Abstract

Tissue engineering (TE) is a rapidly growing interdisciplinary field, which aims to restore or improve lost tissue function. Despite that TE was introduced more than 20 years ago, innovative and more sophisticated trends and technologies point to new challenges and development. Current challenges involve the demand for multifunctional bioscaffolds which can stimulate tissue regrowth by biochemical curves, biomimetic patterns, active agents and proper cell types. For those purposes especially promising are carefully chosen primary cells or stem cells due to its high proliferative and differentiation potential. This review summarized a variety of recently reported advanced bioscaffolds which present new functions by combining polymers, nanomaterials, bioactive agents and cells depending on its desired application. In particular necessity of study biomaterial-cell interactions with in vitro cell culture models, and studies using animals with in vivo systems were discuss to permit the analysis of full material biocompatibility. Although these bioscaffolds have shown a significant therapeutic effect in nervous, cardiovascular and muscle, tissue engineering, there are still many remaining unsolved challenges for scaffolds improvement.

Keywords: Innovative materials, Biomimetric materials, Scaffolds, Regenerative medicine

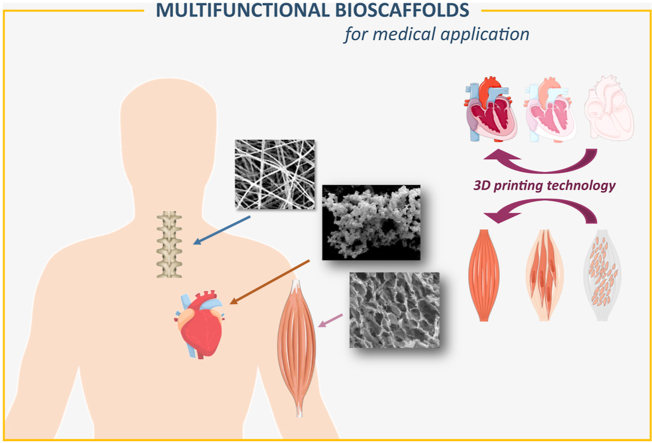

Graphical abstract

Highlights

-

•

Challenges, limitations and future prospects in tissue engineering are presented.

-

•

Strategies for enhanced neural, cardiovascular and muscle regeneration are discussed.

-

•

Topographical, mechanical and chemical guiding enhance nerves regeneration.

-

•

Multifunctional scaffolds provide cardiac tissue-like environment.

-

•

Hybrid biomaterials mimic and improve regeneration of muscle tissue.

1. Introduction

Currently, one of the most intensively studied field of medicine is regenerative medicine (RM), it is a broad field about the potential and ability to regenerate and replace damaged tissues and organs. Recently regenerative medicine has shown a number of promising results for the regeneration variety of tissues and organs including joints, bones, skin, cardiovascular and nervous system [[1], [2], [3], [4], [5], [6], [7], [8]]. The main strategies of RM are i. cell therapies, that aim to injection of stem cells to induce direct regeneration and rebuild tissues and organs; ii. Immunomodulation therapies which involve biologically active molecules which stimulate tissues to regenerate; and iii. Tissue engineering. The tissue engineering (TE) field is mainly based on applying scaffold for cell attachment and growth by designing and fabricating three-dimensional cell-containing matrices that can be implanted into the body to disease treatment or defect repair [9]. Analogous to the natural extracellular matrix topography of scaffold regulate cell behavior. Scaffolds morphology and composition influence on cell adhesion, proliferation, differentiation and migration. There are multiple requirements for scaffolds usage in TE. Such scaffolds should be biocompatible, immunologically inert and support the normal functioning of cells and tissues. The most important requirement of biomaterials for scaffold applications is biocompatibility which refers to a wide range of effects that access possible clinical usage. The most intensively studied is material cytotoxicity which is determined by cell lysis leading to apoptosis or the inhibition of cell proliferation. Scaffolds should exhibit a lack of cytotoxic effect toward cells, which should be deeply investigated over a long period of time. Another aspect of biocompatibility is also the absence of genotoxicity in particular DNA destruction, chromosomal aberrations and gene mutations [10]. Carcinogenicity is another aspect of material biocompatibility that should be carefully investigated, especially according to tissue organization field theory (TOFT). TOFT claiming that cancer arises from the deregulation of extracellular matrix (ECM) architecture. It is well-known that changes in native ECM micro/nano environment and composition lead to local stiffening, tissue fibrosis which enhanced cancer development [11]. Therefore materials structure, architecture and composition should imitate the architecture of native ECM as more precise as it’s possible to fully mimic target tissue environment. Furthermore, scaffolds should be immunologically inert or influence minimal immunological reaction. When biomaterial induce inflammatory response by inducing foreign body reaction, that can lead to rejection of the implant [12]. The degradation products also cannot cause toxicity toward cells. It should be also considered while designing natural biomaterials due to their possible bioactive degradation products which can stimulate immunological response [12]. Therefore scaffolds for possible biomedical applications should be carefully examinated in terms of their long-term toxicity which can be crucial for their clinical trials. In vitro cell culture studies are valuable in investigating the effects of biomaterial-cell interactions, while in vivo studies using animals permit the analysis of full material biocompatibility.

There are numerous materials used to fabricate scaffolds, but polymers are the most popular basal materials for scaffolds production [13,14]. Those polymers can be categorized on two groups natural and synthetic which can be divided into biodegradable and non-degradable. Usage of certain polymer type and its composition depends on the target application. Table 1 compares the most popular polymers, their advantages, limitations and promising usage in different tissue engineering fields. Natural biomaterials are often processed from either whole ECMs or purified certain ECM components. Alternatively, pure ECM architecture and composition can be obtained by removing the cellular components from tissues by a process called decellularization of ECM. Many reports show the possibility of decellularization of tissues and even organs. Decellular scaffolds have no cells in structure and require recellularization by proper cell type. Their clinical use has been documented for TE applications such as blood, cardiac valves and renal bladders. Nevertheless, these acellular constructs differ depending on the source and isolation method which is one of the main disadvantages. The natural origin of that biomaterials is the potential danger of infection which potentially can lead to donor-derived infection. However, the main limitation is necessity for chemical usage during isolation and complicated preparation process. This can potentially trigger high immune response and inflammation [15,16].

Table 1.

The most popular polymers for scaffolds fabrication, their main advantages and limitations and current potential application in different tissue engineering fields.

| POLYMER | TYPE | EXAMPLE | ADVANTAGES | LIMITATIONS | PROMISING IN | REF. |

|---|---|---|---|---|---|---|

| Natural | polysaccharides | chitosan | biocompatibility, hemostatic activity, biodegradability, antibacterial activity, easily metabolized | stiff, brittle, low mechanical resistance | skin, nervous, bone, cartilage, cardiac, liver, and muscle tissue engineering | [[17], [18], [19], [20], [21], [22], [23]] |

| cellulose | biocompatibility, bioactivity, good mechanical properties depending on the source | non-biodegradable | skin, neural, bone, cardiovascular, muscle, tendons, cartilage regeneration | [[24], [25], [26], [27], [28]] | ||

| alginate | biocompatibility, non-immunogenicity, biodegradability, non-antigenicity, bioactivity | limited strength, toughness, difficulty in controlled gelation | skin, cartilage, bone, neural regeneration | [20,[29], [30], [31], [32], [33], [34]] | ||

| hyaluronic acid | biocompatibility, biodegradability, easy chemical modification, bioactivity | poor mechanical properties, rapid degradation | neural, skin, regeneration | [[35], [36], [37], [38], [39], [40], [41], [42]] | ||

| proteins | collagen | biocompatible, biodegradable, ECM mimicking, poorly immunogenic, bioactive | poor mechanical properties, | skin, cornea, dental, vascular, cartilage, bone regeneration | [41,[43], [44], [45], [46], [47], [48]] | |

| gelatin | biocompatible, biodegradable, ECM mimicking, low immunogenic, inexpensive, water-soluble, bioactive | poor mechanical properties, fast enzymatic degradation, low solubility in concentrated aqueous media | skin, bone, cartilage, adipose neural, regeneration | [[49], [50], [51], [52], [53], [54]] | ||

| fibrin | biocompatible, biodegradable, ECM mimicking, low immunogenic | rapid degradation rate, poor mechanical properties, expensive, risk of contamination | liver, retina, cartilage, vascular, neural regeneration | [[55], [56], [57], [58], [59]] | ||

| silk fibroin | biocompatibility, biodegradability, bioactivity, low immunogenic, high tensile strength, excellent mechanical properties, water-based processing, low cost | Weak, brittle as scaffolds. | skin, vascular, bone, cartilage, tendon, cornea, hepatic, Neural regenration | [[60], [61], [62], [63], [64], [65]] | ||

| elastin | biocompatibility, bioactivity, good biophysical and biomechanical properties | Water-insoluble, difficult to manipulate in vitro, risk of contamination, risk of inflammation, difficulties in sourcing | skin, cartilage, cardiovascular, tendon, skin, liver regeneration | [[66], [67], [68], [69], [70], [71], [72]] | ||

| Synthetic | Biodegradable | PCL | biocompatible, easy to modificate and fabricate, good organic solvent solubility, controllable degradation rate, inexpensive, good mechanical properties, thermoplastic | poor cellular adhesion due to hydrophobicity, relatively slow degradation rate (2–4 years), | skin, bone, vascular | [[73], [74], [75], [76], [77], [78]] |

| PLA | biocompatibility, easy to modificate and fabricate, obtained from renewable sources, | lack of bioactivity, low cell adhesion, biological inertness, acid degradation by-products, risk of inflammation, low porosity, low degradation rate (but faster than PCL) | skin, bone, cardiovascular, cartilage, ligament, neural regeneration | [[79], [80], [81], [82], [83], [84], [85]] | ||

| PGA | biocompatible, bioresorbability, high tensile strength, | fast degradation rate, acidic degradation products, low solubility | bone, cartilage, ligament regeneration | [[86], [87], [88], [89], [90], [91]] | ||

| Non-biodegradable | PDMS | biocompatibility, easy to fabricate, flexible, thermo-tolerant, tunable hardness, good biostability, the high solubility of oxygen in PDMS, | non-bioactivity due to hydrophobicity, non-biodegradable | skin, bone, neural regeneration | [[92], [93], [94], [95], [96]] | |

| PPy | electrical conductivity, easy to synthesized, environmental stability, low inflammatory response, | non-biodegradable, not easy to modify, non-thermoplastic, water insoluble, mechanically rigid, brittle, possible long-term toxicity, non-biodegradable | neural cardiovascular, liver regeneration | [[97], [98], [99], [100], [101], [102], [103], [104]] | ||

| PVDF | piezoelectric properties, high flexibility, non-toxicity, chemical and physical resistance | hydrophobicity, insufficient biocompatibility, non-bioactive, non-biodegradable | bone, neural, bladder, skeletal muscle regeneration | [[105], [106], [107], [108], [109], [110]] |

Natural polymers can be classified as polysaccharides (chitosan, cellulose, alginate, chitin, hyaluronic acid, and dextran) and proteins (collagen, gelatin, fibrin, elastin, silk, keratin, actin, and myosin). The greatest advantage of scaffolds made of naturally derived sources is their great biocompatibility and more closely mimicking natural ECM. Bioscaffolds refer to naturally-derived scaffolds made by natural polymers or with the addition of active bioagents. Because of their natural origin natural polymers tend to be highly bioactive what support cell attachment and growth. Scaffolds are environmental friendly what is another advantage of their usage in tissue engineering. However, materials derived from humans and animals hold a serious risk of potential diseases. Moreover, most of the natural polymers exhibit poor mechanical properties and a fast degradation rate. Proper chemical modification as well as crosslinking can overcome these disadvantages, contributing to enhanced mechanical properties. On the other hand, synthetic materials are also often used as scaffolds. The main advantage of synthetic polymers is their excellent mechanical properties, such as viscosity, strength, solubility and controllable degradation. There are many examples of synthetic polymers with conductive and piezoelectric properties which makes them attractive in electrically sensitive tissues such as nerve and heart muscle. Another benefit of some synthetic polymers is thermoplastic properties which make them easy-to-fabricate leading to versatility in fabrication. However polymeric degradation products could induce long term toxicity causing inflammation. Another drawback is the lack of cell-binding sites due to their hydrophobicity which makes them unattractive for the biomedical field. Fully synthetic scaffolds are generally composed of manufactured polymers, metals, or other synthetically derived substrates. Synthetic polymers can be precisely manufactured and therefore their properties such as mechanical strength and degradation rate can be readily tuned. Consequently, multiple polymers can be easily integrated within one material to obtain composite. An especially promising approach is to combine synthetic polymers characterized by good mechanical properties with natural biomaterials as they provide natural micro/nano environmental niche for functional tissue regeneration. To improve biological properties, scaffolds can also be enriched with bioactive signaling molecules. Commonly it could be adhesive peptides, extracellular matrix proteins, growth factors, cytokines, or hormones. These bioactive agents can have profound biologic activity leading to direct cell adhesion, proliferation, modulate cell survival, vascularization and targeting differentiation fate of stem cells. Such bioscaffolds achieve both the 3D matrix structure of the native ECM and the natural ligand landscape [111]. Designing and fabricating an ECM scaffold that fully mimics the biochemistry and architecture of native tissue ECM can be achieved by careful selection of the materials, bioactive additives and fabrication technique. The proper method for obtaining the 3D bioscaffolds enables their desire application and functional character. Typical scaffold architecture is made by 3D printing, electrospinning, lithography methods that enable to obtain fibers, hydrogels, meshes, sponges or foams.

Proper choice of a cell type model is another crucial aspect of basic research and possible transplantation success. Cell lines are broadly available, easy to maintain and cultivate. Mostly are immortalized through genetic manipulations by e.g. integration of relevant genes by viral transfections. Companies provide a wide range of immortal cell lines under constant growing conditions derived from healthy and unhealthy donors. However, during numerous passages, cells exhibit alterations in morphology, growth rates and response to stimuli compared to lower passage cells. Mentioned alterations often occur in parallel with cellular mutations, therefore continual cell lines subculture intensify genomic instabilities. Additionally, because of high immunogenicity, cell lines are not proper for clinical use. Despite those disadvantages, cell lines are useful as a proof of concept and basic research study. Primary cells are mature cells derived directly from tissue or organ of interest without viral transfections and any modifications, representing a better physiological model than cell lines [15]. These cells can be isolated from certain patients, cultivated in vitro on the scaffold and then transplanted in the target place of the host body. Primary cell transplantation gives less immunogenic response than cell lines which gives great clinical potential. The main limitation of the use of primary cells in tissue engineering tends to dedifferentiation followed by a low proliferation rate. On the other hand, primary cells have low capacity to differentiate, and many cell types should be isolated to rebuilding multicellular construct which could be challenging due to their limited quantity and accessibility [112]. Another useful cell model is stem cells. A wide range of stem cells are used in tissue engineering, including mesenchymal stem cells (MSCs), embryonic stem cells (ESCs), cardiac stem cells (CSCs), neural stem cells (NSCs), muscle stem cells, dental pulp stem cells (DPSCs), and induced pluripotent stem cells (iPSCs). In general, their availability in hosts is limited and the origin of certain stem cells raises ethical doubts. Commercially available stem cells should be considered only as in vitro model, because of their immortalization and potentially triggering immune responses. Moreover, immortal stem cells, similar to cell lines often differ in function from their in vivo counterparts. iPSCs reprogramed from host somatic cells have gained increasing attention. That stem cells can differentiate into cell types of all three germ layers giving huge opportunities in tissue engineering. In the beginning, scientists assumed no risk of rejection after iPSCs transplantation, but the immune rejection was observed after transplantation of autologous iPSC-derived cells. That suggests the impact of in vitro operations on the immunogenicity of the iPSC [113]. An interesting approach is that iPSCs offer the opportunity to correct pathogenic genetic variants in advance of transplantation in the mutation-carrying patient. The limitation is time-consuming protocols that require multiple complicated intermediate steps [15]. Despite that, iPSCs exhibit a low risk for teratoma formation and immune response but reveal the risk of tumorigenesis. Over that unknown is the impact of reprogramming somatic cells on the epigenetic modifications and their overall safety.

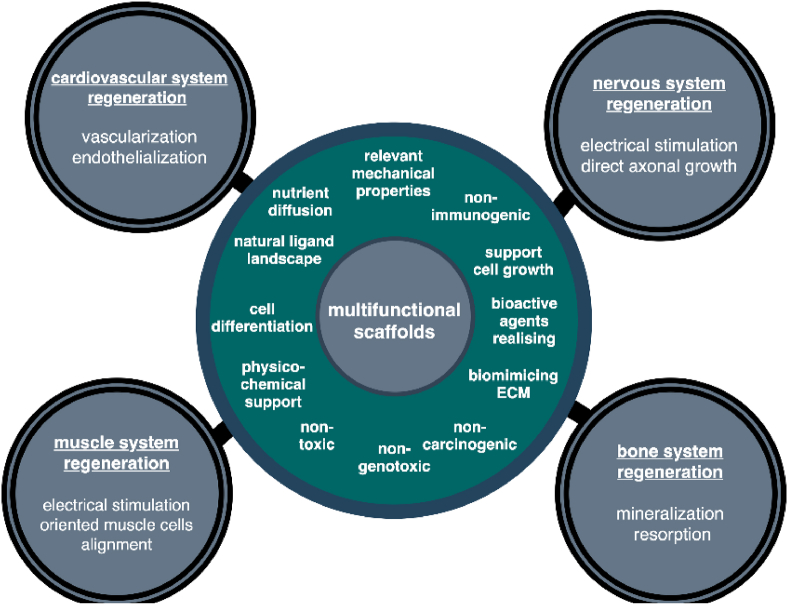

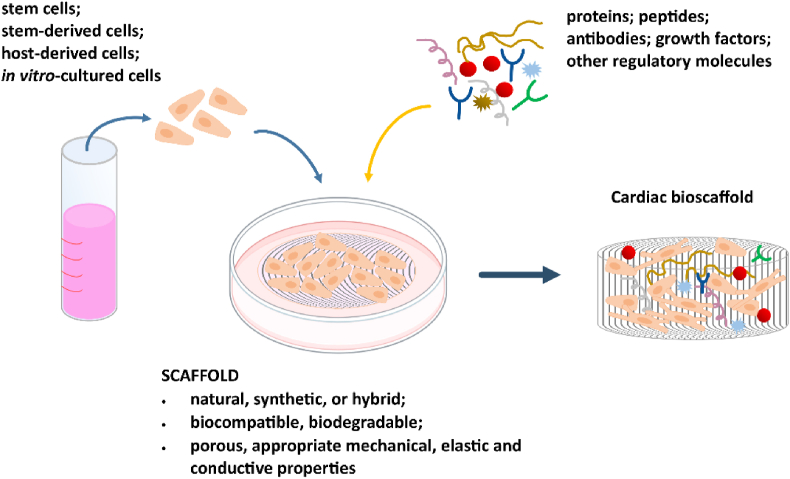

Bioscaffolds beyond mimicking of native ECM and interaction with cells, can influence more than one cell type and provide additional advanced functions. This includes releasing bioactive agents such as antibacterial molecules to prevent infection; growth factors to induce direct cell differentiation and anti-inflammatory agents to prevent excessive inflammation. Specific cell types incorporation within scaffold structure also provide new function, by their active spreading, releasing their growth factors leading to active tissue regeneration. In this regard, highly desirable are multifunctional scaffolds that provide physicochemical support to many cell types and deliver bioagents/drugs/antibacterial molecules. Such multifunctional bioscaffolds gained attention as the new generation of biomaterials for applied cardiovascular, nervous, muscle and bone tissue engineering as shown in Fig. 1. This review highlight recent insights of multifunctional biomaterials fabricating in order to be applied in clinical practice. The review provides crucial information about the biological effect of biomaterials in cardiovascular, muscle and nervous tissues regeneration as electrical sensitive systems. Due to the many works in this area in recent years, the aim of the review was to identify the latest trends in this field, with particular emphasis on the role of primary materials, which not only provide scaffolds but also support that enhance cell adhesion, proliferation, and differentiation. This approach allows for a broader view of bioactive materials, both in the research context but also in the application context, and an analysis of the polymers used, taking into account their nature and structure. It should be noted that the authors deliberately omitted the aspect related to the regeneration of the bone tissue due to many interesting and very detailed reviews in this area [[114], [115], [116], [117], [118]]. These works include scaffolds based on hydroxyapatite, as well as a number of polymers, including bio-polymers (e.g. cellulose, chitosan, gelatin, alginate and fibroin as well as and synthetic polymers (e.g. poly(lacticacid) (PLA), poly(glycolic acid) (PGA), and their copolymers PLGA] [[119], [120], [121], [122], [123], [124]]. The hybrid solutions such as hydroxyapatite/collagen [[125], [126], [127]], poly l-lactic acid [128,129] or κ-carrageenan [[130], [131], [132]] scaffolds or lanthanide-doped hydroxyapatite [8,[133], [134], [135]] for bone and osteochondral regeneration were also proposed and described in literature. Therefore this review highlights the new achievements, emerging trends and strategies in the field of neural, cardiovascular and muscle tissue engineering. Challenges, limitations and future prospects in tissue engineering are discussed.

Fig. 1.

Multifunctional bioscaffold's requirements and their possible usage in different areas of tissue engineering.

2. Bioscaffolds for nervous system regeneration

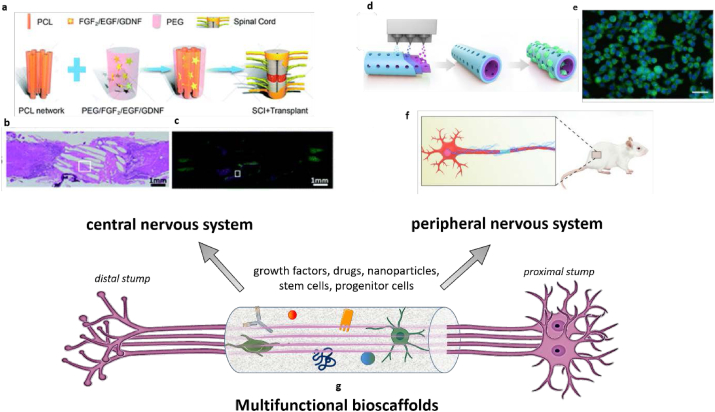

The nervous system is the most significant and complex tissue in the human body. The nervous system is a highly specialized network which can be divided into two main parts: the central nervous system (CNS includes the brain and the spinal cord) and the peripheral nervous system (PNS include the spinal and automatic nerves). Hundreds of millions of people worldwide are affected by numerous neurological disorders. The symptoms of nervous system abnormalities depend on their localization and the generating factors. Neurological disorders such as traumatic injuries (spinal cord injuries), strokes and neurodegenerative disorders belong to incurable diseases. Neurological disorders can be caused by loss of neurons and glia cells functionality in the central nervous system (CNS) and peripheral nervous system. The most important stem cells for the nervous system is neural stem cells (NSCs), which are multipotent stem cells, precursors of both neurons and neuroglia (oligodendrocytes and astrocytes) during not only embryonic development but also in the adult mammalians Mentioned process called neurogenesis appears in specific brain regions. Lately developed strategies in PNS and CNS by using multifunctional bioscaffolds were presented in Fig. 2.

Fig. 2.

Recent strategies for regeneration of CNS (left) and PNS (right) by multifunctional bioscaffolds. CNS approach a) Scheme of cytokine-containing hydrogel embedded in a electrospun PCL scaffold composite b) Tissue bridging and neuronal axon regeneration observed by hematoxylin and eosin (H&E) staining and c) immunofluorescence staining of anti-microtubule-associated protein-2 (MAP2) neuron marker. PNS approach d,f) Scheme of fabrication of scaffolds composed of (−)-epigallocatechin gallate-loaded polycaprolactone using integrated molding and nerve conduit implantation in rat models e) anti‐oxidant marker NF-E2-related factor (Nrf2) immunofluorescent staining for RSCs on EGCG/PCL scaffolds. Reproduced with permission from Ref. [136]. Copyright © 2019 Cell Proliferation published by John Wiley & Sons Ltd. Reproduced with permission from Ref. [137]. Copyright 2020 RSC.

2.1. Peripheral nervous system

While the nervous system belongs to the most significant system with contemporaneously highly histological and anatomical structure and compound, the main issues with regeneration is a small number of NSCs and their progenitors in the specific niches. A low number of stem cells essential in CNS provide to the limited ability of the central nervous system regeneration. On the other hand, peripheral nerve axons have an intrinsic capacity to regenerate after injuries by making functional connections between two ends of a severed nerve. However, it is challenging to achieve full functional recovery after injury of the proximal nerve causing nerve gaps. Several approaches are typically used to induce increased regeneration in the gap between injured axons, including nerve autografts, nerve allografts and biologically-derived and synthetic scaffolds as an alternative. Autografts are the gold standard in PNI treatment however, it has several critical limitations, including donor site morbidity. Alternatively to autografts, nerve allografts are human decellularized nerve available commercially (e.g. Avance™). While traditional, artificial PNS scaffolds can occur in form of nerve guidance multi-channels and nerve guide conduits (NGCs) [43]. Guidant scaffolds for PNS regeneration have often tubular shape designed to bridge axonal gaps, prevent scarring and non-physiological accumulation of neurotropic and neurotrophic factors locally, protect the injured nerve from mechanical disruption and finally mechanically guide regenerating axons from proximal and distal nerve segment.

Many synthetic and naturally-derived NGCs have been approved for clinical use. Natural, biodegradable conduits based on collagen type I (Neuromatrix™, Neuroflex™) are fully biodegradable and widely used. Synthetic tubes made by synthetic biodegradable polymers such as: poly(glycolic acid) (PGA) (Neurotube™) and poly(d,l-lactide-co-e-caprolactone) (PLCL): Neurolac™, NeuroMend™) is resorbable and semipermeable. Non-biodegradable polyvinyl alcohol (PVA) polymer has been used as nerve grafts (SaluTunnel™, SaluBridge™), however clinical utilization of non-resorbable conduits has declined with the advent of absorbable natural and synthetic grafts. The main limitation of using those systems is their ability to bridge longer axonal gaps was highly questionable and non-optimal [138]. Nevertheless, the studies on the above conduits suggest that those scaffolds are effective in the case of only small gaps up to 3 cm which gives similar outcomes to nerve autograft. Moreover, traditional NGC remains insufficient for their effectiveness in nerve regeneration, and failures were reported due to persistent loss of nerve function and neuroma formation. Therefore the huge need for advanced multifunctional scaffolds for full PNI regeneration remains one of the principal goals of neural tissue engineering [139]. Advanced conduit should be biocompatible, biodegradable, flexible and additional have electrical conductivity. One of the promising electrical conductive materials are carbon-based nanomaterials, such as carbon nanotubes (CNT) and graphene (G) which have been widely used as neuronal electrodes. CNT and G have excellent electrical properties, which may have great potential in the development of scaffolds. Carbon-based materials are capable to increase the neural activity and these results were confirmed by experimental models [140].

Lately, Junggeon Park et al. fabricated conductive hydrogel-based NGCs by combining widely-used gelatin methacryloyl (GelMA) and conductive reduced graphene oxide (GO). Conductive r(GO/GelMA) hydrogel had excellent mechanical (flexibility and durability) and electrical properties. Biological in vitro studies performed on PC12 cell line after 5 DIV show relevant cell attachment via integrin binding and cell spreading on the construct. Cultured PC12 cells with differentiation medium result in significant neuritis outgrowth compared to GO-free GelMA. In vivo studies on adult male SD rats with a 10 mm peripheral injury successfully demonstrated facilitate neural myelination and regrowth after 4 and 8 weeks. Importantly, r(GO/GelMA) conduits supported functional regeneration of both nerve tissues and muscle tissues without long-term toxicity to other organs. A developed multifunctional scaffold was as effective as traditional autografts in peripheral nerve regeneration positively influenced nerve regeneration in a relatively short period of time. The report strongly suggests the potential for the treatment of PNI using electrically conductive hybrid conduits [141]. It is well-known that scaffold morphology influences cell adhesion, proliferation, differentiation and migration. Analogous to the natural extracellular matrix topography of the scaffold can regulate cell behavior and even stem cell fate. This phenomenon was used by fabricating defined micropatterns of nerve tissue on the inner surface of the construct coupled with interconnected permeable pores. Conduit made by PLGA was coated by 3,4-dihydroxy-l-phenylalanine (DOPA) for the hydrophilicity of the inner surface (PP-NGC DOPA). Construct enhanced the neuritis elongation and migration of PC12 cells as well as neural differentiation of fetal mouse NSCs comparing to patterns without patterns. In vivo studies on rats with a 12 mm peripheral injury show significant acceleration of host neuronal tissue migration, improved neurofilament elongation, Schwann cell deposition at the distal region, contributing to enhanced neural regeneration. However sciatic function index and velocity of electrophysiological analysis were not significantly different comparing other groups. Nevertheless presented multifunctional conduit not only promotes cell migration and alignment of nerve cells in vitro but also guiding Schwann cell deposition and accelerates nerve regeneration in vivo [142]. Multifunctional effect on axon and muscle tissue regeneration by using environmentally safe natural agents is especially desirable. An interesting approach was suggested by Yun Qian et al. about nerve repair after peripheral neuropathy caused by radiation treatment. They used a porous PCL scaffold loaded with active natural bioagents. An example of a polyphenolic compound is (−)-epigallocatechin gallate (EGCG) which is abundant in green tea. EGCG is considered as one of the most natural effective free radical oxygen scavenger. Effect of EGCG loaded PCL with aligned pores (20 μm in diameter) was investigated in vitro on rat Schwann cells (ESCs) and rat skeletal muscle cells (RSMCs). Results indicated that hybrid scaffold reduced ROS levels and stimulated RSCs and RSMCs proliferation more discernably than the PCL scaffold without active bioagent. In a rat peripheral radiation injury model with 15 mm of 40-Gy radiation, studies on hybrid PCL-EGCG scaffold showed improvement of not only nerve but also muscle recovery with significantly increased nerve myelination as well as muscle fibre proliferation. Results proved reduced lipid peroxidation, macrophage infiltration, oxidative stress indicators, and inflammation. That combined strategy gives new insights into research on polyphenols for peripheral nerve regeneration [136].

2.2. Central nervous system

Spinal cord injury (SCI) causes permanent sensory and motor dysfunction. Traumatic insults of the central nervous system (CNS) such as traumatic brain injury and spinal cord injury (SCI) often affect sensory and motor function disorders [143]. This neuronal disturbance causes interruption of signaling pathways. Central nervous system regeneration is more challenging than PNS, due to more complex anatomical and histological structure. In contrast to PNS, CNS axons do not spontaneously regenerate after injury in adult mammals. Moreover, the CNS environment acts inhibitory for axon outgrowth [144]. In place of CNS injury glia cells express inhibiting factors, that inhibitors of regeneration. That factors include specific CNS myelin proteins and molecules associated with the astroglial scar formation [144]. Axon growth-supportive effect can be achieved by a variety of molecules such as growth factors (e.g. glial-derived growth factor (GDNF)) and extracellular matrix molecules (e.g. laminin) [145]. Lastly, Wang et al. fabricated a hybrid PCL-PEG based composite system, embedded with axonal growth factors. PCL provided physical curves for axonal outgrowth while growth factors (FGF2 and EGF) stimulated increase axon growth-supportive substrates (such as laminin). Additionally, for further chemoattract propriospinal axons GDNF was incorporated within the hydrogel. In vitro studies on PC12 cell line cultured with scaffolds exhibited no significant cytotoxicity after 3 DIV. However long-time toxicity studies were not performed. Neurite's elongation/directional growth was not clearly presented enough. In vivo studies on rats with a 2 mm spinal cord injury show promoted the axon's directional regeneration after 8 weeks of scaffolds implantation. Promotion of the motor function recovery after SCI was observed and preceded by the production of laminin which played an important role in the axon growth-supportive substrates. This data indicates the utility of incorporating growth factors in bioscaffolds for increase regeneration of the spinal cord after SCI [137]. The composition of scaffold primary material is essential for mimicking nervous tissue followed by a proper regeneration process. Hyaluronic acid, known also as hyaluronan (HA) is one of the main, highly abundant natural compounds of the normal central nervous system. The presence of HA with bioactive agents (neurotrophic factors, growth factors) provides a pivotal role in axonal guidance formation of synapses. HA usage as bioscaffolds gives many advantages including biocompatibility, bioactivity, but also limitation due to its poor mechanical properties (Table 1). Nonetheless, HA is known for neuroprotective effect after SCI and reduction of the formation of the glial scar by inhibition the chemotaxis, migration and lymphocytes proliferation [146]. Interdisciplinary research publicated on ACS Nano presented new combined approach in biomaterial engineering for spinal cord regeneration. HA hydrogel with dotted MnO2 NPs as antioxidant bioactive agents was used as primary scaffold. Hydrogel was additionally modificated by the laminin-derived peptide called PPFLMLLKGSTR, that was chosen or possible promototion of stem cells adhesion and bridging of damaged nerve tissue. In vitro studies on MSCs derived from human placenta cultured on hydrogels after 3 DIV exhibit no obvious toxicity. Hybrid hydrogel with MnO2 NP significantly reduced the H2O2 content after MSC incubation for 1 and 2 h, indicating an efficient antioxidant function of hybrid scaffolds. In vivo investigation on a 4 mm rat transection SCI model with implanted multifunctional hydrogel-containing multipotent MSC cells exhibit scaffold integration and increased neural differentiation, followed by efficient spinal cord regeneration. Composition studies showed partial elimination of Mn from the site of the lesion during 4 weeks. Finally, a multifunctional construct containing MSC enhanced motor function restoration after on a long-span rat spinal cord transection, which remains one of the principal goals of neural regenerative medicine [147]. Stem cells are widely used in regenerative medicine due to their differentiation capability and releasing their own growth factors [148]. But it should be carefully policed to enable ethical and safe usage. The main issue of introducing commercial multipotent stem cells to clinical use is possible immunogenicity, risk of teratoma, and tumorigenesis. Therefore for clinical application should be considered the only host-derived stem cells (iPSC, adult stem cells) which can significantly reduce the immune response. In general, undifferentiated stem cells (ESCs, iPS) by stemness potential have a relatively high capacity to form teratomas and tumors [149]. Therefore promising perspective for the treatment of neural disorders brings more specialized stem cell therapies. An example is neural progenitor cells (NPCs) which hold lower potential for tumorigenesis than e.g. ESCs. A combined approach of NPCs incorporation in personalized scaffold was recently investigated by J. Koffler et al. Complex CNS structure for spinal cord regeneration was printed using microscale continuous projection printing method (μCPP). Poly(ethylene glycol) diacrylate (PEGDA)–GelMa scaffold architecture was tailored precisely to the dimensions of 1.8 mm SCI rat lesion. NPCs suspended in the collection of fibrin matrix and growth factors (BDNF to support NPCs survival, bFGF to promote angiogenesis and calpain inhibitor for neuroprotection) were incorporated in scaffold channels. In vivo studies on rat SCI model at 1 month, post-implantation showed scaffold-NPCs the ability to support stem cell survival. Scaffolds loaded with NPCs induced host serotonergic axons regeneration, which modulates spinal motor systems. Injured host axons regenerated into multifunctional 3D biomimetic scaffolds providing synapse onto implanted NPCs, which lead to restoring not only synaptic transmission but also improve functional outcomes [150]. After SCI in the damaged spinal cord occurs complex physiological and pathological changes. Conventional treatment of SCI focuses on preventing further injury by using potent anti-inflammatory drugs, such as corticosteroids. One of them is methylprednisolone (MP) which was used to improved neurological functions recovery after acute spinal cord injuries. However, since 2013 use of MP has decreased dramatically due to comparative recent studies that have shown the potential side effects, such as blood clots, respiratory, urinary tract, wound infections, and steroid-induced myopathy [151]. Despite that, MP was recently used to fabricate multifunctional scaffold. The hybrid scaffold was fabricated via electrospinning from both natural materials (Polysialic acid (PSA)) and synthetic polymer (PCL) with incorporated MP. The nanofiber scaffold was biodegradable, and actively release MP over a short period of time. In vitro cytotoxicity studies on human neuroblastoma cell line (SH-SY5Y) and primary astrocytes indicated no significant differences between different scaffolds composition for cell proliferation for 7 DIV. In vivo studies on rats with 2 mm SCI effectively showed that the transplantation of hybrid PCL/PSA/MP scaffold effectively suppressed apoptosis and acute inflammation. Moreover, it attenuated glia scar formation. Construct supported axonal regeneration, leading to improvement of the functional recovery after SCI. Actively releasing MP from a multifunctional scaffold could be incorporated in could be beneficial through lesion site-specific drug administration [152].

Multifunctional bioscaffolds have great potential in providing cell support, inhibiting the glial scar formation and damaged neurons guidance by tubular conduits, actively releasing bioagents and drugs and combining stem/progenitor cells therapy which stimulates the release of axon regeneration-promoting neurotrophic factors. It has been confirmed that multifunctional scaffolds are an effective strategy to improve therapeutic benefits in animal models, resulting in the functional recovery of SCI rats in many cases. However, it is still a challenge to build an ideal scaffold for the full regeneration of damaged nervous tissue.

3. Bioscaffolds for cardiovascular system regeneration

Cardiac regeneration has been a subject of scientific reports for over 100 years [153,154]. Heart regeneration can be defined as the restoration of damaged heart tissues and their impaired function. Restoration of the injured human heart is limited in comparison with other vital organs, such as muscles, skin, lung, or liver, and deteriorates with age [155]. There are many types of cardiovascular diseases (CVD) responsible for heart tissue disorders, i.e. heart failure, myocardial infarction, dilated cardiomyopathy, or coronary artery disease [156]. According to the WHO data, CVD are the main cause of death worldwide and results in more than 50% of all deaths in Europe [157]. The WHO mortality statistics show also that most of these premature deaths could be avoided by changing a human lifestyle. Unfortunately, the change in health-related behavior is difficult, thus searching for new treatment methods is extremely important.

Numerous approaches for regeneration of injured heart tissues are currently investigated, ranging from surgical implantation of cardiac grafts over the biomolecules or cell injection, and advanced cell-modified scaffolds implementation. Heart surgeries entail various risks, such as infections, bleeding, stroke, or even death. Therefore, scientists are constantly looking for ways to boost current procedures and find new minimally invasive treatment methods based on the self-renewal of tissues [154]. Regeneration of heart tissues requires cardiomyocytes proliferation, but the cardiomyogenesis is very slow (less than 1% of cardiomyocytes can renew per year) and decreases with age. Thus, cardiomyocyte's loss exceeds its renewal, causing cardiac pathologies [158].

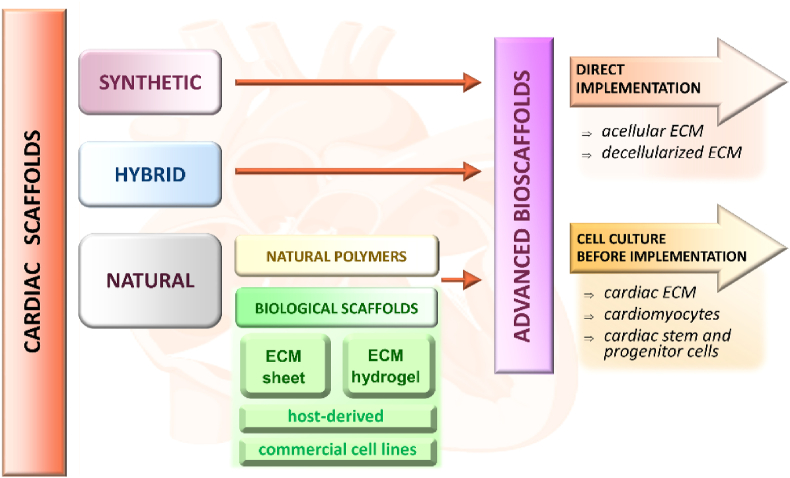

Currently, one of the most extensively investigated strategies to stimulate cardiomyocytes generation is a therapy based on advanced bioscaffolds. There are two main strategies to employ bioscaffolds for cardiovascular system regeneration (Fig. 3). The first one is based on the direct implementation of bioscaffolds into impaired heart tissue. In the second strategy, bioscaffolds serve as cardiac cells (and/or biomolecules) delivery system for myocardial repair.

Fig. 3.

Cardiac scaffolds classification based on materials and implementation techniques.

In the last decade, the extracellular matrix (ECM) from myocardium tissues has been intensively examined to design new optimal ECM bioscaffold for cardiac tissue regeneration [[159], [160], [161]]. ECM plays a crucial role in the regulation of cell functions (such as survival, proliferation, differentiation, migration, and adhesion), both, in homeostasis, and a response to injury [162,163]. The composition of ECM is different among particular tissues. Generally, ECM consists of four types of proteins, i.e. collagens, elastin, glycoproteins, and proteoglycans, as well as carbohydrates [161]. For instance, collagens (I and II) and elastin provide the strength and elasticity of tissues and organs. In turn, proteoglycans and glycoproteins (mainly fibronectin and laminin) are responsible for various growth factors binding, and regulation of their activity [164]. The ECM-bioscaffold in tissue engineering is a promising one due to its basic functions: i) it provides tissue maintenance, ii) ensures the formation of boundaries between different tissues, iii) regulates the activity of growth factors, and iv) regulates of signal transduction via cell interactions [165].

ECM bioscaffolds can be acellular or decellularized. Acellular ECMs bioscaffolds are usually surgically implemented into impaired heart region to facilitate the vasculogenesis and angiogenesis (endogenous cardiac regeneration) [165]. Additionally, these bioscaffolds can prevent the infract-derived scar thickening via inhibition of cardiac fibroblast activation [166]. Svystonyuk and co-workers demonstrated the fibroblast-mediated post-injury remodeling of cardiac tissues, stimulated by acellular ECM bioscaffold (neutralized SiS-ECM; porcine small intestinal submucosal extracellular matrix) [167]. The authors indicated that cardiac fibroblast combined with SiS-ECM-based bioscaffold may promote blood vessel formation and avoid scar expansion, due to upregulated gene expression and release of robust paracrine factors. There are some reasons to prefer decellularized ECM (dECM) bioscaffolds over the acellular ones for heart tissue engineering. The dECM bioscaffolds reveal the naturally bioactive composition and ability to partial recellularization in vivo. However, decellularization procedure is complicated and usually requires several physical, chemical, and enzymatic methods to remove all cellular components, while preserving the native ECM composition [168]. Several tissues or even whole organs can be decellularized to produce dECM bioscaffolds for regeneration of injured tissues, such as hearts, heart valves, lungs, kidneys, small intestine or urinary bladder [[169], [170], [171]]. Decellularization of tissues results in planar ECM sheets formation, which can be applied as patch graft materials [172] or processed into hydrogels [173]. Whole organ decellularization is used for 3D ECM bioscaffolds preparation. These 3D biostructures after further repopulation with host-derived cells may help to design the human organs for transplantation. Decellularization can be also employed to harvest ECM components in vitro. Cell-derived ECM scaffolds are useful for regeneration of damaged tissues, but also to examine the stem cells differentiation and proliferation [174].

After successful decellularization, ECM scaffolds must be recellularized by specific cell types to mimic the natural functions of tissue, such as drug response or electrical conduction. Moreover, cardiac dECM scaffolds should be modified with various pro-angiogenic factors and additional proteins to improve cell attachment/seeding and vasculogenesis (Fig. 4). For instance, pluripotent stem cells represent a source of cell that can differentiate into various cellular building blocks. Therefore, they hold a promise for regenerative medicine. Wang and co-workers designed and prepared human cardiac patches based on dECM from rat heart, pluripotent stem cells-derived cardiac cells, and fibroblasts [175]. The authors showed that this cardiac scaffold can reduce the infarct area of the heart of rats with induced-myocardial infarction, as well as enhance its function, such as normal beating, electrophysiological activity, and pharmaceutical response. In turn, Chamberland et al. demonstrated that embryonic decellularized cardiac scaffold reseeded with specific progenitor cells can serve as efficient support for cardiac cell growth. These progenitor cells were able to graft into the scaffold structure and form beating cardiac tissue [176].

Fig. 4.

Preparation of bioscaffolds for cardiac tissue engineering.

Godier-Furnémont designed a biological composite scaffold produced by seeding mesenchymal progenitor cells (MPCs) dispersed in fibrin hydrogel on decellularized ventricular human myocardium. The implanted scaffold improved the formation of the vascular network in the infarct area of the heart, leading to its functional recovery (rat ischemic myocardium model). The revascularization was related to MPCs migration and their ability to secrete SDF-1 (stromal cell-derived factors), which induced migration of further cells, and preservation of myocardial functions [177]. Some promising results were presented by a scientists team from Spain [178]. Perea-Gil et al. designed a cell-enriched myocardial graft based on a decellularized myocardial matrix modified with adipose tissue-derived progenitor cells (EMG-ATDPC) to regenerate the infarcted area of a swine heart. The in vivo studies showed that EMG-ATDPC- based bioscaffolds significantly enhanced cardiac function, promoted a new blood vessel formation, and inhibited progression of fibrosis in the impaired myocardium [178]. It should be pointed out that various types of cells can graft and differentiate into functional cardiomyocytes in vitro and in vivo, including bone marrow-derived cells, skeletal myoblasts, or mesenchymal stem cells [[179], [180], [181], [182]].

Most of the experimental studies suggest that the transfer of stem cells and progenitors may facilitate the regeneration of myocardium. The ECM offers an excellent source of various pluripotent cells, however, the decellularization and recellularization procedures still face many challenges.

Generally, cardiac scaffolds can be classified into three main groups on the basis of the biomaterial type: i) natural materials, including ECM-based scaffolds, and biocompatible polymers, ii) synthetic materials and iii) hybrid materials (Fig. 3).

Several natural polymers, such as collagen, chitosan, fibrin, hyaluronic acid, alginate, several self-assembling peptides, and polymer composites, can be applied as a structural template for heart tissue formation (Table 2). They are excellent candidates for tissue engineering due to their biocompatibility, biodegradability, renewability, and structure that can be easily modified with various stimuli and growth factors, or biomolecules to promote specific cell growth and proliferation.

Table 2.

Examples of natural polymers widely applied for cardiac regeneration (preclinical stage).

| BIOSCAFFOLD | COMPOSITION | FUNCTION | REF. |

|---|---|---|---|

| NATURAL POLYMER MATERIALS | |||

| Stem cell-capturing collagen scaffold | Collagen scaffolds covalently conjugated with stem cell specific antibody Sca-1 | Collagen scaffold facilitated the regeneration of cardiomyocytes and improved the tissue regeneration | [183] |

| Chitosan-collagen (C/C) scaffold | Stem cell-derived human cardiomyocyte seeded on the mico-structured chitosan-collagen scaffold | C/C scaffolds allowed the attachment, spreading, and orientation of human cardiomyocytes | [184] |

| 3-D collagen scaffold | Porous collagen sponge (type I) | Collagen scaffold promoted angiogenesis and arteriogenesis in the cryoinjured heart | [185] |

| Stem cells‐CREKA‐fibrin | Bone marrow stem cells modified with CREKA peptides | Stem cells-CREAKA-fibrin-targeting system revealed the ability to localize the stem cells to the fibrin-rich injured heart | [186] |

| Hyaluronic acid-based bioscaffold | HA-based hydrogel and mesenchymal stem cells; mixed esters of HA with butyric acid and retinoic acid; HA/silk fibroin-based scaffold |

HA-based sponges, meshes and hydrogels improved the myocardial structure formation, promote cell survival, reduce the inflammatory reaction, and increase neovascularization | [187] |

| Peptide‐functionalized alginate scaffold | Embryonic stem cell-derived cardiomyocyte co-seeded with dermal fibroblast in macroporous alginate scaffolds, modified with RGD and HBP peptide | RGD/HBP-modified alginate scaffolds promoted the formation of functional cardiac tissue from embryonic stem cell-derived cardiomyocytes co-cultured with dermal fibroblasts. | [188] |

| Self-assembling peptide scaffold | VEGF combined with RADA16-heparin domain | Combined RADA16-scaffold induced angiogenesis, recruitment, and differentiation of cardiac stem cells into cardiomyocytes | [189] |

| Chitosan-hyaluronan-silk fibroin cardiac scaffold | Silk fibroin modified with chitosan, and hyaluronan (in situ formulated) | Composite scaffold improved left ventricle functions and angiogenesis in myocardial infarction regions | [190] |

| SYNTHETIC POLYMER MATERIALS | |||

| PEEUU-PCL scaffold | Poly(ester-ether urethane urea) - poly-caprolactone blend | PEEUU-PCL scaffold enhanced functional activities of the cardiomyoblast cells | [191] |

| PLGA-IGF-1 scaffold | Poly(D,L-lactide-co-glycolide) nanoparticles modified with insulin-like growth factor | PLGA-IGF-1 NPs inhibited the cardiomyocyte cells apoptosis and reduced the infarct sizes | [192] |

| Cardiomyoctes-modified PU scaffold | Polyurethane film modified with lamin and gelatin | PU film supported the formation of cardiomyocyte multilayered construct of heart tissues | [193] |

| Stem cell-derived cardiomyocytes-modified PU scaffold | Polyurethane film modified with lamin, gelatin and collagen (type IV) | PU films supported the formation of fully contractile cardiomyocyte cells layers | [194] |

| Protein-functionalized PLA:PGS scaffold | Poly(lactic acid)- poly(glycerol sebacate) fibres modified by lamin or Matrigel | PLA:PGS scaffold induced neovascularization after implantation into mouse heart | [195] |

| HYBRID MATERIALS | |||

| Chitosan/Carbon scaffold | Carbon nanofibres dispersed into chitosan matrix | Chitosan/carbon scaffold improved the mechanical properties of cardiac tissue constructs and enhanced transmission of electrical signals between cells | [196] |

| PLL-GO scaffold | Graphene oxide sheet coated with poly-l-lysine | PLL-GO sheets improved electrophysiological function and mechanical integrity of tissue | [197] |

| rGO-GelMA scaffold | Reduced graphene Oxide‐ gelatin methacryloyl hybrid hydrogels | Cardiac cells cultured on rGO‐GelMA scaffolds exhibited excellent biological activities, i.e. cell viability, proliferation, and maturation | [198] |

| Au NPs- PCL scaffolds | Fibres modified embedded with gold nanoparticles | Scaffold induced the formation of tissue with structure resembled cardiac cell bundles | [199] |

| AdSCs-statin-PLGA scaffold | Adipose‐derived stem cell and statin-modified poly(lactic‐co‐glycolic) acid nanoparticles | Facilitated endogenous functional cardiac regeneration | [200] |

For instance, stem cells-collagen scaffolds modified with monoclonal specific antibody Sca-1, was applied as a patch to promote regeneration of surgical heart defects (C57/BL6 mouse, in vivo model). The authors highlighted the double efficiency of the collagen-based scaffold, i.e. it serves as a scaffold for stem cell proliferation and differentiation, and increases the enriching capacity for autologous stem cells [183]. In turn, Huang and co-workers reported the use of clot-binding pentapeptide (CRECA: cysteine-arginine-glutamic acid-lysine-alanine) to target the exogenous stem cells to the injured heart. Based on the fibrin-targeting theory, fibrin exhibits potential as a target in stem cell therapy for the myocardial infarction, due to its spatial‐specific distribution in myocardial injury. The CRECA-functionalized stem cells injected to the left ventricle of the fibrin‐rich rat heart (in vivo model of myocardial ischemia-reperfusion injury) revealed the ability to localize the damaged region and promoted the cardiomyocyte proliferation [201]. An interesting in vivo studies were published by Chi et al. [190]. Natural silk fibroin modified with chitosan and hyaluronan was examined as a cardiac patch to repair myocardial infraction hearts of rats. These three polymers were selected due to their biological activity and low inflammatory response. Silk fibrous proteins are known as a material for tendon regeneration. Chitosan is commonly applied for the regeneration of nerves and bones, and hyaluronic compounds can promote angiogenesis and cartilage repair. The performed studies indicated that chitosan-hyaluronan-silk fibroin cardiac scaffold markedly increased the thickness of the left ventricle of heart walls and enhanced their fractional shortening.

The application of natural polymers in regenerative medicine is limited to some extent, due to poor mechanical properties, low electrical conductivity, and rapid degradation in physiological conditions. The main challenge in myocardium tissue regeneration is to design advanced cardiac scaffolds, which is elastic and at the same time mechanically strong to endure the dynamic contractions of heart. Currently, synthetic polymers or hybrid materials consisting of synthetic and natural polymers, polymers modified with micro- or nanoparticles, or surface-functionalized organic and inorganic nanostructures, may provide the enhancement of mechanical, electrical, and surface properties of bioscaffolds. However, their surface should be also functionalized with biomolecules or growth/differentiation factors to improve biocompatibility and provide a tissue-like environment for cell attachment, growth, proliferation, and differentiation (Table 2).

High metabolic activity of cardiomyoblast cells was observed after the implementation of a porous scaffold made of poly(ester-ether urethane urea) and poly-caprolactone blend (PEEUU-PCL scaffold) The PCL-additive provided excellent mechanical properties, similar to those of heart tissues. Based on in vitro and in vivo studies, it was proven that the designed scaffold was surrounded by connective tissue and new-formed blood vessels [191]. Chang and co-authors demonstrated the application of poly(D,L-lactide-co-glycolide) nanoparticles (PLGA) modified with insulin-like growth factor (IGF)-1 as a new scaffold for cardioprotection. The IGF-1 plays a crucial role in the regulation of myocardial functions, including cardiomyocyte survival, growth, and protection from ischemia. Additionally, IGF-1 can improve myocardial function after heart infarction. The authors indicated that PLGA-IGF-1 NPs prolonged IGF-1 retention in heart tissue, and significantly inhibited the cardiomyocyte cells apoptosis (in vitro and in vivo studies) [192]. Another interesting biodegradable synthetic polymer for cardiac repair is polyurethane (PU). McDevitt et al. reported PU films as a scaffold for cardiomyocytes' growth (in vitro studies). To improve the adhesion of cells to the PU layer, its surface was coated with proteins, i.e. laminin and gelatin. Cardiomyocytes cultured on the PU dishes formed a multilayered construct of tissues with mechanical properties similar to native heart matrix [193]. The mechanical and conductive properties of scaffolds can be also improved by functionalization with various nanoparticles [202]. For instance, the conduction of electrical signals through cardiac tissue was enhanced by the incorporation of electrically conductive carbon nanofibres into the chitosan matrix [196]. Chitosan/carbon scaffolds supported the cultivation of the cardiac cells and improved their cardiogenic properties. In another study, a nano-patterned PEG scaffold was modified with graphene [203]. The authors indicated that the graphene-PEG scaffold improved the myofibrils and sarcomere structures and increased the electrical coupling of cardiac cells. Fleischeret and co-workers fabricated the conductive nanocomposite scaffold consists of gold nanoparticles and PCL fibers [199]. The addition of gold nanoparticles induced the formation of tissue with structure resembled cardiac cell bundles in vivo.

The structure of scaffolds allows delivering of nutrients, metabolites, nucleic acids, regulatory molecules, and cardioprotective drugs within the cells [204]. Delivery of active substances via nanocarriers is a promising tool to restore the injured heart function [205]. Somasuntharam et al. demonstrated DNAzyme gold NPs conjugates as a drug delivery system for the regulation of TNF-α expression in the rat model of myocardial infarction [206]. The authors showed that injection of DNAzyme gold scaffold in the myocardium resulted in the improvement of acute cardiac function due to significant TNF- α gene silencing. Yokoyama et al. examined adipose‐derived stem cells (AdCs) and statin-loaded PLGA nanoparticles as multifunctional bioscaffolds to stimulate the infarcted myocardium regeneration. The AdSCs were seeded to the scaffold structure to reduce the risk of inflammation, and statin was attached to recruit the circulating progenitor cells for angiogenesis [200]. The authors showed that AdCs-statin-PLGA scaffolds can facilitate cardiac regeneration, and may serve also as an efficient statin (or other active substance) delivery carrier. Diaz-Herraez et al. formulated PLGA microparticles loaded with neuregulin-1 (NRG) and further modified with ADCs. The presence of NRG (growth factor) promoted cardiomyoctyes proliferation and reduced infarct size (rat and pig models). The authors reported that ADCs-PLGA-NRG delivery system allowed to control the release of NRG in the infarcted region, accompanied by stimulation of vessel, arterioles and capillaries formation [207].

Synthetic materials in comparision with natural biomaterials exhibit improved mechanical, elastic, and conductive properties, better durability, stability, and controlled degradation rate [208]. However, there are many concerns related to their toxicity and potential hazardous health effects. Regardless of the type of material used to heart tissue regeneration, bioscaffold must be biocompatible, biodegradable, and possess a naturally cardiac tissue-like environment to facilitate cell attachment, growth, proliferation, and differentiation into mature. The degradation rate must be sufficient to support cell integration with native tissues. Additionally, bioscaffold should act as a reservoir of nutrients, and regulatory molecules and provide their slow release.

The outcomes of these in vitro, in vivo, and ex-vivo studies mark the future direction for the application of both, natural and synthetic materials for cardiac tissue regeneration. However, despite the positve premises, the use of bioscaffolds for cardiomyocytes regeneration is still lagging at the preclinical stage.

4. Regeneration of muscle system

There are three main types of muscle tissue: skeletal (or striated) muscle, smooth (or non-striated) muscle, and cardiac muscle. This chapter is focused on the first two types of muscles, while the last one is discussed in the chapter Bioscaffolds for cardiovascular system regeneration. The main difference between skeletal and smooth muscles is the presence or absence, respectively, of organized, regularly repeated arrangements of myofibrillar contractile proteins – myofilaments. The skeletal muscles are used in locomotion and to maintain posture, while smooth ones are part of the walls of organs and structures such as the uterus, esophagus, stomach, blood vessels. Because, depending on the type of muscle tissues, their structure as well as their functions differ, the way of regeneration is different. It should be noted that repairing an injured muscle is a multi-stage process that uses immune, muscle, perivascular and nerve cells. Without this repair, it leads to structural and functional deficits in the body, which in turn leads to a reduction in the quality of life not only due to a deficiency in the functioning of the muscles, but often also for aesthetic reasons.

4.1. Hydrogels

Hydrogels are water-swollen high-dimensional polymer chain networks which specific properties which depending on the origin source exhibit high biocompatibility, that makes them an ideal class of materials in tissue engineering. Hydrogels may display reversible structural or just volume deformations, induced by various stimuli, such as temperature, pH, wave length of light, ionic strength, and specific molecules [[209], [210], [211], [212]]. Moreover, they can withstand significant stress, which proves their flexibility, and combined with sensitivity to stimuli makes them ideal materials to compose artificial muscles [209,[213], [214], [215], [216], [217]]. The above features are important, however, not sufficient to fully replace natural muscle tissue. Actuation characteristics are required in special tissues reconstruction such as skeletal or to provide mechanical support to injured cardiac tissues [[218], [219], [220], [221], [222], [223], [224], [225]]. Therefore over last years, structure modulation has become a crucial step for developing hydrogel‐based artificial muscles. Various graft materials have been tested to promote skeletal muscle regeneration. Natural hydrogels are a popular choice for tissue engineering due to their low immunogenicity, porosity, good permeability, biodegradability and structural biocompatibility towards tissues, which minimizes the inflammatory response just at the outset. This type of hydrogel can not only act as a gentle scaffold for cell alignment in connective tissue, but also plays a dynamic and flexible role that determines cell behaviour and tissue function as scaffold for the growth of many types of tissue. Collagen is a fibrous protein found most commonly in the extracellular matrix and can be formulated as a scaffold for the growth of many types of tissues [226] (Table 1). It supports proliferation, differentiation and myotube formation of immortalized and primary murine myoblasts [[227], [228], [229]]. Cheema et al. have indicated that contraction forces depend on mioblast morphology. At low contraction forces myoblasts maintained a rounded morphology, and when contraction forces increases, myoblasts started to align and form myotubes under uniaxial tension [230]. Disadvantage of the collagen scaffolds is lack mechanical strength and structural stability upon hydration, which limit their applications in particular tissues. Problem can be solved throughout physical or chemical methods leading to intermolecular cross-linking of collagen scaffolds, but blending with other materials, such as synthetic polymers is also used. The effectiveness of myoblasts and mesenchymal stem cells in combination with fibrin gel in repairing volumetric muscle loss was also assessed by Matthias et al. [231] The obtained results have confirmed muscle mass restoration as well as fibrosis reduction with active contribution of transplanted cells in the muscle and vascular regeneration. In further studies Neal et al. have proposed method according which using fibrin hydrogel skeletal muscle tissue with a high volumetric density and perfect cell alignment along the axis can be created [232]. In these studies artificial muscle was accomplished by integration of gel fiber based fibrin containing mouse C2C12 immortalized myoblast cell line [232]. Fibrin scaffold with a populated satellite cell niche, enable to vascular integration and functional in vivo maturation was also used to construct a highly functional biometric muscle tissue [233], and functional neuromuscular junctions [234]. It was also confirmed the applicability of fibrin hydrogel in seeding of human umbilical cord mesenchymal stem cells (HUCMSCs) [235], and in production an engineered skeletal muscle with structural resemblance to in vivo tissue [236]. The microfabrication of new skeletal muscle tissue using smooth muscle cells incorporated in fibrin hydrogel was also tested to fabricate ureteral replacements [237]. Although high potential fibrin gel has been demonstrated, the most promising seems to be fibrin scaffolds with microthread architecture, in which scaffolds favour the ingrowth of nascent myofibers into the wound site, and the functional regeneration of skeletal muscle [238]. Alginate hydrogels have also been tested as a material supporting the regeneration of muscle tissues [239]. This type of material is mostly chemically modified to provide tighter control over properties such as stiffness and degradability. Its structure also allows for various types of use, e.g. in the form of a hydrated gel, microspheres or as highly porous, freeze-dried cryogenic gels [240,241]. Borselli et al. reported that an injected alginate gel can provide long-term delivery of incorporated myogenic and angiogenic growth factors, and when injected into the hind limbs of ischemic mice, it promote functional muscle regeneration by stimulating myogenesis, angiogenesis, and re-innervation [242]. As cryogels, alginate scaffolds promoted muscle regeneration by secreting bioactive factors that have a profound effect on the functioning of C2C12 mouse-derived myogenic progenitor cell line [243]. The RGD-alginate porous hydrogel provided a sustained release of incorporated IGF-1 and VEGF165 and adherence MSCs to the biomaterial walls (Fig. 5). Indeed the outward migration of muscle cells has been shown to be of vital importance on subsequent muscle regeneration. For example, Hill et al. have indicated that transplanting the cells with the highly porous alginate scaffold that simultaneously delivers of growth factors (hepatocyte growth factor (HGF) and fibroblast growth factor 2(FGF2)) led to increase in muscle mass and the overall extent of regeneration [244]. Passipieri and Chris have also shown that the alginate three-dimensional scaffolds can be used to deliver growth factors into a variety of volumetric muscle loss injuries [245]. But in newest work Quigley et al. have tested alginate fibers with enclosed muscle precursor cells for delivery of dystrophin-expressing cells to dystrophic muscle, and the constructed material reported more robust regenerative results than did myoblasts attached to synthetic fibers [246,247].

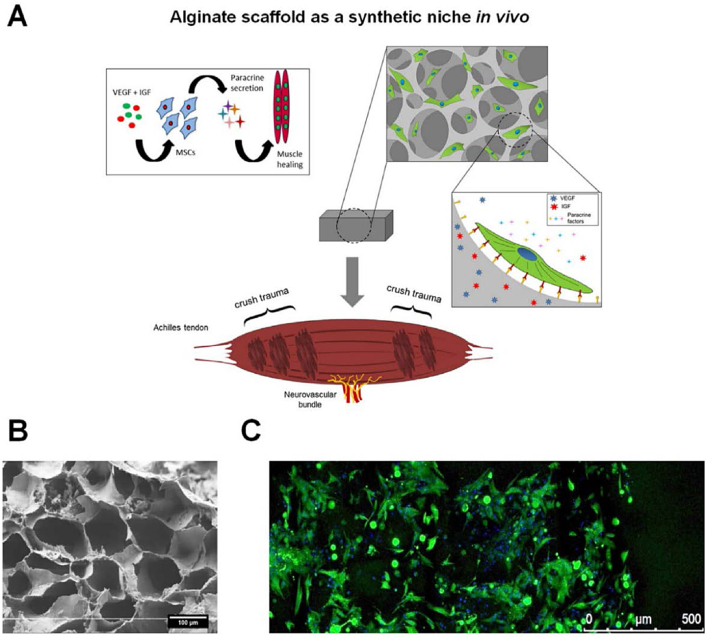

Fig. 5.

An engineered synthetic niche provides MSCs with a structural and chemical environment that is optimal for paracrine secretion. (A) Strategy of using porous alginate scaffold in muscle regeneration. (B) Representative SEM image showing the macroporous structure of the alginate scaffold. (C) Representative fluorescent image of rat bone marrow derived MSCs 24 h after seeding on the scaffold. Reproduced with permission from Ref. [243]. Copyright 2016 Elsevier.

Hyaluronic acid is a popular scaffold material for the regeneration of different tissues because it is biocompatible, promotes skeletal myoblast proliferation, and differentiation, regulates tissue hydration and facilitates the diffusion of nutrients [248] (Table 1). However, fabrication of hyaluronic acid-based scaffolds has been achieved through different chemical modifications such as a Michael addition reaction with thiol as nucleophile [249,250], photopolymerization of methacrylated or thioglycated hyaluronic acid [251,252]. The first one is dedicated to fibres scaffolds formation, the second one to preparation of hydrogel beads. For example the hyaluronic acid based photopolymerizable hydrogel was used for transplantation satellite cells and muscle progenitor cells, which enable generation of new myofibers, and recovery of muscle contraction strength [253]. It was also shown that modifying hyaluronic acid with both methacrylate and 3,4-dihydroxyphenylalanine groups obtained materials, which can be use in minimally invasive procedures to foster maxillofacial tissue repair [254]. Tanaka et al. have found combination scaffolds of salmon fibrin and hyaluronic acid form compliant hydrogels matching the physical properties of most tissues [255]. Other natural polymers such as chitosan and gelatin have also a good capacity of supporting cell attachment, however, their main drawback is immunogenicity [256]. The potential was found for gelatin-based hydrogels stabilized through reaction with lysine diisocyanate ethyl ester [257] or using gelatin as a component of other natural hydrogels e.g. cross-linked oxidized alginate-gelatin hydrogel [258].

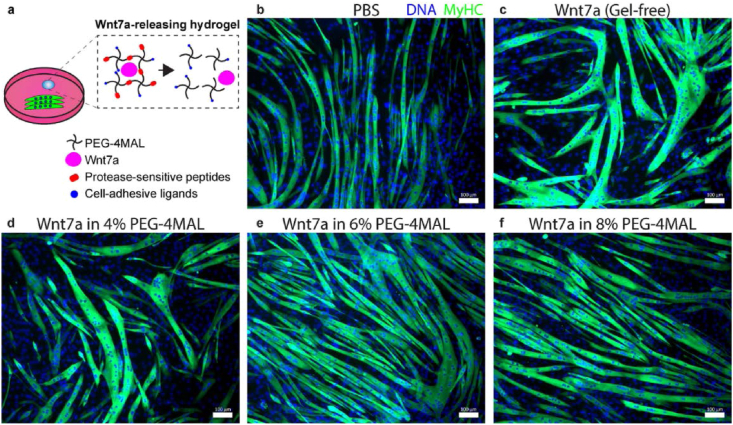

The natural hydrogels due to their resemblance to native tissue are the preferred materials in tissue engineering especially for controlling cell growth, proliferation and differentiation, however as biological materials they have mostly and nonreplicable structural composition, limiting their in vivo application. Synthetic hydrogels mainly composed of poly(ethylene oxide) (polyethylene glycol), poly(vinyl alcohol), poly(lactic acid) or polypeptides, unlike their natural counterparts, can be closely adapted to certain requirements of a cell therapy application, in particular the mechanics that most closely resemble the native cellular microenvironment. Using synthetic polymers enables important material properties such as viscoelasticity, modulus, permeability and degradability. Another advantage over natural materials is that synthetic hydrogels have a relatively low risk of transmitting pathogens. Polyethylene glycol is one of the most widely used macromers in tissue engineering because its hydrophilicity, cytocompatibility, low non-specific protein adsorption, and is nondegradable under mammalian enzymes. Mechanical properties of PEG-based hydrogels can also be easy controlled, but active hydroxyl groups can be easily chemically functionalized through photopolymerization or Michael addition. Example of using functionalized PEG as hydrogel Han et al. presented [259,260]. In the studies a synthetic bioactive hydrogel based on a branched poly(ethylene glycol) with ends maleimide functionalized groups was used for incorporation muscle satellite cells to dystrophic skeletal muscles also with comorbid trauma. This material may also be suitable for treating craniofacial and limb muscle trauma. In newest papers the co-delivery of muscle satellite cells and Wingless-type MMTV Integrated 7a protein using the maleimide functionalized PEG hydrogel was studied. This work has confirmed that the hydrogel-encapsulated Wnt7a significantly increases hypertrophy of the muscle fiber, endogenous muscle satellite cells expansion, and exogenous cells migration during the implantation process [166]. The effect of the different Wnt7a-loaded PEG-4MA hydrogel on C2C12 myotubes hypertrophy is illustrated in Fig. 6. A major drawback of the polyethylene glycol-maleimide hydrogel is that the fast gelation speed can result in crosslinking heterogeneities. The decreasing of reaction kinetic and hence uniformity of particle dispersion can be achieved by the coupling a glutamate near the cysteine of the peptide crosslinker, as well as appropriate pH and ionic strength [261,262]. A wide range of protein-based hydrogels have also been developed as scaffold. They are very attractive due to their inherent cell adhesively as conferred by the presence of integrin-recoginizing peptide sequences [263]. The polysaccharides hydrogels are not bioactive and lack integrin binding domains, since such modification of polysaccharide molecules requires the attachment of chemical molecules that can facilitate cell adhesion [264,265].

Fig. 6.

Hydrogel-released Wnt7a retains its bioactivity in vitro. (a) Schematic diagram of the experiment. Differentiating C2C12 myotubes treated with (b) PBS, (c) Wnt7a (gel-free), (d) Wnt7a in 4% PEG-4MAL hydrogel, (e) Wnt7a in 6% PEG-4MAL hydrogel, and (f) Wnt7a in 8% PEG-4MAL hydrogel. Day 5. Scale bar 100 lm. Reproduced with permission from Ref. [259]. Copyright 2019 Elsevier.

An alternative approach to pre-vascularization of engineered muscle involves plating endothelial cells, fibroblasts, and myoblasts onto the poly(lactic-co-glycolic acid) scaffold [266]. This studies have confirmed that flap consisting both endothelial cells, fibroblasts and myoblasts underwent the most effective integration and caused the most advanced regeneration of host tissue. The used material enabled successful muscle flap engineering. Furthermore, the increased mechanical strength of the transplanted tissue, which was caused by the myocytes became vascularized and innervated and finally, mature as myofibers. Worth attention are also hybrids natural and synthetic polymers. An example is photopolymerizable hydrogel based upon polyethyleneglycol and fibrinogen, which is enable to generate a complete and functional artificial muscle [267]. This type of hydrogel supports myogenic differentiation, cell survival after transplantation and angiogenic infiltration in vitro and in vivo [268]. The amine-reactive polyethylene glycol modified fibrinogen hydrogel with a decellularized extracellular matrix scaffold showed a high expression of ITGA5, ITGB1, and FN and a synergistic up-regulation of ang1 and tie-2 transcripts [269]. Scaffolds composed of collagen and polylactic acid is also a promising choice as it combines the good mechanical and processing properties of a synthetic component with the bioactivity of a natural polymer [270]. Conductive polymers such as polypyrrole, polyaniline, and polythiophene have formed hydrogels not only showing good biocompatibility, but also possessed suitable electroconductivity [271]. Sasaki et al. have developed a series of molecular permeable electronic devices to help to regenerate the muscle tissues. The hybrid of poly(3,4-ethylenedioxythiophene) and polyurethane have been biocompatible with muscle, as well as neural cells. Moreover, this displays excellent stability and high conductivity over physiological strain levels, making them highly suitable for low-invasive electrical stimulation [272]. Poly(acrylic acid) were modified with polyaniline, which provided not only a microfluidic pattern, but also a three-dimensional environment of nanofiber tissue formation [273]. In another work as the main body polyaniline grafted quaternary chitosan and cross-linked with oxidized dextran was fabricated to obtain a conductive hydrogel [274]. C2C12 cells have also exhibited a higher proliferation on conductive hydrogel than, for example on the chitosan hydrogel, indicating their potential application in skeletal muscle tissue engineering [275]. The micro-patterned electrically conductive reduced graphene oxide-incorporated/polyacrylamide hydrogel was found as an ideal multifunctional and high performance biomaterial platform to construct muscle tissue scaffolds [276].

4.2. Electrospun