Abstract

Sedentary lifestyles and evolving work environments have created challenges for global health and cause huge burdens on healthcare and fitness systems. Physical immobility and functional losses due to aging are two main reasons for noncommunicable disease mortality. Smart electronic textiles (e-textiles) have attracted considerable attention because of their potential uses in health monitoring, rehabilitation, and training assessment applications. Interactive textiles integrated with electronic devices and algorithms can be used to gather, process, and digitize data on human body motion in real time for purposes such as electrotherapy, improving blood circulation, and promoting wound healing. This review summarizes research advances on e-textiles designed for wearable healthcare and fitness systems. The significance of e-textiles, key applications, and future demand expectations are addressed in this review. Various health conditions and fitness problems and possible solutions involving the use of multifunctional interactive garments are discussed. A brief discussion of essential materials and basic procedures used to fabricate wearable e-textiles are included. Finally, the current challenges, possible solutions, opportunities, and future perspectives in the area of smart textiles are discussed.

Keywords: Wearable electronics, Smart textiles, e-textiles, Light therapy, Digital health

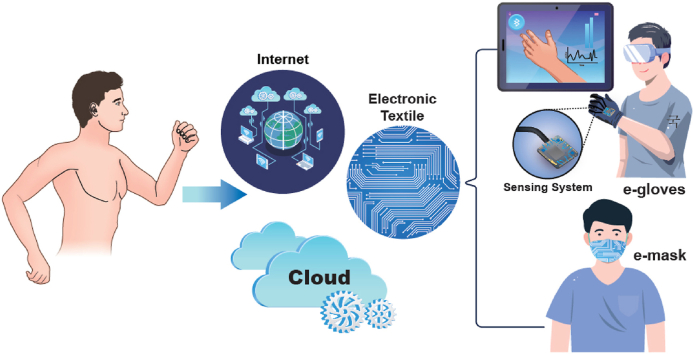

Graphical abstract

1. Introduction

1.1. General overview

A current trend is the development of high-mass-consumption printable electronic devices that are flexible, wearable, and integrated into fabrics in the form of smart apparel. E-textiles are being recognized for their usefulness in monitoring and diagnosis of daily activities and health conditions and for the treatment of many health conditions, with the help of digital electronics and computer algorithms [[1], [2], [3], [4], [5], [6], [7], [8]]. COVID-19 has led to a spike in the development of wearable systems with sensors for early detection of signs of SARS COV-2 [[9], [10], [11]]. For example, stretchable strain sensors printed on clothes can monitor the expansion of the chest and hence deviations in breathing patterns. Clothes with embedded actuators can be used as exoskeletons and rehabilitation devices for ailments such as stiff necks and joints. The engineering of flexible, stretchable devices and circuits is the key component of electronically functional wearable textiles capable of sensing, heating, illuminating, and transmitting data [12,13]. The integration of electronics and communication into shirts and trousers, blankets and bed sheets, bandages and head caps, etc., facilitates functions for making human lives easier [14].

The integration of electronics into conventional fabrics is called e-textiles, which also named as smart or intelligent garments [1,[15], [16], [17]]. Smart e-textiles can sense, react, and interact with a range of ambient stimuli conditions and respond to perform a task in a manual pre-programmed processing manner [18]. E-textiles require electrical components to function with external stimuli such as chemical, mechanical, thermal, electromagnetic field, radiant, moisture, pH etc [18,19]. The different characteristics of intelligent garments differs according to the integrated electronic components or technology platform. The integration of electronic components creates a new functionality in traditional clothes that enhances their functions and provide added value for advanced state-of-the-art applications. The working mechanism or electronic feedback process of e-textiles is based on eliciting or stimulation is received by the senses or any physical response/action from any object or environment in form of touch, heat, sound and light. Then smart e-textiles detect the stimulation and process the information in form quantitative data as a resulting function to deliver response or action [20,21]. Consequently, e-textiles can sense changes that take place due to human body movements, gather data from the wearer, and transmit the data to a computer or smartphone, which can give appropriate feedback. Because e-textiles integrate electronics into textiles, it is anticipated that e-textile technology will continue to advance to include the major product types and a wide range of application areas and markets.

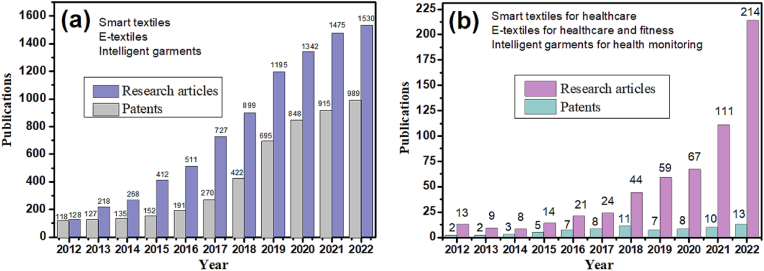

The immense growth of the e-textiles’ market and the number of scientific papers published in the last 10 years in this field have increased. Fig. 1 shows the number of papers published over the past 10 years in e-textiles or smart textiles. The data was taken from the Lens Scholarly Search (www.lens.org) using keywords, smart textiles or smart fabrics, e-textiles and intelligent garments. According to the Lens search data, the number of patents and research articles on smart e-textiles have increased exponentially since 2017 (Fig. 1(a)). Thus, over the past few years, smart e-textiles have gained huge attention from research investigators, as shown by the expanding of the application areas and the rise in the number of publications. Fig. 1(b) shows the total number of publications and patents on smart textiles, e-textiles and intelligent garments specifically designed for healthcare, fitness and health monitoring applications over the last 10 years. The data indicate only a limited research papers and patents on e-textiles have been published however number of publications on the applications to health and fitness are increasing with time. The e-textiles in medical and sports sectors will gain more considerable attention in coming years.

Fig. 1.

(a) Total research papers and patents yearly publications in past 10 years in area of e-textiles and smart textiles or intelligent garments. (b) Total research articles and patents published in the area of e-textiles, smart textiles and intelligent garments for healthcare and fitness applications. Data Source: Lens Scholarly Search, LENS.ORG.

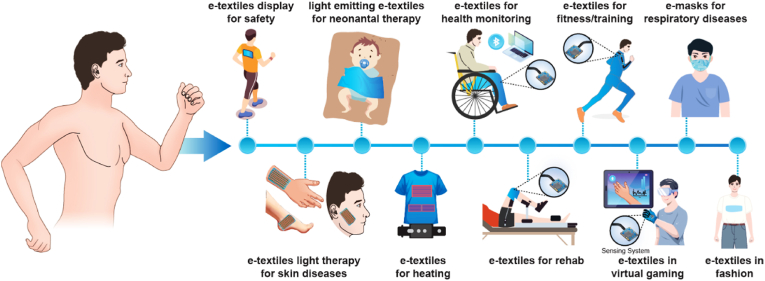

In the last decade, e-textiles have attracted significant attention because of successful applications in several fields, including medicine [1,5,22], sports [23,24], rehabilitation and personalized healthcare [18,25,26], safety [[27], [28], [29]], and virtual reality [30,31]. Fig. 2 shows a pathway of e-textiles’ applications in various fields for the prevention of respiratory illnesses, joint injury, skin diseases, neonatal jaundice, road safety, training, and fashion. Worldwide, the elderly population and the number of people with disabilities are increasing every day. Thus, wearable e-textile prototypes are becoming increasingly important for health monitoring and treatment [25,32]. For example, e-textiles integrated with interactive sensors can send a user's real-time monitoring data to a hospital, thereby minimizing the dependence on bulky and expensive monitoring tools and reducing hospital visit frequency. Fitness training is another large potential market for the use of e-textiles. In nearly every sport, athletes can benefit from e-textiles as an advanced, affordable, and compelling new wearable technology to assess and improve performance. Advances in wearable smart garments are not limited to healthcare and fitness but are also driving the technology into soft robotics, virtual reality, and the internet-of-smart-textiles with the rise of the Internet of Things (IoT) [33]. Within the next decade, in the age of IoT, it is likely that e-textile technology will transform human lives, along with artificial intelligence, human–machine interfaces, and cloud technology [5,34]. It is anticipated that the e-textile prototypes will grow rapidly into commercial products and increase their market size, especially in the healthcare and sports sectors [35,36]. According to a report published by IDTechEx, the market for e-textiles has been growing rapidly and is forecasted to grow to $5 billion by 2027 [37]. The market for wearable e-textiles is expected to be growing at a rate of more than $1.3 billion per year by 2031 [38].

Fig. 2.

Schematic illustration of a pathway of e-textile applications in different areas.

Wearable e-textiles are currently facing numerous challenges because they are still in an early phase of development [39,40]. As most electronic devices are delicate and fragile, they have limited washability and hence a short life. Reliability and washability are major hurdles currently facing the e-textile industry. In addition, primarily off-the-shelf sensors and electronics are currently used with wearables [41]. Another issue is poor adhesion of devices, which fall off easily under active conditions and are obstructive [42]. Despite great progress, there remain some limitations in applications to health monitoring-particularly because the benefits of e-textiles may come at the cost of user comfort. Seamless integration of functionalities with garments that can withstand high levels of deformation/deflection is needed. Deformation/deflection properties typically depend on adhesion, which has considerable operational limitations (<10% strain) due to poor embedding of sensors or gluing of components directly onto textiles [43,44]. Complicated wiring, external electric circuits, and reliance on external power sources are other limiting factors that need reliable solutions [45]. For now, research in the area of smart textiles is advancing as it has the potential to achieve goals such as conformability, low cost, low weight, and comfort in self-management [46,47]. The miniaturization of functional materials has led to advances in fabrication techniques, such as the direct printing of devices and electronics onto clothes [48,49]. This can bring the seamless integration of devices and electronics into clothing a step closer.

Several review articles have been published in area of smart or e-textiles developed for different applications [1,5,18,25,50,51]. Wang et al. discussed a textile-based strain sensors for human motion detection [52]. Most recently, Tat et al. published a perspective which describes the smart textiles as functional wearable systems for healthcare and sustainability [53]. Additional critical reviews have been reported on self-powered energy harvesting and sensing e-textiles from Professor Wang's research group [47,[54], [55], [56]]. In area of smart wearable bioelectronics, Wu et al. published two reviews on advanced electrospun nanofibers/yarns-based textiles for biomedical and spinal cord injury regeneration applications [57,58]. Most of the review article discussed the smart e-textiles applications for diagnosis, monitoring and textile devices for disease prevention and phototherapy. In last few years, a lot of research papers has been published on smart e-textiles or intelligent apparels combined with more advanced technologies interface as the gateway for real-time monitoring, collect and processing the information for self-health and fitness management. Thus, an additional comprehensive review on e-textiles for personalized healthcare and fitness assessments could be very helpful for people actively working in this filed.

1.2. The vision of this review

The primary focus of this review article is on smart e-textiles as a wearable technology specifically designed for health monitoring, diagnosis, and fitness assessment. This review article is very specific which provides a broad analysis to the researchers in area of e-textiles as a solution to medical and sports sectors. It is expected that in future, smart apparels will promote the digital health and IoT with huge market potential. This review paper is divided into several sections that cover recently published important research in the field of wearable e-textiles consisting of discrete devices and electronics. We briefly discuss historical developments, potential applications, and future market growth for smart apparel. In the next section, we highlight the necessary materials and fabrication methods for sensors and devices integrated into textiles for use in the medical and fitness sectors. This is followed by descriptions of different health concerns and fitness problems and their possible solutions using interactive smart textiles. We then summarize the current challenges associated with the materials and techniques used in the fabrication of e-textiles. Finally, we present conclusions regarding the prospects for smart e-textiles, emerging solutions, and products, along with future research directions.

2. Historical developments and current progress in e-textiles

Although innovations in textiles began with the advent of human civilization, which spans thousands of years, a revolution started in the 16th century with key inventions [59,60]. The focus was initially on enhancing the artistic and stylistic aspects of textiles but later shifted to improving the functionality of garments for various applications. The first example of an electronic textile dates back to 1883 with the debut of illuminated headbands in the ballet La Farandole Inn at the Conservatoire in Paris [61]. The performers wore electric headbands with lights on their heads, and the lights were illuminated when they touched buttons on their belts. At the end of the 20th century, developments in material chemistry and electronics widened the potential for integrating electronics into textiles. Another important development took place in the mid-1990s when a team of researchers at the Massachusetts Institute of Technology (MIT) led by Steve Mann began to develop a wearable computer, which consisted of traditional computer hardware attached to textiles and carried on the human body [62]. Textile technology has also been highly impacted by the development of nanometer-scale systems. In the last two decades, advances in nanotechnology and fabrication methods have had huge impacts and brought about tremendous changes in large-area flexible and stretchable electronics. Nanotechnology has contributed significantly to major advances in smart textiles with the incorporation of additive features to increase their commercial value [63]. At present, classical electronic components such as conducting yarns and wires, integrated circuits, sensors, light-emitting diodes (LEDs), and power sources embedded into garments are in high demand for wellness and fitness. In the past two decades, a considerable amount of research has resulted in vast numbers of patents and publications on the integration of electronic components and devices with textiles.

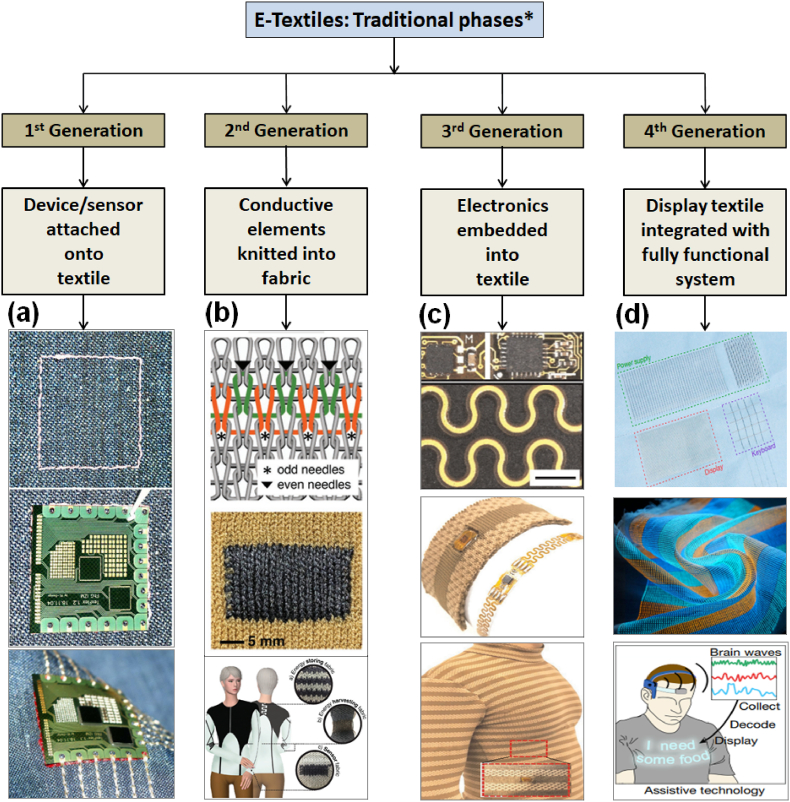

Since the beginning of the e-textile era, various ways to integrate electronics into textiles have been demonstrated. Wu et al. categorized developments in e-textiles into various phases referred to as the first to third generations of this technology [39].

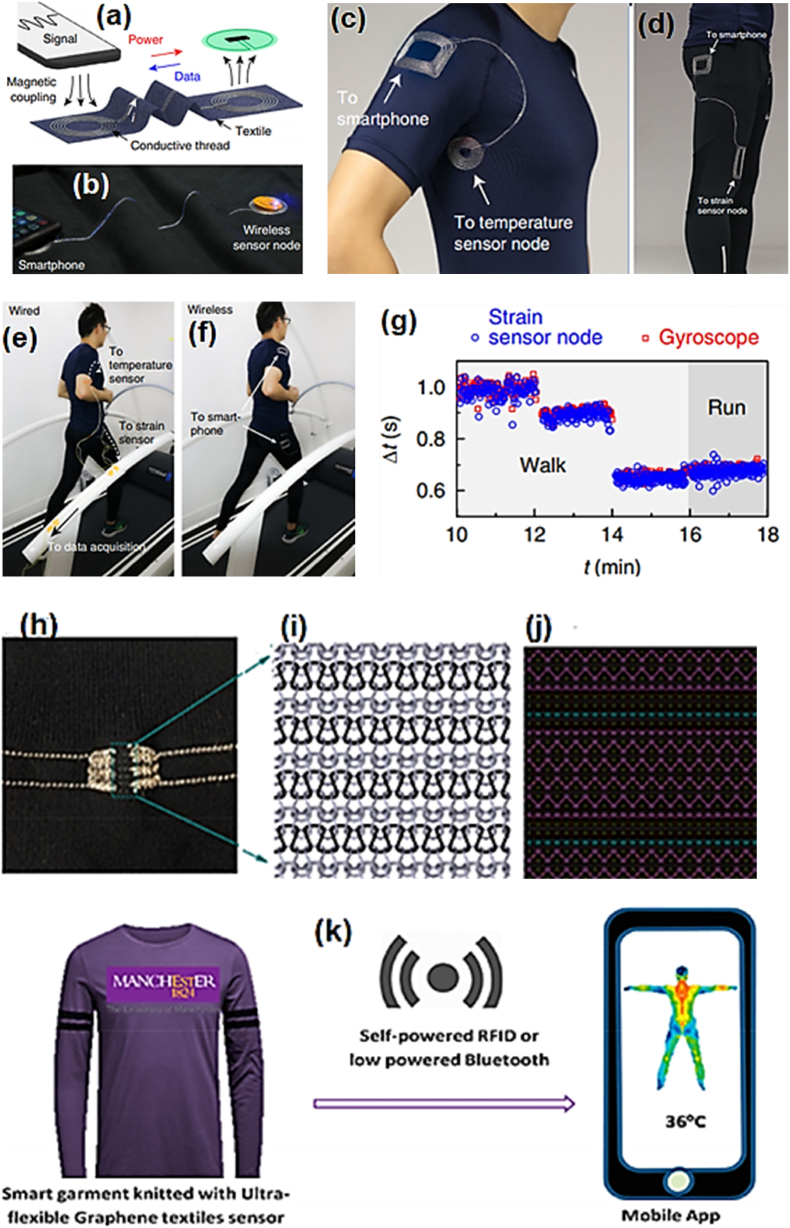

First-generation e-textiles involve a hard component, such as an antenna or an electronic device, stitched or attached to the surface of a garment as shown in Fig. 3 (a). In first-generation types of e-textiles, a soft electronic module is embroidered on a piece of textile using conductive yarn [64]. In this way, an electrical and mechanical connection is made using the basic yarn embroidery process. This approach has been adopted and continues to be developed by some well-known sportswear brands [65]. However, as might be expected, first-generation e-textile products tend to be bulkier and more rigid than is practical for everyday use.

Fig. 3.

Summarize the development of the e-textiles from phase-one to the current fourth-generation phase. (a) Embroider mark (top); placing of the flexible circuitry device along with the marker, and then embroidered through the contact pads sequentially. Images are reproduced with permission [64], Copyright 2005, IEEE Publishing Group. (b) Interlocked knitted fabric using different stitch patterns (top) resulted in dense fabric (middle) and the concept illustration of a garment integrated with sensing device; insets show actual device prototypes. Images are reproduced with permission [66], Copyright 2019, Wiley-VCH Publishing Group. (c) Illustration of embedding flexible-stretchable electronic strips (top) microscopic image and woven electronic strip in a knit textile (middle) and showing its conformability to the wearer. Images are reproduced with permission [41], Copyright 2020, Springer Nature. (d) Real image of a fully integrated textile system comprising of display, keyboard and power supply (top), photograph of multicolor display textile (middle) and concept design displaying brain waves can be decoded into messages that is displaying on a shirt made from a fully functional display textile. Images are reproduced with permission [71] Copyright 2021, Springer Nature. ∗ Information deduced from published research papers/publicly available information.

In second-generation wearables, conductive yarns are knitted or woven into the textile structure to make it electronically functional. Conductive yarns are intertwined into various stitch patterns using industrial-scale knitting machines to fabricate fully functional wearable electronic textiles as depicted in Fig. 3(b) [66]. The process is very simple. This approach is most frequently used to develop electronically functional apparel without any noticeable flaws or discomfort for the wearer. Examples of second-generation smart textiles include wearable cloth sensors fabricated by knitting or weaving conductive yarns [39] and LEDs interwoven with electrically conductive yarns into the textile pattern [67]. Second-generation e-textiles are usually soft but are limited in terms of comfort and adaptability. Athos, a sportswear brand and important player in the market, has patented the world's first intelligent clothing to measure the strength of a wearer's muscles based on the principle of electromyography (EMG). Firm, CuteCircuit, has been producing electronic clothes of second and even next-generation electronic garments that can play music, display messages and tweets [68]. Some retail brands, such as Amazon and Flipkart, are selling second-generation sensing and display clothes.

Third-generation intelligent textiles have sensors and electronics embedded into garments integrating the technology and the fabrics together (Fig. 3(c)) [41]. Third-generation e-textiles are more suitable than the e-textiles of the first two generations for producing durable, comfortable, and reliable electronic systems with better functionality. Firms such as Samsung, Alphabet, Ralph Lauren, AdvanPro, Tamicare, and BeBop Sensors have developed third-generation products and are growing rapidly in this direction [69].

This review also describes a future generation or fourth generation intelligent e-textiles that may represent the future of e-textile products, although they are currently in fabrication at lab scale and exist only as concept designs and/or prototypes. The fourth generation is the state-of-art technology that will be able to fully integrate electronic functionality into textiles seamlessly. Fourth-generation products should conform to the essential e-textile requirements of softness, comfort, flexibility, washability, and durability. For example, a light-emitting device could be manufactured as a textile fiber that illuminates without an external power source [70,71]. Fig. 3(d) shows next generation fully integrated intelligent textile system comprising of display, keyboard and power supply as well photograph of display textile and concept design demonstrating brain waves can be decoded into messages that is exhibiting on a shirt [71]. The seamless light-emitting or interactive textile could transform the concept of wearable e-textile display directly onto human skin, leading to the modernization of fashion, visual retailing, and individual safety. Most of these wearable textiles will connect to a user's smartphone via a wireless communication system such as Bluetooth or Wi-Fi and transmit data to boost big data cloud computing [1,33,72]. Fundamentally, e-textile technology is in a transformation period in which the focus is shifting from embedding or embroidering approaches to more user-friendly e-textiles with the technology manufactured into the garment itself. Developing the fourth generation of e-textiles will place substantial demands on the innovation capability of the clothing industry-demands that also offer huge potential for growth in new business sectors. Wearable textile technology is moving forward, and in the next decade, it will increasingly be connected to the IoT, along with artificial intelligence, human–machine interfaces, and cloud technology.

3. Prospective application areas of smart e-textiles

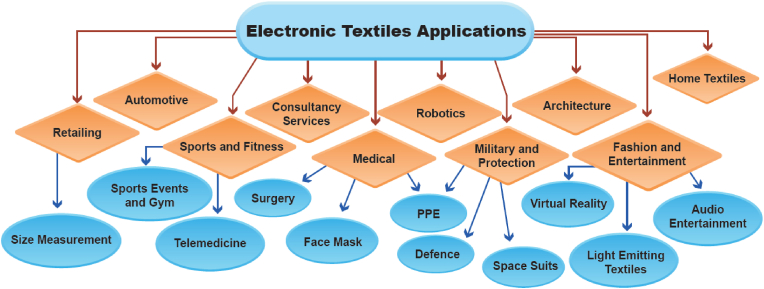

E-textiles with intelligent designs and enhanced capabilities offer potential solutions to several medical and fitness problems. Today, e-textiles have numerous applications in the clothing industry. E-textiles are indeed an asset because technologically advanced textiles are more adaptable and have the potential to be used not only in the medical and safety industries but in many other sectors. Fig. 4 illustrates various state-of-the-art application areas of e-textiles. There is currently a great emphasis on applications that are affordable and wearable. Current prototypes of e-textiles are being developed for sports and medical applications such as sports training and patient monitoring. In the future, the automotive, retailing, military, fashion, and entertainment industries will also be niche application areas [73,74]. The shift is toward the design and development of technically advanced high-performance garments that are not just attractive and interactive but also offer substantial added value in terms of functionality [75]. The incorporation of flexible and stretchable sensors offers excellent capabilities for monitoring human actions and physical activities. These e-textiles could be effectively employed to detect human motions, and the data collected could be analyzed to track movement accurately. Such e-textiles may be used for real-time body measurements in retailing and for self-protection. E-textiles can be used in numerous sectors, depending on their basic functionality. Some specific developments of e-textiles in the areas of health and fitness are described below, based on recently published reports and research articles.

Fig. 4.

Application areas of e-textiles.

3.1. Medical: E-textiles use for telehealth remote patient monitoring

Conventional textile products, such as diapers, braces, breathable prostheses/orthoses, spiral dressings, rubs, breathing masks, bedding, and covers, are used for numerous human hygiene and medical applications [76]. Recently, some e-textiles have been used in the manufacture of other health products, such as surgical masks [77], personal protective equipment (PPE) [78], light therapy systems [79], wound dressings [1,80], flexible sensors [81], and actuators [82]. A recent study by Yang et al. [45] looked at the use of e-textiles to support healthy aging, including monitoring health conditions, treating chronic diseases, rehabilitation, and improving health and social lifestyles. A breakthrough has been the ability to monitor a patient in a health care center or at home using e-textile technology [83]. However, a gap still exists in the care provider's ability to assess the current and historical physiological state of the patient. The use of sensors has enabled wearables to carry out virtual health assessments and collect real-time feedback on health and fitness [[84], [85], [86]].

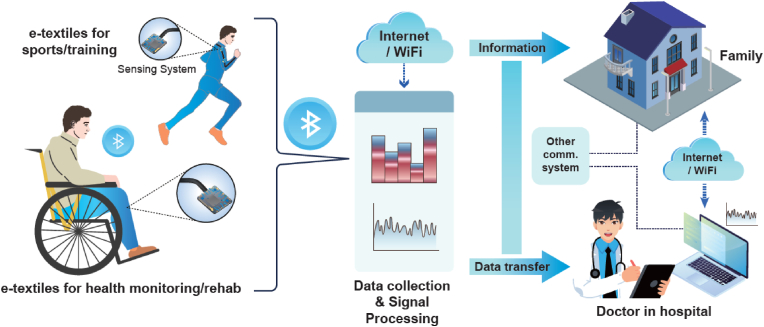

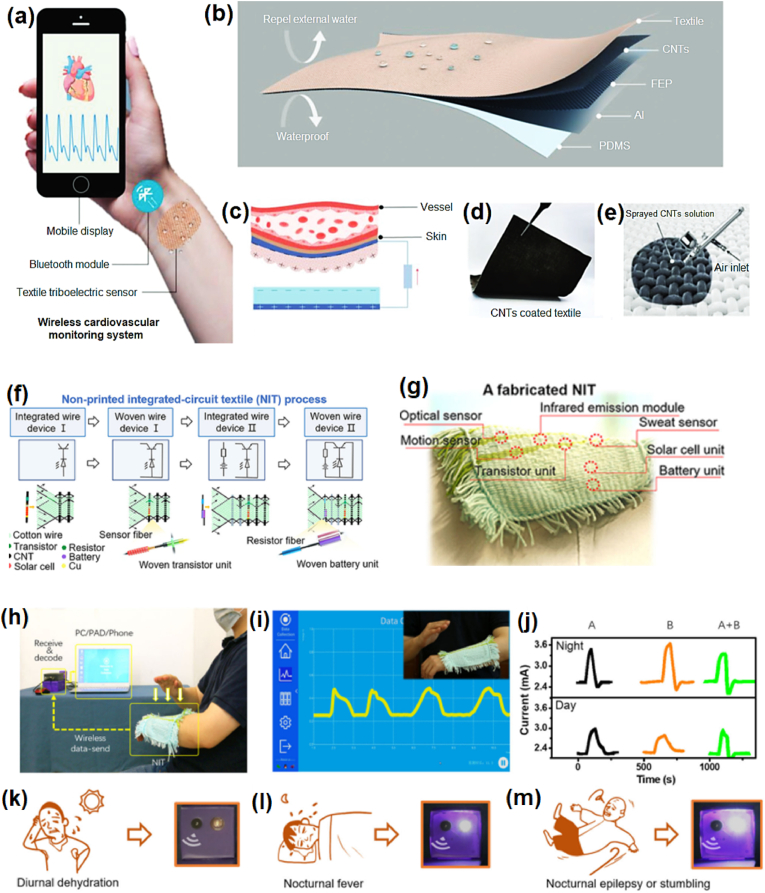

In the future, advanced e-textile-based sensing systems can be developed that can monitor chronic diseases and collect biometrics and other vital signs/disease signals wirelessly via Bluetooth and send them to a doctor/physician through the internet. Fig. 5 illustrates such a health and fitness monitoring system based on wearable sensors for rehabilitation or health monitoring to recovery via data analyses. E-textile technology could be used to detect patients’ movements and body positions. E-textile could be used to send emergency alerts: for example, it could distinguish whether a patient was sitting, lying down, or walking or whether there was a rapid change in position, such as would result from a fall [87]. E-textiles could also help achieve improvements in telemedicine, such as decreases in appointment times, faster diagnosis processes, and time savings for patients in getting concerns addressed. These improvements may provide patients and doctors more time to strategize effective treatment plans.

Fig. 5.

Illustration of a remote fitness and health monitoring system based on wearable sensors. The e-textile could access information from real-time body movements from personalized rehabilitation and other physical training/exercise and transmit that data to a smartphone via wireless communication signals (e.g., Bluetooth) and to a home system and clinic/hospital for analysis.

Wearable e-textiles could also provide smaller, more reliable, more lightweight, easier-to-use, and more cost-effective self-health management systems. Light-emitting device-based textiles are potentially useful for wearable therapy systems and as displays for self-protection. Finally, we hope that e-textiles will eventually become integral to home-based wearable health care systems that are integrated seamlessly into the wearer's everyday routine and offer more advanced functionality than the currently available stiff and wired harness devices.

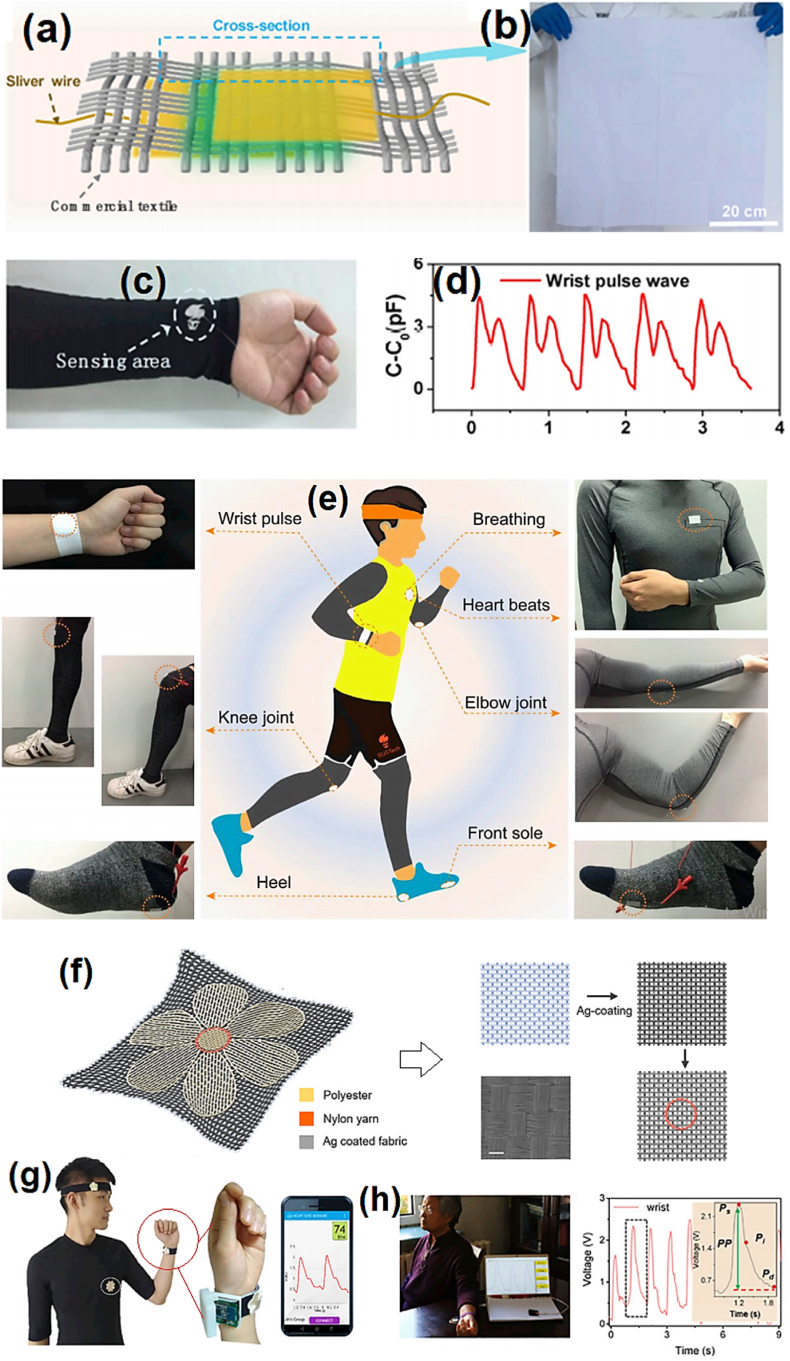

3.2. Sport: E-textiles use for training data accumulation and rehabilitation

Edmison et al. stated in 2004 that advanced sensing structured e-textiles could be used for motion analyses [88]. Applications of e-textiles for sports and daily routine activities are extremely important to tracking performance. The growing attention and participation worldwide of people in active sports and outdoor leisure activities, such as walking, dancing, running, hiking, and swimming, has resulted in great demand for textile products in sports, games, and physical training. Fig. 5 (person running image) shows examples of e-textiles with printed sensors that can detect body movements during exercise or training and then transmit the collected data to a cell phone via Bluetooth or another wireless communication device. E-textiles for sports have the potential to substantially change the way athletes/trainers train and participate at all levels. In particular, applications of e-textiles include strain and bending sensors mounted on textiles and worn on body joints such as knees, arms, and necks. E-textiles can collect information about different knee positions and decipher physical actions, such as walking, running, jumping, and crouching [89]. Consequently, e-textiles can sense the body's position and muscle movements and offer feedback. Thus, we can access and then evaluate the performance of a person for further improvement. Commercial production of such systems has already begun, as two Canadian startups, OMsignal, smart clothing lab [90] and Myant [91] have introduced electronic sports garments that can monitor a wearer's heart rate, breathing, and movement and then send the collected data to a smartphone using Bluetooth Low Energy (BLE) for real-time analysis [92].

3.3. Elderly: E-textiles aim for physical activity tracking usage

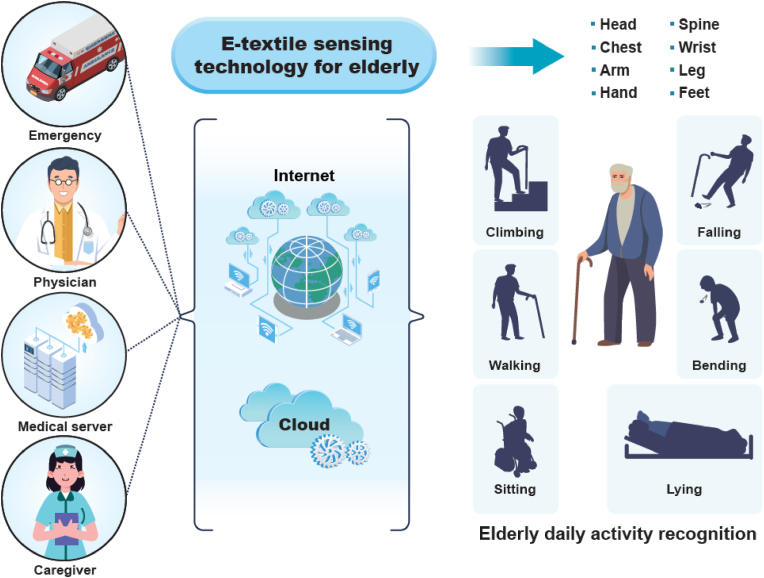

According to world population prospects (United Nations, 2019), health concerns are increasing in an aging society, and the elderly account will account for more than 16% of the world's population by 2050 [93]. Worldwide, the population of people aged 65 and above is growing faster than all other age groups. Thus, the health of elderly people is a major concern now and will continue to be so in the near future. In addition, the prevalence of modern unhealthy lifestyles and diets is expected to lead to ailments such as diabetes and high blood pressure (BP) in nearly half of the population [94]. In the telecare realm, obtaining information about the movement of the body is vital to ensuring the wellness of the elderly. As mentioned above, telehealth and telemedicine concepts, i.e., health and fitness-associated information being obtained from a distance by a health care provider (e.g., a fitness trainer, a doctor in a clinic/hospital, a physiotherapist, etc.) while users remain at home, can play a major role [95]. E-textiles could easily track all the movements of an elderly person using a sensing system for real-time monitoring. Thus, e-textiles can be used by emergency medical services (EMS) to give essential and urgent pre-hospital treatment and stabilizing medication for severe injuries and other illnesses, such as heart failure, asthma attacks, unconsciousness, etc., while transporting patients to hospitals. Fig. 6 shows an example of a future wearable e-textile sensing technology that can be highly beneficial for the care of the elderly to track movements and other parameters. The technology can be used for the detection of accurate positioning, tracking of physical activity, and monitoring of vital body signs. There is a vital need to develop a smart wearable for the elderly that can accurately sense body positions and remain connected in real time with modules for data processing and extraction. The data or information from the sensing system should be delivered to a controller lump/access and then to a cloud center, where it could be processed by data analysis algorithms.

Fig. 6.

Future application of an e-textile sensing system for the care of the elderly to monitor real-time movements (sitting, lying, climbing, walking, bending, and falling) and process data to track daily activity.

The impact of e-textiles is more evident in pandemics, such as the current coronavirus (COVID-19) pandemic, during which people face involuntary mass quarantines and must prevent human-to-human interaction to reduce virus transmission. These constraints can contribute to physically inactive lifestyles, which are associated with health problems such as obesity, lower back pain, poor blood circulation, osteoarthritis, and cardiovascular diseases [96]. As a consequence, a lack of physical inactivity may jeopardize the health of the elderly and people suffering from diabetes and chronic organ diseases. Wearable real-time sensing textiles can be used at home and in hospitals, care centers, and other training or fitness facilities to remotely monitor the elderly and other vulnerable people (e.g., COVID-19 patients) to ensure their safety throughout the day without the need for a risky visit to a hospital/clinic or care center. Recently, firm Sleeptite has launched a portable smart bed to monitor elderly's daily activities to improve the health and wellbeing through technologically advanced solutions [97]. In coming years, a portable e-textile sensing systems could become essential components of solutions for monitoring the health and safety of an aging population, an area likely to see growing market demand in the coming years. We believe that the significant advances made in miniaturization and development of smart materials will help to create a fifth generation of e-textiles that are integrated with cloud and wireless services and are suitable for the speedy adoption of cognitive technologies.

4. E-textiles market growth

The e-textile technology trend is gaining momentum, and the market will be a witness to an increasingly large number of new e-textile products soon. With the increasing demand in the already competitive market, there has also been a steady rise in new design, technology, and innovation. As a result, many technology companies and individual textile manufacturers around the world have started selling and working on an expanding array of new high-tech advanced electronic garments. We have summarized a few of commercially available wearable smart textiles/or e-textiles solutions for healthcare and fitness in Table 1.

Table 1.

Commercialized smart textiles/or e-textiles for healthcare and fitness applications.

| Company | Commercial smart/e-textile product |

Healthcare/fitness solution | Main Mechanism/technology |

Reference (Website) |

|---|---|---|---|---|

| Nextiles | Nextiles fabric | Mobility, physical therapy | Piezoresistive sensors | [98] |

| Sleeptite | Remi | Mobility, sleep monitoring | Flexible sensors | [97] |

| MesoMat | Sensing fibers | Physical mobility, real-time monitoring | Strain sensors | [99] |

| Toray Inc. | Hitoe | Respiratory monitoring, physical therapy | Strain sensors, conductive fabric | [100] |

| e-skin Meva | Xenoma | Mobility, Physical therapy, | Flexible sensors | [101] |

| Palarum | Smart socks | Mobility, physical therapy | Pressure sensors | [102] |

| Texisense | Texisock | Mobility, physical therapy | Pressure sensors | [103] |

| Carre Technologies Inc. | Hexoskin | Cardiovascular, Physical therapy, Mobility, breath monitoring | Strain and pressure sensors | [104] |

| Nanowear Inc. | SimpleSense | Cardiovascular, Physical therapy | Flexible sensors | [105] |

| DuPont | Intexar | Respiratory monitoring, Physical therapy | Electrodes | [106] |

| Clim8 | Heating gloves | Thermo-physiology | Joule Heaters | [107] |

| Loomia | LEL | Pressure monitoring, Seat heating | Electrodes, Heaters, Pressure sensors | [108] |

| Myant Inc. | Skiin | Mobility, thermotherapy, physical therapy | Strain sensors, Joule heaters | [91] |

| Souyarn | Heated garments, Sensing textiles | Mobility, sweat, respiration, and heart rate monitoring | Pressure sensors, Heaters | [109] |

| Smart Fabric Inks | Fabric heaters, | Thermotherapy | Heaters, Electrodes | [110] |

Moreover, wearable technologies are growing exponentially, and every day, new textile products are reaching the market, with functionalities such as heat regulation, luminousness, and touch sensitivity. James Hayward, a principal analyst at IDTechEx, has observed that many of the companies in the emerging smart textile trade create most of their revenue on a project-by-project basis, with consulting and R&D often being more profitable than focusing on specific products [83]. The total worth of the wearable electronics market is currently US$70 billion, but only approximately US$0.5 billion is derived from electronic fabric-based products [111]. The market revenue could increase further with the increasing miniaturization of electric components and circuits integrated/printed into textiles to create more robust e-textile products. Seamless integration of functionalities might help to avoid the possible bionic stigma and clinch market insight of wearable e-textiles. Further information is provided below on the remarkable records on profits being realized by e-textiles corporations, as well as examples of types of products available in each sector.

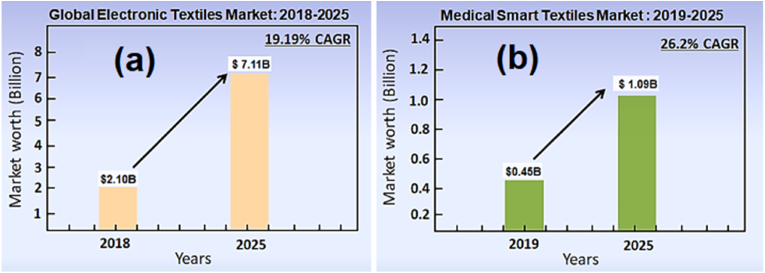

Hundreds of firms are actively working in the early-stage development and commercialization of smart e-textiles. According to a forecast from the IDTechEx report, in the next 10 years, the market for wearable e-textiles is expected to grow in value to US$2.0 billion (US$2000 million) per year by 2028 [112]. Information published in the Global Electronic Textiles Market Report suggests an even higher growth rate. According to this report, the global Electronic Textiles market size was US$2.1 billion in 2018, and it is expected to reach approximately US$7.1 billion by the end of 2025, with a compound annual growth rate (CAGR) of 19.19% between 2019 and 2025, as shown Fig. 7(a) [113]. This report shows the e-textiles market size in terms of value and dimensions by firms, regions, product types, and end-users, historical statistics for 2014–2018, and projections for 2019–2025. The scope of this report encompasses North America, South America, Europe, the Middle East, Africa, and the Asia-Pacific region. An analysis based on a market study report suggests that over the next few years, the medical smart textile market will exhibit a CAGR of approximately 26.2% in terms of returns. The global market size is projected to increase from $0.45 billion in 2019 to $1.09 billion by 2025, as shown in Fig. 7(b) [114].

Fig. 7.

(a) Global electronic textile market growth for years 2018–2015 and (b) medical smart textile market growth for years 2019–2025, based on quantitative data [113,114].

However, possessing a more progressive technology does not always result in a more effective product with a more complex design and competitive price, which are essential to adding value. The data presented above represent two different perspectives on common smart wearable product types. Their differences demonstrate how some important narratives can deviate from market realities. Advances in smart apparel with wearable sensors and light-emitting devices and several types of smart clothing exist as prototypes or are already on the market. The global e-textiles market can be described as following the example of integrated/printed electronic devices and their applications, as shown in reports on the progress of commercial e-textiles projects. The market encompasses e-textiles using first-generation electronic devices and those using modern third-generation electronic devices. In general, a driving force for the e-textiles industry is an emerging market in sensing coupled with internet connectivity. This combination makes it possible to communicate data on body movements and vital signs (e.g., heart rate), which are important for trade in healthcare, sports, and fitness. Electronic outfits (e.g., t-shirts/trousers) can capture heart rates to track physical activity, and thus such intelligent clothes are expected to stimulate demand from health- and fitness-conscious people. Recently, wearable devices have been in huge demand in the market, as demonstrated by the rate of growth of the wearable fitness market to US$34 billion in 2020, and this growth is likely to continue in the future [115,116]. Sensing wearables have also developed rapidly in the smart textile market, and this trend is expected to continue in the next few years. This trend is expected to influence a major portion of the global market globally, based on the data forecast in the IDTech report. Applications in the medical and sports sectors and others are expected to lead the global e-textiles market in the next decade and beyond. Apart from medicine and sports, another major sector for applications of e-textiles will be the military/defense sector, which would serve as a driving force for escalating growth opportunities for e-textile market revenue. There is also a considerable demand for self-regulating smart textile products in the architecture, automotive, consultancy services, fashion, and entertainment sectors. Therefore, these sectors will also account for notable proportions of the e-textile market. Sensors and light-emitting devices are currently the most commonly used components in smart electronic garments, which account for a large proportion of smart textiles. This is because sensing ability and electronics are the most vital characteristics of any type of smart e-textile product [117,118]. Despite e-textiles being extremely useful in the medical, sports, PPE, fashion, shelter, defense, and aerospace sectors, where they are already used for sensing and monitoring, they need to be more efficient and convenient if they are to be integrated with pliable electronics and power sources (e.g., batteries).

Face masks are currently one of the most used and demanded products in the world because of the COVID-19 pandemic [119]. Furthermore, because of the alarming spread of the SARS-CoV-2 virus around the world, face masks, respirators, and PPE garments are in high demand [120]. This has had an economic impact on the global market, and the growth of the respiratory fabric market has been among the top apparel industry trends in the last two years. The COVID-19 pandemic has drastically increased demand for face masks and encouraged the development of electric anti-viral face masks to meet the current high market demand [121]. The Wall Street Journal reported in July 2020 that N95 face mask manufacturers increased production substantially to meet COVID-19 demand. Some companies, such as 3 M, Honeywell, and Prestige Ameritech, are capitalizing on the fabrication of technical masks and PPE. With the increase in demand, electric face masks could become more desirable and fulfill current and future market needs to prevent the spread of respiratory infections. There are clear indications of growth in the market for electric respiratory apparel, with annual growth projected to increase over the next few years.

5. Textiles forming strategies: from fiber to fabric

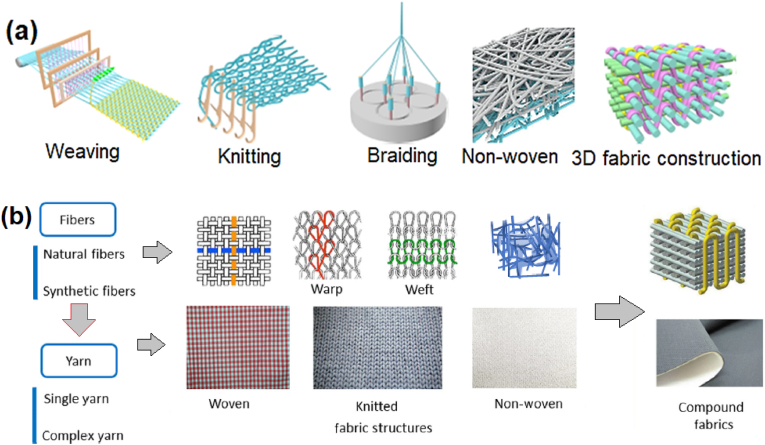

A textile is a hierarchical material, and it is important to understand basic formation process of textile fabric. Textile is 2D/3D composite structure constructed by fiber/yarn interlacing [15,122]. Fiber (natural/synthetic) is the most fundamental or raw material used to make fabric [123]. Yarns are made from fibers when they spun or twisted together [124,125]. Fabrics are made from yarns or threads when they interlaced or bonded together using different methods. Wu et al. described and compared some commonly explored textile forming strategies like weaving, knitting, braiding, non-woven and 3D textile structure [57]. The schematic designs of these textile forming strategies are shown in Fig. 8(a). Weaving is a highly recognized textile making technique. In this technique, a set of weft yarns is normally interwoven into other set of warp yarns that lie perpendicular to each other to create different weaving forms. In knitted process, various yarn loops connected to each other and to the nearest columns and rows. Braiding is a simple technique in which interlacing three or more yarns using a machine or manually using hands that they cross one another and are laid diagonally overlapping pattern to form a narrow strip or flat fabric. Nonwoven fabric is a web-like structure manufactured with fibers that are held together by using various techniques such as electrospinning, stitching, thermal, mechanical, and chemical bonding. Lastly, the 3D flat interlaced woven fabric structure made of three yarn sets (warp, weft and z-yarn) [126]. In this process, warp yarns are interlaced with weft yarns to the weave pattern in in-plane primary directions, while z-yarns are interlaced with warp yarns according to the weave pattern in out-of-plane at each layer.

Fig. 8.

Summarization of various fabric making strategies: (a) weaving, knitting, braiding, nonwoven and 3D formation. Images are reproduced with permission from Ref. [57], Copyright, 2022 Elsevier Ltd., [18], Copyright, 2022 Springer Nature Ltd. (b) Fabric production stages and hierarchy from fibers to multilayers compound fabric. Images are adopted with permission from Ref. [52], Copyright, 2019 Zhengzhou University.

In addition, Wang et al. also discussed the manufacturing methodologies from fiber to yarn and then to multilayers compound fabric as shown in Fig. 8 (b) [52]. These constructed fabrics can be further utilized for regular clothing and e-textiles applications.

Although fiber created yarns are basic building blocks of the textiles, but their physical properties are highly reliant on the types of elementary materials and fabrication strategies utilized. Various materials and yarns construction strategies are reported for different applications from advanced e-textiles to bio-textiles [[127], [128], [129], [130], [131], [132]]. Wu et al. have also discussed the merits and demerits of textile fabrications strategies [57]. For instance, in weaving, the fabric could be created with controllable size, shape and air absorbency but relatively nonextensile in the warp and weft directions and remain opposite in other preferable directions. In braiding, fabric showed high stiffness and excellent durability but showed low porosity than other strategies like knitting and weaving. In knitting, fabric could be designed with controllable size, structure and porosity and it is able to stretch in all desirable directions but showed poor Youn's modulus. Woven fabric is stronger and structurally sound better than non-woven fabric, but it showed defective selvage and broken ends/picks (warp/weft). 3D structured fabric could be constructed with controllable size and porosity with excellent mechanical characteristics, but its fabrication process is very complex.

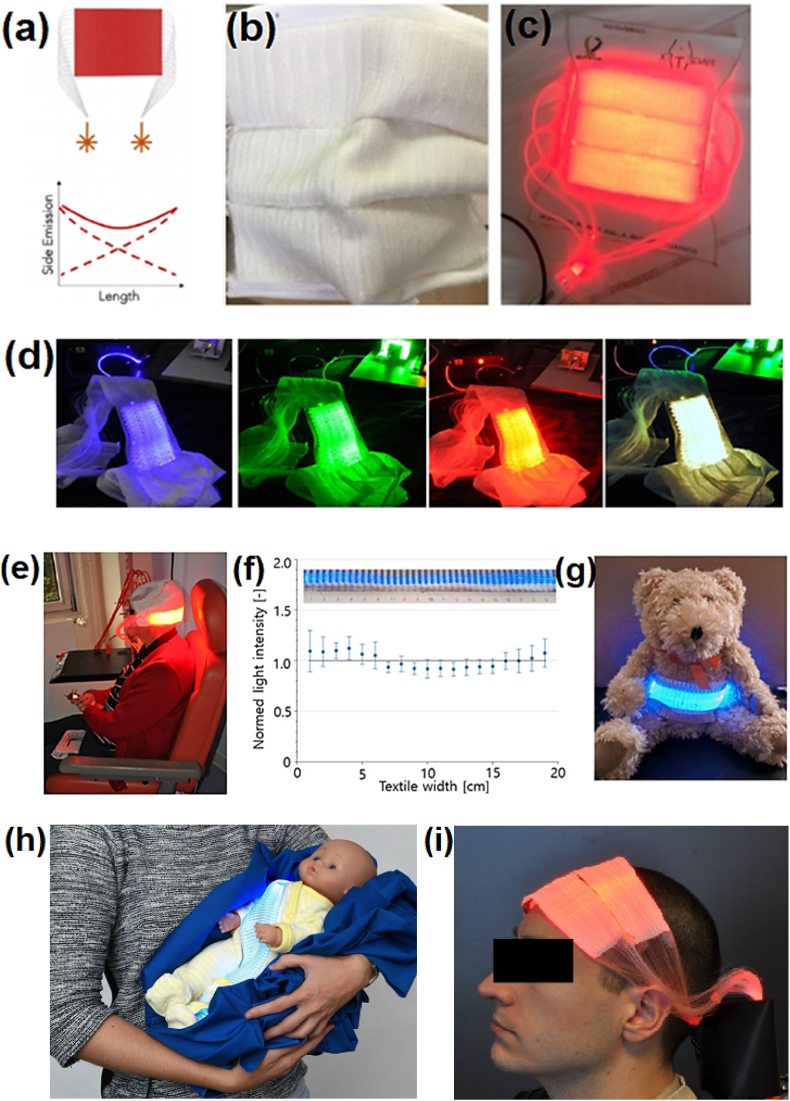

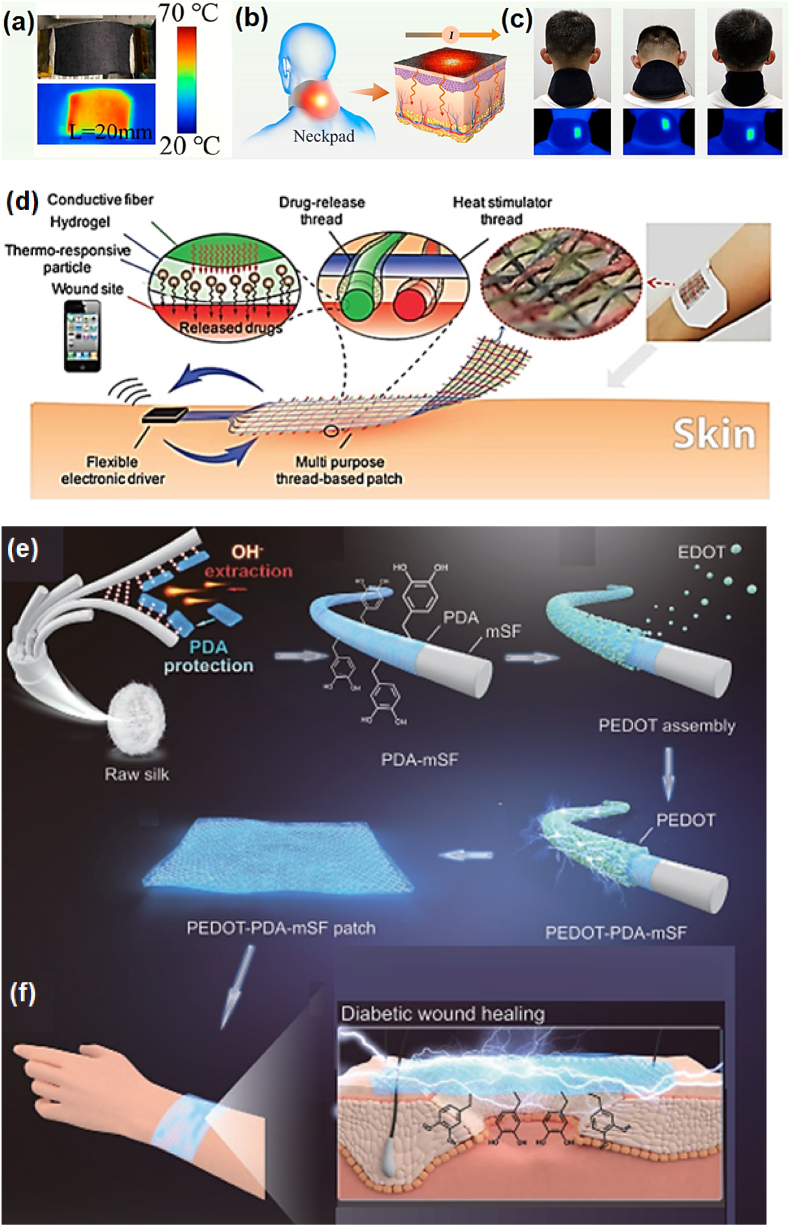

6. Materials and techniques required for fabrication of e-textiles

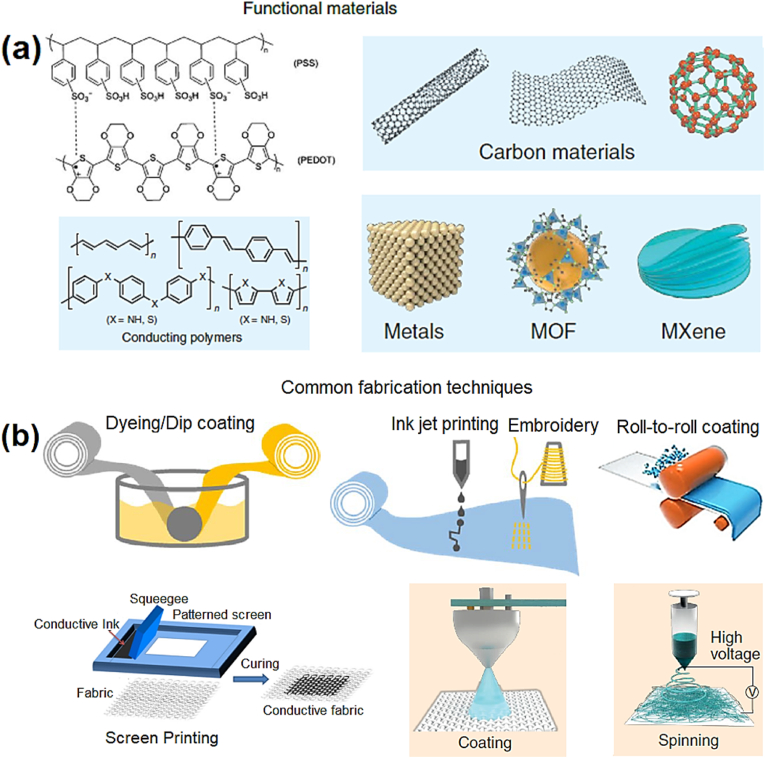

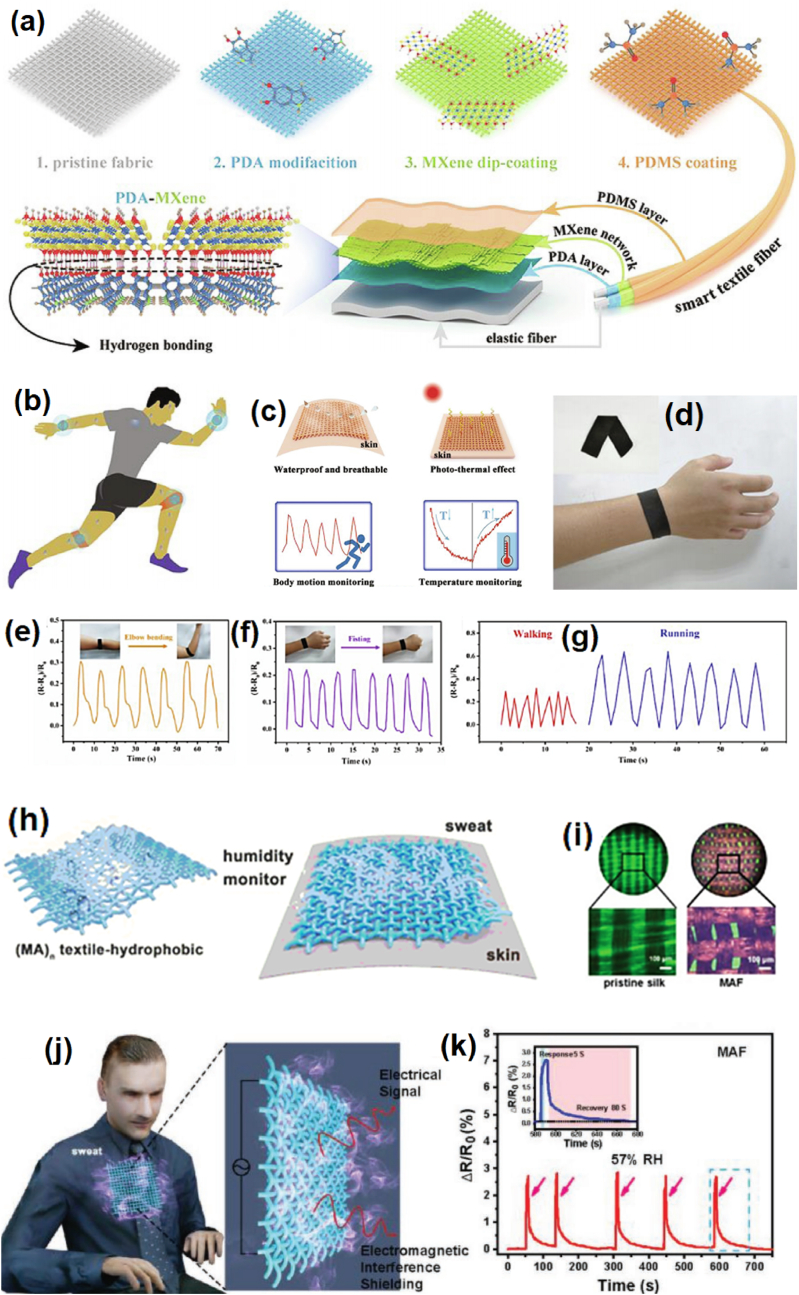

This section describes essentially functional materials and fabrication techniques for smart textiles/e-textiles and their application areas. Currently, a wide range of functional materials and techniques are being used in the development of electrically functional clothes for healthcare, fitness, and many other uses [1,20,123]. Smart textiles/e-textiles can be customized to measure strain, pressure, chemicals, humidity/sweat and temperature variations. Examples include dry conductors for monitoring, diagnosis, and treatment; dielectric elastomers for stretchable capacitive sensors; resistive and piezoelectric materials for sensors; electroactive polymers (EAPs) for actuators; carbon materials-based filament; dielectric adhesive-coated conductive yarns for conductors and heaters; and light-emitting active polymers for phototherapy, thermotherapy and electrotherapy [1,22,39,133]. Although, several materials and fabrication strategies and electronic device integration into textiles have been reported to produce e-textiles prototypes in academic research laboratories and mass scale production in industries. However, in this section we provide some most common materials and techniques being used in fabrication of e-textiles. Fig. 9(a) shows most common materials such as conductive polymers (Poly (3,4-ethylenedioxythiophene)-poly (styrenesulfonate) (PEDOT: PSS)), carbon materials, metals, metal-organic frameworks (MOF) and carbide/carbonitride (Ti3C2Tx) MXene, being used in development of e-textiles in recent years [1,18,127]. Fig. 9 (b) shows commonly explored methods such as dyeing, dip-coating, jet printing, embroidery (conductive fiber/thread), roll-to-roll coating, screen/stencil printing, spray-coating and spinning being used to produce conductive textiles and device/sensor integration into fabrics [15,18,134]. Moreover, metals can be integrated onto the textile fibers or co-mingled with their pristine form using thin metal nanoparticles and nanowires form. It has been observed from the literature sufrvey that for wearable applications, it is most common to combine metals or other conductive materials as a thin layer on the insulating surface of a pristine fabrics. Lastly, the electrically conductive fabrics can be transformed into proper wearable e-textile system integrated with computer/mobile and power source via connectors/wireless module to data accumulation for health and fitness assessment.

Fig. 9.

(a) Common conductive materials (conductive polymers, carbon materials, metals, MOF and MXene). Images are reproduced with permission from Ref. [18], Copyright, 2022 Springer Nature Ltd. (b) Fabrication techniques (dyeing, dip-coating, jet printing, embroidery, roll-to-roll coating, screen/stencil printing, spray-coating and spinning) using for the development of electrically functional textiles. Images adapted with permission from Ref. [15], Copyright, The Author(s) 2021.

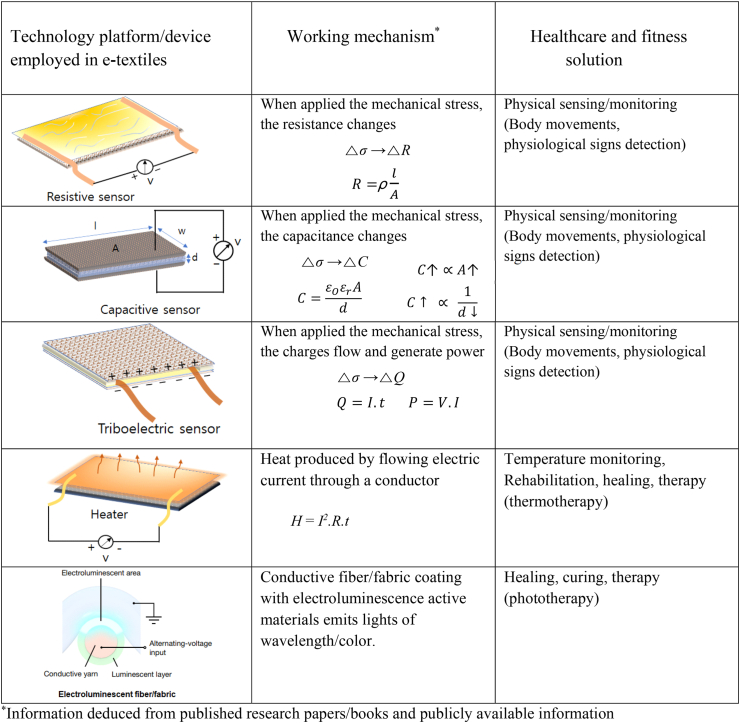

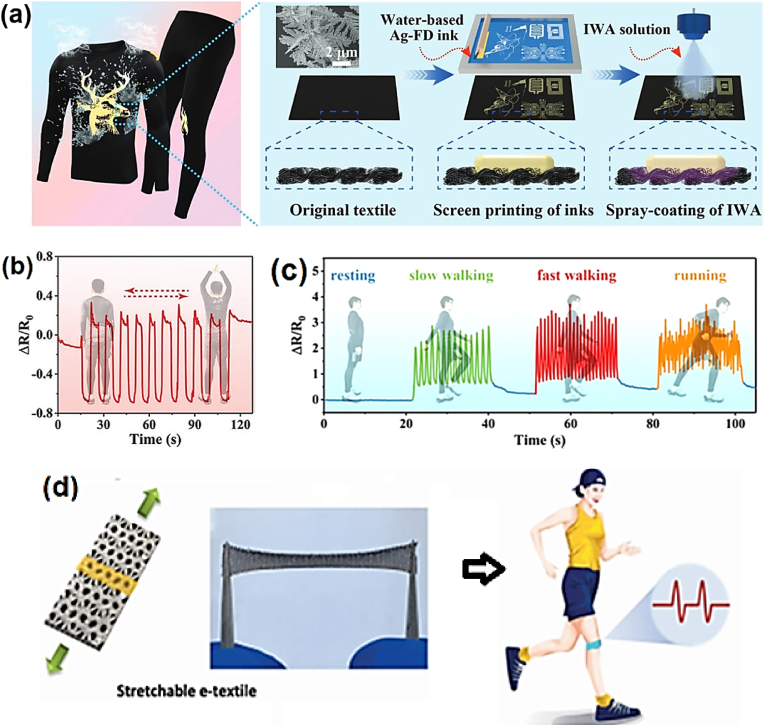

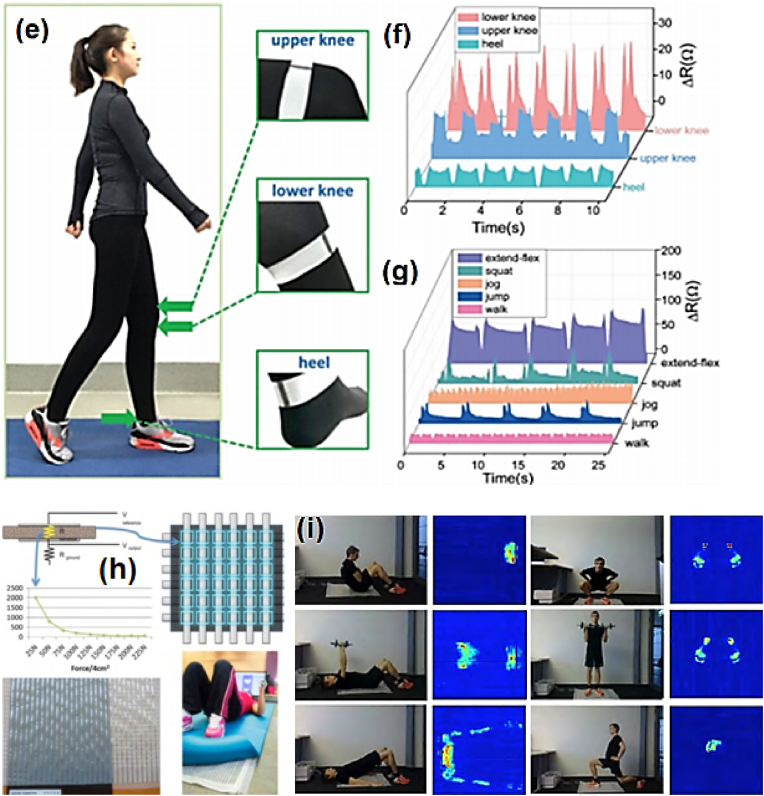

We have summarized the five main categories of electronic devices/technology have been employed so far for wearable e-textiles developments in Table 2. Basically, e-textiles comprises resistance, capacitance and triboelectric sensors for body movements and physiological detection. Wearable heaters integrated into fabric and light-emitting fibers/fabric used in rehabilitation and therapy treatments. Triboelectric, piezoresistive, capacitive and resistance-types strain and pressure sensors have used for physical sensing/monitoring to advance the e-textile technology [51,52,123,127,135]. Restive-type heaters [136,137] and light-emitting fibers and fabrics have utilized for therapeutic applications [79,138,139]. Herein, we describe only selected devices/technology platform used in smart e-textiles but there are many other materials and devices are being used in the development of the e-textiles for several applications.

Table 2.

Although we have cited most of the e-textile-related literature in this review, we provide more information about active materials and fabrication approaches. Several material preparation methods and manufacturing technologies that have been used in the last few years to develop wearable, comfortable, electronically functional garments for healthcare and fitness applications are summarized in Table 3.

Table 3.

Functional materials, fabrication procedures, and textile-based electronic devices and their applications in various sectors.

| Functional material(s) | Fabrication method | Type of e-textile device/technology | Application | Reference |

|---|---|---|---|---|

| Acrylamide cross-linking cotton fabric | Dip coating | Textile-based capacitive sensor | Real-time breath monitoring, talking, winking, and joint motions for rehab exercises | [26] |

| Silver (Ag)/silicone carbon paste | Printing | e-sleeve for functional electrical stimulation | Stroke rehabilitation/human body stimulation | [45] |

| MXene-coated cellulose yarns | Seamless knitting | Textile-based capacitive pressure sensor | Sensing body (finger) pressures and weights | [65] |

| Poly (3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT: PSS) | Printing | ECG monitoring device | Chest and wrist monitoring | [146] |

| Single-wall carbon Nanotube | Coating | ECG-conductive cotton yarn | Body monitoring | [147] |

| Piezoresistive carbon | Stencil printing | Stretchable sensor | Human joint movement | [148] |

| Stainless steel yarn | Flat-knitting | Fabric strain sensors | Physiological monitoring | [149] |

| Carbon black | Dip coating process | Core-sheath fiber strain sensor | Triaxial trunk motion angles | [150] |

| Ag/AgCl-coated yarn | Knitting and sewing | Functional electrical stimulation fabric | Electrical stimulation of the body | [151] |

| Polymer optical fibers | Weaving | Luminous textile | Neonatal skin therapy | [152] |

| Cu-doped zinc sulfide (ZnS:Cu) | Roll-to-roll-compatible patterning | Light-emitting fiber | Electronic skin | [70] |

| Silver (Ag) ink | Knitting | EMG | Interossei muscles | [153] |

| Graphene | Dip coating | Electrooculography (EOG)- elastic headband | Forehead | [154] |

| Ag/AgCl-coated thread | Seamless knitting | Electroencephalography (EEG) | Forehead | [155] |

| rGO/single-wall carbon nanotube (SWCNT) | Dip coating | Fabric strain and pressure sensor | Body/joints movements | [156] |

| AgNW-coated P(VDF-TrFE) fiber sensor | Electrospinning/yarn dip-coating | Textile strain sensors | Heart rate monitoring | [157] |

| Carbon nanotube (CNT) | Spinning/chemical vapor deposition (CVD) | Strain sensor | Assessment of body movements | [158] |

| Polyurethane (PU) core/nylon cover fiber yarns decorated with AgNWs | Dip coating | Piezoresistive strain sensor | Health monitoring/artificial skin | [159] |

| Poly (ethylene terephthalate) (PET) yarns and PEDOT enclosed with PMMA | In situ polymerization | Textile strain sensor | Human motion monitoring | [160] |

| One-ply terylene yarns/stainless steel fiber | Stitching/knitting | High-pressure textile sensor array | Epidermal physiological signal monitoring | [161] |

| Eeonyx conductive thread | Sewing/embroidery | Conductive fabric sensor | Knee angle measurement | [162] |

| Silver/polyester fibers | Dyeing | E-textile strain-electric sensor | Physical kinesis monitoring | [163] |

| Ecoflex/carbon black | Machine sewing/embroidery | Battery-free textile temperature/strain sensor | Human physiological signals | [7] |

| Graphene flakes | Yarn dyeing/knitting | Wearable textile sensors | Wireless body temperature monitoring | [164] |

| Silicone/silk-coated wire/tencel yarn | Weaving/printing | Wearable electrotherapy | Pain relief | [165] |

| Graphene-based conductive pattern | Ink-jet printing | Wearable e-textiles | Health monitoring | [166] |

| Stainless steel/cotton fiber | Weave design/seam construction | E-textile jumpsuit | Motion capture | [167] |

| Carbon nanotube (CNT)/polyurethane (PU) | Dip coating process | Pressure-sensing textiles | Tactile touch/pressure perception | [168] |

| CNT ink/cotton composite fabric | Direct screen printing | Strain sensor | Electrical heating/color changing | [169] |

| PEDOT:PSS/zirconate titanate (PZT) | Dip coating | Pressure-based sensing socks | Sports and health monitoring (gait, sweat analysis, etc.) | [170] |

| Electroactive ferroelectric/copper | Embedding/entrenching | Capacitive pressure sensor-based smart sock | Human gait segmentation and analyses | [171] |

| Liquid metal paste | Printing | Stretchable biomechanical strain sensor | Measurement of elbow flexion angle | [172] |

| Silicone foil with silver particles | Weaving | Electroconductive textile device | Electrotherapy | [173] |

| Photodiode and LED-embedded textiles | Woven, knitting | Photoplethysmography (PPG) sensing textile | Heart rate monitoring | [174] |

| MXene | Electrospinning | Near-infrared (NIR) irradiation nanobelt fibers | Wound healing | [175] |

| MXene | Dip coating | Multifunctional nonwoven smart fabric | Joule heating for healthcare and thermotherapy | [176] |

| Polydopamine (PDA)/PEDOT:PSS | Self-assembly dip coating | Conductive silk microfiber patch | Analysis and wound treatment in diabetes cases | [177] |

| Silver fractal dendrites (Ag-FD) Conductive ink | Screen printing | Stretchable aesthetic e-textile | Human motion detection and body-temperature management | [178] |

| CNT films, PEDOT:PSS | Electrospray | Stretchable thermoelectric woven fabric | Sensing, energy harvesting, thermal management | [179] |

| Silkworm cocoons, water-soluble poly (vinyl alcohol) (PVA)-assisted Ag nanofibers | Electrospinning, Magnetron sputtering | Battery-free sensing fabric | Compression sensor for movement monitoring | [180] |

| PVDF/AgNWs nanofibrous membrane | Electrospinning | Self-powered pressure sensor textile | Motion sensing and pulse monitoring | [181] |

| Nylon, Polytetrafluoroethylene (PTFE) | Weaving | Breathable and washable sensing textile | Human activity and pulse monitoring | [182] |

| Cotton fabric, PEDOT:PSS | Dip coating | Three-dimensional (3D) thermoelectric spacer fabric | Self-powered pressure−temperature-sensing | [183] |

| Polyaniline (PANI) with nanodiamond (ND) | In situ polymerization | Strain-sensing fabric | Human motion detection | [184] |

| Silver flakes, PU | Screen/stencil printing | Large-scale e-textiles for health care and sports | EMG health monitoring | [185] |

| AgNWS | Screen printing | Supersensitive all-textile pressure sensors | Human motion detection and human–machine interaction | [186] |

| CNT/Ni on polyester/nylon textile | Electroless plating, dip coating | Large-area fully textile pressure sensor | Human motion and physiological signals monitoring | [187] |

| AgNPs/PU | Thermal bonding approach | Pillow-shaped hierarchical 3D pressure sensor | Physiological activities (sleep posture and breath status) | [188] |

| GO, l-ascorbic acid (l-AA) reduction (rGO) | Pad dyeing | Wool-knitted fabric strain sensor | Breathing, perspiration, movement | [189] |

| Polypyrrole (Ppy) | In situ polymerization | Knitted fabric wearable sensor | Strain sensing | [190] |

| Graphene/PDMS | CVD, spin coating | Woven fabric strain sensor | Fitness tracking and communication | [191] |

| MXene/PU/cellulose nanocrystal | Dip coating | Nonwoven fabric tunable wearable strain/pressure sensor | Motion detection, human physical signal detection | [192] |

| MXene | Dip coating, pad trying | Breathable, durable, and bark-shaped MXene/textiles | Pressure sensor and heat physiotherapy | [193] |

7. Current health problems and their potential e-textile solutions

7.1. Viral infection caused by coughs and sneezes

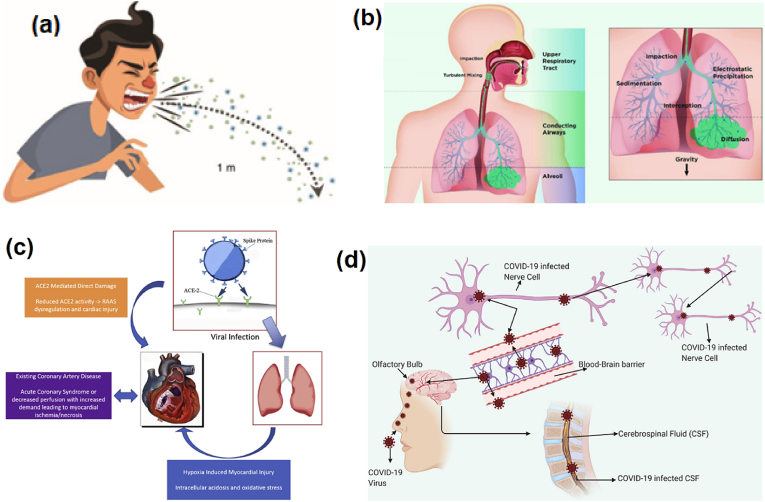

Transmittable illnesses such as flu, colds, SARS, and strep throat spread from human to human through close interaction or physical contact, such as touching or kissing somebody who is infected. Infection also spreads when infectious germs travel through the air when someone nearby sneezes or coughs. Cold and influenza are common viral infections caused by coughs and sneezes that disperse a large number of droplets into the environment, and they transmit respiratory viral infections by physical contact or through inhalation, leading to mild to severe illness. Respiratory droplets remain the most common source of contagion, with the limit of transmission typically being a distance of 1 m in the case of normal breathing, as shown in Fig. 10(a) [194]. Germs can easily be spread by coughing, sneezing, or talking and can cause the spread of serious respiratory diseases, such as influenza, respiratory syncytial virus (RSV), and the novel SARS-CoV-2 corona (COVID-19) virus. The COVID-19 pandemic has resulted in people facing mass quarantine to prevent human-to-human interaction to reduce transmission.

Fig. 10.

(a) Acute respiratory virus propagation by droplets. Reproduced with permission [194]. Copyright 2020, Society to Improve Diagnosis in Medicine. (b) Mechanisms of deposition of inhaled particles in the lung. Reproduced with permission [195]. Copyright 2020, ATS journals. (c) Possible mechanisms of cardiac and lung injury with COVID-19. Reproduced with permission [196]. Copyright 2020, Elsevier. (d) Model of COVID-19 virus entry into the brain and effectual antiviral drugs. Drugs that can cross the blood–brain barrier could be advantageous in treatment strategies. Reproduced with permission [197]. Copyright 2020, Elsevier.

Coronavirus particles enter the body generally through the nose and mouth and from there can enter the lungs, causing potentially serious illness, as shown in Fig. 10(b) [195]. The coronavirus can also invade the heart and the central nervous system (CNS), leading to neurological diseases. Fig. 10(c) shows the mechanisms of cardiac and lung ailments associated with COVID-19 that can have serious consequences, including death, for patients with lung infections and heart diseases [196]. The virus can enter the CNS through olfactory nerves upon nasal infection, resulting in inflammation and demyelination. The virus can also enter the brain via the blood–brain barrier and cerebrospinal fluid (CSF) through the blood–CSF artery in just a few days. The coronavirus can thereby damage the entire CNS. A few days is sufficient time for the virus to spread and harm the medullary neurons. The mechanism of the spread of SARS-CoV-2 once it has invaded the CNS is illustrated in Fig. 10(d). In a recent study, Vellingiri et al. observed that the symptoms that might point to lung disease are related to a failure of air flow into the lungs, which might be due to weakened inhalation, which is controlled by the nervous system [197]. The novel coronavirus's association with respiratory illness has put unprecedented strain on the global healthcare system. The COVID-19 epidemic remains a threat to populations around the world and may contribute to alarming types of respiratory diseases in the future. Fabric masks and surgical masks are designed to keep other people safe from the spread of viruses by the mask wearer. There have recently been considerable advancements in the design and production of masks that are highly effective in controlling virus transmission.

In the face of evidence that the coronavirus and other infectious disease-causing particles may spread by talking and breathing, as well as coughing and sneezing, the World Health Organization (WHO) recommends that people cover their faces with specially designed cloth or fabric masks in public places to help stop the spread of germs and viruses [198]. There are various types of face masks currently available on the market that protect the mouth and nose in various ways. The most common and affordable masks, such as cloth face masks, simple face masks, more specially designed masks (R95, R99, R100, P95, P99, P100), surgical face masks (N95, N99, N100), and electric face masks are all reported to be effective against various virus sizes [119,[199], [200], [201]]. Konda et al. described the filtration effectiveness of different types of fabrics as depending strongly on the aerosol particle size of aerosol, with the best results achieved for particles from 10 nm to 6 μm in size [202]. Not all fabrics meet the requirements for power-driven face masks, which use battery power and fan filters to enable air circulation. This could be the reason that such masks can be quite comfortable to use because they do not retain humidity around the mouth and nose.

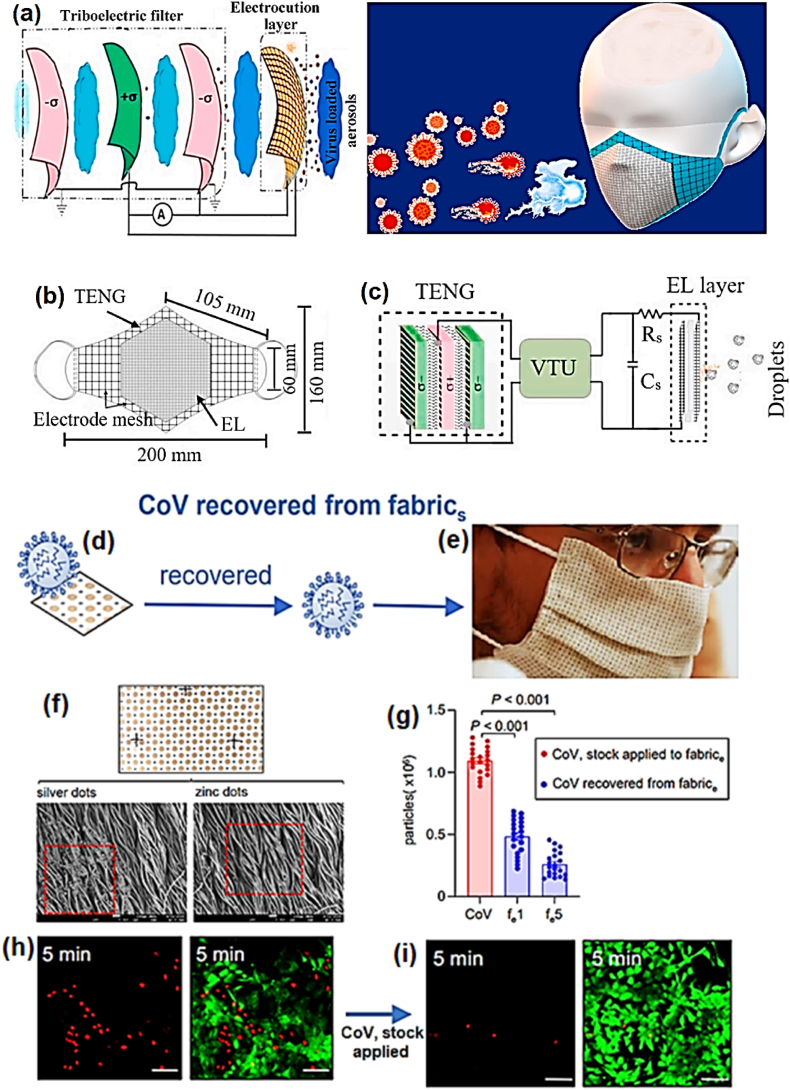

7.2. Use of e-masks to control respiratory disease transmission

The effectiveness of electronically functional fabric masks is under evaluation by various research groups worldwide to assess how useful they may be in preventing the spread of respiratory diseases. According to Leung et al. [203], surgical masks are less effective than electric masks in reducing the transmission of influenza and seasonal viruses that cause common colds. To overcome these complications and suppress sneak currents, the use of electronic fabric masks is highly desirable. For example, Ghatak et al. reported a newly designed self-powered e-mask for the prevention of COVID-19 [204]. Although simple fabric masks [202], as well as surgical masks [205], are considered to protect others from virus spread by the mask wearer, this newly designed mask is believed to be able to kill the COVID-19 virus within the range of the electrical field and protect the user from the deadly virus. Fig. 11(a) shows a schematic representation of a multilayered face mask in which the inner and middle layers consist of tribo-series materials (TSM), together with a self-charged triboelectric nano-generator. The proposed design and the working mechanism of the self-powered mask are shown in Fig. 11(b and c, respectively). The design is based on a triboelectric nanogenerator (TENG) device with an electrocution layer (EL) that may work for the deactivation and filtration of SARS-CoV-2. A latex rubber–polyurethane (PU) was used in the fabrication of this self-powered electric mask. The mask was able to induce power in the μW range based on its maximum triboelectric charge density. The study showed that because of the contact electrification of the triboelectric layers (TLs), the power generated in the mask helped to deactivate the virus transmission. The working mechanism of the mask is derived from the triboelectricity and proper use of the electric field to stimulate the EL. Other factors are also considered in obtaining effective filtration, such as the inhalation/exhalation rate and the distance between TLs. This work shows that technology could be very helpful in stopping the transmission of the novel coronavirus through the charge adsorption method. Electrocution by triboelectrification offers effective protection against the potentially fatal effects of SARS-CoV-2 or other similar viruses that may exist in the future. The outer layer of the mask functions as a smart layer, and the tribo-charges induced through contact electrification and triboelectrification between tribo-pairs help to decimate virus particles in aerosols. The triboelectric nano-generator would be self-charged, i.e., no external power is required to turn it on. The mask can work efficiently even when the user is resting or sleeping and retains additional charge when the inward and outward aerosol flow contains no virus particles. In addition, the integration of the outer layer provides extra protection for the wearer in case inward aerosols interact with the mask. Consequently, the electrically charged virus can be killed by electrocution when exposed to the smart layer. This gives double-layered protection from middle and inner TLs in a self-powered mask. The storage capacity of the self-powered mask lets the wearer act immediately to deactivate charged viruses comfortably. The results of this study motivate the development of textile-based e-masks that are capable of operating without external control or intervention to keep users safe from the spread of viruses. This e-mask has huge potential to be used for critical purposes by anyone, as it is inexpensive to manufacture, self-powered, and safe.

Fig. 11.

(a) Proposed schematic view of triboelectric self-powered mask with multiple layers. The first three layers (left side) function as a triboelectric filter, and the outer layer function as a conducting mesh. (b) Concept design. (c) Working mechanism of the proposed multilayered self-powered prototype mask. Reproduced with permission [204]. Copyright 2020, Elsevier. (d) Sketch of SARS-CoV recovered from fabric when pre-exposed to the electroceutical fabric for 5 min and the stock applied on fabric. (e) Digital photograph of fabricated mask used on a volunteer that can generate a weak electric field to destroy the virus. (f) Photomicrographs of electroceutical fabric and SEM images of Ag and Zn dots. (g) Calculation of viral particles from stock applied to fabric and recovered from fabric, when SARS-CoV contacts the electroceutical fabric. ST cells infected with viruses exposed to the electroceutical fabric for 5 min each and loss of cell viability. (h & i) Eradication of respiratory coronavirus (CoV) subjected to contact with the charged mask for 5 min, which indicates that the effectiveness of the cartridge improves from 85% to approximately 95%. Reproduced with permission [206], Copyright 2021, Springer Nature.

Ghatak et al. developed an electric facemask using electroceutical fabric to kill coronaviruses that come into contact with the mask [206]. This electroceutical fabric mask was first tested against a pig coronavirus and then on a human coronavirus that causes the common cold or fever. Although it was not tested against the SARS-CoV-2 virus, it could also be effective against this deadly virus. This work offers potential benefit to the scientific community by contributing to providing a solution to ending the COVID-19 pandemic. Fig. 11(d and e) shows illustrations of virus-pre-exposed fabric and the prototype face mask on a wearer. The mask is fabricated using stretchable electroceutical textiles referred to as electroceutical fabric (fe). A polyester fabric was used to produce the electroceutical fabric, printed with various spherical dots of silver (Ag) and zinc (Zn) particles, as shown in Fig. 11(f). Scanning electron microscopy (SEM) showed the deposition pattern of the Ag and Zn dots on the fabric. Fragments (∼105) of a pig respiratory coronavirus were put into direct contact with the fabric for 1–5 min, and approximately 104 virus particles were recovered. The mask consists of a designed pattern of Ag and Zn dots printed onto a piece of fabric made of polyester or cotton material. These Ag and Zn dots create a power source that generates a weak electric field when exposed to a conductive medium, such as sweat or gel. Electrons move from the Zn to the Ag in an oxidation–reduction (redox) reaction that produces a voltage of 0.5 V. Fig. 11(g) shows a size distribution plot demonstrating the presence of a cluster of the virus. The calculated yield of the viral dots was 44.29%, and recovery of 23.73% from the fabric was achieved when exposed to electroceutical fabric for 1–5 min. The loss of coronavirus infectivity when exposed to electroceutical fabric for testing cell viability is shown in Fig. 11(h and i). The contamination of cells with CoV was found to affect the apparent loss of cell viability. A cytopathic effect of CoV was entirely absent when the virus was exposed to the fabric. This work demonstrates the potential of electric fabrics for use in stopping the spread of viruses such as COVID-19. No external power source is required to induce the electric field; instead, the electroceutical fabric coated with Ag and Zn particles serves as the source of a weak electric field. The term “electroceutical” indicates a pattern of embedded microcell batteries that generates an electrical field and produces a low amount of power in the presence of moisture (humidity) or gel particles. Research has shown that viruses can be electrically charged and eliminated or destabilized [[207], [208], [209]]. According to these studies, coronaviruses can be destroyed or disabled when exposed to the low-level electric field produced [204,206]. The results suggest that it is feasible to recharge the masks post sterilization and regain filtration efficacy. This is an encouraging technological development that merits additional study, as it may be useful for everyday purposes, such as in PPE.

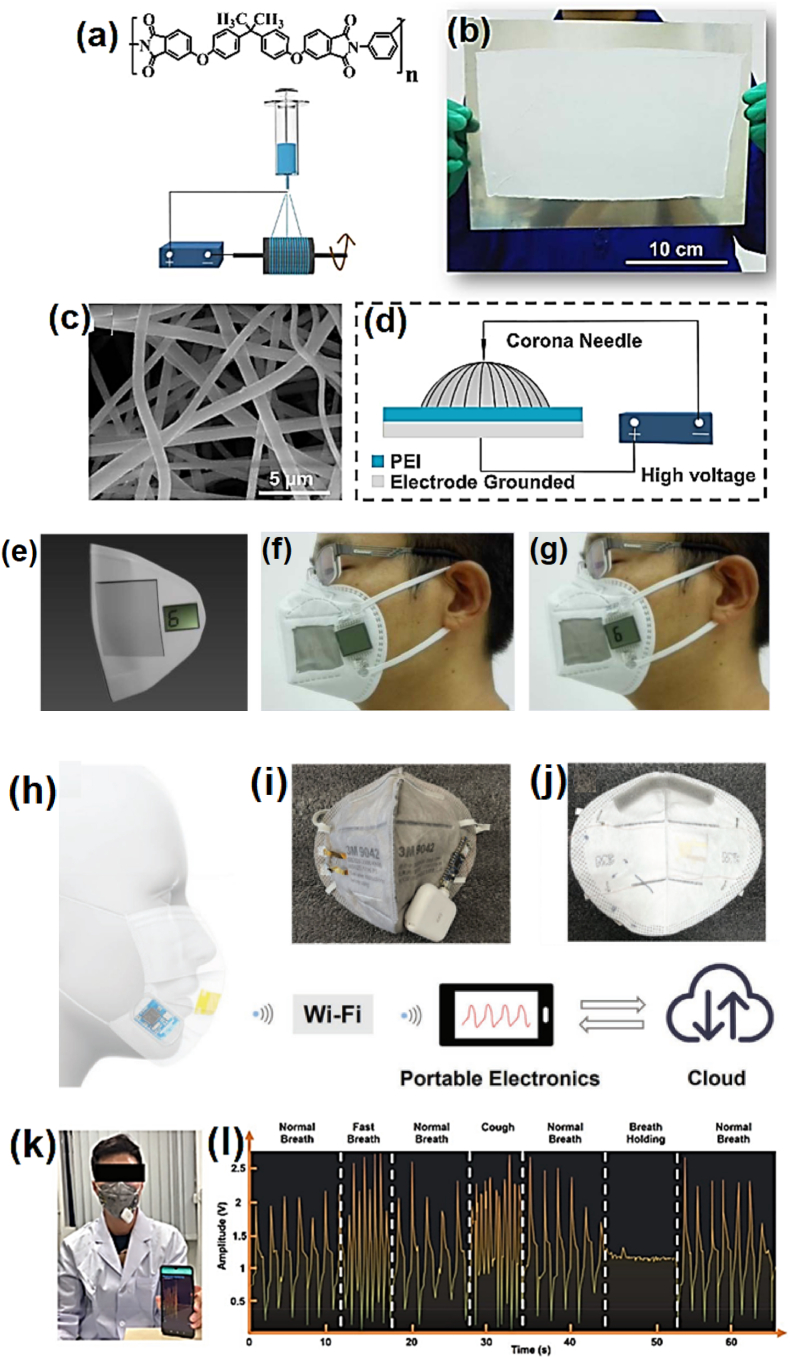

A recent study by Cheng et al. proposed a bi-functional electronic face mask fabricated using a nonwoven polyetherimide (PEI) fabric as an electret material using an electrospinning technique [210]. The mask was used to eliminate particulate matter (PM, also called particle pollution) and monitor a person's breath rate. The smart electric face mask has two functions: removing PM and generating electricity. The electric mask was designed to maintain residual charges steadily in the nonwoven PEI. The chemical formula of PEI and the electrospinning process used to produce the nonwoven PEI fabric are shown in Fig. 12(a). In this study, PEI was used because of its chemical stability and low cost as an electret material. Fig. 12(b) shows the developed uniform and large-area free-standing nonwoven PEI produced using an electrospinning technique. A PEI solution was used to form the robust and flexible nonwoven PEI at a high applied voltage of 25 kV. Fig. 12(c) shows an SEM image of the PEI fibers (1 μm diameter) deposited via layer-by-layer (LBL) assembly to produce the nonwoven PEI. Next, a corona charging method was used to insert charges into the nonwoven PEI, as schematically illustrated in Fig. 12(d). Furthermore, the nonwoven PEI was capable of working as an electrostatic field supplier when assembled in a sandwich-structured nanogenerator. The assembled nonwoven PEI was integrated with a commercially available mask to supply power to a low-consumption liquid crystal display (LCD), as shown in Fig. 12(e). At any state of motion of the nanogenerator, negative charges (σ0) in the nonwoven PEI generated resultant positive charges in the upper (σ1) and bottom (σ2) net electrodes, distributed as σ0 = −(σ1 + σ2) [211]. For example, exhalations might stimulate the nanogenerator to produce electricity to light up an LCD, as shown in Fig. 12(f and g). The PEI exhibited a maximum removal efficiency of approximately 99.6% of sub-micron particulate matter (0.3 μm size). This work demonstrated a novel approach to the development of wireless self-powered wearable electronics and electric smart air filters with low manufacturing cost and high efficiency.

Fig. 12.

(a) Chemical formula for PEI and schematically designed electrospinning technique for creating nonwoven fabric. (b) Digital image of nonwoven PEI fabric produced on a metal sheet. (c) SEM image of nonwoven PEI fibers. (d) Graphic representation of corona charging technique. (e) Smart electric mask. (f) Digital photograph of the mask. (g) Digital image of exhalation producing electricity that illuminates an LCD, which displays the number “6.” Reproduced with permission [210]. Copyright 2017, Elsevier. (h) Schematic representation of cordless self-powered face mask for breath monitoring. Digital images of the smart face mask (i) front and (j) back sides. (k) Digital photograph of demonstration of wireless real-time breath monitoring procedure for an actual application. (l) Screenshot illustrating the quantified constant and consecutive breathing activity during a sequence of normal breathing, rapid breathing, normal breathing, coughing, normal breathing, breath holding, and normal breathing. Reprinted with permission [212]. Copyright 2021, Wiley-VCH GmbH.

Recently, Zhong et al. designed a self-powered wireless smart face mask for real-time monitoring of breathing conditions in daily life [212]. The smart face mask was constructed by incorporating a pressure sensor and a wireless readout circuit into a regular fabric mask, as shown in Fig. 12(h). Breathing conditions are monitored using this smart face mask, and the data are transmitted wirelessly using a portable device such as a smartphone. The pressure sensor was integrated into a typical mask, and the circuits were connected to a battery power supply. Breath gestures were sensed by the electric mask and then transmitted to the cloud database via a portable device. The breathing data of an individual or a group of people can be transmitted to a cloud database to populate a health database for further analysis. Front- and back-side images of the prototype electric face mask images are shown in Fig. 12(i and j, respectively). The pressure sensor was manufactured using double gold bonding (Au–Au) of two Au/parylene/Teflon films that produced internal electric dipoles. These electric dipoles permit pressure sensing through the generation of a piezoelectric-like response [213]. The smart face mask exhibited excellent outcome stability and could be used for continuous monitoring and analysis of breathing patterns, such as normal breathing, rapid breathing, breath holding, and coughing. The smart mask was tested on a healthy 28-yr-old old male volunteer to assess its practicality and for data validation, as shown in Fig. 12(k). Fig. 12(l) shows the different breath conditions detected by the wireless smart facemask. Thus, we can conclude from this work that a suitable and convenient breath-monitoring e-mask can detect and store long-term breath data for use in the health care of an individual or a group of people.

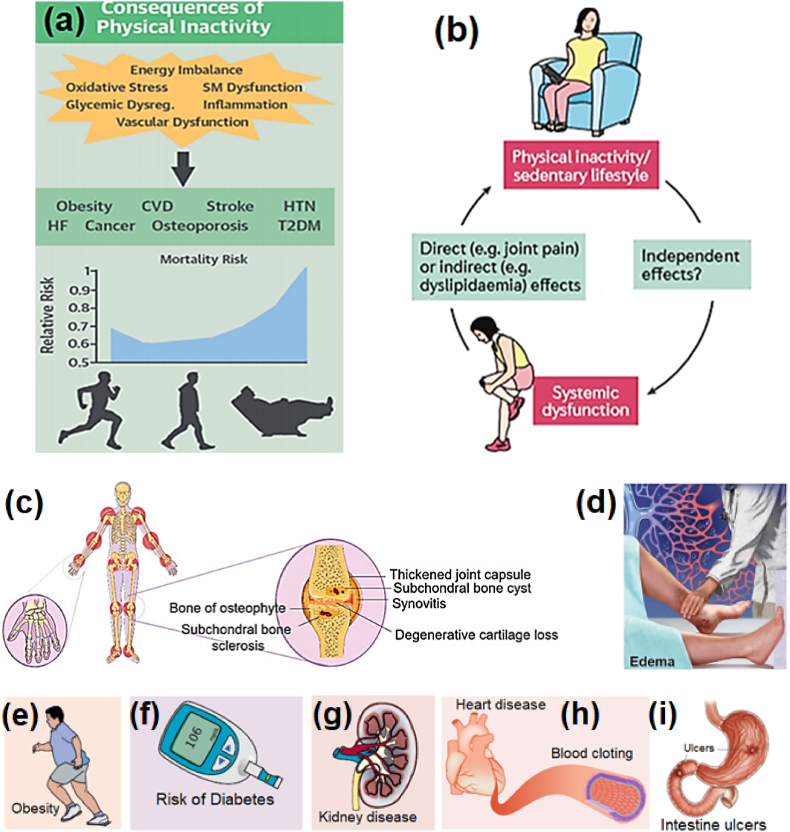

7.3. Health problems due to sedentary lifestyles

Any physical movements due to skeletal muscle actions of the body are recognized as parts of a physically active or sedentary routine. In 2018, WHO reports indicated that physical inactivity (lack of body movements) had been recognized as the fourth primary cause of 6% of deaths worldwide [214,215]. Some of the health problems associated with physical inactivity for people in any age group, from teenagers to the elderly, are shown in Fig. 13. Because of the lack of physical activity, the risk of noncommunicable diseases is increasing and causing increasing numbers of deaths worldwide. Physically inactive people are projected to be at a 20%–30% greater risk of casualties than people who are physically active [216]. Physical inactivity accompanied by pathophysiology is one of the major causes of the increased incidence of metabolic and heart diseases, osteoporosis, ulcers, and cancers. An active lifestyle significantly decreases the risk of contracting such ailments and reduces the risk of mortality, as shown in Fig. 13(a). Inactive lifestyles increase the risk of death from all causes; double the risks of cardiac diseases, obesity, diabetes, and edema; and increase the risk of cancer. Fig. 13(b) shows that physical idleness and sedentary behavior lead to systemic dysfunction and the aggravation of symptoms of pediatric rheumatic illnesses. Certain symptoms can have direct effects; for example, joint pain can affect physical functioning. Other systems can have indirect effects, such as inclining a patient to a more inactive routine [217]. As the aging population worldwide continues to increase, more patients are projected to suffer from marked physical disabilities by 2050 [93].

Fig. 13.

(a) Consequences of a sedentary lifestyle: mortality risk vs. relative risks. Reproduced with permission [216]. Copyright 2018, Elsevier. (b) Vicious cycle of physical inactivity and/or sedentary lifestyle and systemic dysfunction leads to systematic dysfunctions. Reproduced with permission [217]. Copyright 2017, Macmillan Publishers, Ltd. (c) Schematic illustration of osteoarthritis, which affects all of the joints in the human body. Reproduced with permission [218]. Copyright 2019, Taylor & Francis Group. (d) Edema: fluid accumulation or swelling. Reproduced with permission [220]. Copyright 2013, American Academy of Family Physicians. Other risks, such as (e) obesity, (f) diabetes, and (g) kidney disease. Reproduced with permission [221]. Copyright 2018, Elsevier. (h) Heart diseases and blood clotting. Reproduced with permission [222]. Copyright 2018, Springer Nature. (i) Intestinal ulcers. Reproduced with permission [223]. Copyright 2017, Elsevier.

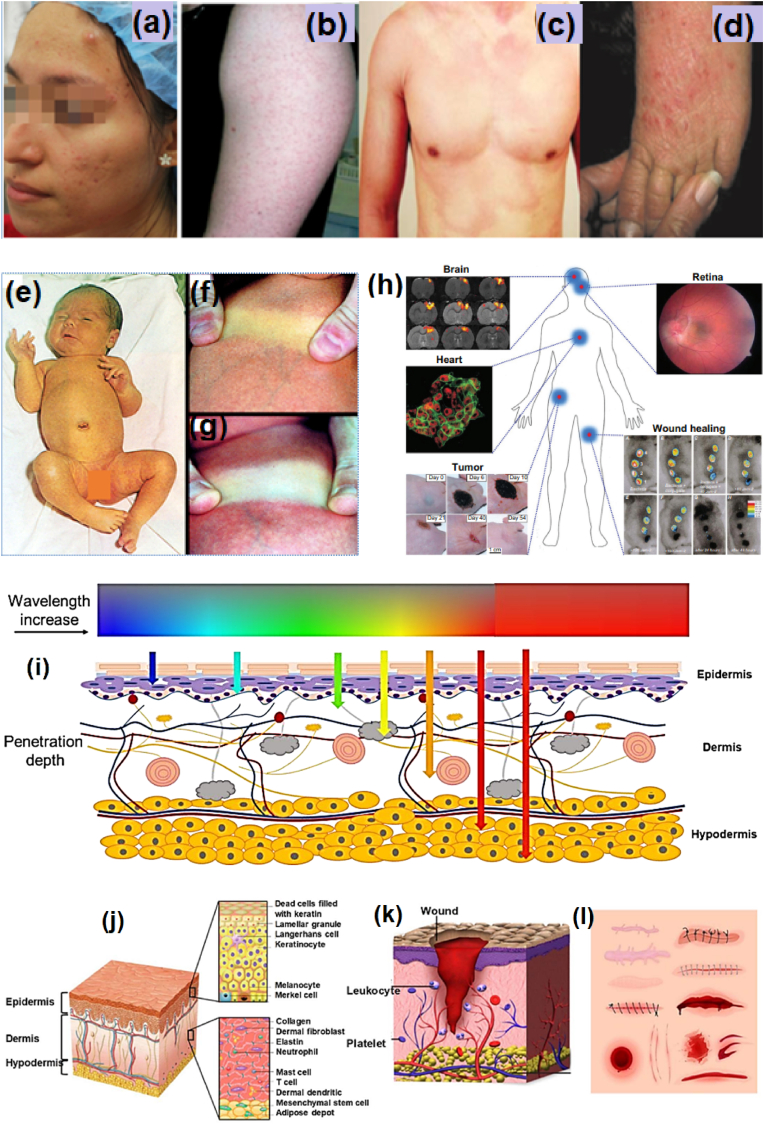

Kou et al. described osteoarthritis as a progressive and degenerative ailment that affects the whole joint system [218]. Like most of the diseases associated with aging, osteoarthritis is a primary cause of chronic disability, affecting approximately 40% of those 60 or more years of age [219]. Fig. 13(c) shows damage from joint osteoarthritis that has affected the joint structure and articulation functionality. The human body's skeletal system includes the synovial membrane, articular cartilage, subchondral bone, joint sheath, and other parts of the body joints. Edema is the accumulation of fluid in the legs that results in swelling, particularly in the elderly and women during the last trimester of pregnancy, as described by Trayes et al. [220]. Edema (Fig. 13(d)) can result in blood clots that block arteries and cause heart attacks.