Abstract

Hydrogels have long been explored as attractive materials for biomedical applications given their outstanding biocompatibility, high water content, and versatile fabrication platforms into materials with different physiochemical properties and geometries. Nonetheless, conventional hydrogels suffer from weak mechanical properties, restricting their use in persistent load-bearing applications often required of materials used in medical settings. Thus, the fabrication of mechanically robust hydrogels that can prolong the lifetime of clinically suitable materials under uncompromising in vivo conditions is of great interest. This review focuses on design considerations and strategies to construct such tough hydrogels. Several promising advances in the proposed use of specialty tough hydrogels for soft actuators, drug delivery vehicles, adhesives, coatings, and in tissue engineering settings are highlighted. Whilst challenges remain before these specialty tough hydrogels will be deemed translationally acceptable for clinical applications, promising preliminary results undoubtedly spurs great hope in the potential impact this embryonic research field can have on the biomedical community.

Keywords: tough hydrogels, drug delivery, tissue engineering, tough adhesives, tough hydrogel coatings

1. Introduction

As one of the most popular biomaterials designed for clinical use, hydrogels – water-swollen, three-dimensional networks of crosslinked polymers – are fascinating materials whose application potential has tremendously expanded from traditional research areas in biomaterials and drug delivery systems to now include microfluidics, soft electronics, and nanotechnology.[1] In recent years, hydrogels with substantially improved and tunable physicochemical properties for applications in clinical settings have been enabled by interdisciplinary, collaborative efforts to rationalize design at molecular levels while controlling multiscale architecture.[2] Yet, despite several idyllic traits (e.g., biocompatibility, biodegradability, ease of fabrication, controllable permeability, etc.), conventional hydrogels suffer from being mechanically weak (stiffness ~10 kPa and toughness <10 J m−2), tremendously limiting their application in continuous load bearing scenarios such as tissue engineering given that tissues typically possess high toughness (1,000 J m−2), high tensile strength (30 MPa), and high stiffness (1 MPa).[3] In addition, the biodegradation profiles of many polymer networks are not suitable for long term in vivo applications because many hydrogels degenerate too quickly - especially in electrolyte solutions - to achieve desirable therapeutic effects, with degradation often being accompanied by the generation of acidic byproducts.[4, 5] Moreover, propagation and accumulation of damage within hydrogel networks can adversely cause a loss of structural integrity, potentially limiting the functional lifespan of the hydrogel. These limitations have drawn attention to designing materials with enhanced stretchable and toughness properties.[5–14] However, formulating mechanically robust hydrogels that are also morphologically and chemically stable for clinical use remains a challenge. For example, disruption of covalent bonds in tough interpenetrating network hydrogels can lead to irreparable network damage, employing hydrophobic associations is hampered by poor solubility of hydrophobes, competition from water for binding sites limits the association strength of hydrogen bonds, and ionic crosslinks are vulnerable to mobile ions typically encountered in physiological conditions.[9, 15, 16] All these issues could lead to undesirable swelling and degradation of mechanical properties. In fact, many tough hydrogels reported to date cannot maintain their mechanical properties during tissue culture or after implantation.[17–19] Thus, there remains a need to develop high-water-content, mechanically robust hydrogels that can prolong the lifetime of clinically suitable materials by reliably avoiding property degradation under aggressive in vivo conditions.

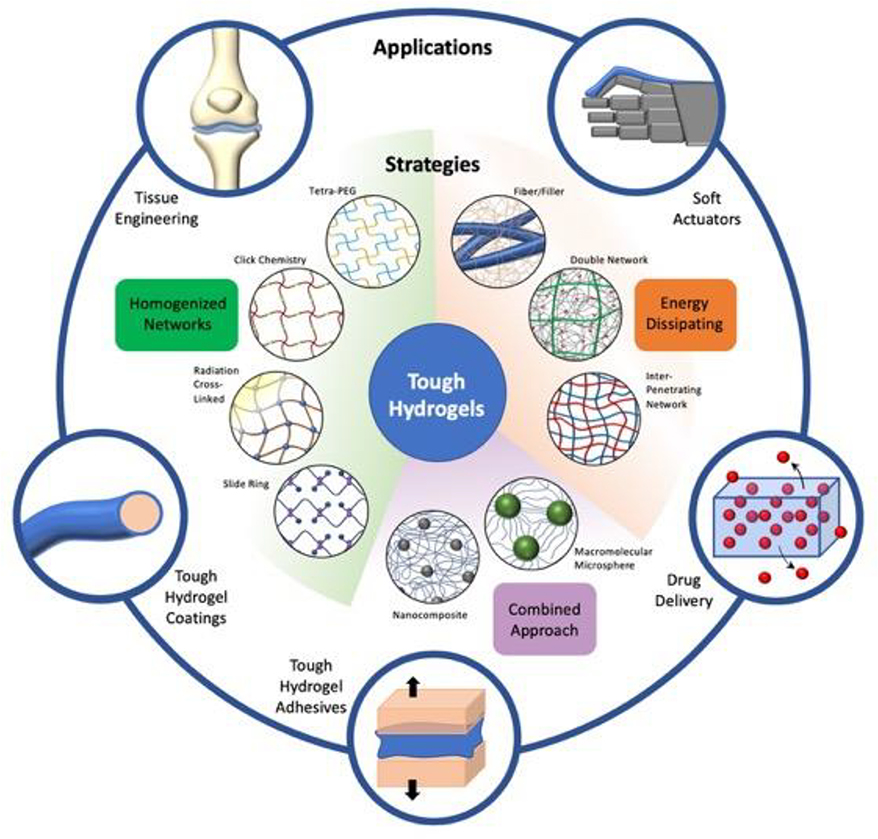

This review, as organized in Figure 1, presents current advances in the field of tough hydrogels while highlighting roadblocks in translating such materials for robust use in medical settings. We begin by briefly introducing underlying factors influencing material failure in conventional hydrogels, followed by commonly employed strategies to construct tough hydrogels given design considerations. Finally, we highlight some promising advances in biomedical applications of tough hydrogels, specifically focusing on tough hydrogels used as actuators, drug delivery vehicles, adhesives, hydrogel coatings, and in tissue engineering applications (i.e. cartilage, cardiovascular, and corneal tissue engineering). While many of these specialty tough hydrogels are not yet viable for clinical trials/applications, promising preliminary in vitro and in vivo data emphasize the exciting potential use of materials to tackle a wide array of challenging and pressing medical needs.

Figure 1. Overview of different strategies to make tough hydrogels and their biomedical applications.

Schematic representation of strategies used to formulate tough hydrogels, namely, Tetra-PEG, click chemistry, radiation crosslinked, slide ring, fiber/filler enforced networks, interpenetrating network hydrogels, double network, nanocomposite, and macromolecular microsphere composite hydrogels. Such specialty tough hydrogels have shown exciting promise as tough coatings and adhesives, and for use in soft actuators, drug delivery, and tissue engineering applications.

2. Design Considerations for Hydrogel Toughening

To design hydrogel devices and components with precisely tuned properties, evaluating the damage process at the crack tip becomes critical to determine what underlying factors lead to material failure and, consequently, material toughening.[20] When subjected to cyclic loading, hydrogels will undergo fatigue, meaning the progressive degradation of material properties or the nucleation and growth of cracks that may cause material fracture.[21] Consequently, a hydrogel’s strength is governed by its ability to withstand mechanical loads that lead to the formation and subsequent propagation of cracks: material failure occurs when the tip of a crack begins to propagate at its weakest point.[22] A static crack will lose stability and begin propagating when the change in potential energy released after an infinitesimal extension of the crack surpasses the fracture energy threshold (i.e. the energy needed to form two new surfaces).[23] Specifically, the energy dissipated during crack growth is equal to the energy where network strands are extended to the equivalent point of their dissociation energy.[24]

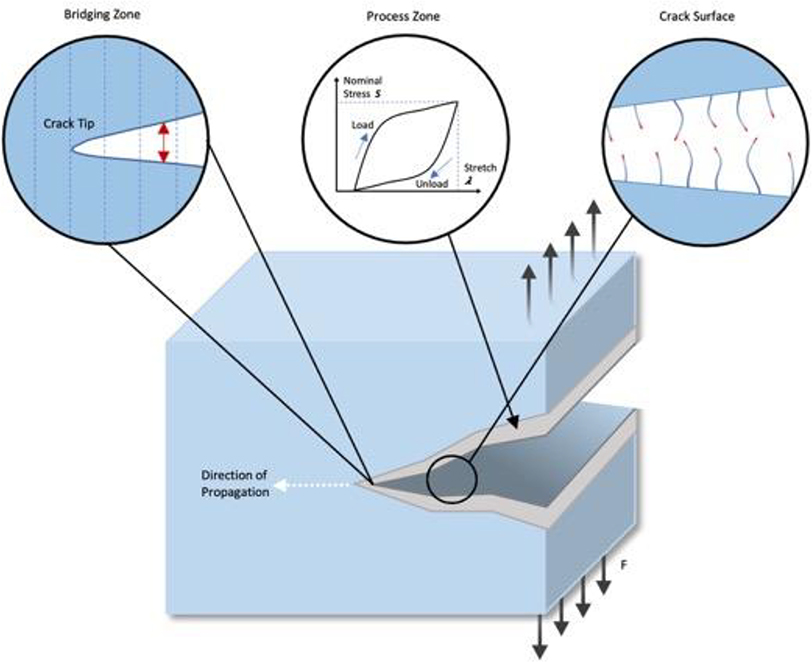

Unlike conventionally elastic materials, hydrogels exhibit large strain values at their fracture point and undergo deformation predominantly influenced by entropic rather than enthalpic phenomenon given that exerted forces drive changes in polymer chain configurations.[11] As such, during crack propagation, polymer chains undergo large deformation both along the crack path and in the surrounding area called the process zone (Figure 2).[11] In the process zone, all energetic dissipative processes that occur when the material is stretched beyond linear elastic deformation are assumed to take place, which are represented on stress-strain curves of materials as hysteresis loops.[22, 25] The size of the process zone varies significantly from material to material and can range anywhere from a few nanometers to a few millimeters. The added deformation in the process zone protects the crack tip from extending further from additional forces supplied by external loads and accounts for an added increase in the fracture energy of hydrogels. Subsequently, hydrogels with higher fracture energy would be better able to sustain greater stress and strain levels prior to rupture and could thereby be considered to have higher toughness.

Figure 2. Schematic representation of crack propagation in a hydrogel network.

When a crack forms, energy is released and transferred to the crack tip. The crack will continue to propagate if this energy is sufficient to rupture the polymer chains lying across the crack plane. The fracture energy of hydrogels is divided into two parts: fracture energy from polymer chains rupturing at the crack surface, and the mechanical energy dissipated by loading/unloading the hydrogel in the process zone. Adapted with permission.[26] Copyright 2013, The Royal Chemistry Society.

Generally, however, synthetic hydrogels are very brittle (fracture energy ~10 Jm−2 compared to 1000 Jm−2 for cartilage and above 10,000 Jm−2 for natural rubber) upon mechanical loading from a lack of significant energy dissipation in the process zone.[27] This problem is further intensified due to several other factors, including irregular distribution of crosslinking points, variations in polymer chain lengths at crosslinking junctions, and/or high water content.[12] Structural inhomogeneity inside polymer networks tends to arise as a result of differences in reactivity between monomers and crosslinkers: more densely cross-linked microgels initially form, which are then connected into a larger network, leading to an inhomogeneous network.[27] Along the same lines, it is difficult to ensure that crosslinking of polymer chains occurs at equal intervals when using crosslinking agents, thereby resulting in a wide range of chain lengths.[12] The resulting heterogeneity of the material, in turn, gives rise to defects that act as stress concentrators much greater than those experienced by the overall hydrogel. Regarding water uptake by the material, higher water contents result in a reduced crosslinking density, thereby reducing fracture energy given that fewer chains are broken for crack propagation. Moreover, crystallization or viscoelastic energy dissipation – additional energy dissipation mechanisms— are reduced by the greater separation distance of network chains in swollen hydrogel networks.[12, 24] While increasing the crosslinking density or polymer concentrations can slightly enhance a hydrogel’s mechanical strength, the mechanical properties of single network hydrogels remains insufficiently robust.

From a quantitative perspective, as reviewed by Zhao, the fracture energy of hydrogels is predominantly governed by two components: (i) the intrinsic fracture energy (i.e. the energy required to break the polymer chains lying across the crack path) and (ii), the fracture energy from mechanical dissipation in regions surrounding the crack path (i.e. process zone).[26] As mentioned above, the intrinsic fracture of polymers is highly dependent on the swelling ratio of hydrogels given that increased swelling leads to a reduction in the number of chains per cross-sectional unit area, thereby lowering intrinsic fracture energy.[24] Additionally, for polymers with fixed monomer units and crosslinking density, the value of the intrinsic fracture energy becomes relatively constant and very difficult to significantly increase. On the other hand, hydrogels that can sustain higher levels of stress and strain with more substantial stress–strain hysteresis and process zones lead to materials with higher fracture energy.[28] This was quantitatively modeled by Zhang et al., who used cohesive-zone and Mullins-effect models to show that toughening of a soft material relies on high intrinsic fracture energy of the material, high value of maximum hysteresis, and quick transition to the maximum hysteresis in the material under deformation.[25]

Considering these material properties and design constraints, there are broadly three overarching approaches to constructing endurant, tough hydrogels that maintain structural integrity following large deformation: (i) Reducing the presence of heterogeneities in the material by forming homogenous gels to evenly distribute load over a significant fraction of chains, thereby presenting fewer sites for micro-crack formation; (ii) Introducing one or several strategies to dissipate mechanical energy in order to limit macro-crack propagation; (iii) Incorporating both mechanisms by using multifunctional crosslinkers (e.g. micro and nano particles) to control inter-crosslinking distances, thereby forming homogenous networks while allowing for energy dissipation from rupture of bonds between the particles and polymer chains. In the following sections, different hydrogel fabrication methods and toughening mechanisms based on these three approaches are evaluated.

3. Strategies to synthesize and fabricate tough hydrogels

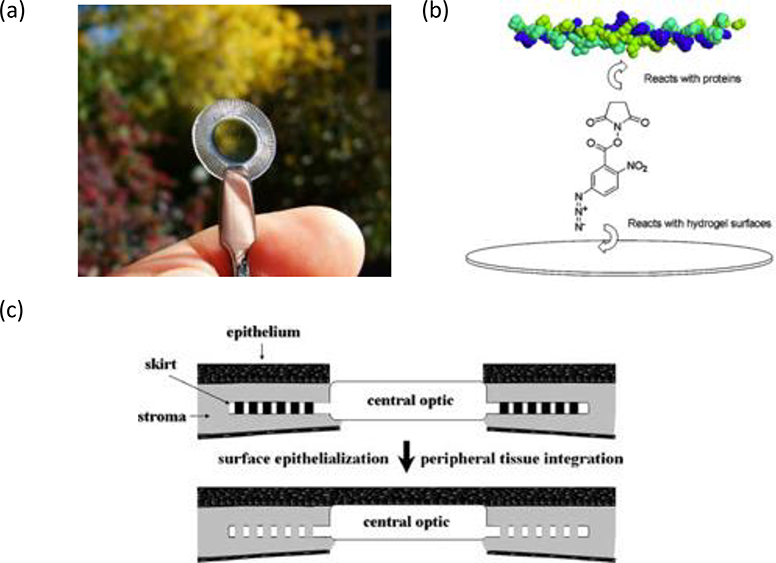

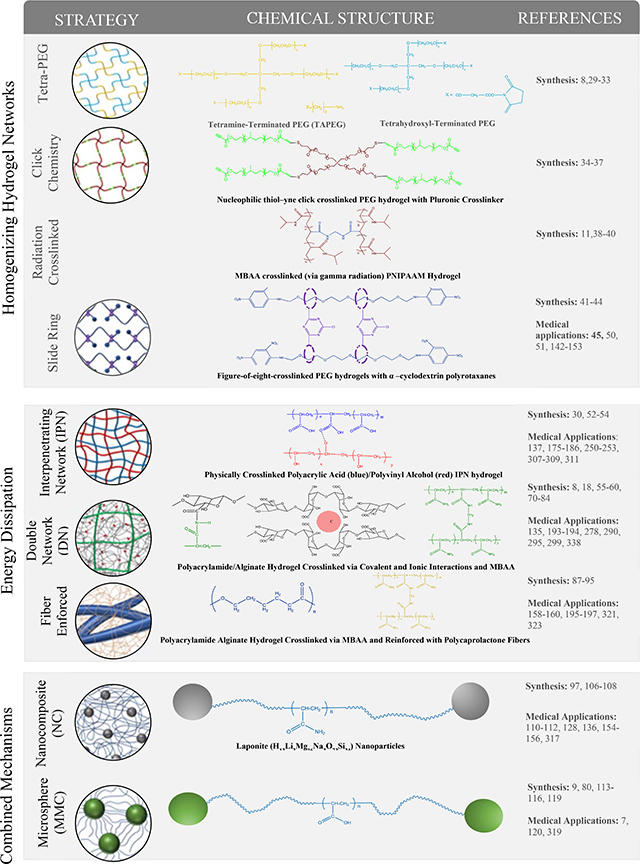

Several strategies have been proposed to fabricate which are broadly reviewed as three groups: (1) Homogeneous tough hydrogels, which encompasses tetra- polyethylene glycol (Tetra-PEG) hydrogels, click chemistry hydrogels, radiation crosslinked hydrogels, and slide ring hydrogels; (2) Energy-dissipating hydrogels, specifically interpenetrating network hydrogels, double network hydrogels, and fiber-reinforced hydrogels; and finally (3) Tough hydrogels with multifunctional crosslinkers (Table 1).

Table 1.

Schematic representation and chemical structure of different strategies (e.g. homogenizing polymer networks, introducing energy dissipation mechanisms, or combining both mechanisms) used to make tough hydrogels. Adapted with permission.[12] Copyright 2015, Elsevier.

|

3.1. Homogenizing polymer networks to form tough hydrogels

Traditional hydrogels generally suffer from inhomogeneous networks due to poorly controllable crosslinking methods. Thus, if one can carefully synthesize hydrogels with increased network cooperativeness, resulting gels would be endowed with improved mechanical properties compared to inhomogeneous counterparts, given an even distribution of load over network chains. The following section discusses some example strategies to synthesize homogenous hydrogels with mechanically superior properties.

3.1.1. Tetra PEG Hydrogel networks

Asymmetrical combinations between multifunctional crosslinkers and telechelic polymers endow hydrogel networks with an increased degree of freedom that results in the formation of micro inhomogeneities such as loops and entanglements.[8] To limit the formation asymmetric combinations and form uniform hydrogel networks, one can decrease the degree of freedom of the reactants involved in the reaction.[11] To do so, Sakai et al. developed a tetra- polyethylene glycol (PEG) gel combining two symmetrical macromers (tetraamine-terminated PEG (TAPEG) and tetra-NHS-glutarate-terminated PEG (TNPEG)) with equal sizes and defined lengths.[8] The polycondensation reaction obeyed second-order kinetics regardless of gelation threshold, suggesting that the prepolymers mix homogeneously after initiation, with reactions occurring between adjacent prepolymers.[29] Given that the length of the PEG arms define the nano-structural organizations of the hydrogel, resulting networks were found to have extremely homogenous 3D tetrahedral structures; topological defects (e.g. entanglements and loops) were found to be negligible in the hydrogel network.[30] The resulting high mechanical strength of the gel was found to be comparable to that of human cartilage: at a one—to—one mole ratio of the two PEG macromers, the gel had a compressive strength of 2.5 MPa and compression modulus of 40 kPa.[31] When investigating gelation mechanisms of Tetra-Peg hydrogels, gelation was independent of pre-polymer molecular weight and polymer concentration polymer concentration, thereby indicating that a reaction-limited rather than diffusion-limited reaction was key to fabricate the homogeneous polymer networks.[32] Further functionalization with poly(ethylglycidylether) (PEGE) to form amphiphilic Tetra-PEG–PEGE gels endowed the tough hydrogel with rapid phase transition behavior similar to PNIPAM-based hydrogels.[33] This facile method to fabricate homogenous, tough hydrogels is limited in scope of monomers and polymers available since symmetrical macromers are necessary to successfully synthesize such materials.

3.1.2. Click Chemistry Hydrogels

A similar strategy to formulate hydrogels with improved mechanical performance through controlled architecture is employing “click chemistry.” “Click chemistry” is used to describe a reaction that is high yielding, wide in scope, stereospecific, and generates inoffensive byproducts that are removable via nonchromatographic techniques.[34] Through copper (I)-catalyzed cycloaddition chemistry, diacetylene-functionalized and tetraazide-functionalized PEG derivatives were used to form a tough-PEG based hydrogel with a well-defined network structure.[35] The drastically improved mechanical properties of the gel compared to photochemically crosslinked PEG hydrogels are attributed to an even dispersion of crosslinking points stemming from a more controlled crosslinking reaction. Moreover, material properties can be further fine-tuned via changes in azide/acetylene ratios, with unreacted azide and/or acetylene groups left available for subsequent functionalization, allowing for chemical tailoring to form a diverse repertoire of tough hydrogels. Other groups have similarly employed click chemistry to formulate tough hydrogels via controlled polymer network structures.[36] However, despite the benefit of spatiotemporal control and fast gelation times of thiol-ene and thiol-yne click chemistry reactions, potential toxicity from photo-initiators and radicals, along with cross-reactivity with thiols, remain concerning.[37] Likewise, copper (I) catalyzed reactions tend to use toxic copper catalysts, strain-promoted azide-alkyne cycloaddition is limited by difficult synthesis of cyclooctynes, and native chemical ligation suffers from cross-reactivity with amines.[37] Thus, complicated synthesis routes and potential side reactions between biomolecules and the hydrogels should be considered when choosing click-chemistry methods for developing tough hydrogels for medical applications.

3.1.3. Radiation Crosslinked Hydrogels

Norisuye et al. compared the structural profile of poly(N-isopropylacrylamide) (PNIPAM) gels prepared via conventional radical polymerization versus those prepared via γ-ray irradiation (γ-ray gels) using small-angle neutron scattering.[38] From their structural analysis, they found that γ-ray gels were more homogenous from a microscopic point of view than the chemical gels. This phenomenon is attributed the increased probability of achieving an even distribution of crosslinks via γ-ray irradiation mediated crosslinking because radicals can disperse evenly throughout the hydrogel network and crosslinking is independent of a monomer’s reactivity or concentration.[11] Using γ-ray irradiation mediated polymerization, Wang et al. synthesized polyacrylic acid (PAA) and polyacrylamide (PAAm) hydrogels.[39] The mechanical properties of the hydrogel were enhanced compared to classically polymerized PAA/PAAm hydrogels. More recently, Xu et al. fabricated a double crossed linked hydrogel from hyperbranched PEG-polymers that formed hydrogels in situ and could be further strengthened by γ-ray irradiation.[40] While controlling the degree of crosslinking is advantageous to form homogenous networks, a balance of risk to benefits must be considered, as extended exposure to γ-ray irradiation may result in un-intended toxicity, loss of biocompatibility, and potential loss of functionality of the hydrogel for medical settings where in situ polymerization is required.

3.1.4. Slide Ring Hydrogels

Okumura and Ito developed a novel polyrotaxane gel based on PEG chains and crosslinked cyclic α-cyclodextrin (α-CD) molecules.[41] In the so-called “slide-ring” hydrogel, polymer chains with bulky end groups are not chemically nor physically crosslinked but instead are interlocked by figure-of-eight crosslinks.[42] The freely movable crosslinks can slide along the threading polymer chain to equalize the tension i.e. the pulley effect.[42] This unique feature allows the hydrogel to stretch up to 24 times in length, and have a substantial volume change of up to 24,000 times in weight. [43] Furthermore, by modifying the hydroxyl groups of CDs with different functional groups, tough hydrogels with different stimuli-responsive properties have been formulated such as thermo-responsive, photo-responsive, and slide ring elastomer materials.[44] Although much less frequently reported, polyrotaxane gels can also be diversified with cyclic molecules other than CDs, such as pillararenes, cucurbiturils, and calixarenes.[44] Likewise, efforts to use polymer backbones other than PEG (e.g. poly (dimethyl siloxane), polybutadiene, polyester, a copolymer of poly(propylene glycol) and PEG or polyethyleneimine) have been explored, although efforts have been greatly limited due to the complexity of synthesis.[44] Ongoing research efforts to improve and simplify the synthesis of functionalized polyrotaxanes will undoubtedly expand the potential use of such materials for an array of medical applications.[45]

3.2. Incorporating Mechanical Energy-Dissipating Systems

Rather than homogenizing the polymer network, another approach to formulate tough hydrogels focuses on exploiting heterogeneity to produce an energy dissipation mechanism. As previously explained, when a crack forms in a hydrogel, energy released is transferred to the crack tip. The crack will continue to propagate only if this energy is sufficient to rupture polymer chains along the crack path. By incorporating an energy-dissipating system to diffuse this energy, the energy transferred to the crack tip will be insufficient to allow the crack to continue propagating in the hydrogel, thereby “toughening” the hydrogel. Such energy dissipation typically occurs from the rupture of bonds – physical and/or covalent—in the polymer network or from the fracture of embedded fibers.[11] Interpenetrating polymer networks and fiber/filler-reinforced composite hydrogels are two kinds of hydrogels fabricated with such energy-dissipating mechanisms.

3.2.1. Interpenetrating Polymer Networks

Interpenetrating polymer networks (IPNs) are amalgams of two or more crosslinked polymeric chains interconnected through noncovalent means that form unique multicomponent materials with distinct property profiles compared to their individual counterparts. According to their fabrication procedure, they can be classified as one of two kinds of IPNs: (1) Simultaneous IPNs in which precursors of the networks are mixed and synthesized simultaneously by independent, noninterfering routes (e.g. free radical and condensation polymerization) or; (2) Sequential IPNs, where after forming a hydrophilic polymer network, that network is then swollen in a second monomer solution, after which the latter is polymerized to form the resulting hydrogel.[46, 47] If one of the polymer chains is not crosslinked (i.e. linear), a semi IPN is formed, which can later be prepared into a full IPN by selective crosslinking of the linear polymer chain. IPNS are advantageous given that dense hydrogel matrices can be produced with stiffer and more widely controllable mechanical properties, allowing for more versatile combinations compared to single network counterparts. [47] Typically, long chains are interpenetrated with short chains that may be fractured or physically de-crosslinked under deformation, thereby dissipating energy while the long network chains maintain the elasticity of the network.[26] It must also be noted, however, that with IPNS, the polymers may become interpenetrated to such an extent that releasing encapsulated bioactive molecules becomes difficult, not to mention that the quality of the final polymer is highly susceptible to process parameters including reaction mechanism, reactor type, and reactor operating conditions.[48, 49] Likewise, limited fatigue resistance can restrict the clinical translation of many chemically crosslinked tough IPNS, thereby promoting more investigation into designing facile fabrication methods to produce IPNs that are both tough and self-healing with tunable application properties.[50]

Double Network Hydrogels

Pioneered by Gong et al., double network (DN) hydrogels are IPNs with tremendous mechanical properties that are typically composed of a stiff yet brittle first network and a ductile secondary network.[6] Under optimized conditions, DN hydrogels -with a water content as high as 90% - possess hardness (elastic modulus of 0.1–1.0 MPa), strength (failure tensile stress 1–10 MPa, strain 1000–2000%, failure compressive stress 20– 60 MPa, strain 90–95%) and toughness (tearing fracture energy of 100–1000 Jm2).[51–53] Such incredible properties are attributed to following essential features of DN: (1) A rigid and brittle polymer as the first network and a soft and ductile polymer as the second network; (2) A molar concentration of the second network 20–30 times that of the first network; (3) Tight crosslinking of the first network while the second loosely cross-linked, requiring a very high molecular weight of the second polymer.[6, 16]

Okumura, Brown, and Tanaka have proposed theories explaining the large fracture toughness of double network hydrogels.[54] The Brown-Tanaka model stipulates that crack propagation in DN gels occurs in two parts: (i) Failure of the first network -due to its brittle nature- causes the formation of multiple micro-cracks. As the external strain increases, these cracks are prevented from coalescing into macro-cracks by the second network through viscous dissipation, leading to the formation of damage zones around the crack tip.[55] The formation of these internal micro-cracks is a prominent form of energy dissipation, with the value of fracture energy increasing linearly with the size of the damage zone.[11, 56] Moreover, due to local necking and yielding around the crack tip, the gel becomes much softer, thus tremendously reducing stress concentration and increasing toughness.[53, 57, 58] Large hysteresis from the breakage of first network bonds, covalent interconnections, increased physical entanglements, and molecular associations are likewise stipulated to contribute to the superior mechanical strength of DN gels; and (ii) Second network failure leads to crack propagation that causes overall material failure.[52, 58, 59]

While DN hydrogels are traditionally formed by two-step free radical polymerization processes, molecular stent methods, one-pot synthesis methods, extrusion 3D printing, and free shapeable methods of production have also been explored.[6, 60] Void DN gels, biopolymer-based DNs, microgel enforced particle DN gels, liquid crystalline DN gels, bi-layered tough gels, and ultrathin DN gels are amongst the many novel techniques used to further enhance the mechanical properties of DN for practical use in biomedical applications.[61–63]

One consideration to keep in mind, however, is that while both classical and “molecular stent” strategies expanded the range of polymers available to fabricate DN hydrogels (e.g. neutral and polyelectrolyte polymers), both strategies necessitate multi-step synthesis. As such, the following limitations are encountered: (i) multistep synthesis is time-consuming as it generally involved swelling, diffusion, and two polymerization processes, resulting in a one to two day process to complete the DN hydrogel; (ii) only simple sheets and disc-like DN gels have been reported because it may be challenging to use the multi-step method to prepare complex shaped gels; and (iii) both “molecular stent” methods result in chemically cross-linked hydrogel networks and so the fracture of those networks—particularly the first network—causes irreversible damages to the DN hydrogels.[61]

To overcome these limitations, “one-pot” synthesis methods can prepare hybrid physically-chemically crosslinked DN gels in a faster and controllable way, while both extrusion 3D printing and free shapeable methods of production have facilitated the production of complex shaped DN hydrogels.[61] While these and other novel preparation methods of DN hydrogels have led to the formation of hybrid DN gels that are better able to withstand damage than traditionally chemically crosslinked hydrogels from reversible binding of physical crosslinks, poor fatigue resistance remains a key limitation of DN hydrogels.[61] Further exploration is warranted to design novel preparation to develop DN gels with robust mechanical properties, self-healing abilities, and multifunctional properties (e.g. magnetic, optical, electric properties, etc.) in an efficient manner.

3.2.2. Fiber Reinforced Composite Tough Hydrogels

Another method to design tough hydrogels involves embedding stretchy fibers or fillers into the hydrogel matrix with the idea that the fracture of fibers/fillers along the crack plane requires additional energy. This energy, coupled to the energy required to overcome cohesive forces of the matrix, increases the availability of dissipative energy, thereby increasing the overall toughness of the composite hydrogel network. For example, steel wool fibers, woven poly(ϵ-caprolactone) fiber scaffold, and polyacrylonitrile nanofibers were incorporated to improve the mechanical properties of alginate-PAAm gels.[64] Similarly, poly(ε-caprolactone), PLA, cellulose, and silk nanofiber composite tough hydrogels have been produced for intended medical applications, particularly for cell encapsulation purposes given that 3D woven fiber scaffolds can mimic layered structures innate to many tissues.[65, 66] Moreover, embedded fibers/fillers can enhance the compressive and wear properties of the gel scaffolds compared to single network hydrogels. Further biochemical modification of the hydrogel can likewise enhance the overall biocompatibility of the matrix. Additional investigation into architectural and spatial control of fiber distribution within the scaffolds will undoubtedly improve network cooperativeness of the composite to enhance the mechanical and biomimetic properties of such composites, as current hydrogels are yet to be able to suitably mimic the diverse microstructures and compositions of tissue ECMs.

3.3. Multifunctional Crosslinkers

Micro and nano-composite hydrogels are cross-linked polymer networks swollen with micro or nanostructures that endow the gel with higher elasticity and strength compared to their individual counterparts. The micro/nanoparticles can either crosslink the gel, be used to attach or absorb polymer chains, or add new properties (i.e. responsiveness to mechanical, optical, thermal, magnetic, electric stimulation, etc.) by physical entrapment within the network.[67] Multifunctional cross-linking via these micro/nano structures can allow for improved control over crosslinking densities and inter-crosslinking distances and thus facilitate better load redistribution within hydrogel networks to prevent macro-crack propagation. Similarly, reversible breaking of physical bonds between the particles and hydrogels serves to effectively dissipate energy to prevent crack propagation via an increase of fracture toughness. The rupture and reformation of bonds between the particles and polymer chains also advantageously endow such materials with superior self-healing properties compared to other tough hydrogels discussed prior.

3.3.1. Nanocomposite Tough Hydrogels

Haraguchi et al. developed transparent nanocomposite (NC) gels with excellent mechanical properties and structural homogeneity by using water-swellable silicate nanoplatelets (Laponite) as multifunctional crosslinkers for N-iso-propylacrylamide, N,N-dimethylacrylamide, or acrylamide polymers.[68] The inorganic clays are first exfoliated and uniformly dispersed in an aqueous media, after which radical polymerization is initiated thermally from the clay surface, thereby effectively crosslinking polymer chains by the clay sheets. Rather than being randomly crosslinked with haphazard and broad distributions of chain lengths as is common in traditional radical polymerization, the large distance between clay sheets allows the polymer chains to adopt long and flexible orientations with random conformations. Given that multiple polymer chains attach to individual clay NPs, detachment of single chains from NP has negligible effects on the overall structure of the hydrogel network.[11] Moreover, since the polymer chains can easily be reattached to the clay NPs via physical bonding interactions, the overall integrity and fatigue resistance of the hydrogel are enhanced. [11]

Regarding the mechanical properties of NC gels, the hydrogel demonstrate superior mechanical toughness, with the tensile modulus and tensile strength increasing almost proportionally with clay content, whereas the elongation at break tends to decrease slightly on increasing clay.[69, 70] However, at sufficiently high clay contents, the coil-to-globule transition of poly(N-isopropylacrylamide (PNIPAM) chains is inhibited due to steric hinderance. NC gels generally withstand 90% compression, are highly stretchable (elongation at break > 1000%), and under high loading conditions, can withstand sliding friction; yet frictional forces are affected by environmental conditions (wet or in-air), clay content, and drying of the gel surface.[69, 71] Interestingly, using other synthesis methods –simply mixing clay and polymer solutions or using other inorganic nanoparticles instead of clay—led to poorer mechanical performances of the resulting gels, thereby implying that the formation of the tough, organic/inorganic networks innate to this hydrogel are specifically realized via in situ polymerization in the presence of clay.[72]

The surface of the NC gels, while primarily hydrophobic in nature due to the spontaneous alignment of N-isopropyl groups at the hydrogel-air interface, exhibits reversible hydrophilic-hydrophobic changes based on exposure to different environmental conditions (e.g. in water versus air).[73, 74] The NC gels also demonstrated self-healing capacities and reversible swelling behavior from salt promoted coil-to-globule transitions of PNIPAM.[75] The fabrication process could be easily adapted to form platinum polymer clay nanocomposite hydrogels, copolymer nanocomposite hydrogels, and porous nanocomposites with characteristic layered morphologies.[76] Furthermore, NC gels were able to support the culture of HepG2 human hepatoma cells, human dermal fibroblasts, and human umbilical vein endothelial cells.[77] Other materials such as carbon-based nanomaterials (carbon nanotubes (CNTs), graphene, nano-diamonds), polymeric nanoparticles (polymer nanoparticles, dendrimers, hyperbranched polyesters), inorganic/ceramic nanoparticles (hydroxyapatite, silica, silicates, calcium phosphate), and metal/metal-oxide nanoparticles (gold, silver, iron-oxide) have since been combined with polymeric networks to obtain novel and tough nanocomposite hydrogels for medical applications.[78] One important consideration when using such materials for medical purposes is the in vivo degradation and subsequent the fate of the nanoparticles released from the composite materials.[13] Moreover, choosing the appropriate nanoparticles becomes critical, as different nanoparticles demonstrate different levels of biocompatibility, and the mechanical and self-recovery properties of the composite gels have been found to be affected by the choice of nanoparticle.[13]

3.3.2. Macromolecular Microsphere Composite Hydrogels

With a similar concept to nanocomposite tough hydrogels, the mechanical properties of hydrogels can likewise be reinforced by adding microspheres or microgels to form macromolecular microsphere composites. These composites allow for controlled crosslinking density and the inter-crosslinking distance through polymer chain attachment to microspheres, thereby enabling the network to sustain the stress cooperatively to enhance the overall mechanical integrity of the hydrogel.[12]

Huang et al. irradiated macromolecular microspheres (MMs)- composed of styrene, butyl acetate- with 60Co γ-rays in oxygen, forming peroxides on the surface of the evenly distributed MMs that then decompose under heat to form free radicals that act to initiate the grafting of acrylic acid monomers onto the MMs surface and initiate PAA homo-polymerization.[7] Transient inter and intramolecular hydrogen bonds between PAA chains act to dissipate energy, while the well-defined structure formed by long PAA chains crosslinked via MMs acts to sustain stress cooperatively, thereby forming a tough hydrogel whose crosslinking density and the inter-crosslinking distance can be tuned by adjusting the peroxide concentration and/or the concentration of MMs.[12] Notably, the composite was able to sustain a compressive stress of 10.2 MPa at a strain of 97.9% while being able to elastically recover to its original shape for strains greater than 90% despite having a high water content (~89%).[7] Hydrogels prepared by using peroxidized MMs and AAm exhibited moderate moduli (60− 270 kPa), high fracture tensile stresses (up to 0.54 MPa), high extensibilities (up to 2500%), and high fracture energies (270− 770 J m−2).[79]

Building on this concept, Xu et al. prepared multi-responsive composite hydrogels by treating core-shell microgels- composed of PNIPAA as the core and poly(vinyl amine) (PVAm) as the shell- with potassium persulfate to generate radicals on the amine nitrogens of PVAm that can be used to initiate graft polymerization of AAm onto the microgels.[80] The gels demonstrated high compressive strength (17–30 MPa) and rapid pH induced volume changes. He et al. developed an elegant synthesis method to formulate high mechanical strength microgels from micelles.[81] These micelles are formed by a nonionic surfactant in water, with subsequent nanoparticle formation via crosslinking under γ-ray irradiation; radiation-peroxidized micelles promote the grafting of polymer chains following the thermal decomposition of peroxides formed on the surface of the micelles. Composite networks of poly(2-acrylamido-2-methylpropanesulfonic sodium) (PNaAMPS) with sparsely crosslinked PAAm networks microgels have also been developed.[63, 82] The toughness and strength of the composites hydrogels depended on the PNaAMPS concentration in the microgel and the molar ratio of the PAAm to PNaAMPS.[83] Like DN hydrogels, the polyelectrolyte networks of the microgels serve as sacrificial bonds to increase the facture energy of the resulting network.[84] Remarkably, evaluation of hysteresis curves showed that DN microgels had a four-fold higher fracture efficiency from the rupture of polyelectrolyte networks than conventional DN gels at the same strain.[83]

To investigate the mechanical properties of temperature-sensitive microgel composites, Meid et al. embedded temperature-sensitive PNIPAAm microgels within PAAm hydrogel networks.[85] Results showed an increasing elastic modulus and storage modulus with increasing microgel content, with effects shown to be more pronounced for temperatures above the volume phase transition temperature.[85] Interestingly, swelling experiments showed a decrease in swelling capacity of composite materials – microgels promote chain entanglements, thereby reducing the ability of the material to absorb water – indicating that incorporating temperature-responsive microgel particles can endow composite hydrogels with temperature-sensitive mechanical behaviors.

Like nanocomposite tough hydrogels, MMCs overcome a classic limitation of organic crosslinkers (e.g. low number of reactive groups) given that the reactive surface of the microspheres presents several binding sites for polymer chains, forming strong yet reversible binding to aid in energy dissipation and self-healing processes. In contrast to NCs hydrogels that are typically made from highly specific polymers with water-swellable clay, MMC hydrogels only require organic components, with different compositions and properties easily formulated by changing microspheres and monomers. Many MMC tough hydrogels, however, are formulated with synthetic particles, which might present biocompatibility and biodegradability issues. While clinically ready materials have yet to come to fruition, several microgel organic/inorganic composites have been developed with promising applications for regenerative medicine applications.[5, 86] With further exploration into the incorporation of non-synthetic microparticles will undoubtedly facilitate the fabrication of desirable and translatable MMC hydrogels with ideal biocompatibility and mechanical properties for medical uses.

Overall, many of the strategies to enhance the mechanical properties of hydrogels discussed in this review have undoubtedly transformed and expanded the scope of hydrogel applications. However, only a small niche has shown feasible translatability towards medical applications. Complex fabrication methods with harsh solvents and extensive curing/irradiation time remain impractical, excessive swelling in aqueous solutions results in a tremendous reduction of mechanical properties, limited anti-fatigue properties leading to irreversible structural damage, and limited control over degradation profiles with non-toxic byproducts are a few unresolved challenges that still need to be addressed to design tough hydrogel devices and components that maintain their structural integrity for robust clinical use. In the following section, promising efforts to achieve the latter with tough hydrogels specifically for medical applications are reviewed.

4. Applications in Medicine

The intriguing properties of hydrogels that enable them to superficially resemble native soft tissues make them ideal material candidates for devices and components used in clinically relevant therapies. In the following section, proposed applications of tough hydrogels as soft actuators, vehicles for drug delivery, adhesives, coatings, and in tissue engineering are focused on and reviewed. While many materials have yet to be used in clinical settings/trials, promising preliminary in vitro and in vivo results using various animal models presage the use of such specialty, tough hydrogels for a wide array of medical applications with further optimization.

4.1. Soft Actuators

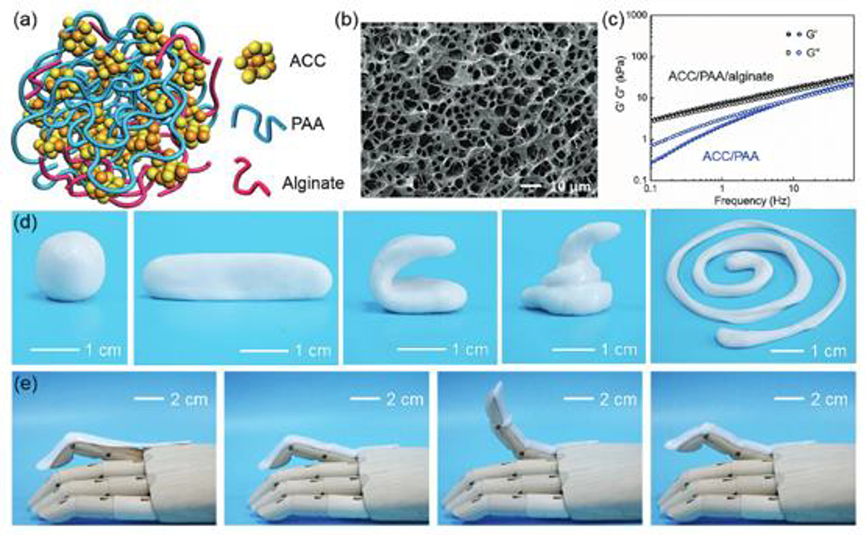

The use of soft matter in robotics has tremendously expanded the medical application of robots in the field, particularly in areas where soft patient interactions are preferred such as for replacement of limbs via prosthetics, artificial organs, body-part simulators, and drug delivery vehicles.[87] The principle behind using hydrogel-based soft actuators is that the hydrogel material is able to swell/shrink in response to external stimuli, which allows for the generation of various actuations and motions.[88] One application of interest of such actuator systems is developing artificial skin that is able to mimic both the flexibility and sensory sensitivity capabilities of the native skin, which has been explored using a wide range of materials from compliant conductors, semiconductors, to dielectrics.[89] Specifically, “electronic skin” is generally regarded as a stretchable sheet with area above 10 cm2 carrying sensors for various stimuli, including deformation, pressure, light, and temperature.[90] Using a hydrogel actuator, Sun et al. developed a transparent sensory sheet termed “ionic skin” from polyacrylamide (PAAm) hydrogels that could detect a wide range of stimuli (strains from 1% to 500%).[90] However, ionic skins made from chemically crosslinked PAAm generally suffer from poor self-healing properties propelling efforts towards the use of tough and/or autonomous self-healing hydrogels in the development of the next generation of ionic skins.[90, 91] For example, Lei et al. physically crosslinked calcium carbonate (ACC) nanoparticles in a PAA and alginate hydrogel to form an ionic skin with high pressure sensitivity (up to 1 kPa) and > 90% recovery even after ten drying–swelling cycles (Figure 3).[92] In the same spirit, Pu et al. developed a soft skin-like triboelectric nanogenerator TENG (STENG) using a PAAm-LiCl hydrogel- elastomer (PDMS and 3M VHB 9469) composite.[93] The sandwich structure of the STENG imparted the material with ultrahigh stretchability (uniaxial strain, 1160%) and transparency (average transmittance, 96.2% for visible light).

Figure 3. Soft actuator composed of a polyacrylic acid (PAA)/alginate hydrogel with calcium carbonate (AAC) nanoparticles to form an ionic skin.

a) Schematic of the hydrogel structure consisting of ACC, PAA, and alginate. b) SEM image of the composite ACC/PAA/alginate hydrogel following lyophilization. c) Storage modulus (G′) and loss modulus (G″) of the ACC/PAA/alginate and ACC/PAA hydrogels as a function of frequency. d) Images demonstrating facile manipulation of ACC/PAA/alginate hydrogel into different shapes. e) Images demonstrating dynamic adherence of the hydrogel to irregular surfaces and an ability to accommodate motion of the prosthetic finger. Reproduced with permission.[92] Copyright 2017, WILEY-VCH.

Stimuli-responsive polyelectrolyte hydrogels have also harnessed attention given their ability to transform chemical energy into mechanical motion without requiring external mechanical stimulation. A walking gel actuator made of cationic (acrylamide/sodium acrylate) and anionic (acrylamide/quaternized dimethylaminoethyl methacrylate) legs achieved unidirectional motion by alternate bending of each leg in response to changes in the direction of the applied electrical field.[94] A six-layered muscle-like actuator was developed that could undergo linear contraction (rather than bending) in response to an applied electric field.[95] Similarly, tough polyelectrolyte hydrogels with ionic nano-micelle macro-crosslinkers actuated by electric fields when immersed in salt solutions were recently reported.[96] Both positively and negatively charged hydrogels physically crosslinked via F127DA micelles were produced, yet cationic nano-micelle hydrogels interestingly decreased the toughness and strength of hydrogels compared to anionic analogs: anionic nano-micelle hydrogels demonstrated ionic strength dependent swelling behaviors, and exhibited significant, cyclic electric field sensitivity (e.g., bending angle up to 87° in 120s). Fatigue resistant, controllable, fast-acting actuation affords exciting opportunities to produce biosensors and artificial muscles, thereby broadening the potential for the development of “smart” prosthetics.

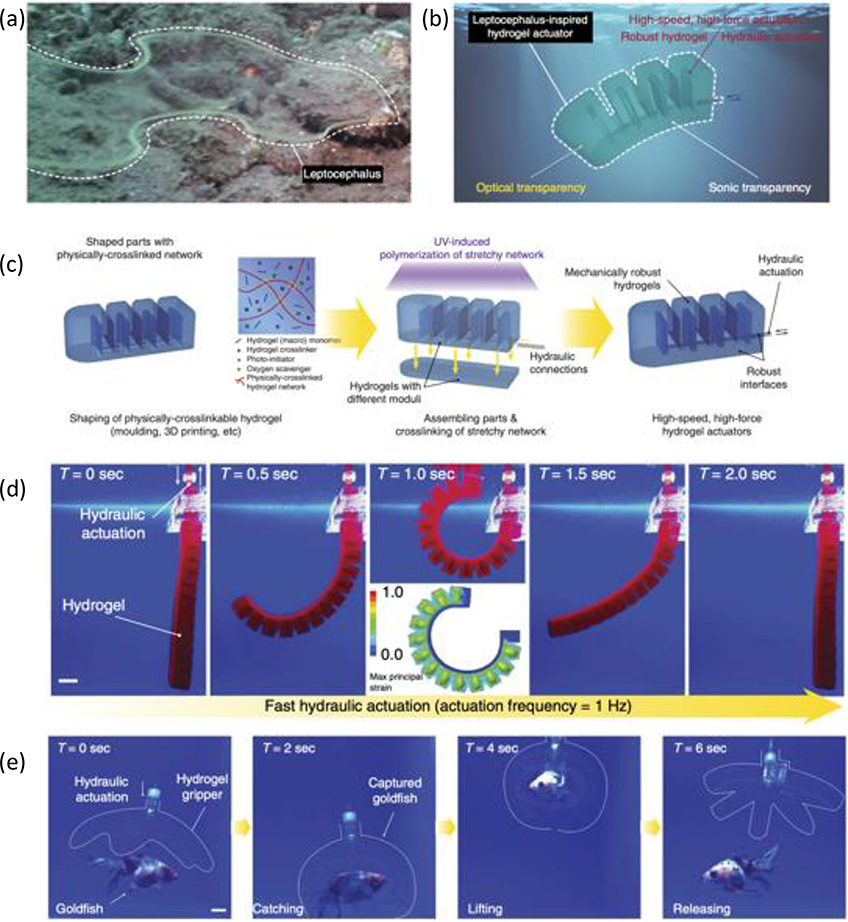

In terms of bi-layered tough hydrogel-based actuators, Liu et al. developed nanocomposite polyelectrolyte hydrogels composed of negatively charged (acrylamide and 2-acrylamido-2-methylpropanesulfonic acid) and positively charged (dimethylaminoethyl methacrylate methylchloride) hydrogel-exfoliated sodium montmorillonite nanosheets.[98] The actuator showed excellent fatigue resistance and high tensile strength toughness while demonstrating reversible actuation from the contrasting responsiveness of each gel component to the ionic strength of the immersion buffer. Zheng et al. developed a tough bi-layered actuator based on an interpenetrating network hybrid of physically cross-linked alginate and chemically cross-linked PNIPAM, which was used to make a four-arm robotic gripper that could sustain an estimated maximum load ∼1.21 g.[99] Similarly employing tough alginate/PNIPAM, Yuk et al. developed an optically transparent robust hydrogel actuator that could impressively catch, lift, and release a live ryukin goldfish via hydraulic pressure mediated actuation (Figure 4).[97] Further optimization of such materials can lead to the development of powerfully strong yet soft devices that improve the biomimetic stimulation of biological phenomena.

Figure 4. Example of an optically transparent, robust hydrogel actuator.

(a) Image of a leptocephalus in a marine environment. (b) Schematic of a hydrogel actuator inspired by the leptocephalus (c) Schematic of the hydrogel development process for hydraulic actuators. (d) Images of the hydraulic hydrogel actuator’s rapid actuation process. (e) Images demonstrating the implementation of a hydraulic hydrogel actuator to safely and rapidly capture and release a live ryukin goldfish. Adapted with permission.[97] Copyright 2017, Springer Nature.

Dalaney et al. constructed a valve within a microfluidic device using photo-responsive spiropyran functionalized onto thermoresponsive pNIPAAm hydrogels.[100] Initially, the hydrogel is in a swollen state, blocking flow through the valve. Once stimulated by LED light, the photo-responsive spiropyran is photoisomerized, contracting the hydrogel to allow fluid to move through the channel. Santiello et al. similarly developed a hydrogel carbon nanotube composite valve that could be used to control flow via bending actuation.[101] Such tough materials expand the potential of creating physical models to investigate human physiological and pathological conditions, such as controllable opening and closing of body passages and orifices. Several other biomedical, hydrogel-based sensors and actuators have been explored as reviewed by Banjernee et al., however, the design and implantation of biomimetic hydrogel actuators is very much still in early developmental stages given that many systems have yet to show in vivo functionality.[88] Moreover, despite the increase in mechanical stability provided by tough hydrogels, soft actuators that demonstrate excellent fatigue resistance and self-healing properties after continuous use while maintaining optical clarity, high water content, and strong adherence to robotic parts has yet to be achieved. Further collaborative, cross-disciplinary efforts to develop mechanically stable, high water content hydrogels for robotic applications will be critical to propel such technologies into clinically ready materials.

4.2. Drug Delivery

Hydrogel delivery systems should ideally- whilst optimizing patient compliance- maintain drug bioactivity through appropriate packing, transport, and storage, while the delivery should maximize the drug’s efficacy to achieve desirable therapeutic outcomes.[102] Though there are still challenges to overcome before these systems can be clinically applied, significant progress has been made in improving drug release kinetics from hydrogels, expanding the kind of drugs which can be delivered, and the efficacy of delivery.[103] Below are some examples of tough hydrogel-based drug delivery vehicles.

4.2.1. Polyrotaxanes for Drug and Gene Delivery

Polyrotaxanes consisting of α-CD molecules and PEG chains have garnered much attention for drug delivery applications given that CDs are FDA approved and PEG has been successfully employed to conjugate biologically active agents (e.g. proteins and drugs).[104] As such, several supramolecular polymers based on cyclodextrans have been developed specifically for drug and gene transfection activity (Figure 5).[105, 106] In one such example, Liu et al. immobilized hydrophobic cinnamic acid molecules onto the terminal groups of PEG (Cin-PEG) that were then threaded into α-CDs to form polyrotaxane nanoparticles.[107] Given that the polyrotaxanes are amphiphiles, they could self-assemble into vesicle-like nanoparticles used to encapsulate the hydrophobic antitumor drug doxorubicin, thereby increasing encapsulation efficiency compared to most polymer micelles. The polyrotaxane nanoparticles were non-toxic to NIH 3T3 fibroblasts and exhibited better in vivo tumor growth suppression than nanoparticles loaded with doxorubicin hydrochloride. By further functionalizing the hydroxyl groups of α-CDs with functional moieties, polyrotaxanes can be endowed active targeting properties.[108] For example, Ooya et al. found that saccharide modified polyrotaxanes had enhanced binding affinities to targeted lectins, while Yui et al. developed self-assembling micelles with triblock copolymers as a promising as a drug delivery carrier.[109] However, the clinical translation of these polyrotaxanes is limited by their poor degradability, unfavorable biocompatibility, and complicated synthesis routes of block copolymers. To remedy these limitations, Liu et al. recently developed α-CD and PEG polyrotaxane capped with cholic acid to load the anticancer drug doxorubicin, which interestingly exhibited selective recognition with cancer cells 4T1 via their high level of expression of glucose transporters.[110]

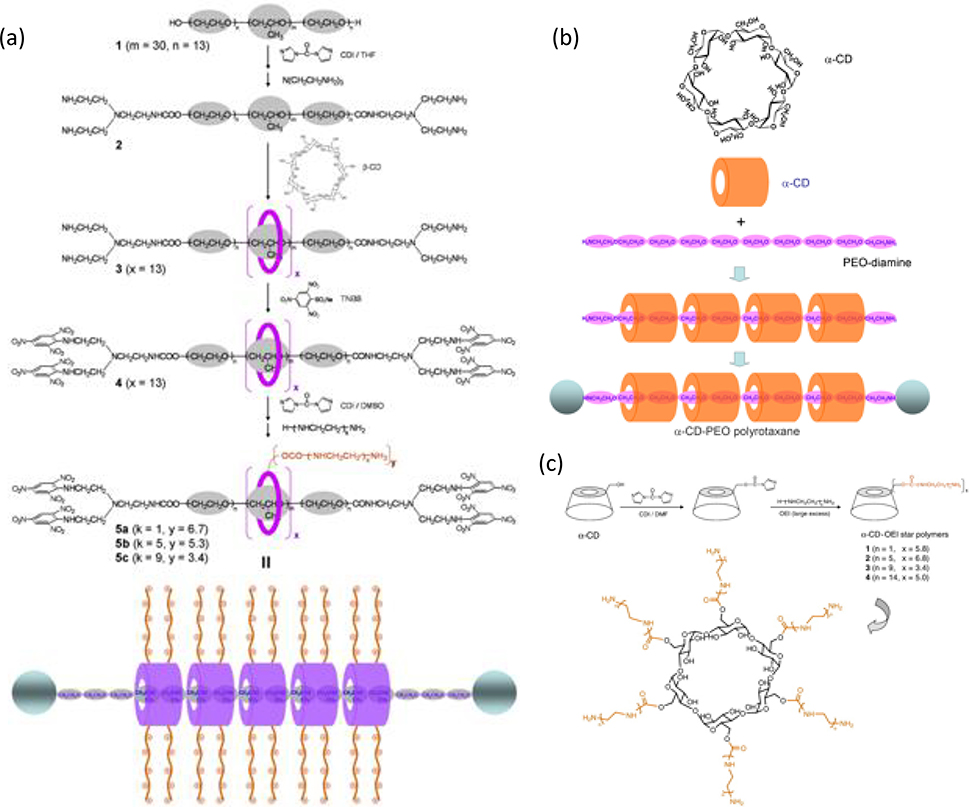

Figure 5. Schematic illustrations of synthesis routes for various polyrotaxanes used for drug and gene delivery.

Schematic illustration of the self-assembly (a) Fabrication of cationic polyrotaxanes with multiple β-CD rings featuring OEI grafting. (b) α-CD structure and polyrotaxane synthesis using α-CD and PEO-diamine. (c) α-CD–OEI star polymer fabrication process and structures. Adapted with permission.[106] Copyright 2008, Elsevier.

4.2.2. Composite Hydrogels for Drug Delivery

Considerable research efforts have promoted exciting progress in the use of hydrogel nanocomposite technologies for controlled drug delivery.[111] For instance, Li et al. developed an in vivo biocompatible alginate-clay nanoparticle composite for localized release of PEGylated insulin-like growth factor 1 (IGF1) mimetic protein.[112] At a neutral pH, the protein has a net positive charge and is therefore able to interact with the negatively charged surface of clay nanoparticles through electrostatic interactions. The nanoparticles enable significant loading of PEGylated IGF1 (8 mg/mL for 8% clay), while protein release – enabled by an ionic exchange—was upregulated by the low pH of injured tissues (Figure 6).[112] Choi et al. developed super tough hydrogel composites via an alginate/polyacrylamide DN embedded with mesoporous silica particles, and demonstrated the potential of such a network to exhibit on-demand BSA drug release via external mechanical stimulation.[113] Carboxymethyl guar gum (CMG)-chemically modified multiwalled carbon nanotube (MCNT) hybrid hydrogels were similarly developed for sustained trans-dermal release of diclofenac sodium an anti-inflammatory pain reliever and analgesic drug.[114]

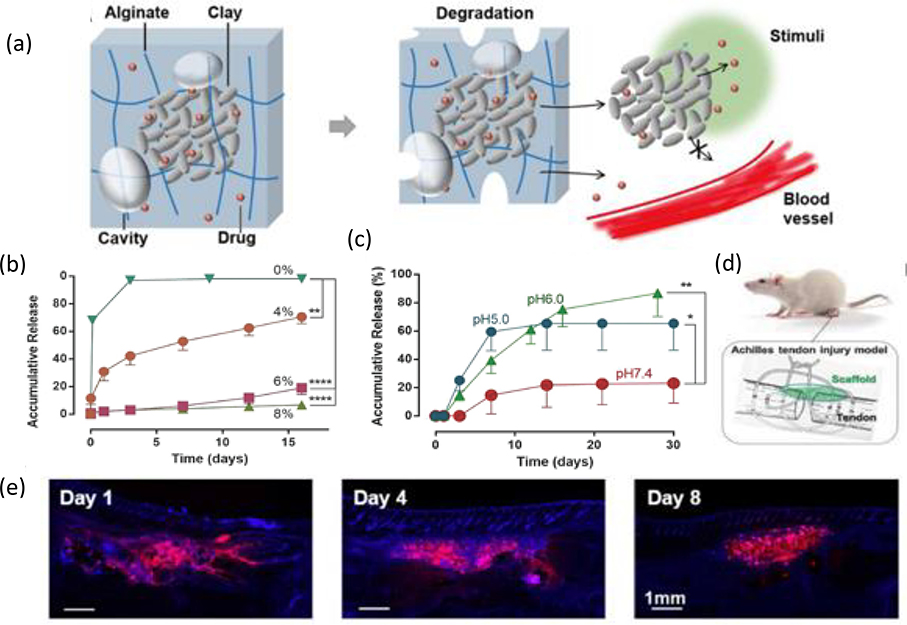

Figure 6. Composite hydrogel with high loading and local release of IGF1.

(a) Clay composite microparticles containing Laponite nanoparticles (represented by gray discs) and adsorbed drug molecules (red spheres) localized within a biodegradable alginate network containing micro-sized basins (gray ovals) and free drug (not sequestered within the microparticle). (b) In vitro drug release profiles from composite hydrogels containing various percentages of clay in cPBS medium at a pH of 7.4. (c) In vitro drug release profiles from 6% clay composite hydrogels within release medium at different values of pH. (d) Use of drug-releasing scaffolds (green) to treat Achilles tendon injury in a rat model. (e) DAPI staining (blue) of tissue sections to examine the distribution of the fluorescein-labeled protein (red) as it changes over time in vivo. Adapted with permission.[112] Copyright 2018, WILEY-VCH.

When exposed to an external stimulus, embedded nano or micro particles can trigger material phase transitions propelling the hydrogel network to expel large amounts of water and absorbed therapeutics, subsequently delivering encapsulated drugs. For example, Servant et al. used electrosensitive poly(methylacrylic acid) (PMAA) containing multiwalled carbon nanotubes (pMWNT) for controllable pulsatile drug (i.e. sucrose) release-via reversible de-swelling of the gel matrix-upon applying an electrical field stimulation.[115] While sucrose release was sharper in response to electric fields both in vitro and in vivo, the quantity of sucrose release upon the second electrical stimulation was lower than control gels because of surface damage on the gels. Using graphene rather than pMWNT improved the antifatigue properties of the gels, allowing for large deformation and volumetric changes under applied electric fields without material degradation after repeated stimulation.[116] Similarly, a chip like device formed from a PVA matrix with graphene oxide (GO) nanosheets sustained repeated, pulsatile release of lidocaine hydrochloride, an anesthetic, with high precision under electrical field treatment.[117] Another electrically modulated chip-like device, this time composed of genipin-cross-linked carboxymethyl-hexanoyl chitosan (CHC)–silica hydrogels, supported the in vitro the anticonvulsant drug, ethosuximide.[118]

Drug delivery via optically induced stimuli from nanocomposite hydrogels has also been explored. GO sheets interconnected by hierarchical peptide- composed of pyrene at the N terminus, a glycine-alanine (GA) repeat sequence and tyrosine at the C-terminus- interactions were used to form an injectable composite for pulsatile triggered delivery: localized temperature increase from NIR irradiation results in partial unfolding of β-sheets and weakening of π–π interactions between GO and GA repeats, triggering the release of encapsulated drugs.[119] In vivo release of the anticancer drug doxorubicin (2 mg mL−1) successfully reduced tumor size in mice after a treatment course of 23 days. Similarly, poly(N-isopropylacrylamide-co-acrylamide) hydrogel with silica–gold nano-shells likewise employed NIR irradiation to deliver to doxorubicin co-delivered with dsDNA for potential applications in cancer therapies.[120] Delivery of water-insoluble paclitaxel and other hydrophobic drugs, as well as magnetically mediated composite drug delivery have also shown promise.[121]

4.2.3. Interpenetrating Network Hydrogels for Drug Delivery

Several IPN hydrogel systems have been developed towards anticancer, anti-asthmatic, antibiotic, anti-inflammatory, anti-tuberculosis and anti-hypertensive drug delivery applications, as has been extensively reviewed.[48, 122] In recent developments, Pacelli et al. developed a DN hydrogel by using a methacrylate derivative of gellan gum (GG-MA) with clay Laponite – incorporated to increase the stiffness, while reducing the swelling ability of the GG-MA hydrogel- as the brittle network and polyethylene glycol dimethacrylate (PEG-DMA) as the second soft and elastic network. [123] The DN IPN was non-cytotoxic when cultured with HUVECs. Moreover, incorporating Laponite improved the loading efficiency of the antibiotic, ofloxacin, while reducing its in vitro release rate, promoting the possibility for local, sustained release of antibiotics. Similarly, a DN composed of allylated chitosan and PNIPAAm was used to bind the anti-inflammatory drug diclofenac sodium (DCF) via electrostatic attractions between the carboxylic acid groups of DCF and amino groups on the chitosan chain.[124] The in vitro release of DCF was conducted in simulated gastric fluid (SGF) at pH 1.2, and simulated intestinal fluid (SIF) at pH 7.4, with higher dosages observed to be released at lower pH due to activation of Schiff base bonds increasing the pore size of the gel, thus promoting greater drug unloading. Another anti-inflammatory drug (i.e. Ibuprofen; (IBF)), was delivered from a poly(vinylalcohol) (PVA) poly(ethyleneglycol) (PEG) IPN crosslinked via glutaraldehyde.[125] Incorporation of solid inclusion complexes of IBF in β–cyclodextrin improved the aqueous solubility, bioavailability and dissolution properties of normally poorly soluble IBF and thus the gels were better able to support sustained drug release behavior. A different pH-responsive IPN based on cellulose and poly-dopamine was developed to deliver the hydrophobic drug, ciprofloxacin.[126] Dopamine’s active amino group can be exploited to combine with carboxyl or carbonyl groups typically found on hydrophobic drugs to form a pH-sensitive amide bond that can be used to self-release bound medication at desired sites. In vitro release experiments showed an almost three order higher drug release at pH=4 than at pH=7, demonstrating the strong acidic responsive property of the material. The drug-carried hydrogel sustained a five-day antibiotic effect on Escherichia coli, demonstrating a promising potential application of such a system to treat bacterial infections on wound surfaces. While some in vivo drug release studies have been performed with IPNs with promising results, further investigation is needed to prevent issues such a burst release/incorrect dosing or device failure, either from fibrotic engulfment or mechanical damage, while promoting long term release.[127]

4.2.4. Bioactive delivery via cellular encapsulation

Cell encapsulation involves immobilizing cells within a device that is generally surrounded by a polymeric membrane that permits the exchange of nutrients and oxygen and the egress of therapeutic protein products.[128] Significant effort has been devoted to create artificial 3D scaffolds for cell encapsulation as an alternative strategy to overcome current difficulties with whole organ graft rejection, limited availability of functional donor organs, and potentially harmful secondary side effects from the use of heavy immunosuppressive drugs.[129] When designing devices for cellular encapsulation, a careful balance must be found between biocompatibility, durability, and diffusional properties to guarantee long-term functionality of cells to, in turn, allow for long-term drug delivery for treatment of diseases. Moreover, the mechanical properties of the cell encapsulating material become critical given that hydrogels may lose their functionality and structural integrity following exposure to the host’s immune system.[130]

Truong et al. used click chemistry to prepared DN hydrogels under physiological conditions that displayed high compressive and tensile stresses without fracture or hysteresis and could be used to encapsulate human mesenchymal stem cells with excellent viability, although cultured for a short time period (48 hours).[131] Similarly employing a DN hydrogel, Zhang et al. designed and formed an alginate sericin IPN via calcium ion and glutaraldehyde crosslinking agents.[132] The IPN supported cell adhesion, mouse myoblast migration and proliferation, while showing more stable degradation kinetics compared to pure alginate hydrogels. Interestingly, the IPN hydrogels inherited sericin’s photoluminescence property with sufficient transdermal transmission that could be used for in vivo tracking. In vitro horseradish peroxidase (HRP) release from the IPN hydrogels showed promising results that such a gel could become a versatile platform for cellular and drug delivery with further optimization.

Forming a functional cellular delivery device, Zhang et al. devised resilient, high-water-content PEG-based hydrogels that could be fabricated into hydrogel tubes.[18] The covalently crosslinked, highly coiled water-swellable PEG chains endowed the material with elasticity, while the incorporated N-acryloyl glycinamide (NAGA) contained reversible, swelling resistant, dual hydrogen bonding that resisted deformation and dissipated energy during mechanical loading, thus forming a robust tough hydrogel. By optimizing the NAGA content, the devices exhibited low fibrotic response when implanted in vivo in mice, and supported in vitro MDA-MB231 cells and human islets (for five days and three days, respectively) with no loss of mechanical properties. Incorporating nanofibers to form robust hydrogel composites, An et al. developed nanofiber enabled encapsulation devices (NEEDs)- with tubular or planar geometries- for cell encapsulation.[134] Poly(caprolactam) (Nylon 6), polysulfone (PSU), polyacrylonitrile (PAN) and polycaprolactone (PCL), Polystyrene (PS) were used to form porous nanofibers that are then infiltrated by alginate, PEG-DA, collagen, or chitosan solutions via surface tension-driven wicking, forming a tough interlocked hydrogel nanofiber device. NEED was able to correct the diabetes of C57BL/6 mice with minimal fibrosis for two months when encapsulated with rat pancreatic islets. Similarly employing surface tension-driven wicking, a robust device produced from Ca2+-releasing poly(methyl methacrylate) (PMMA) coated nylon fibers was used to form a Thread-Reinforced-Alginate-Fiber-For-Islets-enCapsulation (TRAFFIC) device.[133] By coating the modified thread with a solution of islets suspended in alginate, diabetes correction was achieved in C57BL/6 mice using rat islets for three months and in SCID-Beige mice using human islets for four months, with scale-up potential and facile retrievability shown in a large animal model study (Figure 7). Mechanically robust, injectable scaffolds and tough composite hydrogels have likewise been explored for cellular-based delivery.[135]

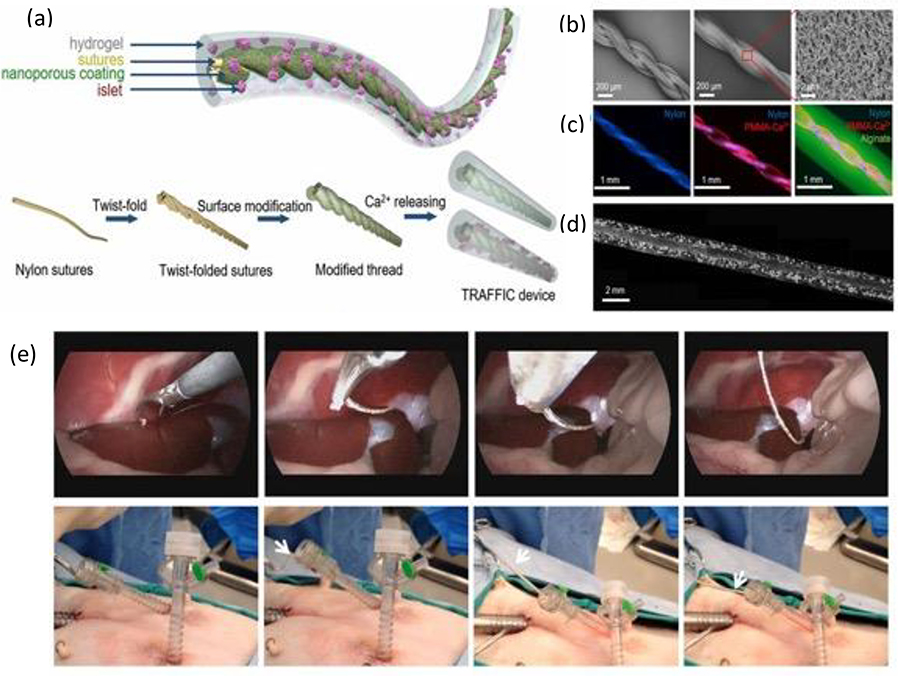

Figure 7. TRAFFIC device for potential treatment of Type 1 Diabetes.

(a) Schematic of the design and fabrication process of the TRAFFIC device. (b) SEM images of the thread featuring nanoporous modifications uniform across the surface. (c) Fluorescent images of the thread, coated thread, and a cell-free TRAFFIC device. (d) Microscopic image of TRAFFIC device containing isolated rat islets. (e) Laparoscopic images demonstrating the device retrieval process from the trocar in a dog. Adapted with permission.[133] Copyright 2018, National Academy of Sciences.

Yet, tough hydrogel-based cell encapsulation devices are currently unable to sustain long term in vivo implantation given that incorporating cells and simply maintaining their viability in vitro often tremendously decreases the mechanical properties of the encapsulating hydrogel. This mechanical failure, in turn, reduces the functional lifetime of the device prior to achieving desired therapeutic results. Moreover, such devices are often susceptible to immune attacks from the host in response to the antigens presented by the encapsulated therapeutic cells, potentially leading to the formation of a thick fibrotic capsule around the implant that would likewise reduce its clinical lifetime. Thus, more development is warranted to formulate tough hydrogels with desirable mechanical toughness and immunomodulatory properties that can structurally protect transplanted cells for long-term clinical use.

4.2.5. Gastric Drug Release Devices

Liu et al. tested the in vivo use of triggerable tough hydrogels (TTH) as prolonged gastric resident drug depots in Yorkshire pig animal models.[136] The TTHs consist of intertwined and separately crosslinked alginate and polyacrylamide networks by stimuli-responsive bonds (ionic Ca2+ and disulfide bonds), which can be triggered to with biocompatible agents (i.e. ethylenediaminetetraacetic acid and glutathione) on demand. A single gastric administration of the TTH was able to maintain a constant blood drug concentration of lumefantrine, an antimalarial drug, for four days.[136] Insulin, rifampicin, and dimethyl sulfoxide (DMSO) were likewise deliverable with the TTH device, demonstrating that such a device could potentially be applicable for other drug delivery uses.

Inspired by the pufferfish, Liu et al. created a device composed of uperabsorbent polyacrylic acid particles encapsulated in a freeze-thawed PVA membrane.[137] The superabsorbent hydrogel facilitated rapid water uptake while the porous and antifatigue PVA membrane maintains the long-term robustness of the device (Figure 8). The hydrogel device (original size ~3 cm3) swelled to a size of ~50 cm3 after absorbing gastric fluids for 60 minutes. The device impressively retained its swollen shape for 9 to 29 days before evacuation through the pylorus. [137] Beyond applications as a gastric drug depot device, a temperature sensor was implanted in the device which could monitor and record the temperature of porcine stomachs for 29 days, demonstrating the feasibility of such a device to monitor in-situ physiological signals for an extended period of time.

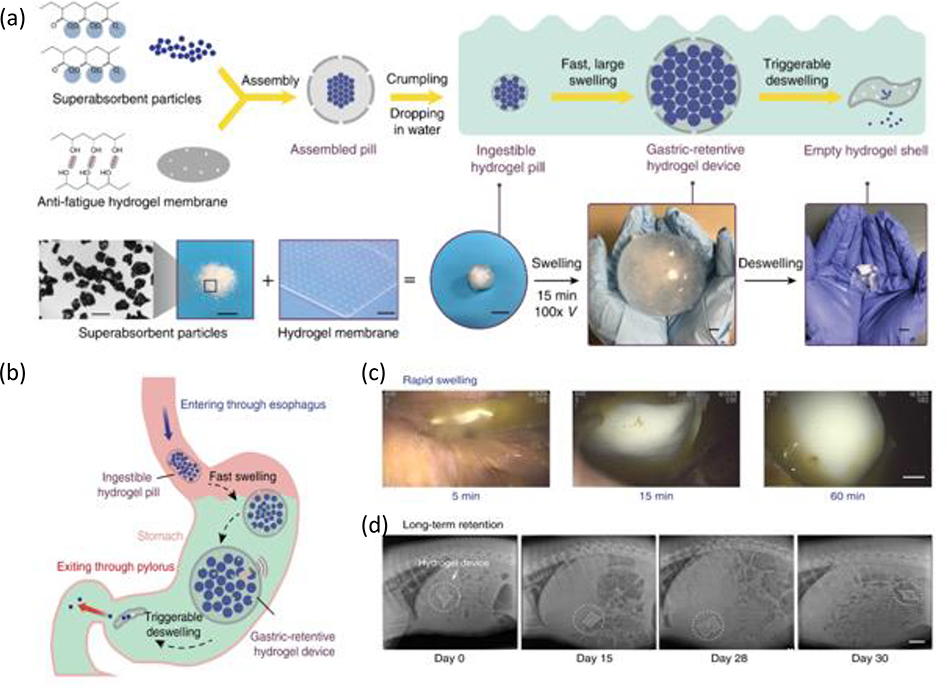

Figure 8. Ingestible hydrogel device for long term gastric retention and physiological monitoring.

a) Schematic and images of the synthesis and functionalities of the hydrogel device. b) Proposed mechanism of action of the gastric-retentive hydrogel device as it enters the stomach through the esophagus as hydrogel pill, swells and is retained within the stomach for a prolonged period, and finally exits through the pylorus in the form of a shrunken capsule and small particles. c) Endoscopic images demonstrating rapid swelling of the hydrogel device as it resides within the porcine stomach. d) X-ray images demonstrating the residence of the hydrogel device within the porcine stomach before eventually being emptied into the GI tract (shown here for a period of 29 days within the stomach). Adapted with permission.[137] Copyright 2019, Springer Nature.

Wu et al. synthesized a pH-responsive, mechanically tough, biodegradable hydrogel via photoinitiated copolymerization of 2-vinyl-4,6-diamino-1,3,5-triazine (VDT) and GelMA.[138] The excellent mechanical properties of PVDT-GelMA hydrogel -compressive strength 7.24 MPa, tensile stress 1.87 MPa, and compressive strength 13.9 MPa at pH 7.4 -deteriorated when placed in simulated gastric fluid solution (pH 1.2) due to disruption of diaminotriazine (DAT)-DAT hydrogen bonding: protonation of DAT leads to an increased swelling degree from an increase in charged DAT moieties, thereby loosening the polymer network and decreasing mechanical properties. When implanted in a rabbit model experiment, the PVDT-GelMA hydrogel resided in the stomach for 48 hours before being completely degraded, with no in vivo toxicity report from the metabolites.

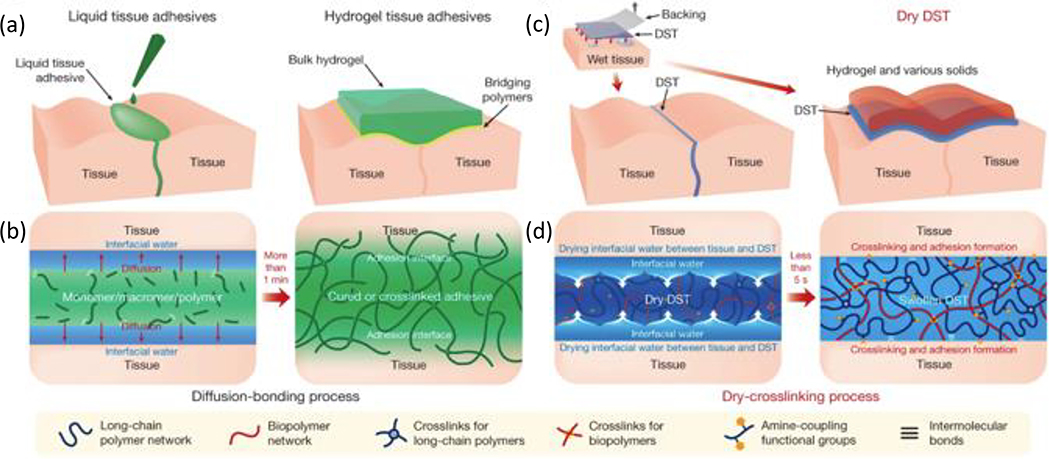

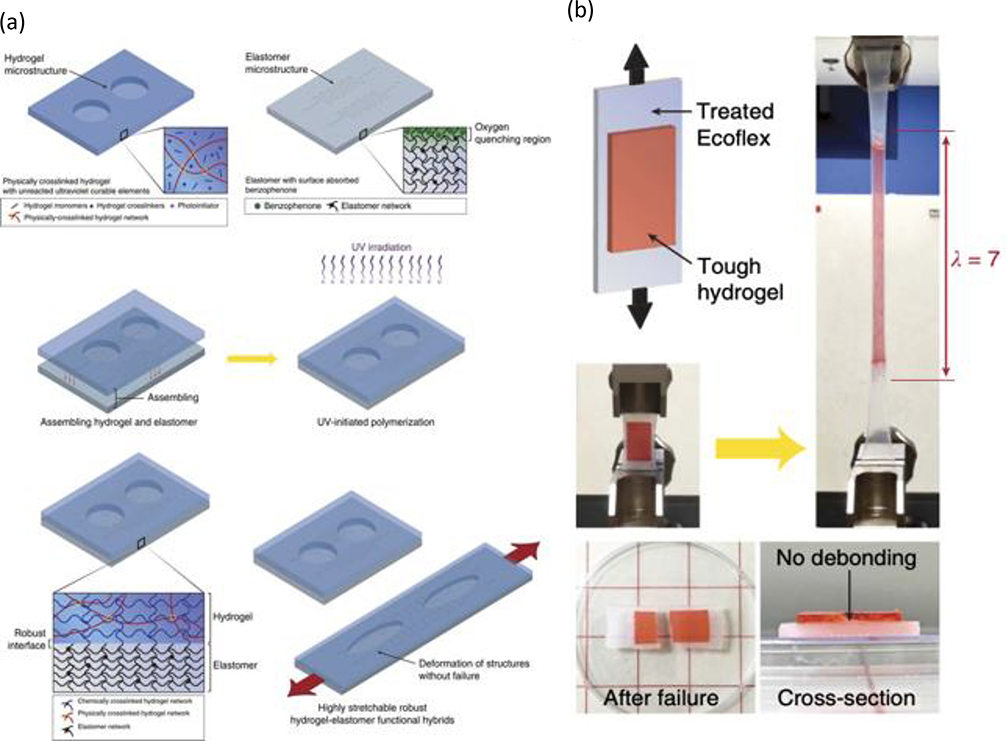

4.3. Tough Hydrogel Adhesives

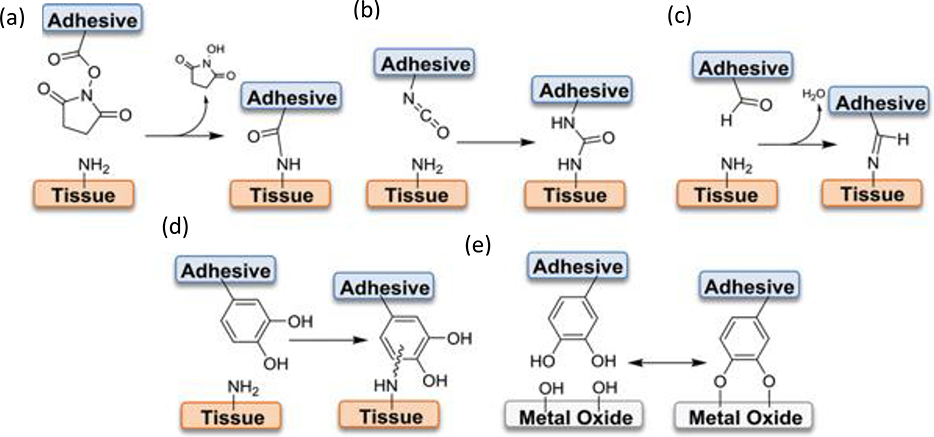

Hydrogel adhesion is dependent on anchoring stretchy polymer networks onto substrates, with high interfacial strength and capacity for energy dissipation being key to enhance interfacial toughness.[139] In addition to forming strong interfacial bonds, the adhesive must maintain cohesive strength after application throughout its service lifespan (Figure 9). [140] In terms of applications, surgical adhesives have emerged as an appealing alternative to conventional closure techniques (e.g. sutures, tacks, or stables) due to advantageous features including ease of application, reduction in surgical time and complications (e.g. infections), hemostasis, and no removal requirement. [141] However, commercially available tissue adhesives (e.g. fibrin glues, collagen adhesives) are expensive, exhibit relatively poor mechanical and tissue-bonding properties, and risk being pro-inflammatory given that many are protein-based, thereby propelling ongoing efforts to develop robust adhesives with improved biocompatibility and mechanical properties than those currently commercially available.[142] Several excellent reviews have evaluated the biomechanical/chemical properties of adhesives for biomedical applications.[140, 143] In this section, protein-based, polysaccharide based, and synthetic tough hydrogel adhesives are briefly reviewed.

Figure 9. Interfacial bonds employed by bioadhesives.

(a-d) Various interfacial crosslinking chemistries using NHS-activated ester, isocyanate, aldehyde, and catechol with nucleophilic functional groups abundant on soft tissue surfaces in order to functionalize tissue with adhesives. (e) Adhesive functionalization utilizing catechol’s ability to form coordination bonds with metal oxide surfaces (potential application to surface functionalization of implants or devices). Reproduced with permission.[140] Copyright 2019, WILEY-VCH

4.3.1. Protein-Based Adhesives

Albumin, an abundant blood serum protein, has been widely explored as an adhesive. In recent efforts, an adhesive termed BCD composed of albumin, citrate acid, and dopamine was synthesized using a two-step EDC/NHS coupling reaction.[144] The biocompatible adhesive showed 10-fold greater wet adhesion than commercial fibrin glue, and in rat mastectomy model and rat hemorrhaging liver model it was shown that the BCD adhesive could successfully be used for seroma prevention and in vivo hemostatic usage. The adhesive also exhibited a controllable degradation rate (1–25 days), but the use of PEG resulted in excessive swelling of the hydrogel adhesive. Using hydrophobic 1,8-octanediol instead resulted in stronger adhesion with improved control over the water content and thus swelling properties of the adhesive.[145] BioGlue® and ProGel® are currently two FDA-approved albumin-based hydrogel adhesives. [146] BioGlue® -made of bovine albumin and glutaraldehyde- is used to repair acute thoracic aortic dissections and leak sealing in large blood vessels in conjunction to sutures and staples, while ProGel® -made with non-toxic poly(ethylene glycol) disuccinimidyl succinate instead of glutaraldehyde- is used to seal leaks in surgical lung resection.[147] Gelatin, a protein prepared from collagen, has also been explored as a hydrogel for use as a tough adhesive.[148, 149] However, a primary concern of using protein-based hydrogel adhesives remains that they may be vectors for allergic reactions and infectious diseases given that the proteins are typically derived from animal sources.[147] Moreover, primary crosslinkers used with these adhesives (e.g. formaldehyde and glutaraldehyde) have been shown to have cytotoxic side effects.[147]

4.3.2. Polysaccharide-Based Adhesives

Using polysaccharide-based hydrogel adhesives is of interest given that polysaccharides are biocompatible, biodegradable, and induce minimal immune responses.[147] Chitosan is a natural polysaccharide that has been greatly explored for wound closure, hemostatic applications, and as mucoadhesive materials when combined with catechol-containing moieties.[150] A dextran aldehyde-based tissue adhesive was applied to a 5 mm corneal incision on an enucleated rabbit eye and successfully sealed the corneal incisions to pressures of >10 psi (500 mmHg).[148] A dually crosslinked methacrylated gelatin dopamine (GMD) hydrogel has also shown promise as a polysaccharide based adhesive.[151] A concern with using polysaccharides, however, is that they are poorly soluble in aqueous solutions and thus need fuctionalization along the backbone to introduce water-soluble moieties.[147] Likewise, when cross-linked via imine groups, hydrolysis is rapid and thus adhesion strength is often reduced prior to proper wound healing, preventing their use in applications where long adhesion times are necessary.

4.3.3. Synthetic Polymer-Based Adhesives

Given the limitations of polysaccharide and protein-based adhesives, extensive efforts have been dedicated to the exploration of synthetic polymer-based adhesives. Tunable mechanical and adhesive properties have enabled investigators to design several novel hydrogels via selective tailoring of cross-linking agents and optimization of gelation time that are biocompatible, biodegradable, and mechanically robust during their service lifetime.

DOPA Chemistry-Based Adhesives

Mussels secrete specialized adhesive proteins containing a high content of the catecholic amino acid 3,4-dihydroxy-L-phenylalanine (DOPA), which can form extremely strong (dissociation force 800 pN) and reversible bonds with surfaces.[152] Moreover, the catechol group exhibits highly dynamic crosslinking given that it can form non-covalent metallo-catecholate complexes with multivalent metal ions (e.g. Fe3+, Cu2+, and Ti3+) and can be oxidized into o-quinone under alkaline or oxidation environment, forming irreversible covalent crosslinks with biological surfaces via amino groups on tissues.[144] As such, catechol-based adhesives provide an attractive option to synthesize tough hydrogels with strong wet adhesive properties.

Fan et al. developed a double-crosslinked tissue adhesive (DCTA) mimicking the formation of byssal cuticles in mussels.[153] By grafting dopamine onto a gelatin backbone via EDC/NHS chemistry, gluing is rapidly achieved through catechol-Fe3+ coordination complexation on tissues, while genipin crosslinking provides stable, long term covalent crosslinks through primary amino groups found in gelatin. The double crosslinking mechanism enhances the hydrogel’s toughness and adhesive properties, endowing it with higher wet tissue adhesion to porcine skin and cartilage compared to commercially available fibrin glue. Likewise, employing catechol-metal ion coordination, Gao et al. developed dopamine-functionalized hydrophobic association polyacrylamide hydrogels.[154] Reversible crosslinking points between catechol-Fe3+ complexes and disentanglement of hydrophobic segments from embedded micelles effectively dissipated large amounts of energy to endow the hydrogel with tough mechanical properties. The hydrogel also demonstrated temperature and pH-dependent self-repairing behavior and exhibited excellent adhesion to various mice tissues via catechol-matrix hydrogen bonding.

A pH-responsive adhesive was developed by copolymerizing dopamine methacrylamide (DMA) and 3-acrylamido phenylboronic acid (AAPBA).[155] To trigger catechol-boronate complexation via changes in pH, the oxidation state and thus adhesive strength of the catechol side chain of DMA was controlled by adding acrylic acid: incorporating acrylic acid shifted the catechol-boronate complexation to a more basic pH, allowing the adhesive to function at physiological relevant pH ranges.[156] Regarding injectable adhesives, a tough adhesive was developed by using citric acid to provide pendant reactive carboxyl groups to conjugate dopamine and prepare biodegradable polyesters with PEG.[157] Likewise, a series of tough, biocompatible, injectable, and self-healing hydrogels were designed via in situ crosslinking of hydrazide-modified poly (L-glutamic acid) (PLGA-ADH) and dually functionalized alginate (catechol- and aldehyde-modified alginate, ALG-CHO-Catechol).[158] The adhesive supported the culture of adipose stem cells and demonstrated hemostatic capacities in vivo.

Composite Adhesives

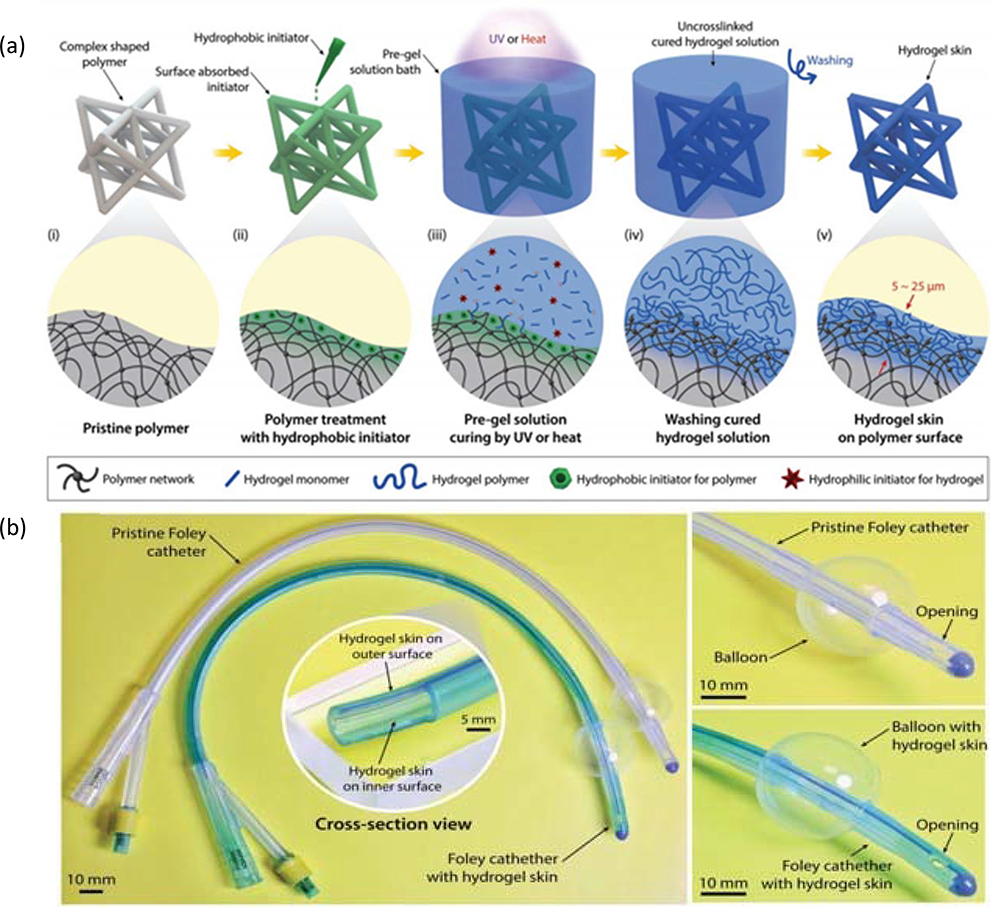

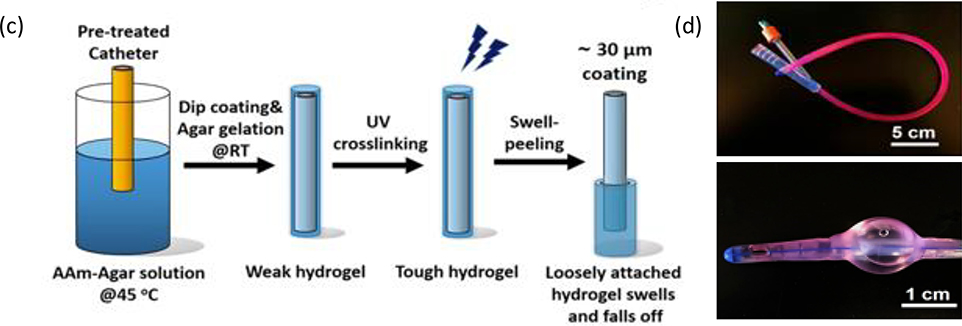

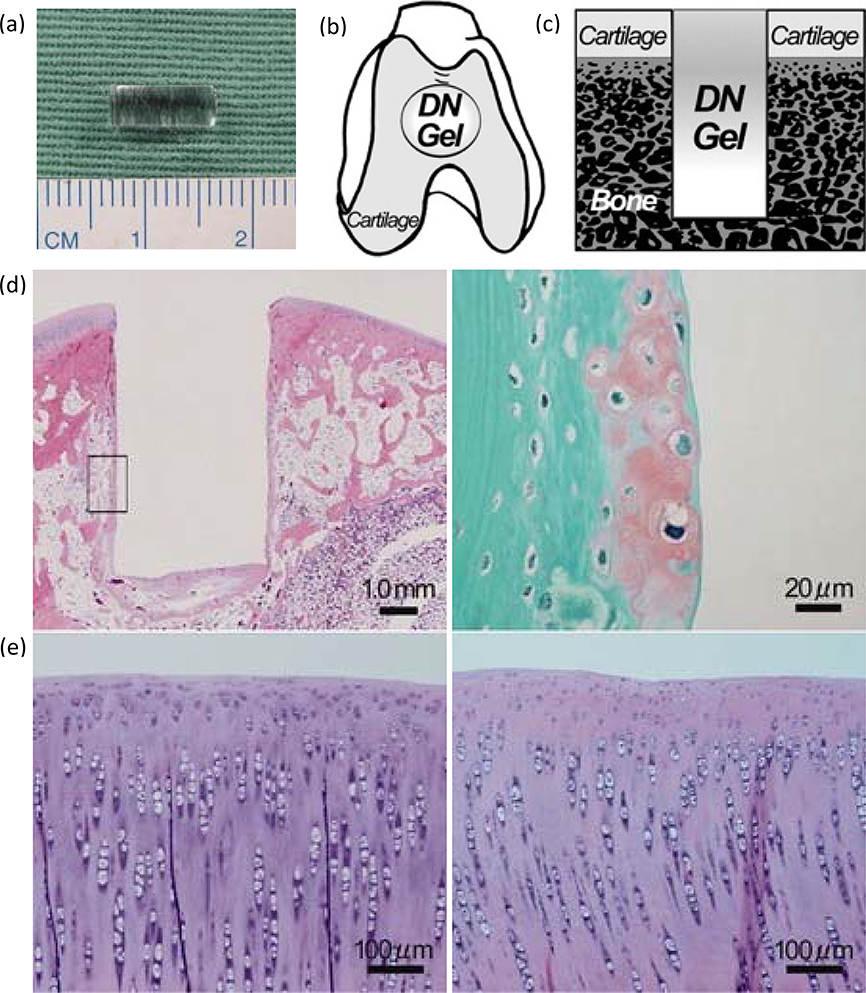

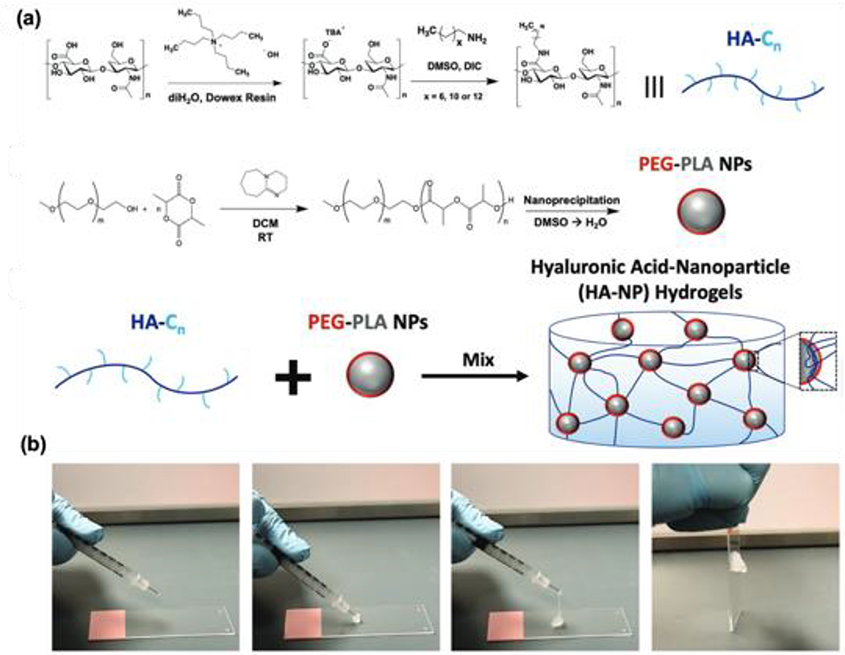

Feng et al. developed a mechanically robust, PEG-catechol adhesive containing collagen and embedded hydroxyapatite nanoparticles.[159] The ionic nanoparticles function as multivalent crosslinkers that bind with dopamine end groups in the PEG chain while the catechol units react with nucleophiles on collagen to form an overall tough, interconnected network. The material showed tunable adhesion and when testing the adhesive strength on wet/blood-covered porcine skin, the adhesive outperformed commercially available cyanoacrylate (six-fold) and fibrin (12-fold) based adhesives, as determined by adhesion strength calculated from the maximal of the stress vs. strain curves. An injectable, synthetic nano-silicate (i.e. Laponite) PEG-catechol-based adhesive likewise enhanced the mechanical strength and toughness of the hydrogel while promoting cellular infiltration at the device tissue interface.[160] However, the formation of the thick fibroblast may limit the applications of such an adhesive for tissue repair requiring rich vasculature.