Abstract

Regenerative engineering converges tissue engineering, advanced materials science, stem cell science, and developmental biology to regenerate complex tissues such as whole limbs. Regenerative engineering scaffolds provide mechanical support and nanoscale control over architecture, topography, and biochemical cues to influence cellular outcome. In this regard, poly (lactic acid) (PLA)-based biomaterials may be considered as a gold standard for many orthopaedic regenerative engineering applications because of their versatility in fabrication, biodegradability, and compatibility with biomolecules and cells. Here we discuss recent developments in PLA-based biomaterials with respect to processability and current applications in the clinical and research settings for bone, ligament, meniscus, and cartilage regeneration.

Keywords: Poly (lactic acid), PLA, processing, regenerative, engineering, growth factors, small molecules, cells, tissue, bone, ligament, cartilage, meniscus regeneration

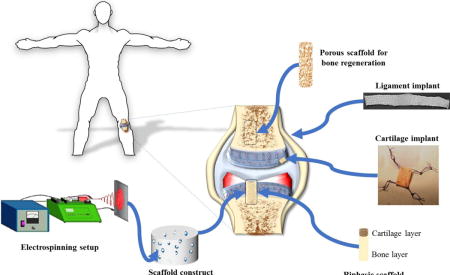

Graphical abstract

A schematic illustrating the application of PLA based biomaterials in the form of sintered microspheres, electrospun nanofibers, porous biphasic, and 3-D braided microfiber scaffolds for bone, cartilage, meniscus, and ligament regeneration.

1. Introduction

Orthopaedics-related medical diagnoses accounted for 225 million visits, costing about 215 billion dollars between the years 2009–2011 [1]. These figures include more than a million total hip and knee replacements, and about 100,000 ligament reconstruction procedures performed annually at a cost of about 25 billion dollars [2, 3]. Current orthopaedic surgical procedures primarily utilize autografts, allografts, and metal and plastic implants [4]. The metal and plastic implants suffer from a variety of challenges such as low fatigue, creep, poor adhesion, and biocompatibility issues with native tissue [5–7]. Similarly, autografts, currently considered as the gold standard, suffer from donor site morbidity, pain, and unavailability of large tissue-volumes [8]. In the case of allografts, donor-site morbidity is not an issue, however, some of its drawbacks includes the risk of communicable diseases, immunogenicity, and inadequate donors [9, 10].

In addition, various biodegradable and biocompatible polymers, of both synthetic and natural origin, have been developed for biomedical applications [11]. Some of these polymeric-materials have found applications in sutures and are fast emerging as implant-material alternatives. Aliphatic polyesters, also known as poly (α-hydroxy esters), are one such bioresorbable and biocompatible group of polymers that have great potential for use in the regeneration of large tissues. This class of polymers include: poly (lactic acid) (PLA), poly (glycolic acid) (PGA), poly (ε-caprolactone) (PCL), poly (dioxanone) (PDO), and poly (trimethylene carbonate) (PTMC) [12, 13]. Within this group, PLA possesses chirality enabling the mid-chain residues to exist in three enantiomeric states, L-Lactide, D-Lactide, and meso-lactide [14]. Of these, the most widely used polylactides are the poly (L-Lactide) (PLLA) and poly (D-Lactide) (PDLA), respectively [13].

PLLA is a slow crystallizing, semi-crystalline polymer with crystallinity, melting and glass transition temperature values ranging from 40–50%, 55–80 °C, and 170–180 °C, respectively [15, 16]. Likewise, PDLA, which is also a semi-crystalline polymer with crystallinity, melting, and glass transition temperature values ranging from 30–45 %, 40–50 °C, and 120–150 °C, respectively [16, 17]. Both PLLA and PDLA have comparable tensile strength (4–8 GPa), elongation at break (1–8%), and tensile strength values (40–70 MPa) [17, 18]. Their slow crystallizing nature predisposes these materials to be typically hard and brittle. The crystallizability of these materials can be improved by processing via isothermal annealing [19], co-polymerizing [20], nucleating by additives [21], and strain induced crystallizing [22]. The random distribution of PLLA and PDLA in PDLLA causes disruption of stereo-regularity, leading to an amorphous poly (D,L-lactic acid) PDLLA [23]. Altering the stereo-regularity of the isomers (PDLLA) is also one way to manipulate the degradation rate of this polymer. In-vivo studies have shown highly-crystalline PLLA to degrade completely in 2–5 years; whereas mostly-amorphous PDLLA loses strength in less than 2 months, and completely degrade within 12 months [12].

The processability, material properties, degradation rates, and tissue compatibility of PLA have been also modulated by copolymerizing it with other monomers resulting in copolymers such as poly (lactic acid-co-glycolic acid) (PLGA), poly (lactic acid-co-caprolactone) (PLCL), poly (lactic acid-co-ethylene glycol) (PLEG), and poly (lactic acid-co-glutamic acid) (PLGM); thus, providing PLA-based biomaterials with tunable-properties for diverse biomedical applications [24–26]. Another advantage with these degradable biomaterials are that unlike non-degradable implant biomaterials, these do not require additional surgery for implant removal [27]. Additionally, the ease of processing PLA based biomaterials by extrusion, injection molding, stretch blow molding, film casting, thermoforming, foaming, fiber spinning, electrospinning, melt electrospinning, and micro- and nano-fabrication techniques into various shapes and sizes have played a critical role in expanding the applications of these materials [28, 29].

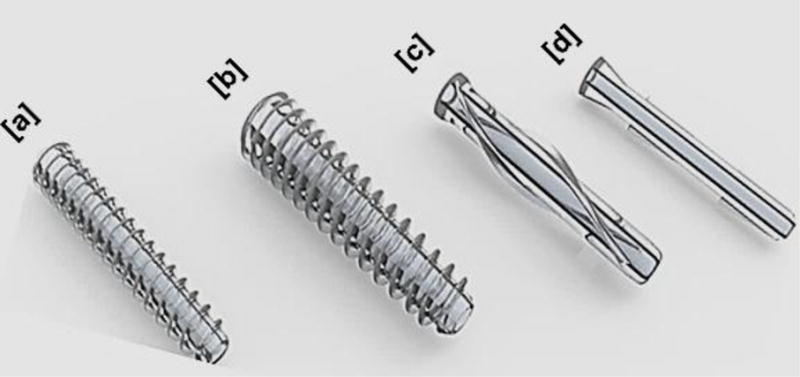

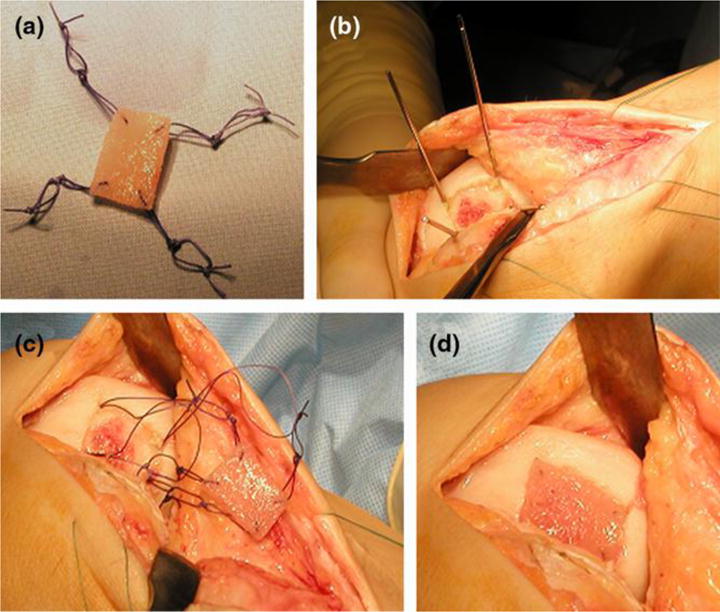

In orthopaedic and dental applications, PLA based materials have been extensively used as fixation-devices such as screws, pins, washers, darts, and arrows in reconstructive surgeries including those of the mandibular joint; facelifts; thoracic, hand, leg, finger, and toe fractures; ligament reconstruction procedures; soft and hard tissue fixations; alignment of osteochondral and bone fragments; meniscus repair; and hyaline cartilage fixation [11]. Some of the PLA based implants are shown in Figure 1, and the composition, purpose of those degradable implants are summarized in Table 1. This review summarizes the recent progress in PLA based biomaterials for bone, ligament, cartilage, and meniscus regeneration.

Figure 1. Representative PLA based medical devices currently employed in orthopaedic and dental applications – Biotrak® pins and screws.

(a) Mini screw used for fixation in treating osteochondral defects and in foot, ankle, and hand surgeries, (b) standard screw used for treating osteochondral defects, osteotomies, and navicular fractures, (c) helical nail used for fixing radial styloid fractures and hammertoes, and (d) pin used for the repair of ulnar styloid fracture. Images reprinted with permission from Acumed LLC.

Table 1.

PLA based commercial medical devices currently used in orthopaedic and dental applications.

| Manufacturer (Country) | Product | Composition | Application |

|---|---|---|---|

| Biomet (USA) | LactoSorb® | PLLA-PGA | Pediatric craniofacial and reconstructive surgery |

| RapidFlap® | PLLA-PGA | Pediatric craniotomy fixation | |

| Lactosorb Distraction Device® | PLLA-PGA | Craniofacial microsomia | |

| Lactosorb Endobrow Screw® | PLLA-PGA | Facelift surgery | |

| LactoSorb SE Delivery® | PLLA-PGA | Restrict screw migration | |

| Takiron (Japan) | Osteotrans-MX® | PLLA-μHA | Bone fracture and fragments fixation; ligaments, and soft tissue fixation |

| Osteotrans-OT® | PLLA-μHA | Ligament reconstruction (ACL, PCL) | |

| Gunze (Japan) | Grand Fix™ | PLLA | Finger and toe fracture fixation; transplanted bone fixation |

| Acumed (USA) | Biotrak® | PLLA | Osteochondral defects; osteotomies; navicular fracture fixation |

| Conmed (USA) | Genesys ™ Matrix Interference Screws | PLDA/β-TCP | ACL/PCL graft fixation |

| Pinn-ACL® Crosspin System | PLLA | ACL reconstruction | |

| BioScrew® Bioab sorbable Interference Screws | PLLA | Graft fixation | |

| EndoPearl® Fixation Device | PLLA | Soft tissue grafts fixation (ACL reconstruction) | |

| BioStinger® Meniscal Fixation System | PLLA | Meniscus repair | |

| Contour™ Meniscus Arrow™ | PLDLA | Meniscus repair | |

| SmartNail® | PLLA | Bone fractures and osteochondral fragments alignment | |

| Arthrex (USA) | Sheathed Bio-Interference Screw | PLLA | Facilitate screw insertion and graft rotation |

| Chondral Dart ™ | PLLA | Osteochondral tear fixation | |

| Trim-It Spin Pin™ | PLLA | Intraosseous ligament and tendon fixation; small bone and soft tissues fixation | |

| Bio-TransFix® Implant | PLLA | Soft tissues; bone-tendon-bone grafts fixation | |

| Stryker (USA) | Biosteon® | PLLA-HA | Ligament reconstruction surgery screw; anchor rotator cuff |

| Bioabsorbable | PLLA | Soft tissue and bone-to-bone grafts fixation | |

| Zimmer (USA | Bio-statak ® | PLLA | Soft tissue fixation |

| Sysorb (Switzerland) | Sysorb® Bioresorbable Interference Screw | PDLA | Juxta-articular graft fixation |

| Depuy (USA) | Rapidsorb™ | PLLA/PGA | Craniofacial fracture repair and reconstruction |

| Biocryl® | PLLA/β-TCP | Soft tissue and bone-to-tendon grafts fixation | |

| Biocryl® Rapide® | PLGA/TCP | Knotless tying (rotator cuff); Bankart repair | |

| Orthomesh® | PLLA | Bone grafts or fragments fixation | |

| Absolute® Interference Screw | PLLA | Soft tissue and bone-bone fixation | |

| BIOINTRAFIX® | PLA/TCP | Tibial fixation (ligament reconstruction) | |

| RIGIDFIX® Cross Pin System | PLLA/β-TCP | ACL reconstruction |

2. Processing

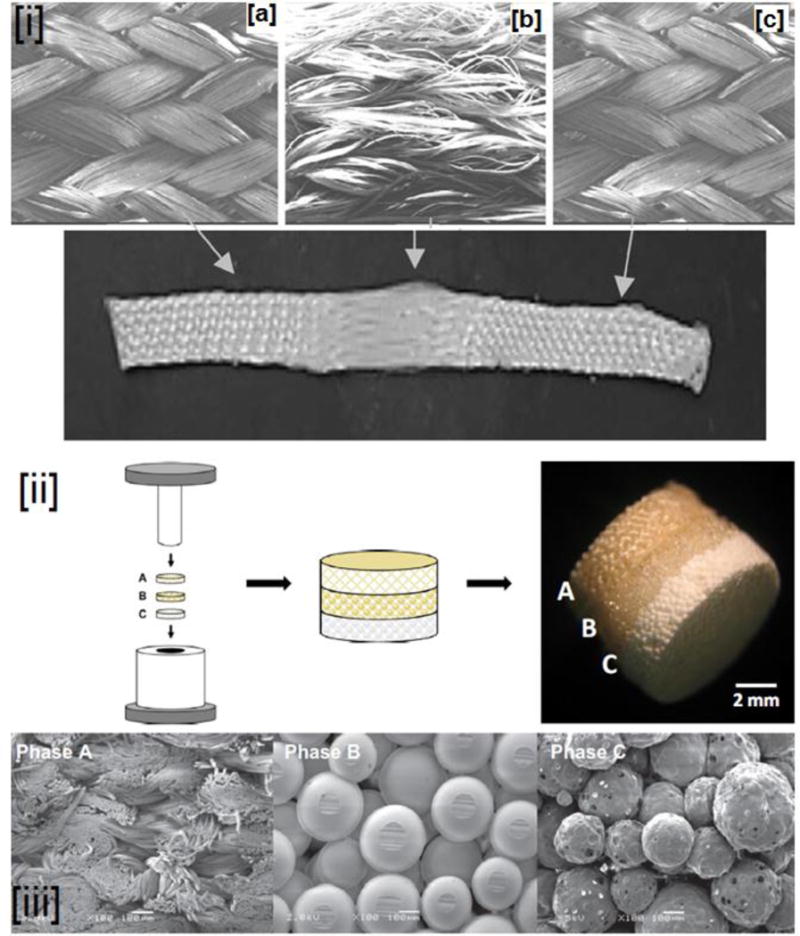

i. Fiber Spinning

An advantage of PLA based biomaterials has been their ability to be fabricated into a variety of structures with the appropriate mechanical properties, topography, geometry, and architecture as required for diverse biomedical applications. One of the oldest methods to fabricate PLA based products has been fiber-spinning from either polymer solution or melt. As PLA is soluble in a wide array of solvents, solution spinning processes has also been widely utilized to fabricate fibers for biomedical applications [30]. Historically, mono- and multi-filament sutures have been prepared from PLA based fibers by spinning; but due to their longer degradation times, other aliphatic polyesters such as PGA have now replaced PLA [30]. In addition, woven, knitted, and braided structures produced from spun fibers have found orthopaedic applications in bone, ligament, and cartilage regeneration (discussed later) [31–33].

PLA based devices currently used for orthopaedic applications (Fig.1, Table 1) are made by rapid processing techniques resulting in poor mechanical properties and crystallinity. PLA based fibers are commonly utilized to enhance the crystallinity and mechanical properties of those orthopaedic fixation devices [34]. While evaluating PLA fibers (self-reinforced) reinforced PLA composites (SR-PLLA) for long term complication and fixation failure rates, Juutilainen et al. noted lower fixation failures (<5%), and higher bone mineral density (BMD) in SR-PLLA composites, compared to metal and unreinforced PLA implants [35]. Similarly, another study showed significant improvements in mechanical properties (tear strength) of PLLA reinforced with PLA fibers (yarns and fabrics) attributed to enhanced interfacial bonding between PLA fibers and PLLA sheets [36]. Besides the linear stresses, orthopaedic devices are also commonly subjected to torsional forces, hence resistance to those forces are also required for low fixation failure rates. A recent study by Wu et al. showed drastic enhancements in the flexural modulus values of PLA composites self-reinforced with braided yarns (3- and 5-direction) [37]. A key notable difference between the studies is that, due to the braided structure of the fibers, modulus values increase significantly throughout the composite structure, thereby increasing the horizon of these composites with enhanced mechanical properties.

The fabrication of SR-PLLA composites is made possible due to the contrasting melting temperatures of the PLLA fibers and the PLLA matrix. But in solution, as both the fibers and matrix are soluble, fabrication of SR-PLLA composites are not possible. However, a recent study demonstrated the possibility of reinforcing an amorphous solution cast PDLLA film with PLLA fibers retaining their architecture. In addition, a 2-fold improvement in the tensile modulus (1.40 vs 0.79 GPA for non-reinforced), and a 3-fold improvement in tensile strength (50 MPa vs 16 MPa) was realized by the authors, thus demonstrating the significance of these PLA fibers in composites for orthopaedic applications [38]. These studies indicate, by judicious selection of matrix/fiber and morphology of the fiber phase, SR-PLLAs can be fabricated using wide array of techniques increasing the application of these devices for orthopaedic applications that require significantly higher modulus and strength.

To improve healing and enhance bony fixation, devices such as interference screws rods, and nails are routinely coated with inorganic materials such as tricalcium phosphate (TCP) or hydroxyapatite (HA), and or antibiotic drugs to prevent osteomyelitis. Compared to PLLA films and sheets, PLA based fibers/rods are more attractive as a carrier for the controlled delivery of these molecules, as these devices possess larger surface area in addition to promoting strong interface between the fiber and matrix. For example, recently Charles et al. showed that PLA composites reinforced with PLLA fibers/HA fabricated by a compaction technique exhibited a linear increase in tensile modulus with increasing HA content (9.7 GPa for 15% HA vs 8.3 GPa for 0% HA) [39]. Likewise, Chen et al. utilized braided and a multilayered PLA fabric to improve the mechanical properties of the otherwise brittle calcium phosphate (CaP) composites [40]. Similarly, incorporation of bioactive glass into SR-PLAs was also observed to result in improved mechanical properties of the composites, making these screws more suitable for intervertebral ossification [41].

Osteomyelitis is a serious condition caused by inflammation in the bone, and it is difficult to treat. Current treatment approaches are based on the use of antibiotics. Similar to the TCP/HA or bioglass coating on PLLA fibers/rods to induce osteogenesis, ciprofloxacin, a commonly used antibiotic have been coated onto PLA rods to treat osteomyelitis. In one study by Veiranto et al., SR-PLA biointerference screws coated with ciprofloxacin elicited a rapid burst followed by which, a controlled delivery of the over a 44-week study was noted [42]. Similar to ciprofloxacin, gentamicin, another commonly used antibiotic for treating osteomyelitis have been frequently embedded in PLA rods, and have shown controlled release, thereby effectively preventing infection to the bone [43]. As gentamicin is a hydrophilic antibiotic molecule, careful selection of the carrier molecule is required for its controlled delivery. In current clinical settings, gentamicin is delivered through PMMA based bone cements to prevent localized infection. But as PMMA is a non-biodegradable, this method requires secondary surgery to remove the PMMA [44]. In this regard, PLA based devices have significant advantages over other biomaterials; primarily by their hydrophobic nature that prevents rapid dissolution of gentamicin, and secondarily by their ability to bind to gentamicin, further delaying the delivery of gentamicin [45, 46]. These studies demonstrate the versatility of PLA based fibers/rods in improving mechanical properties (modulus, strength, wear resistance, flexural modulus), inducing ossification (in conjunction with inorganic materials) and in addition to their capability in preventing osteomyelitis with the incorporation of a suitable antibiotic.

ii. Extrusion and Injection Molding

By far, the extrusion process has been the most important technique to melt process PLA for various orthopaedic applications. Most processing techniques including injection molding, blow molding, and fiber spinning incorporate some of the salient features of the extrusion process [28]. Bioresorbable screws, plates, meshes, rods, and nails currently used in clinical applications (Fig.1, Table 1) have been traditionally made via extrusion and injection molding processes. In addition, extrusion and injection molding processes are also routinely utilized to evaluate new materials for potential clinical applications. For example, it was shown recently by Danoux et al. that composites containing PLA and PLA/nano-hydroxyapatite (n-HA) fabricated by an extrusion process, despite a solid dense structure, demonstrated proliferation of hMSCs in an in vitro and in vivo canine model. In addition, upregulation of alkaline phosphatase (ALP) expression was observed in n-HA containing composite resulting in heterotopic bone formation [47]. Similarly using PLGA, Simpson et al. systematically evaluated the upregulation of rheological, thermal, and mechanical properties by reinforcing with CaCO3, HA, and two bioglass systems prepared by an extrusion process [48]. These results suggest the utility of extrusion as a technique to fabricate dense solid composites that could eventually replace currently used medical device biomaterials.

Extrusion and injection-molding processes predominantly result in dense and solid bulk structures. On the other hand, emerging alternative tissue engineering technologies for orthopaedic applications prefer fabrication techniques such as electrospinning, rapid prototyping, and micro/nano-fabrication techniques, as these techniques give greater control over the micro- and nano-structures of the scaffolds. Sometimes, extrusion is also combined with these emerging techniques to take advantage of multiple processes, resulting in hybrid materials. Rapid prototyping which imbibes the concept of extrusion is now favored for developing complex structures appropriate for tissue regeneration applications.

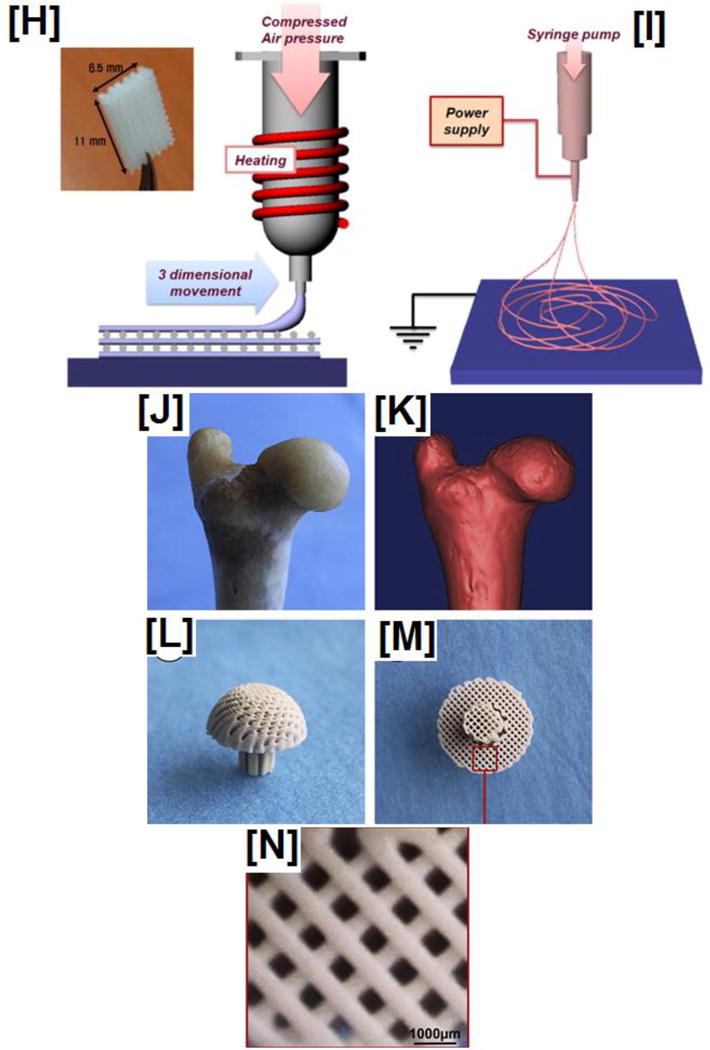

iii. Rapid Prototyping (RP)

Ever since Giordano and coworkers fabricated complex structures via a layer-by-layer approach called rapid prototyping (RP), interest in applying this technique for tissue engineering applications has grown exponentially [49]. This is partly also because, in recent years, efforts to fabricate tissue engineered scaffold structures using conventional techniques such as solvent casting/particulate leaching, gas foaming, and freeze-drying have been found to be sub-optimal (pore size, mechanical properties, toxicity concerns) for tissue regeneration. Currently, various rapid prototyping techniques such as fused deposition modeling (FDM), meniscus-confined electrodeposition, conformal printing, UV-assisted printing, and solvent-cast printings have been developed with the aid of computer-aided design/manufacturing (CAD/CAM) to fabricate scaffolds that satisfy specific requirements for tissue engineering applications [50].

Due to their suitable mechanical and rheological properties, PLA has been considered as an ideal material for RP process using FDM, conformal printing, and solvent-cast methods. Fused deposition process, a process similar to melt extrusion, has been utilized to fabricate 3-D structures via a layer-by-layer deposition process; by utilizing a robotically-controlled extruder, free standing 3-D structures having fabricated out of PLA [49, 51, 52]. Likewise, by the extrusion of PLA filaments onto a rotating drum, using a conformal printing approach, free standing PLA structures have been also fabricated [53]. Initial concerns with the RP process were if RP could be utilized to (1) prepare tissue engineering scaffolds with the appropriate geometry, (2) embed proteins/growth factors within these scaffolds, and (3) whether the cells would grow on them. These concerns were mitigated by several studies that showed scaffolds could indeed be fabricated with suitable geometry along with the incorporation of growth factors and cells [54–56], and the focus has moved to the dimensional accuracy of these constructs to mimic physiologically-relevant structures.

Several approaches have been reported recently utilizing RP process to fabricate precise scaffolds for tissue regeneration. A recent study reported fabrication of PLA structures by a 3-D printing process that exhibited excellent structural integrity with superior thermo-mechanical characteristics. Such superior structural integrity was achieved by cross-linking the extruded PLA structures by ionizing radiation [57]. Another approach was reported recently by Senatov et al. who reported 3-D printing of dimensionally stable PLA/HA structures which demonstrated a shape-memory effect via multiple compression-heat-compression cycles [58]. This characteristic can be clinically useful as implants are expected to adhere and conform to the site of tissue repair. In addition to improving structural stability as explored by these studies, a complicated set of structures were recently fabricated with high dimensional accuracy for 15 anatomical components of the vertebra [59] offering the possibility of utilizing 3-D printed PLA based materials for regenerating complex tissues. A unique advantage of RP process is their capability to fabricate not only structurally and dimensionally stable structures, but also complex structures comprised of different materials that have suitability for engineering complex tissue such as osteochondral regeneration [60].

iv. Nanofabrication Technologies

a) Nanofibers

Electrospinning as a fiber forming technique was first reported more than a hundred years ago, but interest in those fibers for biomedical applications has emerged only in the past 15 years. Due to their versatility and in-expensive setup costs, it is fast emerging as a technique to prepare fibers with sub-micron diameters [61, 62]. In principle, an electrospinning apparatus consists of (1) a high precision pump to deliver solution, (2) a high voltage generating source, and (3) a collector to collect fibers in the form of a non-woven mat. As the polymer solution or melt is ejected out of the spinneret at a certain rate, the electrical force between the spinneret and the collector causes the formation of spherical droplets at the end of the needle [63]. The droplet then undergoes distortion resulting in the formation of a conical shaped structure, known as a Taylor cone [64]. The Taylor cone thus formed is highly unstable, and as the surface tension is continuously overcome by the electrostatic force, Taylor cone continues to undergo elongation and whipping resulting in the formation of submicron fibers that are collected in the form of a non-woven mat on the collector [65]. By using parallel plates, rotating drum or discs as collectors, the morphology of the resultant fibers can be varied [66]. In addition, the porosity and fiber diameter can be carefully controlled by varying solution properties (concentration, surface tension, molecular weight, additives, conductivity) or processing (potential difference, tip to collector difference, delivery rate, humidity, needle size). For example, by carefully selecting the solvents, the morphology of the electrospun PLA fibers can be varied from porous to smooth [67]. PLA based scaffolds are primarily intended for tissue engineering and drug delivery applications. In addition to tissue engineering applications, PLA based scaffolds have been extensively reported for encapsulating and delivering bioactive agents such as pharmaceutical agents, nanoparticles, anti-microbial, and anti-bacterial agents [68–73]. This is typically accomplished by simply mixing these agents in polymer solution and electrospinning or can be achieved by either co-electrospinning or core-shell electrospinning.

In principle, electrospinning is similar to melt and solution spinning, except that electrospinning utilizes electrostatic force, rather than mechanical extrusion to spin the solution or melt into fibers. Due to the combined effect of solvent evaporation and strong electrical fields between the polymer (solution or melt) and the collector, the polymeric jet undergoes significant elongation, resulting in a drastic reduction in fiber diameters [74]. The resulting low (sub-micron) fiber diameters that mimic extra cellular matrix (ECM) protein structure combined with the high surface area to volume ratio of the electrospun fibers allow cell attachment and easy transport of nutrients and waste have made this process ideal for tissue engineering applications. Our group was the first to evaluate the electrospin PLA nanofibers for skin and cartilage tissue engineering applications [75]. In addition, our group evaluated these biomaterials for several soft and hard tissues, including muscle, ligament, tendon, and bone [76–82]. Despite their capability to mimic the native ECM, typically not seen in scaffolds fabricated by other techniques, few major drawbacks such as the necessity to use a solvent and subsequent removal the applicability of scaffolds made from electrospinning.

To overcome this drawback, currently, melt electrospinning is emerging as an ideal alternative which do not require the use of toxic solvents [83]. Although, first reported by Larrondo and coworkers more than 30 years ago, melt electrospinning process did not find significant advancements primarily due to larger increases in the viscosity resulting in fibers with thicker diameters [84–86]. However, a systemic evaluation indicated applied voltage to play a significant role in the fiber diameters. Another key draw back with melt electrospinning, especially temperature sensitive polymer such as PLA have been their susceptibility to degrade upon thermal exposure [87]. One study investigated the experimental factors that can be attributed to the thermal degradation of PLA including temperature, distance travelled by the jet, type and content of antioxidant. It was found, temperature had a minimal impact on thermal degradation, when compared with the oxidant content or the distance travelled by the jet [88]. As large viscosities lead to thermal degradation of the resultant fibers, one way of overcoming them have been by using biocompatible plasticizer such as PEG. The addition of PEG not only causes reduction in thermal degradation but also enhances the melt electrospinnability and biological performance of PLA composites [89]. Another method was recently reported by Ogata et al., who utilized a laser beam to cause focalized melting of polymer chains in spinning process resulting in sub-micron fiber diameter, but their molar mass still decreased marginally [90].

Despite several drawbacks associated with the process, more recently, several strategies have been developed to make this process more effective for various tissue regeneration application. Direct writing of the electrospun jet, a term coined and extensively reported by Hutmacher and Dalton’s research groups, is one such technique that focuses on directing the melt electrospun jet into localized and targeted collection [91, 92]. This is typically accomplished by an automated lateral translation of the collector with respect to the polymer melt, thus making it possible for precise control of the architecture, similar to what can be achieved by RP process [93]. For example, one study reported the fabrication of a 1 mm × 1 mm × 1mm 3-D structure by carefully stacking new layer atop the previously fabricated layers [94]. Besides such linear 3-D structures, same group have also successfully fabricated 3-D structures with macroscopic pores, patterned and tubular structures that exhibited excellent cellular proliferation, and more importantly that resulted in even distribution of ECM proteins [95–99]. Due to their relative flexibility and thermal stability, most of these studies were performed on PCL. However, few studies were recently reported on PLLA using direct writing approach that explored fabrication of 3-D structures containing n-HA, and another study reported direct writing onto a pork liver demonstrating, although by limited studies, the possibility of melt electrospinning PLLA based fibers for tissue regeneration [29, 100].

b) Nanoparticles

Nanoparticles (NPs) have been classically defined as particles that are within the sub-micron (<1 μm) size range [101]. Based on the mode of loading of the carriers and the drugs, they can be further classified as nanospheres and nanocapsules. Nanospheres are obtained, when the drugs or small molecules are embedded and distributed throughout the matrix. Similarly, nanocapsules are obtained when the drugs or small molecules are confined in a small cavity surrounded by the polymer matrix [102]. Nanoparticles have been considered as superior carriers for proteins, short chain peptides and genes, as they protect the drug from premature degradation and also due to their ability to control the release rate [103, 104]. Furthermore, these nano-carriers, have the potential to permeate biological barriers such as the blood-brain barrier and result in higher cellular uptake compared to micro particles [105].

NPs derived from natural and synthetic polymers have been studied extensively over the past several decades. PLA has been one of the most widely used synthetic polymeric material in the preparation of NPs, due to its excellent biodegradability, non-toxic nature, and biocompatibility [106]. Most importantly, by co-polymerizing lactic acid with a variety of co-monomers such as glycolic acid, ethylene glycol, ε-caprolactone, the degradation rates of the NPs can be modulated [107]. Furthermore, surface properties of the preformed PLA-NPs can be modified by post-processing with PEG, chitosan, dextrans, polyoxamer, polysorbate, and thiol groups to enhance the compatibility and improve the circulation of the NPs in the blood [108–113]. Modulating the surface properties of PLA nanoparticles is attractive as it can help control the cell-material interaction at the polymeric surface [114]. In a recent study, Jain et al., showed that PLA nanoparticles coated with PEG and polysorbate were the least to be taken up by liver and kidney cells in an in-vitro model. This study further demonstrated that by modulating the surface properties, PLA based NPs have the potential for targeted drug delivery [115]. Several methods such as emulsion, nanoprecipitation, salting out, and spray-drying have been reported to encapsulate drugs in in PLA-NPs [116–118]. These studies demonstrate the capability and potential of these nanoparticles to deliver drugs at the site of interest with great temporal and spatial control.

3. The Principles of Regenerative Engineering

After the emergence of tissue engineering as a field, past 30 years has seen significant strides made from simple application of injecting appropriate cells to developing scaffold with topographical, biological, and mechanical cues required to simulate the regeneration of tissues. Tissue engineering, in its infancy focused on utilizing biomaterial to improve or restore the diseased tissue [119]. The paradigm of regenerative engineering, an interdisciplinary field, has emerged from the convergence of tissue engineering, advanced materials science, stem cell science, and developmental biology to regenerate damaged complex tissues [120, 121]. Advanced material science provides scaffolds with the right geometry and architecture to provide adequate mechanical support and modulate the cellular activities by sequestering and presenting the chemical and biochemical cues with precise spatial and temporal control. In parallel, developmental biology provides the understanding of the fundamental processes that drive the development of functional tissue, which may be applied to tissue healing and regeneration. Vital cues provided by developmental biology may need to be recapitulated for complex tissue regeneration beyond critical size defects. In this aspect, growth factors and small molecules (discussed later) play key roles in exercising control over cellular fate [122].

Stem cells play a crucial role in the regenerative engineering as most of the resident cells originate from these cells. Currently, stem cells are being investigated for the repair and regeneration of cartilage, bone, ligament, tendon, and muscle tissue [123]. These cells have the capability to (1) replicate; (2) release bioactive substances such as growth factors, cytokines, and chemokines for the growth and migration of cells, (3) immuno-modulate the tissue environment, allowing the tissue healing; (4) differentiate into the cell phenotype of the tissue of interest [124]. A significant challenge has been to develop suitable carriers to deliver these cells to the injury site to take advantage of their healing potential. Likewise, controlling and tracking the fate of stem cells once delivered are other significant challenges [125]. Beyond its traditional application in tissue engineering, PLA biomaterials offer tremendous potential for use in the regenerative engineering of orthopaedic tissue via innovative application with advanced material fabrication processes, stem cells, and understanding from developmental biology.

4. Bone Regeneration

i. Anatomy

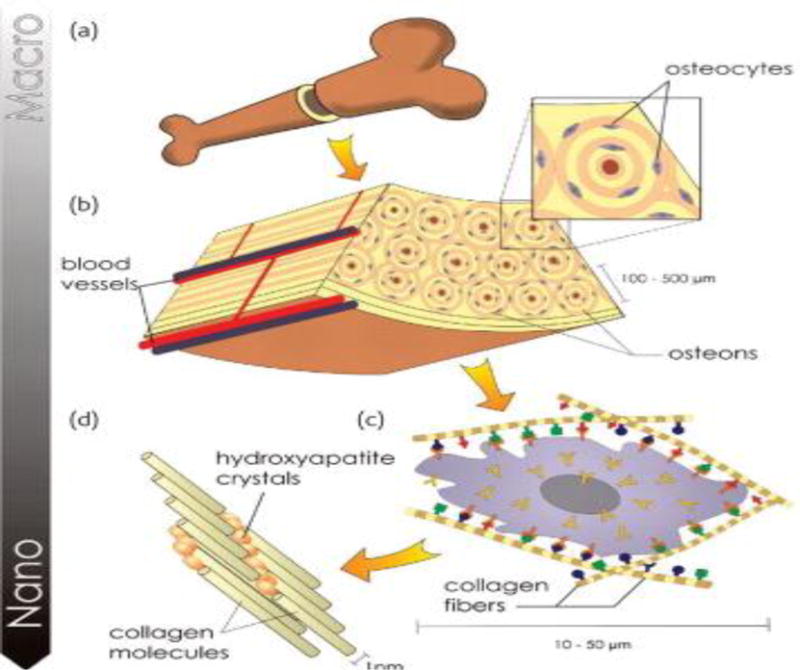

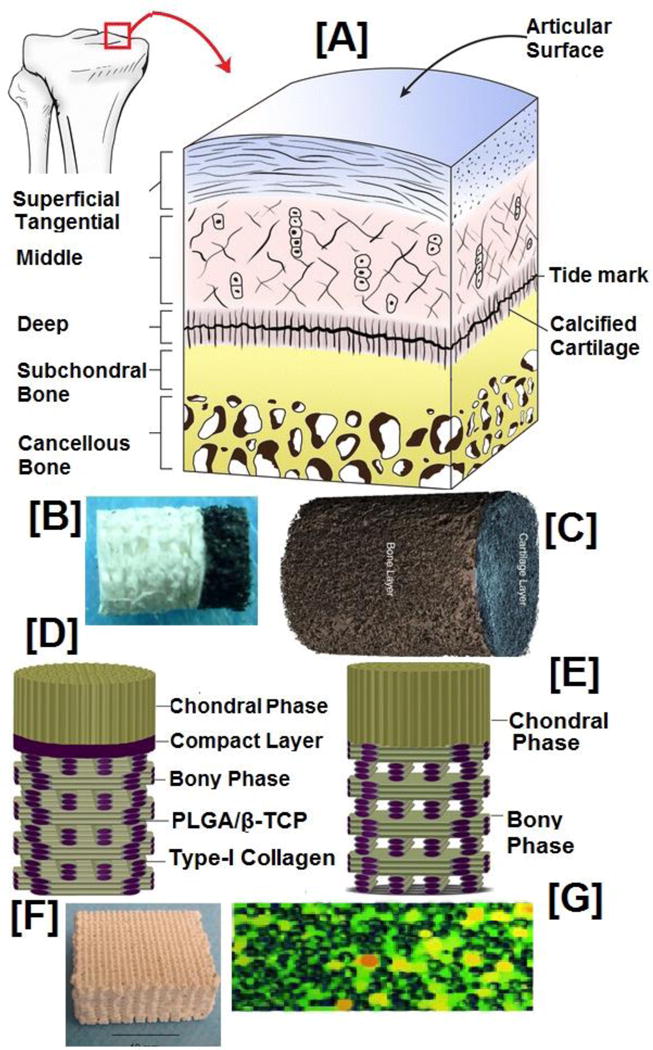

As a dynamic tissue with moderate vasculature, bone provides physical support, locomotion and strength, protects soft tissues, and maintains pH in the body. The bone marrow contains mesenchymal stem cells, calcium and phosphorous ions that are essential for numerous physiological processes [126]. Bone is an organic/inorganic composite organized in a hierarchical structure comprising an organic phase mostly containing type-I collagen (30%) and an inorganic phase containing hydroxyapatite crystals (Fig.2) [127, 128]. In addition to type-I collagen, small amounts (5%) of glycoproteins, glycosaminoglycan, and other proteoglycans are also found in the organic phase. Likewise, small amounts of bicarbonates, citrates, magnesium, potassium and sodium are found in the inorganic phase [129].

Figure 2.

(a) The hierarchical organization of bone structure. (b) Internal structure of the bone is seen with osteons running parallel to the bone structure and centrally-running blood vessels for nutrient and waste transport. (c) Microstructure of the osteon is seen with the constituents of bone extracellular matrix (ECM). (d) Nanostructure of ECM consisting of collagen molecules nucleated with n-HA crystals. Image reproduced with permission from ref [128],copyright Elsevier (2008).

Organic phase (collagen) provides the tensile strength and fracture toughness, whereas the inorganic phase provides the compressive strength to the tissue. The bone structure can be classified by its mechanical properties, geometry, and architecture into cortical (compact) and cancellous (trabecular) bone types. The cortical bone has Young’s modulus values ranging from 17 to 20 GPa and compressive strengths in the range of 130–220 MPa, while trabecular bones has Young’s modulus and compressive strengths in the range of 50–100 MPa, and 5–10 MPa, respectively [130]. The micro/nano sized damage encountered by bone tissue due to routine activities heals by itself via remodeling. In remodeling, cellular components of bone tissue including osteoblasts, osteoclasts, and osteocytes, various growth factors, hormones, and signaling molecules play a key role in establishing the new tissue. The bone formation process, osteogenesis, occur via an endochondral ossification or an intramembranous ossification pathway. Both modes of osteogenesis are highly regulated and share several molecular regulators such as Indian hedgehog, parathyroid hormone related peptides, bone morphogenetic proteins (BMPs), vascular endothelial growth factors (VEGFs) and fibroblast growth factors (FGFs) [131, 132].

ii. Scaffold Based Strategies for Bone Regeneration

Bone tissue undergoes frequent remodeling; however, this process is compromised in individuals with genetic defects, trauma, bone tumors, hormonal imbalance. Current treatment strategies such as allo-, auto-, and xeno-grafts have their own set of complications necessitating the development of biomaterial-based substrates for bone tissue regeneration [133, 134]. The biomaterial based scaffolds intended for bone regeneration must have (1) biodegradable, biocompatible, bio-functional, and non-toxic characteristics; (2) surface epitopes for cells to adhere and proliferate (osteoconductive); (3) degradation rates closely matching the tissue regeneration rates; (4) chemical and physical features, similar to that of native bone tissue (organic/inorganic composite structure); (5) highly interconnected three dimensional pore structure with sufficient pore size (ideal: 300 μm, acceptable: 200 μm) for cells to proliferate, and allow mass transfer (nutrients, and metabolic waste); (7) potential to encapsulate growth factors, stem cells, anti-inflammatory agents, and additional necessary factors (osteogenicity); (8) strong adhesion and bond with the newly formed bone tissue (osteointegrity); (9) ability to recruit progenitor cells and differentiate into desired lineages, and induces new bone growth (osteoinductive).

From a biomaterial standpoint, several materials satisfy most of the requirements in terms of mechanical, chemical, and cell-material interactions. Collagen, for example, would be the most obvious choice as it constitutes the organic phase of the bone tissue [135]. Similarly, ceramics would be another choice as they constitute the inorganic phase of the tissue [136]. However, both have drawbacks: poor processability and brittleness in the case of ceramics, and poor mechanical strength in the case of collagen fibers. Therefore, polymeric biomaterials such as PLA have been extensively investigated for bone and orthopaedic regeneration applications. Since the native bone is a large and three-dimensional tissue (3-D), several fabrication processes such as electrospinning, solvent casting/particulate leaching, gas blowing, microsphere sintering, thermally-induced phase separation, 3-D printing, and self-assembly techniques have been employed to make 3-D scaffolds out of PLA biomaterials. A summary of PLA based scaffolds reported for bone tissue regeneration is shown in Table 2, and representative scaffolds are illustrated in Figure 3.

Table 2.

List of scaffolds that have been reported for bone tissue regeneration.

| Process | Composition | Porosity | Study | Ref |

|---|---|---|---|---|

| Salt leaching | PLLA fiber/PCL | Bimodal (1–10 μm; 100–400 μm) | in-vitro study (Human osteoblasts and MSCs) indicated enhanced osteogenic potential due to higher exposure of bioceramics | [137] |

| Freeze drying | PLLA/Collagen | 400–500 μm | Gradual dexamethasone release from collagen microbeads enhanced the osteogenic differentiation of MSCs | [138] |

| Sugar leaching | PLLA | 200–300μm, and 300–500 μm | Highly porous and interconnected structure made from a non-solvent sugar leaching method resulted in enhanced proliferation of rabbit-MSCs | [139] |

| RGD-g-PLGA/HA-g-PLLA | 100–200μm, >85% porous | RGD peptide grafted porous PLA scaffolds facilitated complete regeneration of bone tissue in a rabbit model. | [140] | |

| Compression molding/particulate leaching | PLLA/β-TCP | 200–400μm, 70% porosity | Porous scaffold (PLA/β-TCP) with high interconnectivity made from organic solvent free technique showed higher cellular adhesion and osteoblasts differentiation in an in vitro model | [141] |

| Particulate leaching | PLGA-g-HA | 152±76 μm, >80% porous | nHA grafted on PLGA scaffolds demonstrated faster and higher mineralization, compared to HA coated scaffolds. | [142] |

| Melt spinning | PLGA-HA | >70% porous | Micro/nonporous scaffold (PLGA/HA) resulted in higher proliferation and differentiation of MSCs. Higher ALP and mineralization was observed in vitro; in addition, rapid bone healing observed in a rabbit model. | [143] |

| Salt and sugar porogen | PLGA | >90% porous | Unique microstructure with pore walls containing microgrooves and micropits controlled the release of BSA, simultaneously facilitating growth of pre-osteoblasts (MC3T3) | [144] |

| Electrospinning | PLGA-nDd | Fiber dia: 270±9nm | Addition of nDd increased the hardness of the PLGA nanofibers and elicited no cytotoxicity. | [145] |

| PLGA-GO | Fiber dia: 0.8–1.5μm | Addition of GO enhanced hydrophilicity, protein binding capability. GO also accelerated cell adhesion, proliferation and differentiation of MSCs into osteogenic lineage. | [146] | |

| PLGA-mSi | >85% porous | Addition of mSi increased cellular adhesion and osteogenic potential of BMSCs. It also facilitated higher loading of BMP-2 and modulated its release. | [147] | |

| PLGA/PCL | Fiber dia: PLGA 2.4±0.66μm | Electrospun biphasic aligned PCL and random PLGA nanofibers facilitated BMSC differentiation into cartilage and osteogenic phenotypes | [148] | |

| PLGA-Willemite | Fiber dia: 300±500 nm | Willemite coating on electrospun PLGA nanofibers had no cytotoxic effects, and facilitated bone regeneration in a rat model. | [149] | |

| Microspheres | PLLA nanofibers/PLLA microspheres | Pore size: 300–355 μm; 425–600 μm; 600–710 μm | Hybrid scaffold (PLLA/HA microspheres and PLLA nanofibers) mimicked the ECM characteristics of the bone. Addition of nanofibers did not hinder the proliferation of murine osteoblasts. | [150] |

| PLLA or PDLLA | Diameter or pore size: not determined | Modification of microspheres by physical adsorption of cationic polymers or addition of copolymer containing PLA and chitosan, enhanced fibroblast attachment and proliferation. | [151] | |

| Hybrid nanofiber (PLLA/PCL)/microsphere (dextran-FGF2) system | Fiber dia:1300±400 nm; 1100±300 nm | Growth factor delivery was modulated by the gradient scaffold with three phases (electrospun nanofiber/microsphere/electrospun nanofiber) making it suitable for interface tissue engineering | [152] | |

| 3-D printing | PLGA/TCP/icarit in | Pore size: 500 μm | Controlled release of icaritin observed from PLGA/HA. The higher loading of icaritin retained the porous structure of the matrix throughout the 12-week study. | [153] |

| PLGA/TCP | Pore size: varying | Controlled porosity and interconnectivity, promoted bone tissue in-growth. Higher bone regeneration observed in these constructs with precise geometry. | [154] | |

| PLGA/nHA/TGF-β1 | Pore size:500 μm | Controlled release of TGF-β from PLGA microspheres modulated bone and cartilage regeneration. | [155] | |

| PLLA | Pre size: varying | The dimensions of 3-D printed vertebrae matched 15 different anatomical features of vertebral body. | [59] |

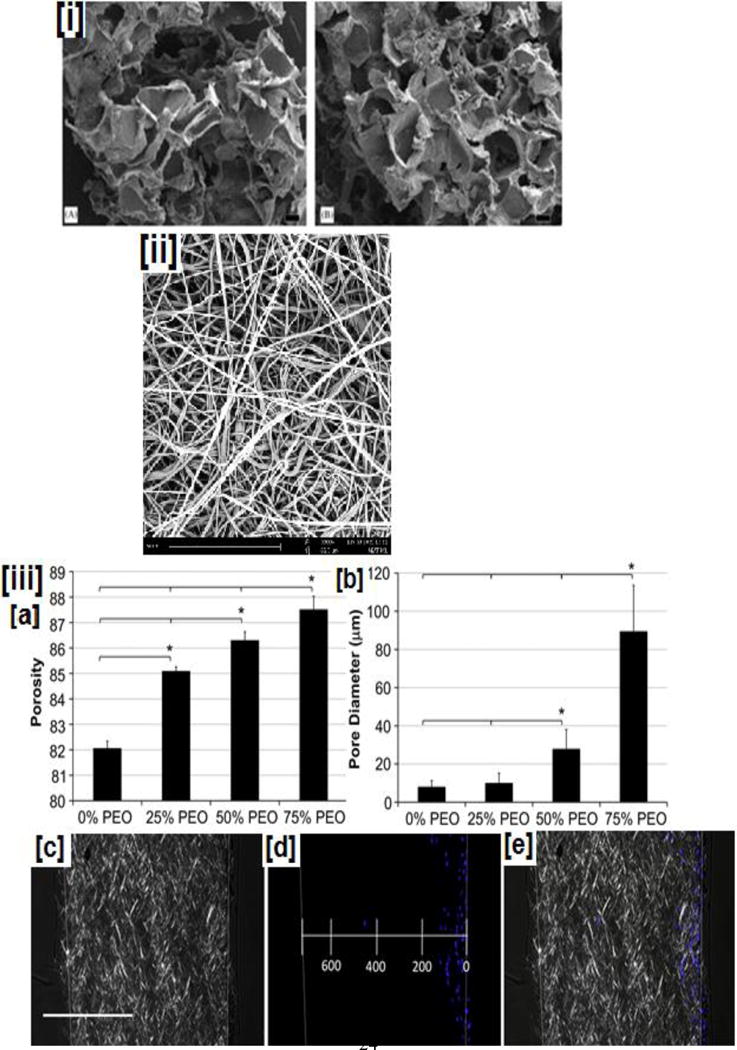

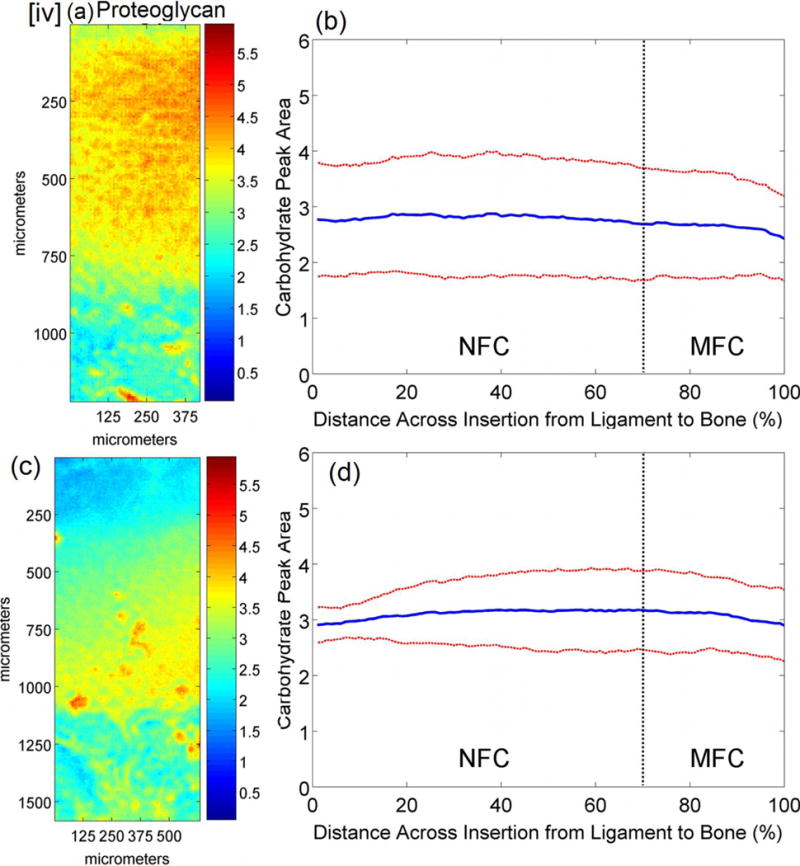

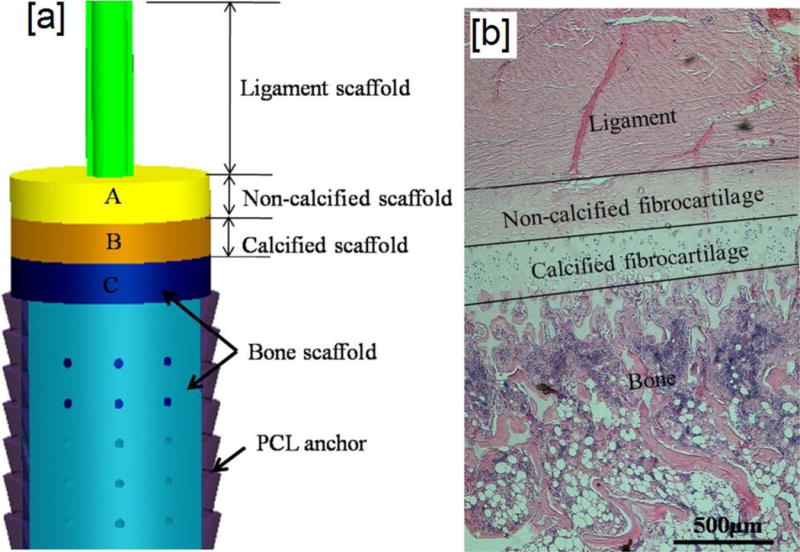

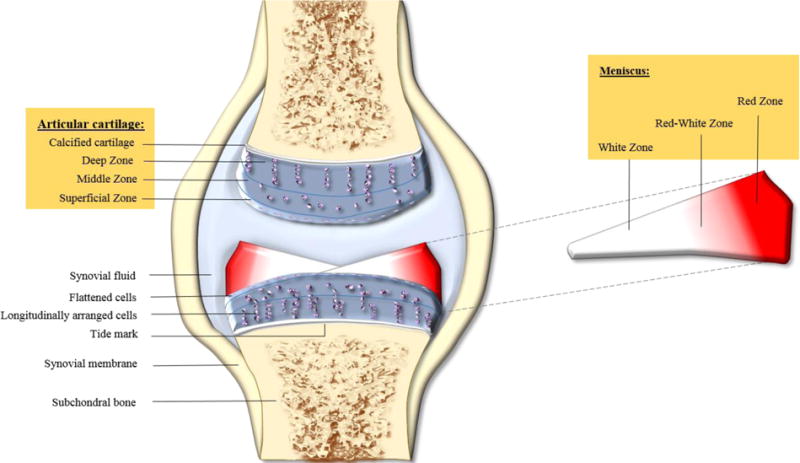

Figure 3. Scaffolds reported for bone tissue regeneration applications.

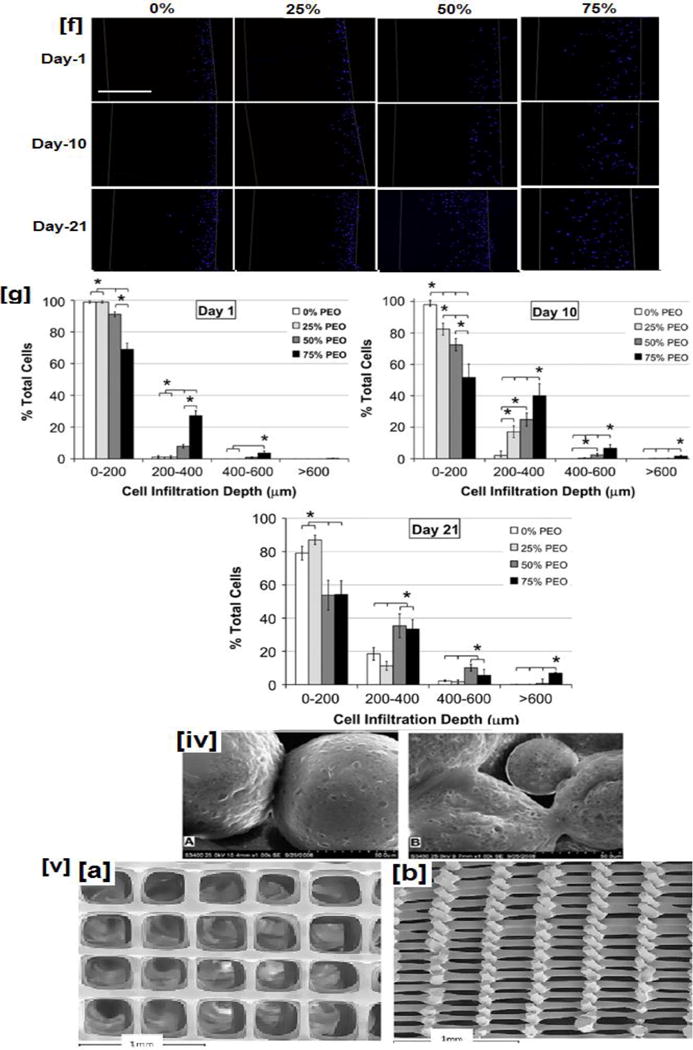

(i) SEM micrographs of (i) PLGA/HA composite obtained from solvent casting/particulate leaching method, (ii) representative electrospun nanofibrous scaffolds, (iii a–b) porosity and pore diameter of electrospun dependence of PLLA nanofibers on the added PEG content, (iii c–e) combined polarized bright field and fluorescent imaging indicate the cellular infiltration through the scaffolds, (iii f) cellular infiltration observed for scaffolds made with varying PEG content at various time points. Higher cellular infiltration is observed in scaffolds containing higher PEG contents even at shorter time points, while scaffolds with lower PEG content exhibit poor cellular infiltration at shorter time points, (iii g) quantification of cellular infiltration through scaffolds made with varying PEG content (iv) PLGA based microspheres: (a). before and (b) 7-days after in-vitro cell culture with osteoblast cells (MG-63), (v) Top (a) and cross sectional view (c) of PLA based scaffolds obtained by nozzle deposition system (3-D printing process). Image (i) reprinted with permission from [137], copyright Elsevier 2006. Image (ii) reproduced with permission from ref [168], copyright American Chemical Society 2015. Images (iii) reproduced with permission from ref [172]. Images (iv) and (v) reprinted with permission from refs [197, 198], copyright Elsevier 2010 and 2013.

PLA based materials, have excellent mechanical properties, processability, biocompatibility, favorable degradation rates, and do not elicit significant inflammatory response. However, their major drawback is the absence of any surface epitopes that could facilitate cell adhesion and proliferation. Several ways have been developed, including the use of plasma treatment, protein adsorption, immobilization of hydrophilic molecules, and surface functionalization with bioactive epitopes to overcome this drawback and to make these materials more conducive for bone regeneration applications[156, 157].

One of the oldest techniques to prepare scaffolds with relatively high porosity and interconnectivity have been by solvent casting/porogen leaching technique (Fig. 3i) [137], This is accomplished by leaching a porogen (salt, saccharides, proteins, or wax) from polymer-porogen blend. Since the 1990’s, both PLLA as well as PLGA scaffolds have been prepared and studied extensively using this technique for bone tissue engineering applications [158, 159]. Key drawbacks of this technique are the use of toxic organic solvents, phase separation of organic/inorganic phases, low thickness (0.5 to 2 mm), and poor cellular infiltration into the interior pores of the scaffolds [160]. A modified approach via thermal phase separation (TIPS) has been extensively studied to prepare polymer solutions at higher temperatures, and induce phase separation between the solids and liquids by lowering the temperature. By removing the liquid phase by freeze-drying or alternative techniques, a large porous structure is formed. Advantages of this method include, uniform and larger pore structures (>100 μm), and better mechanical properties compared to solvent casting-porogen leaching [161, 162].

The necessity for the use of toxic inorganic solvents has been a disadvantage till now; however, several modifications have been proposed using more green solvents such as ethyl acetate (FDA approved food ingredient), dimethyl carbonate, etc., making this process attractive for bone tissue regeneration application [163, 164]. Another approach (gas foaming) employs CO2 or compounds such as ammonium bicarbonate to create pores in the polymeric scaffold structure (Fig.3ii) [137, 165]. This approach completely eliminates the necessity of organic solvents, while resulting in polymer foams with pore sizes of 100 μm and porosity >90% [166, 167]. However, non-uniform pore sizes and poor interconnectivity have been their major drawbacks [167].

Electrospun fibers typically have diameters in the nano-submicron size range and offer a high surface area to volume ratio (Fig.3iii) [168]. In addition, due to their small fiber diameters, they mimic the nano-sized physical characteristics of the ECMs. Growth factors, anti-bacterial drugs, inorganic minerals, and other factors have been embedded and sequestered in the electrospun nanofibrous matrix (for example, using NPs), and delivered appropriately [104, 169, 170]. However, these scaffolds do not possess the appropriate pore size (>200 μm) for osteoblasts/MSCs migration and proliferation. To make the nanofibers more conducive for bone tissue engineering, several methodologies have been explored. In one study, the ECM matrix with its nano-and microstructural architecture was recreated by combining micro- and nanofiber technology[171]. In one study reported by Whited and coworkers, used a three-step methodology to create larger pores while retaining the nanofiber characteristics. In this, initially, electrospun PLLA-PEG nanofibers were obtained followed by the dissolution of the PEG layer. The nanofibers were then subsequently mineralized using an elaborate technique [172]. This methodology holds significant potential as the resulting scaffolds mimic osteogenesis by initially creating a disordered collagen-I nanofibrous matrix followed by mineralization [173]. In this process, active osteoblasts adhered and secreted more ordered/controlled matrix completing the osteogenesis process.

The results confirmed the hypothesis that with higher sacrificial-PEG content, porosity profiles and interconnectivity would support cellular attachment and proliferation through the scaffold. The authors observed a linear increase in porosity with increasing PEG content (Fig 3 (iii a–b)). When visualized by polarized bright field and fluorescent imaging, authors noted significant enhancements in cellular proliferation caused by higher porosity profiles generated by removal of PEG content (Fig 3 (iii c–e)). In addition to cellular proliferation, authors observed that at even shorter time points (1-day), in porous scaffolds, especially those made with 50 and 75% PEG content, 20% of osteoblast-like cells proliferated to 200–400 μm. It was interesting to note in scaffolds made without PEG, cells were not able to proliferate until the next time point (10-days). Finally, even at 10-day time, in 50% and 75% PEG scaffolds, cell proliferation up to 600 μm was possible, and their numbers increased significantly at 21-day point. Furthermore, ALP, an early stage marker for osteoblast attachment was upregulated with higher sacrificial-PEG. Moreover, conclusive evidence was provided by osteocalcin and calcium content, a late-stage marker significantly upregulated indicating the effectiveness of novel porous scaffolds in regenerating bone tissue [172].

Apart from low porosity, lack of bioactive surface epitopes in PLA based biomaterial has been a major drawback for its application in bone regeneration. Incorporation of biological macromolecules such as heparin has been observed to improve surface properties of PLLA. As the incorporated heparin has binding domains for various proteins, growth factors, and bone cells, differentiation of MSCs into osteogenic lineages can be anticipated [128]. More recently, two different approaches were reported by Cui et al [174]., and Dinarvand et al. [175] to address this issue. Cui et al. fabricated PDLLA nanofibers and subsequently functionalized them with various chemical groups (amino-, hydroxyl, and carboxyl-). Upon mineralization from a simulated body fluid, they observed mineralization with smallest crystal size in the scaffolds functionalized with all three groups in a particular ratio of 2:3:5. In addition, higher cell proliferation and osteogenesis was observed in these scaffolds [174]. Dinarvand et al. recently electrospun PLLA scaffolds which was subsequently oxygen plasma treated and mineralized with bioglass (BG), hydroxyapatite (HA), and tricalcium phosphate (TCP) [175]. In addition to plasma treatment and mineralization, the authors studied the bone formation induced by these scaffolds in vivo in a rat model. Post plasma treatment, HA and BG were noted to have a nano-sized coating on the scaffolds; whereas TCP had a microporous structure. Histological, μ-CT, and digital mammography experiments conclusively showed complete regeneration of the bone occurred in the HA-BG-PLLA scaffolds. Similar results were also reported by Andrić et al.[176], who demonstrated that presence of gelatin-PLLA nanofibers not only aided in increased mineralization, but also lead to significantly increased osteoblast attachment, proliferation, and differentiation [176, 177]. These studies cumulatively demonstrate that both porosity as well as surface epitopes are important for successful bone regeneration using PLLA nanofibers.

Another approach to develop scaffolds with high porosity and interconnectivity for bone tissue engineering is by thermal, solvent, and solvent-nonsolvent mediated sintering of microsphere matrices (Fig.3iv) [178]. These sintered matrices, in addition, can also act as a reservoir and delivery vehicles to release bioactive molecules, growth factors, and cytokines required for tissue regeneration [179–183]. Our group has reported preparation of heat, solvent-nonsolvent mediated sintering of several polymeric microspheres [181, 184–193]. In one study, we reported fabrication of orderly packed PLGA sintered microsphere scaffolds with mechanical properties (modulus: ca. 300 MPa) closely matching mid-range values of human trabecular bone [194]. In a sintered matrix, the cells occupy and proliferate through the pores with concurrent matrix degradation providing further volume for new cells to proliferate. However, this technique also suffers from low porosity in the interior of the scaffold resulting in poor nutrient and oxygen supply to cells [195]. To overcome this problem, Amini et al. recently reported scaffolds with pore size gradients that resulting in efficient nutrient and oxygen transfer, enhancing cell survivability [196]. Recent developments in this field include: precise 3-D printing of microspheres with topographies applied to the 3-D sintered microsphere system is the utilization of nanolithography [199] to develop grooves and pits that can not only mimic the ECM’s physical characteristics, but also aid in stem cell differentiation into osteogenic lineage [200].

iii. Nanoparticle-Mediated Bone Tissue Engineering

Nanoparticles (NPs) have been extensively investigated as payload carriers to deliver drugs, proteins, and other bioactive molecules to induce osteogenesis, anti-microbial properties, and enhance mechanical properties of the tissue engineered scaffolds. As bone tissue consists of collagen fibers nucleated with an inorganic phase containing hydroxy apatite particles (Fig.2), initial efforts were focused to replicate this intricate architecture in the scaffold. Nanoparticles of HA, TCP, and bioglass have been well known for their ability to induce osteogenesis, and improve the adhesion, proliferation, and differentiation of osteoblasts and osteoprogenitor cells. In addition, many research groups have demonstrated silver, TiO2, MgO, carbon nanotubes, carbon fibers, alumina, boron nitride nanotubes, cellulose nanocrystals, polyanilines, reduced graphenes, graphene oxides, nano-diamonds, and mesoporous silica-based nanoparticles for their osteogenic properties.

In addition to mechanical stimulation, as bone tissue is a piezoelectric tissue, application of electrical stimulation is thus an innovative way to direct osteogenesis [201]. In fact, some studies have shown the possibility of tissue regeneration with modest electrical stimulation resulting in DNA synthesis and proliferation [202]. A recent study by Cao et al. evaluated the effects of electrical stimulation via electrically conductive aniline pentamer-PLGA composites on bone cells [203]. The study showed, composites containing a minor portion of aniline pentamer (5% by wt) elicited a 50% increase in cell viability at earlier time points (1-day) and a slightly lower (30%) cell viability at longer time points (7-days). In addition to cell viability, they further showed that BMP-2, collagen-I, and osteonectin expression were upregulated at all time points in composites containing aniline pentamers, thereby demonstrating the usefulness of electrical stimulation on osteogenesis [203]. Similarly to this study, Bagchi et al. studied the electrical, mechanical, and chemical properties of three perovskite ceramic filled (calcium-, barium-, and strontium titanate) aliphatic polyester based composites on their capability to induce osteogenesis. The study demonstrated that all the perovskite containing composites exhibited higher conductivities, cell attachment, proliferation, and differentiation of osteoblasts [204]. Similar to AP and ceramics, graphene oxide NPs in PLA matrix was evaluated for their capability to induce cell adhesion and osteoblast differentiation. The study demonstrated excellent attachment due to higher wettability, and differentiation of osteoblasts towards bone formation [205]. These demonstrate by wisely choosing electrically conductive polymer or by adding conductive nanoparticles, osteogenesis can be triggered resulting in neo-tissue formation.

Current strategies to satisfy the mechanical requirements of the scaffolds have been primarily achieved by the incorporation of HA or TCP nanoparticles. However, with concomitant requirements for high porosity, even the addition of such nanoparticles, mechanical properties have still been inferior for cortical bones. In this aspect, as carbon nanotubes (CNT) (modulus >0.5 TPa) and boron nitride-based nanotubes (BNNT) (>0.5 TPa) are few of the strongest materials known to mankind, their application offers significant potential in bone regeneration. One study by Paiyz et al. evaluated the mechanical compatibility and cellular behavior of PLGA microsphere scaffolds reinforced with surface-modified (OH- and COOH-) multi-walled CNTs. They observed a 3-fold improvement in compressive strength and modulus values compared to neat PLGA scaffolds. In addition, no cytotoxic effects by surface modified (OH-) CNTs on PLGA composites was observed. Asides from cytocompatibility, higher cellular proliferation was observed, especially at shorter time points, observed by DNA content. Furthermore, these effects observed in vitro was confirmed by an in vivo rat subcutaneous model that showed delayed of PLGA microparticles due to the presence of MWNTs; however the mechanism of MWNT clearance in vivo was not established [206].

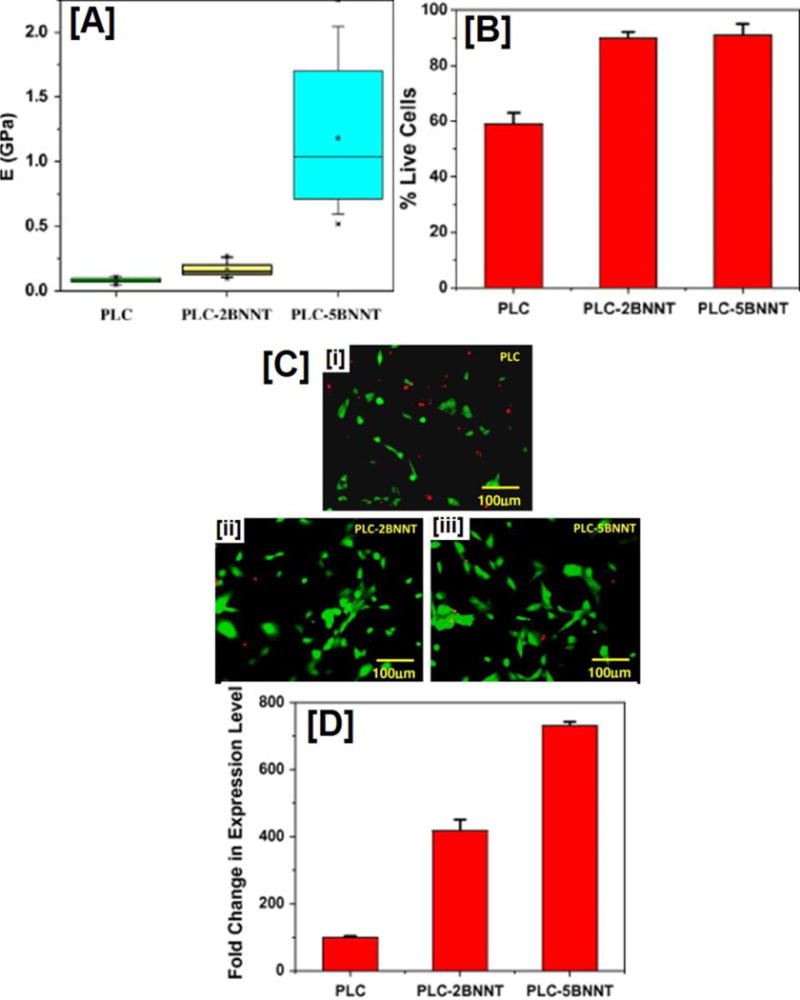

Similar to MWNTs, a study by Lahiri et al. reported the fabrication and subsequently evaluated the osteoblast activity of BNNT reinforced PLLA-PCL nanocomposites [207]. That study demonstrated with the addition of BNNT-NPs, as expected, a 10-fold increase in the modulus values (Fig 4A). But contrastingly, addition of NPs not only elicited cytocompatibility, but in fact, an 8-fold increase in cell viability (Fig 4B). Most important of all, Runx2 expression (Fig.4D), a regulator of osteoblast differentiation tremendously increased (up to 7-fold) with the addition of NPs. [207]. Although, this study particularly report possible reason for such high cell viability and gene expression towards osteoblast differentiation, a recent report suggested the presence of trace boron, and their subsequent interaction with the osteoblasts to cause differentiation of osteoblasts [208]. Boron nitride nanotubes or carbon nanotubes are external agents that trigger osteoblast differentiation of cells by enhancing the mechanical properties of the composite structures. But native bone tissue consists of small amounts of metallic or metal nanoparticles such as cooper, magnesium, zinc, iron, nickel, cobalt, and manganese [209]. As native bone tissue consists of these essential trace elements, few studies have hypothesized that addition of these elements would cause osteogenesis. Although mechanism through which they induce osteogenesis is currently not known, most trace metals are hypothesized to induce angiogenesis, a process interlinked with osteogenesis [209].

Figure 4. Mechanical properties, cell viability, and gene expression (Runx2) of PLLA-PCL scaffolds containing BNNT (2 and 5 wt %).

(A) Nano-indentation experiments demonstrate significant increases in modulus values in composites reinforced with BNNTs. The effect is more pronounced in composites containing 5 wt% BNNT. (B and C) quantification and fluorescent images of human osteoblast cells seeded on PLLA-PCL composites with and without BNNTs obtained by live-dead cell assay. Both quantified chart as well as fluorescent image indicate cytocompatibility of cells in scaffolds containing BNNTs; no statistical difference was observed in scaffolds with varying BNNT wt%. Finally, (D) several fold increases in Runx2 expression: a key regulator of osteoblastic differentiation. Images adapted with permission from ref [207], copyright Elsevier Ltd 2010.

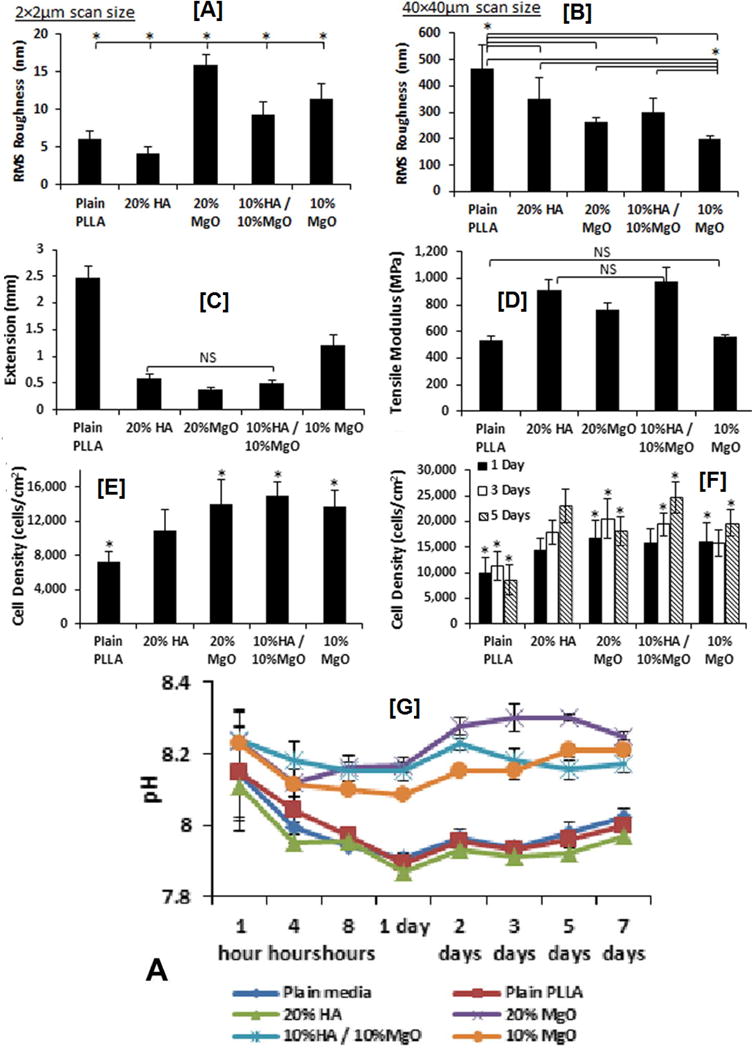

In particular, magnesium asides from being a component of bone tissue, have been found to play key role in various physiological functions. Their role in viability of osteoblasts and in inducing osteogenesis was evaluated by Hickey and coworkers, who investigated the adhesion, proliferation, and differentiation of osteoblasts in PLLA-nHA nanocomposites containing MgO NPs. Addition of MgO caused nanoscale roughness, while at microscale level, PLLA control had higher surface roughness (Figs 5A–B). Furthermore, NP size and concentration of NPs were found to have profound impact on the surface roughness of the composites at nanoscale level. Moreover, addition of MgO NPs increased the modulus values of the composites with concomitant decrease in elongation, indicating significant improvements in stiffness of the composites (Fig 5C–D). While, addition of HA in the composites increased both the modulus as well as the elongation values, indicating the ductile-like failure modality. Unlike other NPs (CNTs and BNNTs) which remained in the scaffolds for longer duration, as MgO NPs have faster degradation especially in physiological conditions, two dilemmas existed. Firstly, their effect on cell toxicity and secondly, their effect on pH as they degraded. However, the study showed favorable cell viability and proliferation, in addition to marginal increase in the pH of the solution (Figs.5E–G). Infact, at shorter time points (4h), MgO containing samples elicited 50% and 30% higher cell viability, when compared to neat PLLA and PLLA/20% HA scaffolds, respectively. As with cellular activity, low pH change, especially at longer time points demonstrated low cytotoxic effects [210].

Figure 5. Surface roughness, mechanical properties, cell viability and proliferation, and degradation induced pH changes observed in MgO/HA reinforced PLLA composites.

(A) Effect of MgO addition causing surface roughness at nanoscale level, while having minimal effect (B) at microscale level. (C) Lower elongation at failure and higher modulus (D) of composites containing higher loading of MgO indicating higher stiffness, while neat PLLA and 20% HA containing samples exhibit a ductile-like failure. (E) Higher cell viability and proliferation (F) observed in scaffolds containing higher MgO content (20% or 10%MgO/10%HA) compared to neat PLLA scaffolds. (F) pH changes in the cell culture media caused by degrading MgO NPs. While neat PLLA, plain media, and HA containing samples caused the media to turn acidic, MgO containing scaffolds caused sharp decrease at shorter times followed by a marginal increase at longer time points indicating low cytotoxic effects. Images adapted with permission from ref [210] copyright Elsevier Ltd 2015.

Bacterial, microbial, and fungal infections, and bone cancer (osteosarcoma) have been major concerns in the treatment of bone pathology. In addition to silver nanoparticles that have been widely studied for anti-bacterial/microbial applications, graphene oxide [208] and selenium nanoparticles have been demonstrated to be excellent candidates for this purpose [211, 212]. One recent study indicated a significant decrease in long term proliferation of osteoblast-like sarcoma cells, while the proliferation of osteoblasts were two times higher, indicating the dual purpose of these nanoparticles. Additionally such superior performance was realized without the use of chemotherapeutics or any drugs [213]. These studies demonstrated not only their capability to induce osteogenesis via electrical, mechanical stimulation, but also simultaneously provide/stimulate anti-microbial/fungal functionalities to the scaffolds.

iv. Proteins, Growth Factors, and Small Molecules Mediated Bone Regeneration

Bone regeneration requires a carefully orchestrated sequence of events involving osteogenic cells, scaffolds, and growth factors culminating with the vascularization of the newly formed bone tissue. Growth factors have been observed to play a key role in orchestrating the cascade of events from the onset of injury until the formation of tissue. Einhorn and others have carefully investigated this cascade, and have excellently summarized their observations for successful bone regeneration [214–217].

Several growth factors (GFs) such as transformation growth factor-Beta (TGF-β), platelet derived-growth factor (PDGF), bone morphogenetic proteins (BMPs), fibroblast growth factor (FGFs), insulin like growth factors (IGFs), vascular endothelial growth factors (VEGF), and angiopoietins have been implicated to have significant role in the bone remodeling process [215].

BMPs have been the most widely studied GFs for bone regeneration due to their excellent osteoinductive characteristics [218, 219]. Although, they have been approved by FDA, and some in vitro and in vivo studies have indicated their capability to induce bone formation [220], controversy still exists due to their toxicity at the required dosage, and with some studies demonstrating conflicting results [221]. Further, application of individual growth factors has been suboptimal for bone regeneration, as bone formation depends on coordinated events, suggesting the need for several growth factors in combination. Compounding the problem, GFs have a very short life in vivo as they are readily removed, and due to their large size, penetration into the cellular membrane is also low. Controlling the fate of GFs in vivo with temporal and spatial control is key to their utilization in regenerative engineering [222]. To this end, several interesting strategies have been reported. In one study, Su et al. reported incorporation of BMP-2/dexamethasone (Dex)/bovine serum albumin (BSA) in core-shell PLCL nanofibers. Of the several combinations they evaluated, they reported higher stability of BMPs in the core region with Dex contained in the shell region (with PLCL/collagen). The stability and controlled release of BMPs from the core region resulted in higher ALP activity (initial stage marker for osteogenic differentiation), and also osteocalcin expression (late stage marker for osteogenic differentiation) [223]. Likewise, using core-shell nanofibers, Yang and coworkers demonstrated controlled release of BSA from PLA nanofibers. BSA release was observed to be Fickian in nature, and the structure of BSA was retained during the electrospinning process [224]. These studies demonstrated that sequestering GFs in nanofibers had very low impact on the conformation of proteins and growth factors.

A more viable option was demonstrated by Shah and coworkers who showed that by enhancing the interaction between polyelectrolyte coated PLGA scaffolds containing growth factors (BMP-2 and PDGF-BB) fabricated by a layer-by-layer approach, the release of GFs can be temporally modulated to induce osteogenesis. They further showed that with careful arrangement of growth factors, both sequential and simultaneous delivery of GFs can be achieved. In addition, in vivo results indicated complete regeneration of the bone tissue (calvaria) without the necessity of autologous stem cells [225]. Dopamine coating has been widely demonstrated to exhibit higher levels of cellular attachment and proliferation in scaffolds that have significantly high hydrophobicity, and inert materials such as poly tetrafluoroethylene (PTFE), glass, and silicon [226]. Dopamine coating also affords the possibility of immobilizing GFs due to the presence of various surface groups. Shin and coworkers recently utilized a dopamine coated PLCL scaffold for immobilizing VEGF and FGF, and showed that dopamine coating enhanced the immobilization of both the GFs, improving the biochemical activity of human umbilical vein endothelial cells (HUVECS) [227]. In addition, GFs have also been immobilized on biomaterial substrates utilizing benign chemistry such as N-hydroxysuccinimide/N-ethylcarbodiimide or by using spacer molecules such as collagen and heparin [228]. These studies demonstrate significant progress in immobilizing GFs, and presenting these with temporal and spatial control for guiding cell-GF interactions.

Despite progress in GF delivery, the necessity of supra-physiological doses, low permeation into the cells, and higher costs, have caused significant interest in other molecules that function similar to GFs. Smaller therapeutic molecules have the capability to permeate the cell membrane, and can act as signaling molecules in several cell signaling pathways. Furthermore, they have the added advantage of higher stabilities, lower immunogenicity, non-conformation dependent characteristics, and lower costs [229]. Moreover, several extra-and intra-cellular proteins have been reported to act antagonistically to GFs. For example, smad proteins (smurf1, smad 6 and smad7), noggin, and gremlin have been reported to act as negative regulators of the BMP signaling pathway [230]. In orthopaedics, small molecule mediated tissue regeneration are increasingly being reported for bone, cartilage, and ligament regeneration. In a recent study, SVAK-12 has been observed to induce osteogenesis of C2C12 myoblasts by negating the antagonistic smurf-1 pathway [231]. Via a similar mechanism, utilizing a small molecule phenamil, our group recently reported in vitro bone formation through the downregulation of Smurf1 in sintered PLGA microsphere scaffolds [232]. In addition to BMP/smad pathway, several other pathways such as protein kinase A (PKA) simulated by 4-Bnz-cAMP,Wnt, Hh, and BMP/MAPK signaling cascades have also been observed to induce osteogenesis [233–236]. Other small molecules that have been observed to induce bone formation by these pathways include rapamycin, FK-506, and tilorone [237]. Similar to bone tissue regeneration, small molecules also find niches in engineering other orthopaedic tissues such as cartilage and ligament.

5. Ligament Regeneration

i. ACL Anatomy

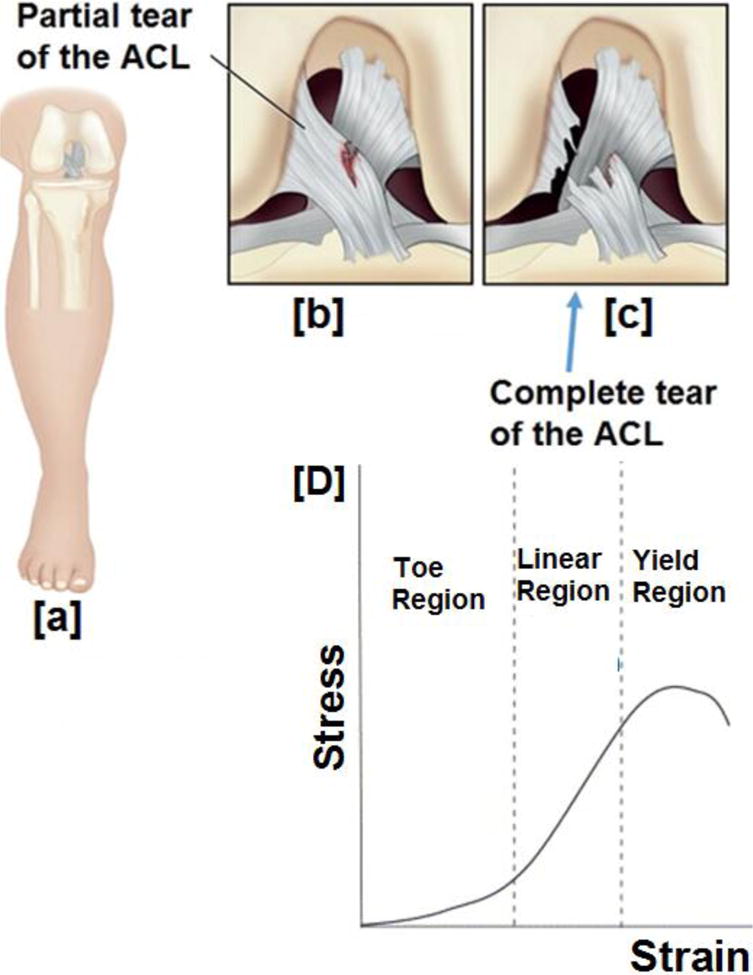

Ligaments (Fig. 6) are dense, well-organized connective tissues that connect bone to bone. As a connective tissue, ligaments are subjected to and transfers high tensile and torsional loads, thereby mediating normal movement, and further providing stability to the joint [238]. Despite having a thin sheath of synovium, of the four ligaments in the knee, anterior cruciate ligament (ACL) is an avascular tissue [239]. Thus, without external intervention, injuries to ACL typically do not heal on their own. In addition, the ACL deficient knee typically leads to further damage in the meniscus and articular cartilage, resulting in tibial laxity [240, 241]. Due to the avascular nature of ACL and the high failure rates, primary repair by surgical suturing is currently not preferred, and ACL reconstruction using auto- and allo-grafts are the most preferred techniques to treat ACL tear [242]. Similar to bone regeneration, significant issues with auto- and allografts necessitates investigation of biomaterial based strategies for ACL regeneration [243].

Figure 6.

A schematic representation of the ACL progressing to a complete tear (b) partial tear of the ACL caused by an injury, (c) gradually progressing to a complete tear, (D) three stages of behavior encountered by the ligament under mechanical strain. Under strain, there is a toe region where applied strain is not translated to stress because of the straightening of the crimp fibers, while in the linear region, after crimp straightening, applied strain is directly proportional to the stress (Hookean limit). Finally, beyond linear region, ligament yields to undergo rupture. Image (6A–C) modified and reprinted with permission from ref [244], copyright Elsevier (2014). Image 6D reprinted with permission from ref [33]

Strategies to engineer a scaffold suitable for ACL regeneration is hampered by the incapability to mimic the three distinct regions (ligament, fibrocartilage, and bony ends) with unique features present in the ACL tissue. In addition, upon tensile loading, unique crimp pattern present in the ligament causes it to undergo three distinct stress-strain regions before failure. To further add to its complexity, ligaments are comprised of two bundle regions: anteromedial and posterolateral (AM, PL), with each bundle exhibiting distinctive behavior under tension and flexion loads. Thus, strategizing a suitable biomaterial for ACL regeneration is complex. But, based on the physical, chemical, biochemical, and cellular environment of the ACL tissue, an ideal biomaterial for successful ACL regeneration is expected to possess or promote (i) porosities in a gradient fashion to promote ligament-cartilage-bone regeneration; (ii) similar degradation characteristics coinciding with the tissue regeneration; (iii) appropriate biochemical cues (growth factors/small molecules/receptors) to facilitate stem cell differentiation into appropriate lineages; (iv) appropriate biomechanical properties (three zones as shown in Fig.6 D); (v) two bundles (mimicking AM and PL bundles) with crimp pattern; (vi) angiogenesis and provide neovascularization of ACL tissue.

ii. Scaffold Based ACL Regeneration

a) Fiber Based Scaffolds

Similar to bone regeneration, collagen was the first material investigated for ACL regeneration. The choice of collagen was obvious as over 80% (dry mass) of native ACL is comprised of collagen. As was seen with bone regeneration, results were abysmal necessitating search for alternatives. For example, when collagen fibers seeded with ACL fibroblasts were evaluated for ACL regeneration, although the fibroblasts were observed to be viable for 6 months, the collagen scaffold had been completely resorbed by this time point [245, 246]. In addition to collagen, other natural biomaterials such as alginates, chitosan, and silk were also studied. The presence of sericin (in silk) and the poor mechanical properties (of chitosan and alginates) have been their major disadvantage for ACL regeneration [247, 248]. To investigate the feasibility of utilizing biodegradable polymers for ACL regeneration, Bourke et el. evaluated PLLA and poly (Desaminotyrosyl-tyrosine ethyl ester carbonate) (poly DTE carbonate) fibers in an in vitro study for ACL repair. Although PLLA and poly (DTE carbonate) fibers had higher cellular attachment and proliferation, but after 30 weeks of incubation in PBS, only 7% of the initial mechanical strength of PLLA fibers was retained [249]. This was in contrast to a previous study that reported only a marginal decrease in the stiffness of PLLA fibers after 20 weeks of incubation in PBS [250]. One possible reason for the low mechanical properties observed in PLLA fibers was due to the construction technique employed (fiber bundles), resulting in poor transfer of the load.

In our laboratory, to specifically address this issue, we have fabricated 3-D braided scaffolds from PLA based biomaterials with specific geometry and architecture closing mimicking the architecture (intra-articular regions with the femoral and tibial ends) of native ACL tissue. In one study, degradation kinetics, mechanical properties, and cellular performance of these braided scaffolds for ligament regeneration were evaluated [251]. To overcome the drawback of lack of surface epitopes in PLA based materials, in a subsequent in vitro optimization study, Lu et al. studied the temporal, mechanical, cellular response, and degradation properties of braided scaffolds coated with fibronectin (Fn). Due to the fibronectin modification of the PLLA scaffolds, the braided PLLA-Fn scaffolds had higher cell adhesion, long-term cell proliferation, while retaining the degradation rates and higher mechanical properties of PLLA [252]. In addition, a follow-up in vitro study demonstrated braided PLLA-Fn scaffolds to promote larger extracellular matrix production by ACL fibroblasts at longer time points [253]. These studies indicate braided PLLA/PLLA-Fn to be a suitable biomaterial for ACL regeneration applications.

Similar to our approach (Fn coating), several approaches have been investigated to improve cell attachment, proliferation and ECM deposition rates. For example, Sarukawa and coworkers showed that coating PLA fibers with chitosan enhanced the adhesion and proliferation of ACL fibroblast cells. In addition to cell adhesion and proliferation, they further observed chitosan coating improved ECM matrix production [254]. As the selection of appropriate cell source is key for neoligament formation in vivo, one study evaluated ACL fibroblasts and fibroblasts from neighboring connective tissues (MCL, achilles- and patellar tendon) on a 3-D braided PLLA scaffold. The study showed that ACL fibroblasts had remarkable attachment and enhanced matrix production in the scaffolds [255]. Based on promising results from these studies, a 12-week in vivo study was conducted in a rabbit ACL model. At shorter time points (4-weeks), fibrous capsule and tissue infiltration were observed at the periphery of the engineered ligament seeded with ACL cells. But at longer time points, infiltration and strong attachment of cell and collagen-deposition was observed throughout the ligament, further illustrating the potential of braided PLLA fibers for ACL regeneration [256].

In addition to braided PLA based fibers, woven and knitted PLA based scaffolds have also been studied for ACL regeneration [257]. One study showed knitted PLLA yarns to have higher porosities, slower degradation, and structural stability for a long study time (up to 20 weeks). However, knitted PLLA yarns also exhibited lower mechanical properties as they had lesser capability to transfer load. Furthermore, high porosities observed in the knitted scaffolds, caused significant difficulties in cell seeding [31]. Woven scaffolds, on the other hand, reportedly had higher mechanical properties, similar to braided fibers in uniaxial direction, but due to their architecture, lesser cell growth was typically observed in woven constructs [258]. Hence, most preferred textile structure for ligament regeneration are braided structures due to excellent mechanical properties.