Abstract

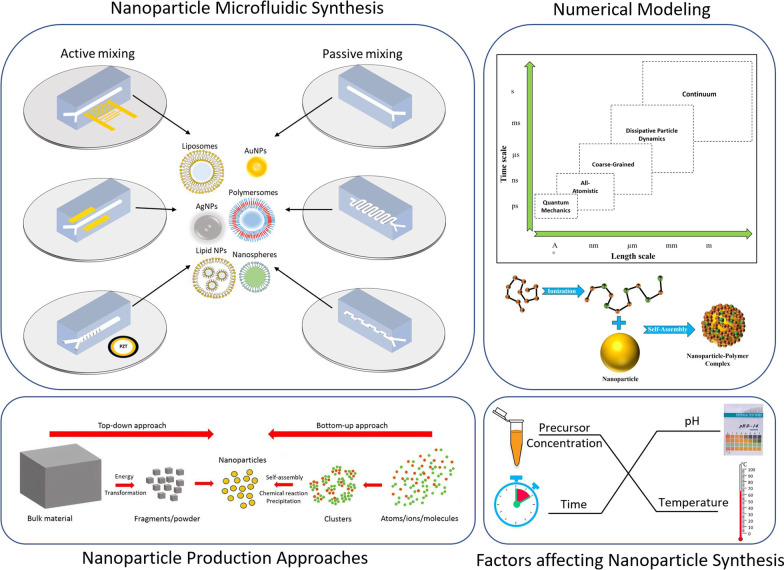

Recent years have witnessed an increased interest in the development of nanoparticles (NPs) owing to their potential use in a wide variety of biomedical applications, including drug delivery, imaging agents, gene therapy, and vaccines, where recently, lipid nanoparticle mRNA-based vaccines were developed to prevent SARS-CoV-2 causing COVID-19. NPs typically fall into two broad categories: organic and inorganic. Organic NPs mainly include lipid-based and polymer-based nanoparticles, such as liposomes, solid lipid nanoparticles, polymersomes, dendrimers, and polymer micelles. Gold and silver NPs, iron oxide NPs, quantum dots, and carbon and silica-based nanomaterials make up the bulk of the inorganic NPs. These NPs are prepared using a variety of top-down and bottom-up approaches. Microfluidics provide an attractive synthesis alternative and is advantageous compared to the conventional bulk methods. The microfluidic mixing-based production methods offer better control in achieving the desired size, morphology, shape, size distribution, and surface properties of the synthesized NPs. The technology also exhibits excellent process repeatability, fast handling, less sample usage, and yields greater encapsulation efficiencies. In this article, we provide a comprehensive review of the microfluidic-based passive and active mixing techniques for NP synthesis, and their latest developments. Additionally, a summary of microfluidic devices used for NP production is presented. Nonetheless, despite significant advancements in the experimental procedures, complete details of a nanoparticle-based system cannot be deduced from the experiments alone, and thus, multiscale computer simulations are utilized to perform systematic investigations. The work also details the most common multiscale simulation methods and their advancements in unveiling critical mechanisms involved in nanoparticle synthesis and the interaction of nanoparticles with other entities, especially in biomedical and therapeutic systems. Finally, an analysis is provided on the challenges in microfluidics related to nanoparticle synthesis and applications, and the future perspectives, such as large-scale NP synthesis, and hybrid formulations and devices.

Graphical abstract

Article highlights

In this review article we have covered the state-of-the-art microfluidic methodologies for the synthesis of a broad range of nanoparticle (NPs) for potential applications in the fields of biomedicine and drug delivery.

Apart from the experimental methodologies, this review also details the most common multiscale simulation methods used to unravel the critical mechanisms involved in nanoparticle synthesis and their interactions with other entities.

A comprehensive summary of the microfluidic techniques, divided into passive and active micro-mixing methods, have been provided, while highlighting advantages and disadvantages of individual methods.

We have discussed challenges related to NPs synthesis, their application in new fields, and future perspectives.

Introduction

The utilization of nanoparticles (NPs) in the medical and pharmaceutical fields holds great potential for applications in drug discovery [1, 2], translational medicine [3, 4], clinical diagnosis [5, 6], and disease prevention [7–10]. NPs with their unique physicochemical properties exhibit distinct physical (e.g., electrical [11], and optical [12]), chemical [13], and biological properties (e.g., solubility, and toxicity [14]). As a drug carrier, NPs tend to enhance the stability and solubility of the encapsulated drug by protecting them from rapid metabolism and clearance while decreasing toxicity due to their controlled drug release and specific delivery [15]. For example, many newly discovered drugs are hydrophobic, making them difficult to be conventionally administered due to their low solubility and bioavailability [16]. However, when encapsulated in NPs, drug dissolution is improved due to high surface area-to-volume ratio offered by the NPs. Moreover, NPs can be engineered to escape clearance by the immune cells, and target specific sites in the body, e.g., micro-tumor environments [17]. This feature is of tremendous importance, especially to cancer patients, as conventional antitumor chemotherapeutics are non-specific, therefore, toxic to both the normal cells and cancerous cells [18]. In this regard, NPs can reduce the harmful side effects of cancer treatments and improve drug efficacy by increasing the drug circulation time and availability to the tumor [19]. As a result, there has been tremendous interest over the past decade to engineer NPs for targeted drug delivery [15, 20, 21]. Furthermore, due to the unique qualities of NPs, the field of nanotechnology is diverse with a wide range of applications in gene therapy [10], photocatalysis, catalytic reduction [22], electrochemical sensing [23, 24], energy storage, and environmental remediation [25]. For example, solid lipid nanoparticles (SLN) were used as gene carriers in the treatment of degenerative retinal disorders in rat models [26] and poly lactic-co-glycolic acid (PLGA) NPs were used in the delivery of locked nucleic acids for the treatment of cystic fibrosis [27]. Carbon nanomaterials are considered promising because of their excellent electrical, mechanical, and optical properties [28], where carbon NPs have been used in the removal of hazardous organic pollutants from seawater and groundwater [29], carbon nanotubes-graphene hybrid thin films were added to gold electrodes for the electrochemical detection of toxic arsenic (V) [30], and reduced graphene oxide-iron oxide NP nanocomposite electrodes were utilized for the detection of melatonin and dopamine [31]. Iron oxide NPs have attracted much attention due to its superparamagnetism and easy separation process (separation by a magnet), where they have been utilized as contrast agents in T2 magnetic resonance imaging [32], labeling of cells for tracking and monitoring of therapeutic delivery [33], drug delivery systems to deliver peptides, DNA, and chemotherapeutic drugs [34], and used as pigments to color construction materials [35] and in food coloring [36]. In addition, iron oxide NPs can be synthesized from precursors recycled from mill scale waste to prevent the possible contamination of soil and groundwater [37]. Moreover, silver chloride NPs have the ability to eliminate pollutants from water by the photocatalytic degradation of many dyes [38], functionalized gold and silver NPs were used for colorimetric sensing of glucose [39] and pesticides [40], gold NPs have shown to have anti-hyperglycemic effects in diabetic rat models [41] and were used in aqueous electrochemical capacitors for energy storage applications [42]. Copper oxide [22] and cadmium oxide [43] have shown to have antimicrobial activities against microorganisms.

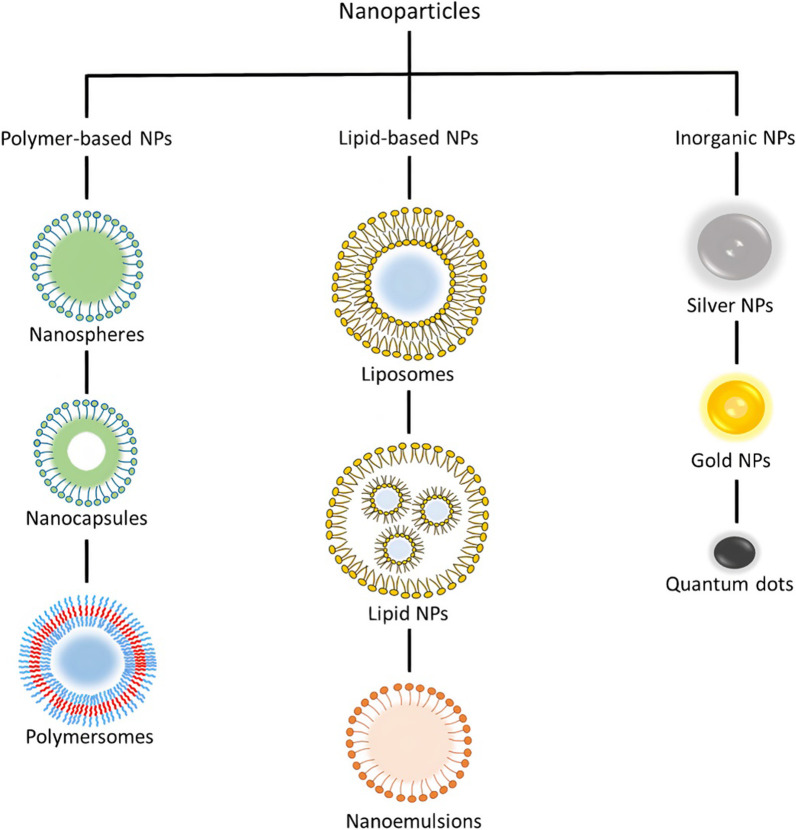

There are numerous types of NPs depending on their chemical building blocks. These are broadly categorized as: organic (lipid and polymeric), inorganic (metals and metal oxides), and hybrid NPs. Each type is utilized in applications depending on the required characteristics. Organic NPs exhibit high biocompatibility and bioavailability [44, 45], whereas metal-based NPs can be synthesized with variable size, structure, and geometry [46]. Hybrid NPs are nanomaterials consisting of two or more distinct nanocomponents [47], where the formulated particles exhibit new or enhanced properties depending on the individual component. For example, combining magnetic NPs and PLGA NPs for simultaneous MRI imaging and drug delivery [48]. One of the earliest Food and Drug Administration (FDA) approved organic NP-based drug for cancer treatment, was Doxil® in 1995 [49], which consisted of lipid NPs (liposomes) loaded with doxorubicin and coated with poly(ethylene glycol) (PEG) to increase circulation time. Other FDA approved nanodrugs include the polymer-based Glatopa® [50] and iron oxide-based Feraheme® [51], which are used to treat multiple sclerosis and kidney disease, respectively. Recently, two liposome-based messenger RNA (mRNA) vaccines have been developed by Moderna, Inc. and BioNTech/Pfizer for the Severe Acute Respiratory Syndrome Coronavirus 2 (SARS‑CoV‑2) [9].

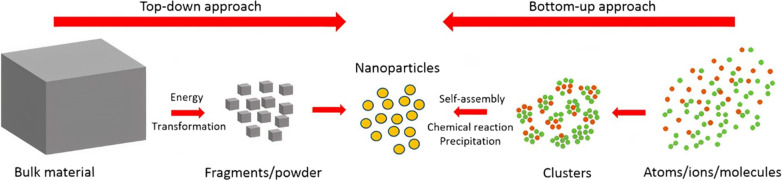

Nanoparticle performance in vivo is governed by its physicochemical properties, and these include size, surface charge, morphology, and polydispersity index (PDI) [52]. Controlling these parameters is highly important for effective administration, correct dosage, and accumulation of NPs in target sites. For instance, liposomes in the range of 50–100 nm are required to evade the mononuclear phagocyte system (MPS) and accumulate into the leaky tumor vasculature due to the enhanced permeability and retention (EPR) effect. NPs in the size range of 20–100 nm can enter the spleen, bone marrow, and liver [53]. Thus, a wide size distribution (high PDI) could result in a significant portion of the administered nanodrugs being ineffective and cleared by the MPS. More specifically, the cellular uptake of NPs is carried out in a process called endocytosis [54] which involves three fundamentals steps (i) specific binding of NPs on cell surface, (ii) plasma membrane budding and pinching off to form endocytic vesicles, and (iii) transport to intracellular compartments. Depending on NP size, two types of endocytosis can occur, phagocytosis (i.e., cell eating) which uptakes NPs > 500 nm and is usually performed by macrophages, monocytes, and neutrophils, and pinocytosis (i.e., cell drinking) which engulfs fluids surrounding the cell and the suspended smaller NPs [55]. Surface charge is another important parameter influencing cellular uptake, NP stability, and interactions with the biological surroundings [56]. Where it is a major factor in the initial adsorption into the cell membrane prior to endocytosis [57]. For example, liposomes can either be cationic, anionic, or neutral depending on the charge of their constituent phospholipids, where cationic liposomes were found to be more effective in delivering drugs to the angiogenic blood vessels of solid tumors, neutral and anionic liposomes were used in drug delivery to the extravascular compartments of tumors [58]. In addition, NP stability in suspensions is determined by the zeta potential which depends on the surface charge, where values > + 30 mV and < − 30 mV indicate good stability against aggregation [59]. Moreover, the hydrophilicity and hydrophobicity of the administered drug carrier plays a role in its half-life and circulation time. Where hydrophobic NPs have a higher tendency to bind with plasma proteins (opsonins) in the bloodstream which are then eliminated by the MPS [60]. Thus, significant efforts are spent on the modification and functionalization of NP surfaces to escape the MPS and increase circulation time [61, 62]. One of the most common ways of functionalizing organic (lipid and polymer) NPs is by polyethylene glycol (PEG) coating (PEGylation) which is a nonionic hydrophilic polymer. Where after PEGylation, a hydrophilic protective layer is formed around the NP that reduces the adhesion of plasma proteins making them invisible to the MPS and increasing their circulation half-life by several times. Nanoparticles are conventionally synthesized by two approaches: top-down and bottom-up [63] (Fig. 1). Top-down methods involve mechanical work of macro-materials to produce nanoparticles followed by post processing steps such as extrusion and high-pressure homogenization to further decrease particle size. Because of its scalability, it is currently the preferred method in the industry [64]. However, this method is energy-demanding, requires expensive equipment, and produces particles with high PDI and batch-to-batch variation [65]. Examples of top-down methods include ball milling, thermal evaporation, and laser ablation [66]. On the other hand, bottom-up approaches rely on NP growth via precipitation from bulk mixing of precursors [67]. Since NP formation generally occurs in an environment with a millimeter or centimeter scale, local fluctuations in precursors' concentrations can develop that result in particle size heterogeneity and variation [68]. In comparison with top-down approaches, bottom-up techniques require less energy, space, and material to produce particles with better properties, thus making it suitable for research-setting synthesis at low cost [69, 70]. Bottom-up methods include co-precipitation and chemical vapor deposition [66, 71]. Detailed reviews of conventional (top-down and bottom-up) NP synthesis methods were presented in references [33, 38]. Overall, conventional methods lack precise control over experimental parameters, producing NP with a wide size distribution and batch-to-batch variation in physicochemical properties [72]. Other limitations include: the requirement of additional chemical and physical processes (freeze thaw, high pressure homogenization and extrusion), waste of resources, insufficient macro-mixing, and potential contamination. These drawbacks associated with conventional methods impede the translation of NP drugs from laboratory to clinical use [73]. Thus, it is a crucial matter to investigate and develop innovative techniques to address these challenges and synthesize NPs with high reliability and control.

Fig. 1.

Schematic drawing of top-down and bottom-up approaches for nanoparticle production

An alternative approach to conventional methods is miniaturizing the synthesis process by utilizing microfluidic channels. Microchannels offer the ability to overcome the limitations of top-down approaches and bulk mixing by their micro-scale dimensions and mixing, precise control of flow parameters, particle size tunability, and reproducibility [74]. Similar to bulk mixing of bottom-up approaches, microfluidic NPs are affected by various factors including temperature, precursor concentration, time, and pH. However, due to the continuous flow operation of microfluidics, additional factors such as total flow rate (TFR), flow rate ratio (FRR) and residence time also influence these parameters and the physicochemical properties of NPs. Where TFR is the sum of flow rates entering a microchannel, and FRR is the ratio of aqueous flow rate to NP precursor flow rate. These flow parameters are closely related to the concentration and time in microfluidic synthesis. Of these factors, FRR is more influential on NP size and PDI. Where, as FRR increases (higher ratio of aqueous flow rate to NP precursor) shear stress between the streams increase, and the width of precursor stream is decreased (lower concentration of NP precursor). This results in a shorter mixing time and length, and smaller NP formation. Moreover, pH gradients in aqueous solvents can be used in liposome drug loading [75] and produce smaller lipid nanoparticles at more acidic conditions (6 vs 7.4) [76]. Elevated temperatures can be used to speed up chemical reaction, facilitate in fluid mixing, and synthesize smaller NPs. For example, when using distearoylphosphatidylcholine (DSPC) for liposome synthesis, temperatures above the transition temperature tend to decrease liposome size [77].

Microfluidic devices can be fabricated from a variety of materials, including glass [78], silicon [79], polydimethylsiloxane (PDMS) [80], lithium niobate (LiNbO3) [81], and cyclic olefin copolymer (COC) [82, 83]. In addition, depending on the material, different fabrication techniques can be employed, for example, soft lithography for PDMS, and etching for glass and silicon [84], and hot embossing for COC [85]. Jahn et al. [86] in 2004 were the first to produce liposomes in a microfluidic hydrodynamic focusing (MHF) channel. Liposome size was controlled by the tuning of solvent flow rates and concentrations. Following this breakthrough, microfluidic-based liposome synthesis gained much attention from the engineering, medical, and pharmaceutical fields [76, 87–89]. However, since the flow in microfluidics is characterized by a low Reynolds number, mass transfer occurs by diffusion between the laminar streams, therefore, MHF devices are limited by diffusion to mix NP precursors, which results in a long mixing time and low mixing efficiency [90]. Thus, the next step in the evolution of the microfluidic NP synthesis was to induce mixing inside microchannels to overcome the laminar flow nature of microfluidics. Mixing is achieved in two ways in microchannels: passive and active mixing. Passive mixing relies on inducing flow disturbances by designing unique geometrical structures in the microchannel, such as staggered herringbone [91], serpentine [92], and tesla [93] structures. Passive microchannels have a simple setup and fabrication and can operate at high flowrates. However, tunability is only achieved by changing the flow rates. Whereas active mixing depends on external physical fields such as acoustic [94] and electric [95], to generate body or surface forces on the fluids and induce mixing. With this approach, tunability can be achieved by altering the flow rate and changing the external field parameters. However, fabrication is generally more complicated, and the devices are operated at relatively low flowrates.

In this article, a comprehensive review of advances in microfluidic-synthesized NPs is presented. Several review articles related to NP formulation and applications were published in the past [73, 96–99] However, given the rapid advancements in the synthesis and application potentials of nanoparticles, it is imperative to update the knowledge and keep up with all the newest developments and trends in this research area. Furthermore, the recent review articles [73, 96–99] have given less emphasis on active microfluidic NP synthesis and more attention on the progress in passive microfluidic methods to synthesize NPs. In contrast, the novelty of the current work lies in the detailed insight into the fundamental driving mechanisms and progress in active and passive microfluidic mixing techniques for NP production. In addition, a significant portion of the current work is dedicated to understanding the basics of multiscale computational methods and their advancements in synthesizing nanoparticles and understanding the roles of nanoparticles at molecular levels in different physical phenomena. The computational methods hold great importance in nanoparticle research because they provide an alternative to the real experiments and allow the researchers to perform “computer experiments” where mimicking physical conditions is difficult in the real-world experiments. The remaining sections of this article are organized as follows: “Types of NPs” Section presents various types of nanoparticles and their advantages and disadvantages. “Micromixing for NP production” Section provides a detailed description of the passive and active mixing methods to synthesize NPs. “Computational Approaches to study NPs” and “Molecular Simulations of Nanoparticles” Sections discuss the available computational approaches and progress to simulate systems involving nanoparticles. Finally, “Conclusions, outlook and future aspects” section provides the conclusion and future perspective in the field of NPs and microfluidics.

Types of NPs

In this section, a brief introduction is presented on several types of NPs including lipid NPs, polymer-based NPs, and inorganic NPs.

Lipid-based NPs

Early work on lipid-based nanoparticles began in the 1960s by Alec Bangham [100]. Initially, they were considered a model to study cell membrane functions due to their structural similarity. The shift to lipid drug delivery system applications started later in the 1970s [101]. Lipid NPs can be further classified into various subsets depending on their structure and formulation [102]. However, they are generally spherical vesicles with at least a single lipid bilayer and an internal compartment. As a carrier, lipid NPs have the advantages of self-assembly, biodegradability, biocompatibility, bioavailability, simple synthesis, and surface functionalization [15]. As a result, liposomes constitute the most NP-based drugs approved by the FDA [103].

Liposomes are one of the most studied drug delivery systems due to their biocompatibility, bioavailability, and ability to carry hydrophilic and lipophilic drugs simultaneously [19, 88]. They are spherical vesicles composed of phospholipids with one (unilamellar) or multilayer (multilamellar) membrane separating the inner aqueous core from the external environment. Its synthesis starts with a polar solvent such as water and a nonpolar organic solution. The nonpolar solution is comprised of phospholipids (e.g., phosphatidylcholine (PC), 1,2-distearoyl-sn-glycero-3-phosphocholine (DSPC), and 1,2-dioleoyl-sn-glycero-3-phosphatidylethanolamine (DOPE)) and an organic solvent miscible in both water and lipids such as ethanol or isopropanol [104]. As the polar and nonpolar solvents mix, phospholipids close upon themselves, forming liposomes in a process called self-assembly [105]. Depending on the type of application and specific requirements for liposomes, different phospholipids can be incorporated into the process. For example, DOPE is added to prepare pH-sensitive liposomes and DSPC enhances the drug amount and release rate [106]. In addition, cholesterol modifies the fluidity/elasticity of liposomes [107]. However, liposomes show low drug encapsulation efficiency and leakage [108]. Table 1 shows the advantages and disadvantages of lipid-based NPs along with other types of NPs.

Table 1.

Advantages and disadvantages of different nanoparticles as delivery systems

| Nanoparticle | Advantages | Disadvantages | |

|---|---|---|---|

| Lipid based |

Liposomes SLN Emulsions |

Formulation simplicity High bioavailability Payload flexibility Biodegradable Biocompatible |

Low encapsulation efficiency Poor stability Leakage May trigger immune response |

| Polymer based |

Nanocrystals Nanospheres Polymersomes Dendrimers |

Biodegradable Payload flexibility Precise control of characteristics Easy surface modification |

Possibility of aggregation Toxicity Low cell affinity |

| Inorganic based |

AuNP AgNP Iron oxide Quantum dots |

Unique electrical, optical, and magnetic properties Variable size, structure, and geometry Easy functionalization |

Poor solubility Toxicity |

Another class of lipid NPs are solid lipid nanoparticles (SLN) developed in the 1990s to overcome the low efficiency of drug encapsulation in liposomes [108, 109]. They can be synthesized from various lipids, including mono-di- or triglycerides, glyceride mixtures, and lipid acids that remain in a solid state in vivo and at room temperature [19]. Generally, SLNs are modified with polyethylene glycol (PEG) to improve stability and circulation [110]. In addition, they are distinguished from liposomes in that they possess a solid matrix core to encapsulate drugs [15]. SLNs exhibit significant advantages, including physical stability, site-specific targeting, and controlled release. However, they are still limited by drug loading and leakage.

Polymer-based NPs

Polymer-based NPs have been investigated for applications in drug delivery and contrast imaging since the 1970s [111, 112]. They were developed because of their biocompatibility, biodegradability, stability and can be prepared to enable precise control of NP characteristics and action duration [113]. They can be synthesized from synthetic or natural polymers. Synthetic polymers include poly(lactide-co-glycolide) (PLGA), poly(lactic acid) (PLA), polyanhydrides, and polycaprolactone (PCL), whereas natural polymers include chitosan, gelatin, hyaluronan, and alginate [113, 114]. Figure 2 shows the different types of polymer-based NPs along with other classes of NPs. In addition, they can be synthesized using various methods such as nanoprecipitation [115], emulsification [116], and microfluidics [117]. Depending on the material and technique used, different final NP products are obtained with a variety of structures and characteristics [15]. A subset of polymer-based NPs is polymeric NPs, which are solid colloidal systems where the therapeutic material is either encapsulated, dissolved, or absorbed into the polymer matrix. Depending on the formation process, these NPs can be classified as nanospheres, which are matrix systems where the drug is dispersed throughout the NP [118], and nanocapsules, which are vesicular systems where the drug is entrapped in an oily liquid surrounded by a single polymer layer. Nanospheres and nanocapsules are typically synthesized from PLGA, PLA, PCL, and chitosan [118]. On the other hand, if the core of the vesicular system is aqueous and surrounded by amphiphilic block copolymers, the NP is referred to as polymersomes, which are analogous to liposomes and are formed by self-assembly [119].

Fig. 2.

Different classes of nanoparticles

Inorganic NPs

Inorganic NPs include materials such as gold (AuNP), silver (AgNP), metallic oxides, and semiconductors. They are used as drug carriers and imaging contrast agents because of their unique optical, magnetic, and electrical properties [98]. In addition, these NPs can be engineered into a variety of structures and geometries. AuNPs are among the most studied inorganic NPs and can be synthesized in various forms, such as nanorods, nanocubes, nanoshells, nanospheres, and nanostars [120, 121]. Magnetic NPs are usually composed of iron oxide or ferrites such as magnetite (Fe3O4), metallic NPs (iron and cobalt), or alloy NPs (cobalt–platinum alloys) [122]. Where iron oxide NPs make up the majority of inorganic approved nanomedicines by the FDA [123]. Quantum dots are a class of NP typically made of semiconductors such as silicon, germanium [123], and cadmium [124].

Hybrid NPs

Hybrid NPs can be defined as nanomaterials consisting of two or more distinct types of nanocomponents [47]. Where different types of materials are combined to enhance certain properties, synthesize hybrid NPs with new unique properties, or to overcome limitations of individual NPs [125]. Hybrid NPs can be broadly categorized into three groups: organic/organic NPs, organic/inorganic NPs, and inorganic/inorganic NPs. Each of these combinations can be customized in terms of constituent material and structure by tuning their ratios to result in the optimal hybrid NP for the selected application [126]. Organic/organic NPs are hybrid NPs consisting of various types of lipids and polymers that combine the biomimetic characteristics of lipid NPs and the structural properties and stability of polymer NPs to improve the nano-carrier system [127]. Examples of lipid-polymer hybrid NPs include polymer core–lipid shell hybrid NPs, polymer-caged nanobins, and monolithic polymeric lipid hybrid NPs/mixed polymer–lipid hybrid NPs [125]. Organic/inorganic hybrid NPs combine organic materials such as lipid or polymer NPs with metal, metal oxide, or semiconductor materials to take advantage of their unique electrical, optical, and magnetic properties. For example, magnetoliposomes [128] consist of a magnetite NPs encapsulated in liposomes for applications in molecule separation and targeted drug delivery. Other examples include zeolitic imidazolate framework NPs (metal organic framework (MOF)) [129], and gold (core)–polystyrene (shell) NPs [130], in addition to numerous organic/inorganic core–shell combinations [131]. Similarly, inorganic/inorganic hybrid NPs can be made from a combination of metals, metal oxides, and semiconductors, such examples include gold NPs (unique optical properties) coated with a silica nanometric layer (high stability), NP–quantum dot NPs, and core–shell bimetallic NPs [47].

Micromixing for NP production

Efficient mixing is crucial for the synthesis of NPs, where the interaction of fluids causes the generation of NPs [132]. Mixing time and uniformity dictate the size and size distribution of NPs [133], such that a shorter mixing time results in smaller particles and a lower PDI. In microfluidics and bottom-up methods, size and PDI depend on the interplay between mixing time (tmix) and precipitation time (tprecipitation) [134]. When the mixing time is less than the precipitation time (tmix < tprecipitation), smaller NPs are produced with lower PDI as solvents and antisolvents mix in a timeframe less than the time required for precipitation to occur, and vice versa (tmix > tprecipitation). In bottom-up methods, NP synthesis occurs in a millimeter or centimeter scale environment, leading to local fluctuations of concentration that result in large particle size and size distribution (tmix > tprecipitation) [68]. In contrast, mixing in microfluidics occurs at a micrometer scale, where efficient mixing can result in tmix < tprecipitation. However, microchannels are generally known for their laminar flow nature [135], and diffusion-based mixing (straight microchannel), characterized by a low Reynolds number (Re ~ 1):

| 1 |

where ρ is the fluid density, U is the fluid velocity, Dh is the hydrodynamic diameter of the channel, and η is the dynamic viscosity of the fluid. For example, water with ρ ~ 1000 kg/m3 and, η ~ 0.001 Pa s, in a microchannel with a Dh of 100 µm, the Re of the flow approaches 1 for a mean flow velocity of 0.01 m/s, which is commonly achieved in microfluidic operations [136].

Given the intrinsic properties of microfluidic channels (channel size, fluid velocity, density, and viscosity), inducing vortices and chaotic mixing by transitioning to turbulent flow (Re > 2000) is out of the question. Thus, passive and active mixing strategies are implemented to achieve efficient mixing and overcoming diffusion. Another important dimensionless number is the Peclet number, which characterizes the type of mixing in microchannels, given in Eq. 2, where it compares advection transport to diffusion transport. Chaotic mixing enhances advection transport and increases the Peclet number [137]. It can also be interpreted as the ratio of diffusion time to advection time. Lower advection time (high mixing rate) leads to a higher Peclet number:

| 2 |

where U is the fluid velocity, Dh is the hydrodynamic diameter of the channel, D is the diffusivity, tD is the diffusion time, and tA is the advection time, where the diffusion length LD, D, and tD are related by . A molecule with a diffusivity D of 10–10 m2/s will take approximately 100 s to diffuse across a 100 µm channel, a larger particle with 10–11 m2/s diffusivity will diffuse in 1000 s across the same width.

This section introduces the fundamentals of mixing in microchannels, followed by a comprehensive review of the literature concerning NP synthesis in microchannels along with the factors affecting their production such as concentration, temperature, flow rate (flow rate ratio and total flow rate), and time.

Passive micromixing

Passive micromixers are microfluidic devices that use geometrical features and embedded microstructures to induce chaotic advection or fluid interruption for the purpose of fluid mixing.

Background on passive mixing methods

This section is mainly concerned with the mixing techniques employed in the microfluidic devices without any involvement of the external fields. The process of mixing in microfluidics devices is a crucial step for preparing NPs because mixing a solvent with another solvent (or an anti-solvent) initiates the formation of NPs. The time required for mixing is directly linked to the diameter and size distribution (monodispersity) of the resulting NPs [105]. Small-sized NPs with excellent monodispersity are created by faster mixing processes in which the mixing time is less than the nucleation period of the nanoparticles. In contrast, slow mixing (where the mixing time exceeds the time required for NP nucleation) results in larger NPs with a broad range of sizes.

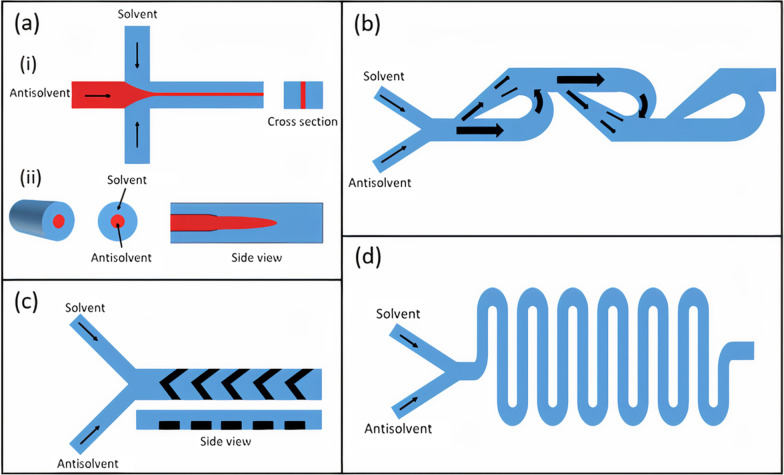

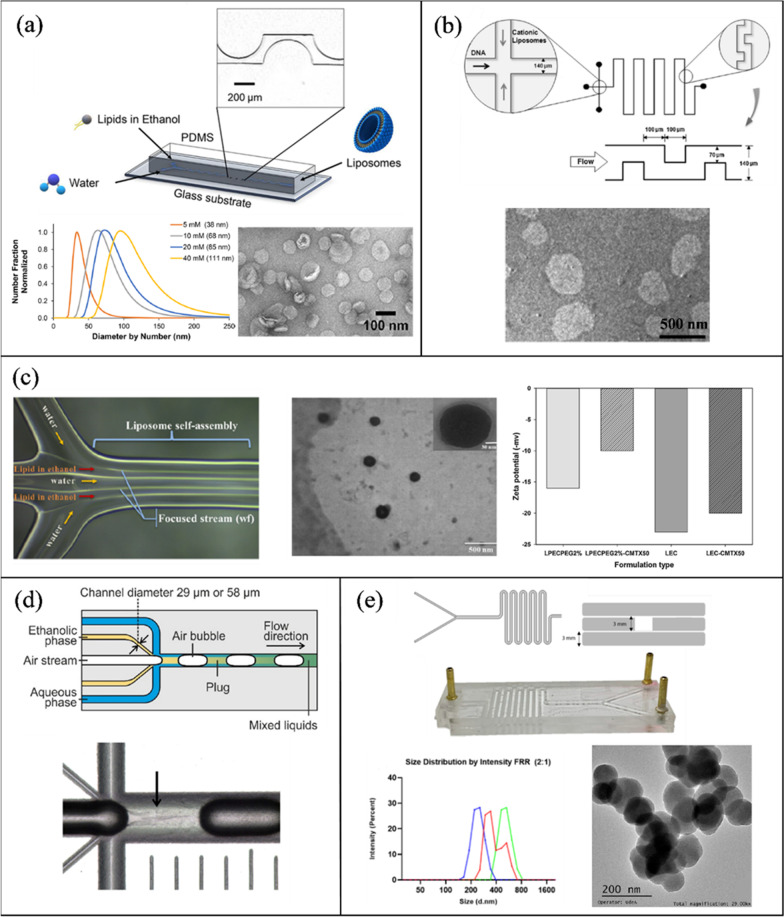

Among the passive microfluidic mixing techniques, the simplest one is based on microfluidic hydrodynamic focusing (MHF). MHF employs multiple fluids flowing in parallel in the microchannel in the laminar regime (Re ~ 1) [135]. A central hydrodynamically focused fluid stream at a lower flow rate co-flows with outer sheath streams at relatively high flow rates. As a result, the diffusion length (viz. width of the inner stream) is reduced, which reduces the mixing time dramatically and facilitates faster mixing [138]. The decreased mixing time may also enhance the quality of the nanoparticles. The MHF is simple in operation since the most crucial feature for NP synthesis is the flow behavior of the participating solvents, which can be accurately manipulated by tuning their flow rates. Other controlling factors are the microchannel geometry and the choice of material. Thus, the quality of the synthesized NPs can be easily controlled using this technique. The MHF platforms can be classified into two types [139]: (i) planar or 2-D MHF platforms, and (ii) coaxial based or 3-D MHF devices. In a 2-D MHF platform, the central fluid stream is focused in a single plane (Fig. 3ai), whereas, in a 3-D MHF platform, the outer sheath flow focuses the central solvent in both horizontal and vertical planes (Fig. 3aii). Ideally, a 3-D MHF platform is desired because it results in more uniform velocities in both planes. Nevertheless, the 2-D MHF platforms are ubiquitous owing to their ease of manufacturing and integration.

Fig. 3.

Passive mixing methods. a (i) 2D MHF, (ii) 3D MHF. b Microfluidic Tesla mixer. c Staggered herringbone micromixer. d Serpentine micromixer

In general, MHF platforms have an easier fabrication process due to their simple, straight design compared to the other mixing platforms discussed below. Moreover, the technique is easier to simulate since it involves the surface tension force at the interface between the two liquid solvents. Hence, the outputs can easily be predicted before even manufacturing the prototypes to perform actual experiments. Furthermore, high flow rates may be accommodated in MHF, allowing for high-throughput applications [140, 141].

The second class of passive microfluidic mixing platforms involve the split-and-recombine (SAR) method of the fluid streams. In the SAR method (also termed as co-lamination), the microchannel splits in two branches forcing the fluids to follow in dissimilar path lengths, followed by the merger of channel branches which recombines the fluid streams [142]. Repeating the process multiple times induces rapid chaotic mixing. Chaotic mixing is a fast mixing process that relies on chaotic advection, which may be achieved by stretching and folding a fluid volume repeatedly [143].

Similar to MHF, SAR-based mixing can be achieved in-plane or out-of-plane. The in-plane SAR mixers are simpler to fabricate and thus more common. The two most efficient SAR-based in-plane mixers are: (i) the bifurcating mixer, and (ii) the Tesla mixer (Fig. 3b). The bifurcating mixer comprises a series of circular toroids that subjects the fluids under centrifugal forces to achieve a fast mixing process [144]. The second type of in-plane mixer, called the Tesla mixer, employs the Coandă effect, which is the propensity of a fluid initially flowing in a straight direction to follow and remain attached to a convex-shaped curved surface instead of flowing in the original direction [145]. By exploiting this effect and introducing alternate convex curves on the opposite sidewalls of the channel, the Tesla mixer achieves chaotic mixing efficiently.

Chaotic mixing can also be achieved in the microchannel by embedding microstructures, such as ridges, on the floor of the microchannel. The ridges are placed at an oblique angle at the bottom of the channel [146] and can be easily incorporated into the microchannel using standard lithography and soft-lithography techniques. These oblique ridges induce an anisotropic resistance to the fluid flow, which generates vortices in the flow, and enhanced chaotic mixing is obtained. Another architecture is to use the ridges that are in the shape of staggered herringbone [147]. In the staggered herringbone configuration (Fig. 3c), the ensuing circulating fluxes continually stretch and fold the fluid volume, thus enhancing the concentration gradient substantially.

Numerous microchannel architectures also aim to employ fluid inertial effects to perform passive mixing. As is known, the inertial effects are dominant relative to the viscous effects if Re > 1. Thus, the fluid is introduced into the microchannel at higher flow rates and if it encounters a curvature in the microchannel geometry, vortices are formed. These micro-vortices are formed because of the mismatch between the velocities of different portions of the fluid. Incorporating sudden expansions in the microchannel is also an effective way of generating micro-vortices in the microchannel [148]. This expansion can be planar (2-D) obtained by increasing the width of the microchannel, or 3-D, which is achieved by arranging tubes of different diameters in a coaxial arrangement. Another effective method that is used to obtain inertial-based mixing is based on using Dean flow, a secondary cross-sectional flow field obtained by introducing curvature in microchannels such as the serpentine micromixer (Fig. 3d) [149]. The Dean flow is characterized by the existence of two counter-rotating vortices that are perpendicular to the flow direction and are positioned above and below the channel's plane of symmetry.

Organic NP synthesis

By utilizing the aforementioned passive mixing mechanisms, numerous types of NPs have been fabricated in a controlled manner (Table 2).

Table 2.

Microfluidic synthesis of nanoparticles by passive mixing methods

| Nanoparticle type | Mixing mechanism/microchannel | Size (nm) | PDI | Organic/precursor concentration | FRR | TFR | ME | MT | Year | References |

|---|---|---|---|---|---|---|---|---|---|---|

| Liposomes | Concentric laminar flow/PDMS mixer | 120 | – | 1 mM | 4 | 20.4 µL/min | – | – | 2012 | [150] |

| Liposomes | Semicircular contraction–expansion array (Dean flow)/PDMS/glass microchannel | 50 | – | 10 mM | 9 | 18 mL/h | 90% | – | 2013 | [151] |

| Liposomes | Periodic disturbance mixer (Dean flow)/PDMS/glass microchannel | 30 | 0.22 | 5 mM | 3 | 18 mL/h | > 90% | < 120 ms | 2021 | [152] |

| Liposomes | Serpentine microchannel with baffles (contraction–expansion regions)/PDMS/glass microchannel | 118 | 0.2 | 25 mM | 5 | 11.8 mL/min | – | – | 2013 | [153] |

| Liposomes | Staggered herringbone mixer/PDMS/glass microchannel | 30 | 0.1 | 5 mg/mL | 10 | 500 µL/min | 80% | < 300 ms | 2017 | [105] |

| Lipid nanoparticle | 2D-baffle PDMS mixer device (invasive lipid NP production device/PDMS/glass microchannel | 20 | 0.1 | 10 mg/mL | 20 | 500 µL/min | 90% | 6 ms | 2018 | [154] |

| Liposomes | Double flow focusing/PDMS/glass microchannel | 150 | 0.23 | 5 mM | 10 | 65 mL/h | – | – | 2021 | [141] |

| Lipid nanoparticle | Segmented-Axis symmetric glass microchannel | 70 | 0.15 | 5 mg/mL | 10 | 130 μL/min | – | – | 2019 | [157] |

| Liposomes | Periodic disturbance mixer (Dean flow)/PDMS/glass microchannel | 90 | 0.18 | 10 mM | 8.56 | 18 mL/h | – | – | 2020 | [164] |

| Liposomes | Serpentine/PMMA polymer microchannel | 188 | 0.2 | 1.5 mg/mL | 5 | 5 mL/min | – | – | 2020 | [156] |

| Liposomes | Half-moon design/PLA polymer microchannel | 193 | 0.22 | 1 mg/mL | 1 | 3 mL/min | – | – | 2021 | [165] |

| PLGA | 3D origami ship spiral/arc design/PDMS-PDMS microchannel | < 100 | 0.06 | 2% wt | 17 | 2.5 mL/h | – | 16 ms | 2013 | [166] |

| PLGA | Slit interdigital micromixer | 211 | – | 10 mg/mL | 1 | 62.8 mL/min | – | 10 ms | 2016 | [167] |

| PLGA | Spiral mixer (Dean flow)/PDMS/glass microchannel | 69.3 | 0.2 | 5 mg/mL | 5 | 132 mL/min | – | < 90 ms | 2020 | [169] |

| PLGA | Staggered herringbone mixer (NanoAssemblr™)/COC microchannel | 120 | 0.12 | 10 mg/mL | 3 | 6 mL/min | – | – | 2018 | [170] |

| PLCL | Serpentine design/Asia 320 microfluidic system | 30 | < 0.12 | 0.25 mg/mL | 5 | 2 mL/min | – | – | 2018 | [191] |

| PCL | Concentric glass capillaries microchannel | 200 | – | 1 mg/mL | 10 | 8.3 mL/h | – | – | 2015 | [140] |

| PCL-b-PEO | Segmented flow-based mixer (Taylor flow)/PDMS/glass microchannel | 32 | – | 0.66% wt | 1 | 100 µL/min | – | < 1 s | 2016 | [168] |

| AuNPs | Spiral segmented flow-based mixer (Taylor flow)/silicon/glass microchannel | 3.8 ± 0.3 | – | 1 mM | 10 | 300 µL/min | – | – | 2012 | [171] |

| AuNPs | Serpentine design/PDMS/glass micorchannel | 4.38 ± 0.53 | – | 10 mM | 9:14 | 2.3 mL/h | – | – | 2010 | [172] |

| AuNPs | Integrated micromixer-microreactor-microfluidic platform/PDMS/PDMS microchannel | 27 ± 3.5 | – | 0.02% wt | 1 | 10 µL/min | 83% | – | 2015 | [192] |

| AuNPs | Serpentine design/PMMA micorchannel | 4.5 | – | 10 M | 5:3 | 0.2 mL/min | – | – | 2019 | [177] |

| AgNPs | Double layer Y-shaped split and recombination micromixer/PMMA microchannel | 30.5 ± 4.82 | – | 1 mM | 1.5 | 810 μL/min | – | – | 2020 | [174] |

| AgNPs | T-mixer | 4.7 ± 0.6 | – | 0.5 mM | 1 | 1.9 mL/min | – | – | 2015 | [178] |

| AgNPs | Corning Advanced-Flow Reactor (AFR) curved split and recombination/glass microchannel | 4.6 ± 1.8 | – | 1.58 mM | 2 | 9 mL/min | 60% | – | 2021 | [175] |

| Silica | Gear-shaped serpentine micromixer/PDMS/glass microchannel | 370.3 | – | 0.1 M | – | 1 mL/h | 90% | – | 2020 | [176] |

| Lipid-PLGA | Tesla structure micromixer/PDMS/glass microchannel | 40 | – | 1 mg/mL (PLGA) | 10 | 60 μL/min | – | 10 ms | 2010 | [181] |

| Lipid-QD | Tesla structure micromixer/PDMS/glass microchannel | 60 | – | 0.5 mg/mL (QD) | – | 55 μL/min | – | 10 ms | 2010 | [181] |

| Lipid-PLGA | Spiral micromixer/PDMS/glass microchannel | 62.5 ± 1.18 | 0.173 | 2.94 mg/mL (lipid), 10 mg/mL (PLGA) | 80 | 246 mL/h | – | – | 2015 | [182] |

| Lipid-PLGA | Herringbone patterned multi-inlet vortex mixer | 60 | 0.12 | 1 mg/mL (PLGA) | – | 12 mL/min | > 99% | – | 2019 | [183] |

| Au-PLGA | Two consecutive slit-interdigital micromixers | 192 ± 58 | – | 1.25 mg/mL of (PLGA), 0.24 mg/mL (gold) | – | 54 mL/h | – | – | 2017 | [184] |

| Au-Lipid | Asia MF 320 system flow focusing laminar mixing | 130 | 0.2 | 4.5 mg/mL(lipid), 2.5 mg/mL (gold) | 10 | 220 μL/min | – | – | 2019 | [187] |

PDI polydispersity index, FRR flow rate ratio, TFR total flow rate, ME mixing efficiency, MT mixing time

Lipid NPs

Kennedy et al. [150] described the liposomal self-assembly in a laminar flow PDMS mixer. The 3-inlet device has a square cross section and creates a cylindrical organic phase core surrounded by the aqueous phase to increase the interface contact area and prevent lipid deposition on channel surfaces. The organic phase was comprised of 1,2-dipalmitoyl-sn-glycero-3-phosphocholine (DPPC), 1,2-distearoyl-sn-glycero-3-phosphoethanolamine-N-[amino(polyethyleneglycol)-2000] (DSPE-PEG), and cholesterol (10:1:10) dissolved in ethanol. Liposomes with an average size of 100–200 nm were produced with a flow rate ratio (FRR) ranging from 5 to 20, and a total flow rate (TFR) of 20.4 μL/min. Lee et al. [151], reported on the synthesis of liposomes in a PDMS/glass semicircular contraction–expansion array (CEA) microchannel. The reported micromixer is based on Dean vortices where the geometrical features were only designed on one side of the channel. Dimyristoylphosphatidylcholine (DMPC) and cholesterol (1:1, 10 mM concentration) were dissolved in isopropanol as the organic phase. At a TFR of 18 mL/h and 9 FRR, the CEA device produced 50 nm NPs in comparison to 200 nm particles produced from a MHF channel. In addition, the highest mixing efficiency (90%) was achieved at a TFR ranging from 12 to 15 mL/h.

In a different work, López et al. [152] utilized a PDMS/glass CEA micromixer, termed “periodic disturbance mixer” (PDM) to conduct a parametric study on factors affecting liposome size and PDI. At a constant FRR of 8.56 and temperature of 70 °C, increasing the TFR from 5 to 20 mL/h decreased liposome (DMPC, cholesterol, dicetyl phosphate (DHP), 5:4:1) size from 50 to 30 nm with a constant PDI of 0.22 (measured by dynamic light scattering (DLS)). On the other hand, varying the FRR from 1 to 3 at a constant TFR of 18 mL/h reduced the size from 120 to 35 nm. This makes the PDM valuable in comparison to other devices, as it produces small NPs with good PDI at a low FRR of 3. Morphological characterization of liposomes was performed by transmission electron microscopy (TEM) (Fig. 4a) and NP stability was determined by measuring the ζ-potential with values >|30 mV|. Balbino et al. [153] evaluated the performance of two microchannels in the production of plasmid DNA/cationic liposome complexes. Two channels were compared, a MHF design and a serpentine microchannel with baffles (contraction–expansion regions) (Fig. 4b). The organic phase was composed of egg phosphatidylcholine (EPC), 1,2-dioleoyl-snglycero-3-phosphoethanolamine (DOPE), and 1,2-dioleoyl-3-trimethylammonium-propane (DOTAP) with (50/25/25% molar) in ethanol. At an FRR of 5, liposomes produced in the serpentine mixer had an average size of 118 nm and a PDI of 0.2, while the MHF design had an average size of 138 nm and a PDI of 0.35.

Fig. 4.

Passive microfluidic mixers for lipid-based NP synthesis. a Liposomes fabricated using periodic disturbance mixer. Reprinted with permission from [152].

Copyright 2021 American Chemical Society. b Serpentine microchannel with baffles for the synthesis of DNA/cationic liposomes complexes. Reproduced with permission from [153]. Copyrights © 2013 Elsevier. c MTX loaded liposomes in a double flow focusing microchannel. Reprinted with permission from [141]. Copyright 2019 American Chemical Society d LNP fabrication in a segmented flow glass microchannel. Reproduced with permission from [155]. Copyrights © 2020 Elsevier. e PMMA serpentine platform for the synthesis of LNP (open access) [156]

Maeki et al. [105] investigated the influence of flow parameters and herringbone structure height (31 μm and 11 μm) on liposome size. The microchannel with 31 μm structures was able to produce liposomes (1-palmitoyl-2-oleoyl-sn-glycero-3-phosphocholine (POPC) 5 mg/ml in ethanol) less than 100 nm (30–60 nm) across all FRR (3–9) and TFR (5–500 μL/min) outperforming the 11 μm design. Kimura et al. [154], demonstrated the precise control of LNP size in a 2D-baffle PDMS mixer device (invasive lipid NP production device (iLiNP)). POPC at a concentration of 10 mg/ml in ethanol and saline solution were injected into the device at flow rates ranging from 50 to 500 μL/min and a FRR of 3–9. Where LNP size was tuned at a 10 nm interval from 20 to 100 nm by changing the flow conditions and channel dimensions. In addition, they showed the scalability and high drug encapsulation ability (> 90%) of their design.

Aghaei et al. [141] synthesized methotrexate (MTX) loaded liposomes in a double flow focusing microfluidic device. MTX is a cytotoxic drug for the treatment of cancer and other diseases. Since MTX is hydrophilic, it was incorporated into the aqueous phase with deionized water, whereas the organic phase included EPC, cholesterol, and PEG-DSPE at 5 mM in ethanol. Non-pegylated MTX loaded liposomes had an average size ranging from 90 to 230 nm and a PDI < 0.32, while the pegylated loaded liposomes had sizes ranging from 118 to 250 nm and a PDI < 0.23 with an encapsulation efficiency > 60%. Characterization including nano-structural morphology and ζ-potential are presented in (Fig. 4c).

Erfle et al. [157] utilized an axis symmetric glass microchannel with five inlets for the production of LNPs. The mixing mechanism is based on the segmentation of the continuous flow with a gaseous phase, resulting in a periodic gas–liquid flow known as Taylor flow (Fig. 4d). The central inlet injects nitrogen gas while the remaining four inlets pump the organic phase (5 mg/ml castor oil and polysorbate 80 at 2.5 mg/ml) and deionized water. With 10% organic phase and a TFR from 31 to 130 μL/min, LNP size ranged from 70 nm (130 μL/min) to 90 nm (31 μL/min) and a PDI of 0.12–0.15, respectively. In another work by the same group [155], the segmented flow glass microchannel was compared to a high pressure micromixer and a staggered herringbone micromixer (NanoAssemblr™ platform) in the preparation of solid lipid NPs from castor oil and glycerol monooleate in ethanol. The herringbone and high-pressure mixers resulted in the smallest NP size at the highest flow rates (36 nm with castor oil at 10 mL/min, and 73 nm with glycerol monooleate at 101 mL/min).

A group led by Yvonne Perrie has published numerous articles on the synthesis of liposomes via the commercially available NanoAssemblr™ benchtop staggered herringbone microchannel [88, 158–163]. For example, in [88], they demonstrated for the first time the possibility of loading hydrophilic and lipophilic drugs into liposomes simultaneously. DSPC phospholipid was found to be the most sensitive in term of variation in the aqueous and alcohol solvents. For drug loading, the hydrophilic drug (metformin) was added to the PBS and the lipophilic drug (glipizide) was added to the lipid and alcohol solution. It was found that the encapsulation efficiency was 40% and 25% for the lipophilic and hydrophilic drugs, respectively. Moreover, in [163], they compared the utilization of methanol, ethanol, and isopropanol as the organic solvent in liposome synthesis via the staggered herringbone microchannel. Similarly, López et al. [164] compared these alcohols with Transcutol for the synthesis of liposomes in a PDMS microchannel with a CEA design. Transcutol is an organic solvent used in commercial skincare products and dietary supplements. In its pure form, it is safer to use than methanol and less polar than isopropanol. The use of Transcutol produced liposomes with the smallest size (90 nm) and the second lowest reported PDI 0.18, behind methanol. In addition, it showed greater liposome stability in synthesis temperatures ranging from 25 to 70 °C and after 50 days of storage.

Conversely to the previously reported works where the majority of microchannels were fabricated from glass or PDMS, other researchers explored polymer microfluidic fabrications via cheaper and simpler methods such as 3D printing and laser ablation [83].

Aranguren et al. [156] utilized laser cutting for the fabrication of poly(methyl methacrylate) (PMMA) serpentine microchannels (Fig. 4e). Two PMMA devices were considered: a two-layer design where the channel was engraved on one side and a three-layer design where the laser cuts through the 3 mm PMMA sheet. Similar results were obtained for both configurations, whereas the FRR increased from 2 to 5, at a constant TFR of 5 mL/min, size decreased from 250 to 188 nm (PDI 0.5–0.2). Similarly, Ballacchino et al. [165], investigated the applicability of 3D printing using fused deposition modeling (FDM) to fabricate micromixers for the synthesis of curcumin loaded liposomes. Liposomes were formulated from DMPS and cholesterol, 1 mg/ml in ethanol and PBS. Four designs were printed, including a zigzag design and a half-moon geometry. The half-moon design produced the smallest NPs ranging from 193 to 250 nm and 0.215–0.259 PDI (TFR 1–3 mL/min and 1:1 FRR).

Polymer NPs

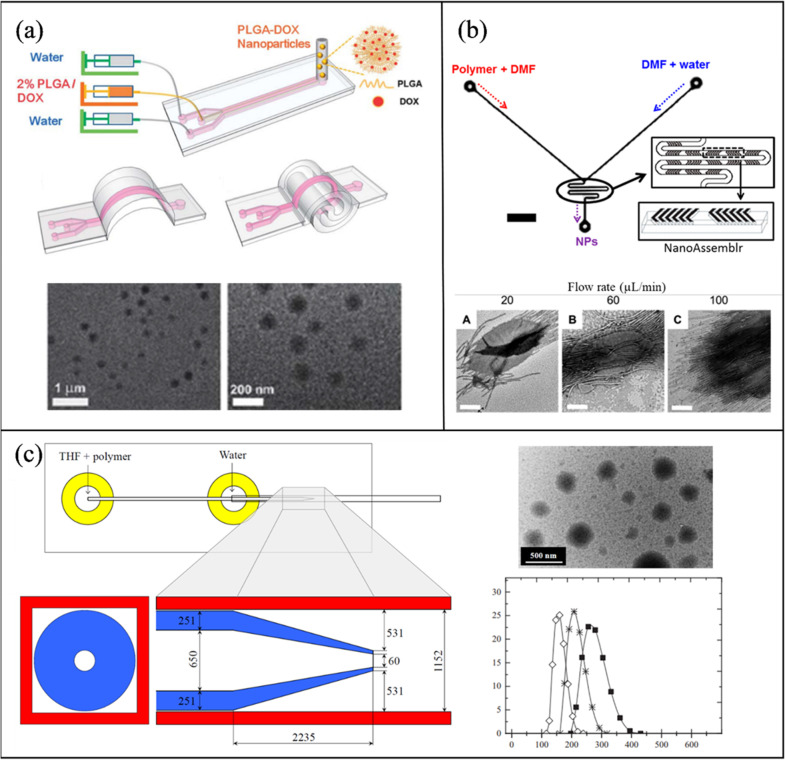

Sun et al. [166] developed a microfluidic chip with a PDMS microchannel and base for the synthesis of doxorubicin (DOX) loaded PLGA NPs. The flexible device was termed “origami” because of its ability to be folded manually into several configurations. The organic solution was prepared by dissolving 2% PLGA-DOX in dimethylformamide (DMF) and trifluoroethanol (TFE). Different origami configurations were compared, i.e., straight, arc, and spiral. The straight channel produced PLGA-DOX NPs in the size range of 100–230 nm, while the other designs resulted in smaller and more uniform NPs (75–100 nm, PDI < 0.13). TEM images of NPs produced in a 3D spiral channel are shown in Fig. 5a. Solorzano et al. [167], were able to continuously synthesize cyclosporine (drug used after organ transplants) encapsulated PLGA NPs in an interdigital micromixer with a mean particle size of 211 ± 62 nm and an encapsulation efficiency of 91%.

Fig. 5.

Passive microfluidic mixers for polymer-based NP synthesis. a A versatile “origami” microchannel for the fabrication of PLGA-DOX NPs [166]. b PCL-b-PEO synthesis in a staggered herringbone mixer (NanoAssemblr™) and a segmented flow-based mixer. Reprinted with permission from [168].

Copyright 2016 American Chemical Society (c) A concentric glass capillary within a square capillary microchannel for PCL and PLA production. Reproduced with permission from [140]. Copyrights © 2015 Elsevier

Abdelkarim et al. [169] tested ten different microfluidic designs and evaluated their performance on the physicochemical properties of PLGA NPs, where 5 mg/ml of PLGA was dissolved in DMF. The parameters under investigation were channel length, FRR, aspect ratio, number of interfaces, and curvature. Channel length did not have a significant effect on size or PDI. When the FRR was increased from 1:1 to 10:1, particle size decreased from 265 to 93 nm. This occurs because of the decrease in the organic stream size, which shortens the diffusion distance. Increasing the aspect ratio (height: width) at the same cross-sectional area, from 1:10 to 4:1 reduced the NP size from 137 to 71 nm at a TFR of 132 μL/min and 5 FRR. Increasing the number of interfaces between the streams (more inlets) increases the diffusion area between the phases and results in a reduced size (130–92 nm). Finally, two spiral designs with different curvatures were compared: 2.23 mm−1 and 0.45 mm−1. Reducing the curvature from 2.27 to 0.45 mm−1, increased the Dean Flow vortex formation and reduced the PLGA NP size from 84.86 to 69.3 nm. Thus, it was shown that the aspect ratio, number of inlets, and curvature are important in tuning NP size without the extra dilution as in the FRR case.

Morikawa et al. [170] utilized the NanoAssemblr™ system to synthesize curcumin-loaded PLGA NPs and study the effects of different stabilizers. The organic phase contained 10 mg/mL of PLGA and 1 mg/mL of curcumin in acetone, while the aqueous phase had either sodium cholate, Tween 80, or Polyvinyl alcohol (PVA) in water. The 1% PVA showed the best NP synthesis at 200 nm, 0.13 PDI, and an encapsulation efficiency of 18%. Moreover, the addition of 5% PEG reduced the particle size to 120 nm and increased the encapsulation efficiency to 50%.

Xu et al. [168], compared the formation, morphology, and crystallinity of PCL-block-poly(ethylene oxide) (PCL-b-PEO) NPs in a staggered herringbone mixer (NanoAssemblr™) (Fig. 5b (i)) and a PDMS/glass segmented flow-based mixer (Taylor flow) (Fig. 5b (ii)). The segmented flow mixer had four inlets, (1) DMF, (2) DMF and polymer, (3) DMF and water, and (4) argon gas. Both experiments were carried out at 20–100 μL/min and 1:1 FRR. Where sizes in the range of 15–21 nm were achieved in both mixers. Othman et al. [140] utilized an inner tapered round glass capillary within an outer square capillary assembled to form a microfluidic mixer. Rapid diffusion occurs due to the 3D exposure of organic solvent to water. A solution of PCL or PLA in THF and the aqueous phase of Milli-Q water were injected into the coaxial and square glass capillaries respectively to obtain polymeric nanoparticles. TEM and DLS were used to characterize the morphology, and size and PDI, respectively (Fig. 5c).

Inorganic NP synthesis

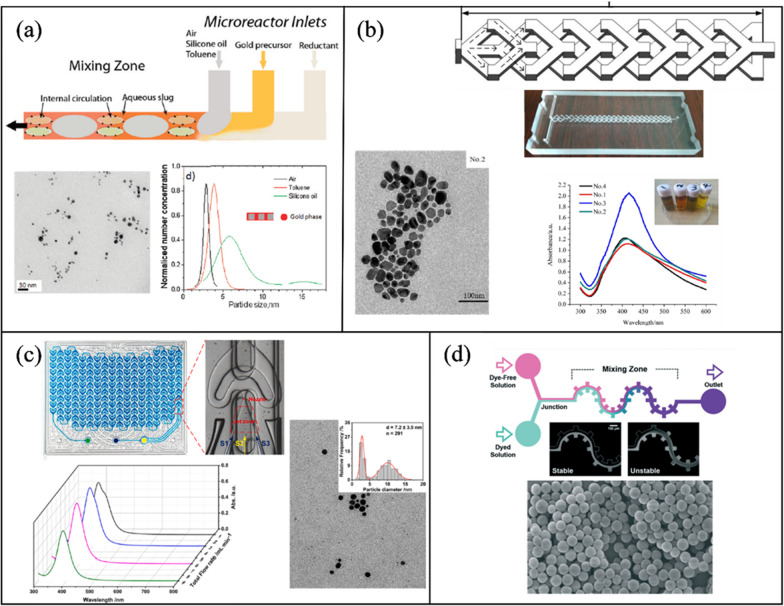

Cabeza et al. [171] designed a three-inlet silicon microchip for the synthesis of AuNPs employing the segmented flow mixing mechanism. A silicon wafer was etched with a spiral design and anodically bonded to a glass slide. The platform was heated to 100 °C where streams of sodium borohydride (NaBH4) (reducing agent), gold precursor chloroauric acid (HAuCl4), and toluene (separating fluid) where injected in to the microchannel to form the segmented flow (1:10:1). An increase in microchannel residence time resulted in the broadening of the size distribution from 3.8 ± 0.3 nm (10 s) to 4.9 ± 3 nm (40 s). AuNPs characterization was determined by TEM imaging and UV–Vis spectroscopy (Fig. 6a). Utilizing the same gold precursor and reducing agent, Lazarus et al. [172] prepared AuNPs in a PDMS serpentine microchannel with good control over size and morphology (4.38 ± 0.53 nm). Sarsfield et al. [173], synthesized AuNPs in a reverse-staggered herringbone PDMS micromixer. Several parameters, such as the ratio of the sodium citrate to HAuCl4, and the pH of the HAuCl4 solution, were considered to study the effect on AuNP size and size distribution.

Fig. 6.

Passive microfluidic mixers for inorganic NP synthesis (a) AuNPs synthesis in a silicon segmented flow microchannel. Reprinted with permission from [171].

Copyright 2012 American Chemical Society. b A double layer Y-shaped split and recombination micromixer for AgNPs fabrication [174]. c A curved split and recombination (Corning AFR) for the synthesis of AgNPs. Reproduced with permission from [175]. Copyrights © 2021 Elsevier. d Silica NPs production in a gear-serpentine microchannel [176]

Zhang et al. [177] utilized a PMMA serpentine microchannel for AuNP preparation. 4.5–7 nm NPs were produced with optimum conditions at 5:3 FRR, 0.2 mL/min, and 100 °C.

Other researchers utilized passive micromixers to produce different types of inorganic NPs. Liu et al. [174] studied the effects of TFR, reducing agent concentration, and PVP on the synthesis of silver NPs (AgNPs) in a double-layer Y-shaped split and recombination micromixer (Fig. 6b). Increasing the reductant concentration increased the average size of AgNPs from 20 ± 6.7 to 31.43 ± 4.47 nm, as more silver atoms accumulate in the crystal growth stage. In addition, increasing the TFR from 6.7 to 810 μL/min varied the size slightly from 29.9 ± 5.3 to 30.5 ± 4.82 nm because of the good mixing performance of the double layer micromixer. Thiele et al. [178] synthesized 4.7 ± 0.6 nm AgNP seeds in a T-mixer for the later production of triangular NPs which was confirmed by AFM and SEM imaging. Yang et al. [175] evaluated the performance of the commercially available Corning AFR (Lab reactor module) on the synthesis of AgNPs. The Corning AFR is glass based with two inlets and relies on the split and recombination mixing mechanism with a curved design. NaBH4 and Ag precursor were used at a TFR of 9 mL/min and 2 FRR, resulting in a NP size of 4.6 ± 1.8 nm. Figure 6c shows UV–Vis spectroscopy data for AgNPs at different flow rates and a TEM image at 1 mL/min. Baki et al. [179] studied the effect of reaction temperature and residence time on the physicochemical properties of magnetic single-core iron oxide NPs. Where tunable NP sizes (20–40 nm) was achieved with high quality magnetic properties by varying these two parameters. Thu et al. [180] synthesized 10 nm magnetite NPs in serpentine PDMS microchannel, where a mixture of iron (II) and iron (III) acidic, and sodium hydroxide were used as precursors for the production.

Hong et al. [176] presented a novel design which combines a serpentine geometry with rectangular sections perpendicular to the channel, forming a gear shaped design (Fig. 6d). Silica NPs were synthesized at 370.3 nm at 1 mL/h with over 90% mixing efficiency.

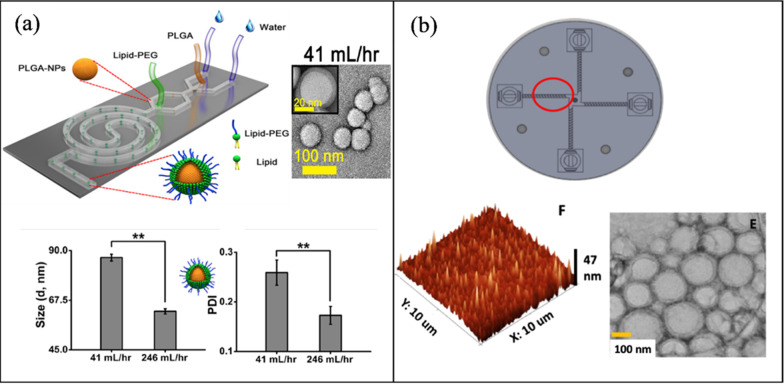

Hybrid NP synthesis

Valencia et al. [181] demonstrated the synthesis of PLGA core lecithin shell NPs, and quantum dots (QDs) coated lecithin in a single step via a PDMS Tesla structure micromixer. Where the lecithin and DSPE-PEG (8.4:1.6 by mol) were incorporated into the aqueous solution and the PLGA (1 mg/mL) dissolved in acetonitrile. At a FRR of 10:1 and a TFR of 50 μL/min, hybrid organic NPs were produced with an average size of 40 nm and a mixing time of 10 ms. Similarly, QD dissolved in THF at a concentration of 0.5 mg/mL produced organic–inorganic hybrid NPs with an average size of 60 nm. Feng et al. [182], employed a two stage microfluidic device for the synthesis of a PLGA (core)/lipid (shell) NP. Initially, PLGA (1% in TFE and DMF) organic solution was injected with an aqueous phase to form the polymer core, followed by a second inlet stage delivering the lipid phase, DPPC, DSPE-PEG and cholesterol (total 2.94 mg/mL) in ethanol. Followed by a spiral channel to enhance mixing and assemble the lipid shell over the polymeric core. At a TFR of 41 mL/h (246 mL/h) and a FRR of 80:1, the hybrid NP had an average size of 86.81 ± 1.5 nm (62.5 ± 1.18 nm) and a PDI of 0.259 (0.173). Figure 7a shows size and PDI measured by DLS along with NP morphology characterization by TEM. Bokare et al. [183] utilized a 3D printed multi-inlet vortex mixer (MIVMS) for the production of lipid-polymer NPs (LPHNPs) (lecithin-PLGA) (Fig. 7b). A comparison was made between a staggered herringbone patterned MIVMS and a regular MIVMS, and a 3-inlet MHF PDMS microchannel. The herringbone patterned MIVMS produced the smallest hybrid NPs with an average size of 60–70 nm and PDI < 0.12 at 12 ml/min and showed better reproducibility in comparison to the other microchannels. The lipid-polymer NPs was characterized by DLS, TEM, and atomic force microscopy (AFM).

Fig. 7.

Passive microfluidic mixers for hybrid NP synthesis (a) PLGA-lipid NPs in a spiral microchannel (open access) [182]. b A staggered herringbone patterned multi-inlet vortex mixer for the synthesis of PLGA-lipid NPs (open access) [183]

Larrea et al. [184] designed a microfluidic system comprised of two consecutive slit-interdigital micromixers to synthesize gold loaded PLGA NPs. Initially, the organic phase (13.5 mL/h) is mixed with an aqueous phase containing HAuCl4, sodium citrate, and water (4.5 mL/h). The effluent is then injected into the second interdigital mixer to mix with sodium cholate and Milli-Q water at 36 mL/h. After encapsulation, the loaded gold is heated to 45 °C and reduced. Thus, they were able to undergo the reduction of AuCl4− ions while encapsulated, which resulted in a 100% encapsulation efficiency. In addition, increasing the TFR from 36 to 54 mL/h decreased the size from 568 to 192 ± 58 nm. Ohannesian et al. [185] presented the synthesis of polymer-10 nm magnet metal oxide NP hybrid in a microfluidic reactor. Where iron sulfate/iron nitrate precursors where mixed with sodium hydroxide/dextran to produce superparamagnetic iron oxide NPs coated with dextran (long chain polymer). Similarly, Ding et al. [186] produced superparamagnetic iron oxide core encapsulated in PMMA NPs with sizes ranging from 100 to 200 nm.

Al-Ahmady et al. [187] synthesized a metal–organic (AuNPs loaded liposomes) NP hybrid in the commercially available Asia MF 320 system (Syrris, Royston, UK). Due to the hydrophobic nature of AuNPs, they were added to the organic phase in methanol. Empty liposomes were produced with an average size of 100 nm, while the AuNPs hybrid had a size range of 130–260 nm which were analyzed and confirmed by AFM. Di Santo et al. [188] utilized the NanoAssemblr™ (staggered herringbone) benchtop to fabricate graphene oxide-cationic lipid NPs (modification confirmed by AFM), and Rohra et al. [189] reported on the synthesis of AuNPs-metal–organic framework (MOF) in a split and recombination channel. The micromixer was made of acrylic sheets and fabricated by computer numerical control (CNC). The MOF was made of zeolitic imidazolate framework-8, a class of MOF that is formed by the self-assembly between imidazolate and Zn2+. Wang et al. [190] synthesized hybrid NPs composed of metal alloy cores and metal oxide shells in a multistep procedure involving programmed microfluidics and batch cooling processes. Such hybrid NPs include Fe(1-x)Znx (core) Zn(1-y)FeyO-(OH)z (shell), an iron-zinc-based NP.

Active micromixing

Active mixing methods rely on external forces to disturb the flow and induce chaotic advection to increase the contact area between the different fluids, thus enhancing the mixing quality and time. Depending on the applied force, active micromixing can be further classified as acoustic [193–199], electrical [200, 201], thermal [202, 203], and pressure [124, 204, 205] field driven methods.

Background on active mixing methods

This section presents a brief background on the various active mixing methods utilized for NP synthesis.

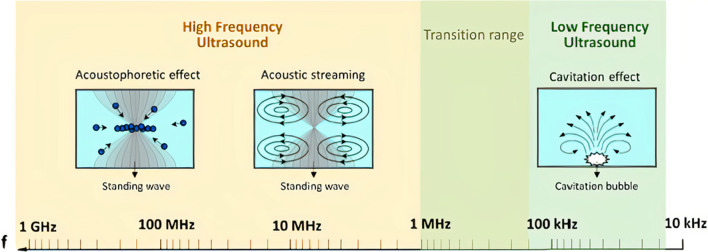

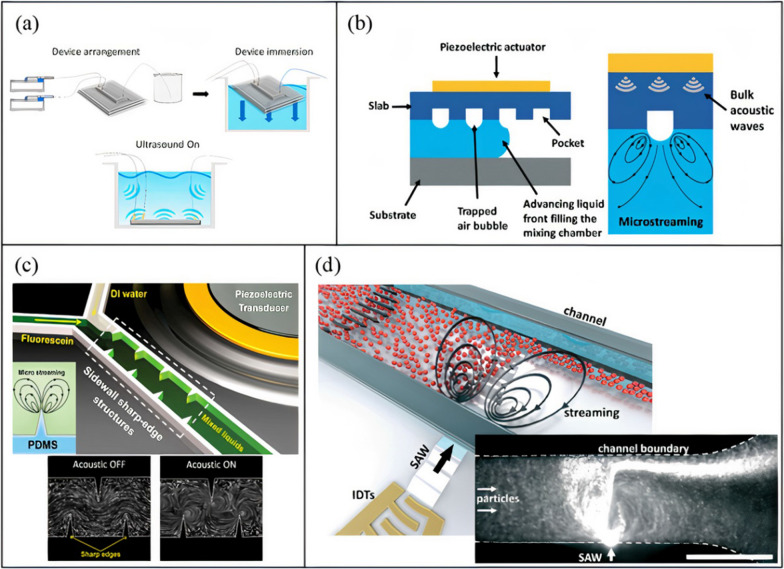

Acoustic mixing

Acoustic-based micromixing is a versatile method of active mixing where it encompasses the application of frequencies ranging from 1 kHz to 1 GHz [206, 207]. One of the most common methods of generating acoustic waves relies on the inverse piezoelectric effect, where electrical signals are transformed into mechanical disturbances. Depending on the applied frequency, the propagating acoustic wave induces different physical mechanisms in the fluid (Fig. 8). At frequencies below 200 kHz, microbubble cavitation is the prominent physical phenomenon that occurs [208], which can enhance mixing [199, 209, 210], and prevent clogging and NP aggregation [211]. During acoustic cavitation, pre-existing and newly formed microbubbles in the liquid medium oscillate vigorously with the applied acoustic pressure. The microbubbles coalesce, grow, and undergo shape and volume oscillations. As the bubble size increases and reaches it resonance size, transient cavitation occurs, resulting in the collapse of the bubble and the generation of strong turbulence (cavitation microstreaming), liquid jets, and shockwaves [212]. These effects enhance mixing by disturbing the laminar flow in microchannels, inducing vortices and chaotic advection. Acoustic cavitation is dominant in low ultrasonic frequencies because of the low acoustic power threshold at the applied frequency. The power threshold increases for higher frequencies, which is why cavitation is not observed at megahertz scales [206]. Acoustic cavitation in microchannels can be realized by several methods including immersing microchannels in ultrasonic baths [152, 162, 166] (Fig. 9a), and actuation by piezoelectric transducers bonded to glass or silicon substrates [213, 214].

Fig. 8.

Acoustic phenomena associated with high and low frequency ultrasound (open access) [206]

Fig. 9.

Acoustic mixing methods. a Ultrasonic bath mixing (open access) [128], b trapped bubble mixing (open access) [219]), c sharp edge mixing (open access) [220], and d SAW acoustic streaming (open access) [221]

Another form of low frequency acoustic mixing is the interaction of the applied acoustic waves with embedded structures in microchannels. There are two main methods of achieving such mixing: trapped bubble and sharp edge oscillations. Both methods rely on the acoustic actuation of a piezoelectric transducer bonded to a silicon or glass substrate via a PDMS microchannel [94, 215–218].

In trapped bubble oscillation, an aqueous solution is initially injected into a PDMS microchannel with microcavities. As the fluid flows, gases are trapped in the cavities due to surface tensions, forming bubbles [222]. Bubble size can be tuned by changing the size of microcavities. As the piezoelectric transducer is driven, bubbles start to oscillate (volume and shape oscillations) and, due to the frictional forces and viscous attenuation of acoustic waves in the fluid, bulk fluid motion arise around the bubbles (Fig. 9b) [223]. When the applied frequency matches the natural frequency of the oscillating bubble, maximum oscillation amplitude occurs [198]. The induced circulatory motion is effective in disrupting the laminar flow and enhancing mixing. Conversely to the acoustic cavitation discussed earlier, in trapped bubble oscillation, bubble size is relatively larger and do not collapse as the required power threshold is not reached, which is also not the purpose of such devices. However, the bubbles can destabilize due to long term actuation of the acoustic transducer and heating of the device, which results in expansion of bubble volume. Therefore, it is vital to keep the channel temperature in check to avoid undesired change in bubble size that can also affect the resonant actuation frequency of the device.

Alternatively, oscillating sharp edges, which are structures protruding inside the microchannels, and generally composed of either PDMS [216] or silicon [218] (same as the base material), are relatively immune to such limitations. Upon actuation of the piezoelectric transducer, the sharp edges will oscillate with the applied frequency and generate a pair of counter-rotating vortices at the tip (Fig. 9c) [216]. Similar to the oscillating bubbles, the generated acoustic streaming can break the interface of the laminar flows and enhance mass transfer and mixing. However, there are two main operational differences between the two methods: (i) with trapped bubble oscillation, the applied frequency must coincide with the natural frequency of the bubble, (ii) whereas with the sharp edge design, the piezoelectric transducer is operated at its own resonance frequency for optimum mixing conditions. Moreover, optimization of sharp edge mixing includes many parameters, including tip angle, sharp edge size and length, density, pattern, in addition to the applied frequency, number of objects, voltage, and flow rate (which are common with bubble oscillation). For example, smaller tip angles result in stronger acoustic streaming [224], larger sharp edges (to a certain size) are better for mixing, and higher voltages result in larger vibrational amplitudes and stronger acoustic streaming [216].

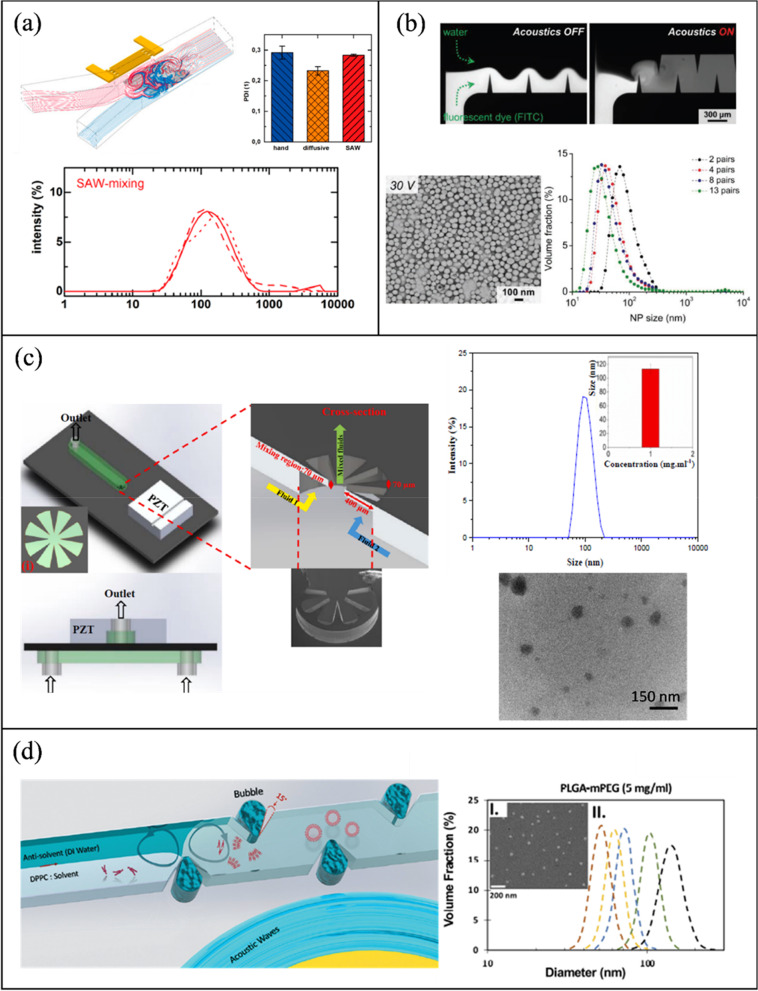

At higher frequencies (> 1 MHz), cavitation is not observed, but acoustic radiation forces and acoustic streaming flows are induced in microchannels, which can be used for microparticle manipulation and mixing [221]. The acoustic streaming flow phenomena occurs because of gradients in the acoustic field brought about by the scattering, absorption, and dampening of the acoustic waves when they interact with the fluid and channel structure [225]. To add to the versatility of acoustic-based mixing, at megahertz scales, different mechanisms and materials are used to produce acoustic waves. One of the most common methods of acoustic actuation at these scales is the utilization of Surface Acoustic Waves (SAW) also known as Rayleigh waves. SAWs are acoustic waves (10–100 μm in wavelength) propagating along the surface of an elastic medium with a penetration depth into the material about five times the wavelength [226]. SAW mixing platforms consist of one or multiple interdigitated transducers (IDTs), which are comb-like metallic electrodes patterned on a piezoelectric substrate, and a PDMS channel (Fig. 9d). IDTs are fabricated using standard photolithography and wet etching, and have a resonance frequency dependent on electrode width, interelectrode gap, and the speed of sound in the piezoelectric substrate. One of the most commonly used piezoelectric materials is lithium niobate (LiNbO3), which can be further classified depending on the cutting angle during the fabrication process. With, 127.68° Y-X-axis-rotated cut, X-propagating LiNbO3 is the most widely used substrate [80, 137, 193, 221, 227–229] because of its high electromechanical coupling coefficient [230]. When an alternating current is applied to an IDT at the resonance frequency, the substrate undergoes mechanical displacement due to the presence of an electric field and the piezoelectric effect [231]. A SAW is generated at the IDT and travels along the surface of the piezoelectric material until it encounters the PDMS channel, where it leaks into the microchannel, generating pressure fluctuations within the fluid [225]. Due to the speed of sound difference between the fluid medium vf and the piezoelectric substrate vs, the leaked waves enter the fluid at an angle known as Rayleigh angle (θR). This angle is determined by Snell’s law: sin (θR) = vf/vs. As the leaky SAW propagates across the microchannel, it is attenuated by viscous dissipation, creating a steady momentum flux in the direction of wave propagation, which results in steady fluid motion in the form of acoustic streaming flow. The induced steady motion is known as Eckart streaming which occurs when the channel width is greater than the acoustic wavelength [229]. The generated acoustic streaming is used to disturb the laminar flow and enhance mixing.

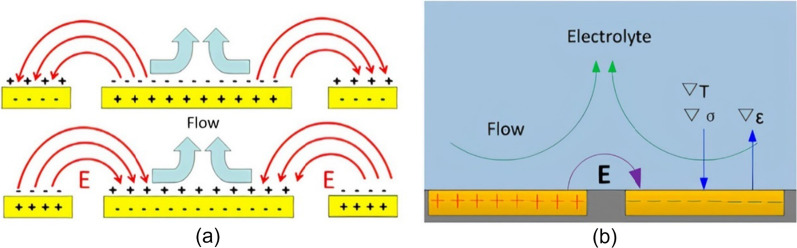

Electrical/thermal mixing

Electrical micromixers are typically embedded with electrodes within the microchannel and, upon DC or AC voltage excitation, fluid motion is induced. Electrical mixing in microchannels can be achieved in various ways, such as electrohydrodynamics (EHD), which relies on the fluids’ distinct electrical properties, and alternating current electrothermal (ACET) and direct current induced thermal buoyancy convection (DCIBC) arising from joule heating [232]. EHD mixing develops from flow instabilities at a fluid–fluid interface when an electrical stress is applied (Fig. 10a). Electrical stresses are generated at the interface due to the sharp discontinuity in electrical properties (conductivity or permittivity) of the fluids in the presence of an electric field [233]. Deionized water and ethanol are examples of such fluids, where they have similar conductivities but distinct permittivities (εwater = 80, εethanol = 24.5) [95]. EHD fluid actuation is strongly affected by the AC frequency, amplitude, and the electrical properties of the fluids [234]. On the other hand, ACET involves inducing micro-vortices in the channel due to the interaction of a temperature gradient in the fluid and a non-uniform AC electric field (Fig. 10b) [235]. A temperature gradient in the fluid arises because of Joule heating, which causes a gradient in the electrical properties (conductivity and permittivity) of the fluid. This variation in electrical parameters generates an electrical body force on each fluid medium, resulting in fluid motion and vortices [202]. The ACET is a function of temperature gradients, higher fluid conductivities, and electrode geometry, where asymmetric electrodes generate non-uniform joule heating and efficient mixing [203].

Fig. 10.

a Electrohydrodynamic mixing (open access) [236], and b alternating current electrothermal mixing. Reproduced with permission from [237]. Copyrights

© 2017 John Wiley & Sons Ltd

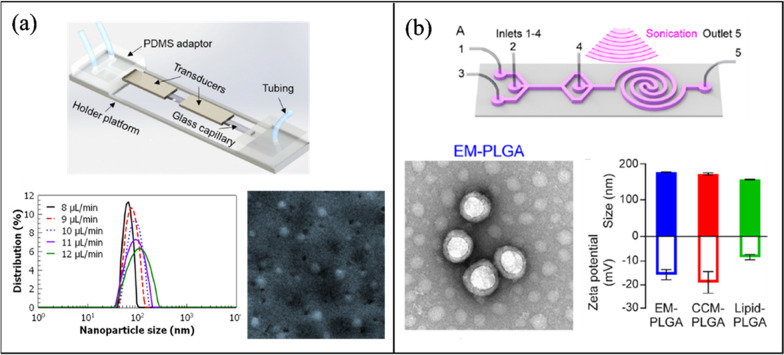

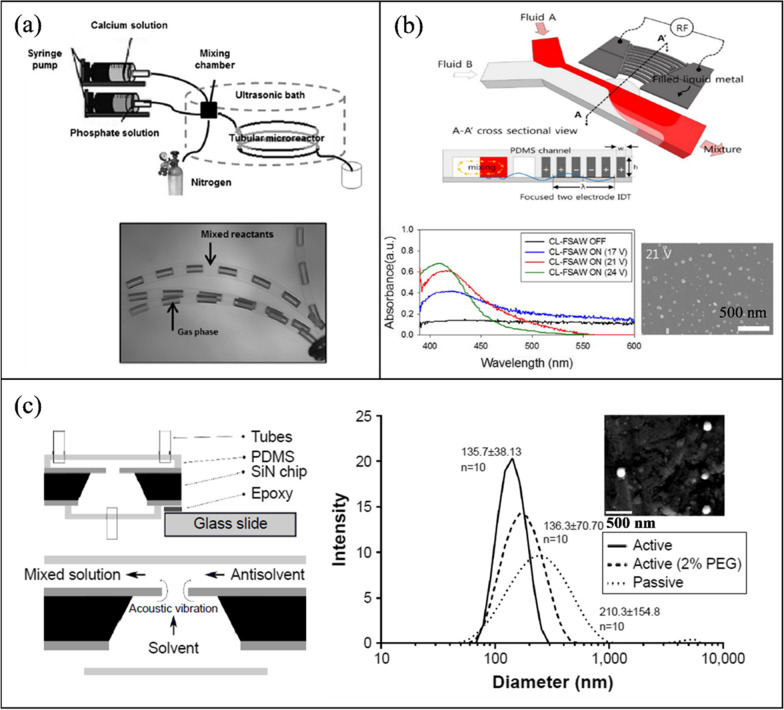

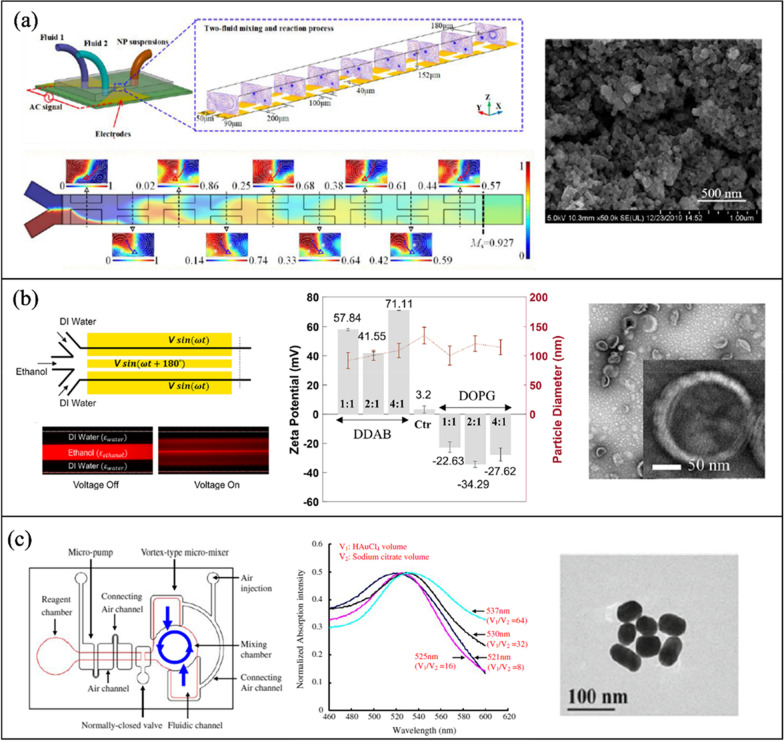

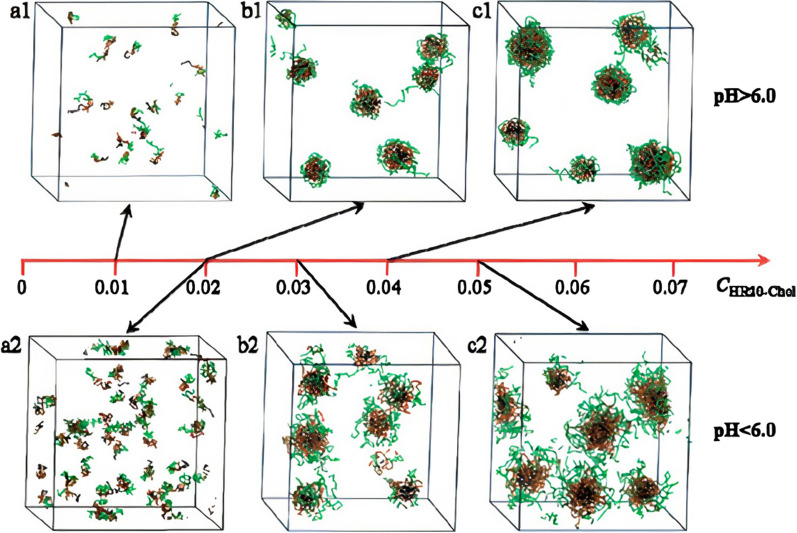

Acoustic NP synthesis

Table 3 outlines the active mixing microchannels and mechanisms for NP synthesis.

Table 3.

Microfluidic synthesis of nanoparticles by active mixing methods

| Nanoparticle type | Mixing mechanism | Microchannel | Voltage (Vpp) | Size (nm) | PDI | Organic/precursor Concentration | FRR | TFR | ME | MT | Year | Ref | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Acoustic | |||||||||||||

| PLGA | Piezoelectric transducer (205 kHz)-acoustic streaming | Glass capillary | 20 | 65 | 0.08 | 30 mg/mL | 0.3 | 8 μL/min | 90% | 103 ms | 2022 | [117] | |

| PLGA | Lotus shaped cantilever (8) mixer (680 kHz)-acoustic streaming | Silicon/PDMS | – | 52.2 | 0.44 | 1 mg/mL | 1:1 | 1400 μL/min | 80% | 2 ms | 2022 | [218] | |

| Budesonide | Square cross section membrane vibration (177.6 kHz)-acoustic streaming | Silicon/PDMS | 200 | 135.7 | 0.044 | 0.2 mg/mL | 1:4 | 10 μL/min | – | 3 ms | 2018 | [250] | |

| PLGA | PDMS sharp edges, 13 pairs (4 kHz)-acoustic streaming | Glass/PDMS | 30 | 64.7 ± 0.7 | 0.13 | 10 mg/mL | – | 10 μL/min | 100% | 54 ms | 2019 | [220] | |

| PLGA | Tesla structures/PDMS sharp edges (4.9 kHz)-acoustic streaming | Glass/PDMS | 56 | 64.5 | 0.062 | 10 mg/mL | 3:7 | 2000 μL/min | 100% | – | 2020 | [241] | |

| PLGA | Bubbles/sharp edges (74.2 kHz)-acoustic streaming | Glass/PDMS | 40 | 40 | 0.072 | 1.25 mg/mL | 1:4 | 20 μL/min | 88% | ~ 1 ms | 2019 | [94] | |

| Liposomes | Bubbles/sharp edges (74.2 kHz)-acoustic streaming | Glass/PDMS | 40 | 80 | 0.125 | 1 mg/mL | 1:6 | 60 μL/min | 88% | ~ 1 ms | 2019 | [94] | |

| SLN | Piezoelectric transducer (500 kHz), acoustic cavitation | Silicon/Glass/PDMS | 100 | 80 ± 2 | 0.34 | 0.4 mg/mL | 3:25 | 56 μL/min | – | – | 2021 | [213] | |

| PFC loaded PLGA | Sonication flow cell | – | – | 160 | 0.2 | – | – | 37.5 mL/min | – | – | 2020 | [242] | |

| bPEI polyplexes | SAW (81.2 MHz)-acoustic streaming | LiNbO3/PDMS | 5.6 | 110.8 ± 0.65 | 0.283 | 0.12 mg/ml (bPEI), 0.156 mg/ml (pDNA) | – | 2.5 μL/min | 100% | 189 ms | 2016 | [239] | |

| AuNP | Rotary SAW mixing, 4 IDT (50 MHz) | LiNbO3/PDMS | 35 | 21.32 ± 4.92 | - | 1 mM (HAucl4) | – | – | – | – | 2018 | [249] | |

| PLGA | PDMS sharp edges, 12 pairs (4 kHz)-acoustic streaming | Glass/PDMS | 38 | 101 | 0.17 | 30 mg/mL | 1:10 | 55 μL/min | 100% | 4 ms | 2021 | [245] | |

| Protein NP | Star shaped cavity (960 kHz)-acoustic streaming | Silicon/PDMS | 1 | 149.6 | 0.38 | 0.3 mg/mL | – | 500 μL/min | 85% | 6 ms | 2020 | [240] | |

| Exosome membrane/PLGA | Spiral channel/sonication (80 kHz) | Glass/PDMS | – | 177.4 | 0.193 | 5 mg/mL | 7:80 | 2900 μL/min | – | – | 2019 | [209] | |

| Cancer membrane/PLGA | Spiral channel/sonication (80 kHz) | Glass/PDMS | – | 172.3 | 0.222 | 5 mg/mL | 7:80 | 2900 μL/min | – | – | 2019 | [209] | |

| Lipid/PLGA | Spiral channel/sonication (80 kHz) | Glass/PDMS | – | 157.2 | 0.195 | 10 mg/mL | 7:80 | 2900 μL/min | – | – | 2019 | [209] | |

| AgNP | SAW (9.2 MHz)-acoustic streaming | LiNbO3/PDMS | 21 | 45 ± 11.5 | – | 0.1 M (AgNO3) | – | 100 μL/min | 100% | 20 ms | 2017 | [248] | |

| Budesonide | Star shaped cavity (1060 kHz)-acoustic streaming | Silicon/PDMS | 1 | 80.53 ± 21.95 | – | 4 mg/mL | 1:4 | 5000 μL/min | 91% | 4.1 ms | 2020 | [252] | |

| DNA NP | Star shaped cavity (1060 kHz)-acoustic streaming | Silicon/PDMS | 1 | 90 | – | – | – | 4000 μL/min | 91% | ~ 4.1 ms | 2020 | [252] | |

| Liposomes | Ultrasonic bath (50–60 kHz) | Glass | – | 66.27 | – | 3 mg/mL | 1:12 | 3740 μL/min | – | – | 2010 | [199] | |

| Electric/Thermal | |||||||||||||

| BaSO4 | Alternating current electrothermal (1 MHz) | Glass/PDMS | 12—20 | 75.3 ± 17.5 | – | 5 mM | – | 0.9 μL/min | 90% | – | 2019 | [202] | |

| Cu2O | Direct current-induced thermal buoyancy convection | Glass/PDMS | 8 | 680 | – | 0.2 M | – | 18 μL/min | 97.3% | – | 2019 | [253] | |

| Liposomes | Electrohydrodynamic micromixing (1 MHz) | Glass/PDMS | 10 | 126.7 ± 0.7 | – | 1 mg/mL | 1:10 | 50 μL/min | 60% | – | 2020 | [234] | |

| Liposomes | Electrohydrodynamic micromixing (1 MHz) | Glass/PDMS | 10 | 97 | – | 0.25 mg/mL | 1:10 | 200 μL/min | – | – | 2020 | [95] | |

| Co-Fe PBA | Alternating current electrothermal (1 MHz) | Glass/PDMS | 22 | 231.1 ± 35.4 | – | 5 mM | – | – | 90% | – | 2020 | [203] | |

| Other | |||||||||||||

| SLN | Oscillator mixer (138.9 Hz) | – | – | 93.4 | 0.184 | 100 mg/mL | 1:9 | 60 mL/min | – | – | 2015 | [132] | |

| AuNP | PZT micropump pulsed Mixing (300 Hz) | Glass/PDMS | – | 21.6 ± 4.83 | – | 1 mM (HAucl4) | – | 4 mL/min | 97% | – | 2015 | [205] | |