Abstract

Besides plants and animals, the Fungi kingdom describes several species characterized by various forms and applications. They can be found in all habitats and play an essential role in the excellent functioning of the ecosystem, for example, as decomposers of plant material for the cycling of carbon and nutrients or as symbionts of plants. Furthermore, fungi have been used in many sectors for centuries, from producing food, beverages, and medications. Recently, they have gained significant recognition for protecting the environment, agriculture, and several industrial applications. The current article intends to review the beneficial roles of fungi used for a vast range of applications, such as the production of several enzymes and pigments, applications regarding food and pharmaceutical industries, the environment, and research domains, as well as the negative impacts of fungi (secondary metabolites production, etiological agents of diseases in plants, animals, and humans, as well as deteriogenic agents).

Keywords: biodeterioration, filamentous fungi, fungal biotechnology, natural products, secondary metabolites

1. Introduction

The fungal kingdom comprises a plethora of eukaryotic species that proliferate in diverse environments; fungi also have essential roles as components of the microbiota, where they act as symbionts, endophytes, parasites, or saprotrophs [1,2]. Studies aiming to characterize the microbiota of diverse species across kingdoms have revealed an unexpected double nature of the fungi in the microbiome: they colonize higher eukaryotes from plants to humans [3]. In the meantime, as with all other eukaryotes, fungi host their microbiota, consisting of microbial communities that adhere to the hyphal surface, develop among the pseudotissues produced by hyphal aggregation, or colonize the fungal cytoplasm. Fungi, generally, can be microscopic to macroscopic, and include unicellular organisms such as yeasts and multicellular organisms such as filamentous fungi. Filamentous fungi grow long 2–10 μm thin filaments (hyphae) into intricate network structures (mycelium) that are observable to the naked eye and can grow to the centimeter to meter scale [4,5].

The filamentous growth mode and the secretion capacity of proteins and primary and secondary metabolites facilitate fungal proliferation in nature. Industry uses these properties to produce proteins, small molecule compounds, and, recently, mycelium materials. These bio-based products could be used as thermal and acoustic insulation and packaging [6]. Pure fungal materials are the result of complete substrate degradation or are obtained by removing the fungal skin from the surface of a substrate. The properties of the mycelium depend on the substrate, the type of fungus, and growth conditions [7].

Fungi could contribute to the aspiration to develop more sustainable manufacturing to protect the environment, being an optimal candidate to produce several products such as textiles and myco-leather, biofuels, building materials, wastewater treatment, and sustainable meat substitutes [8,9]. Besides industrial and food applications, fungi are also used in medicine for the production of a lot of compounds, e.g., antibiotics (such as penicillin), or a compound named cyclosporine, produced by Tolypocladium inflatum, as well as lovastatin, a drug for lowering the cholesterol from blood produced from Aspergillus terreus [10,11].

In agriculture, fungi play a significant role, including plant growth and protection. For example, mycorrhizal fungi establish a mutualistic association with plant roots, improving the plant’s nutrient uptake by increasing the surface area of the root system. This relationship helps the plant to access nutrients, such as phosphorus and nitrogen, that are not readily available in the soil [12,13,14]. Another essential agricultural fungal species is the endophytic fungi that colonize plant tissue. The complex interaction between endophytic fungi and plant tissue involves modulating the plant’s defense mechanism in terms of inhibiting phytopathogens and stimulating the growth of the plants even under biotic and abiotic stress conditions [15]. However, in a specific situation, some fungal species exert a less beneficial action on plant health, causing various plant diseases by colonizing roots, leaves, and tissue [16].

Regarding the environmental issues related to pollution and toxic wastes, fungi are quickly surfacing as essential protagonists, involved in practices such as the bioremediation of pharmaceutical compounds, agricultural wastes, or degradation of various pollutants.

Although fungi are widely spread in the environment and co-exist with many organisms, in certain circumstances, fungi, like any other microorganisms, can harm their host. Fungi are characterized by high resilience in stressful conditions and a remarkable ability to adapt to different environments. Infectious fungi can spread through the air and water and be transmitted by different carriers such as animals, humans, or plants [17,18]. Regarding the interaction of fungi with plant organisms, more than 80% of the plants from our planet are symbiotic with fungi. However, some of the fungal strains can sometimes enter inside plants through damaged leaves and stomata, thus turning themselves into plant pathogens with a high impact on plant health.

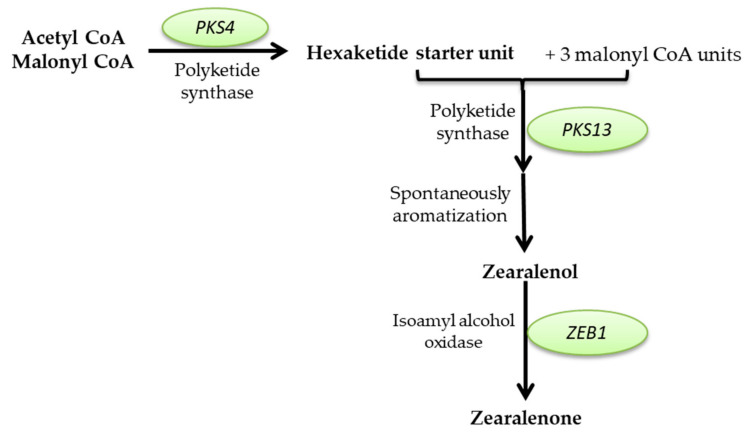

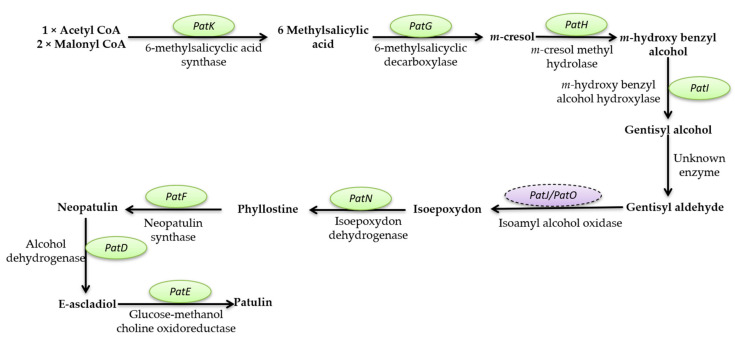

This review aims to characterize the beneficial roles of fungi used for a wide range of applications, such as the production of several enzymes (cellulase, proteinases, amylases, invertase, pectinase, chitinases, lipases, and, respectively, lignocellulolytic enzymes, citric acid, gluconic, itaconic, lactic, fumaric, malic, succinic, and oxalic acids); pigments (such as polyketide pigments, carotenoids, or melanin); applications regarding food (e.g., worldwide farmed mushrooms species such as Agaricus bisporus, Pleurotus ostreatus, Flammulina, and Lentinula shiitake, or the usage of filamentous fungi strains to produce different fermented foods such as cheese, bread, and beer, or the molds to manufacture fermented sausages, or alcoholic beverages production such as wine and beer); and in pharmaceutical industries, the environment (hydrocarbon degrading fungi, bioremediation, biofuels production, mycofiltration), and research domains (as research model organisms). Furthermore, this review summarize the negative impacts of fungi secondary metabolites production (B1, B2, G1, and G2 aflatoxins; A, B, and C ochratoxins; A, B, C, and P fumonisins; more than 200 trichothecenes; zearalenone and its derivatives; patulin), etiological agents of diseases in plants, animals and humans (e.g., Alternaria and Cladosporium genus comprise phytopathogenic species or can are responsible for human or animal infectious diseases), as well as deteriogenic agents of different substrates such as stone, wooden, paintings, textiles, parchments, paper and paper-based materials or heritage buildings.

In terms of novelty, this review brings together comprehensive data regarding the beneficial roles of fungi used for a wide range of applications (e.g., production of several enzymes, medicine, agriculture, industry, environmental safety, and research) and the damaging effects of fungi, acting as etiological agents of diseases in plants, animals, and humans. In addition, in this paper, we present the deterioration action of fungi on cultural heritage objects. Therefore, the rationale for choosing this subject is the impact of fungi on human health and environmental safety. People suffering from opportunistic and primary invasive fungal infections urgently need resources and research efforts to bring them new diagnostics and treatments regardless of commercial potential. In agriculture, the presented applications have the potential to improve crop yield, reduce the use of synthetic fertilizers and pesticides, avoid the use of toxic compounds, and promote sustainable agriculture practices. Thus, further attention must be paid to uncovering the biomolecules from fungi for agriculture and pharmaceutical applications through studying metagenomics, genomics, and proteomics.

2. Significance of Fungi in Different Sectors

2.1. Beneficial Roles

Fungi are the kingdom of those organisms whose species can populate practically all ecosystems. They are found as free-living and symbiotic unicellular or multicellular organisms and exist under varied morphologies [19]. They exist in almost all environmental types, from soil to water, and are best known for their essential roles in ecology as decomposers and symbionts. Fungi have also been used for centuries in several practices in the food and medicine fields. Recently, fungi have emerged as a valuable resource in modern biotechnology, with numerous applications across different sectors and as a sustainable candidate.

Fungi appear in various sizes, starting with microfungi such as molds and yeasts and progressing to macromyctes such as mushrooms or truffles. The macro-sized fungi are most often used for human consumption as supplements or food; on the other hand, the micro-sized fungi, including species such as Aspergillus, Penicillium, and Saccharomyces, are used for synthesizing enzymes and metabolites. According to these described abilities, fungi are considered one of the cornerstones of modern biotechnology [20].

Fungi indubitably dominate the biotechnology sphere; therefore, it is expected that their utilization is going to grow exponentially hereafter. They play a crucial role in various industrial processes, including manufacturing enzymes, pigments, vitamins, and so on [21]. Moreover, they are used to manufacture different types of food pigments such as benzoquinone (Penicillium europium), anthraquinones (Paecilomyces farinosus), melanin (Aspergillus spp.), and β-carotene (Blackeslea trispora) [8,9].

Fungi could contribute to the aspiration to develop more sustainable manufacturing to protect the environment, being an optimal candidate to produce several products such as textiles and myco-leather, biofuels, building materials, wastewater treatment, and sustainable meat substitutes [4,22,23].

Before we identifed the different fungi species and understood the definition of fungi, they had been used to produce various food in different parts of the world, such as fermented food, bread, wine, and cheese [20]. Today, a significant part of worldwide cuisine is represented by products made with fungi, usually products that result after fermentation.

2.1.1. Medicine/Health

Natural products (NPs) produced by fungi are responsible for several effects, such as antimicrobial, immunosuppressive, anticancer, antidiabetic, immunomodulatory, and anti-inflammatory effects, many of which have been developed as treatments and have potential therapeutic applications for human diseases.

NPs such as non-ribosomal peptides (i.e., penicillin produced by Penicillium rubens; cephalosporin C by Acremonium chrysogenum, pneumocandins by Glarea lozoyensis and Pezicula (Cryptosporiopsis), or ribosomal peptides (amatoxins, piperazines), polyketides, lipopeptides, lipodepsipeptides and secondary metabolites produced by fungi mediate antimicrobial resistance and virulence and act in competition against other microorganisms [24].

Regarding antibiotic production by filamentous fungi, it has been proved that they initiated the golden era of natural antibiotics in the 20th century, as a consequence of extensive antibiotic use, especially in hospital settings, with the appearance of antimicrobial resistance phenomenon in the 21st century, especially to ESKAPE pathogens (Enterococcus faecium, Staphylococcus aureus, Klebsiella pneumoniae, Acinetobacter baumannii, Pseudomonas aeruginosa, and Enterobacter species) [25].

In Table 1, we list the NPs known as antimicrobial agents produced by different filamentous fungi strains or macromycetes.

Table 1.

Antimicrobial agents produced by filamentous fungi.

| Antimicrobial Agents | Producer | Active Against | Mode of Action | References |

|---|---|---|---|---|

| Non-ribosomal peptides | ||||

| Mycophenolic acid | Penicillium brevicompactum | several species | antibacterial, antifungal, antiviral, antitumor, antipsoriasis and immunosuppressive, anti-angiogenic activities | [26] |

| Penicillin | Penicillium notatum | Staphylococcus aureus | [27] | |

| Penicillin G | P. rubens | Streptococcus, Staphylococcus, Enterococcus, Clostrodium and Treponema spp. | inhibit the peptidoglycan synthesis | [28,29] |

| Cephalosporin C | A. chrysogenum | broad spectrum antibiotic | [2] | |

| Ribosomal peptides | ||||

| Amatoxin Phallotoxin |

Amanita spp. | anticancer drugs | RNA polymerase II inhibitors | [30] |

| Ustilotoxin | Ustilaginoidea virens | cytotoxicity against different anticancer cell lines | anti-mitotic activity | [31] |

| Depsipeptides Beauvericin (A–H) Beauveriolide |

Fusarium, Alternaria, Calonectria, Cochliobolus, Cordyceps cardinalis, Ophiocordyceps communis Cordyceps militaris |

antimicrobial and insecticidal activity anti-aging activity against S. cerevisiae |

[32,33,34,35] | |

| Piperazines | ||||

| Roquefortine C | Penicillium roqueforti | acute toxicity in mice and dogs | [36,37] | |

| Gliotoxin | Aspergillus fumigatus | antifungal activity against Candida albicans and Aspergillus spp. | inhibit the activation of lymphocyte B and T | [38,39] |

| Polyketides | ||||

| Griseofulvin | Penicillium griseofulvum | dermatophytes fungal infections in humans and animals;non-fungal inflammatory diseases; cardiovascular, antitumor and antiviral applications; |

inhibit fungal cell mitosis and nuclear acid synthesis | [40] |

| Patulin | Aspergillus clavatus | mycotoxin, fungistatic activity against Rhizoctonia solani, S. cerevisiae, Didymella bryoniae, Botrytis cinerea, Fusarium oxysporum, clerotium rolfsii, Pithium ultinum | destabilization of of the plasma membrane integrity, blockage in rRNA, tRNA, and mRNA synthesis | [41,42] |

| Strobilurins | Strobilurus tenacellus, Oudemansiella mucida | antifungal activity | inhibit the transfer of electrons between complexes II and III of the electron transport chain in the mitochondria, resulting in impaired cell respiration and ATP synthesis | [43] |

| Uredinorubellin derivatives | Torrubiella spp. | antibacterial activity against S. aureus strains | [34] | |

| Rubellins antraquinones | Ramularia collo-cygni | antiproliferative, cytotoxic, aggregation inhibitory and antimicrobial activity against B. subtilis, S. aureus, S. aureus MRSA, Enterococcus faecalis clinical and reference strains | phytotoxic activity | [44] |

| Viriditoxin | Penicillium radicum | antimicrobial activity against S. aureus MRSA | inhibiting FtsZ, the bacterial tubulin | [45] |

| Lindgomycin | Lindgomycetaceae family | antimicrobial (against Gram-positive and C. albicans strains) and antiviral activity | [24] | |

| Lipopeptides | ||||

| Echinocandin B | Aspergilllus nidulans | inhibiting β (1,3)-glucan synthase | [46] | |

| Pneumocandin B0 | Glarea lozoyensis | antifungal activity against C. albicans and Pneumocystis carinii | inhibiting β (1,3)-glucan synthase | |

| Caspofungin | G. lozoyensis | blocking cell wall biosynthesis by inhibiting β (1,3)-D-glucan synthase |

[47] | |

| Micafungin | Coleophoma empetri | |||

| Anidulafungin | A. nidulans | |||

| Mulundocandin | Aspergillus sydowii |

Aspergillus niger, C. albicans, Candida non-albicans |

[48] | |

| Anidulafungin | A. nidulans |

Candida parapsilosis, Candida guilliermondii Aspergillus spp. Fusarium spp. |

||

| Rezafungin | Candida spp., Aspergillus spp., Pneumocystis murina | [48,49] | ||

| Cryptocandin | Cryptosporiopsis quercina | antifungal activity against Tricophyton rubrum, Sclerotinia sclerotiorum, Botrytis cinerea | [50,51] | |

| Lipodepsipeptide | ||||

| Aureobasidin A | Aureobasidium pullulans | fungicidal activity against Candida spp., C. neoformans, Blastomyces dermatitidis, and Histoplasma capsulatum | noncompetitive inhibition of the inositol phosphorylceramide synthase | [52,53] |

| Nucleosidic peptide | ||||

| Arthrichitin FR-90403 | Arthrinium phaeospermum and Kernia spp. | C. albicans | chitin synthase inhibitors | [54] |

| Other peptides | ||||

| Aspergillomarasmine | Aspergillus versicolor | Gram-negative rods | inhibit the NDM-1 and VIM-2 metallo-β-lactamases | [55] |

| Cyclosporin A | Tolypocladium nivenum | immunosuppressive, anti- coronaviruses activity | [56] | |

| Peptaibols | Trichoderma reesei | antimicrobial activity against Alternaria alternata, Phoma cucurbitaceum, Fusarium spp., A. fumigatus | [57] | |

| Plectasin | Pseudoplectania nigrella | Streptococcus pneumoniae | [58] | |

| Leucinostatin A | Purpureocillium lilacinum | antifungal activity against Candida spp. (including C. albicans, Candida krusei, Candida tropicalis, and C. guilliermondii); antitrypanosomal and antitumoral activities |

[59,60,61] | |

| Terpene derivated metabolites | ||||

| Enfumafungin Ergokonin |

Hormonema spp. Trichoderma spp. |

antimicrobial activity against Bacillus subtilis, Cryptococcus neoformans, C. albicans, A. fumigatus | glucan synthesis inhibitors | [62,63] |

| Antifungal metabolites | ||||

| Parnafungin | Fusarium lavarum | inhibits inhibit mRNA polyadenylation in Candida albicans and pathogenic fungi | [64,65] | |

| Other pharmaceutical agents | ||||

| Lovastatin | Aspergillus terreus | hypercholesterolemia treatment | [2] | |

| Mevastatin | Penicillium citrinum | [66] | ||

| Pravastatin | Penicillium chrysogenum | [67] | ||

| Other bioactive compounds | ||||

| Clavatol |

A. clavatus, Aspergillus clavatonanicus |

fungistatic activiy against C. albicans, A. niger, F. oxysporum, Rhizoctonia solani, Pythium ultimum, Didymella bryoniae, B. cinerea | [68] | |

| Pyranonigrins A, B, C, D, E, S | A. niger | [69] | ||

| Pyranonigrins A and F | Penicillium brocae | Antimicrobial activity against Gram-positive and Gram-negative strains | [25] | |

2.1.2. Fungi in Agriculture

Fungi can also act as biological control agents against plant pathogens. Trichoderma, for instance, demonstrated antagonistic effects against a wide range of plant-pathogenic fungi [13,70,71,72,73]. Trichoderma species have been used intensively in different biotechnological fields. Even so, they represent an outstanding contribution to agriculture because they show an excellent potential to defend against disease crops and attenuate the unfavorable conditions that can affect plant growth and stimulate plant growth [74,75,76,77,78]. These fungi are involved in biocontrol applications, versus fungi that can be plant-pathogenic, oomycetes, or nematodes [79]. Several fungi are used to control insect pests; for instance, species such as Beauveria bassiana attacks corn borer, Verticillium lecanii is known to control whitefly and aphids, and Metarhizium anisopliae are used against scarab larvae [34,80,81]. The action of the fungi is to infect the body surface, which leads to the attachment of the fungus to the integuments of the affected insect, where it will develop and continue to proliferate until the fungus entirely covers the insect [82]. Plant-parasitic nematodes depict another threat to the wellness of plants. Using fungi can be a sustainable strategy to avoid the intensive use of chemical nematicides. The leading group of filamentous fungi that were studied for the biocontrol of nematode pests is known as Trichoderma. The mechanisms involved in damaging nematodes can be found in the antibiosis (production of secondary metabolites), enzymes, or space competition [83].

The presented applications have the potential to improve crop yield, reduce the use of synthetic fertilizers and pesticides, avoid the use of toxic compounds, and promote sustainable agriculture practices. Therefore, fungi have an essential contribution to the agriculture sector, and they must be exploited [84,85,86].

2.1.3. Industry

Fungi play an essential role in the food industry. They have been used since ancient times for various purposes, such as fermentation, production of enzymes, and as a source of food.

For centuries, humans learned to select and collect several macroscopic fungi known as mushrooms. They can be wild-harvested or commercially raised, and they are rich in protein; also, they can develop on inexpensive substrates, sometimes even agro-industrial wastes [87]. The most frequently farmed species worldwide are A. bisporus, P. ostreatus, Flammulina, and Lentinula edodes, used in salads, soups, and other recipes. Many additional mushrooms are collected from the wild for personal use or sale, amongst which are king boletes, milk mushrooms, morels, chanterelles, truffles, black trumpets, and porcini mushrooms. They frequently appear in upscale cuisine [88].

Filamentous fungi have long been used to produce fermented foods such as cheese, bread, and beer. Soy sauce, miso, tempeh, mold-cheeses, and alcoholic beverages, including beer, wine, and spirits, are all products of traditional fungi and yeast fermentation techniques. Using fungi in these industries has significantly improved the final products’ quality, taste, and shelf life. One example of the use of filamentous fungi is cheese production. The first evidence of various cheese types dates from 897 for Gorgonzola, 1070 for Roquefort, and 1791 for Camembert [89]. Mold-ripening is the central aspect for an increased quality of the cheese for a reason during this process, as the flavor and consistency are improved. P. roqueforti makes blue cheese (Roquefort, Gorgonzola, Danish blue, etc.). It produces blue-green veins and gives the cheese its distinctive flavor after inoculation and growth [90]. On the other hand, Penicillium camemberti is inoculated on the surface of the cheese, and it changes the consistency—a soft texture—more than the flavor. These types of cheese are Camembert and Brie [91].

Molds have been used to manufacture fermented sausages since the Greek and Roman empires, where fermented and air-dried sausage had widespread popularity among peasants due to its long-term stability at room temperature as a replacement for refrigerators nowadays. Various types of meat, including cow, goat, horse, lamb, pork, and chicken, are used to make salami [92]. Penicillium nalgiovense is most frequently used as a starting culture when curing fermented meat products; also, the species is recognized as safe to use [93].

The potential use of fungi is great because, currently, farming is conducted at higher rates. There is a need to find other alternatives to avoid soil erosion speeding up and environmental pollution; therefore, the alternative is microorganism cultivation aiming at the production of edible biomass [94]. Quorn™ is a company with fungi-based food products producing dried fungal biomass from Fusarium venenatum. The product is a mycoprotein, low-fat, low-calorie, cholesterol-free food that is highly popular in Anglo-Saxon nations [95]. Mycoprotein is known to help against body weight issues because it gives a feeling of satiety. Therefore, an investigation of the safety of F. venenatum mycelia for human eating was conducted between 1970 and 1980 following the isolation and subsequent suitability testing of F. venenatum (at that time, still known as F. graminearum). The potential for the fungus to create mycotoxins was a significant worry, as many Fusarium species are notorious for producing these toxins due to their role as phytopathogens [77,96].

For the production of Japanese traditional goods, such as seasonings or alcoholic drinks (soy sauce, miso, soju), Aspergillus oryzae is the predominant species used in fermentation processes. Starting in China between 3000 and 2000 years ago, koji became a popular item in Japan with the purpose of a starter for secondary fermentation [97]. Applying A. oryzae spores to heated rice produces koji. The resulting mixture is combined with soybeans or other steamed rice, water, and yeasts to ferment. Besides A. oryzae, other filamentous fungi are used to make koji, such as Aspergillus sojae, Aspergillus kawachii, and Aspergillus awamori [98].

Manufacturing alcoholic beverages such as wine and beer is another common usage of the fungal species in the food industry. For example, Botrytis cinerea, a plant-pathogenic fungi, is exploited in southern France and other locations to increase the sugar level in grapes before harvesting, producing “noble rot,” a sweet and premium wine [99]. For centuries, mankind has used Saccharomyces yeasts to make beer, bread, and wine. Since high quantities of ethanol harm most other bacteria, yeasts have historically been utilized as efficient methods to protect food and beverages’ nutritional value and security. The most well-known among all the beneficial yeasts is S. cerevisiae. It can be utilized to make wine, beer, and bread. Additionally, kefir is created by the symbiotic relationship between bacteria and Saccharomyces yeasts [100].

One of the numerous beneficial features of fungi is the synthesis of fungal enzymes and organic acids. Cellulase (Penicillium funiculosum, Trichoderma viride), α-amylases and invertase (A. niger, A. oryzae), proteinases (A. oryzae), and citric acid (A. niger) can be listed among them.

Several fungal species have been used regarding food processes since the beginning of agriculture. Fungal biodiversity is undoubtedly an important provider of resources for food as well as other higher value uses.

In the present, society confronts many manufactured challenges, among which high pollution levels or the lack of nutritional resources to support population growth occupy a central position [101,102]. The transition to a zero-carbon sustainable bioeconomy is the only direction that offers humankind the possibility to address these challenges, and it involves the transformation of a linear economy into a sustainable circular economy. Microorganisms are critical players in the circular economy since they harbor many intrinsic characteristics that recommend them for biobased industrial applications [23,102]. Among microbial strains with industrial potential and a high impact on the circular bio-economy, fungal strains have the unique metabolic ability to convert many organic materials (including wastes) into various by-products relevant to different industrial applications [23].

Metabolites Produced by Fungi with Industrial Applications

Different chemical compounds with industrial applications, such as organic acids, enzymes, flavors, vitamins, and colorants, might be obtained more cost-efficiently using fermentation processes based on fungal strains [103].

Organic acids are used in the food industry mainly as acidulants, flavoring agents, or preservatives, but their biotechnological potential is not limited only to the food industry. Citric acid is a weak organic acid highly demanded worldwide, especially in the food and pharmaceutical industries. The bioproduction of citric acid comprises the traditional process of industrial-scale fermentation. Among the most common organic acids used in industry is citric acid, which has a variety of uses, and the global market for 2025 is estimated at USD 3.6 billion [104]. Besides the use in food and beverage industries, the mentioned organic acid is utilized in pharmaceutical, cosmetic, and detergent industries [104]. Karl William Scheele is recognized for the isolation of citric acid for the first time from lemon juice in 1784. James Currie discovered in 1917 that A. niger could create citric acid from sugar using the surface fermentation method, which later served as the foundation for Aspergillus’s application in industrial production. Because of its higher production yield, A. niger is better than other microorganisms for the industrial synthesis of citric acid. It provides excellent yields, can ferment a variety of inexpensive basic materials, and is simple to handle [105].

In the food and beverage industry, it is used as a preservative or as a flavors and aromas enhancer, for preventing the deterioration of frozen food products or for the development of non-toxic plastic films for foodstuffs protection, and also as an emulsifying agent for ice cream and cheese-based food products [106]. In the pharmaceutical industry, as an antioxidant, citric acid is used to preserve vitamins, as a pH buffer, and in association with other chemicals such as iron (as iron citrate tables) or for the development of citrate-based biomaterials with potential use for regenerative engineering [107,108]. Other possible applications of citric acid are for the chemical industry, mainly for producing conditioners and laundry detergents or as chelating agents in cleaning solutions used for removing limescale [106,109,110]. Every year more than 6 million tons of citric acid are used for beverages, food, detergents, cosmetics, and pharmaceutical production. High quantities of citric acid are assured using the fungal submerged fermentation of sucrose and molasses or synthetically from acetone or glycerol. Numerous Aspergillus strains belonging to A. niger, A. awamori, Aspergillus foetidus, Aspergillus wentii, Aspergillus aculeatus, Aspergillus carbonarius species or T. viride, Penicillium restrictum, and Mucor piriformis are currently evaluated as being good producers of citric acid [103,105,111]. However, among them, A. niger is considered most suitable for industrial production due to its high ability to assimilate and ferment many cheap agro-industrial derived materials, and thus it is a cost-effective technology [105]. Among cheap agro-industrial wastes used for citric acid production using A. niger, it is worth mentioning pineapple peels [112]; apple processing wastes [113]; banana peels [114]; cocoa pod and coffee husk processing wastes [115,116] or sweet potato starch hydrolyzate [117]. Gluconic acid is another highly valuable organic acid for the food industry, which can be obtained using fungal fermentation [103]. Gluconic acid is a mild organic acid frequently used to pickle foods, prevent milkstone in the dairy production industry, or for clean cans used in these circumstances. Gluconic acid derivatives such as D-glucono-δ-lactone are important as leavening agents for preleavened products, for reducing fat absorption in doughnuts, for the coagulation of soybean proteins in tofu manufacture, and for improving the heat stability of milk [118,119]. Gluconic acid salts (sodium gluconate, calcium gluconate, ferric gluconate) have a broadened industrial potential from metallurgy where they can act as alkaline derusting agents and anticorrosive agents to use as additives to cement [120,121]. Calcium and iron salts of gluconic acid have important biomedical potential, being used for calcium therapy for osteoarthritis [122] and the treatment of anaemia [123], and they also can be used in animal feed [124] or in agriculture as foliar feed formulations [118]. Annually, more than 60 thousand tons of gluconic acid and its derivatives are produced worldwide through various chemical, electrochemical, or fermentation processes. By far, fermentation is considered the most efficient and dominant technique that can be used to obtain gluconic acid. Among the microbial strains involved in gluconic acid production through fermentation, A. niger, Penicillium funiculosum, Penicillium variable, Penicillium amagasakiens, and members of Glicladium, Scopulariopsis, Gonatobotrys, and Endomycopsis genera are well known [118]. A. niger is considered a main fungal species that can produce gluconic acid at an industrial level. Members of this species produce all the enzymes involved in converting carbohydrates, such as glucose, into gluconic acid. Since industrial production requires the reduction of costs, a strategy presented in the scientific literature was to replace the substrate represented by glucose with cheaper raw materials such as breadfruit hydrolysate [125], grape must [126], waste office paper hydrolysate [127], whey [128], dry dilute acid pre-treated corn stover [129], corn starch [130], sugarcane molasses [131], or banana must [119].

Apart from citric and gluconic acids, fungi are also used for obtaining other organic acids such as itaconic, lactic, fumaric, malic, succinic, and oxalic acids, but to a lesser extent [103]. Itaconic acid has been commercially available since the mid-twentieth century, significant for the industrial production of adhesives, detergents, and shampoo formulations. More than that, its vinyl esters are relevant for producing plastics, elastomers, and coatings with light colors for carpets and book covers [132]. For the biomedical field, itaconic acid is used for ophthalmic, dental and drug delivery fields [133,134]. A. terreus and Ustilago maydis species are considered model organisms for producing itaconic acid. They are also characterized by outstanding tolerance to acidic pH values. However, apart from them, other fungal species such as Ustilago vetiveriae, Ustilago xerochloae, or Aspergillus niveus were described as being able to produce this organic acid. As an alternative growth substrate for the production of itaconic acid using fungi, it is worth mentioning enzymatically digested wood chips [135], corn stover hydrolysate [136], pre-treated rice husk [137], sweet potatoes, wheat flour, corn starch [138] beech wood [139,140], and glycerol [141]. Lactic acid is widely used in the food industry as a preservative (preventing the proliferation of spoilage microorganisms) and for the production of yogurt and cheese (involved in decreasing pH and casein aggregation) [142]. Apart from the food industry, lactic acid is a precursor for propylene glycol and acrylic polymers that can be used to develop biodegradable packaging and labeling materials [143,144] and also for biomedical prosthetic devices or sutures [145]. Although it can be obtained through chemical synthesis, the main advantage of fermentation processes for obtaining lactic acid for the food industry is that selecting the right microbial strain can yield a pure form of L(+)-lactic acid, which is preferred since it is not harmful to humans [146]. Usually, lactic acid bacteria are preferred for lactic acid production, but since this group of microorganisms exhibits special nutritional requirements, fungal strains represent a cheaper yet productive alternative. Rhizopus spp. represents the most critical fungal genera that can be used for lactic acid production. Members of this genus have the advantage of producing only L-lactic acid isomers, thus reducing the cost associated with the purification of the fermentation products. Although glucose is preferred as a carbon source for producing lactic acid using Rhizopus strains, other substrates such as raw starch from potatoes, cassava, wheat, corn, and rice wastes [147,148,149,150] or lignocellulose wastes [151,152,153] can contribute to cost reduction [146]. Malic and fumaric acids are other valuable organic acids that can be obtained using fungal strains. Their industrial applications vary from the manufacture of chemical products such as resins, biodegradable polymers, lubricating oils, inks, plasticizers, or lacquers to the production of food and pharmaceutical additives (acidulants, flavor enhancers, precursors for malic or aspartic acid) or drugs (including those with antimicrobial properties, antioxidant, and anticarcinogenic effects) [154]. Fungi species such as Rhizopus arrhizus, Rhizopus oryzae, Mucor spp., Cunninghamella spp., or Aspergillus spp. are presented as good producers of fumaric acid, both through aerobic and anaerobic fermentation, while for malic acid good results are reported for A. oryzae, A. niger and Aureobasidium pullulans [155,156,157]. Good yields of fumaric acid production were obtained using different substrates for fungal biomass accumulation, of which it is worth mentioning: apple industry waste biomass [158] or different food wastes disposed by restaurant, kitchens, and cafeterias [155,159,160].

Filamentous fungi are also used for producing enzymes at large scales. Their versatile metabolism assures obtaining large quantities of amylases, proteases, pectic enzymes, galactosidases, lipases, chitinases, or lignocellulolytic enzymes.

Amylases with biotechnological importance are extracellular enzymes involved in starch degradation. These enzymes represent approximately 25% of the world enzyme market, relevant to many industrial processes such as those in the food, fermentation, textile, paper, and pharmaceutical industries (Table 2). Three types of amylases are produced using microbial strains: α-amylases, β-amylases, and γ-amylases. α-amylases or endo-1,4-α-D-glucan glucohydrolase (EC 3.2.1.1) catalyze the hydrolysis of random 1,4-α-D-glycosidic bonds between glucose units from short linear amylase chains [161]. Unlike these, the β-amylases or β-1,4-glucan maltohydrolase (EC 3.2.1.2) are responsible for the hydrolysis of the second 1,4-α-D-glycosidic bond from the non-reducing end of the starch molecule, thus producing disaccharides such as maltose.

On the other hand, γ-amylases and glucan 1,4-α-glucosidase (EC 3.2.1.3) are usually highly stable enzymes in acidic conditions, and these enzymes are mainly responsible for the cleavage of 1,4-α or 1,6-α-D-glycosidic bonds on the external glucose residues of amylose or amylopectin from the non-reducing end, thus producing only glucose [162]. The industrial production of amylases usually involves submerged fermentation, but recently solid-state fermentation has received greater interest due to its superior productivity, reduced energy requirement, and simpler fermentation media. In addition, many studies have reported the optimal production conditions of fungal amylases in terms of the cultivation conditions (pH, presence of different inhibitors, temperature a.s.o) and the substrate used to obtain the biomass (Table 2).

Proteases constitute a large group of enzymes responsible for hydrolysis peptide bonds. In general terms, according to the position of the cleaved peptide bond, proteases can be divided into two major groups: endopeptidase and exopeptidase. Fungal strains can produce both types of protease, thus having great importance for their production. Fungal proteases can be obtained using both submerged fermentation and solid-state fermentation. Both options seem more advantageous in fungi than other protease-producing organisms (microbial or not) [103,163]. Among the protease-producing fungi, thermophilic fungi such as Thermoascus aurantiacus [164] or Thermomyces lanuginosus [165] are of great interest since they possess the ability to secrete thermostable proteases that act in the temperature range 60–85 °C.

Pectinase, in general terms, refers to a group of enzymes that catalyzes pectic substance depolymerization (pectin hydrolases and lyases) and de-esterification (pectin esterases). Pectinase represents approximately 10% of the overall production of enzymes, and its utilization is highly valuable for the food industry, but not only. Microbial pectinases, in general, are relevant for the natural carbon cycle involved in the decomposition of dead plant material. However, for the producing microorganism itself, these enzymes represent a tool in the phytopathologic process and plant-microbe symbiosis [166]. Either way, pectinase can be successfully used in the industry for various applications (Table 2).

According to their substrate specificity, the galactosidases are glycoside hydrolases classified as α-galactosidases or β-galactosidases. α-Galactosidases (EC 3.2.1.22) catalyze the removal of α-linked terminal non-reducing galactose residues from small oligosaccharides. This enzyme is also responsible for the cleavage of α-1,6 linkage between galactose and glucose in melibiose. α-Galactosidases have proven helpful in the food and feed industry, mainly increasing the sucrose yield by eliminating raffinose [167]. β-Galactosidase (EC. 3.2.1.23), also known as lactase, is responsible for the hydrolysis of D-galactosyl residues from polymers. Fungal β-galactosidases are highly stable to acidic pH, thus being an excellent instrument for whey reintegration into the economic circuit [168,169,170].

Chitinases (EC. 3.2.1.14) are enzymes responsible for chitin—the second-most-abundant polymer found in nature—degradation. Fungi are the most important group of microorganisms able to produce and secrete chitinase. Fungal chitinases are the only enzymes that can efficiently degrade chitin by hydrolyzing chitin to form chito-oligosaccharides with a minimum chain length of two carbon atoms [171]. Apart from their involvement in fungal morphogenesis, cell division, mycoparasitism, and autolysis, from a biotechnological point of view, chitinases are essential for the functional reintegration of chitin trapped in the biomass in the economic circuit [172].

Lipases (EC. 3.1.1.3), or triacylglycerol hydrolases, catalyze glycerol and fatty acids hydrolysis. It was also noticed that their processes, including the extraction and purification of lipases from fungi, are comparatively more accessible and cheaper than other sources of lipases. Fungal lipases have applications not only in the hydrolysis of fats and oils (triglycerides) but are also involved in synthetic reactions such as esterification, acidolysis, alcoholysis, interesterification, and aminolysis. Although some fungal species produce intracellular lipases, most can secrete this enzyme outside the cell. Major genera of filamentous fungi capable of producing lipases are Rhizopus, Aspergillus, Penicillium, Mucor, and Geotrichum, and the lipases produced have special biotechnological applications that are intensively studied both from a functional and genetic point of view [173,174].

Lignocellulolytic enzymes are involved in lignocellulose degradation, and this group of enzymes includes ligninases, hemicellulases, and cellulases. Ligninases are responsible for deleting lignin into more minor compounds that microorganisms can assimilate. In general, ligninases can be divided into laccase or phenol oxidase and peroxidases or lignin peroxidases. Laccases (EC 1.10.3.2), or p-diphenol: dioxygen oxidoreductases, are the enzymes responsible for the attack of the phenolic subunits of lignin leading to Cα-Cβ cleavage and aryl-alkyl cleavage [175]. Lignin peroxidase (EC. 1.11.1.14), or diaryl propane oxygenase, is a heme-containing enzyme that catalyzes lignin’s hydrogen peroxide-dependent oxidative degradation. These enzymes belong to the oxidase group and are mainly used for reducing environmental pollution. Ligninases are widely found in nature and produced by various plants, fungal species, or bacteria. Among fungal species, white rot fungi are the best ligninases producers, and their biotechnological and industrial potential has been intensely studied in recent decades [176]. Cellulases are a group of enzymes that contain endoglucanase (EC 3.2.1.4), exoglucanase (EC 3.2.1.91), and β-D-glucoside glucanhydrolase (EC 3.2.1.21). Among the microorganisms, fungi are the principal cellulose decomposers, responsible for about 80% of the cellulose breakdown on earth. In industry, fungal cellulases are usually preferred, being much easier to be obtained in large quantities. Fungal species, including T. reesei, Rasamsonia emersonii, Aspergillus spp., and Penicillium spp. produce extracellular cellulases during their growth in aerobic conditions, and thus are promising candidates for various industrial applications [177,178].

Table 2.

The most common filamentous fungi enzyme producers and their applications in industry.

| Enzymes | Fungal Species | Non-Conventional Growth Substrates | Applications | References | ||

|---|---|---|---|---|---|---|

| Amylases |

A. niger A. oryzae A. fumigatus Aspergillus flavus; A. awamori; A. kawachii; Penicillium brunneum; Penicillium expansum; P. roqueforti; P. camemberti; Helminthosporium oxysporum; Penicillium frequestans P. chrysogenum Penicillium fellutanum |

Coconut oil cake; groundnut oil cake; sesame oil cake; olive oil cake; wheat bran; corncob leaf; rye straw; wheat straw; banana waste; residues obtained from rice husking; cassava peels; yam peels; pomegranate peel; molasses |

|

[161,162,179,180,181,182,183,184,185,186] | ||

| Proteases |

A. flavus; Aspergillus ochraceus Conidiobolus coronatus; Rhizomucor miehei; Endothia parasitica; Mucor circinelloides; Mucor pusillus; P. camemberti; P. citrinum; Penicillium griseoroseum; Penicillium restrictum; P. roqueforti; A. flavus; A. oryzae; A. niger; R. oryzae; T. reesei; Trichoderma harzianum |

Wheat and rice bran, soybean meal; oil seed cake |

|

[49,163,187,188,189,190,191,192,193,194,195] | ||

| Pectinase |

A. niger

A. flavus A. sojae A. terreus Alternaria citri Claviceps purpurea Fusarium moniliforme Botrytis cinerea A. kawakii Thermoascus aurantiacus Acrophialophora nainiana Aspergillus japonicus |

Wheat bran; rice husk and bran; papaya peel; mango peel; sugarcane bagasse; sunflower head; grape and strawberry pomace |

|

[166,196,197,198,199,200,201,202,203,204] | ||

| Galactosidases | α-Galactosidases |

Mortierella vinaceae

Tricholoma matsutake A. niger A. oryzae A. fumigatus |

Soybean meal and wheat bran red gram plant waste; soy flour |

|

[101,102] | |

| β-galactosidase |

A. niger

A oryzae A. flavus Aspergillus uvarum P. brevicompactum F. oxysporum |

Lemon peel, pineapple peel, musk melon peel, banana peel, musambi peel, pomegranate peel, orange peel; soybean residue, okara, soymilk; wheat straw, rice straw, and peanut pod |

|

[168,205,206,207,208,209] | ||

| Chitinases |

Thermomyces lanuginosus; T. viride; T. harzianum; A. nidulans, A. fumigatus, P. chrysogenum |

Wheat bran; rice bran; chitin flakes; waste products obtained from crabs, shrimps and prawn |

|

[171,210,211,212,213,214] | ||

| Lipases |

Mucor circinelloides

Penicillium aurantiogriseum Rhizopus rhizopodiformis Rhizomucor pusillus Rhizopus oligosporus P. restrictum Penicillium simplicissimum Aspergillus carneus Penicillium verrucossum P. chrysogenum A. awamori A. terreus Fusarium solani |

Soya bean oil; olive oil cake; babassu oil cake Almond meal; mustard oil cake, sunflower oil; soybean bran; rice bran oil; olive mill wastewater |

|

[215,216,217,218,219,220,221,222,223,224] | ||

| Lignocellulolytic enzymes | Cellulase |

A. niger

T. reesei Aspergillus heteromorphus A. fumigatus R. oryzae |

Wheat straw and bran; maize straw; banana peel Coir waste; grass; sugarcane bagasse; corn cob residue |

|

[225,226,227,228,229,230] | |

| Ligninanses | Laccases |

Aspergillus niveus

Rhizoctonia solani B. cinerea Myceliophthora thermophila Pycnoporus cinnabarinus Trametes villosa Coriolopsis gallica Coprinopsis cinerea |

Wheat bran, rice husk, mango peel, orange peel, groundnut husk and saw dusk |

|

[175,231,232,233,234,235,236,237,238] | |

| Peroxidases |

Phanerochaete chrysosporium; A. sclerotiorum Cladosporium cladosporioides M. racemosus Neurospora discreta |

Cocopeat, sugarcane bagasse |

|

[239,240,241] | ||

Pigments: Filamentous fungi are also known for their ability to produce natural pigments with a high potential of replacing artificial synthetic dyes. Even today, synthetic colorants are widely used in foodstuff, cosmetics, pharmaceutical, and textile manufacturing, but some are hazardous to human health. In this context, there is a strong interest in replacing these colorants with their natural alternative [242]. Fungal pigments are an excellent alternative to synthetic dyes, which are easy to obtain and less expensive [243]. Many fungal species of Aspergillus, Fusarium, Penicillium, and Trichoderma genera produce large amounts of pigments during their growth. Fungal pigments are classified into polyketides, polyketide-derivates, carotenoids, and melanins [242]. Polyketide pigments have a polyketide chain with four or eight C2 units, and in this group are included secondary metabolites such as anthraquinone, hydroxyanthraquinones, naphtoquinone, and azaphilone. These compounds are responsible for a wide range of colors from yellow to red and even blue shades [244] and are successfully used for textile dyeing and as antibacterial agents. Polyketide pigments-producing fungi mainly belong to Fusarium sporotrichioides, Penicillium spp., Aspergillus ustus, and Monascus purpureus, and their potential utilization in the benefit of humankind varies from developing anti-aging, anti-acne, and skin-whitening agents to anticancer drugs [245]. Some species of fungi are used in the production of pigments, such as Monascus species, which produce red, orange, and yellow pigments used as natural colorants in the food, cosmetic, and pharmaceutical industries, as well as the dyeing, textile, and printing domains [246]. Carotenoids are tetraterpenoid pigments comprising xanthophylls and carotenes. In this class of natural pigments, more than 750 chemical compounds are included; among them, most important is β-carotene, a vitamin A precursor and a vital antioxidant agent. It is used as an orange-red pigment in the food industry and is mainly produced by Blakeslea trispora strains [103]. Other carotenoid-producing fungi belong to Aschersonia aleyrodis; Aspergillus giganteus; B. trispora; F. fujikuroi; M. circinelloides; B. trispora; Sclerotinia sclerotiorum; Fusarium sporotrichioides; Phycomyces blakesleeanus; Neurospora crassa; Puccinia distincta and Allomyces arbusculus [247]. At the industrial level, B. trispora is widely known, with members of this species being used to produce β-carotene [245]. More than that, fungal carotenoids can be obtained in a cost-efficient manner using alternative growth substrates such as waste cooking oil [248], deproteinized hydrolyzed cheese waste [249], or oat flakes/spent malt grain [250]. Melanins are dark brown or black pigments widely found in animals, plants, and microorganisms. From an industrial point of view, fungal melanins have gained significant interest in the last decades, being eco-friendly and biodegradable. According to their chemical structure and precursors involved in their biosynthesis, fungal melanins are classified into five main groups: eumelanin, 1,8-dihydroxynaphtalene melanins, pyomelanin, pheomelanin, and glutaminylhydroxybenzene melanin [251]. Being extremely diverse from a chemical point of view, fungal melanins positively impact biomedicine; the dyeing industry; the food industry for developing new packaging materials; for cosmetic industry; and environmental protection a.s.o [252].

2.1.4. Fungi and the Environment

Currently, concerns about environmental safety are emerging since there are issues relating to pollution and toxic wastes. Therefore, there is a need to develop new strategies to sustain the environment’s health. Fungi are an integral part of the environment and play essential roles in many ecosystems. Besides the impact on nutrient cycling, decomposition, and soil health, fungi exhibit great potential for developing strategies that enhance environmental protection. For instance, in the fight against pollution, climate change, and various other issues, fungi are quickly surfacing as essential protagonists, involved in practices such as the bioremediation of pharmaceutical compounds, agricultural wastes, or degradation of various pollutants.

Mycoremediation is mediated by two mechanism types: enzymatic (fungal secreted enzymes) and non-enzymatic (adsorption of toxic compounds inside the cell wall, biosurfactants production) [253]. For example, filamentous fungi belonging to the Trichoderma, Penicillium, and Aspergillus genera are able, through absorption mechanisms, to absorb heavy metals such as copper and cobalt [254].

A study by Asemoloye et al. established that two fungal strains belonging to Mucor irregularis and A. oryzae, isolated from oil-contaminated places, could be used to clean up the soil after hydrocarbon contamination. Moreover, the two fungi displayed a remarkable capacity to degrade hydrocarbons [255].

Filamentous fungi are highly efficient in the process of decolorization. There is evidence that filamentous fungi produce the enzymes laccase and manganese peroxidase to achieve this. By converting complex synthetic dye molecules into non-colored, safer, and environmentally secure structures, fungal laccases were widely used for bioremediation [253]. It has been demonstrated that microorganisms exploit agricultural waste, specifically cellulose—the most renewable source of biomass in the biosphere—to produce valuable goods, such as sugars, cheap energy resources, and enzymes. Waste products from industry and agriculture are some of the things that pollute the environment [228]. Their transformation into beneficial products might lessen the issues they create. These wastes, including grains, leaves, corn cobs, and other materials, are underutilized.

As mentioned in the previous section, fungi can secrete cellulase, enzymes responsible for breaking down the cellulose in agricultural wastes into simple glucose molecules. Cellulolytic fungi, including Chaetomium, Fusarium, Myrothecium, and Trichoderma, produce celluloses through cellulolysis [256].

Another way to save the environment is using renewable energy from living organisms, known as biofuels. Biodiesel production was greatly enhanced by cultivating filamentous oleaginous fungi with lignocellulosic biomass, such as Mortierella isabellina and Aspergillus terreus [257]. A second way to produce biofuels is to develop bio-ethanol. Biomass of crops from grains and corn, rich in sugar and starch, is the base of bio-ethanol production. Filamentous fungi can convert sugars to ethanol. The pre-treatment of the biomass is realized with the aid of fungi and lignin-degrading enzymes (pectinases, xylanases, mannanases). Pre-treatment methods can improve enzyme cellulose availability during enzymatic hydrolysis, which converts sugars into fermented ethanol [258].

Utilizing biofuels is an excellent alternative to diminish the use of petroleum oil, which leads to reducing carbon dioxide emissions, air pollution, and a safe environment.

The additional use of fungi to enhance environmental wellness is described by a new strategy named mycofiltration. Mycofiltration, or the process of treating contaminated water by passing it through a network of fungal mycelium, is one way that fungi are used in mycoremediation [259]. For example, a preliminary study by Taylor and their team proved the use of basidiomycete Stropharia rugoso-annulata as an adjuvant to improve synthetic stormwater Escherichia coli removal through wood chips [260].

2.1.5. Research

In order to facilitate the study of particular biological phenomena, yeasts and filamentous fungi are used as research model organisms. Studies on these fungi provide relevant biological insights into other organisms, such as genetics, cell biology, meiosis, and pathogenesis. Yeasts and filamentous fungi are fascinating lower eukaryotes involved in understanding cellular processes. Their advantages are that they are easy to grow on inexpensive media and have easy access to molecular and classical genetics. The fact that fungi are more closely related to animals than plants underscores these organisms’ value as convenient models of human cells [261]. Fungi provide an excellent model for understanding the structure and function of chromatin in both actively transcribed regions (euchromatin) and transcriptionally silent regions (heterochromatin). Saccharomyces and Aspergillus are among the most prevalent fungi preferred by geneticists and molecular developmental biologists, but the first species used was Neurospora. Learning about epigenetic phenomena in other systems without the filamentous fungus N. crassa would have been challenging or impossible. S. cerevisiae, for instance, does not have the same characteristics in Neurospora, including DNA methylation and unique RNA interferences that act in mitotic and meiotic cells. Moreover, it contains an (RNAi)-based silencing system [262].

The initial usage of fungi for nanotechnology applications dates back to the early 2000s, making fungal nanotechnology a relatively new field of study. For example, palladium is a precious metal frequently used in catalysis, and in 2002, researchers at the University of California, Riverside, reported synthesizing palladium nanoparticles using a fungus called N. crassa. It has now been proven for the first time that fungi can operate as biological factories to create nanoparticles with distinct features. Since then, fungal nanotechnology has proliferated and has a wide range of potential uses, including the production of antibacterial agents, biosensors, and drug delivery systems. In addition, researchers are investigating methods to create various nanoparticles with varying shapes, sizes, and surface qualities utilizing several fungal species, including Aspergillus, Fusarium, and Trichoderma [263]. Apart from S. cerevisiae, many other yeast species, such as Kluyveromyces (K. marxianus and K. lactis); Pichia (Pichia pastoris renamed Komagataella phaffii, Pichia anomala renamed Wickerhamomyces anomalus); Hansenula polymorpha (renamed Ogataea polymorpha) and Yarrowia lipolytica were described as suitable research models, especially for biotechnological studies. Members of K. marxianus species are Crabtree-negative, can metabolize a broad spectrum of low-cost feedstocks such as whey and dairy industry wastes, and presents an exceptional ability to grow at elevated temperatures, thus being helpful in their use as a versatile host for a wide range of applications in the food, feed and pharmaceutical industries [264,265]. Y. lipolytica is considered a real industrial workhorse—the most extensively studied non-conventional yeast. Members of this species are strictly aerobic and are used to produce a variety of industrially important metabolites such as lipids, biosurfactants, and enzymes. Additionally, Y. lipolytica was used as a research model for dimorphism studies in yeasts and as a popular system for expressing heterologous proteins [266,267]. K. phaffii was recognized as an important host for the industrial production of heterologous proteins due to its possibility to run high-density fermentation associated with high secretory efficiency and its specific eukaryotic post-translational modifications [268].

2.2. Damaging Effects

2.2.1. Etiological Agents of Diseases in Plants, Animals and Humans

The pathogenic potential of microorganisms, in general, is described as their ability to invade the host and produce toxic compounds that affect the well-functioning host. Although fungi are widely spread in the environment and co-exist with many organisms, in certain circumstances, fungi, like any other microorganisms, can harm their host. Fungi are characterized by high resilience in stressful conditions and a unique ability to adapt to different environments. Infectious fungi can spread through the air and water and be transmitted by different carriers such as animals, humans, or plants [18]. Regarding the interaction of fungi with plant organisms, more than 80% of the plants from our planet are symbiotic with fungi. However, some of the fungal strains can sometimes enter inside plants through damaged leaves and stomata, thus turning themselves into plant pathogens with a high impact on plant health. Plant fungal pathogens can be classified into biotrophs, hemibiotrophs, and necrotrophs, according to the mechanism involved in pathogenicity and the time required for complete host damage [269].

Necrotrophic fungi infect many hosts and can produce and secrete large hydrolytic enzymes that degrade plant cell walls. Thus, their pathogenic effect is rapid, causing the host’s death [270].

Both biotrophic and hemibiotrophic fungi require living plant tissue for their development, so their negative impact is much slower than necrotrophic fungi. Biotrophic fungi interact with the living host via special haustoria hyphae and can secrete specific molecules that suppress the plant’s immune system. The invasion of the plant organisms is assured by appressoria, which is involved in the attachment of the fungus to the substrate, allowing the cell wall penetration using mechanical force followed by affecting the plant’s normal metabolism by taking its nutrients [271]. Hemibiotrophic fungi combine both biotrophic and necrotrophic invasion mechanisms. First, these fungal pathogens invade the plant organism through mechanisms similar to those described for biotrophic fungi, followed by a necrotrophic phase that ends with the death of the affected plant [269,271]. Although tremendous progress has been made in recent decades to prevent and combat the fungal contamination of crops, devastating crop yield losses are still a significant problem. Therefore, many fungal species were described as phytopathogens associated with significant economic losses. Members of the Botrytis genus include pathogens of monocotyledons and dicotyledonous plants. Among the 22 species of Botrytis, B. cinerea is considered the most damaging, being able to infect numerous hosts [76,267]. The other 21 species have a narrow host range, especially infecting monocotyledonous plants. Gray mold is the most common disease caused by B. cinerea, affecting the mature or senescent tissue of the dicotyledonous host. Usually, the contamination occurs on the field, but severe damage is caused during storage in an improper condition of crops [272,273,274]. B. cinerea routes of infection vary according to the plant species and the environmental conditions. In general, B. cinerea conidia attach to the plant surface and germinate. Later it forms germ tubs that differentiate simple appressoria and infection cushions, structures involved in host penetration. Many models for the establishment of B. cinerea were presented. However, in general, after host invasion, the fungi produce specific molecules to suppress the death of host cells, which allows the fungi to accumulate enough biomass. After that, the fungus replaces autophagy-suppressing molecules with proteins that promote the plant’s ability to secrete enzymes involved in apoptosis, thus leading to the plant tissue’s death [275]. Cladosporium fulvum is responsible for tomato leaf mold, a common disease affecting production. The disease is associated with the exposure of tomato plants to high temperatures and humid environments, which promotes the growth of the pathogenic fungus. Usually, leaves are the main organs infected, and after contamination on the foliar surface appears, irregular chlorotic spots and the leaves edge becomes curly and wilted [276]. C. fulvum is a biotrophic fungus belonging to the Dothidiomycete class. Its infectious cycle starts with the germination of the conidia and the development of hypha, which enters the host through open stomata. Within two weeks, C. fulvum produces many conidiophores that block the stomata and cause leaf necrosis [273]. The Magnaporthe grisea species complex includes many fungal species responsible for causing disease in grass and sedge crops such as rice, wheat, barley, maize, oats, and finger millet. Magnaporthe oryzae occupies a central position among members of this group since it is a hemibiotrophic ascomycete known as the etiological agent of rice blast disease. This fungus mainly affects the rice plant’s aerial parts, leading to leaf, collar rot, and node blasts [277]. When invading the host, M. oryzae conidia develop melanized appressorium penetrating the rice cell wall through mechanical pressure. After that, the primary hyphae spread through plant cells and form a complex structure responsible for the secretion of effectors that suppress the plant’s defense responses. In time, the fungus changes its metabolism, secreting other toxins responsible for inducing the death of the plant tissue [273]. Another fungal species considered phytopathogenic is Ustilago maydis. Members of this species are also biotrophic plant pathogens responsible for causing corn smut disease. In this case, rapid proliferation is triggered after invading the host, which is associated with the development of tumors. Although this species has fewer damaging crops, U. maydis is considered a prime model organism for smut fungi characterized by a biphasic life cycle. The triggering of the pathogenic character is associated with the formation of diploids due to the mating of haploid cells that have contaminated the host plant [278]. Mycosphaerella graminicola (Septoria tritici) is responsible for septoria tritici blotch (STB), the most important foliar disease of wheat, which is associated with necrotic lesions on leaves and stems [279]. Members of this species are well characterized regarding their pathogenic character. This pathogen is spread by wind, and its propagation is ensured by both sexual ascospores and asexual pycnidiospores [280].

As mentioned before, the pathogenicity of a microorganism is strongly influenced by the affected host. Therefore, when an organism is analyzed as a potential host for microbial infections, it must be taken into account that in terms of intracellular organization, there are some similarities between plant and animal cells (organelles with similar or standard functions, cytoskeleton elements a.s.o), but the differences between them are that they are significantly more numerous when discussing the cell wall or the cell membrane. More than that, in the case of multicellular organisms, the plant cellular immune systems are entirely different from those of animals. In these circumstances, plant and animal pathogens have a divergent evolution that allows them to adapt to the conditions encountered in the infected organism [245].

Despite their divergent evolutionary pathways, there are some pieces of evidence that phytopathogenic fungi can cause infections in humans or animals. A good example is supported by another Alternaria species, Alternaria alternata, which is a phytopathogenic fungi [281]. In addition, Alternaria infectoria, a fungal species responsible for causing severe blossom blight [282], might also be involved in causing phaehyphomycosis after renal transplant [283]. Other examples are the members of the Cladosporium genus, which were isolated both from infected plant and animal hosts [18,284,285,286].

Among the numerous amounts of different types of fungi, only a tiny percentage of these species are responsible for human infections or diseases. However, these pathogens cause various infections, starting from affecting internal organs to superficial infections of the skin and mucosal surfaces, allergies, and mycoses, and are more likely to arise in immunocompromised people with weakened immune systems [287,288]. Since the human body temperature is a significant barrier to fungal development, only a few fungi are potentially harmful organisms. Therefore, they are frequently seen outside the human body, such as ringworm or athlete’s foot [289].

The most common fungal infection is represented by fungal nail infection. The principal fungi responsible are fungi from the genera Trichophyton and Microsporum. This infection enters the nail bed and diffuses into the margins on the sides of the upper side of the nail, causing the nail to develop a white surface, discoloration, and thickening. In addition, this infection causes the skin around it to become scaly. Chlorazol Black E is used in microscopic and staining procedures to identify the onchomycosis. Chemical remedies or surgery are both options for treating nail infections. Terbinafine and itraconazole are just a few medications used to treat onchomycosis. However, they all have some adverse side effects. The typical infection is athlete’s foot, mostly in wet areas [290].

Cryptococcus neoformans, a fungal pathogen, can cause fatal fungal pneumonia and meningitis among immunocompromised patients. Naturally, it lives on waste and soil polluted with chicken, pigeon, and bat excrement. It penetrates the brain, extrapulmonary tissues, and the lungs. These infections most frequently result in infections of the lungs, skin, prostate, central nervous system, and eyes. If left untreated, it produces deadly cryptococcal meningoencephalitis. Antifungals such as flucytosine and intraventricular miconazole are used during treatment [288].

A. fumigatus is the fungus that causes aspergillosis. It is a saprophytic fungus that makes asexual spores from vegetative mycelium found in soil. The inhalation of A. fumigatus conidia results in lung infection. These strains can lead to invasive fungal infection in people with deficient immune systems. Patients with compromised immune systems can develop chronic pulmonary aspergillosis, one of the most prevalent invasive fungal diseases. Galactomannan antigen may be used to diagnose it. In addition, antifungal medications are used to treat aspergillosis. To treat aspergillosis, ergosterol, components of the fungal membrane, and 1,3 glucan are among the potential targets for antifungal compounds [288,291].

A healthy part of the human microbiome is C. albicans. C. albicans, however, transforms into a pathogen when the harmonious relationship between the organism and the host cells is perturbed. It then overgrows on skin and mucosal surfaces, invades host tissue, spreads to circulation, and colonizes solid organs. Patients with this illness have excruciating pain and agitation, especially immunocompromised patients. Oropharyngeal and esophageal candidiasis are both conditions, and the agent that causes them is C. albicans [292].

R. oryzae is a fungus that causes a medical condition known as mucormycosis. It is a member of the Mucorales order. Based on where the illness occurs, mucormycosis can be classified into five different groups: gastrointestinal, cutaneous, pulmonary, disseminated, and miscellaneous. Patients with neutropenia and dysfunctional phagocytes (caused by acidosis and hyperglycemia) are more likely to contract the illness. Mucormycosis etiology is associated with higher patient serum iron, such as cryptococcosis. Therefore, a quick and accurate diagnosis is crucial for illness therapy. Unfortunately, no PCR-based or serological assays are available for quick diagnosis. Therefore, treatment includes quick detection and surgical excision of the diseased tissue. Treatment options include quick diagnosis, surgical removal of the infected tissue to stop further invasion, and the use of antifungal medications such as amphotericin B deoxycholate and its lipid derivatives, azoles such as itraconazole, voriconazole, posaconazole, and ravuconazole, investigational triazoles, and echinocandins such as caspofungin [288,293].

2.2.2. Mycotoxin Production

Mycotoxins are toxic secondary metabolites produced by numerous fungal species with a high negative impact on the health of humans and livestock, which can persist in food commodities after harvesting or processing [294]. Although in recent decades tremendous advances in understanding the biochemistry, genetics, and regulation of mycotoxin biosynthesis have been made, mycotoxin contamination of food products remains a problem far from being solved. These secondary metabolites are produced by toxigenic fungi belonging to Aspergillus, Fusarium, Talaromyces, and Penicillium genera. In food security and safety, their involvement in reducing the quality and quantity of food commodities requires intensive research [295]. Today, more than 300 mycotoxins of fungal origin are known, and their chemical structure varies from simple molecules with four carbon atoms to more complex ones. Although mycotoxins are secondary metabolites of different fungal strains, they do not intervene in fungal growth but rather act as a defensive mechanism against other organisms and as a strategy to maintain the oxidative status of the fungal cell [296]. In general, there are six types of mycotoxins considered most dangerous for human health: aflatoxins, ochratoxins, trichothecene, patulin, fumonisins, and zearalenone [297,298,299].

Mycotoxins Biosynthetic Pathways—Mechanisms and Genetic Background

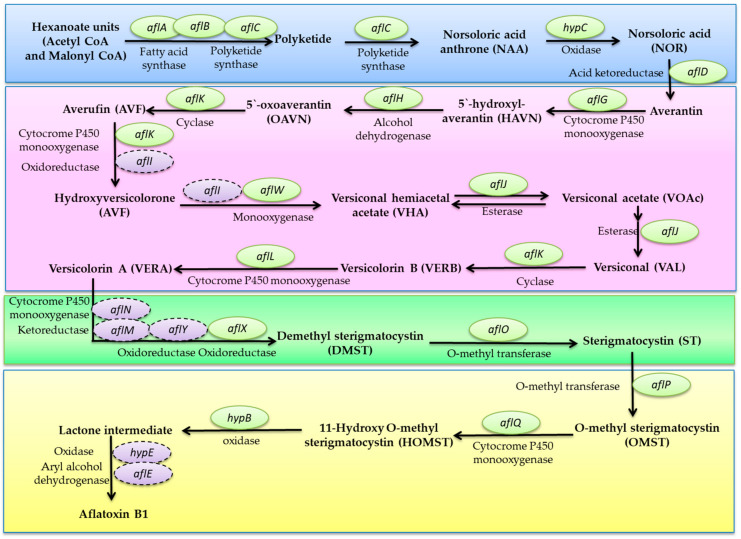

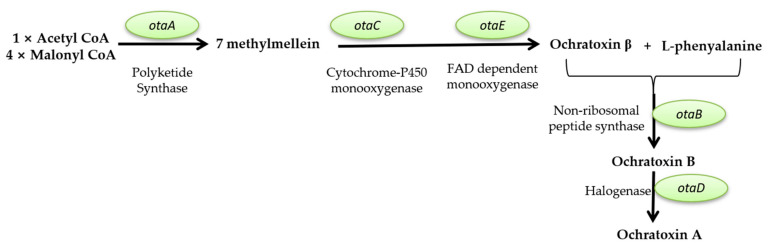

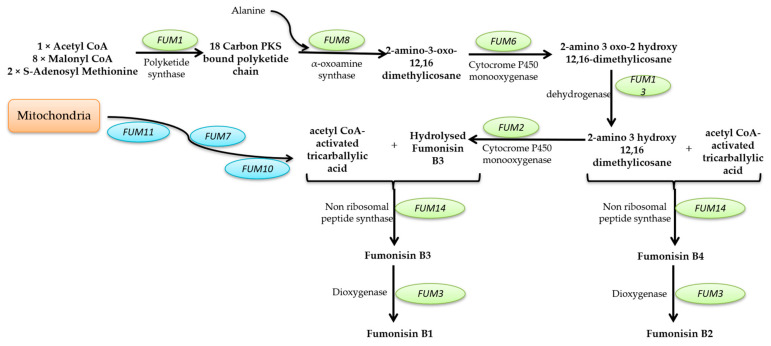

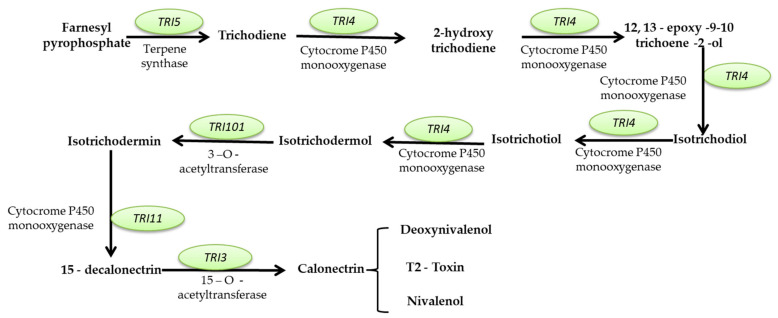

Aflatoxins are produced mainly by A. flavus and A. parasiticus strains, found in soil, decaying vegetation, or grains, and less frequently by Aspergillus bombycis, A. ochraceus, Aspergillus nomius, and Aspergillus pseudotamari species. Depending on their fluorescence underneath UV light and relative chromatographic mobility, four main types of aflatoxins (B1, B2, G1, and G2) were described [297], but based on their toxicity, B1 aflatoxin is considered the most genotoxic [292,293]. Aflatoxin B1 (AFB1) biosynthesis is a complex process that involves at least 27 enzymatic reactions. Based on the intermediates formed during the entire cascade, the biosynthesis pathway of AFB1 can be divided into four main stages. The first stage is the conversion of acetate into norsolorinic acid. The cascade reaction starts with forming hexanoate units from acetyl-CoA and malonyl-CoA and their transformation into norsolorinic acid (NOR). The first reaction is catalyzed by two fatty acid synthases encoded by aflA (fas-2) and aflB (fas-1) genes. After that, the acetate derivatives are subjected to chain elongation catalyzed by a polyketide synthase encoded by the aflC (pksA) gene [300,301,302,303]. The resulting norsolorinic acid anthrone (NAA) is oxidized to norsolorinic acid (NOR) by the anthrone oxidase HypC encoded by the hypC (hypB1) gene [304] (Figure 1, blue color). The second stage of AFB1 synthesis is converting norsolorinic acid into versicolorin A through a series of 10 enzymatic reactions. First, the norsolorinic acid is transformed into averantin (AVN) by a ketoreductase encoded by the aflD (nor-1) gene. The averantin is hydroxylated in a reaction catalyzed by a P-450 monooxygenase encoded by the aflG (avnA) gene to form 5’-hydroxyaverantin (HAVN), which is subsequently converted to 5’-oxoaverantin (OAVN) through a reaction catalyzed by an alcohol dehydrogenase encoded by aflH (adhA) gene. A cyclase encoded by aflK (vbs) catalyzes the reaction of transforming 5’-oxoaverantin (OAVN) in averufin (AVF), which is further transformed to versiconal hemiacetal acetate (VHA) through two successive reactions catalyzed by monooxygenases (a P450 monooxygenase encoded by aflV (cypX) and a cytosolic monooxygenase encoded by aflW (moxY)), the intermediate compound being hydroxyversicolorone (HVN). In this process, an enzyme encoded by the aflI (avfA) gene also intervenes, which might be responsible for the reaction needed for the ring-closure step in the formation of hydroxyversicolorone (HVN) [301,303,305]. Versiconal hemiacetal acetate (VHA) is further transformed into versiconal (VAL) by an esterase encoded by the aflJ (estA) gene, and versiconal (VAL) is transformed into VERB through a reaction catalyzed by the cyclase encoded by aflK (vbs) [306]. Versicolorin B (VERB) is the critical branch point leading to forming AFB1/AFG1 or AFB2/AFG2. VERB contains both a tetrahydrobisfuran ring (such as AFB2/AFG2) and a dihydrobisfuran ring (such as AFB1/AFG1), so the conversion of versicolorin B (VERB) to versicolorin A (VERA) requires the desaturation of the bisfuran ring under the action of a P450 monooxygenase encoded by aflL (verb), whose activity is highly dependent of the cultural conditions [303,307] (Figure 1, pink color). The third stage of AFB1 biosynthesis is the conversion of versicolorin A into sterigmatoxystin through a series of three successive reactions catalyzed by different enzymes encoded by aflM (ver-1), aflN (verA), aflY (hypA), aflX (ordB) and aflO (omtB) genes. The intermediate compounds formed are not yet fully understood, but the final step of this stage is the conversion of demethylsterigmatoxystin (DMST) into sterigmatocystin (ST) through a reaction catalyzed by an O-methyltransferase [301,308,309] (Figure 1, green color). The last stage of AFB1 production is the conversion of sterigamtocystin into aflatoxin B2. The conversion of sterigamatocystin into O–methylsterigmatocystin (OMST) is catalyzed by an O-methyltransferase encoded by the aflP (omtA) gene, whose expression is highly influenced by the growth conditions [310,311]. The A-ring of O–methylsterigmatocystin (OMST) is oxidized, and an intermediate named 11-hydroxy-O-methylsterigmatocystin (HOMST) is formed. The reaction is catalyzed by a P450 monooxygenase encoded by the aflQ (ordA) gene. Moreover, 11-hydroxy-O-methylsterigmatocystin (HOMST) is further oxidized to a lactone intermediate by an oxidase encoded by hypB (hypB2), whose expression is also strongly influenced by the culturing conditions, and the final steps of aflatoxin B1 biosynthesis are catalyzed by different enzymes most probably encoded by hypE (aflLa) and aflE (norA) genes (Figure 1, yellow color) [301,312,313].

Many genes involved in aflatoxin production are organized as a cluster from chromosome 3 in the case of A. flavus. A similar cluster was also described for A. parasiticus, the second-most-critical fungal species that can produce large quantities of aflatoxins. Between the two of them, the homology of the clustered genes is 90–99%, and in terms of functionality, the main difference is that A. flavus strains are mainly producers of B types of aflatoxins while A. parasiticus strains produce both B and G types. Although many questions regarding the biosynthetic pathway of AFB1 have found their answer, many other problems remained unsolved in recent years. Apart from the genes that encode enzymes directly involved in AFB1 biosynthesis for other genes, such as aflT and hypD (aflNa), the function was not fully elucidated [301,314]. In the case of A. flavus, the aflatoxin pathway is regulated by a transcriptional factor encoded by the aflR gene. The Cys6Zn2 transcriptional factor binds to at least 17 genes from the aflatoxin genes cluster and acts as a positive regulator enhancing their transcription and, thus, aflatoxins production up to 50 times. Similar transcriptional factors were also characterized for A. parasiticus and A. nidulans strains [301,315]. Another possible transcriptional factor in the aflatoxin biosynthesis pathway is a protein encoded by the aflS gene. This factor might influence the expression of aflC, aflD, aflM, and aflP genes, but its exact mechanisms of action are not yet fully elucidated [301,305,316].

Figure 1.

Aspergillus spp. aflatoxin B1 biosynthesis pathway and the genes involved (according to [305,312,314,317,318] (green circles with full border- genes with proven function; purple circles with dashed edges- putative genes).