao P. S., in Nanomaterials in Tissue Engineering, ed. A. K. Gaharwar, S. Sant, M. J. Hancock and S. A. Hacking, Woodhead Publishing Limited, 1st edn, 2013, ch. 1, vol. 1, pp. 27–63 [Google Scholar]

- Huang K. He Y. Zhu Z. Guo J. Wang G. Deng C. Zhong Z. ACS Appl. Mater. Interfaces. 2019;11:22171–22180. doi: 10.1021/acsami.9b05827. [DOI] [PubMed] [Google Scholar]

- Yilmaz Z. E. Jérôme C. Macromol. Biosci. 2016;16:1745–1761. doi: 10.1002/mabi.201600269. [DOI] [PubMed] [Google Scholar]

- Zhan F. Chen W. Wang Z. Lu W. Cheng R. Deng C. Meng F. Liu H. Zhong Z. Biomacromolecules. 2011;12:3612–3620. doi: 10.1021/bm200876x. [DOI] [PubMed] [Google Scholar]

- Häring M. Rodríguez-López J. Grijalvo S. Tautz M. Eritja R. Martín V. S. Díaz Díaz D. Mol. Pharm. 2018;15:2963–2972. doi: 10.1021/acs.molpharmaceut.7b01049. [DOI] [PubMed] [Google Scholar]

- Vandghanooni S. Eskandani M. Int. J. Biol. Macromol. 2019;141:636–662. doi: 10.1016/j.ijbiomac.2019.09.020. [DOI] [PubMed] [Google Scholar]

- Pinelli F. Ortolà Ó. F. Makvandi P. Perale G. Rossi F. Nanomedicine. 2020;15:2707–2727. doi: 10.2217/nnm-2020-0274. [DOI] [PubMed] [Google Scholar]

- Lallana E. Sousa-Herves A. Fernandez-Trillo F. Riguera R. Fernandez-Megia E. Pharm. Res. 2012;29:1–34. doi: 10.1007/s11095-011-0568-5. [DOI] [PubMed] [Google Scholar]

- Ulbrich K. Holá K. Šubr V. Bakandritsos A. Tuček J. Zbořil R. Chem. Rev. 2016;116:5338–5431. doi: 10.1021/acs.chemrev.5b00589. [DOI] [PubMed] [Google Scholar]

- Masood F. Mater. Sci. Eng., C. 2016;60:569–578. doi: 10.1016/j.msec.2015.11.067. [DOI] [PubMed] [Google Scholar]

- Clemons T. D. Singh R. Sorolla A. Chaudhari N. Hubbard A. Iyer K. S. Langmuir. 2018;34:15343–15349. doi: 10.1021/acs.langmuir.8b02946. [DOI] [PubMed] [Google Scholar]

- Wang X. Li S. Shi Y. Chuan X. Li J. Zhong T. Zhang H. Dai W. He B. Zhang Q. J. Controlled Release. 2014;193:139–153. doi: 10.1016/j.jconrel.2014.05.028. [DOI] [PubMed] [Google Scholar]

- Sharmiladevi P. Girigoswami K. Haribabu V. Girigoswami A. Mater. Adv. 2021;2:2876–2891. doi: 10.1039/D1MA00069A. [DOI] [Google Scholar]

- Aykaç A. Noiray M. Malanga M. Agostoni V. Casas-Solvas J. M. Fenyvesi É. Gref R. Vargas-Berenguel A. Biochim. Biophys. Acta, Gen. Subj. 2017;1861:1606–1616. doi: 10.1016/j.bbagen.2017.01.016. [DOI] [PubMed] [Google Scholar]

- Vasile C. Pamfil D. Stoleru E. Baican M. Molecules. 2020;25:1539. doi: 10.3390/molecules25071539. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Soni K. S. Desale S. S. Bronich T. K. J. Controlled Release. 2016;240:109–126. doi: 10.1016/j.jconrel.2015.11.009. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Owens D. E. Peppas N. A. Int. J. Pharm. 2006;307:93–102. doi: 10.1016/j.ijpharm.2005.10.010. [DOI] [PubMed] [Google Scholar]

- Gordon M. R. Zhuang J. Ventura J. Li L. Raghupathi K. Thayumanavan S. Mol. Pharm. 2018;15:1180–1191. doi: 10.1021/acs.molpharmaceut.7b01011. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sharma A. Garg T. Aman A. Panchal K. Sharma R. Kumar S. Markandeywar T. Artif. Cells, Nanomed., Biotechnol. 2016;44:165–177. doi: 10.3109/21691401.2014.930745. [DOI] [PubMed] [Google Scholar]

- Akhtar M. F. Hanif M. Ranjha N. M. Saudi Pharm. J. 2016;24:554–559. doi: 10.1016/j.jsps.2015.03.022. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sivaram A. J. Rajitha P. Maya S. Jayakumar R. Sabitha M. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnol. 2015;7:509–533. doi: 10.1002/wnan.1328. [DOI] [PubMed] [Google Scholar]

- Sasaki Y. Akiyoshi K. Chem. Rec. 2010;10:366–376. doi: 10.1002/tcr.201000008. [DOI] [PubMed] [Google Scholar]

- Wang H. Chen Q. Zhou S. Chem. Soc. Rev. 2018;47:4198–4232. doi: 10.1039/C7CS00399D. [DOI] [PubMed] [Google Scholar]

- Sultana F. Manirujjaman Imran-Ul-Haque Md. Arafat M. Sharmin S. J. Appl. Pharm. Sci. 2013;3:95–105. [Google Scholar]

- Avti P. K. Maysinger D. Kakkar A. Molecules. 2013;18:9531–9549. doi: 10.3390/molecules18089531. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yi G. Son J. Yoo J. Park C. Koo H. Biomater. Res. 2018;22:1–8. doi: 10.1186/s40824-017-0112-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mauri E. Giannitelli S. M. Trombetta M. Rainer A. Gels. 2021;7:1–23. doi: 10.3390/gels7020036. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhang X. Malhotra S. Molina M. Haag R. Chem. Soc. Rev. 2015;44:1948–1973. doi: 10.1039/C4CS00341A. [DOI] [PubMed] [Google Scholar]

- Lovell P. A. Schork F. J. Biomacromolecules. 2020;21:4396–4441. doi: 10.1021/acs.biomac.0c00769. [DOI] [PubMed] [Google Scholar]

- Beyazit S. Tse Sum Bui B. Haupt K. Gonzato C. Prog. Polym. Sci. 2016;62:1–21. doi: 10.1016/j.progpolymsci.2016.04.001. [DOI] [Google Scholar]

- Gao H. Li W. Matyjaszewski K. Macromolecules. 2008;41:2335–2340. doi: 10.1021/ma702823b. [DOI] [Google Scholar]

- Kim S. Sikes H. D. Polym. Chem. 2020;11:1424–1444. doi: 10.1039/C9PY01801H. [DOI] [Google Scholar]

- Hein C. D. Liu X. M. Wang D. Pharm. Res. 2008;25:2216–2230. doi: 10.1007/s11095-008-9616-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Huang Z. Zhou Y. Wang Z. Li Y. Zhang W. Zhou N. Chin. J. Polym. Sci. 2017;35:317–341. doi: 10.1007/s10118-017-1902-0. [DOI] [Google Scholar]

- Kolb H. C. Finn M. G. Sharpless K. B. Angew. Chem., Int. Ed. 2001;40:2004–2021. doi: 10.1002/1521-3773(20010601)40:11<2004::AID-ANIE2004>3.0.CO;2-5. [DOI] [PubMed] [Google Scholar]

- Chaturvedi P. Chaturvedi N. Gupta S. Mishra A. Singh M. Siddhartha T. Int. J. Pharm. Sci. Rev. Res. 2011;10:111–117. [Google Scholar]

- Meghani N. M. Amin H. H. Lee B. J. Drug Discovery Today. 2017;22:1604–1619. doi: 10.1016/j.drudis.2017.07.007. [DOI] [PubMed] [Google Scholar]

- Meldal M. Diness F. Trends Chem. 2020;2:569–584. doi: 10.1016/j.trechm.2020.03.007. [DOI] [Google Scholar]

- Kim E. Koo H. Chem. Sci. 2019;10:7835–7851. doi: 10.1039/C9SC03368H. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wang K. Amin K. An Z. Cai Z. Chen H. Chen H. Dong Y. Feng X. Fu W. Gu J. Han Y. Hu D. Hu R. Huang D. Huang F. Huang F. Huang Y. Jin J. Jin X. Li Q. Li T. Li Z. Li Z. Liu J. Liu J. Liu S. Peng H. Qin A. Qing X. Shen Y. Shi J. Sun X. Tong B. Wang B. Wang H. Wang L. Wang S. Wei Z. Xie T. Xu C. Xu H. Xu Z. K. Yang B. Yu Y. Zeng X. Zhan X. Zhang G. Zhang J. Zhang M. Q. Zhang X. Z. Zhang X. Zhang Y. Zhang Y. Zhao C. Zhao W. Zhou Y. Zhou Z. Zhu J. Zhu X. Tang B. Z. Mater. Chem. Front. 2020;4:1803–1915. doi: 10.1039/D0QM00025F. [DOI] [Google Scholar]

- Mashayekh K. Shiri P. ChemistrySelect. 2019;4:13459–13478. doi: 10.1002/slct.201902362. [DOI] [Google Scholar]

- Dheer D. Singh V. Shankar R. Bioorg. Chem. 2017;71:30–54. doi: 10.1016/j.bioorg.2017.01.010. [DOI] [PubMed] [Google Scholar]

- Rani A. Singh G. Singh A. Maqbool U. Kaur G. Singh J. RSC Adv. 2020;10:5610–5635. doi: 10.1039/C9RA09510A. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gazzali A. M. Colombeau L. Arnoux P. Wahab H. A. Frochot C. Vanderesse R. Acherar S. Tetrahedron. 2017;73:532–541. doi: 10.1016/j.tet.2016.12.037. [DOI] [Google Scholar]

- Singh G. Priyanka Singh A. Satija P. Sushma Pawan Mohit Singh J. Singh J. New J. Chem. 2021;45:7850–7859. doi: 10.1039/D1NJ00943E. [DOI] [Google Scholar]

- Kaur P. Lal B. Kaur N. Singh G. Singh A. J. Photochem. Photobiol., A. 2019;382:111847. doi: 10.1016/j.jphotochem.2019.05.010. [DOI] [Google Scholar]

- Saini P. Sonika Singh G. Kaur G. Singh J. Singh H. Mol. Catal. 2021;504:111432. doi: 10.1016/j.mcat.2021.111432. [DOI] [Google Scholar]

- Singh G. Sushma Singh A. Satija P. Shilpy Mohit Priyanka Singh J. Khosla A. Inorg. Chim. Acta. 2021;514:120028. doi: 10.1016/j.ica.2020.120028. [DOI] [Google Scholar]

- Thirumurugan P. Matosiuk D. Jozwiak K. Chem. Rev. 2013;113:4905–4979. doi: 10.1021/cr200409f. [DOI] [PubMed] [Google Scholar]

- Naja S. Talebpour Z. Mehdi A. Tetrahedron. 2019;118:556–573. [Google Scholar]

- Seda N. El-gindi J. Galla H. De Cola L. Microporous Mesoporous Mater. 2011;144:9–14. doi: 10.1016/j.micromeso.2010.11.030. [DOI] [Google Scholar]

- Croisy A. Maillard P. Tetrahedron. 2011;67:4924–4932. doi: 10.1016/j.tet.2011.04.080. [DOI] [Google Scholar]

- Wang S. Placzek W. J. Stebbins J. L. Mitra S. Noberini R. Koolpe M. Zhang Z. Dahl R. Pasquale E. B. Pellecchia M. J. Med. Chem. 2012;55:2427–2436. doi: 10.1021/jm201743s. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gruber A. Navarro L. Klinger D. Adv. Mater. Interfaces. 2019;7:1901676. doi: 10.1002/admi.201901676. [DOI] [Google Scholar]

- Kaur J. Saxena M. Rishi N. Bioconjugate Chem. 2021;32:1455–1471. doi: 10.1021/acs.bioconjchem.1c00247. [DOI] [PubMed] [Google Scholar]

- Obhi N. K. Peda D. M. Kynaston E. L. Seferos D. S. Macromolecules. 2018;51:2969–2978. doi: 10.1021/acs.macromol.8b00138. [DOI] [Google Scholar]

- Crescenzi V. Cornelio L. Di Meo C. Nardecchia S. Biomacromolecules. 2007;8:1844–1850. doi: 10.1021/bm0700800. [DOI] [PubMed] [Google Scholar]