Abstract

Poly(3-hydroxyalkanoates) (PHAs) are a class of microbially produced polyesters that have potential applications as conventional plastics, specifically thermoplastic elastomers. A wealth of biological diversity in PHA formation exists, with at least 100 different PHA constituents and at least five different dedicated PHA biosynthetic pathways. This diversity, in combination with classical microbial physiology and modern molecular biology, has now opened up this area for genetic and metabolic engineering to develop optimal PHA-producing organisms. Commercial processes for PHA production were initially developed by W. R. Grace in the 1960s and later developed by Imperial Chemical Industries, Ltd., in the United Kingdom in the 1970s and 1980s. Since the early 1990s, Metabolix Inc. and Monsanto have been the driving forces behind the commercial exploitation of PHA polymers in the United States. The gram-negative bacterium Ralstonia eutropha, formerly known as Alcaligenes eutrophus, has generally been used as the production organism of choice, and intracellular accumulation of PHA of over 90% of the cell dry weight have been reported. The advent of molecular biological techniques and a developing environmental awareness initiated a renewed scientific interest in PHAs, and the biosynthetic machinery for PHA metabolism has been studied in great detail over the last two decades. Because the structure and monomeric composition of PHAs determine the applications for each type of polymer, a variety of polymers have been synthesized by cofeeding of various substrates or by metabolic engineering of the production organism. Classical microbiology and modern molecular bacterial physiology have been brought together to decipher the intricacies of PHA metabolism both for production purposes and for the unraveling of the natural role of PHAs. This review provides an overview of the different PHA biosynthetic systems and their genetic background, followed by a detailed summation of how this natural diversity is being used to develop commercially attractive, recombinant processes for the large-scale production of PHAs.

INTRODUCTION TO POLY(3-HYDROXYALKANOATES)

Storage Material

Poly(3-hydroxyalkanoates) (PHAs) are structurally simple macromolecules synthesized by many gram-positive and gram-negative bacteria. PHAs are accumulated as discrete granules to levels as high as 90% of the cell dry weight and are generally believed to play a role as sink for carbon and reducing equivalents. When nutrient supplies are imbalanced, it is advantageous for bacteria to store excess nutrients intracellularly, especially as their general fitness is not affected. By polymerizing soluble intermediates into insoluble molecules, the cell does not undergo alterations of its osmotic state and leakage of these valuable compounds out of the cell is prevented. Consequently, the nutrient stores will remain available at a relatively low maintenance cost and with a secured return on investment (36, 182, 239, 240, 286).

Once PHAs are extracted from the bacterial cell, however, these molecules show material properties that are similar to some common plastics such as polypropylene (20). The bacterial origin of the PHAs make these polyesters a natural material, and, indeed, many microorganisms have evolved the ability to degrade these macromolecules. Besides being biodegradable, PHAs are recyclable like the petrochemical thermoplasts. This review summarizes the chemical and physical properties of PHAs and the biochemical and genetic studies of the pathways involved in PHA metabolism. Within this framework, the scientific advances that have been made with the available pha genes for economic PHA production processes will be described.

Chemical Structure

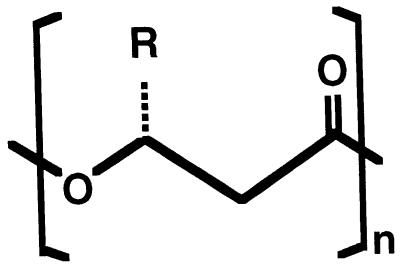

The many different PHAs that have been identified to date are primarily linear, head-to-tail polyesters composed of 3-hydroxy fatty acid monomers. In these polymers, the carboxyl group of one monomer forms an ester bond with the hydroxyl group of the neighboring monomer (Fig. 1). In all PHAs that have been characterized so far, the hydroxyl-substituted carbon atom is of the R configuration, except in some special cases where there is no chirality. At the same C-3 or β position, an alkyl group which can vary from methyl to tridecyl is positioned. However, this alkyl side chain is not necessarily saturated: aromatic, unsaturated, halogenated, epoxidized, and branched monomers have been reported as well (1, 25, 32, 44, 58–60, 85, 125, 126, 135, 247). Specialized, unnatural monomers such as 4-cyanophenylvalerate have been incorporated to obtain new polymers with special properties (124). As well as the variation in the alkyl substituent, the position of the hydroxyl group is somewhat variable, and 4-, 5- and 6-hydroxy acids have been incorporated (51, 131, 277–279). Substituents in the side chains of PHAs can be modified chemically, for instance by cross-linking of unsaturated bonds (39, 67, 68). This variation in the length and composition of the side chains and the ability to modify their reactive substituents is the basis for the diversity of the PHA polymer family and their vast array of potential applications that are described below.

FIG. 1.

Chemical structure of PHAs. PHAs are generally composed of (R)-β-hydroxy fatty acids, where the pendant group (R) varies from methyl (C1) to tridecyl (C13). Other fatty acids that have been incorporated have the hydroxy group at the γ, δ, or ɛ position, while the pendant group may be saturated or unsaturated or contain substituents. The best-known PHAs are P(3HB) (R = methyl), P(3HB-3HV) (R = methyl or ethyl), and P(3HO-3HH) (R = pentyl or propyl).

Historically, poly(3-hydroxybutyrate) [P(3HB)] has been studied most extensively and has triggered the commercial interest in this class of polymers. P(3HB) is the most common type of PHA, and the ability of bacteria to accumulate P(3HB) is often used as a taxonomic characteristic. Copolymers of P(3HB) can be formed by cofeeding of substrates and may result in the formation of polymers containing 3-hydroxyvalerate (3HV) or 4-hydroxybutyrate (4HB) monomers. Together, polymers containing such monomers form a class of PHAs typically referred to as short-side-chain PHAs (ssc-PHAs). In contrast, medium-side-chain PHAs (msc-PHAs) are composed of C6 to C16 3-hydroxy fatty acids. These PHAs are synthesized from fatty acids or other aliphatic carbon sources, and, typically, the composition of the resulting PHA depends on the growth substrate used (17, 105, 135). msc-PHAs are also synthesized from carbohydrates, but the composition of these PHAs is not related to the carbon source (84, 102, 270). The vast majority of microbes synthesize either ssc-PHAs containing primarily 3HB units or msc-PHAs containing 3-hydroxyoctanoate (3HO) and 3-hydroxydecanoate (3HD) as the major monomers (6, 142, 249, 252).

Physical Characteristics

The molecular mass of PHAs varies per PHA producer but is generally on the order of 50,000 to 1,000,000 Da. Although aliphatic polyesters have been studied extensively since the 1920s, their properties were not remarkable and did not initiate a great commercial interest at that time. This was primarily due to the use of relatively impure substrates at the time, which limited the molecular masses of these polymers to 20,000 to 30,000 Da (159). Bacterially produced P(3HB) and other PHAs, however, have a sufficiently high molecular mass to have polymer characteristics that are similar to conventional plastics such as polypropylene (Table 1).

TABLE 1.

Properties of PHAs and polypropylenea

| Parameter | Value forb:

|

||||

|---|---|---|---|---|---|

| P(3HB) | P(3HB-3HV) | P(3HB-4HB) | P(3HO-3HH) | PP | |

| Tm (°C)c | 177 | 145 | 150 | 61 | 176 |

| Tg (°C)d | 2 | −1 | −7 | −36 | −10 |

| Crystallinity (%) | 70 | 56 | 45 | 30 | 60 |

| Extension to break (%) | 5 | 50 | 444 | 300 | 400 |

Data from reference 42.

P(3HB) is poly(3-hydroxybutyrate), P(3HB-3HV) is poly(3-hydroxybutyrate-co-3-hydroxyvalerate) containing 20% 3HV, P(3HB-4HB) is poly(3-hydroxybutyrate-co-4-hydroxybutyrate) containing 16% 4HB, P(3HO-3HH) is poly(3-hydroxyoctanoate-co-3-hydroxyhexanoate) containing 11% 3HH, and PP is polypropylene.

Tm is melting temperature.

Tg is glass transition temperature.

Within the cell, P(3HB) exists in a fluid, amorphous state. However, after extraction from the cell with organic solvents, P(3HB) becomes highly crystalline (43) and in this state is a stiff but brittle material. Because of its brittleness, P(3HB) is not very stress resistant. Also, the relatively high melting temperature of P(3HB) (around 170°C) is close to the temperature where this polymer decomposes thermally and thus limits the ability to process the homopolymer. Initial biotechnological developments were therefore aimed at making PHAs that were easier to process. The incorporation of 3HV into the P(3HB) resulted in a poly(3-hydroxybutyrate-co-3-hydroxyvalerate) [P(3HB-3HV)] copolymer that is less stiff and brittle than P(3HB), that can be used to prepare films with excellent water and gas barrier properties reminiscent of polypropylene, and that can be processed at a lower temperature while retaining most of the other excellent mechanical properties of P(3HB) (159). In contrast to P(3HB) and P(3HB-3HV), msc-PHAs have a much lower level of crystallinity and are more elastic (73, 208). These msc-PHAs potentially have a different range of applications from the ssc-PHAs.

Biological Considerations

The diversity of different monomers that can be incorporated into PHAs, combined with a biological polymerization system that generates high-molecular weight materials, has resulted in a situation where an enormous range of new polymers are potentially available. The advent of genetic engineering combined with modern molecular microbiology now provides us with the exceptional framework for studying plastic properties as a function of genetic and metabolic blueprints. In fact, it presents an enormous challenge to our scientific discipline to fully explore this biology to ensure that environmentally friendly polyesters are available for generations to come.

Biodegradability.

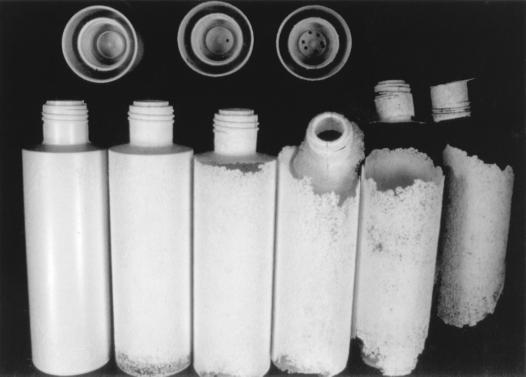

Besides the typical polymeric properties described above, an important characteristic of PHAs is their biodegradability. In nature, a vast consortium of microorganisms is able to degrade PHAs by using secreted PHA hydrolases and PHA depolymerases (for a review of the microbiology and molecular genetics of PHA degradation, see reference 111). The activities of these enzymes may vary and depend on the composition of the polymer, its physical form (amorphous or crystalline), the dimensions of the sample, and, importantly, the environmental conditions. The degradation rate of a piece of P(3HB) is typically on the order of a few months (in anaerobic sewage [Fig. 2]) to years (in seawater) (111, 167–169).

FIG. 2.

Degradation of P(3HB-3HV) in aerobic sewage sludge. Bottles made of P(3HB-3HV) were incubated during the summer (average temperature, 20°C) in aerobic sewage sludge. The progress of degradation is demonstrated with bottles that have been subjected to this treatment for 0, 2, 4, 6, 8, and 10 weeks (from left to right). Photograph courtesy of Dieter Jendrossek, Georg-August-Universität, Göttingen, Germany.

Renewable nature.

As important as the biological characteristics and biodegradability of PHAs is the fact that their production is based on renewable resources. Fermentative production of PHAs is based on agricultural products such as sugars and fatty acids as carbon and energy sources. These agricultural feedstocks are derived from CO2 and water, and after their conversion to biodegradable PHA, the breakdown products are again CO2 and water. Thus, while for some applications the biodegradability is critical, PHAs receive general attention because they are based on renewable compounds instead of on our diminishing fossil fuel stockpiles (293).

Applications

PHAs are natural thermoplastic polyesters, and hence the majority of their applications are as replacements for petrochemical polymers currently in use for packaging and coating applications. The extensive range of physical properties of the PHA family of polymers and the broadened performance obtainable by compounding and blending provide a correspondingly broad range of potential end-use applications, as described in numerous patents.

Initial efforts focused on molding applications, in particular for consumer packaging items such as bottles, cosmetic containers, pens, and golf tees (9, 10, 287). U.S. patents 4,826,493 and 4,880,592 describe the manufacture of P(3HB) and P(3HB-3HV) films and their use as diaper backsheet (163, 164). These films can also be used to make laminates with other polymers such as polyvinyl alcohol (91). Diaper backsheet materials and other materials for manufacturing biodegradable or compostable personal hygiene articles from P(3HB) copolymers other than P(3HB-3HV) have been described (180, 181, 241). PHAs have also been processed into fibers which then were used to construct materials such as nonwoven fabrics (248). P(3HB) and P(3HB-3HV) have been described as hot-melt adhesives (118). PHAs with longer-side-chain hydroxyacids have been used in pressure-sensitive adhesive formulations (229). PHAs can also be used to replace petrochemical polymers in toner and developer compositions (65) or as ion-conducting polymers (221, 222). PHAs can be used as a latex, for instance for paper-coating applications (160), or can be used to produce dairy cream substitutes (298) or flavor delivery agents in foods (299).

In addition to its range of material properties and resulting applications, PHAs promise to be a new source of small molecules. PHA can be hydrolyzed chemically, and the monomers can be converted to commercially attractive molecules such as are β-hydroxy acids, 2-alkenoic acids, β-hydroxyalkanols, β-acyllactones, β-amino acids, and β-hydroxyacid esters (293). The last class of chemicals is currently receiving attention because of potential applications as biodegradable solvents.

PHA BIOSYNTHESIS IN NATURAL ISOLATES

Since 1987, the extensive body of information on P(3HB) metabolism, biochemistry, and physiology has been enriched by molecular genetic studies. Numerous genes encoding enzymes involved in PHA formation and degradation have been cloned and characterized from a variety of microorganisms. From these studies, it is becoming clear that nature has evolved several different pathways for PHA formation, each optimized for the ecological niche of the PHA-producing microorganism. Genetic studies have, furthermore, given insights into the regulation of PHA formation with respect to growth conditions. The cellular physiology of the cell and the important role of central metabolism have become apparent by studying PHA mutants with modifications in genes other than the phb genes. Not only do such studies provide a fundamental insight into microbial physiology, but also they provide the keys for designing and engineering recombinant organisms for PHA production. This section deals with the molecular details of the PHA enzymes and corresponding genes and how their activities blend with cellular metabolism to synthesize PHA only at times where their synthesis is useful.

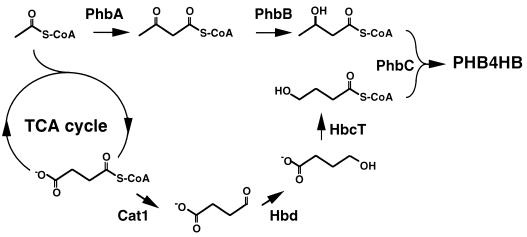

Of all the PHAs, P(3HB) is the most extensively characterized polymer, mainly because it was the first to be discovered, in 1926 by Lemoigne at the Institute Pasteur (152). The P(3HB) biosynthetic pathway consists of three enzymatic reactions catalyzed by three distinct enzymes (Fig. 3). The first reaction consists of the condensation of two acetyl coenzyme A (acetyl-CoA) molecules into acetoacetyl-CoA by β-ketoacyl-CoA thiolase (encoded by phbA). The second reaction is the reduction of acetoacetyl-CoA to (R)-3-hydroxybutyryl-CoA by an NADPH-dependent acetoacetyl-CoA dehydrogenase (encoded by phbB). Lastly, the (R)-3-hydroxybutyryl-CoA monomers are polymerized into poly(3-hydroxybutyrate) by P(3HB) polymerase (encoded by phbC). Although P(3HB) accumulation is a widely distributed prokaryotic phenotype, the biochemical investigations into the enzymatic mechanisms of β-ketoacyl-CoA thiolase, acetoacetyl-CoA reductase, and P(3HB) polymerase have focused on only two of the natural producers, Zoogloea ramigera and Ralstonia eutropha (formerly known as Alcaligenes eutrophus).

FIG. 3.

Biosynthetic pathway for P(3HB). P(3HB) is synthesized in a three-step pathway by the successive action of β-ketoacyl-CoA thiolase (PhbA), acetoacetyl-CoA reductase (PhbB), and P(3HB) polymerase (PhbC). The three enzymes are encoded by the genes of the phbCAB operon. A promoter upstream of phbC transcribes the complete operon.

Essential Genes for PHA Formation

The first phb gene to be isolated was from Z. ramigera (190), an interesting bacterium for biopolymer engineering since it produces both P(3HB) and extracellular polysaccharide (50). By using anti-thiolase antibodies the phbA gene was detected in Escherichia coli carrying a Z. ramigera gene library and was subsequently cloned (190). It was found that phbA and phbB form an operon, while phbC is located elsewhere on the chromosome of Z. ramigera (191). The cloning of phbA and phbB facilitated the purification of the encoded ketoacyl-CoA thiolase and acetoacetyl-CoA reductase for kinetic and mechanistic characterization of these enzymes as described in later sections.

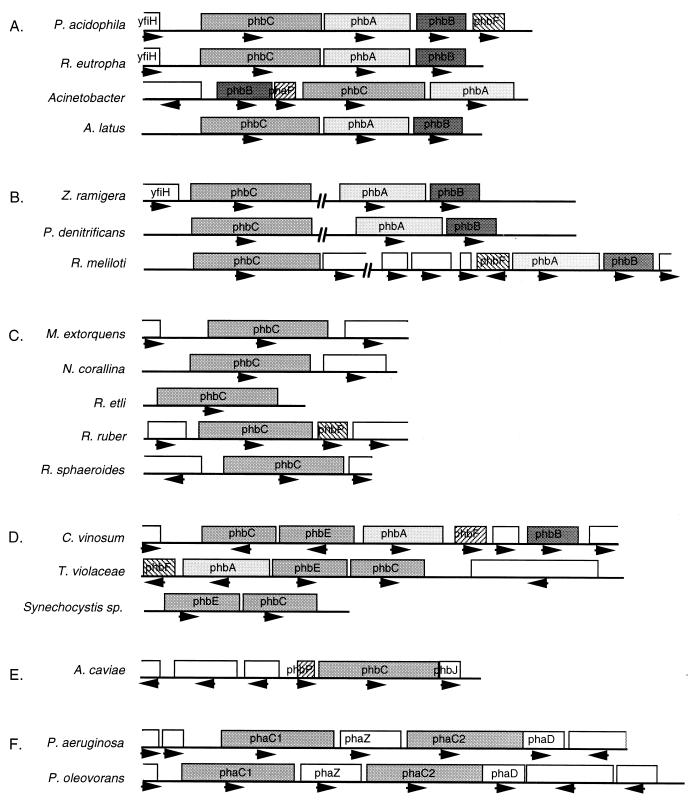

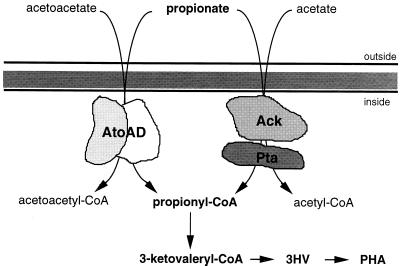

Since the original discovery of these phb genes, many genes encoding enzymes from the PHA pathway have been cloned from different organisms (Fig. 4). Given the diversity of P(3HB) biosynthetic pathways, it is not surprising that the pha loci have diverged considerably. In Acinetobacter spp., Alcaligenes latus, Pseudomonas acidophila, and R. eutropha, the phbCAB genes are in tandem on the chromosome although not necessarily in the same order (108, 192, 193, 232, 274). In Paracoccus denitrificans, Rhizobium meliloti, and Z. ramigera, the phbAB and phbC loci are unlinked (141, 191, 271, 273, 297). PHA polymerase in Chromatium vinosum, Thiocystis violacea, and Synechocystis is a two-subunit enzyme encoded by the phbE and phbC genes. In these organisms, phbAB and phbEC are in one locus but divergently oriented (87, 154, 155). The phb loci in C. vinosum, P. acidophila, R. eutropha, Rhizobium meliloti, and T. violacea all have an additional gene, phbF, that has a hitherto unknown function in PHA metabolism (202), while part of a gene encoding a protein homologous to the hypothetical E. coli protein YfiH is located upstream of the P. acidophila, R. eutropha, and Z. ramigera P(3HB) polymerase genes. In Methylobacterium extorquens, Nocardia corallina, Rhizobium etli, Rhodococcus ruber, and Rhodobacter sphaeroides, only the PHB polymerase-encoding gene has been identified thus far (23, 78, 109, 195, 280). The PHA polymerase gene in Aeromonas caviae is flanked by a unique PHA biosynthetic enzyme encoded by phaJ, which is discussed in further detail below (61). In msc-PHA-producing P. oleovorans and P. aeruginosa, the pha loci contain two phaC genes (107, 269) separated by phaZ, which encodes an intracellular PHA depolymerase (107). The two PHA polymerases are 50 to 60% identical in their primary structure and appear to have a very similar substrate specificity (102, 107).

FIG. 4.

pha and phb operons. The loci encoding the genes for PHA formation have been characterized from 18 different species. Genes specifying enzymes for ssc-PHA formation are designated phb, and those specifying enzymes for msc-PHA formation are designated pha. Not all pathways have completely been elucidated in these strains. The emerging picture is that pha and phb genes are not necessarily clustered and that the gene organization varies from species to species. Other genes possibly related to PHA metabolism may be linked to the essential pha and phb genes. (A) Complete phbCAB operons. (B) Interrupted phb loci. (C) Incomplete phb loci. (D) phb loci from organisms that encode two subunit P(3HB) polymerases. (E) The phbCJ locus of A. caviae involved in P(3HB-3HH) formation. (F) pha loci for msc-PHA formation in Pseudomonas.

Figure 4 provides grounds for some speculation on the evolution of PHA formation. When the first PHA-forming bacteria used this pathway, the purpose of the pathway was probably different from synthesis of a storage material (see also below). PHA formation was most probably a minor metabolic pathway in these organisms, perhaps resulting only from a side reaction. When PHA formation became beneficial for the microbe, evolution selected for improved PHA-accumulating strains under conditions of which we are unfortunately not aware. Knowledge of such conditions would be extremely helpful in the current efforts to optimize PHA production that employ recombinant PHA producers and are described in later sections. Over the course of evolution, phaC was sometimes combined with genes that supply monomer, such as phbAB or phaJ, or with genes involved in other aspects of PHA metabolism, such as phaZ. The selective pressures active at the time resulted in the clustering of pha genes in an operon in some organisms (as in P. acidophila, R. eutropha, Acinetobacter, Alcaligenes latus, and Aeromonas caviae) or as separate transcriptional units in others (as in Z. ramigera, P. denitrificans, Rhizobium meliloti, C. vinosum, T. violacea, P. oleovorans, P. putida, and perhaps other microorganisms for which no thiolase and reductase genes have been identified yet). A second evolutionary force must have worked on the pha genes since some but not all of these diversely structured loci contain phbF and phbP genes or homologs of yfiH. Whether the ancestral PHA polymerase was encoded by one (phaC) or two (phaEC) open reading frames is an open question. Since the two-subunit polymerase systems in C. vinosum and T. violaceae do have neighboring thiolase and reductase genes whereas phaEC in Synechocystis does not, fusion of phaEC or splicing of phaC may have preceded the rearrangements in the pha loci.

Although B. megaterium was the first strain from which P(3HB) was isolated and identified, its biosynthetic machinery has not yet been characterized. The recently isolated B. megaterium mutants impaired in P(3HB) formation (55) should allow the cloning and characterization of the phb genes from this historically relevant P(3HB) producer.

The Three-Step ssc-PHA Biosynthetic Pathway

β-Ketoacyl-CoA thiolase.

β-Ketoacyl-CoA thiolase catalyzes the first step in P(3HB) formation. The P(3HB) biosynthetic thiolase (acetyl-CoA:acetyl-CoA-acetyl transferase; EC 2.3.1.9) is a member of a family of enzymes involved in the thiolytic cleavage of substrates into acyl-CoA plus acetyl-CoA. These β-ketoacyl-CoA thiolases are found throughout nature from higher eukaryotes to yeasts to prokaryotes and are divided into two groups based on their substrate specificity. The first group consists of thiolases with a broad specificity for β-ketoacyl-CoAs ranging from C4 to C16. This class of enzymes is involved mainly in the degradation of fatty acids and is located in the cytoplasm of prokaryotes and in the mitochondria and peroxisomes of mammalian and plant cells. The second class of β-ketoacyl-CoA thiolases is considered biosynthetic and has a narrow range of chain length specificity, from C3 to C5. Throughout nature, these biosynthetic thiolases are specialized for a variety of roles such as ketone body formation, steroid and isoprenoid biosynthesis, and P(3HB) synthesis. The thiolase involved in P(3HB) formation is a biosynthetic thiolase with specificity primarily for acetoacetyl-CoA (166).

R. eutropha contains two β-ketothiolases (enzyme A and enzyme B) that are able to act in the biosynthetic pathway to P(3HB) synthesis. The major difference between these two enzymes is their substrate specificity. Enzyme A is a homotetramer of 44-kDa subunits and converts acetoacetyl-CoA and 3-ketopentanoyl-CoA (but only at 3% relative activity in comparison to acetoacetyl-CoA). In contrast, enzyme B, a homotetramer of 46-kDa subunits, has a broader substrate specificity and cleaves acetoacetyl-CoA as well as 3-ketopentanoyl-CoA, 3-ketohexanoyl-CoA, 3-ketoheptanoyl-CoA, 3-ketooctanoyl-CoA, and 3-ketodecanoyl-CoA (30, 17, 19, 10, and 12% activity relative to acetoacetyl-CoA, respectively). Originally it was thought that the major role of enzyme B is in fatty acid degradation while the primary role of enzyme A (PhbA) is in the biosynthesis of P(3HB) (81). Recently, however, it has been shown that enzyme B is the primary source of the 3HV monomer for P(3HB-3HV) formation (244).

The enzymatic mechanism of PhbA consists of two half-reactions that result in the condensation of two acetyl-CoA molecules into acetoacetyl-CoA. In the first half-reaction, an active-site cysteine attacks an acetyl-S-CoA molecule to form an acetyl-S-enzyme intermediate. In the second half-reaction, a second cysteine deprotonates another acetyl-CoA, resulting in an activated acetyl-CoA intermediate that is able to attack the acetyl-S-enzyme intermediate and form acetoacetyl-CoA (165). The involvement of a cysteine(s) in the active site of the P(3HB) thiolase was first hypothesized in 1953 because the thiolase was inhibited by sulfhydryl-blocking agents (156). In the late 1980s, the roles of cysteines in the active site of the P(3HB) thiolase were definitively determined, after the thiolase gene from Z. ramigera had been cloned and the enzyme had been overproduced and purified. The cysteine involved in the acetyl-S-enzyme intermediate was identified as Cys89 by peptide sequencing of the radioactive peptide after tryptic digestion of radiolabeled enzyme with [14C]iodoacetamide or [14C]acetyl-CoA (35, 267). A C89S thiolase mutant was also constructed and determined to be severely affected in catalysis but not substrate affinity (165, 267). The second cysteine in the active site of P(3HB) thiolase was determined by using affinity-labeled inactivators such as bromoacetyl-S-pantethene-11-pivalate. By using this inhibitor, Cys378 was identified as a potential residue for the second active-site cysteine that deprotonates the second acetyl-CoA molecule (34, 186) and the C378G mutant was virtually inactive (165, 186). So far, all P(3HB) thiolases contain these two active-site cysteines, and it is believed that all the P(3HB) thiolases use the same enzymatic mechanism to condense acetyl-CoA with either acetyl-CoA or acyl-CoA.

Acetoacetyl-CoA reductase.

Acetoacetyl-CoA reductase is an (R)-3-hydroxyacyl-CoA dehydrogenase (EC 1.1.1.36) and catalyzes the second step in the P(3HB) biosynthetic pathway by converting acetoacetyl-CoA into 3-hydroxybutyryl-CoA. The acetoacetyl-CoA reductase from Z. ramigera is a homotetramer of 25-kDa subunits and has been classified as an NADPH-dependent reductase (62, 198, 231). Although both NADPH- and NADH-dependent acetoacetyl-CoA reductase activities have been observed in cell extracts of R. eutropha, only the former is involved in P(3HB) synthesis (82). The only known NADH-dependent acetoacetyl-CoA reductase involved in P(3HB) formation to date was found in C. vinosum (155). Although the phbB gene product from Paracoccus denitrificans was initially ascribed to be NADH dependent (297), subsequent overexpression of this enzyme and characterization proved this reductase to be active only with NADPH (29).

The enzymatic reactions involved in P(3HB) synthesis have been extensively analyzed by biochemical techniques and provide clues about the regulation of this pathway. The preferred reaction for the thiolase is thiolytic cleavage, which occurs in the direction opposite to the P(3HB) biosynthetic pathway. However, under P(3HB)-accumulating conditions the enzyme acts against its thermodynamically favored direction when the activities of acetoacetyl-CoA reductase and P(3HB) polymerase pull the condensation reaction (reviewed in reference 166). The availability of reducing equivalents in the form of NADPH is therefore considered to be the driving force for P(3HB) formation.

In the P(3HB) biosynthetic pathway, the reactions catalyzed by thiolase and reductase provide the monomer for PHA polymerization. The kinetic characteristics and substrate specificities of these two enzymes are therefore crucial in determining the range of products that can be expected to be synthesized in a thiolase, reductase, polymerase pathway, as depicted in Fig. 3. Table 2 shows a compilation of the kinetic characteristics of the best-studied thiolase and reductase enzymes, which provides insights in the use of these enzymes for the formation of P(3HB) copolymers. The concept of dividing PHA formation into monomer supply pathways and polymerization is important since in later sections it will be shown that monomers are not necessarily supplied by dedicated pathways. Some of the strategies currently used in fermentative production processes and also the new developments in metabolic engineering provide examples of the incorporation of monomers that are not supplied by thiolase and/or reductase mediated reactions.

TABLE 2.

Kinetic characteristics of P(3HB) biosynthetic enzymes

| Enzyme and species | Km (mM) | Substrate | Product | Reference |

|---|---|---|---|---|

| Thiolase (condensation) | ||||

| Z. ramigera | 0.33 | Acetyl-CoA | Acetoacetyl-CoA | 35 |

| Thiolase (thiolysis) | ||||

| Z. ramigera | 0.024 | Acetoacetyl-CoA | Acetyl-CoA | 35 |

| 0.46 | Acetoacetyl-pantheteine | Acetyl-CoA + acetyl-pantheteine | 35 | |

| 0.073 | Acetoacetyl-pantheteine-11-pivalate | Acetyl-CoA + acetyl-pantheteine-11-pivalate | 35 | |

| (50%)a | 3-Ketovaleryl-CoA | Acetyl-CoA + propionyl-CoA | 166 | |

| R. eutropha | 0.044 | Acetoacetyl-CoA | Acetyl-CoA | 252 |

| (3%)b | 3-Ketovaleryl-CoA | Acetyl-CoA + propionyl-CoA | 252 | |

| (0%)b | 3-Ketohexanoyl-CoA | Acetyl-CoA + butanoyl-CoA | 252 | |

| NADPH-dependent reductase | ||||

| Z. ramigera | 0.002 | Acetoacetyl-CoA | 3-Hydroxybutyryl-CoA | 198 |

| 0.002 | 3-Ketovaleryl-CoA | 3-Hydroxyvaleryl-CoA | 198 | |

| 0.010 | 3-Ketohexanoyl-CoA | 3-Hydroxyhexanoyl-CoA | 198 | |

| 0.99 | Acetoacetyl-pantheteine-11-pivalate | 3-Hydroxybutyryl-pantheteine-11-pivalate | 198 | |

| R. eutropha | 0.005 | Acetoacetyl-CoA | 3-Hydroxybutyryl-CoA | 252 |

| (18%)b | 3-Ketovaleryl-CoA | 3-Hydroxyvaleryl-CoA | 252 | |

| (3.6%)b | 3-Ketohexanoyl-CoA | 3-Hydroxyhexanoyl-CoA | 252 | |

| P(3HB) polymerase | ||||

| R. eutropha | 0.72 | 3-Hydroxybutyryl-CoA | P(3HB) | 252 |

| 1.63 | 3-Hydroxyvaleryl-CoA | PHV | 252 | |

| NDc | 3-Hydroxybutyryl-pantheteine-11-pivalate | None | 69 |

Vmax with respect to acetoacetyl-CoA.

Relative activity with respect to acetoacetyl-CoA and 3-hydroxybutyryl-CoA.

ND, not determined.

P(3HB) polymerase.

P(3HB) polymerase is the third enzyme in the biosynthetic pathway for P(3HB) production. The first phbC nucleotide sequence to be reported was from R. eutropha. This gene was isolated by complementation of R. eutropha P(3HB)-negative mutants (192), and the promoter that drives the expression of phbC (235) and the other genes in the phb operon (192, 193) was mapped. Expression of these three genes in E. coli resulted in the accumulation of P(3HB) up to levels exceeding 50% of the cell dry weight (192, 236, 245).

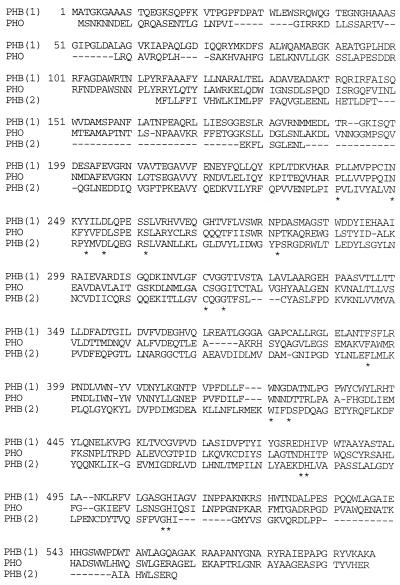

P(3HB) polymerase is just one member of the family of PHA polymerases. All of the polymerases have molecular masses of around 63,000 Da, except for the polymerases from C. vinosum (153), T. violacea (154), and Synechococcus spp. (87, 114), which are composed of two subunits with molecular masses of 40 and 45 kDa. Interestingly, there are only 15 fully conserved residues among the 26 known PHA polymerases, many of which lead only to ssc-PHA formation (Fig. 5). This is remarkable, since these 15 residues represent on average less than 3% of the total number of amino acids in these enzymes. Since PHA polymerase is found in both soluble (hydrophilic) and granule-bound (hydrophobic) states, it may be that evolution has selected for enzymes that are catalytically efficient while presenting few problems related to undesirable “protein–hydrophobic-surface” interactions. The broad variety of PHA-producing microbes would represent a vast spectrum of intracellular conditions to which these enzymes would have to be adapted. This could explain the low level of overall conserved sequence identity between the different PHA polymerases.

FIG. 5.

Sequence similarity of representatives of three types of PHA polymerases. R. eutropha ssc-PHA polymerase (PHB1), P. oleovorans msc-PHA polymerase (PHO), and the PhbC subunit of the two-subunit polymerase from Synechocystis sp. (PHB2) were aligned by using the program of Higgins (MacDNASIS; IntelliGenetics, Mountain View, Calif.). Residues conserved in all PHA polymerases identified to date are marked by an asterisk.

Early biochemical studies of PHB polymerase were hampered by the low activity of the protein purified from the natural PHB producers. These studies, however, indicated that the enzyme exists in both soluble and granule-bound forms (64, 83). It was proposed that two cysteine residues might be involved in catalysis, with one cysteine holding the growing PHA chain while the other cysteine holds the incoming monomer (72). To test this theory, two cysteines (Cys319 and Cys459) in the R. eutropha P(3HB) polymerase were mutated (70). Cys319 is conserved in all the synthases isolated to date (250), while Cys459 is conserved between only the R. eutropha and the P. oleovorans PHA polymerases. Cys319 was shown to be an active-site residue, because serine and alanine mutations rendered the enzyme inactive. In contrast, when the second cysteine (Cys459) was mutated to a serine, the enzyme retained 90% of the wild-type activity (70). By using the tritiated trimer (3HB)3-CoA, it was shown that the P(3HB) polymer is covalently bound to the P(3HB) polymerase through Cys319 (296).

To explain the ability of the enzyme to form ester bonds with only one cysteine residue, a second thiol was proposed to exist via posttranslational modification. Phosphopantetheine was proposed as a potential posttranslational modification moiety for P(3HB) polymerase (70). A phosphopantetheine posttranslational modification has been found in acyl-carrier protein and enzymes in enterobactin biosynthesis (110). By using a P(3HB) polymerase overexpression system, it was shown that the PhbC enzyme is radioactively labeled when β-[3H]alanine, a precursor of phosphopantetheine, is supplied to the culture. The most likely residue to be modified by phosphopantetheinylation is Ser260 (70), a residue conserved in all phaC genes characterized to date (Fig. 5) and part of a region that resembles similar sites in panthethenylated enzymes (70).

Given the function of the polymerases in forming ester bonds, it is not surprising to find the active-site cysteine residue of these enzymes in a lipase box, Gly-X-Cys319-X-Gly-Gly. The active site of a lipase generally consists of a nucleophile, either cysteine or serine, whose reactivity is enhanced by an aspartate residue and a histidine residue (16, 194, 295). Together, these three residues form a catalytic triad. Candidates for these aspartate and histidine residues are conserved in the polymerases, namely, aspartate residues at positions 351, 428, and 480 and histidine residues at positions 481 and 508 (Fig. 5). Given that PHA polymerase may have two active-site thiols, it is possible that two of the three conserved aspartate residues and both conserved histidines are part of a catalytic triad. The occurrence of the strictly conserved Trp425 in the proximity of Asp428 and the conserved dyads Asp480-His481 and Gly507-His508 underscores the likely importance of these residues in catalysis. Analogously, the strict conservation of Pro239, Asn248, Tyr251, and Asp254 in the direct vicinity of the critical Ser260 residues underscores the importance of this stretch of amino acids.

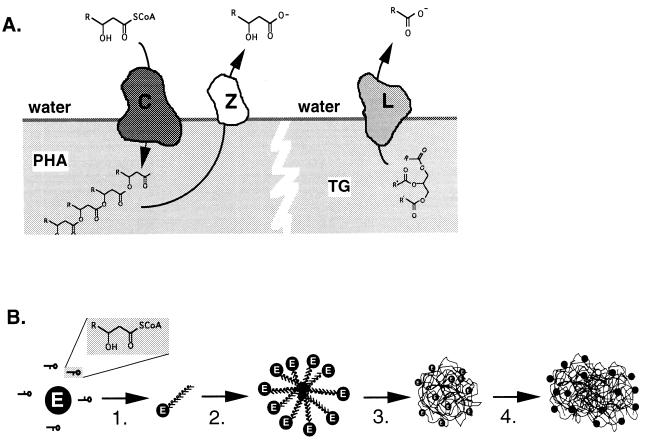

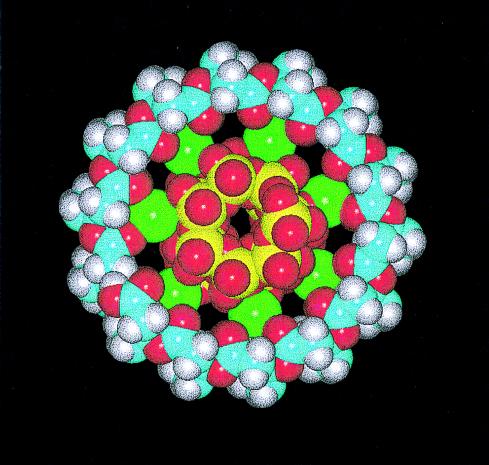

Model for PHA Granule Formation

The resemblance of the active sites of PHA polymerases and lipases, as well as the preferred localization of these enzymes (Fig. 6A), suggests how the process of granule formation may proceed. Both enzymes act on ester bonds at the interface of a hydrophobic vesicle and water. The difference between these enzymes is in the direction of the reaction that they catalyze, either toward ester formation or towards ester hydrolysis. In the aqueous environment of the cytosol, the PHA polymerase is quite a remarkable enzyme since it performs an esterification reaction under typically unfavorable aqueous conditions.

FIG. 6.

(A) Similarities between PHA polymerase and lipase. PHA polymerase (C) acts at the surface of a PHA granule, where soluble precursors are polymerized and deposited in the hydrophobic environment of the granule. PHA depolymerase (Z) also acts at this surface and liberates the monomers from the polymer. Both enzymatic reactions are reminiscent of that of lipase (L), which cleaves ester bonds at triglyceride (TG)/water interfaces, yielding free acids and alkanols. (B) Proposed mechanism for the formation of PHA granules. Soluble enzyme converts monomer-CoA to oligomers, which remain enzyme bound (step 1). At a critical oligomer length and enzyme-oligomer concentration, the enzyme-oligomer complexes form micelles with the enzyme located at the interface, separating the PHA from the cytosol (step 2). Because of this compartmentalization, PHA polymerization is facilitated. Because the hydrophobic polymer can now be extruded into a hydrophobic environment instead of the aqueous phase, the reaction proceeds faster. The micelles are expanded and now appear as intracellular, granular structures visible with the phase-contrast microscope (step 3). As the number of granules increase, they may fuse and coalesce, giving rise to large aggregates of PHA (step 4).

Gerngross and Martin investigated P(3HB) granule formation in vitro and developed a model for P(3HB) granule formation (69). First, soluble P(3HB) polymerase interacts with increasing concentrations of 3-hydroxybutyryl-CoA in the cytoplasm, resulting in priming of the enzyme by an unknown mechanism. During an initial lag phase, HB oligomers are slowly formed and extruded from the enzyme. The HB oligomers then form micelles as the oligomers increase in length and hydrophobicity. Consequently, the micelle-like particles provide a two-phase boundary with the polymerase located at the interface. The enzyme then rapidly proceeds with P(3HB) synthesis, extruding more P(3HB) into the growing granule. Eventually the micelles are thought to coalesce into larger granules that can be visualized by microscopy (69) (Fig. 6B).

In vitro studies of the covalent linkage of the 3HB trimer support this model, since a shift in the conformation of the P(3HB) polymerase from monomer to dimer appeared to coincide with the binding of the trimer. Because the P(3HB) polymerase dimer was more active than the monomer and showed a greatly decreased lag time, it was suggested that the lag time in vitro is related to the initial acylation step. It is not yet clear whether this covalent catalysis in the polymerase-catalyzed reaction relates to in vivo priming (296). Physiologically this makes sense, however, since the formation of relatively few high-molecular-weight PHA molecules is expected to be favored over the formation of many low-molecular-weight PHA oligomers. As pointed out above, PHA is considered an osmotically inert macromolecule which depends on having a high molecular weight. Slow PHA polymerase activation in the priming process, combined with a rapid polymerization once activated enzyme forms micelle structures, appears to ensure the formation of high-molecular-weight materials.

The studies by Gerngross and Martin have, furthermore, established that the minimal requirements for P(3HB) synthesis are the (R)-3-hydroxybutyryl-CoA substrate and P(3HB) polymerase (69). P(3HB) polymerase is present both in soluble and granule-bound forms, but the soluble P(3HB) polymerase appears less active. Because of the higher activity when granule bound, optimal P(3HB) accumulation occurs when more enzyme is associated with the growing granule. Maintenance of the available surface is thus critical for efficient P(3HB) production. In subsequent studies, Martin and Gerngross observed that the size of in vitro-synthesized granules is related to the amount of protein added to the assay mixture, irrespective of whether this protein is PHB polymerase or an unrelated protein such as bovine serum albumin (161).

PhaP is a natural PHA-binding protein that determines the size of PHA granules. phaP was identified in genetic studies as a locus causing a P(3HB) leaky phenotype in R. eutropha. The phaP gene was cloned from a cosmid library and found to encode a 24-kDa protein that binds to the P(3HB) granule. Immunochemical analysis with anti-PhaP antibodies revealed that the protein is always granule bound and no free PhaP is present in the cytoplasm of the wild-type strain. Genetic studies have furthermore shown that the concentration of PhaP is inversely related to the size of the granule, since overexpression of PhaP resulted in the formation of many small P(3HB) granules while a phaP mutant contained only a single P(3HB) granule. The P(3HB) leaky phenotype in phaP mutants may therefore be the result of a decreased surface area available for P(3HB) synthesis and causes the observed low polymerase activity (289). This situation indicates an interesting regulatory phenomenon in which maximal activity is obtained by localization of the enzyme to a site which is created and maintained by a structural protein. PhaP is not essential in this regard, but in vivo this protein is likely to be involved in maintenance of the optimal intracellular environment for P(3HB) synthesis and utilization and as such provides guidance during the process of granule formation.

The characteristics of PhaP and related proteins are reminiscent of those of oleosins, proteins that associate exclusively with the oil bodies of oil-producing plants. For that reason, PhaP-like proteins are generally referred to as phasins. It appears that oleosins play a structural role in maintaining the integrity of individual oil bodies by preventing their coalescence (97). Such a role would be especially valuable upon germination of the seeds, when oil degradation is enhanced by a larger surface-to-volume ratio. PhaP and related proteins like GA14 from Rhodococcus ruber, GA14 and GA23 from Methylobacterium rhodesenium, GA13 from Acinetobacter, and the ORF1 gene product from Aeromonas caviae probably have such a function as well and are generally described as phasins (56, 57, 197, 234).

P(3HB)-negative and leaky mutants have been isolated from R. ruber, and subsequent immunochemical analysis showed that these phenotypes were both related to aberrant levels of a granule-associated protein, GA14. The absence of GA14 in P(3HB)-negative mutants is likely to be caused by the absolute requirement of the protein to bind P(3HB) granules, as was observed in R. eutropha, or by a polar effect on its expression by a phaC mutation (Fig. 4) (197). Two carboxy-terminal hydrophobic stretches were shown to be essential for the binding of PhaP to the P(3HB) granules, since PhaP derivatives that lack the two carboxy-terminal hydrophobic domains were unable to do so. This was further supported by the finding that when these carboxy-terminal hydrophobic regions were fused to acetaldehyde dehydrogenase II, the fusion protein localized to the surface of granules in vivo and in vitro rather than to the cytosol (196).

In vitro as well as in vivo studies revealed a role for PHA polymerase in the control of the molecular weight of P(3HB). Variation of the level of PHA polymerase suggested that the concentration of this enzyme is a critical factor in determining the molecular weight of in vitro-synthesized P(3HB). When decreasing amounts of enzyme were supplied to the assay mixture, a polymer was synthesized that had a higher molecular weight (69). New evidence from in vitro studies suggests that P(3HB) formation is a living polymerization in which no chain termination event takes place and that the molecular weight of the resulting polymer is simply dependent on the initial ratio of substrate to enzyme (257). By using an inducer-controlled system to vary PHA polymerase levels in a recombinant E. coli strain, the molecular weight of the formed P(3HB) could also be manipulated as a function of the inducer concentration in the culture medium (242).

Other Pathways for ssc-PHA Formation

P(3HB) is just one type of the many PHAs that are synthesized by thousands of different microorganisms, all originating from their own ecological niche and with their own evolutionary history. Not all these bacteria use the same biological pathways for PHA biosynthesis, since their metabolic blueprints undoubtedly vary. The three-step P(3HB) pathway involves the reactions catalyzed by thiolase, reductase, and polymerase, as exemplified by R. eutropha and Z. ramigera. However, some PHA producers use alternative pathways for PHA formation.

In the absence of a thiolase and reductase, Aeromonas caviae employs an enoyl-CoA hydratase for the formation of the (R)-3-hydroxy monomer from either crotonyl-CoA or hexenoyl-CoA. Other bacteria synthesize P(3HB-3HV) copolyesters from sugars by using a pathway in which 3-HV is derived from the methylmalonyl-CoA pathway. Two additional pathways are found in pseudomonads of rRNA homology group I, which involve either β-oxidation or fatty acid biosynthesis intermediates for msc-PHA production. The biosynthetic pathways for the two types of PHAs have therefore diverged at the level of monomer-CoA-supplying routes, while the polymerases evolved to accept either short- or medium-chain monomers. These pathways are discussed in more detail in this section.

PHA synthesis with an enoyl-CoA hydratase.

A. caviae produces a random copolymer of 3-hydroxybutyrate (3HB) and 3-hydroxyhexanoate (3HH) when growing on even-numbered fatty acids or olive oil as the sole carbon source. When grown on odd-numbered fatty acids, a PHA is produced that consists primarily of 3HV, but small amounts of 3HB are found as well (45). The crystallinity of a poly(3-hydroxybutyrate-3-hydroxyhexanoate) [P(3HB-3HH)] copolymer decreases from 60 to 18% with an increasing 3HH fraction. This property and its decreased melting temperature make P(3HB-3HH) an interesting polymer for several applications where a material that is more flexible than the P(3HB) homopolymer is desired.

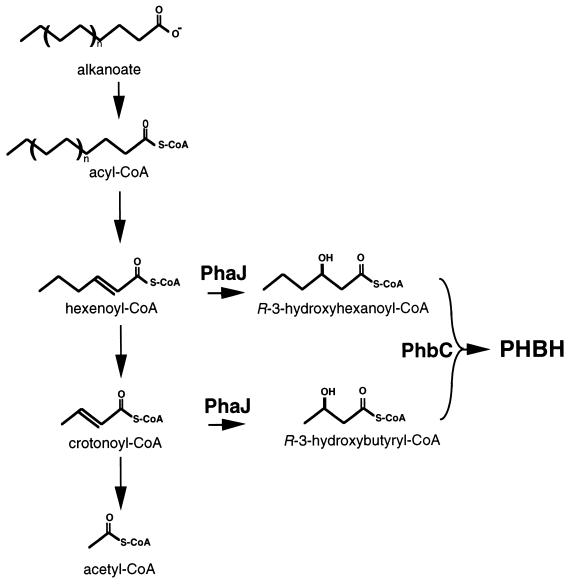

The pha locus from Aeromonas caviae has been cloned and characterized, shedding light on the metabolic pathway that results in P(3HB-3HH) formation (61, 63). It encodes PHA polymerase (encoded by phaC), enoyl-CoA hydratase (encoded by phaJ), and a phasin (encoded by ORF1 or phaP) and is sufficient for PHA formation in PHB-negative heterologous hosts (61, 63, 234). The identification of PhaJ as an (R)-specific enoyl-CoA hydratase suggested that the PHA biosynthetic pathway in A. caviae proceeds from enoyl-CoA derivatives of the fatty acid oxidation pathway (Fig. 7). Besides converting crotonyl-CoA to (R)-3-hydroxybutyryl-CoA, PhaJ converts pentenoyl-CoA and hexenoyl-CoA to PHA precursors, but it does not convert octenoyl-CoA. It was also shown that some PHA-negative mutants of A. caviae are complemented only by phaJ whereas others are complemented only by phaC. phaJ is therefore unique as the first ssc-PHA biosynthetic enzyme besides thiolase, reductase, and polymerase (61, 63).

FIG. 7.

Biosynthetic pathway for P(3HB-3HH). P(3HB-3HH) monomers are derived from fatty acid degradation by converting enoyl-CoA intermediates directly to (R)-3-hydroxyacyl-CoA precursors by an (R)-specific enoyl-CoA hydratase (PhaJ).

The molecular genetic data on P(3HB-3HH) formation in A. caviae provide a new perspective on the work of Moskowitz and Merrick from almost 30 years ago (171). In their work on Rhodospirillum rubrum, these authors proposed a pathway for P(3HB) synthesis that included two hydratases, one specific for the R enantiomer and the other specific for the S enantiomer (171). R. rubrum is able to synthesize PHAs from short- and medium-chain fatty acids up to 20% of the cell dry weight. The major monomers are the C4 and C5 fatty acids, depending on whether the carbon source has an even or odd number of carbons. Small amounts of C6 and C7 monomers were found in PHAs from R. rubrum as well (18). Although this pathway has not been paid much attention for many years, it may now see renewed interest in physiological studies on the formation of PHAs composed of both short- and medium-chain 3-hydroxy fatty acids.

Methylobacterium rhodesenium also uses the activities of two hydratases for P(3HB) synthesis (174). In addition to the two hydratases, this bacterium expresses two constitutive acetoacetyl-CoA reductases, one NADH dependent and one NADPH dependent (173). The combination of these four activities may allow for 3-hydroxybutyryl-CoA synthesis under a range of conditions in the absence of a significant transhydrogenase activity. The analysis of key cofactors in cellular metabolism demonstrated that the flux of acetyl-CoA to the tricarboxylic acid (TCA) cycle or to P(3HB) is determined primarily by the CoA levels (175). Interestingly, the growth substrate has a dramatic effect on the timing of the onset of P(3HB) formation in M. rhodesenium. During exponential growth on fructose, P(3HB) synthesis is used to prevent the formation of excess reducing equivalents. When methanol is the carbon source, reducing power is not excessive until growth is limited by deficiency of other nutrients and P(3HB) is not formed until the stationary phase (3, 172).

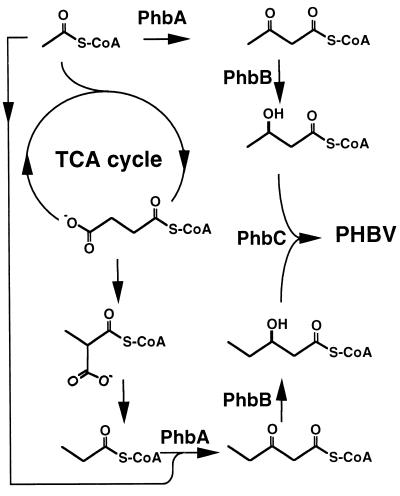

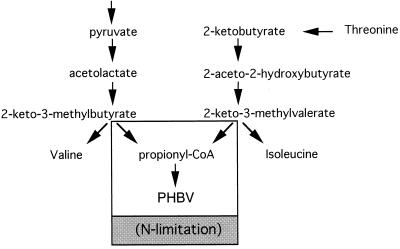

P(3HB-3HV) formation from sugars by the methylmalonyl-CoA pathway.

Rhodococcus ruber and Nocardia corallina accumulate PHAs containing 3HV even in the absence of typical HV precursors such as propionate or valerate in the feed (7, 275). Nuclear magnetic resonance spectroscopy (NMR) studies suggested that the 3HV monomer is derived from acetyl-CoA and propionyl-CoA, where the latter is a product of the methylmalonyl-CoA pathway (290). In this pathway, succinyl-CoA is converted to methylmalonyl-CoA, which is decarboxylated to propionyl-CoA (Fig. 8). A mutant strain of N. corallina was constructed in which the gene encoding the large subunit of methylmalonyl-CoA mutase was disrupted. The 3HV fraction in the PHAs formed by the resulting mutants was reduced from 70 to 4% compared to that in the wild-type strain. However, the mutants still accumulated P(3HB) on glucose and succinate and a P(3HB-3HV) copolyester on valerate (275). It appears that N. corallina derives PHA monomers from both the fatty acid degradation pathway and the traditional P(3HB) biosynthetic pathway, in contrast to A. caviae.

FIG. 8.

Biosynthetic pathway for P(3HB-3HV) from carbohydrates. Some microorganisms accumulate P(3HB-3HV) without supplementation of propionate, valerate, or other Codd fatty acids. Propionyl-CoA in these species is formed through the methylmalonyl-CoA pathway, which originates from succinyl-CoA in the TCA cycle. Propionyl-CoA and acetyl-CoA are converted to P(3HB-3HV) by the typical Phb enzymes.

Pathways for msc-PHA Formation

msc-PHAs from fatty acids.

msc-PHAs were not discovered until 1983, when Witholt and coworkers serendipitously found that P. oleovorans grown on 50% octane formed a material that was pliable under conditions where samples are prepared for freeze fracture electron microscopy. Because these materials left mushroom-like structures in the electron micrographs where P(3HB) formed spike structures, further characterization was warranted (41). By using chemically synthesized standards, the inclusions formed from n-octane were determined to be made of a copolyester consisting of 89% (R)-3-hydroxyoctanoate and 11% (R)-3-hydroxyhexanoate (135).

Subsequent studies showed that the composition of the PHAs formed by pseudomonads of the rRNA homology group I were directly related to the structure of the alkane, alkene, or fatty acid carbon source (17, 105, 135). When the carbon source consists of 6 to 12 carbon atoms, the monomers in the PHA are of the same length as the carbon source or have been shortened by 2, 4, or 6 carbon atoms. When the carbon source is a straight-chain C13 to C18 fatty acid, the composition of the polymer resembles that of the C11- and C12-grown bacteria (105). Use of mixtures of hydrocarbons or fatty acids as the carbon source results in the formation of PHAs in which the composition is a reflection of the ratio of the two carbon sources. For instance, when P. oleovorans is supplied with mixtures of octane and 1-octene, the ratio of monomers with an unsaturated bond ranged from 0 to 50% depending on the fraction of 1-octene in the substrate (135). By analogy, substituted 3-hydroxyalkanoates were introduced to different levels by supplying 7-methyloctanoate, 8-bromooctanoate, phenylundecanoate, or cyanophenoxyhexanoate as the cosubstrate (58–60, 85, 124, 126). Incorporation of the last of these substrates results in PHA with monomer constituents that are hyperpolarizable and may confer nonlinear optical properties to the polymer (124).

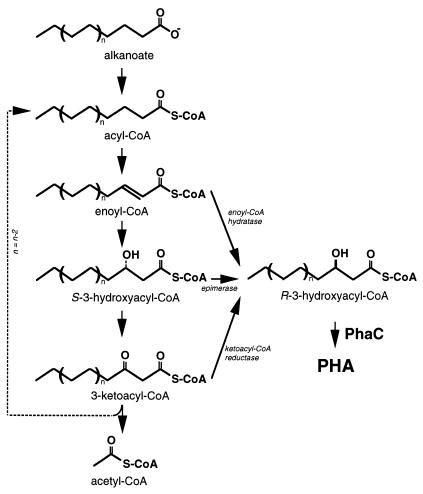

The composition of these PHAs and their direct relationship with the structure of the growth substrate suggested that the msc-PHA biosynthetic pathway is a direct branch of the fatty acid oxidation pathway (Fig. 9) (135). In this pathway, fatty acids are degraded by the removal of C2 units as acetyl-CoA. The remainder of the pathway oxidizes acyl-CoAs to 3-ketoacyl-CoAs via 3-hydroxyacyl-CoA intermediates. The substrate specificity of this msc-PHA polymerase ranges from C6 to C14 (R)-3-hydroxy-alkanoyl-CoAs, with a preference for the C8, C9, and C10 monomers (105). However, because the β-oxidation intermediate is (S)-3-hydroxyacyl-CoA, an additional biosynthetic step is required for synthesis of the (R)-3-hydroxyacyl-CoA monomer. Whether this PHA precursor is the product of a reaction catalyzed by a hydratase (as in A. caviae), by the epimerase activity of the β-oxidation complex, or by a specific 3-ketoacyl-CoA reductase is unknown.

FIG. 9.

Biosynthetic pathway for msc-PHA from hydrocarbons. Fluorescent pseudomonads of rRNA homology group I can derive monomers for PHA from fatty acid degradation. Intermediates from the β-oxidation cycle can be converted to (R)-3-hydroxyacyl-CoA by a hydratase (H), epimerase (E), or reductase (R) activity, whose nature is currently unknown. Any or all of these three enzymes and PHA polymerase determine the limits to the substrate specificity, which is from C6 to C16 3-hydroxy fatty acids.

Given the different biosynthetic pathways, it is not surprising that the pha loci in the msc-PHA-forming pseudomonads are very different from the pha loci in the ssc-PHA-forming bacteria (Fig. 4). Genes involved in msc-PHA formation have been characterized from P. oleovorans (107) and P. aeruginosa (269). In both species, two closely linked PHA polymerases were identified, and PHA polymerase genes are separated by one open reading frame. The two polymerases are approximately 50% identical in their primary structure and appear equally active in PHA synthesis from fatty acids (106, 107) or glucose (102). The open reading frame between phaC1 and phaC2 complements a mutation that prevents the utilization of accumulated PHA. The presence of a lipase box in the primary structure of the product of this gene, phaZ, and the homology of the gene product to other hydrolytic enzymes suggest that this gene encodes a PHA depolymerase (107). Downstream of phaC2 are three genes of unknown function, which may bind to the PHA granules (281).

In vivo experiments with P. putida showed that when either of the two PHA polymerase genes (phaC1 or phaC2) was introduced on a multicopy plasmid, the molecular weights of the PHAs decreased. These reductions were not caused by an increase in PHA depolymerase activity, since the molecular weight of PHA from a depolymerase mutant was not higher than that of PHA from the wild type (106). The latter observation prompted the hypothesis that the molecular weight of PHA is determined by the activity of the PHA polymerase. Based on in vitro analysis of the PHA polymerase from P. oleovorans, it has recently been suggested that the substrate is the limiting factor for PHA formation. Overall, these in vivo and in vitro experiments suggest that the substrate/enzyme ratio, and hence the substrate concentration and enzyme levels, determines the molecular weight of the resulting PHA (129, 130).

msc-PHAs from carbohydrates.

When fluorescent pseudomonads of rRNA homology group I are grown on sugars, a PHA that consists primarily of C10 and C8 monomers is formed (84, 102, 270). Evidence suggests that these monomers are derived from intermediates of fatty acid biosynthesis and that the composition of the PHAs is probably a reflection of the pool of fatty acid biosynthetic intermediates.

It is well known that temperature affects the fatty acid composition of bacterial membranes. Since this effect is due to enzyme activities in fatty acid biosynthesis, the PHA composition was studied in relation to the growth temperature. When P. putida was grown on decanoate, the PHA composition was almost identical irrespective of the growth temperature. In contrast, when glucose was the substrate, the fraction of unsaturated monomers increased from 10 to 20% and the fraction of monomers longer than C10 increased from 18 to 28% when the temperature was lowered from 30 to 15°C. Since the ratio of unsaturated to saturated monomers increases at lower temperature for both membrane lipids and PHA, a metabolic relationship between fatty acid biosynthesis and PHA formation from glucose was suggested (102).

Further corroboration of the involvement of fatty acid biosynthesis in PHA formation for glucose and β-oxidation from fatty acids was obtained by inhibition experiments. Nongrowing cultures of P. putida are able to synthesize PHA from either glucose or fatty acids when carbon sources are in excess. However when cerulenin (a fatty acid synthesis inhibitor) is added to such cell suspensions, no PHA is formed from glucose whereas PHA is still synthesized from fatty acids. Similarly, acrylic acid, a β-oxidation blocker, prevents the formation of PHA from octanoate but not from glucose (100).

These experiments confirmed that PHA formation from glucose is linked to fatty acid biosynthesis (Fig. 10). Since fatty acid biosynthesis proceeds via (R)-3-hydroxyacyl-ACP, a new enzymatic activity was required that converts this intermediate to (R)-3-hydroxyacyl-CoA. Recently, Rehm et al. determined that the gene product of phaG is responsible for this conversion (214).

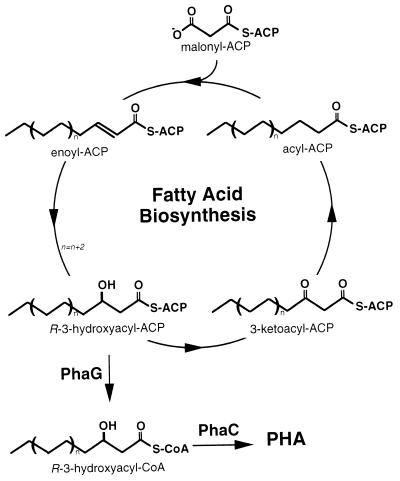

FIG. 10.

Biosynthetic pathway for msc-PHA from carbohydrates. Monomers for PHA are derived from the fatty acid biosynthesis pathway as (R)-3-hydroxyacyl-ACP intermediates and are converted to (R)-3-hydroxyacyl-CoA through an acyl-ACP:CoA transacylase encoded by the phaG gene.

Some Pseudomonas spp. can incorporate both ssc- and msc-PHA monomers in the same polymer chain. Typically, these PHAs are formed when these strains are grown on unrelated carbon source such as carbohydrates or 1,3-butanediol (2, 116, 139, 255). The PHA polymerases synthesizing these ssc- and msc-PHAs must therefore have a very broad substrate range. This type of mixed PHA is probably exceptional since it has been shown that physical constraints prevent the formation of mixed granules containing both P(3HB) and msc-PHA chains. This was concluded from experiments where a recombinant P. putida strain containing both the chromosomal phaC and a copy of the R. eutropha phbC on a plasmid was shown to accumulate individual granules composed of either P(3HB) or PHA (206, 268). The recent isolation of PHA polymerase genes from Pseudomonas sp. strain 61-3, which accumulates P(3HB) and P(3HB)-co-PHA granules from glucose (117), should provide further insights into the simultaneous metabolism of the two types of PHA.

Physiological and Genetic Regulation of PHA Production

The regulation of PHA production is quite complex, since it is exerted at the physiological level, through cofactor inhibition of the enzymes and availability of metabolites, and at the genetic level, through alternative ς-factors, two-component regulatory systems, and autoinducing molecules. Another level of regulation is discussed above and relates to granule size and molecular weight control by levels of PHA polymerase and phasins.

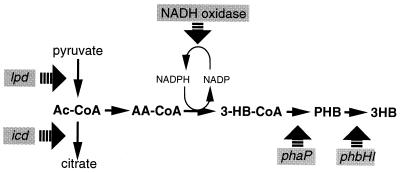

Several leaky mutants of R. eutropha that have a phenotype of reduced P(3HB) synthesis have been isolated. Mutations in phbHI alter the timing of P(3HB) synthesis, suggesting a regulatory role for the corresponding gene products. Whereas the wild-type strain synthesized P(3HB) to approximately 90%, phbHI mutants accumulated P(3HB) to 50% of their dry cell weight, although levels of the P(3HB) biosynthetic enzymes were similar in the wild-type and mutant strains. Upon continued incubation of the mutant strain, the polyester was degraded. This degradation of the polymer was not seen to an appreciable degree in the wild-type strain. The mutant also lacked the ability to transiently secrete 3HB (3 mM maximally), in contrast to the wild-type strain, and secreted pyruvate temporarily up to 8 mM instead (210).

Mapping and nucleotide sequencing of the Tn5 insertions indicated that the phbHI mutants resulted from the inactivation of genes encoding homologs of the E. coli phosphoenolpyruvate phosphotransferase system (PEP-PTS). PhbI has 39% identity to enzyme I of E. coli and Salmonella typhimurium, while phbH encodes a gene product with 35% identity to HPr from E. coli, S. typhimurium, and Staphylococcus aureus (210). The PEP-PTS is involved in the PEP-dependent uptake system of sugars in E. coli and S. typhimurium (201), but HPr has also been implicated in regulating chemotactic signaling in E. coli (74) and in regulating ς54-directed transcription (216). Pries et al. proposed that this “leaky” phenotype of phbHI mutants could actually be caused by aberrant regulation of the P(3HB) degradation pathway and suggested that the activity of the P(3HB)-degrading enzymes was controlled by phosphorylation through metabolic signaling that involves a PEP-PTS (210).

Mutants with mutations in phaL compose a second class of leaky mutants of R. eutropha. This gene encodes the lipoamide dehydrogenase component of the pyruvate dehydrogenase enzyme complex. The phaL mutation resulted in the accumulation of only one-third of the normal amount of P(3HB). Instead of funneling excess carbon into P(3HB) upon nitrogen limitation, this mutant secreted pyruvate up to 33 mM. After the complete consumption of the initial carbon source (fructose), pyruvate was utilized as the carbon source. Apparently the phaL mutation results in a decreased flux of carbon into acetyl-CoA and the TCA cycle. As a consequence, the cells do not efficiently metabolize pyruvate upon nitrogen exhaustion and secrete this intermediate. It is of interest that these mutants grow as well as the wild type, as it was expected that a decreased flux through the TCA cycle would affect the growth rate. Although the phaL mutation is a Tn5 insertion within the gene, the mutant still has residual lipoamide dehydrogenase activity. Indeed, it has been shown that R. eutropha has two enzymes that specify this activity. The regulation of these two genes and the role of the second lipoamide dehydrogenase remain to be determined (209).

Azotobacter vinelandii UWD is a mutant strain that synthesizes P(3HB) during growth (184). This strain is impaired in NADH oxidase and uses the NADH-NADP transhydrogenase and P(3HB) synthesis to regenerate NAD during growth (158). The increased NADPH level that results from this mutation causes inhibition of citrate synthase and the TCA cycle. Consequently, acetyl-CoA accumulates and is converted to P(3HB) through the NADPH-dependent pathway. This branch point in acetyl-CoA metabolism to either the citric acid cycle or P(3HB) biosynthesis is also important in R. eutropha (89). Park et al. created an increased flux of acetyl-CoA to P(3HB) production by introducing a leaky mutation in the isocitrate dehydrogenase of R. eutropha (188). These findings indicate the importance of the redox balance in the cell in the control of PHB formation.

In Acinetobacter spp. P(3HB) synthesis is stimulated by low phosphate concentrations. A promoter that might be responsible for this regulation was identified by primer extension analysis and found to contain a sequence that is homologous to the pho box identified in E. coli. Whereas all three phb genes appear to be preceded by a promoter region, the phosphate-inducible promoter is only found upstream of the first gene, phaB. This could indicate that for efficient P(3HB) synthesis, the reductase enzyme is limiting and only under conditions of phosphate limitation is the P(3HB) biosynthetic pathway optimally induced (233).

Regulation of PHA synthesis in Pseudomonas has been studied to a limited extent. Many pseudomonads are able to synthesize PHAs by two different pathways: through fatty acid biosynthesis when grown on gluconate or through fatty acid degradation when grown on fatty acids. The two PHA polymerases that have been identified in P. putida are functional in either of the two biosynthetic pathways (102). In P. aeruginosa, the pathway from gluconate is strictly controlled by RpoN, the ς54 subunit of RNA polymerase, while the pathway from fatty acids is completely ς54 independent (269). In contrast to other msc-PHA producers, P. putida KT2442 synthesizes PHA during exponential growth when grown on fatty acids (106). Recently, the involvement of a two-component system homologous to the sensor kinase/response regulator couple LemA-GacA was found to regulate PHA synthesis in this strain (15). LemA, GacA, and their homologs can sense environmental conditions and relay these signals to control the expression of a diverse set of genes (30, 71, 95, 137, 228, 294). Given the potential role of PHAs in nature as a store of excess carbon and reducing equivalents, it is not unlikely that PHA formation is part of a regulon that is controlled by growth conditions.

The synthesis of P(3HB) in Vibrio harveyi is regulated by a 3-hydroxybutyryl-homoserine lactone (258), a signaling molecule that accumulates at high cell densities. A variety of microorganisms regulate the expression of genes at high cell density with such acyl-homoserine lactone derivatives (66). The possible involvement of such signals is consistent with the preferred production of PHAs in stationary phase. Since it was recently shown that GacA homologs and acyl-homoserine lactone derivatives may work through a common signaling pathway (137, 215), the regulatory circuits active on the PHA regulon become more complex. Further studies will clarify whether PHA accumulation is generally regulated by these signals and signal transducers and how environmental information is relayed to the PHA biosynthetic genes.

A hitherto unnoticed open reading frame (phaQ) is located on the opposite strand of all but two of the phaC genes (Table 3) (103). It is unknown whether this putative open reading frame is transcribed. Proteins possibly encoded by phaQ have no similarity to any other protein in the GenBank database. We can therefore only speculate on a function of this open reading frame, and a protein or RNA originating from this locus could be involved in regulating PHA metabolism.

TABLE 3.

Location of phaQ with respect to the endogenous PHA polymerase-encoding gene phaC

| Microorganism | Location ofa:

|

% Overlapb | |

|---|---|---|---|

| phaC | phaQ | ||

| A. caviae | 2640–4478 | 2657–4303 | 89.6 |

| Acinetobacter | 2351–4123 | None | |

| C. vinosum | 831–1898 | 907–1953 | 92.9 |

| M. extorquens | 1099–2736 | 591–2741 | 100 |

| N. corralina | 471–2156 | 551–2587 | 95.3 |

| P. aeruginosa 1 | 1266–2945 | 1472–2935 | 87.1 |

| P. aeruginosa 2 | 4259–5941 | 4687–6096 | 74.6 |

| P. denitrificans | 662–2536 | 205–1605 | 50.3 |

| P. oleovorans 1 | 552–2233 | 492–1908 | 80.6 |

| P. oleovorans 2 | 3217–4950 | 3093–5063 | 100 |

| R. eutropha | 842–2611 | 1075–2619 | 86.8 |

| R. etli | 121–2031 | 48–1400 | 67.0 |

| R. meliloti | 316–2049 | <1–1934 | 93.4 |

| R. sphaeroides | 1023–2828 | 918–2773 | 97.1 |

| R. ruber | 786–2462 | 119–2419 | 97.4 |

| Synechocystis | 2242–3378 | None | |

| T. violacea | 3028–4095 | 2028–4016 | 92.6 |

| Z. ramigera | 740–2470 | 733–2373 | 94.4 |

The location of the coding regions with respect to the reported pha sequences is indicated.

The percent overlap indicates the length of the phaC gene that has phaQ sequence on the complementary strand as part of the length of phaC. It is unknown whether phaQ represents coding information for an actual protein or RNA molecule.

Maintenance of Redox Balance in Nitrogen-Fixing Bacteria

PHA formation in Rhizobium spp. is not commonly studied for reasons of PHA production, but it provides an excellent example of the interplay between cellular metabolism and polyester formation. The symbiosis of Rhizobium species with their host plants provides the plant with a system to fix atmospheric nitrogen through the action of the bacterial nitrogenases in the bacteroid. The complex development of Rhizobium bacteria from free-living cells to bacteroids inside the plant vacuoles after infection of the plant root system is an important subject of study for the development of more efficient plant crops. Werner et al. have indicated that the activities of the enzymes acting on the amino acid pool of the bacteroid are directly related to the effectiveness of the nodules in nitrogen fixation (288). Bergersen et al. postulated that P(3HB) plays a role in the physiology of bacteroids in the nodule (11). The metabolic activity of the bacteroid is thus critical for the establishment of successful symbiosis.

Transposon mutants of Rhizobium meliloti with defects in P(3HB) formation were generated and examined for their effects in symbiosis. The phenotypes of four P(3HB)-negative mutants were similar to that of the wild-type strain with respect to induction of nodule formation on alfalfa (Medicago sativa). In addition, the ethylene-reducing activity, a measure of the nitrogenase activity, was also not affected in these phb mutants. Such results prompted the conclusion that efficient symbiosis between R. meliloti and alfalfa is not affected by alterations in the P(3HB) metabolic pathways (203). This finding is actually not surprising, given that R. meliloti bacteroids typically do not deposit P(3HB) (23).

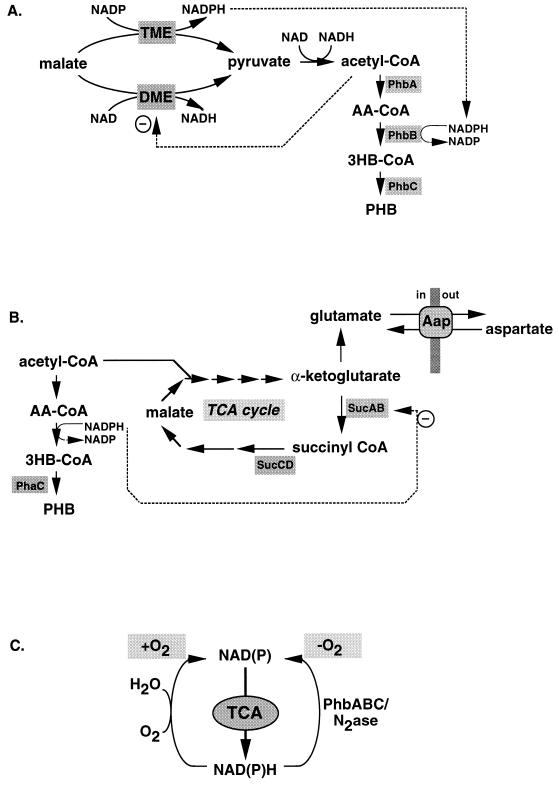

The inability of R. meliloti to form P(3HB) in the bacteroid may be due to low activity of the NADPH-dependent malic enzyme (49). Malate and other four-carbon dicarboxylic acids are provided by the plant and are the preferred carbon sources for the bacteroids (256). In fact, mutants with mutations in either the uptake system for these substrates or the malic enzymes are severely affected in nitrogen fixation. R. meliloti has two malic enzymes, one of which is NADH dependent (encoded by dme) and the other of which is NADPH dependent (encoded by tme). Whereas Dme and Tme are both expressed in the free-living state, Tme expression is repressed specifically in the bacteroid whereas Dme is inhibited by acetyl-CoA. As a consequence, P(3HB) formation is inhibited because too little substrate and too few reducing equivalents are present in the R. meliloti bacteroid to pull acetyl-CoA to 3-hydroxybutyryl-CoA (49) (Fig. 11A). Thus, metabolism in R. meliloti may have evolved so that P(3HB) is not formed in the bacteroid, since P(3HB) formation does not benefit the symbiosis.

FIG. 11.

P(3HB) metabolism and N2 fixation in Rhizobium. (A) In the bacteroid of R. meliloti in symbiosis with alfalfa, the Tme malic enzyme is not expressed while Dme is inhibited by excess acetyl-CoA. Consequently, the levels of NAD(P)H are too low to pull acetyl-CoA into the P(3HB) pathway. In the free-living state, however, both Tme and Dme are active and P(3HB) formation is initiated under the desired conditions. (B) A direct link in central metabolism between the TCA cycle, P(3HB) formation, and amino acid metabolism is apparent from studies of the R. leguminosarum amino acid permease. Mutants that are less sensitive to high levels of aspartate have an increased secretion of glutamate. This increased production of glutamate is caused by inhibition of the TCA cycle either by a mutation in one of the genes encoding a TCA cycle enzyme or by a mutation in the PHA polymerase gene. In the absence of P(3HB) synthesis, the TCA cycle cannot function optimally, since increased reducing equivalents inhibit α-ketoglutarate dehydrogenase. Both types of mutations cause accumulation of α-ketoglutarate, which is directly converted to glutamate. (C) Recycling of reducing equivalents in Rhizobium. The TCA cycle is the most important pathway for supplying precursors of amino acids. To keep the TCA cycle active in the anaerobic bacteroid, P(3HB) biosynthesis and nitrogenase oxidize reducing equivalents. Different Rhizobium spp. have evolved different means to regulate the three NAD(P)H-oxidizing pathways in the free-living or bacteroid state.

In contrast to R. meliloti, R. etli does form P(3HB) in both the free-living and bacteroid state. R. etli CE3 is auxotrophic for biotin and thiamin, cofactors for pyruvate dehydrogenase and α-ketoglutarate dehydrogenase, respectively, and in the absence of these vitamins P(3HB) was accumulated to high levels. As a result of these auxotrophies, the TCA cycle cannot function optimally even in the aerobic free-living state, and the role of the TCA cycle as an overflow mechanism for carbon and reducing equivalents appears to be taken over by P(3HB) formation (53). A P(3HB)-negative mutant of R. etli was constructed by insertion of an antibiotic resistance marker in the phaC gene. This mutant strain was growth impaired when glucose or pyruvate was the carbon source but not when succinate was the carbon source. On succinate the mutant excreted increased levels of organic acids and had a lower ratio of NAD to NADH compared to the parent strain (23). These data underscore the importance of P(3HB) formation for maintaining the redox balance and supporting a functional TCA cycle.

In contrast to the wild-type strain, nodules of the R. etli phaC mutant showed higher and prolonged nitrogenase activity, which fixes atmospheric nitrogen into ammonium ions. As a consequence, plants inoculated with the phaC mutants had a higher nitrogen content (23). It was proposed that the increase in reducing equivalents in the absence of P(3HB) formation is used by nitrogenase, similar to a Rhodobacter sphaeroides P(3HB)-negative mutant which uses the increased reductive power for hydrogen generation (109). The results obtained with the R. etli P(3HB)-negative mutant led to an explanation for the efficiency of alfalfa nodules in nitrogen fixation. These nodules are the result of a symbiosis with phenotypically P(3HB)-negative R. meliloti, which leads to an increased availability of reducing power for the nitrogenase enzyme (90). Apparently, nature has evolved the alfalfa-R. meliloti symbiosis to improve nitrogen fixation by preventing P(3HB) formation. Why the R. etli symbiosis with pea has not selected against P(3HB) formation is a mystery but prompts one to believe that P(3HB) plays another role in this relationship, possibly for survival of R. etli in the free-living state (23).

Hahn et al. studied the nif region of Bradyrhizobium japonicum and found that Tn5 mutants in the nitrogenase-encoding nifD, nifK, and nifH genes resulted in increased P(3HB) accumulation (76). Apparently, the absence of nitrogen fixation in these B. japonicum mutants also results in an energy status of the cell that supports increased P(3HB) synthesis. It seems that P(3HB) synthesis serves as an alternative pathway in these mutants for the regeneration of reducing equivalents.

Studies of amino acid uptake mutants in R. leguminosarum have also indicated a link between amino acid metabolism and P(3HB) formation (Fig. 11B). A general amino acid permease (Aap), which imports amino acids or exports glutamate, has been identified in this organism. However, when glutamate is secreted, no amino acids are taken up. Mutants with reduced activity of this transporter were isolated based on their resistance to aspartate, and the corresponding mutations were mapped in genes encoding the TCA cycle enzymes succinyl-CoA synthetase (sucCD) and 2-oxoglutarate dehydrogenase (sucAB). A second class of mutants had mutations in phaC, encoding P(3HB) polymerase. The increased secretion of glutamate due to mutations in either the TCA cycle or P(3HB) synthesis prevented aspartate uptake to confer the resistance phenotype. Glutamate therefore appears not to be important as a carbon and energy source; instead, the synthesis and secretion of glutamate is important to balance carbon and reducing equivalents, especially in the absence of a functional TCA cycle or PHB pathway. Because bacteroids are typically anaerobic, the TCA cycle requires cofactor regeneration by other means than oxidation with molecular oxygen. Apparently, both glutamate synthesis and P(3HB) synthesis play this role (283).

In the bacteroid stage, the nitrogen fixation apparatus is competing with P(3HB) formation for reducing equivalents. Rhizobium apparently evolved mechanisms to maintain a functional TCA cycle under anaerobic or microaerobic conditions (Fig. 11C). In the bacteroid, the reducing equivalents are used for nitrogen fixation to support symbiosis, but they can be used for P(3HB) formation as well. In the free-living state, nitrogenase is not expressed and P(3HB) plays a role as a sink for excess NAD(P)H when the TCA cycle is not completely active. By regulating the levels of the three different pathways to oxidize NAD(P)H, different Rhizobium spp. have evolved a variety of symbiotic conditions.

Conclusions